Set the clock JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1695 of 2199

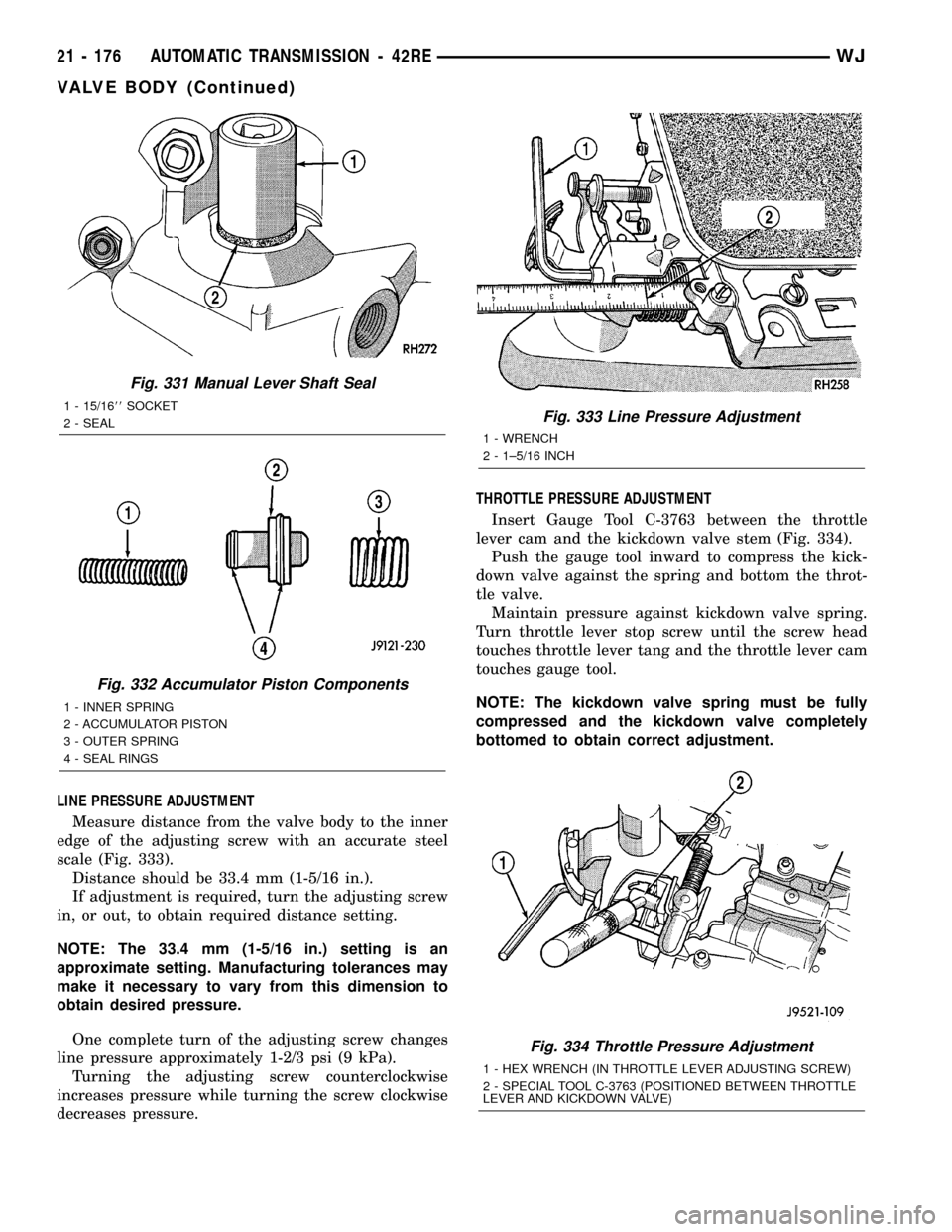

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 333).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 334).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 331 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 332 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 333 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 334 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 176 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1807 of 2199

