throttle JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1052 of 2199

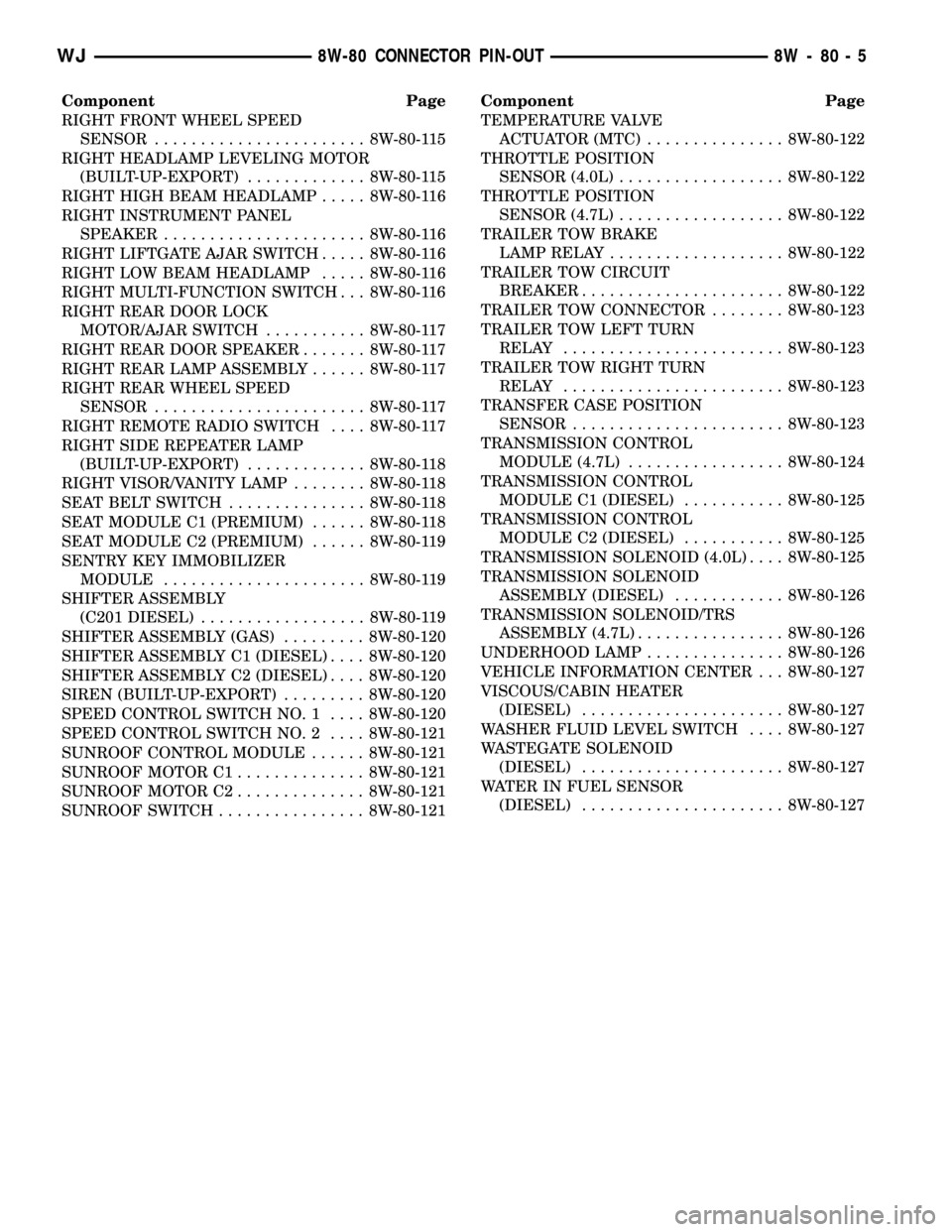

Component Page

RIGHT FRONT WHEEL SPEED

SENSOR....................... 8W-80-115

RIGHT HEADLAMP LEVELING MOTOR

(BUILT-UP-EXPORT)............. 8W-80-115

RIGHT HIGH BEAM HEADLAMP..... 8W-80-116

RIGHT INSTRUMENT PANEL

SPEAKER...................... 8W-80-116

RIGHT LIFTGATE AJAR SWITCH..... 8W-80-116

RIGHT LOW BEAM HEADLAMP..... 8W-80-116

RIGHT MULTI-FUNCTION SWITCH . . . 8W-80-116

RIGHT REAR DOOR LOCK

MOTOR/AJAR SWITCH........... 8W-80-117

RIGHT REAR DOOR SPEAKER....... 8W-80-117

RIGHT REAR LAMP ASSEMBLY...... 8W-80-117

RIGHT REAR WHEEL SPEED

SENSOR....................... 8W-80-117

RIGHT REMOTE RADIO SWITCH.... 8W-80-117

RIGHT SIDE REPEATER LAMP

(BUILT-UP-EXPORT)............. 8W-80-118

RIGHT VISOR/VANITY LAMP........ 8W-80-118

SEAT BELT SWITCH............... 8W-80-118

SEAT MODULE C1 (PREMIUM)...... 8W-80-118

SEAT MODULE C2 (PREMIUM)...... 8W-80-119

SENTRY KEY IMMOBILIZER

MODULE...................... 8W-80-119

SHIFTER ASSEMBLY

(C201 DIESEL).................. 8W-80-119

SHIFTER ASSEMBLY (GAS)......... 8W-80-120

SHIFTER ASSEMBLY C1 (DIESEL).... 8W-80-120

SHIFTER ASSEMBLY C2 (DIESEL).... 8W-80-120

SIREN (BUILT-UP-EXPORT)......... 8W-80-120

SPEED CONTROL SWITCH NO. 1.... 8W-80-120

SPEED CONTROL SWITCH NO. 2.... 8W-80-121

SUNROOF CONTROL MODULE...... 8W-80-121

SUNROOF MOTOR C1.............. 8W-80-121

SUNROOF MOTOR C2.............. 8W-80-121

