wheel torque JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 140 of 2199

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-

tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle.

WJREAR AXLE - 226RBA 3 - 95

REAR AXLE - 226RBA (Continued)

Page 156 of 2199

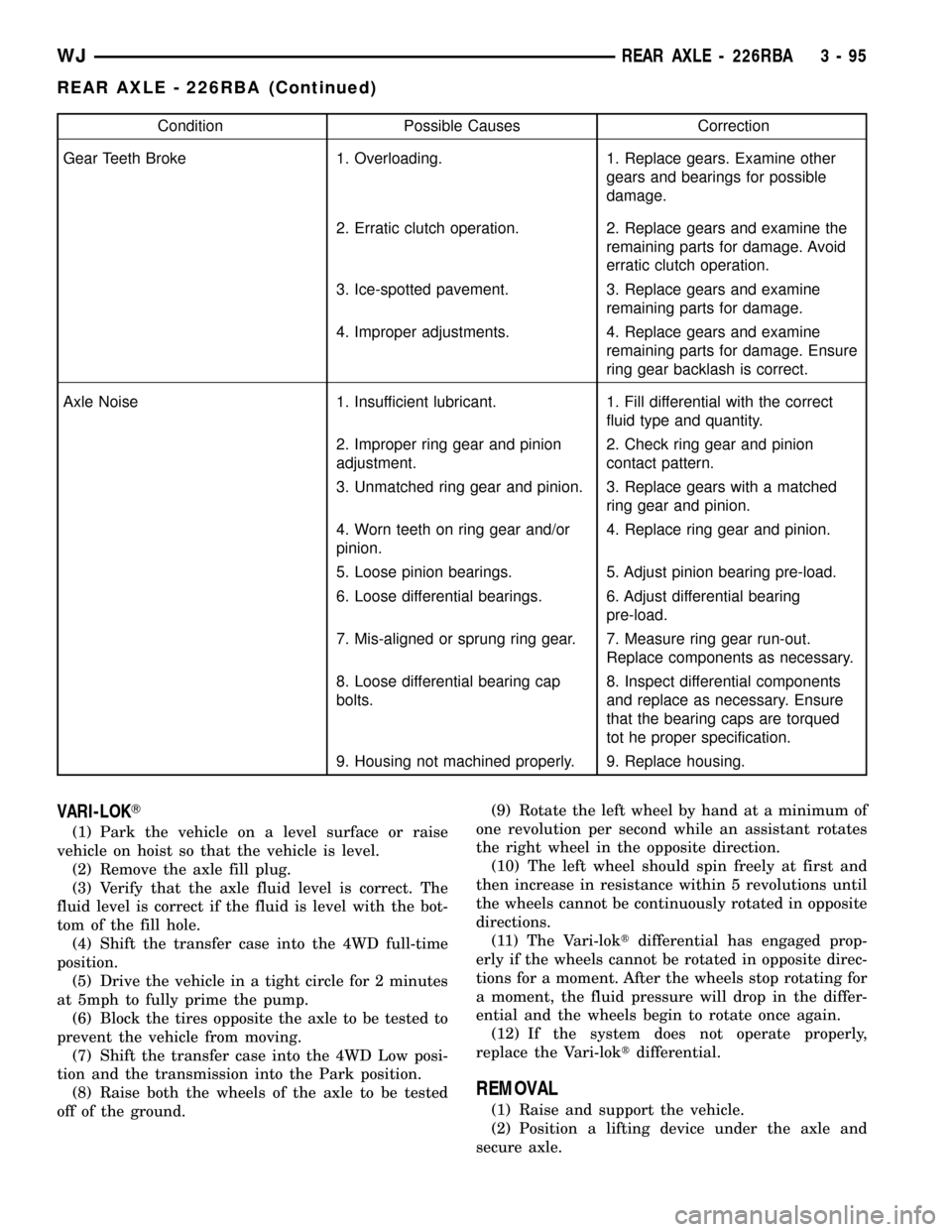

(7) Press metal retaining ring onto axle shaft with

Installer 7913 and a press (Fig. 30).

(8) Install axle in vehicle.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate pinion gear three or four times and ver-

ify that pinion rotates smoothly.

(7) Record torque necessary to rotate the pinion

gear with a inch pound dial-type torque wrench.