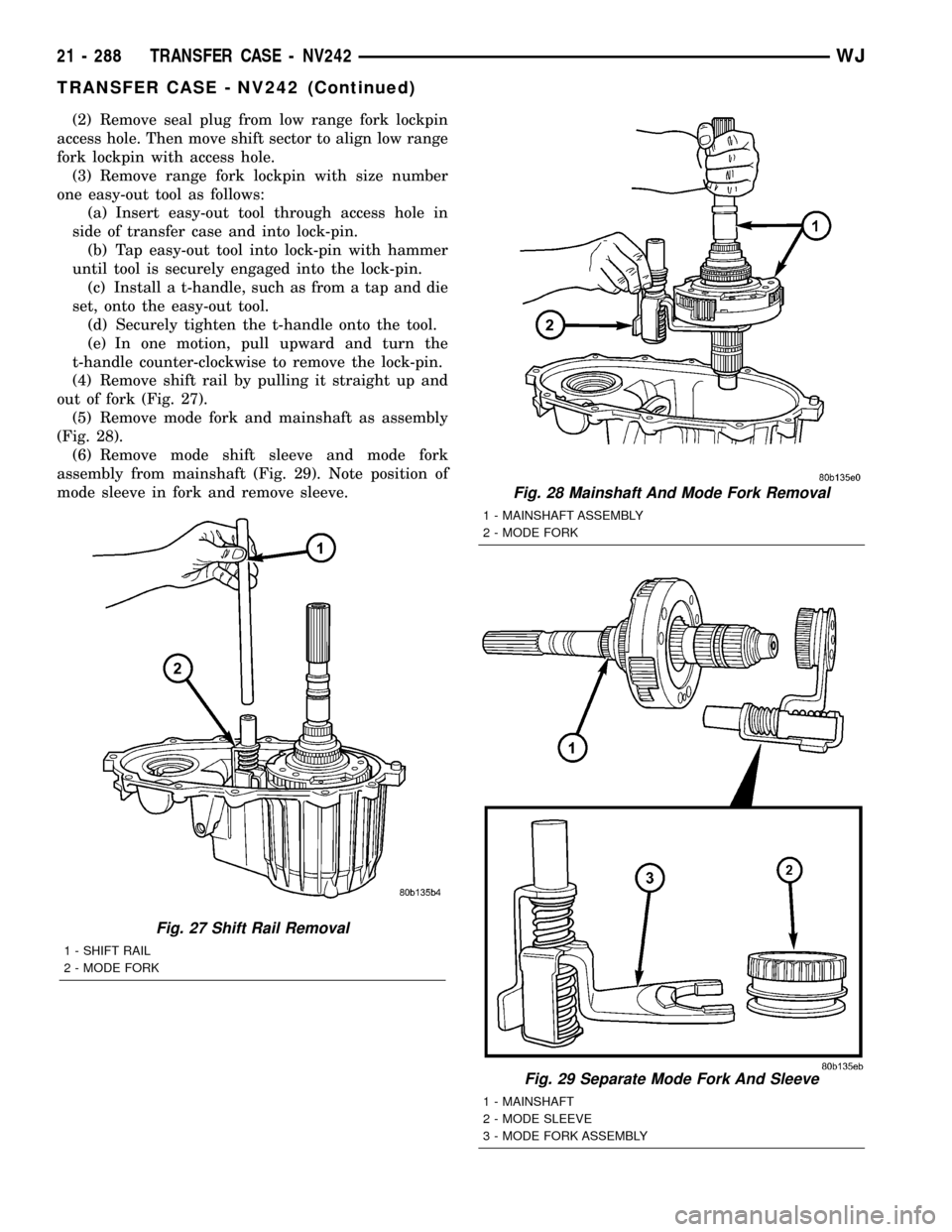

(2) Remove seal plug from low range fork lockpin

access hole. Then move shift sector to align low range

fork lockpin with access hole.

(3) Remove range fork lockpin with size number

one easy-out tool as follows:

(a) Insert easy-out tool through access hole in

side of transfer case and into lock-pin.

(b) Tap easy-out tool into lock-pin with hammer

until tool is securely engaged into the lock-pin.

(c) Install a t-handle, such as from a tap and die

set, onto the easy-out tool.

(d) Securely tighten the t-handle onto the tool.

(e) In one motion, pull upward and turn the

t-handle counter-clockwise to remove the lock-pin.

(4) Remove shift rail by pulling it straight up and

out of fork (Fig. 27).

(5) Remove mode fork and mainshaft as assembly

(Fig. 28).

