Transmission control unit JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 549 of 2199

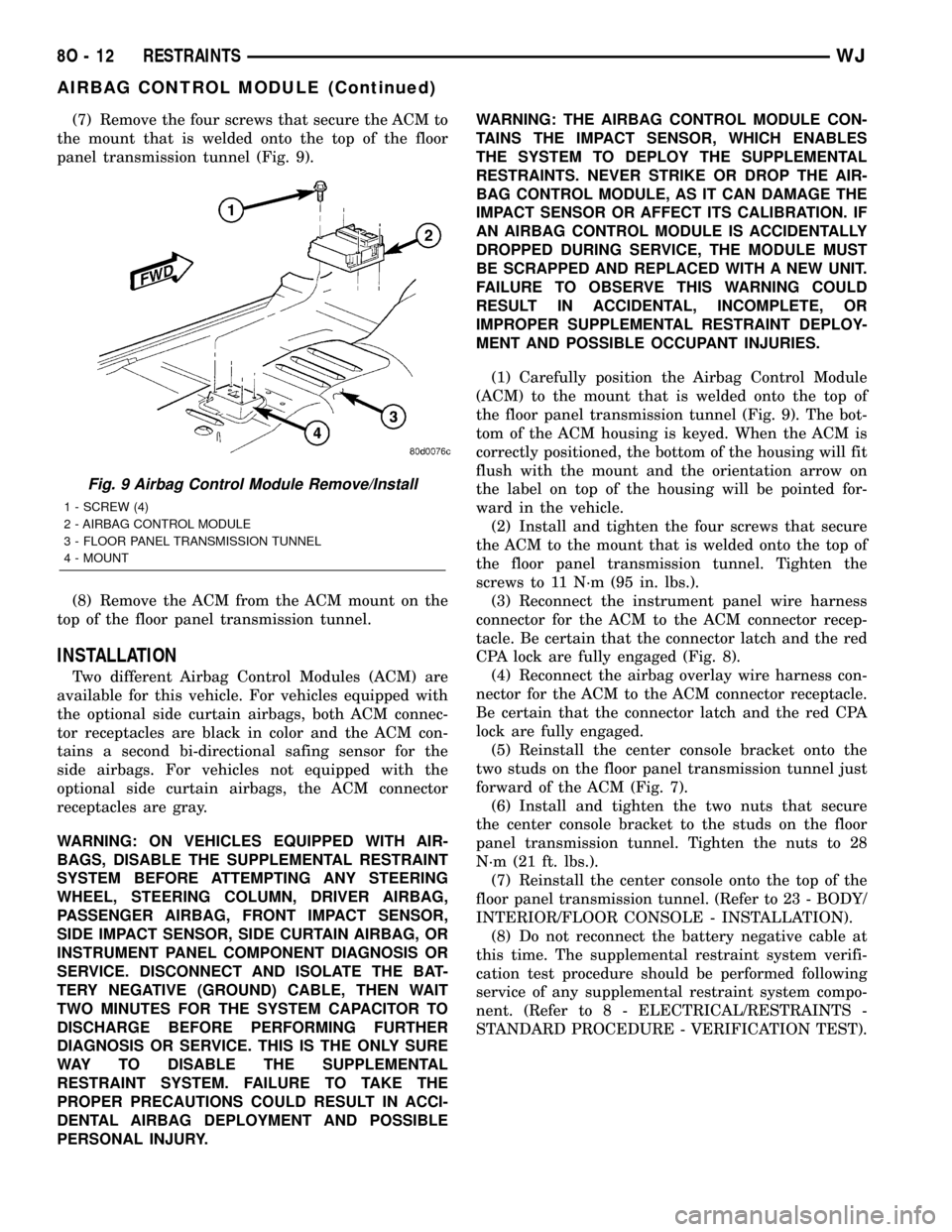

(7) Remove the four screws that secure the ACM to

the mount that is welded onto the top of the floor

panel transmission tunnel (Fig. 9).

(8) Remove the ACM from the ACM mount on the

top of the floor panel transmission tunnel.

INSTALLATION

Two different Airbag Control Modules (ACM) are

available for this vehicle. For vehicles equipped with

the optional side curtain airbags, both ACM connec-

tor receptacles are black in color and the ACM con-

tains a second bi-directional safing sensor for the

side airbags. For vehicles not equipped with the

optional side curtain airbags, the ACM connector

receptacles are gray.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.WARNING: THE AIRBAG CONTROL MODULE CON-

TAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE SUPPLEMENTAL

RESTRAINTS. NEVER STRIKE OR DROP THE AIR-

BAG CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

(1) Carefully position the Airbag Control Module

(ACM) to the mount that is welded onto the top of

the floor panel transmission tunnel (Fig. 9). The bot-

tom of the ACM housing is keyed. When the ACM is

correctly positioned, the bottom of the housing will fit

flush with the mount and the orientation arrow on

the label on top of the housing will be pointed for-

ward in the vehicle.

(2) Install and tighten the four screws that secure

the ACM to the mount that is welded onto the top of

the floor panel transmission tunnel. Tighten the

screws to 11 N´m (95 in. lbs.).

(3) Reconnect the instrument panel wire harness

connector for the ACM to the ACM connector recep-

tacle. Be certain that the connector latch and the red

CPA lock are fully engaged (Fig. 8).

(4) Reconnect the airbag overlay wire harness con-

nector for the ACM to the ACM connector receptacle.

Be certain that the connector latch and the red CPA

lock are fully engaged.

(5) Reinstall the center console bracket onto the

two studs on the floor panel transmission tunnel just

forward of the ACM (Fig. 7).

(6) Install and tighten the two nuts that secure

the center console bracket to the studs on the floor

panel transmission tunnel. Tighten the nuts to 28

N´m (21 ft. lbs.).

(7) Reinstall the center console onto the top of the

floor panel transmission tunnel. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION).

(8) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

Fig. 9 Airbag Control Module Remove/Install

1 - SCREW (4)

2 - AIRBAG CONTROL MODULE

3 - FLOOR PANEL TRANSMISSION TUNNEL

4 - MOUNT

8O - 12 RESTRAINTSWJ

AIRBAG CONTROL MODULE (Continued)

Page 574 of 2199

NOTE: Vehicles equipped with a three-point center

seat belt have the center seat belt lower anchor

secured to the right buckle anchor plate with a

screw instead of the center lap belt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR CENTER SEAT

BELT & RETRACTOR - INSTALLATION).

(3) Fold the rear seat cushion back into the seat-

ing position.