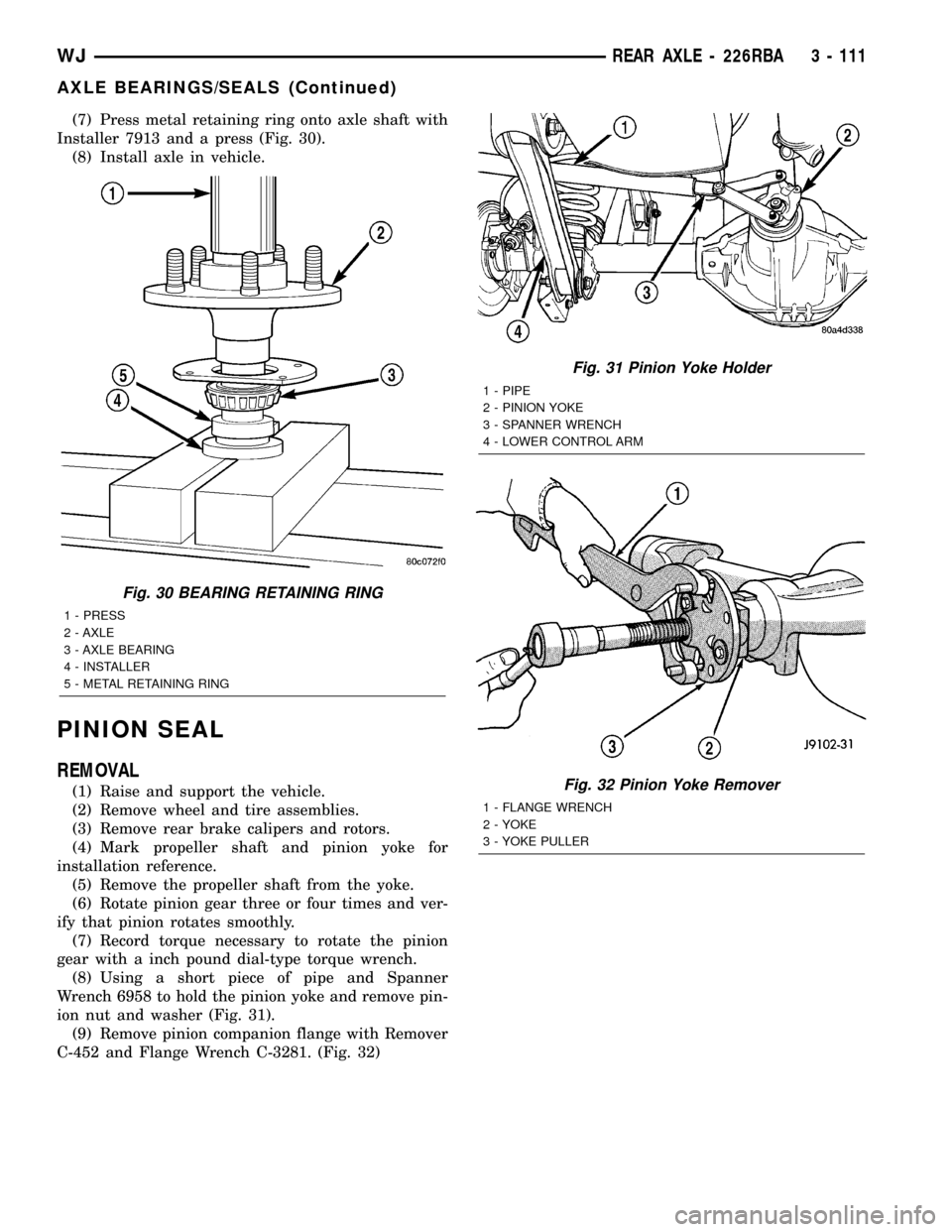

(8) Using a short piece of pipe and Spanner

Wrench 6958 to hold the pinion yoke and remove pin-

ion nut and washer (Fig. 31).

(9) Remove pinion companion flange with Remover

C-452 and Flange Wrench C-3281. (Fig. 32)

Fig. 30 BEARING RETAINING RING

1 - PRESS

2 - AXLE

3 - AXLE BEARING

4 - INSTALLER

5 - METAL RETAINING RING

Fig. 31 Pinion Yoke Holder

1 - PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 32 Pinion Yoke Remover

1 - FLANGE WRENCH

2 - YOKE

3 - YOKE PULLER

WJREAR AXLE - 226RBA 3 - 111

AXLE BEARINGS/SEALS (Continued)

Page 158 of 2199

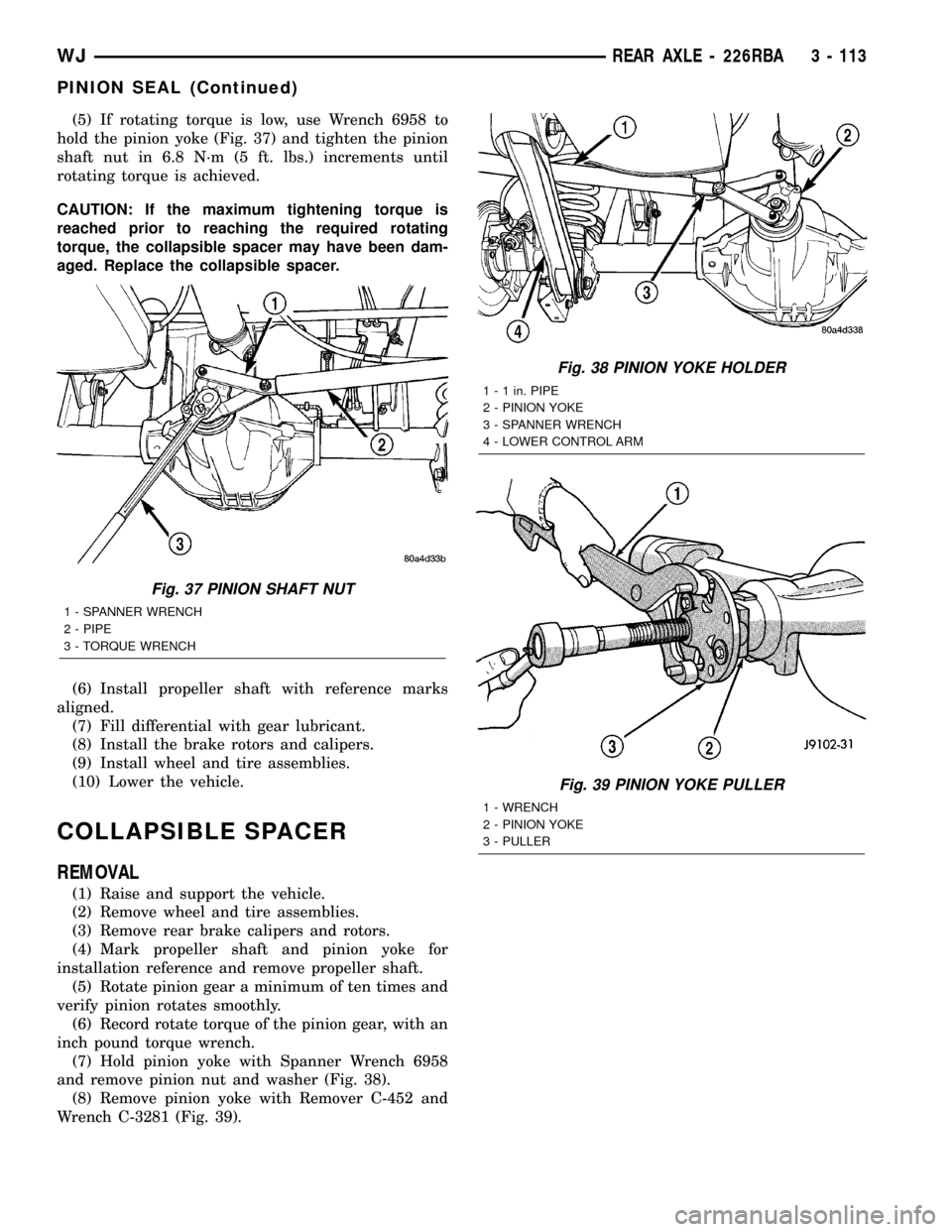

(5) If rotating torque is low, use Wrench 6958 to

hold the pinion yoke (Fig. 37) and tighten the pinion

shaft nut in 6.8 N´m (5 ft. lbs.) increments until

rotating torque is achieved.

CAUTION: If the maximum tightening torque is

reached prior to reaching the required rotating

torque, the collapsible spacer may have been dam-

aged. Replace the collapsible spacer.