SUNROOF SWITCH................ 8W-80-121Component Page

TEMPERATURE VALVE

ACTUATOR (MTC)............... 8W-80-122

THROTTLE POSITION

SENSOR (4.0L).................. 8W-80-122

THROTTLE POSITION

SENSOR (4.7L).................. 8W-80-122

TRAILER TOW BRAKE

LAMP RELAY................... 8W-80-122

TRAILER TOW CIRCUIT

BREAKER...................... 8W-80-122

TRAILER TOW CONNECTOR........ 8W-80-123

TRAILER TOW LEFT TURN

RELAY........................ 8W-80-123

TRAILER TOW RIGHT TURN

RELAY........................ 8W-80-123

TRANSFER CASE POSITION

SENSOR....................... 8W-80-123

TRANSMISSION CONTROL

MODULE (4.7L)................. 8W-80-124

TRANSMISSION CONTROL

MODULE C1 (DIESEL)........... 8W-80-125

TRANSMISSION CONTROL

MODULE C2 (DIESEL)........... 8W-80-125

TRANSMISSION SOLENOID (4.0L).... 8W-80-125

TRANSMISSION SOLENOID

ASSEMBLY (DIESEL)............ 8W-80-126

TRANSMISSION SOLENOID/TRS

ASSEMBLY (4.7L)................ 8W-80-126

UNDERHOOD LAMP............... 8W-80-126

VEHICLE INFORMATION CENTER . . . 8W-80-127

VISCOUS/CABIN HEATER

(DIESEL)...................... 8W-80-127

WASHER FLUID LEVEL SWITCH.... 8W-80-127

WASTEGATE SOLENOID

(DIESEL)...................... 8W-80-127

WATER IN FUEL SENSOR

(DIESEL)...................... 8W-80-127

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 5

Page 1155 of 2199

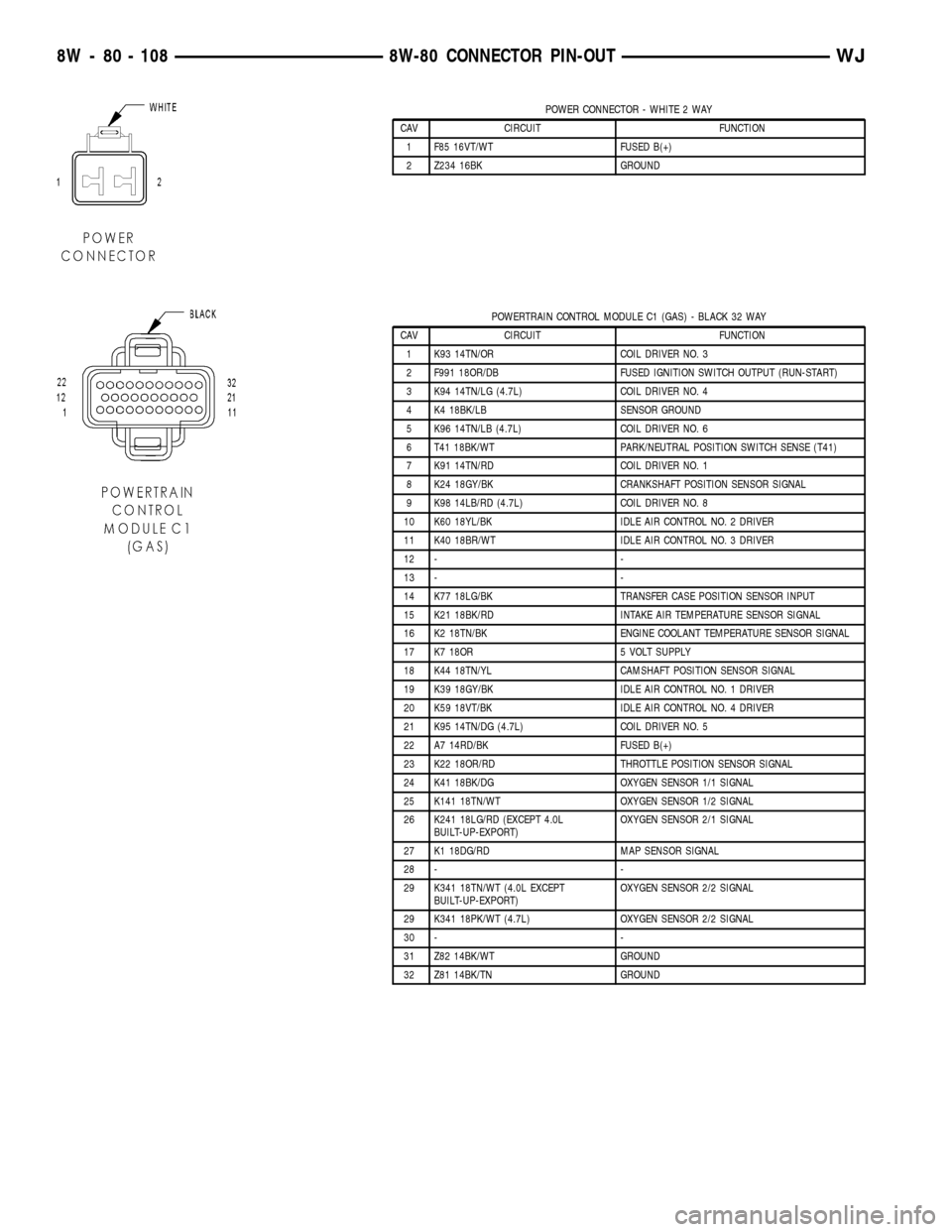

POWER CONNECTOR - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 F85 16VT/WT FUSED B(+)