SEAT BELT SWITCH

DESCRIPTION

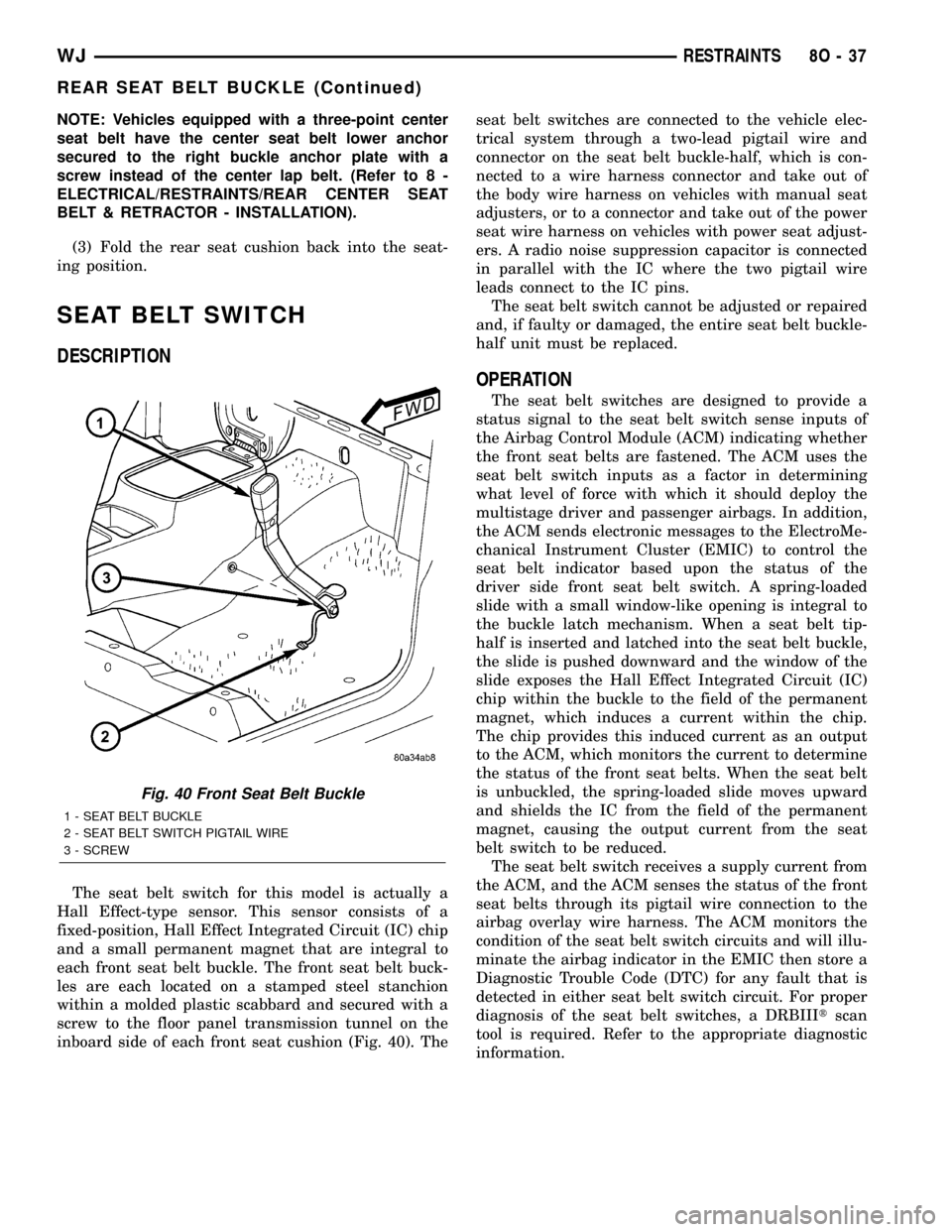

The seat belt switch for this model is actually a

Hall Effect-type sensor. This sensor consists of a

fixed-position, Hall Effect Integrated Circuit (IC) chip

and a small permanent magnet that are integral to

each front seat belt buckle. The front seat belt buck-

les are each located on a stamped steel stanchion

within a molded plastic scabbard and secured with a

screw to the floor panel transmission tunnel on the

inboard side of each front seat cushion (Fig. 40). Theseat belt switches are connected to the vehicle elec-

trical system through a two-lead pigtail wire and

connector on the seat belt buckle-half, which is con-

nected to a wire harness connector and take out of

the body wire harness on vehicles with manual seat

adjusters, or to a connector and take out of the power

seat wire harness on vehicles with power seat adjust-

ers. A radio noise suppression capacitor is connected

in parallel with the IC where the two pigtail wire

leads connect to the IC pins.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire seat belt buckle-

half unit must be replaced.

OPERATION

The seat belt switches are designed to provide a

status signal to the seat belt switch sense inputs of

the Airbag Control Module (ACM) indicating whether

the front seat belts are fastened. The ACM uses the

seat belt switch inputs as a factor in determining

what level of force with which it should deploy the

multistage driver and passenger airbags. In addition,

the ACM sends electronic messages to the ElectroMe-

chanical Instrument Cluster (EMIC) to control the

seat belt indicator based upon the status of the

driver side front seat belt switch. A spring-loaded

slide with a small window-like opening is integral to

the buckle latch mechanism. When a seat belt tip-

half is inserted and latched into the seat belt buckle,

the slide is pushed downward and the window of the

slide exposes the Hall Effect Integrated Circuit (IC)

chip within the buckle to the field of the permanent

magnet, which induces a current within the chip.

The chip provides this induced current as an output

to the ACM, which monitors the current to determine

the status of the front seat belts. When the seat belt

is unbuckled, the spring-loaded slide moves upward

and shields the IC from the field of the permanent

magnet, causing the output current from the seat

belt switch to be reduced.

The seat belt switch receives a supply current from

the ACM, and the ACM senses the status of the front

seat belts through its pigtail wire connection to the

airbag overlay wire harness. The ACM monitors the

condition of the seat belt switch circuits and will illu-

minate the airbag indicator in the EMIC then store a

Diagnostic Trouble Code (DTC) for any fault that is

detected in either seat belt switch circuit. For proper

diagnosis of the seat belt switches, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

Fig. 40 Front Seat Belt Buckle

1 - SEAT BELT BUCKLE

2 - SEAT BELT SWITCH PIGTAIL WIRE

3 - SCREW

WJRESTRAINTS 8O - 37

REAR SEAT BELT BUCKLE (Continued)