(6) Install propeller shaft with reference marks

aligned.

(7) Fill differential with gear lubricant.

(8) Install the brake rotors and calipers.

(9) Install wheel and tire assemblies.

(10) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference and remove propeller shaft.

(5) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(6) Record rotate torque of the pinion gear, with an

inch pound torque wrench.

(7) Hold pinion yoke with Spanner Wrench 6958

and remove pinion nut and washer (Fig. 38).

(8) Remove pinion yoke with Remover C-452 and

Wrench C-3281 (Fig. 39).

Fig. 37 PINION SHAFT NUT

1 - SPANNER WRENCH

2 - PIPE

3 - TORQUE WRENCH

Fig. 38 PINION YOKE HOLDER

1 - 1 in. PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 39 PINION YOKE PULLER

1 - WRENCH

2 - PINION YOKE

3 - PULLER

WJREAR AXLE - 226RBA 3 - 113

PINION SEAL (Continued)

Page 160 of 2199

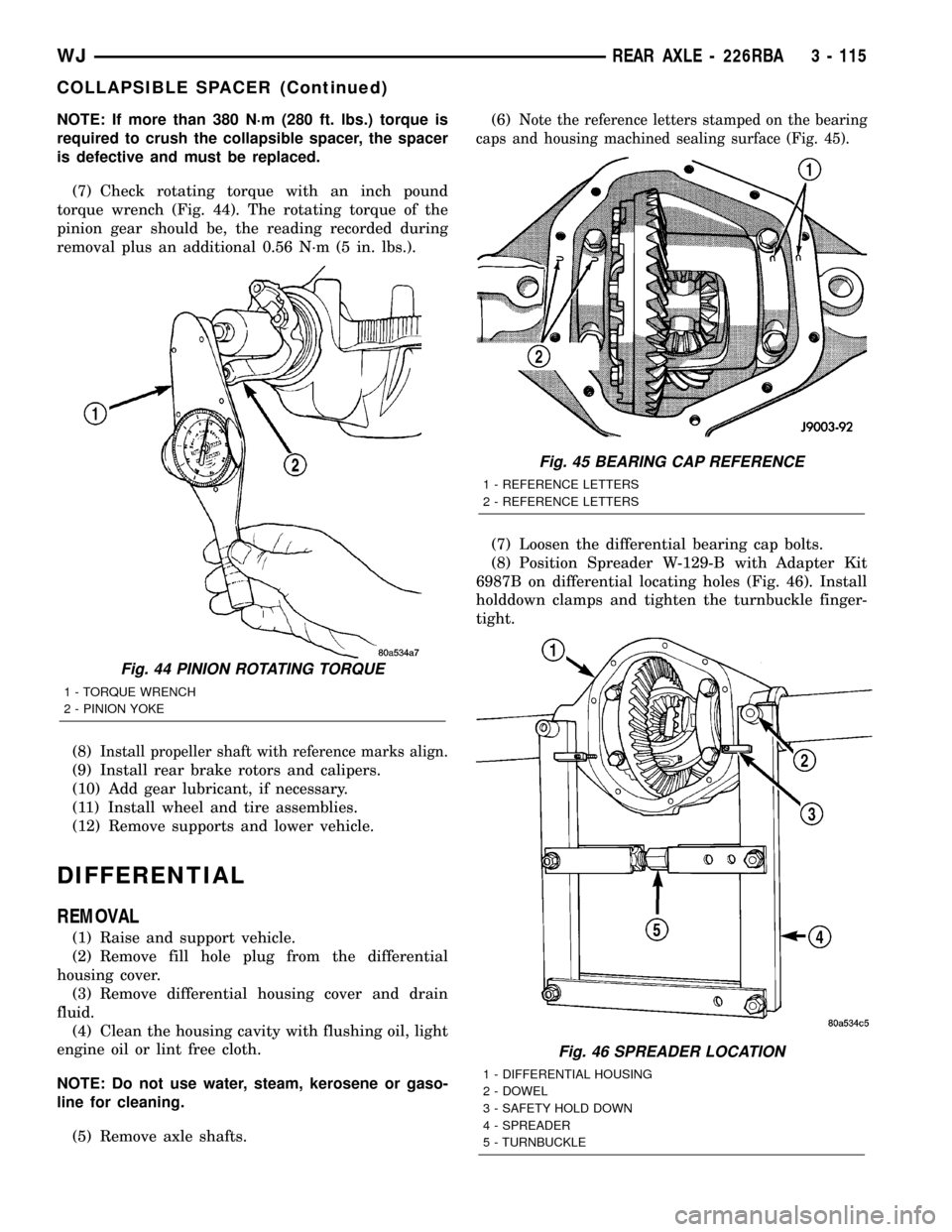

NOTE: If more than 380 N´m (280 ft. lbs.) torque is

required to crush the collapsible spacer, the spacer

is defective and must be replaced.

(7) Check rotating torque with an inch pound

torque wrench (Fig. 44). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8)

Install propeller shaft with reference marks align.

(9) Install rear brake rotors and calipers.

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

fluid.

(4) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.

NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(5) Remove axle shafts.(6)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 45).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 46). Install

holddown clamps and tighten the turnbuckle finger-

tight.

Fig. 44 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 45 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 46 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

WJREAR AXLE - 226RBA 3 - 115

COLLAPSIBLE SPACER (Continued)

Page 164 of 2199

(12) Install cover and tighten bolts in a criss-cross

pattern to 41 N´m (30 ft. lbs.).

(13) Refill the differential with Mopar Hypoid

Gear Lubricant or equivalent to bottom of the fill

plug hole.

(14) Install fill hole plug.