2 Z234 16BK GROUND

POWERTRAIN CONTROL MODULE C1 (GAS) - BLACK 32 WAY

CAV CIRCUIT FUNCTION

1 K93 14TN/OR COIL DRIVER NO. 3

2 F991 18OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

3 K94 14TN/LG (4.7L) COIL DRIVER NO. 4

4 K4 18BK/LB SENSOR GROUND

5 K96 14TN/LB (4.7L) COIL DRIVER NO. 6

6 T41 18BK/WT PARK/NEUTRAL POSITION SWITCH SENSE (T41)

7 K91 14TN/RD COIL DRIVER NO. 1

8 K24 18GY/BK CRANKSHAFT POSITION SENSOR SIGNAL

9 K98 14LB/RD (4.7L) COIL DRIVER NO. 8

10 K60 18YL/BK IDLE AIR CONTROL NO. 2 DRIVER

11 K40 18BR/WT IDLE AIR CONTROL NO. 3 DRIVER

12 - -

13 - -

14 K77 18LG/BK TRANSFER CASE POSITION SENSOR INPUT

15 K21 18BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

16 K2 18TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

17 K7 18OR 5 VOLT SUPPLY

18 K44 18TN/YL CAMSHAFT POSITION SENSOR SIGNAL

19 K39 18GY/BK IDLE AIR CONTROL NO. 1 DRIVER

20 K59 18VT/BK IDLE AIR CONTROL NO. 4 DRIVER

21 K95 14TN/DG (4.7L) COIL DRIVER NO. 5

22 A7 14RD/BK FUSED B(+)

23 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

24 K41 18BK/DG OXYGEN SENSOR 1/1 SIGNAL

25 K141 18TN/WT OXYGEN SENSOR 1/2 SIGNAL

26 K241 18LG/RD (EXCEPT 4.0L

BUILT-UP-EXPORT)OXYGEN SENSOR 2/1 SIGNAL

27 K1 18DG/RD MAP SENSOR SIGNAL

28 - -

29 K341 18TN/WT (4.0L EXCEPT

BUILT-UP-EXPORT)OXYGEN SENSOR 2/2 SIGNAL

29 K341 18PK/WT (4.7L) OXYGEN SENSOR 2/2 SIGNAL

30 - -

31 Z82 14BK/WT GROUND

32 Z81 14BK/TN GROUND

8W - 80 - 108 8W-80 CONNECTOR PIN-OUTWJ

Page 1169 of 2199

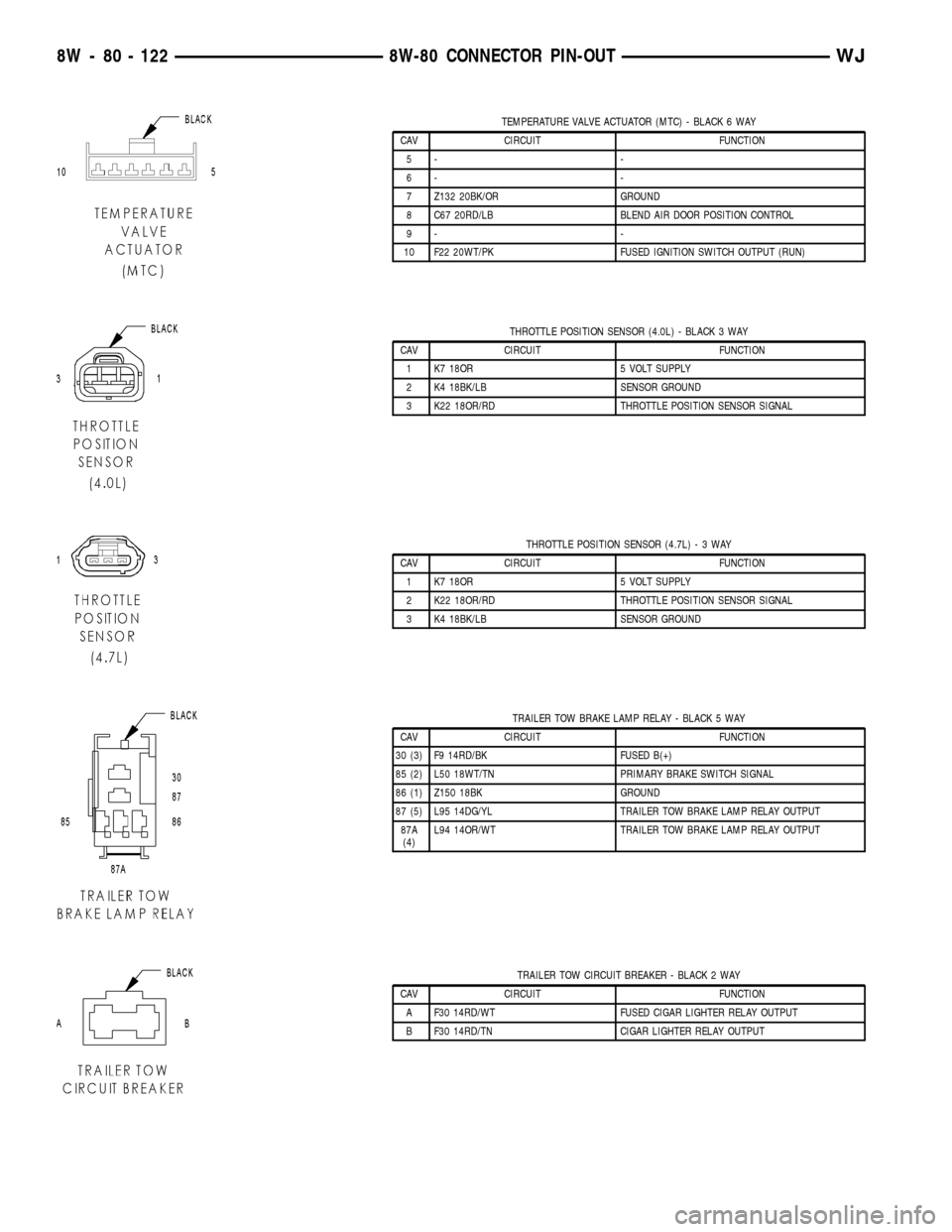

TEMPERATURE VALVE ACTUATOR (MTC) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

5- -

6- -

7 Z132 20BK/OR GROUND

8 C67 20RD/LB BLEND AIR DOOR POSITION CONTROL

9- -

10 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

THROTTLE POSITION SENSOR (4.0L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K7 18OR 5 VOLT SUPPLY

2 K4 18BK/LB SENSOR GROUND

3 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

THROTTLE POSITION SENSOR (4.7L)-3WAY

CAV CIRCUIT FUNCTION

1 K7 18OR 5 VOLT SUPPLY

2 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

3 K4 18BK/LB SENSOR GROUND

TRAILER TOW BRAKE LAMP RELAY - BLACK 5 WAY

CAV CIRCUIT FUNCTION

30 (3) F9 14RD/BK FUSED B(+)

85 (2) L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

86 (1) Z150 18BK GROUND

87 (5) L95 14DG/YL TRAILER TOW BRAKE LAMP RELAY OUTPUT

87A

(4)L94 14OR/WT TRAILER TOW BRAKE LAMP RELAY OUTPUT

TRAILER TOW CIRCUIT BREAKER - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A F30 14RD/WT FUSED CIGAR LIGHTER RELAY OUTPUT