Page 623 of 2199

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block with

the hook (Fig. 10).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

FRONT WIPER MODULE

DESCRIPTION

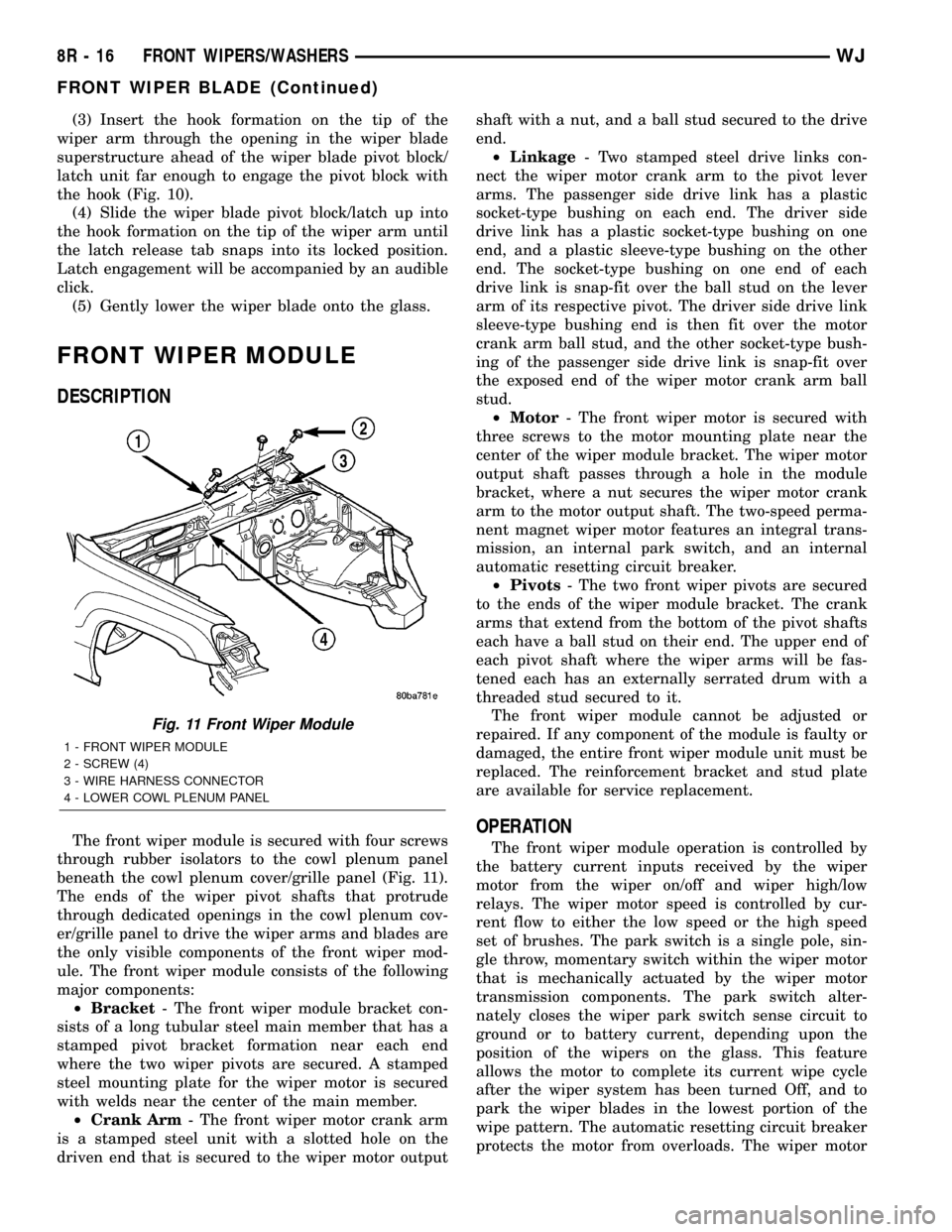

The front wiper module is secured with four screws

through rubber isolators to the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 11).

The ends of the wiper pivot shafts that protrude

through dedicated openings in the cowl plenum cov-

er/grille panel to drive the wiper arms and blades are

the only visible components of the front wiper mod-

ule. The front wiper module consists of the following

major components:

²Bracket- The front wiper module bracket con-

sists of a long tubular steel main member that has a

stamped pivot bracket formation near each end

where the two wiper pivots are secured. A stamped

steel mounting plate for the wiper motor is secured

with welds near the center of the main member.

²Crank Arm- The front wiper motor crank arm

is a stamped steel unit with a slotted hole on the

driven end that is secured to the wiper motor outputshaft with a nut, and a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the pivot lever

arms. The passenger side drive link has a plastic

socket-type bushing on each end. The driver side

drive link has a plastic socket-type bushing on one

end, and a plastic sleeve-type bushing on the other

end. The socket-type bushing on one end of each

drive link is snap-fit over the ball stud on the lever

arm of its respective pivot. The driver side drive link

sleeve-type bushing end is then fit over the motor

crank arm ball stud, and the other socket-type bush-

ing of the passenger side drive link is snap-fit over

the exposed end of the wiper motor crank arm ball

stud.

²Motor- The front wiper motor is secured with

three screws to the motor mounting plate near the

center of the wiper module bracket. The wiper motor

output shaft passes through a hole in the module

bracket, where a nut secures the wiper motor crank

arm to the motor output shaft. The two-speed perma-

nent magnet wiper motor features an integral trans-

mission, an internal park switch, and an internal

automatic resetting circuit breaker.

²Pivots- The two front wiper pivots are secured

to the ends of the wiper module bracket. The crank

arms that extend from the bottom of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each has an externally serrated drum with a

threaded stud secured to it.

The front wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire front wiper module unit must be

replaced. The reinforcement bracket and stud plate

are available for service replacement.OPERATION

The front wiper module operation is controlled by

the battery current inputs received by the wiper

motor from the wiper on/off and wiper high/low

relays. The wiper motor speed is controlled by cur-

rent flow to either the low speed or the high speed

set of brushes. The park switch is a single pole, sin-

gle throw, momentary switch within the wiper motor

that is mechanically actuated by the wiper motor

transmission components. The park switch alter-

nately closes the wiper park switch sense circuit to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the motor to complete its current wipe cycle

after the wiper system has been turned Off, and to

park the wiper blades in the lowest portion of the

wipe pattern. The automatic resetting circuit breaker

protects the motor from overloads. The wiper motor

Fig. 11 Front Wiper Module

1 - FRONT WIPER MODULE

2 - SCREW (4)

3 - WIRE HARNESS CONNECTOR

4 - LOWER COWL PLENUM PANEL

8R - 16 FRONT WIPERS/WASHERSWJ

FRONT WIPER BLADE (Continued)

Page 652 of 2199

motor that is secured with screws to the wiper motor

and to the liftgate inner panel.

²Electronic Controls- The rear wiper module

electronic controls include the rear wiper system

electronic logic and rear wiper motor electronic con-

trols. The electronic controls for the motor include an

electronic speed control that speeds the wiper blade

near the center of the glass, but slows the wiper

blade during directional reversals at each end of the

wipe pattern and during wiper blade off-the-glass

parking for quieter operation.

²Motor- The permanent magnet rear wiper

motor is secured with screws to the rear wiper mod-

ule bracket. The wiper motor includes an integral

transmission, and the motor output shaft.