(15) Remove support and lower the vehicle.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

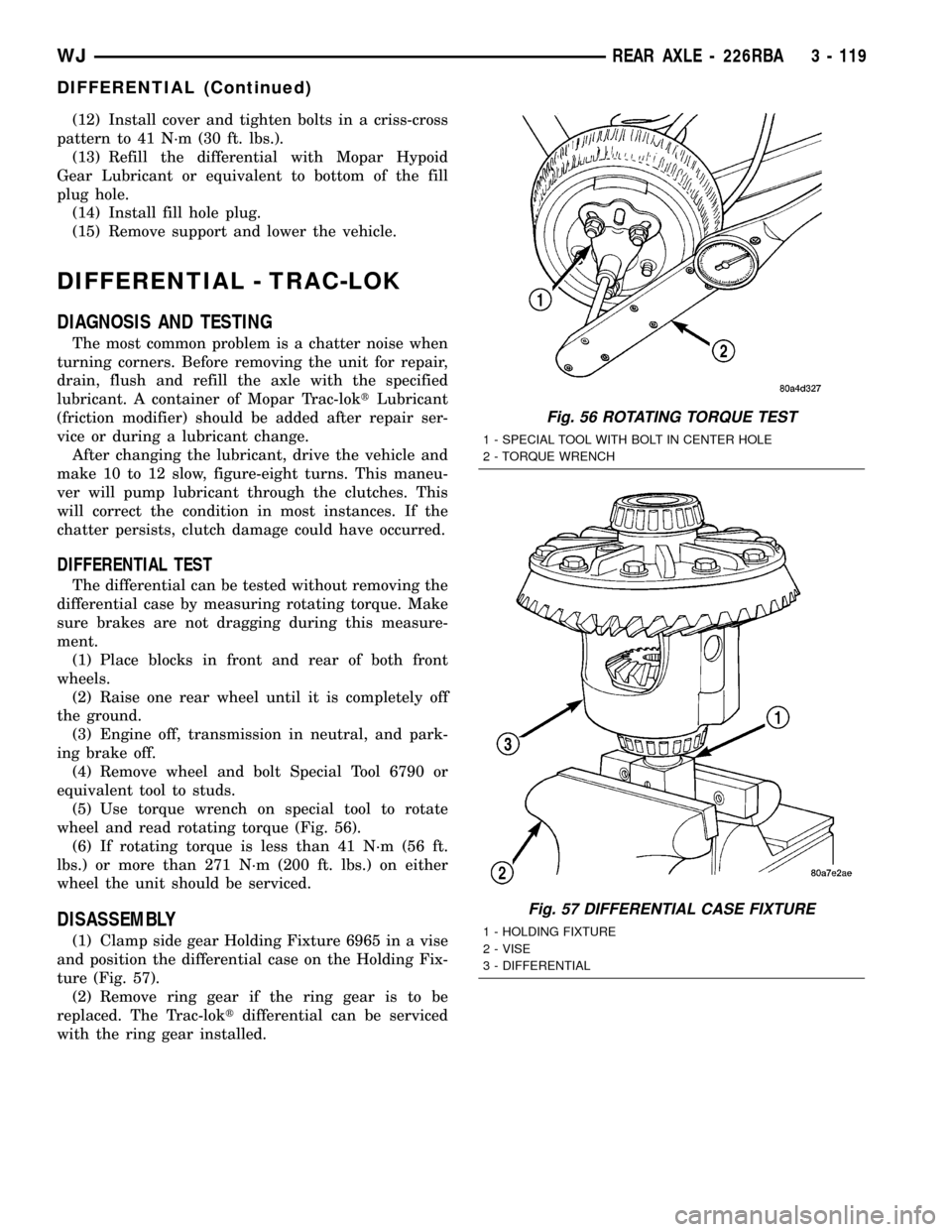

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 56).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

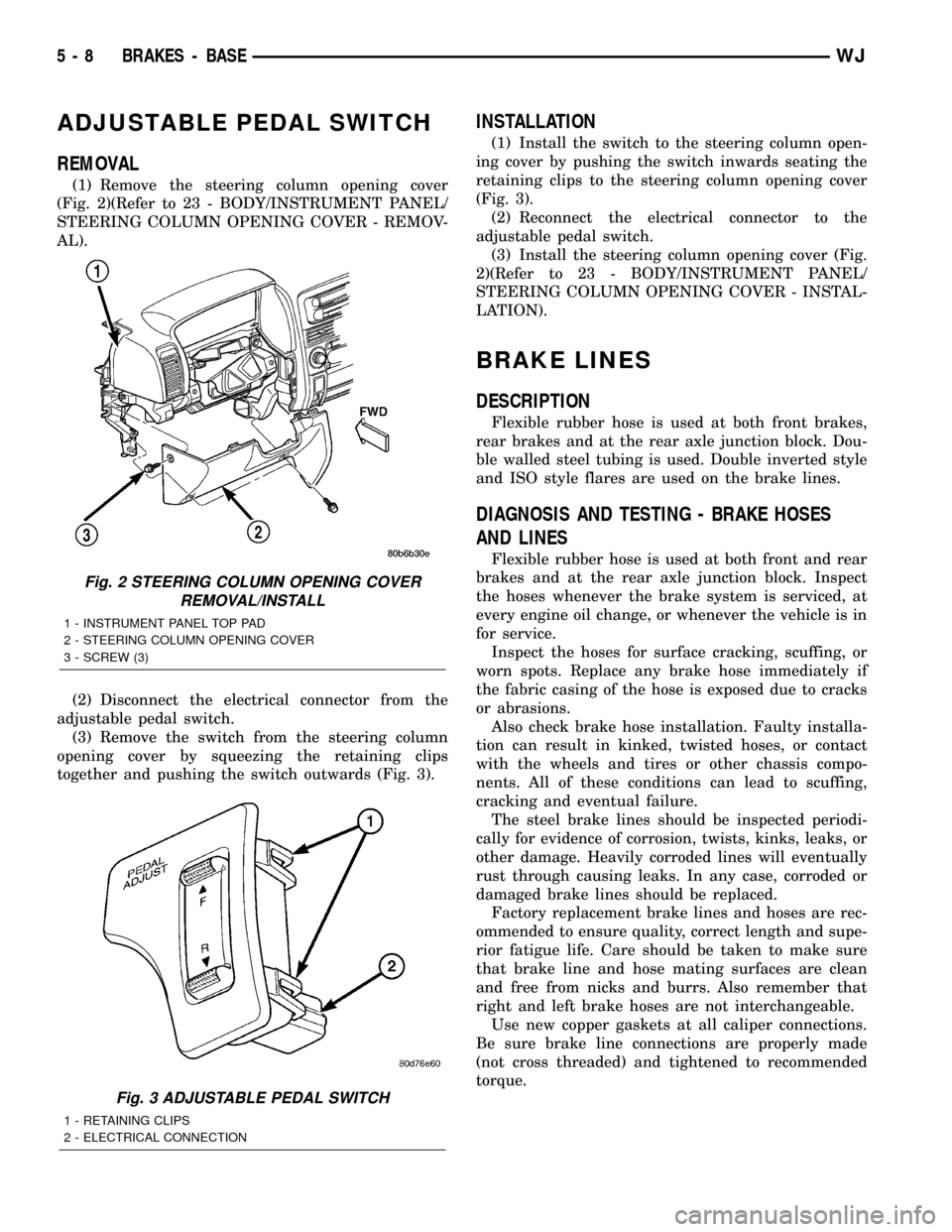

DISASSEMBLY

(1) Clamp side gear Holding Fixture 6965 in a vise

and position the differential case on the Holding Fix-

ture (Fig. 57).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-loktdifferential can be serviced

with the ring gear installed.