B F30 14RD/TN CIGAR LIGHTER RELAY OUTPUT

8W - 80 - 122 8W-80 CONNECTOR PIN-OUTWJ

Page 1171 of 2199

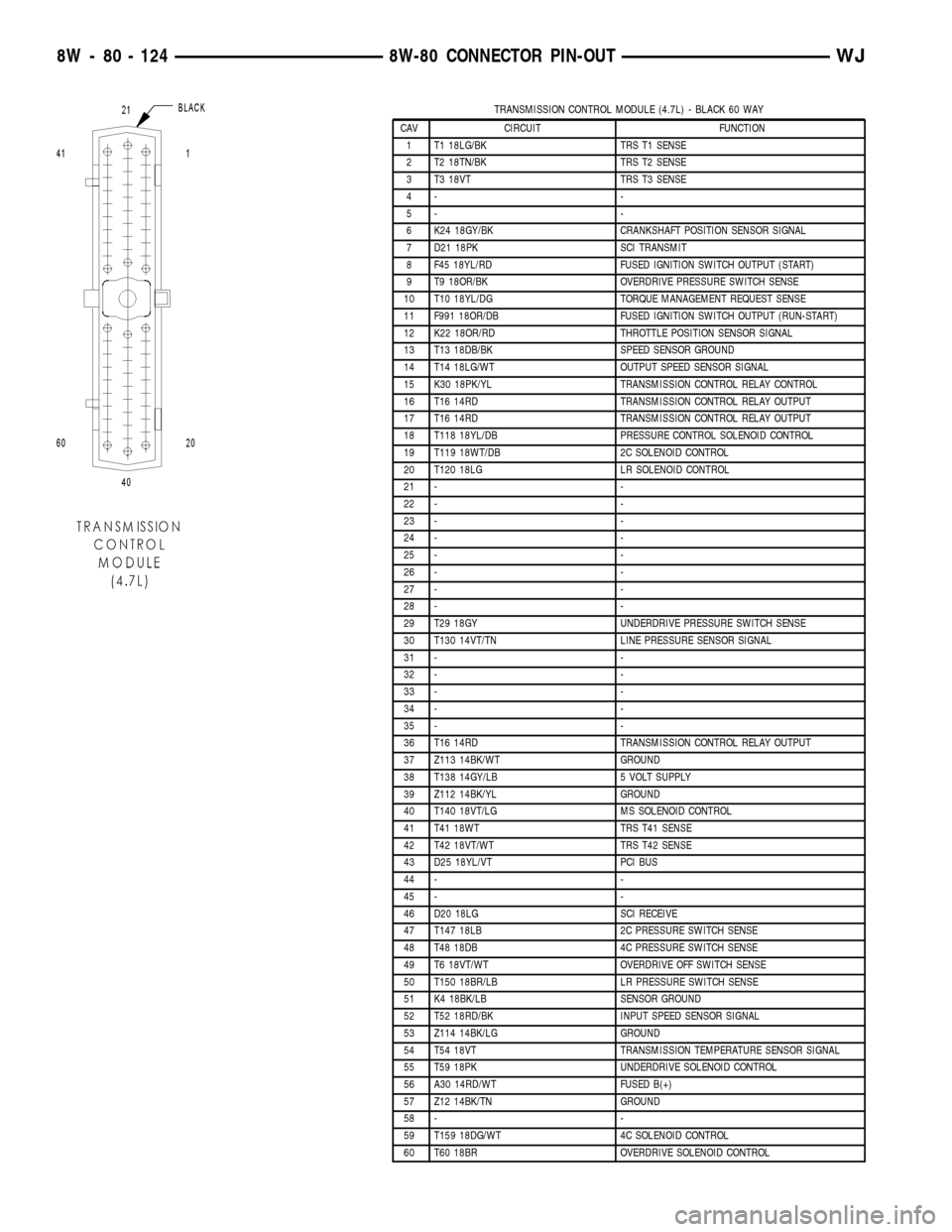

TRANSMISSION CONTROL MODULE (4.7L) - BLACK 60 WAY

CAV CIRCUIT FUNCTION

1 T1 18LG/BK TRS T1 SENSE

2 T2 18TN/BK TRS T2 SENSE

3 T3 18VT TRS T3 SENSE

4- -

5- -

6 K24 18GY/BK CRANKSHAFT POSITION SENSOR SIGNAL

7 D21 18PK SCI TRANSMIT

8 F45 18YL/RD FUSED IGNITION SWITCH OUTPUT (START)

9 T9 18OR/BK OVERDRIVE PRESSURE SWITCH SENSE

10 T10 18YL/DG TORQUE MANAGEMENT REQUEST SENSE

11 F991 18OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

12 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

13 T13 18DB/BK SPEED SENSOR GROUND

14 T14 18LG/WT OUTPUT SPEED SENSOR SIGNAL

15 K30 18PK/YL TRANSMISSION CONTROL RELAY CONTROL

16 T16 14RD TRANSMISSION CONTROL RELAY OUTPUT

17 T16 14RD TRANSMISSION CONTROL RELAY OUTPUT

18 T118 18YL/DB PRESSURE CONTROL SOLENOID CONTROL

19 T119 18WT/DB 2C SOLENOID CONTROL

20 T120 18LG LR SOLENOID CONTROL

21 - -

22 - -

23 - -

24 - -

25 - -

26 - -

27 - -

28 - -

29 T29 18GY UNDERDRIVE PRESSURE SWITCH SENSE

30 T130 14VT/TN LINE PRESSURE SENSOR SIGNAL

31 - -

32 - -

33 - -

34 - -

35 - -

36 T16 14RD TRANSMISSION CONTROL RELAY OUTPUT

37 Z113 14BK/WT GROUND

38 T138 14GY/LB 5 VOLT SUPPLY

39 Z112 14BK/YL GROUND

40 T140 18VT/LG MS SOLENOID CONTROL

41 T41 18WT TRS T41 SENSE

42 T42 18VT/WT TRS T42 SENSE

43 D25 18YL/VT PCI BUS

44 - -

45 - -

46 D20 18LG SCI RECEIVE

47 T147 18LB 2C PRESSURE SWITCH SENSE

48 T48 18DB 4C PRESSURE SWITCH SENSE

49 T6 18VT/WT OVERDRIVE OFF SWITCH SENSE

50 T150 18BR/LB LR PRESSURE SWITCH SENSE

51 K4 18BK/LB SENSOR GROUND

52 T52 18RD/BK INPUT SPEED SENSOR SIGNAL

53 Z114 14BK/LG GROUND

54 T54 18VT TRANSMISSION TEMPERATURE SENSOR SIGNAL

55 T59 18PK UNDERDRIVE SOLENOID CONTROL

56 A30 14RD/WT FUSED B(+)

57 Z12 14BK/TN GROUND

58 - -

59 T159 18DG/WT 4C SOLENOID CONTROL

60 T60 18BR OVERDRIVE SOLENOID CONTROL

8W - 80 - 124 8W-80 CONNECTOR PIN-OUTWJ

Page 1181 of 2199

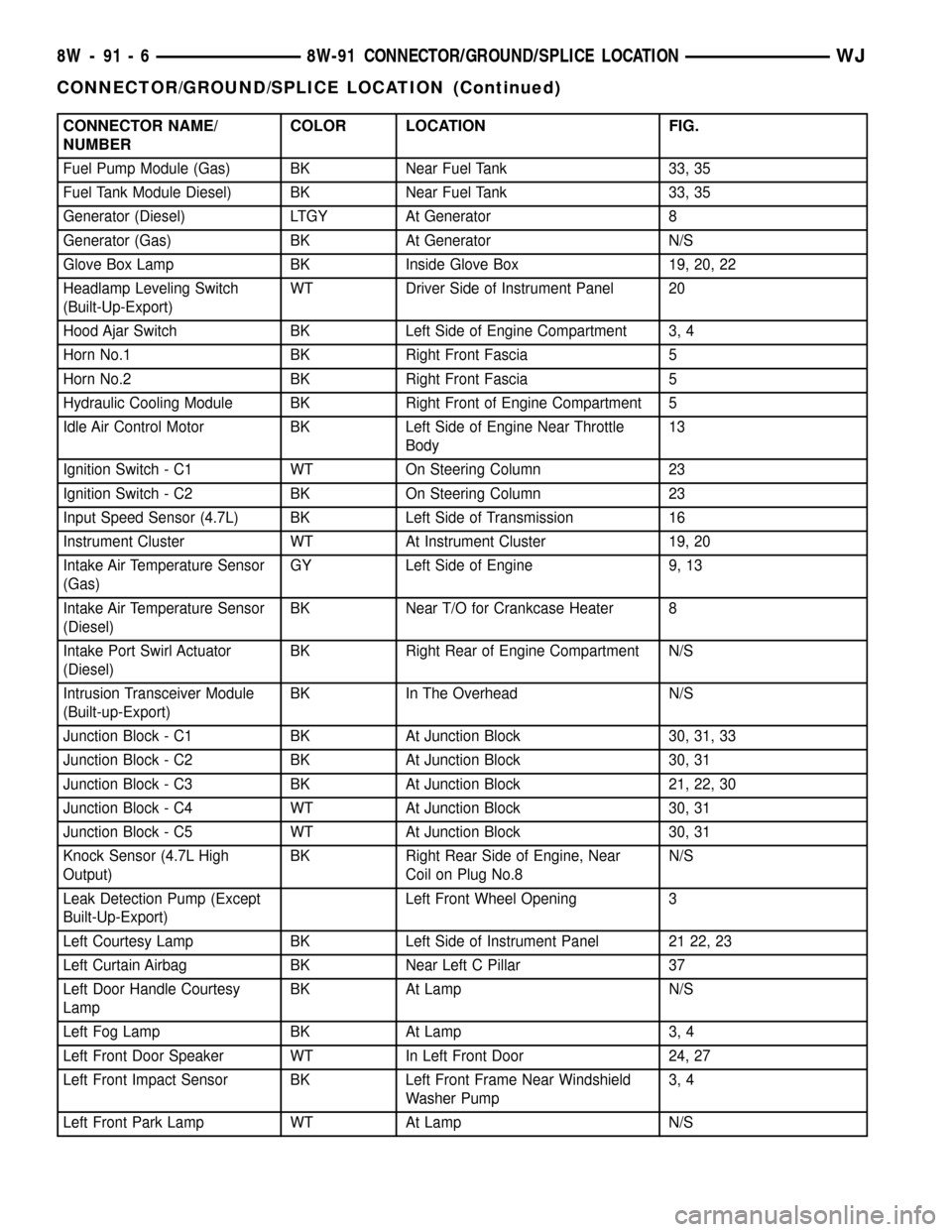

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Fuel Pump Module (Gas) BK Near Fuel Tank 33, 35