(6) Remove mode shift sleeve and mode fork

assembly from mainshaft (Fig. 29). Note position of

mode sleeve in fork and remove sleeve.

Fig. 27 Shift Rail Removal

1 - SHIFT RAIL

2 - MODE FORK

Fig. 28 Mainshaft And Mode Fork Removal

1 - MAINSHAFT ASSEMBLY

2 - MODE FORK

Fig. 29 Separate Mode Fork And Sleeve

1 - MAINSHAFT

2 - MODE SLEEVE

3 - MODE FORK ASSEMBLY

21 - 288 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 2095 of 2199

Both the manual A/C Heater control panel and the

AZC control panel are serviced only as complete

units and cannot be repaired. If faulty or damaged,

the entire control panel unit must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC ZONE

CONTROL SYSTEM

The Automatic Zone Control (AZC) control module

has a system self-diagnostic mode which continuously

monitors various parameters during normal system

operation. If a system fault is detected, a current and

historical fault is recorded. When the current fault is

cleared, the historical fault remains until reset (man-

ually or automatically). Both the current and histor-

ical fault codes can be accessed through either the

front panel, or over the Programmable Communica-

tions Interface (PCI) bus using a DRBIIItscan tool,

and the appropriate diagnostic information.

The AZC control module is capable of three differ-

ent types of self-diagnostic tests, as follows:

²Fault Code Tests

²Input Circuit Tests

²Output Circuit/Actuator Tests

The information that follows describes:

²How to read the self-diagnostic display

²How to enter the AZC control module self-diag-

nostic test mode

²How to select the self-diagnostic test types

²How to perform the different tests

ENTERING THE AZC SELF-DIAGNOSTIC MODE

To enter the AZC self-diagnostic mode, perform the

following:

(1) Depress the a/c and recirc buttons at the same

time and hold. Rotate the left temperature control

knob clockwise (CW) one detent.

(2) If you continue to keep the a/c and recirc but-

tons depressed, the AZC control module will perform

a Segment Test of the Vacuum Fluorescent (VF) dis-

play. In the Segment Test you should see all of the

display segments illuminate as long as both buttons

are held. If a display segment fails to illuminate, the

vacuum fluorescent display is faulty and the a/c

heater control must be replaced.

(3) After viewing the Segment Test, release the

A/C and Recirc buttons and the display will clear

momentarily.Ifa0isdisplayed, then no faults

are set in the system.Should there be any faults,

either9current9or9historical9, all fault codes will be

displayed in ascending numerical sequence (note no

effort is made to display fault codes in chronological

order). Each fault code is displayed for one second

before the next code is displayed. Once all fault codes

have been displayed, the system will then repeat the

fault code numbers. This will continue until the left

side set temperature control is moved at least onedetent position in the CW direction or the ignition is

turned9OFF9.