Fig. 56 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 57 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

WJREAR AXLE - 226RBA 3 - 119

DIFFERENTIAL (Continued)

Page 183 of 2199

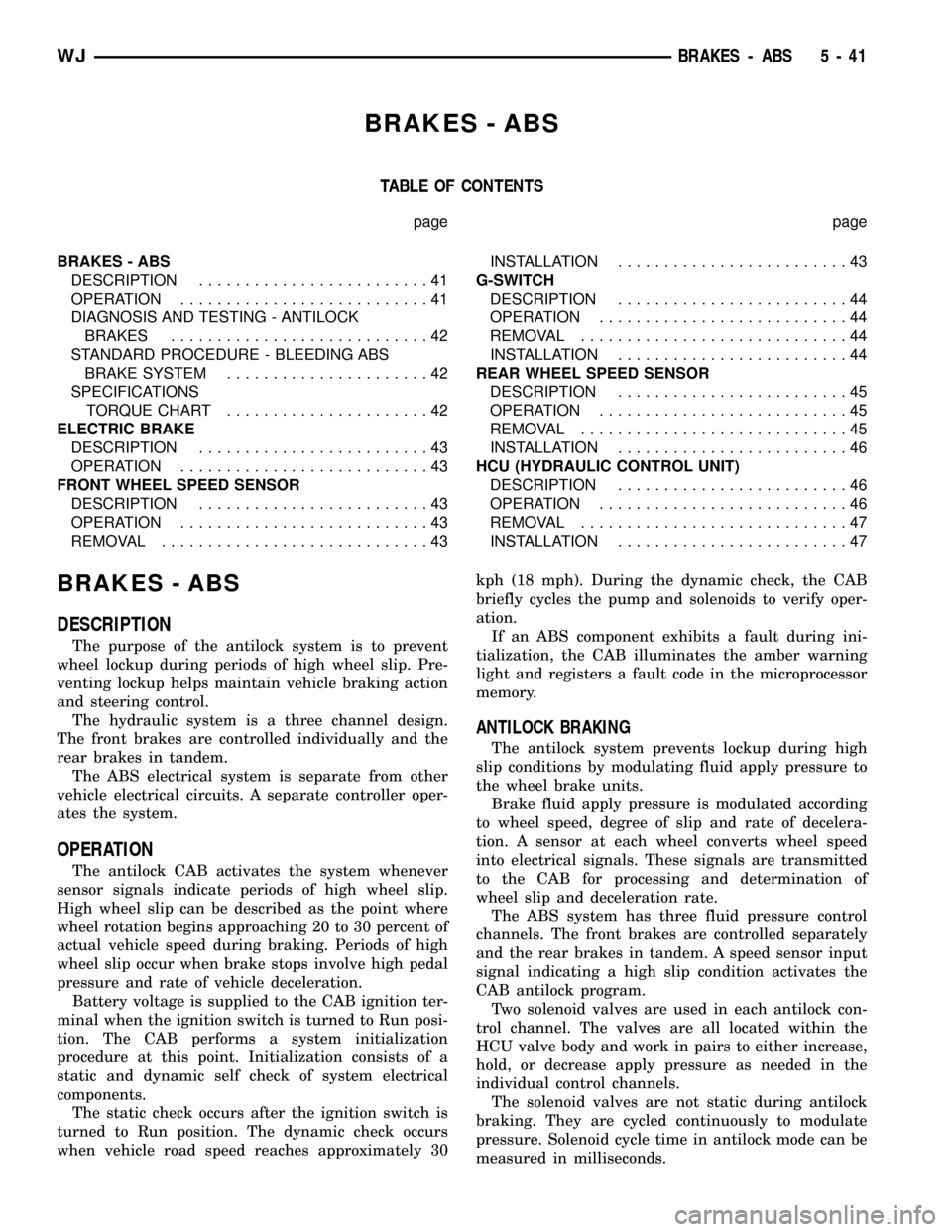

ADJUSTABLE PEDAL SWITCH

REMOVAL

(1) Remove the steering column opening cover

(Fig. 2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - REMOV-

AL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the steering column

opening cover by squeezing the retaining clips

together and pushing the switch outwards (Fig. 3).

INSTALLATION

(1) Install the switch to the steering column open-

ing cover by pushing the switch inwards seating the

retaining clips to the steering column opening cover

(Fig. 3).

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the steering column opening cover (Fig.

2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - INSTAL-

LATION).

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes,

rear brakes and at the rear axle junction block. Dou-

ble walled steel tubing is used. Double inverted style

and ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES

Flexible rubber hose is used at both front and rear

brakes and at the rear axle junction block. Inspect

the hoses whenever the brake system is serviced, at

every engine oil change, or whenever the vehicle is in

for service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper gaskets at all caliper connections.

Be sure brake line connections are properly made

(not cross threaded) and tightened to recommended

torque.

Fig. 2 STEERING COLUMN OPENING COVER

REMOVAL/INSTALL

1 - INSTRUMENT PANEL TOP PAD

2 - STEERING COLUMN OPENING COVER

3 - SCREW (3)

Fig. 3 ADJUSTABLE PEDAL SWITCH

1 - RETAINING CLIPS

2 - ELECTRICAL CONNECTION

5 - 8 BRAKES - BASEWJ

Page 216 of 2199

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................42

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................42

SPECIFICATIONS

TORQUE CHART......................42

ELECTRIC BRAKE

DESCRIPTION.........................43

OPERATION...........................43

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43INSTALLATION.........................43

G-SWITCH

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

REAR WHEEL SPEED SENSOR

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................46

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................46

OPERATION...........................46

REMOVAL.............................47

INSTALLATION.........................47

BRAKES - ABS

DESCRIPTION

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The hydraulic system is a three channel design.

The front brakes are controlled individually and the

rear brakes in tandem.