Fuel Tank Module Diesel) BK Near Fuel Tank 33, 35

Generator (Diesel) LTGY At Generator 8

Generator (Gas) BK At Generator N/S

Glove Box Lamp BK Inside Glove Box 19, 20, 22

Headlamp Leveling Switch

(Built-Up-Export)WT Driver Side of Instrument Panel 20

Hood Ajar Switch BK Left Side of Engine Compartment 3, 4

Horn No.1 BK Right Front Fascia 5

Horn No.2 BK Right Front Fascia 5

Hydraulic Cooling Module BK Right Front of Engine Compartment 5

Idle Air Control Motor BK Left Side of Engine Near Throttle

Body13

Ignition Switch - C1 WT On Steering Column 23

Ignition Switch - C2 BK On Steering Column 23

Input Speed Sensor (4.7L) BK Left Side of Transmission 16

Instrument Cluster WT At Instrument Cluster 19, 20

Intake Air Temperature Sensor

(Gas)GY Left Side of Engine 9, 13

Intake Air Temperature Sensor

(Diesel)BK Near T/O for Crankcase Heater 8

Intake Port Swirl Actuator

(Diesel)BK Right Rear of Engine Compartment N/S

Intrusion Transceiver Module

(Built-up-Export)BK In The Overhead N/S

Junction Block - C1 BK At Junction Block 30, 31, 33

Junction Block - C2 BK At Junction Block 30, 31

Junction Block - C3 BK At Junction Block 21, 22, 30

Junction Block - C4 WT At Junction Block 30, 31

Junction Block - C5 WT At Junction Block 30, 31

Knock Sensor (4.7L High

Output)BK Right Rear Side of Engine, Near

Coil on Plug No.8N/S

Leak Detection Pump (Except

Built-Up-Export)Left Front Wheel Opening 3

Left Courtesy Lamp BK Left Side of Instrument Panel 21 22, 23

Left Curtain Airbag BK Near Left C Pillar 37

Left Door Handle Courtesy

LampBK At Lamp N/S

Left Fog Lamp BK At Lamp 3, 4

Left Front Door Speaker WT In Left Front Door 24, 27

Left Front Impact Sensor BK Left Front Frame Near Windshield

Washer Pump3, 4

Left Front Park Lamp WT At Lamp N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1182 of 2199

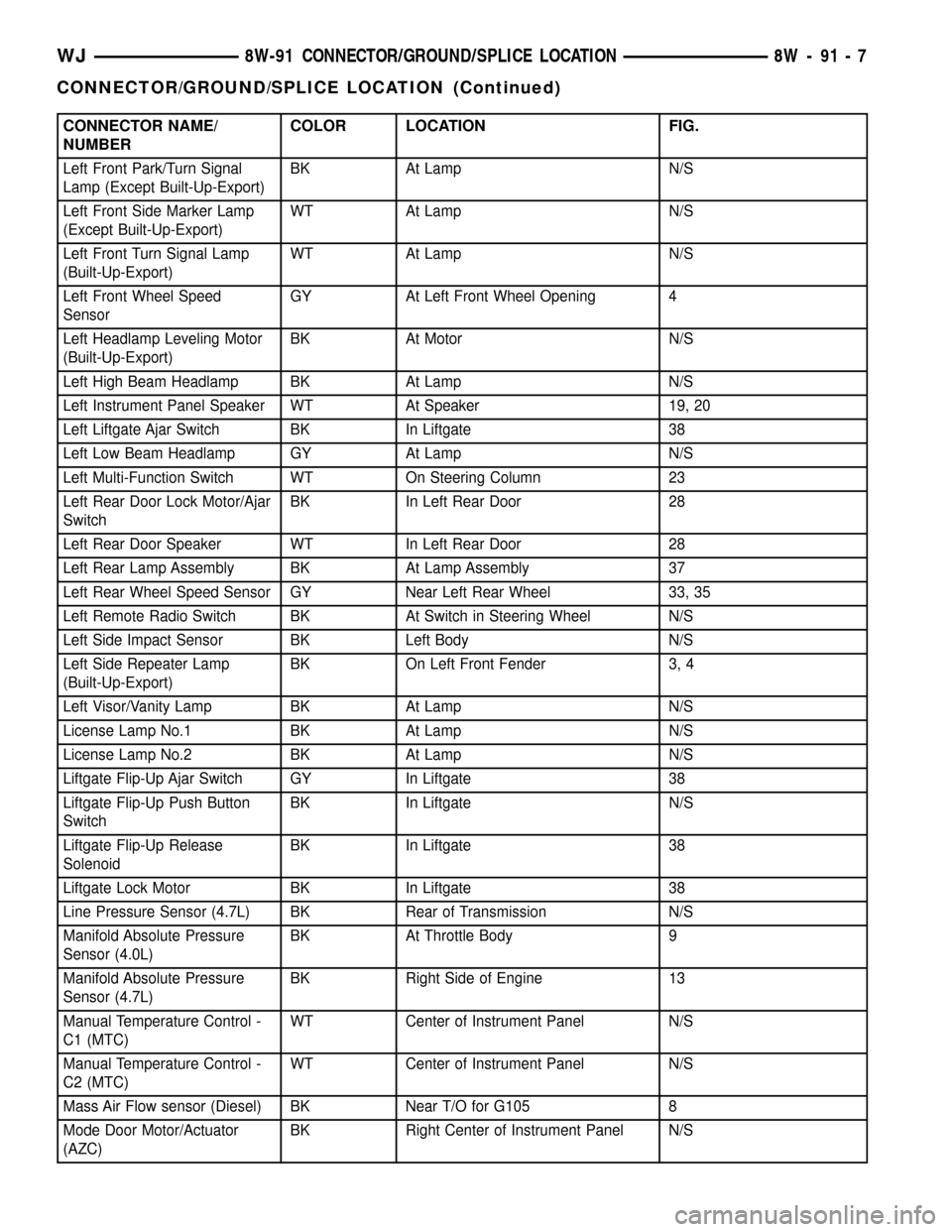

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Left Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Left Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Left Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Left Front Wheel Speed

SensorGY At Left Front Wheel Opening 4

Left Headlamp Leveling Motor

(Built-Up-Export)BK At Motor N/S

Left High Beam Headlamp BK At Lamp N/S

Left Instrument Panel Speaker WT At Speaker 19, 20

Left Liftgate Ajar Switch BK In Liftgate 38

Left Low Beam Headlamp GY At Lamp N/S

Left Multi-Function Switch WT On Steering Column 23

Left Rear Door Lock Motor/Ajar

SwitchBK In Left Rear Door 28

Left Rear Door Speaker WT In Left Rear Door 28

Left Rear Lamp Assembly BK At Lamp Assembly 37

Left Rear Wheel Speed Sensor GY Near Left Rear Wheel 33, 35

Left Remote Radio Switch BK At Switch in Steering Wheel N/S

Left Side Impact Sensor BK Left Body N/S

Left Side Repeater Lamp

(Built-Up-Export)BK On Left Front Fender 3, 4

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp No.1 BK At Lamp N/S

License Lamp No.2 BK At Lamp N/S

Liftgate Flip-Up Ajar Switch GY In Liftgate 38

Liftgate Flip-Up Push Button

SwitchBK In Liftgate N/S

Liftgate Flip-Up Release

SolenoidBK In Liftgate 38

Liftgate Lock Motor BK In Liftgate 38

Line Pressure Sensor (4.7L) BK Rear of Transmission N/S

Manifold Absolute Pressure

Sensor (4.0L)BK At Throttle Body 9

Manifold Absolute Pressure

Sensor (4.7L)BK Right Side of Engine 13

Manual Temperature Control -

C1 (MTC)WT Center of Instrument Panel N/S

Manual Temperature Control -

C2 (MTC)WT Center of Instrument Panel N/S

Mass Air Flow sensor (Diesel) BK Near T/O for G105 8

Mode Door Motor/Actuator

(AZC)BK Right Center of Instrument Panel N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1185 of 2199