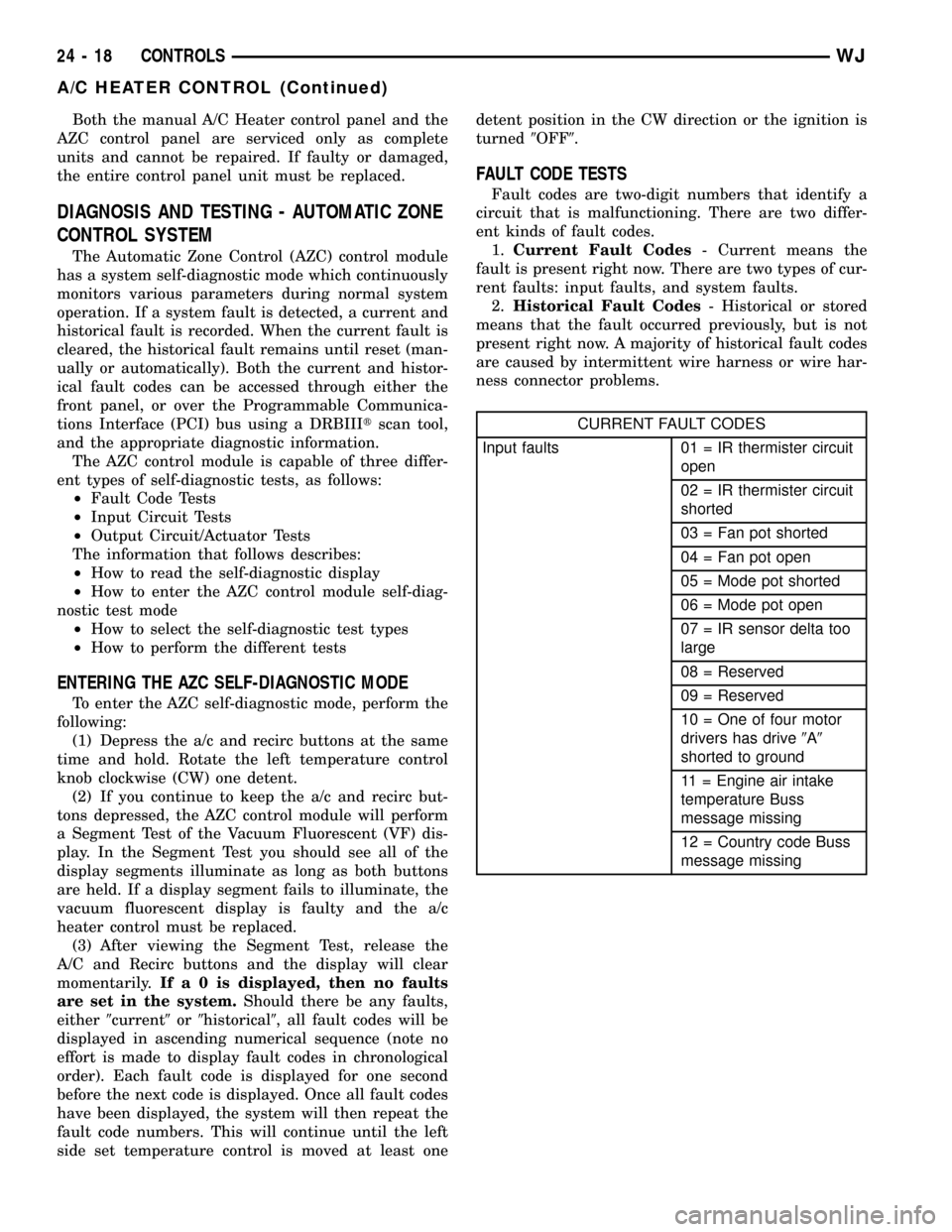

FAULT CODE TESTS

Fault codes are two-digit numbers that identify a

circuit that is malfunctioning. There are two differ-

ent kinds of fault codes.

1.Current Fault Codes- Current means the

fault is present right now. There are two types of cur-

rent faults: input faults, and system faults.

2.Historical Fault Codes- Historical or stored

means that the fault occurred previously, but is not

present right now. A majority of historical fault codes

are caused by intermittent wire harness or wire har-

ness connector problems.

CURRENT FAULT CODES

Input faults 01 = IR thermister circuit

open

02 = IR thermister circuit

shorted

03 = Fan pot shorted

04 = Fan pot open

05 = Mode pot shorted

06 = Mode pot open

07 = IR sensor delta too

large

08 = Reserved

09 = Reserved

10 = One of four motor

drivers has drive9A9

shorted to ground

11 = Engine air intake

temperature Buss

message missing

12 = Country code Buss

message missing

24 - 18 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2098 of 2199

(2)If there are no fault codes, the ª00º dis-

play value will remain in the VF window.Should

there be any codes, each will be displayed for one

second in ascending numerical sequence (note: no

effort is made to display faults in the order they

occurred). The left side set temperature display will

be blanked and the right side set temperature dis-

play will indicate current and historical codes (8 his-

torical max) presently active. Once all codes have

been displayed, the system will repeat the fault code

numbers. This will continue until the left side set

temperature control is moved at least one detent

position in either direction, by pressing both the A/C

and Recirc buttons at the same time, or the ignition

is turned off. Record all of the fault codes, then see

the Current and Historical Fault Code charts for the

descriptions.

CLEARING FAULT CODES

Current faults cannot be electronically cleared.