The ABS electrical system is separate from other

vehicle electrical circuits. A separate controller oper-

ates the system.

OPERATION

The antilock CAB activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching 20 to 30 percent of

actual vehicle speed during braking. Periods of high

wheel slip occur when brake stops involve high pedal

pressure and rate of vehicle deceleration.

Battery voltage is supplied to the CAB ignition ter-

minal when the ignition switch is turned to Run posi-

tion. The CAB performs a system initialization

procedure at this point. Initialization consists of a

static and dynamic self check of system electrical

components.

The static check occurs after the ignition switch is

turned to Run position. The dynamic check occurs

when vehicle road speed reaches approximately 30kph (18 mph). During the dynamic check, the CAB

briefly cycles the pump and solenoids to verify oper-

ation.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ANTILOCK BRAKING

The antilock system prevents lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a high slip condition activates the

CAB antilock program.

Two solenoid valves are used in each antilock con-

trol channel. The valves are all located within the

HCU valve body and work in pairs to either increase,

hold, or decrease apply pressure as needed in the

individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

WJBRAKES - ABS 5 - 41

Page 217 of 2199

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES

The ABS brake system performs several self-tests

every time the ignition switch is turned on and the

vehicle is driven. The CAB monitors the systems

input and output circuits to verify the system is oper-

ating correctly. If the on board diagnostic system

senses that a circuit is malfunctioning the system

will set a trouble code in its memory.

NOTE: An audible noise may be heard during the

self-test. This noise should be considered normal.

NOTE: The MDS or DRB III scan tool is used to

diagnose the ABS system. For additional informa-

tion refer to the Electrical section. For test proce-

dures refer to the Chassis Diagnostic Manual.

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding. (Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

OR (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

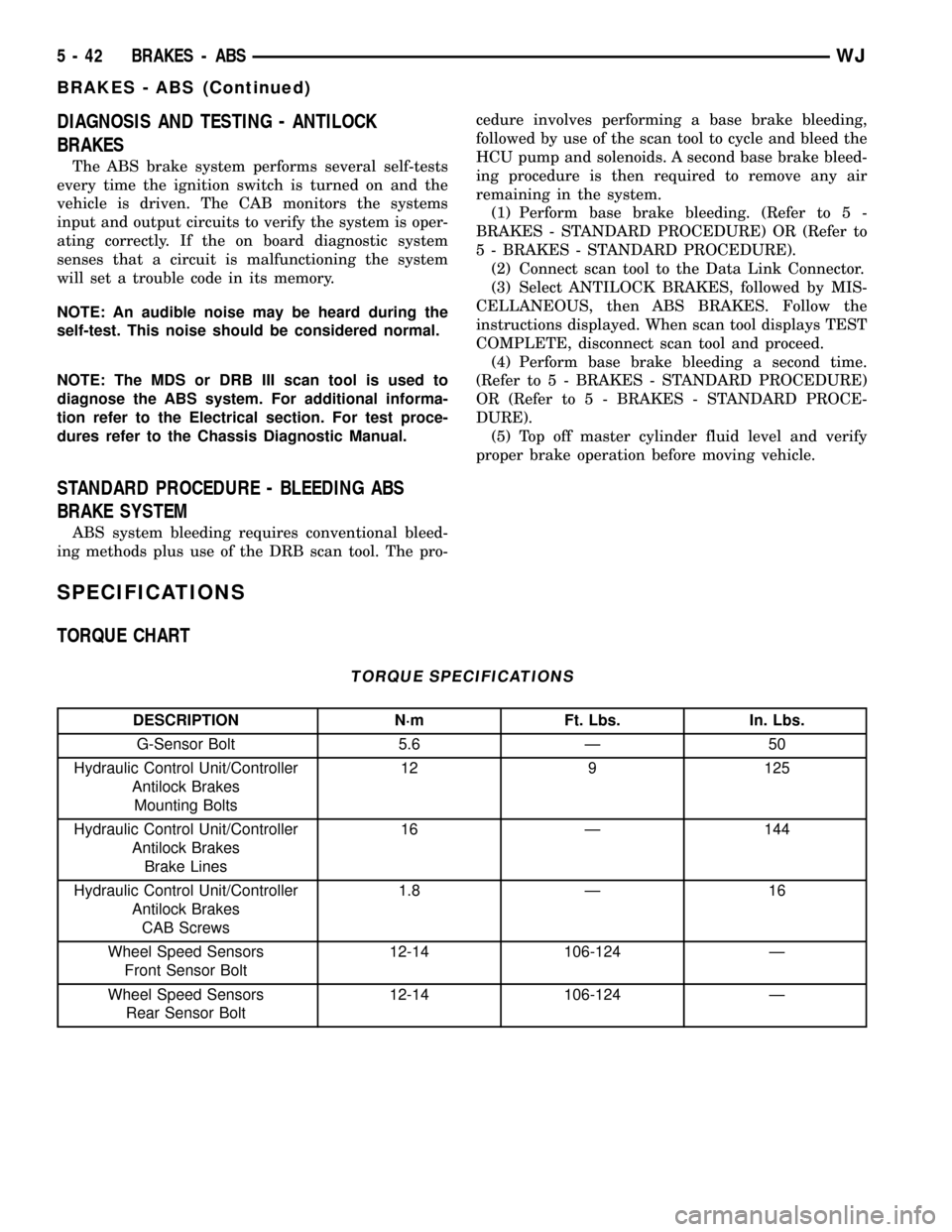

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

G-Sensor Bolt 5.6 Ð 50

Hydraulic Control Unit/Controller

Antilock Brakes

Mounting Bolts12 9 125

Hydraulic Control Unit/Controller

Antilock Brakes

Brake Lines16 Ð 144

Hydraulic Control Unit/Controller

Antilock Brakes

CAB Screws1.8 Ð 16

Wheel Speed Sensors

Front Sensor Bolt12-14 106-124 Ð

Wheel Speed Sensors

Rear Sensor Bolt12-14 106-124 Ð

5 - 42 BRAKES - ABSWJ

BRAKES - ABS (Continued)

Page 412 of 2199

INSTALLATION

4.7L High-Output Engine Only

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors (Fig. 22) into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts.Bolt

torque is critical.Refer to torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor pigtail wiring harness to

engine wiring harness near right / rear of intake

manifold (Fig. 23).