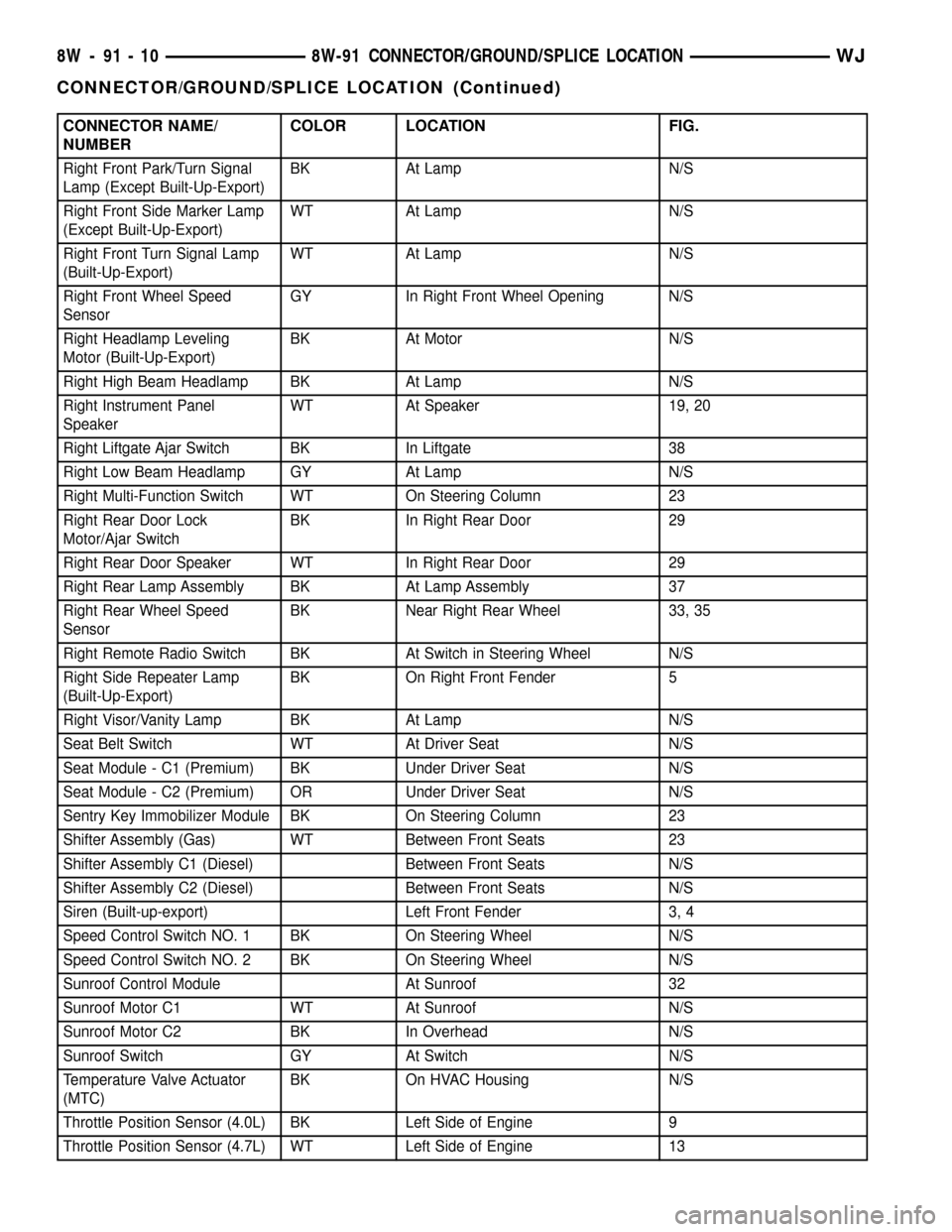

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Right Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Right Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Right Front Wheel Speed

SensorGY In Right Front Wheel Opening N/S

Right Headlamp Leveling

Motor (Built-Up-Export)BK At Motor N/S

Right High Beam Headlamp BK At Lamp N/S

Right Instrument Panel

SpeakerWT At Speaker 19, 20

Right Liftgate Ajar Switch BK In Liftgate 38

Right Low Beam Headlamp GY At Lamp N/S

Right Multi-Function Switch WT On Steering Column 23

Right Rear Door Lock

Motor/Ajar SwitchBK In Right Rear Door 29

Right Rear Door Speaker WT In Right Rear Door 29

Right Rear Lamp Assembly BK At Lamp Assembly 37

Right Rear Wheel Speed

SensorBK Near Right Rear Wheel 33, 35

Right Remote Radio Switch BK At Switch in Steering Wheel N/S

Right Side Repeater Lamp

(Built-Up-Export)BK On Right Front Fender 5

Right Visor/Vanity Lamp BK At Lamp N/S

Seat Belt Switch WT At Driver Seat N/S

Seat Module - C1 (Premium) BK Under Driver Seat N/S

Seat Module - C2 (Premium) OR Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 23