The rear wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire rear wiper module unit must be

replaced. The motor output shaft gasket, bezel, nut,

and nut cover are available for service replacement.

OPERATION

The rear wiper module receives non-switched bat-

tery current through a fuse in the Junction Block

(JB) and is grounded at all times. The rear wiper

module operation is controlled by the vehicle operator

through battery current signal inputs received by the

rear wiper module electronic controls from the right

multi-function switch on the steering column. The

module also receives an external control input from

the liftgate flip-up glass ajar switch circuit. The rear

wiper module electronic control logic uses these

inputs, its internal inputs, and its programming to

provide continuous wipe, delay wipe, wipe-after-wash

and off-the-glass wiper blade parking. The wiper

blade cycling is controlled by the rear wiper module

electronic controls, which control current flow to the

wiper motor brushes. The wiper motor transmission

converts the rotary output of the wiper motor to the

back and forth wiping motion of the rear wiper arm

and blade on the liftgate glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear wiper arm from the rear

wiper motor output shaft. (Refer to 8 - ELECTRI-

CAL/REAR WIPERS/WASHERS/REAR WIPER ARM

- REMOVAL).

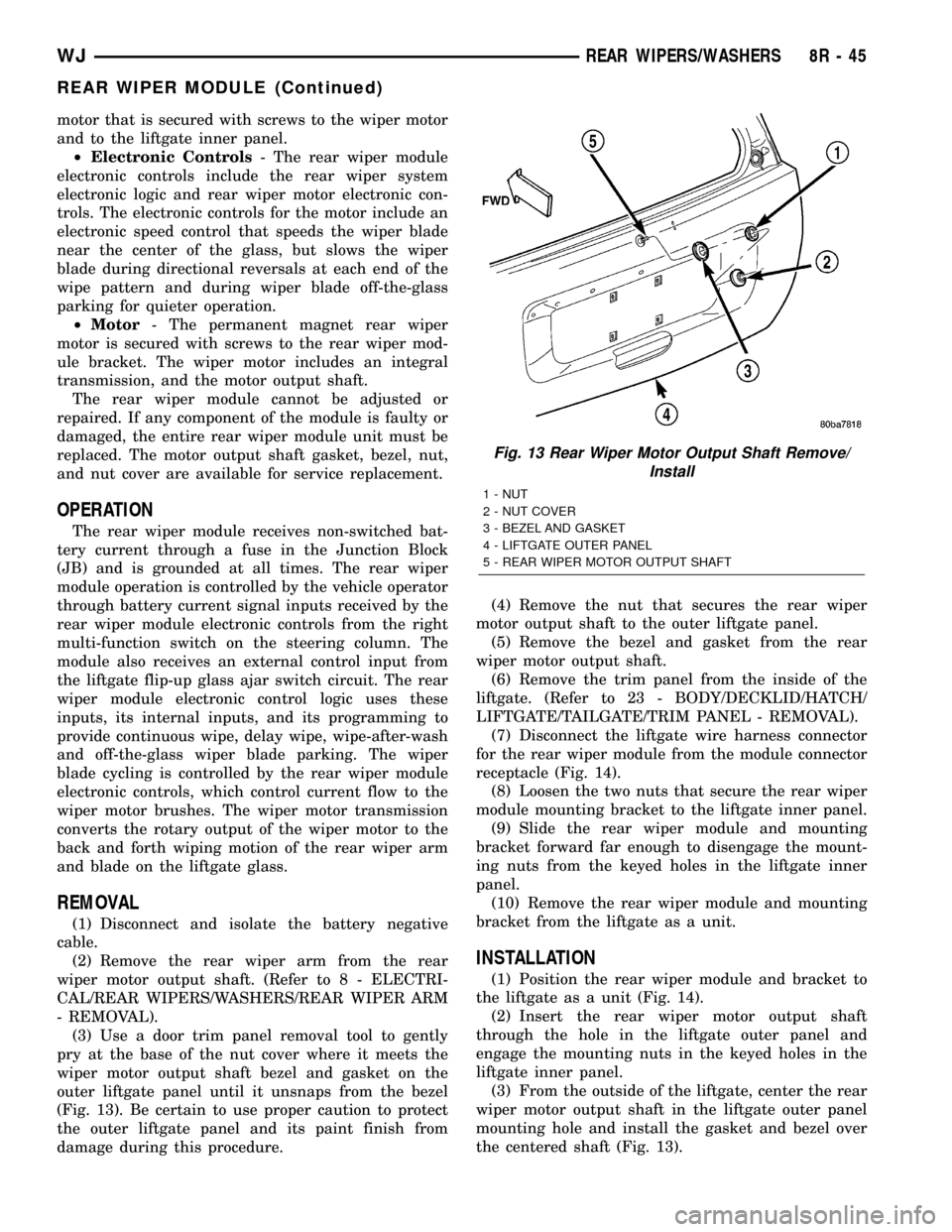

(3) Use a door trim panel removal tool to gently

pry at the base of the nut cover where it meets the

wiper motor output shaft bezel and gasket on the

outer liftgate panel until it unsnaps from the bezel

(Fig. 13). Be certain to use proper caution to protect

the outer liftgate panel and its paint finish from

damage during this procedure.(4) Remove the nut that secures the rear wiper

motor output shaft to the outer liftgate panel.

(5) Remove the bezel and gasket from the rear

wiper motor output shaft.

(6) Remove the trim panel from the inside of the

liftgate. (Refer to 23 - BODY/DECKLID/HATCH/

LIFTGATE/TAILGATE/TRIM PANEL - REMOVAL).

(7) Disconnect the liftgate wire harness connector

for the rear wiper module from the module connector

receptacle (Fig. 14).

(8) Loosen the two nuts that secure the rear wiper

module mounting bracket to the liftgate inner panel.

(9) Slide the rear wiper module and mounting

bracket forward far enough to disengage the mount-

ing nuts from the keyed holes in the liftgate inner

panel.

(10) Remove the rear wiper module and mounting

bracket from the liftgate as a unit.

INSTALLATION

(1) Position the rear wiper module and bracket to

the liftgate as a unit (Fig. 14).

(2) Insert the rear wiper motor output shaft

through the hole in the liftgate outer panel and

engage the mounting nuts in the keyed holes in the

liftgate inner panel.

(3) From the outside of the liftgate, center the rear

wiper motor output shaft in the liftgate outer panel

mounting hole and install the gasket and bezel over

the centered shaft (Fig. 13).