SPARK PLUG

DESCRIPTION

Both the 4.0L 6-cylinder and the 4.7L V-8 engine

use resistor type spark plugs. Standard 4.7L V-8

engines are equipped with ªfired in suppressor sealº

type spark plugs using a copper core ground elec-

trode. High-Output (H.O.) 4.7L V-8 engines are

equipped with unique plugs using a platinum rivet

located on the tip of the center electrode.

Because of the use of an aluminum cylinder head

on the 4.7L engine, spark plug torque is very critical.

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.Do not substitute any

other spark plug on the 4.7L H.O. engine. Seri-

ous engine damage may occur.

Plugs on both engines have resistance values rang-

ing from 6,000 to 20,000 ohms (when checked with at

least a 1000 volt spark plug tester).Do not use an

ohmmeter to check the resistance values of thespark plugs. Inaccurate readings will result.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance.

EXCEPT 4.7L H.O. ENGINE :Spark plugs that

have low mileage may be cleaned and reused if not

otherwise defective, carbon or oil fouled. Also refer to

Spark Plug Conditions.4.7L H.O. ENGINE :Never

clean spark plugs on the 4.7L H.O. engine. Damage

to the platinum rivet will result.

CAUTION: EXCEPT 4.7L H.O. ENGINE : Never use a

motorized wire wheel brush to clean the spark

plugs. Metallic deposits will remain on the spark

plug insulator and will cause plug misfire.

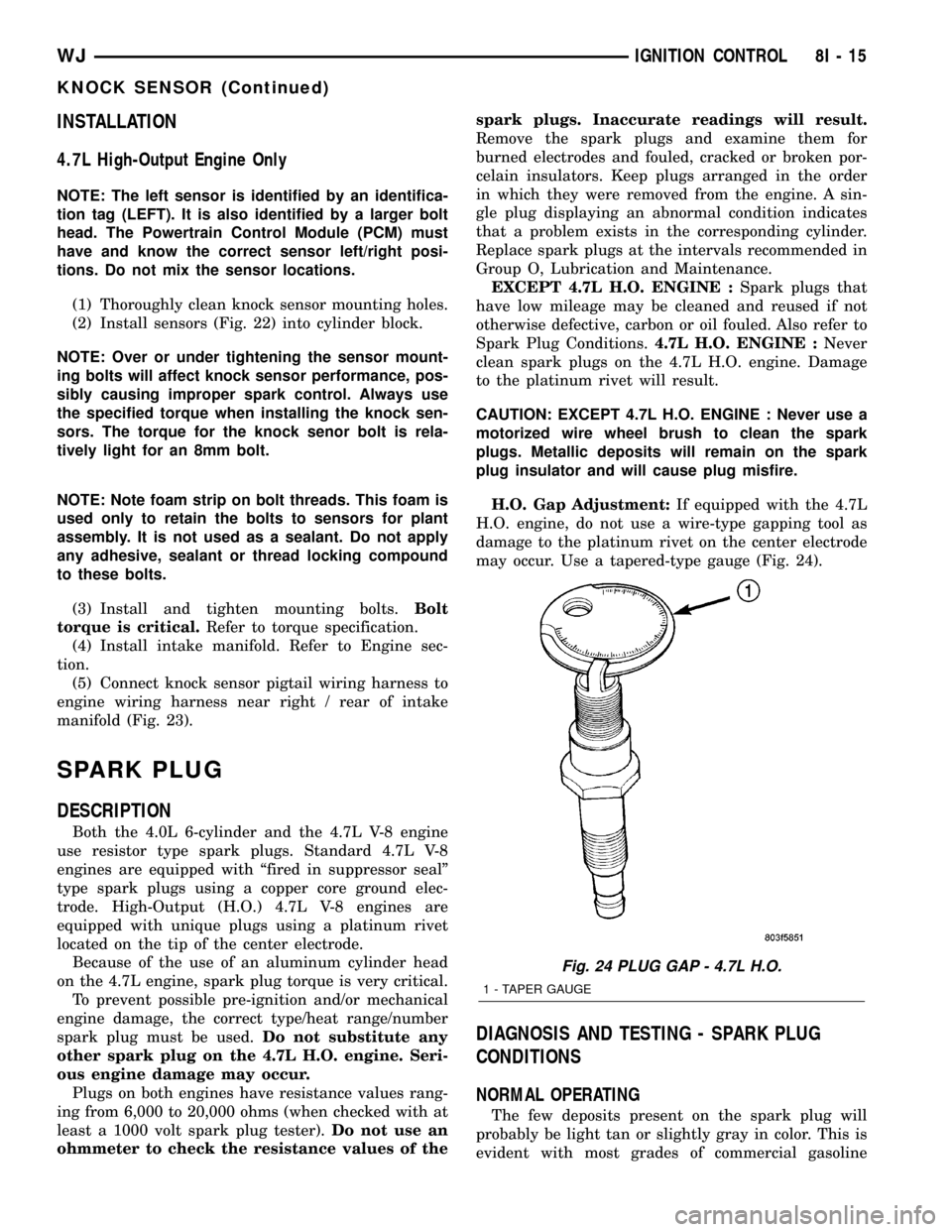

H.O. Gap Adjustment:If equipped with the 4.7L

H.O. engine, do not use a wire-type gapping tool as

damage to the platinum rivet on the center electrode

may occur. Use a tapered-type gauge (Fig. 24).

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

Fig. 24 PLUG GAP - 4.7L H.O.

1 - TAPER GAUGE

WJIGNITION CONTROL 8I - 15

KNOCK SENSOR (Continued)