Shifter Assembly (Gas) WT Between Front Seats 23

Shifter Assembly C1 (Diesel) Between Front Seats N/S

Shifter Assembly C2 (Diesel) Between Front Seats N/S

Siren (Built-up-export) Left Front Fender 3, 4

Speed Control Switch NO. 1 BK On Steering Wheel N/S

Speed Control Switch NO. 2 BK On Steering Wheel N/S

Sunroof Control Module At Sunroof 32

Sunroof Motor C1 WT At Sunroof N/S

Sunroof Motor C2 BK In Overhead N/S

Sunroof Switch GY At Switch N/S

Temperature Valve Actuator

(MTC)BK On HVAC Housing N/S

Throttle Position Sensor (4.0L) BK Left Side of Engine 9

Throttle Position Sensor (4.7L) WT Left Side of Engine 13

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1248 of 2199

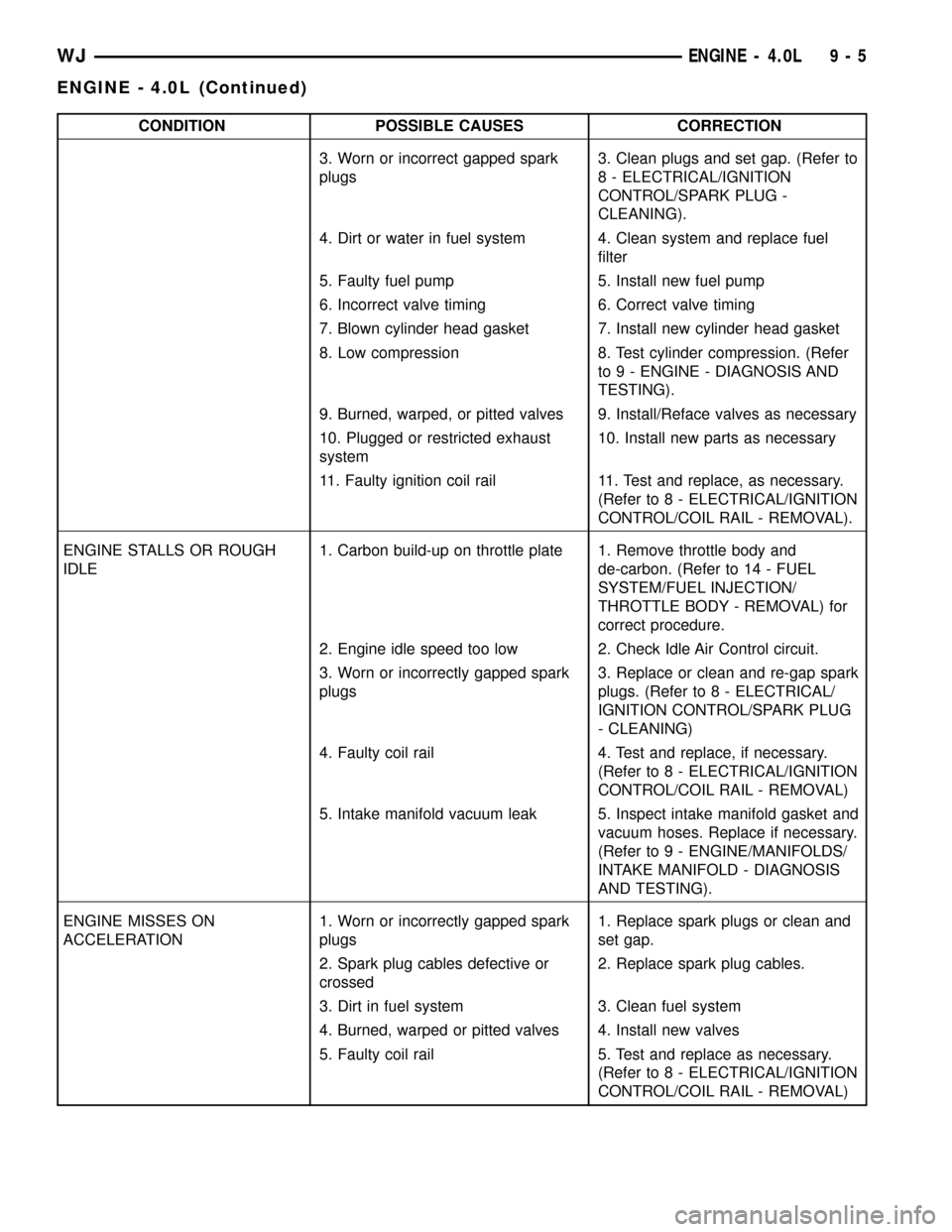

CONDITION POSSIBLE CAUSES CORRECTION

3. Worn or incorrect gapped spark

plugs3. Clean plugs and set gap. (Refer to

8 - ELECTRICAL/IGNITION

CONTROL/SPARK PLUG -

CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel

filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression. (Refer

to 9 - ENGINE - DIAGNOSIS AND

TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust

system10. Install new parts as necessary

11. Faulty ignition coil rail 11. Test and replace, as necessary.

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/COIL RAIL - REMOVAL).

ENGINE STALLS OR ROUGH

IDLE1. Carbon build-up on throttle plate 1. Remove throttle body and

de-carbon. (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/

THROTTLE BODY - REMOVAL) for

correct procedure.

2. Engine idle speed too low 2. Check Idle Air Control circuit.

3. Worn or incorrectly gapped spark

plugs3. Replace or clean and re-gap spark

plugs. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING)

4. Faulty coil rail 4. Test and replace, if necessary.

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/COIL RAIL - REMOVAL)

5. Intake manifold vacuum leak 5. Inspect intake manifold gasket and

vacuum hoses. Replace if necessary.

(Refer to 9 - ENGINE/MANIFOLDS/

INTAKE MANIFOLD - DIAGNOSIS

AND TESTING).

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and

set gap.

2. Spark plug cables defective or

crossed2. Replace spark plug cables.

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil rail 5. Test and replace as necessary.

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/COIL RAIL - REMOVAL)

WJENGINE - 4.0L 9 - 5

ENGINE - 4.0L (Continued)

Page 1251 of 2199

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Secure the throttle in the wide-open position.

(4) Disconnect the ignition coil.

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the third

revolution. Continue the test for the remaining cylin-

ders.

(Refer to 9 - ENGINE - SPECIFICATIONS) for the

correct engine compression pressures.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing)

²Leaks between adjacent cylinders or into water

jacket²Any causes for combustion/compression pressure

loss

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM HOT COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn OFF the

engine.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedure on each cylinder accord-

ing to the tester manufacturer's instructions. While

testing, listen for pressurized air escaping through

the throttle body, tailpipe or oil filler cap opening.

Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder CYLINDER COMBUSTION

PRESSURE LEAKAGE DIAGNOSIS CHART .