Fig. 13 Rear Wiper Motor Output Shaft Remove/

Install

1 - NUT

2 - NUT COVER

3 - BEZEL AND GASKET

4 - LIFTGATE OUTER PANEL

5 - REAR WIPER MOTOR OUTPUT SHAFT

WJREAR WIPERS/WASHERS 8R - 45

REAR WIPER MODULE (Continued)

Page 1187 of 2199

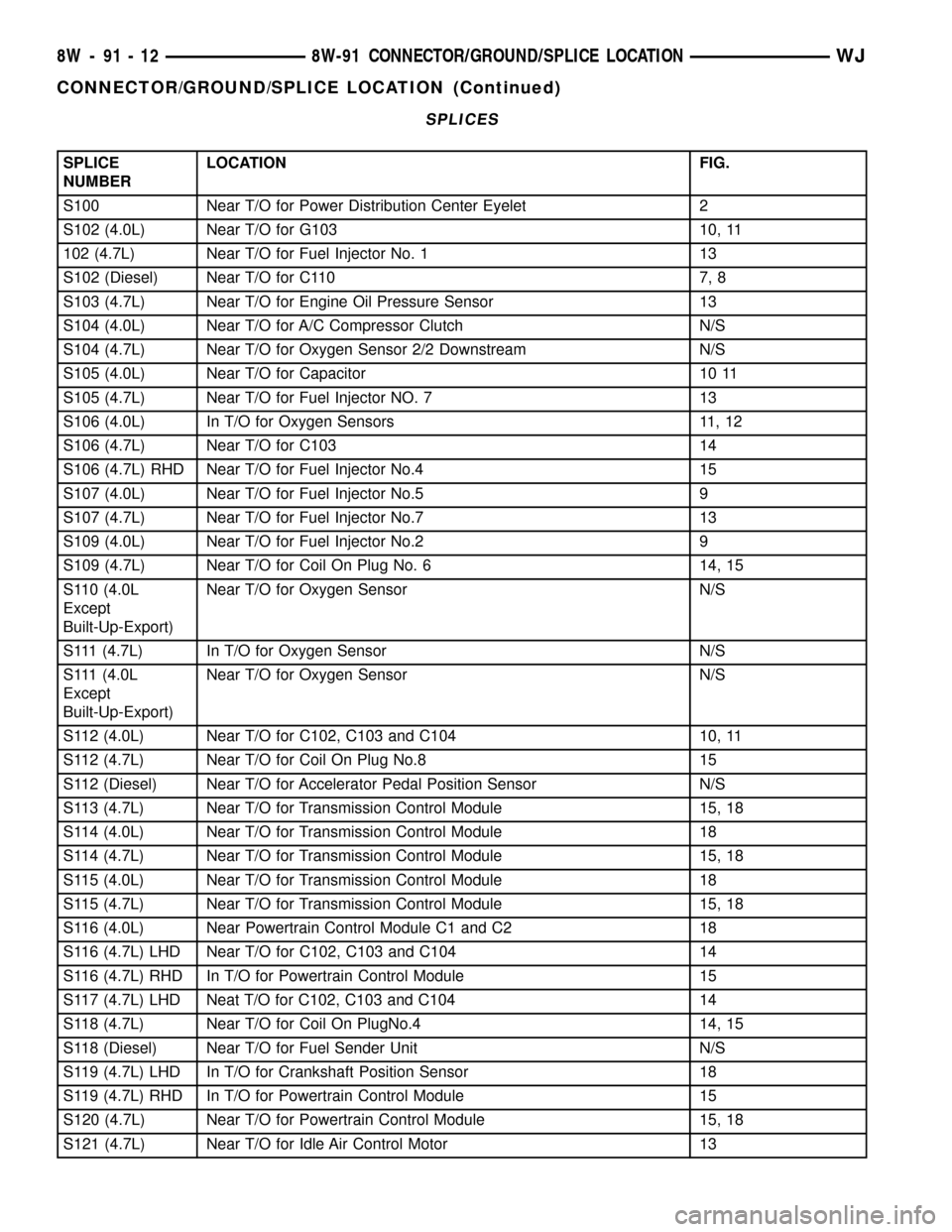

SPLICES

SPLICE

NUMBERLOCATION FIG.

S100 Near T/O for Power Distribution Center Eyelet 2

S102 (4.0L) Near T/O for G103 10, 11

102 (4.7L) Near T/O for Fuel Injector No. 1 13

S102 (Diesel) Near T/O for C110 7, 8

S103 (4.7L) Near T/O for Engine Oil Pressure Sensor 13

S104 (4.0L) Near T/O for A/C Compressor Clutch N/S

S104 (4.7L) Near T/O for Oxygen Sensor 2/2 Downstream N/S

S105 (4.0L) Near T/O for Capacitor 10 11

S105 (4.7L) Near T/O for Fuel Injector NO. 7 13

S106 (4.0L) In T/O for Oxygen Sensors 11, 12

S106 (4.7L) Near T/O for C103 14

S106 (4.7L) RHD Near T/O for Fuel Injector No.4 15

S107 (4.0L) Near T/O for Fuel Injector No.5 9

S107 (4.7L) Near T/O for Fuel Injector No.7 13

S109 (4.0L) Near T/O for Fuel Injector No.2 9

S109 (4.7L) Near T/O for Coil On Plug No. 6 14, 15

S110 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S111 (4.7L) In T/O for Oxygen Sensor N/S

S111 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S112 (4.0L) Near T/O for C102, C103 and C104 10, 11

S112 (4.7L) Near T/O for Coil On Plug No.8 15

S112 (Diesel) Near T/O for Accelerator Pedal Position Sensor N/S

S113 (4.7L) Near T/O for Transmission Control Module 15, 18

S114 (4.0L) Near T/O for Transmission Control Module 18

S114 (4.7L) Near T/O for Transmission Control Module 15, 18

S115 (4.0L) Near T/O for Transmission Control Module 18

S115 (4.7L) Near T/O for Transmission Control Module 15, 18

S116 (4.0L) Near Powertrain Control Module C1 and C2 18

S116 (4.7L) LHD Near T/O for C102, C103 and C104 14

S116 (4.7L) RHD In T/O for Powertrain Control Module 15

S117 (4.7L) LHD Neat T/O for C102, C103 and C104 14

S118 (4.7L) Near T/O for Coil On PlugNo.4 14, 15

S118 (Diesel) Near T/O for Fuel Sender Unit N/S

S119 (4.7L) LHD In T/O for Crankshaft Position Sensor 18

S119 (4.7L) RHD In T/O for Powertrain Control Module 15

S120 (4.7L) Near T/O for Powertrain Control Module 15, 18

S121 (4.7L) Near T/O for Idle Air Control Motor 13

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1265 of 2199

(12) Install the push rods, rocker arms, pivots and

bridges in the order they were removed (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

(13) Install the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

(14) Attach the air conditioner compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 N´m (30 ft. lbs.) torque.

(15) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 N´m (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(16) Install the serpentine drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(17) Install the air cleaner and ducting.

(18) Connect the hoses to the engine thermostat

housing and fill the cooling system to the specified

level (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(19) The automatic transmission throttle linkage

and cable must be adjusted after completing the

engine cylinder head installation (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - AW4/

THROTTLE VALVE CABLE - ADJUSTMENTS).