Repair must be made to the system to eliminate the

fault causing code. Historical fault codes can be

cleared manually, or automatically. To clear a histor-

ical fault manually, depress and hold either the A/C

or Recirc button for at least three seconds while the

display is in the fault code mode of operation. Histor-

ical fault codes are cleared automatically when the

corresponding current fault code has been cleared,

and has remained cleared for a number of ignition

cycles. The faults have been cleared when two hori-

zontal bars appear in the Test Selector display.

EXITING SELF-DIAGNOSTIC MODE

The self-diagnostic mode can be exited by pressing

both the A/C and Recirc buttons at the same time, or

turning off the ignition.

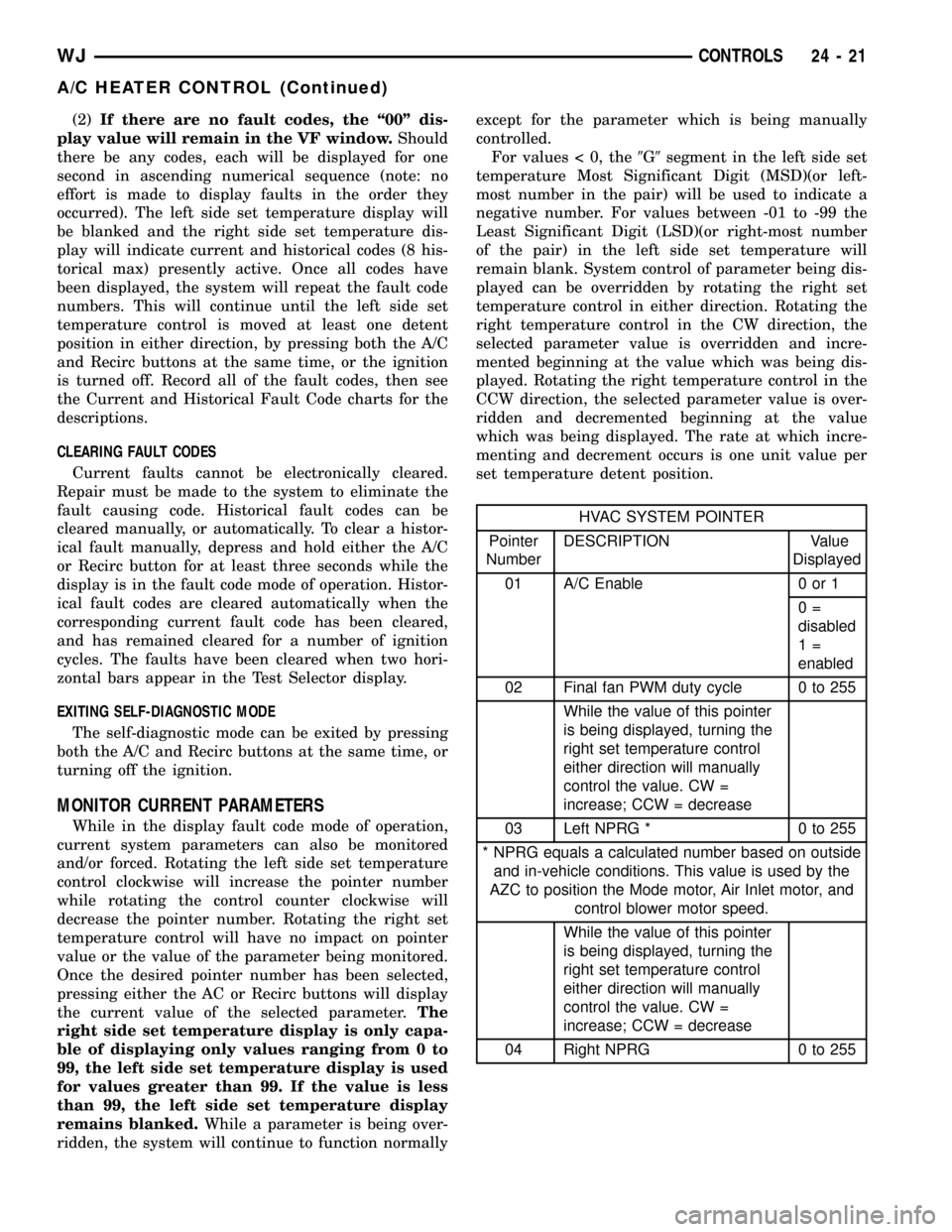

MONITOR CURRENT PARAMETERS

While in the display fault code mode of operation,

current system parameters can also be monitored

and/or forced. Rotating the left side set temperature

control clockwise will increase the pointer number

while rotating the control counter clockwise will

decrease the pointer number. Rotating the right set

temperature control will have no impact on pointer

value or the value of the parameter being monitored.