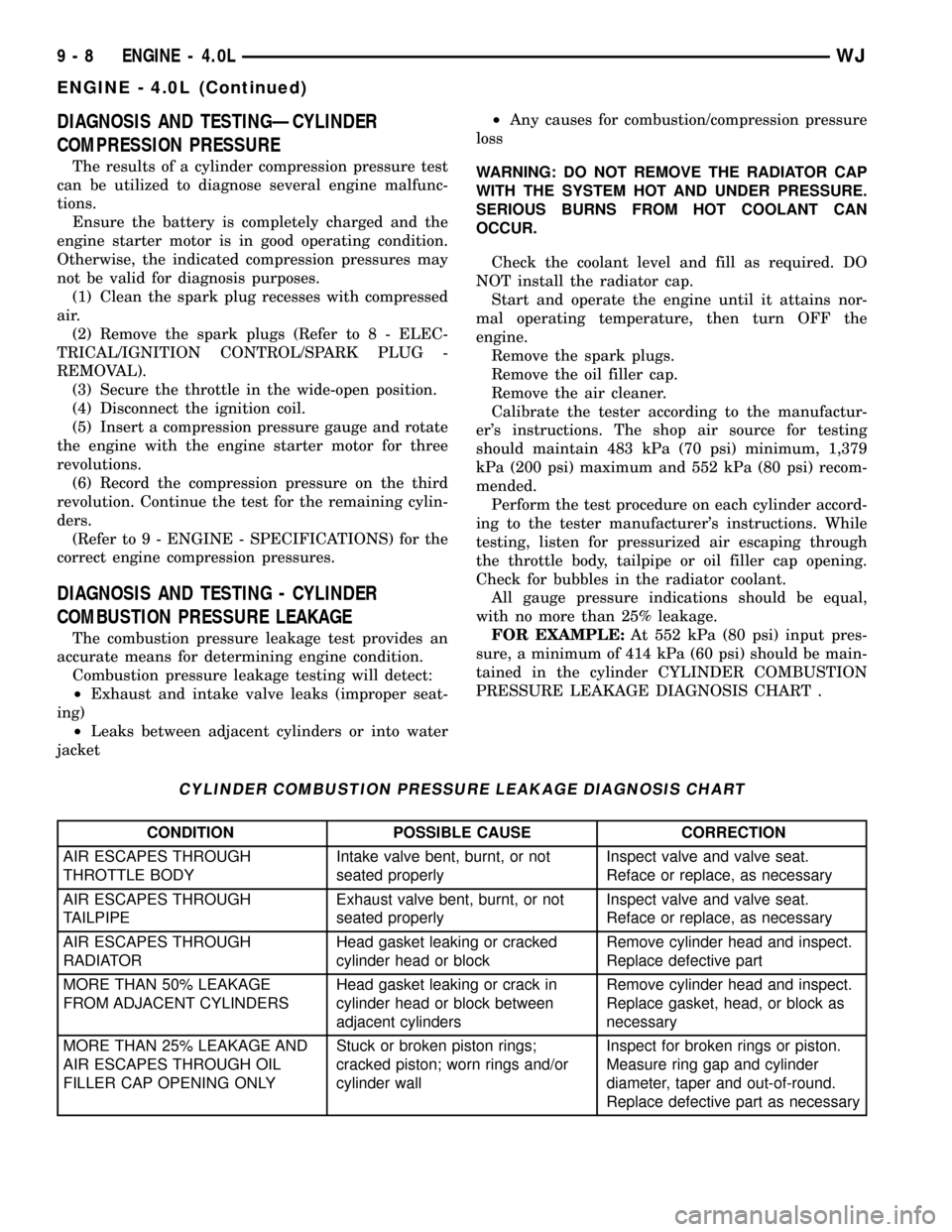

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

9 - 8 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1255 of 2199

(7) Remove the fan assembly from the water pump

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(8) Remove the fan shroud.

(9) Disconnect the transmission fluid cooler lines

(automatic transmission).

(10) Discharge the A/C system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(11) Remove the service valves and cap the com-

pressor ports.

(12) Remove the radiator or radiator/condenser (if

equipped with A/C).

(13) Disconnect the heater hoses at the engine

thermostat housing and water pump.

(14) Disconnect the accelerator cable, transmission

line pressure cable and speed control cable (if

equipped) from the throttle body.

(15) Remove cables from the bracket and secure

out of the way.

(16) Disconnect the body ground at the engine.

(17) Disconnect the following connectors and

secure their harness out of the way.

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(18) Disconnect the coil rail electrical connections

and the oil pressure switch connector.

(19) Perform the fuel pressure release procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(20) Disconnect the fuel supply line at the injector

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(21) Remove the fuel line bracket from the intake

manifold.

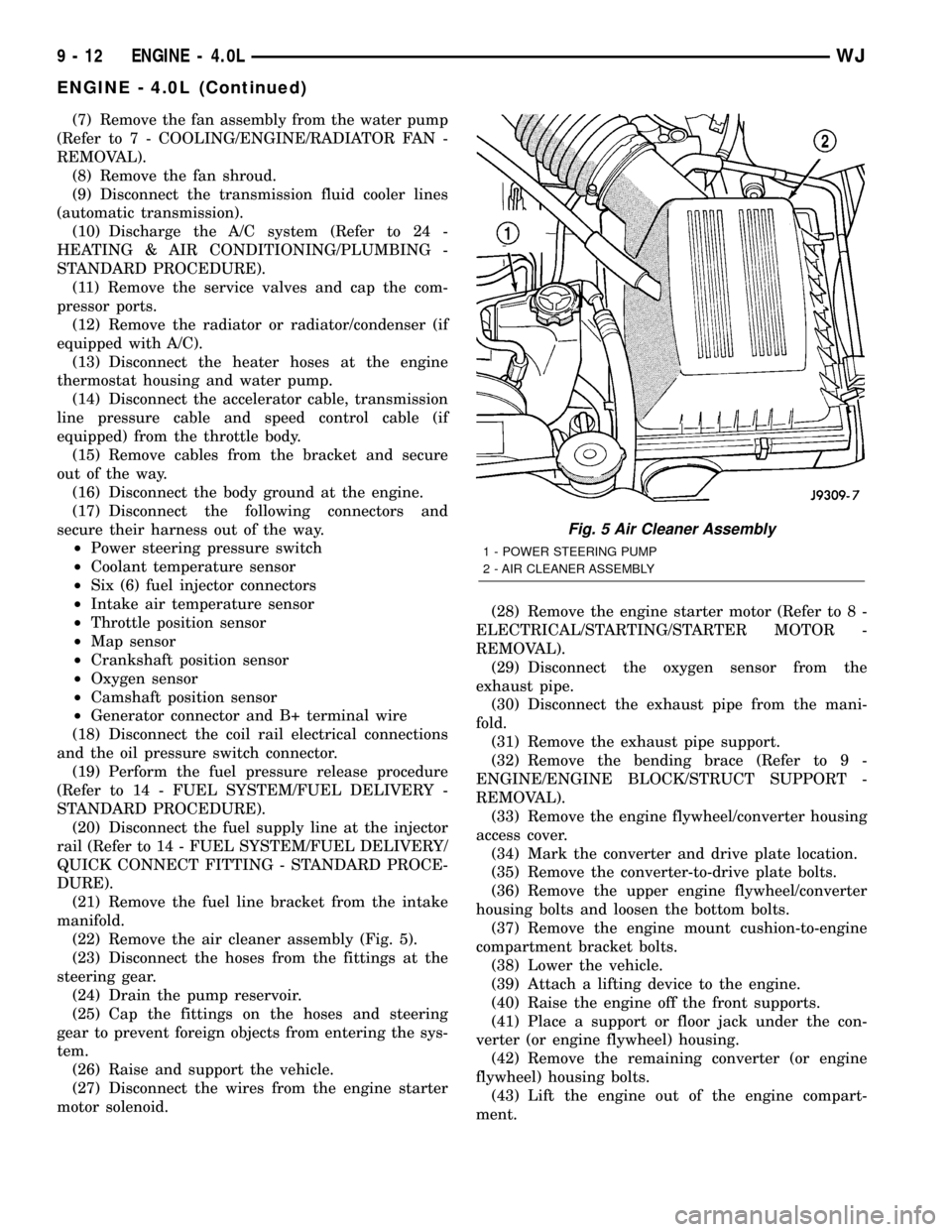

(22) Remove the air cleaner assembly (Fig. 5).

(23) Disconnect the hoses from the fittings at the

steering gear.

(24) Drain the pump reservoir.

(25) Cap the fittings on the hoses and steering

gear to prevent foreign objects from entering the sys-

tem.

(26) Raise and support the vehicle.

(27) Disconnect the wires from the engine starter

motor solenoid.(28) Remove the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

REMOVAL).

(29) Disconnect the oxygen sensor from the

exhaust pipe.

(30) Disconnect the exhaust pipe from the mani-

fold.

(31) Remove the exhaust pipe support.

(32) Remove the bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

REMOVAL).

(33) Remove the engine flywheel/converter housing

access cover.

(34) Mark the converter and drive plate location.

(35) Remove the converter-to-drive plate bolts.

(36) Remove the upper engine flywheel/converter

housing bolts and loosen the bottom bolts.

(37) Remove the engine mount cushion-to-engine

compartment bracket bolts.

(38) Lower the vehicle.

(39) Attach a lifting device to the engine.

(40) Raise the engine off the front supports.

(41) Place a support or floor jack under the con-

verter (or engine flywheel) housing.

(42) Remove the remaining converter (or engine

flywheel) housing bolts.

(43) Lift the engine out of the engine compart-

ment.

Fig. 5 Air Cleaner Assembly

1 - POWER STEERING PUMP

2 - AIR CLEANER ASSEMBLY

9 - 12 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)