(20) Install the temperature sending unit and con-

nect the wire connector.

(21) If equipped with air conditioning, install A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION) and charge A/C system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(22) Connect negative cable to battery.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(23) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the engine thermostat opens. Add coolant, if

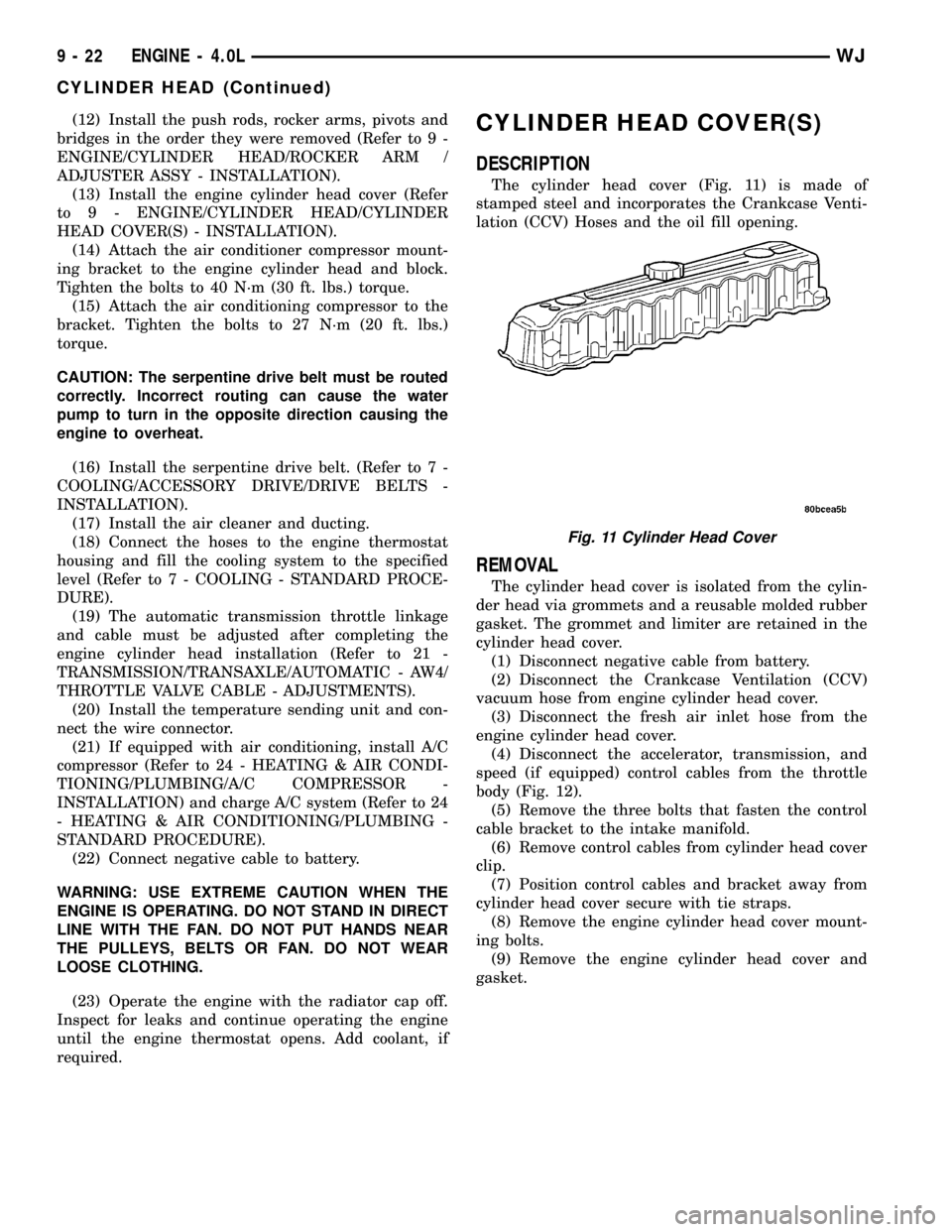

required.CYLINDER HEAD COVER(S)

DESCRIPTION

The cylinder head cover (Fig. 11) is made of

stamped steel and incorporates the Crankcase Venti-

lation (CCV) Hoses and the oil fill opening.

REMOVAL

The cylinder head cover is isolated from the cylin-

der head via grommets and a reusable molded rubber

gasket. The grommet and limiter are retained in the

cylinder head cover.

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover.

(3) Disconnect the fresh air inlet hose from the

engine cylinder head cover.

(4) Disconnect the accelerator, transmission, and

speed (if equipped) control cables from the throttle

body (Fig. 12).

(5) Remove the three bolts that fasten the control

cable bracket to the intake manifold.

(6) Remove control cables from cylinder head cover

clip.

(7) Position control cables and bracket away from

cylinder head cover secure with tie straps.

(8) Remove the engine cylinder head cover mount-

ing bolts.

(9) Remove the engine cylinder head cover and

gasket.

Fig. 11 Cylinder Head Cover

9 - 22 ENGINE - 4.0LWJ

CYLINDER HEAD (Continued)

Page 1491 of 2199

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is concealed within and

integral to the ignition switch, which is mounted on

the steering column. The key-in ignition switch is

actuated by the ignition lock cylinder mechanism,

and is hard wired between a body ground and the

Body Control Module (BCM) through the instrument

panel wire harness.

The key-in ignition switch cannot be adjusted or

repaired and, if faulty or damaged, the entire igni-

tion switch unit must be replaced,(Refer to 19 -

STEERING/COLUMN/LOCK CYLINDER HOUSING

- REMOVAL). For complete circuit diagrams, refer to

Body Control Modulein the Contents of Wiring

Diagrams.

OPERATION

The key-in ignition switch closes a path to ground

for the BCM when the ignition key is inserted in the

ignition lock cylinder, and opens the ground path

when the key is removed from the ignition lock cyl-

inder. The BCM monitors the key-in ignition switch

status through an internal pull-up, then sends the

proper switch status messages to other electronic

modules over the Programmable Communications

Interface (PCI) data bus network. The key-in ignition

switch status is also used by the BCM as an input

for chime warning system operation.

DIAGNOSIS AND TESTING

KEY-IN IGNITION SWITCH

For complete circuit diagrams, refer toBody Con-

trol Modulein the Contents of Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector from the key-in ignition switch connector

receptacle on the ignition switch. Check for continu-

ity between the key-in ignition switch sense and

ground terminals of the key-in ignition switch con-

nector receptacle. There should be continuity with

the key inserted in the ignition lock cylinder, and no

continuity with the key removed from the ignition

lock cylinder. If OK, go to Step 2. If not OK, replace

the faulty ignition switch unit.