Once the desired pointer number has been selected,

pressing either the AC or Recirc buttons will display

the current value of the selected parameter.The

right side set temperature display is only capa-

ble of displaying only values ranging from 0 to

99, the left side set temperature display is used

for values greater than 99. If the value is less

than 99, the left side set temperature display

remains blanked.While a parameter is being over-

ridden, the system will continue to function normallyexcept for the parameter which is being manually

controlled.

For values < 0, the9G9segment in the left side set

temperature Most Significant Digit (MSD)(or left-

most number in the pair) will be used to indicate a

negative number. For values between -01 to -99 the

Least Significant Digit (LSD)(or right-most number

of the pair) in the left side set temperature will

remain blank. System control of parameter being dis-

played can be overridden by rotating the right set

temperature control in either direction. Rotating the

right temperature control in the CW direction, the

selected parameter value is overridden and incre-

mented beginning at the value which was being dis-

played. Rotating the right temperature control in the

CCW direction, the selected parameter value is over-

ridden and decremented beginning at the value

which was being displayed. The rate at which incre-

menting and decrement occurs is one unit value per

set temperature detent position.

HVAC SYSTEM POINTER

Pointer

NumberDESCRIPTION Value

Displayed

01 A/C Enable 0 or 1

0=

disabled

1=

enabled

02 Final fan PWM duty cycle 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

03 Left NPRG * 0 to 255

* NPRG equals a calculated number based on outside

and in-vehicle conditions. This value is used by the

AZC to position the Mode motor, Air Inlet motor, and

control blower motor speed.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

04 Right NPRG 0 to 255

WJCONTROLS 24 - 21

A/C HEATER CONTROL (Continued)

Page 2131 of 2199

ready. The refrigerant system should not be left open

to the atmosphere any longer than necessary. Cap or

plug all lines and fittings as soon as they are opened

to prevent the entrance of dirt and moisture. All lines

and components in parts stock should be capped or

sealed until they are to be installed.

All tools, including the refrigerant recycling equip-

ment, the manifold gauge set, and test hoses should

be kept clean and dry. All tools and equipment must

be designed for R-134a refrigerant.

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

If the air conditioning system is not cooling prop-

erly, determine if the refrigerant system is fully-

charged. (Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING -

A/C PERFORMANCE)

An electronic leak detector designed for R-134a

refrigerant is recommended for locating and confirm-

ing refrigerant system leaks. Refer to the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

An oily residue on or near refrigerant system lines,

connector fittings, components, or component seals

can indicate the general location of a possible refrig-

erant leak. However, the exact leak location should

be confirmed with an electronic leak detector prior to

component repair or replacement.

To detect a leak in the refrigerant system, perform

one of the following procedures:

SYSTEM EMPTY

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(2) Connect and dispense 0.283 kilograms (0.625

pounds or 10 ounces) of R-134a refrigerant into the

evacuated refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

CHARGE)

(3) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(4) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(5) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run with the air conditioning system

turned on for five minutes.

(3) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-

tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(4) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED,

BEFORE CONNECTING TO OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PER-

SONAL INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

24 - 54 PLUMBINGWJ

PLUMBING (Continued)

Page 2173 of 2199

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º

water. The cycle rate of pump strokes is quite rapid

as the system begins to pump up to this pressure. As

the pressure increases, the cycle rate starts to drop

off. If there is no leak in the system, the pump would

eventually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the Air Fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S sensor output. The programmed

memory acts as a self calibration tool that the engine

controller uses to compensate for variations in engine

specifications, sensor tolerances and engine fatigue

over the life span of the engine. By monitoring the

actual fuel-air ratio with the O2S sensor (short term)

and multiplying that with the program long-term

(adaptive) memory and comparing that to the limit,

it can be determined whether it will pass an emis-

sions test. If a malfunction occurs such that the PCM

cannot maintain the optimum A/F ratio, then the

MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

25 - 18 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)