Page 415 of 2199

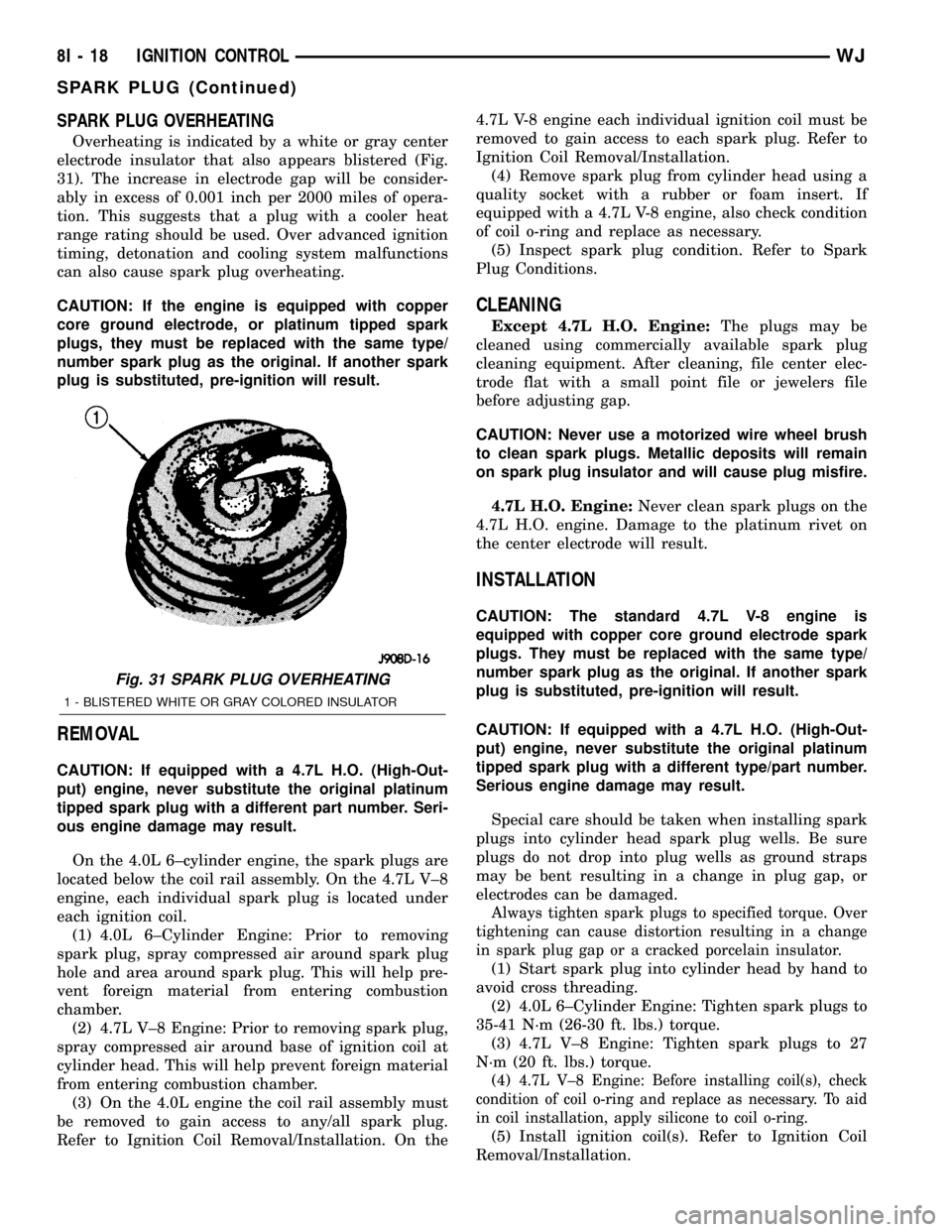

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

31). The increase in electrode gap will be consider-

ably in excess of 0.001 inch per 2000 miles of opera-

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions

can also cause spark plug overheating.

CAUTION: If the engine is equipped with copper

core ground electrode, or platinum tipped spark

plugs, they must be replaced with the same type/

number spark plug as the original. If another spark

plug is substituted, pre-ignition will result.

REMOVAL

CAUTION: If equipped with a 4.7L H.O. (High-Out-

put) engine, never substitute the original platinum

tipped spark plug with a different part number. Seri-

ous engine damage may result.

On the 4.0L 6±cylinder engine, the spark plugs are

located below the coil rail assembly. On the 4.7L V±8

engine, each individual spark plug is located under

each ignition coil.

(1) 4.0L 6±Cylinder Engine: Prior to removing

spark plug, spray compressed air around spark plug

hole and area around spark plug. This will help pre-

vent foreign material from entering combustion

chamber.

(2) 4.7L V±8 Engine: Prior to removing spark plug,

spray compressed air around base of ignition coil at

cylinder head. This will help prevent foreign material

from entering combustion chamber.

(3) On the 4.0L engine the coil rail assembly must

be removed to gain access to any/all spark plug.

Refer to Ignition Coil Removal/Installation. On the4.7L V-8 engine each individual ignition coil must be

removed to gain access to each spark plug. Refer to

Ignition Coil Removal/Installation.

(4) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert. If

equipped with a 4.7L V-8 engine, also check condition

of coil o-ring and replace as necessary.

(5) Inspect spark plug condition. Refer to Spark

Plug Conditions.

CLEANING

Except 4.7L H.O. Engine:The plugs may be

cleaned using commercially available spark plug

cleaning equipment. After cleaning, file center elec-

trode flat with a small point file or jewelers file

before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean spark plugs. Metallic deposits will remain

on spark plug insulator and will cause plug misfire.

4.7L H.O. Engine:Never clean spark plugs on the

4.7L H.O. engine. Damage to the platinum rivet on

the center electrode will result.

INSTALLATION

CAUTION: The standard 4.7L V-8 engine is

equipped with copper core ground electrode spark

plugs. They must be replaced with the same type/

number spark plug as the original. If another spark

plug is substituted, pre-ignition will result.

CAUTION: If equipped with a 4.7L H.O. (High-Out-

put) engine, never substitute the original platinum

tipped spark plug with a different type/part number.

Serious engine damage may result.

Special care should be taken when installing spark

plugs into cylinder head spark plug wells. Be sure

plugs do not drop into plug wells as ground straps

may be bent resulting in a change in plug gap, or

electrodes can be damaged.

Always tighten spark plugs to specified torque. Over

tightening can cause distortion resulting in a change

in spark plug gap or a cracked porcelain insulator.

(1) Start spark plug into cylinder head by hand to

avoid cross threading.

(2) 4.0L 6±Cylinder Engine: Tighten spark plugs to

35-41 N´m (26-30 ft. lbs.) torque.

(3) 4.7L V±8 Engine: Tighten spark plugs to 27

N´m (20 ft. lbs.) torque.

(4)

4.7L V±8 Engine: Before installing coil(s), check

condition of coil o-ring and replace as necessary. To aid

in coil installation, apply silicone to coil o-ring.

(5) Install ignition coil(s). Refer to Ignition Coil

Removal/Installation.

Fig. 31 SPARK PLUG OVERHEATING

1 - BLISTERED WHITE OR GRAY COLORED INSULATOR

8I - 18 IGNITION CONTROLWJ

SPARK PLUG (Continued)