(2) Check for continuity between the ground cir-

cuit cavity of the instrument panel wire harness con-

nector for the key-in ignition switch and a good

ground. There should be continuity. If OK, go to Step

3. If not OK, repair the open ground circuit to ground

as required.

(3) Disconnect the gray 26-way instrument panel

wire harness connector from the Body Control Mod-

ule (BCM) connector receptacle. Check for continuity

between the key-in ignition switch sense circuit cav-

ity of the instrument panel wire harness connector

for the key-in ignition switch and a good ground.

There should be no continuity. If OK, go to Step 4. If

not OK, repair the shorted key-in ignition switch

sense circuit as required.

(4) Check for continuity between the key-in igni-

tion switch sense circuit cavities of the instrument

panel wire harness connector for the key-in ignition

switch and the gray 26-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRB scan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open key-in ignition switch sense

circuit as required.

LOCK CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Disconnect negative battery cable at battery.

(2) If equipped with an automatic transmission,

place shifter in PARK position.

(3) Rotate key to ON position.

19 - 14 COLUMNWJ

Page 1521 of 2199

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT................71

STANDARD PROCEDURE - TRANSMISSION

FILL................................72

FRONT CLUTCH

DESCRIPTION.........................73

OPERATION...........................74

DISASSEMBLY.........................74

INSPECTION..........................74

ASSEMBLY............................74

FRONT SERVO

DESCRIPTION.........................77

OPERATION...........................77

DISASSEMBLY.........................77

CLEANING............................77

INSPECTION..........................77

ASSEMBLY............................77

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE..............................78

REMOVAL.............................78

INSTALLATION.........................79

ADJUSTMENTS - GEARSHIFT CABLE.......79

OIL PUMP

DESCRIPTION.........................80

OPERATION...........................80

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK......................81

DISASSEMBLY.........................81

CLEANING............................83

INSPECTION..........................83

ASSEMBLY............................83

OUTPUT SHAFT FRONT BEARING

REMOVAL.............................85

INSTALLATION.........................85

OUTPUT SHAFT REAR BEARING

REMOVAL.............................85

INSTALLATION.........................85

OVERDRIVE CLUTCH

DESCRIPTION.........................86

OPERATION...........................86

OVERDRIVE OFF SWITCH

DESCRIPTION.........................86

OPERATION...........................86

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS...............87

OVERDRIVE UNIT

REMOVAL.............................87

DISASSEMBLY.........................88

CLEANING............................95

INSPECTION..........................95

ASSEMBLY............................95

INSTALLATION........................104

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION........................105

OPERATION..........................105DISASSEMBLY........................106

CLEANING...........................106

INSPECTION.........................106

ASSEMBLY...........................106

PARK LOCK CABLE

REMOVAL............................108

INSTALLATION........................108

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING - PARK/NEUTRAL

POSITION SWITCH...................109

REMOVAL............................109

INSTALLATION........................109

PISTONS

DESCRIPTION........................110

OPERATION..........................110

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION........................112

OPERATION..........................112

DISASSEMBLY........................112

INSPECTION..........................113

ASSEMBLY...........................113

REAR CLUTCH

DESCRIPTION........................118

OPERATION..........................118

DISASSEMBLY........................119

CLEANING...........................119

INSPECTION.........................120

ASSEMBLY...........................120

REAR SERVO

DESCRIPTION........................122

OPERATION..........................122

DISASSEMBLY........................122

CLEANING...........................122

ASSEMBLY...........................123

SHIFT MECHANISM

DESCRIPTION........................123

OPERATION..........................123

REMOVAL............................123

INSTALLATION........................125

SOLENOID

DESCRIPTION........................125

OPERATION..........................126

SPEED SENSOR

DESCRIPTION........................126

OPERATION..........................126

THROTTLE VALVE CABLE

DESCRIPTION........................126

ADJUSTMENTS - TRANSMISSION THROTTLE

VALVE CABLE.......................126

TORQUE CONVERTER

DESCRIPTION........................128

OPERATION..........................132

REMOVAL............................133

INSTALLATION........................133

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION........................134

OPERATION..........................134

21 - 2 AUTOMATIC TRANSMISSION - 42REWJ

Page 1522 of 2199

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE........134

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................134

OPERATION..........................134

VALVE BODY

DESCRIPTION........................135

OPERATION..........................139REMOVAL............................154

DISASSEMBLY........................155

CLEANING...........................165

INSPECTION.........................166

ASSEMBLY...........................167

INSTALLATION........................175

ADJUSTMENTS - VALVE BODY...........175

AUTOMATIC TRANSMISSION -

42RE

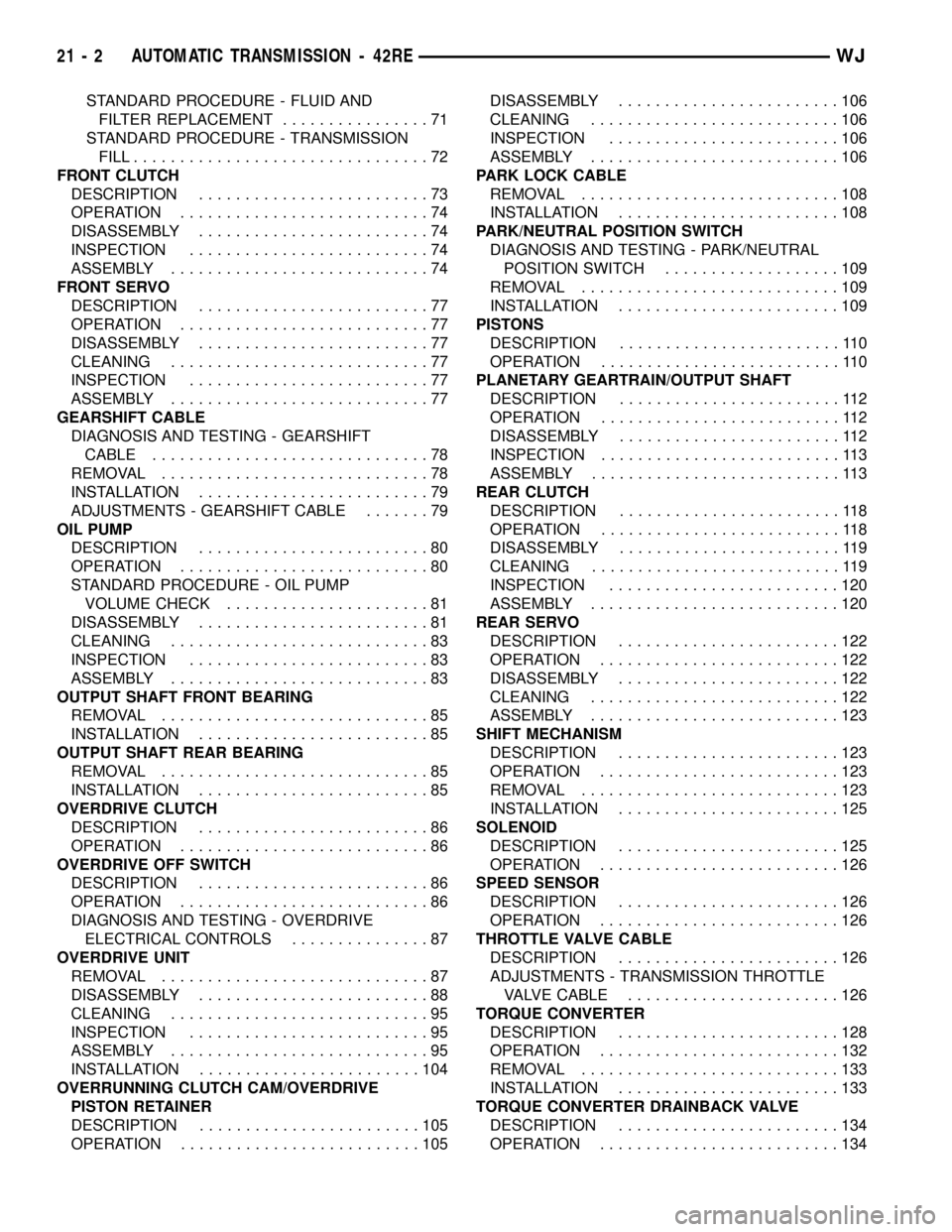

DESCRIPTION

The 42RE is a four speed fully automatic transmis-

sion (Fig. 1) with an electronic governor. The 42RE is

equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and the

low/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 3

Page 1524 of 2199

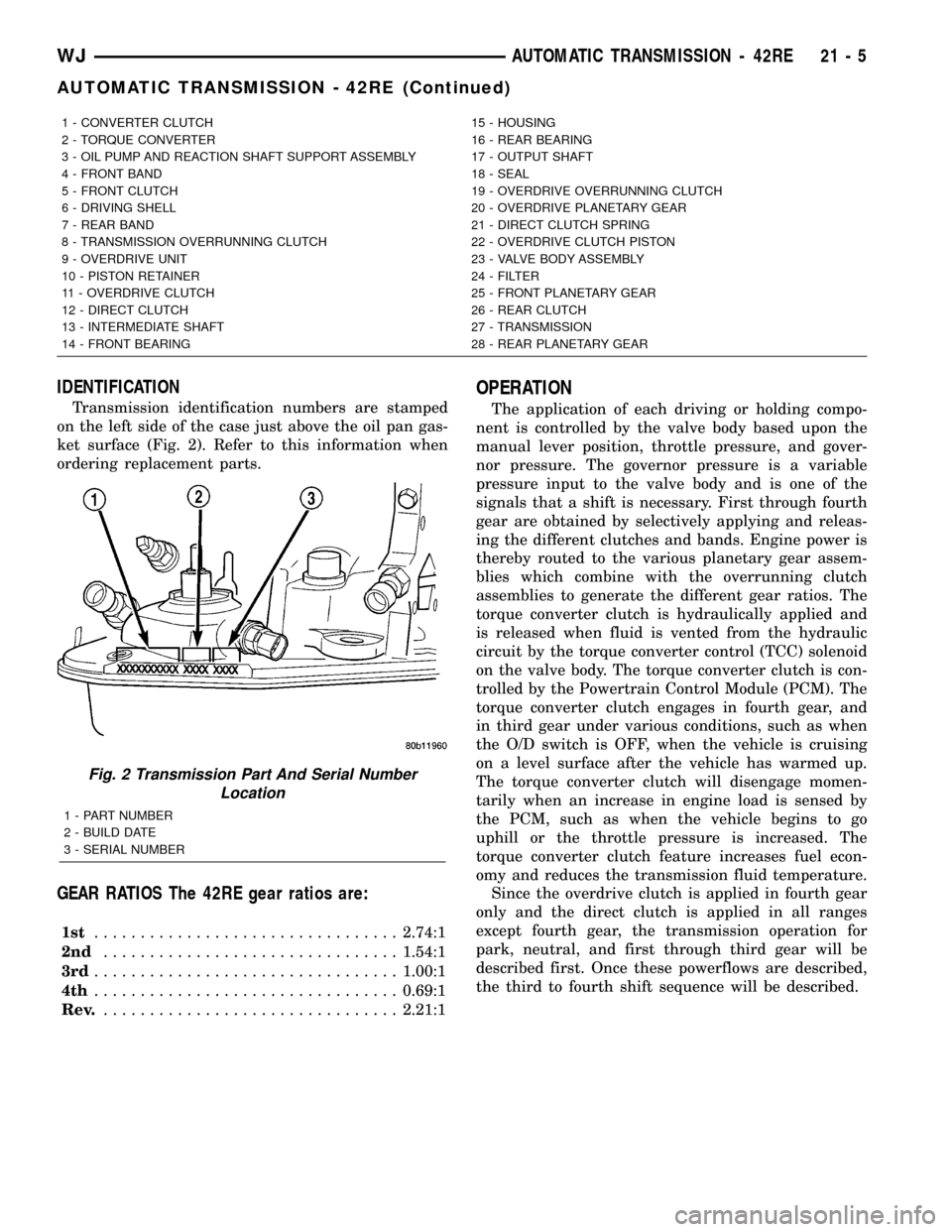

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS The 42RE gear ratios are:

1st.................................2.74:1

2nd................................1.54:1

3rd.................................1.00:1

4th.................................0.69:1

Rev.................................2.21:1

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - CONVERTER CLUTCH 15 - HOUSING

2 - TORQUE CONVERTER 16 - REAR BEARING

3 - OIL PUMP AND REACTION SHAFT SUPPORT ASSEMBLY 17 - OUTPUT SHAFT

4 - FRONT BAND 18 - SEAL

5 - FRONT CLUTCH 19 - OVERDRIVE OVERRUNNING CLUTCH

6 - DRIVING SHELL 20 - OVERDRIVE PLANETARY GEAR

7 - REAR BAND 21 - DIRECT CLUTCH SPRING

8 - TRANSMISSION OVERRUNNING CLUTCH 22 - OVERDRIVE CLUTCH PISTON

9 - OVERDRIVE UNIT 23 - VALVE BODY ASSEMBLY

10 - PISTON RETAINER 24 - FILTER

11 - OVERDRIVE CLUTCH 25 - FRONT PLANETARY GEAR

12 - DIRECT CLUTCH 26 - REAR CLUTCH

13 - INTERMEDIATE SHAFT 27 - TRANSMISSION

14 - FRONT BEARING 28 - REAR PLANETARY GEAR

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 5

AUTOMATIC TRANSMISSION - 42RE (Continued)