seat JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1848 of 2199

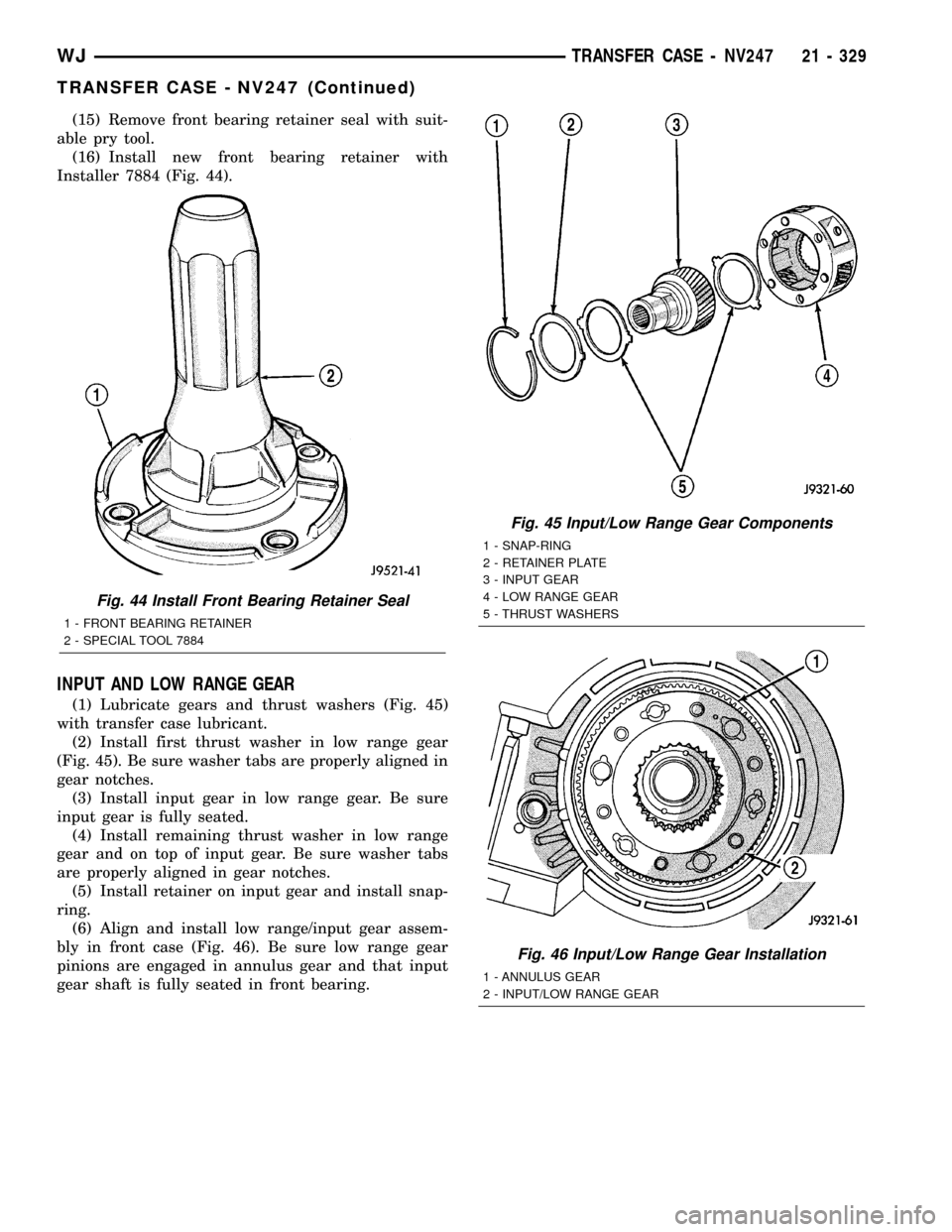

(15) Remove front bearing retainer seal with suit-

able pry tool.

(16) Install new front bearing retainer with

Installer 7884 (Fig. 44).

INPUT AND LOW RANGE GEAR

(1) Lubricate gears and thrust washers (Fig. 45)

with transfer case lubricant.

(2) Install first thrust washer in low range gear

(Fig. 45). Be sure washer tabs are properly aligned in

gear notches.

(3) Install input gear in low range gear. Be sure

input gear is fully seated.

(4) Install remaining thrust washer in low range

gear and on top of input gear. Be sure washer tabs

are properly aligned in gear notches.

(5) Install retainer on input gear and install snap-

ring.

(6) Align and install low range/input gear assem-

bly in front case (Fig. 46). Be sure low range gear

pinions are engaged in annulus gear and that input

gear shaft is fully seated in front bearing.

Fig. 44 Install Front Bearing Retainer Seal

1 - FRONT BEARING RETAINER

2 - SPECIAL TOOL 7884

Fig. 45 Input/Low Range Gear Components

1 - SNAP-RING

2 - RETAINER PLATE

3 - INPUT GEAR

4 - LOW RANGE GEAR

5 - THRUST WASHERS

Fig. 46 Input/Low Range Gear Installation

1 - ANNULUS GEAR

2 - INPUT/LOW RANGE GEAR

WJTRANSFER CASE - NV247 21 - 329

TRANSFER CASE - NV247 (Continued)

Page 1851 of 2199

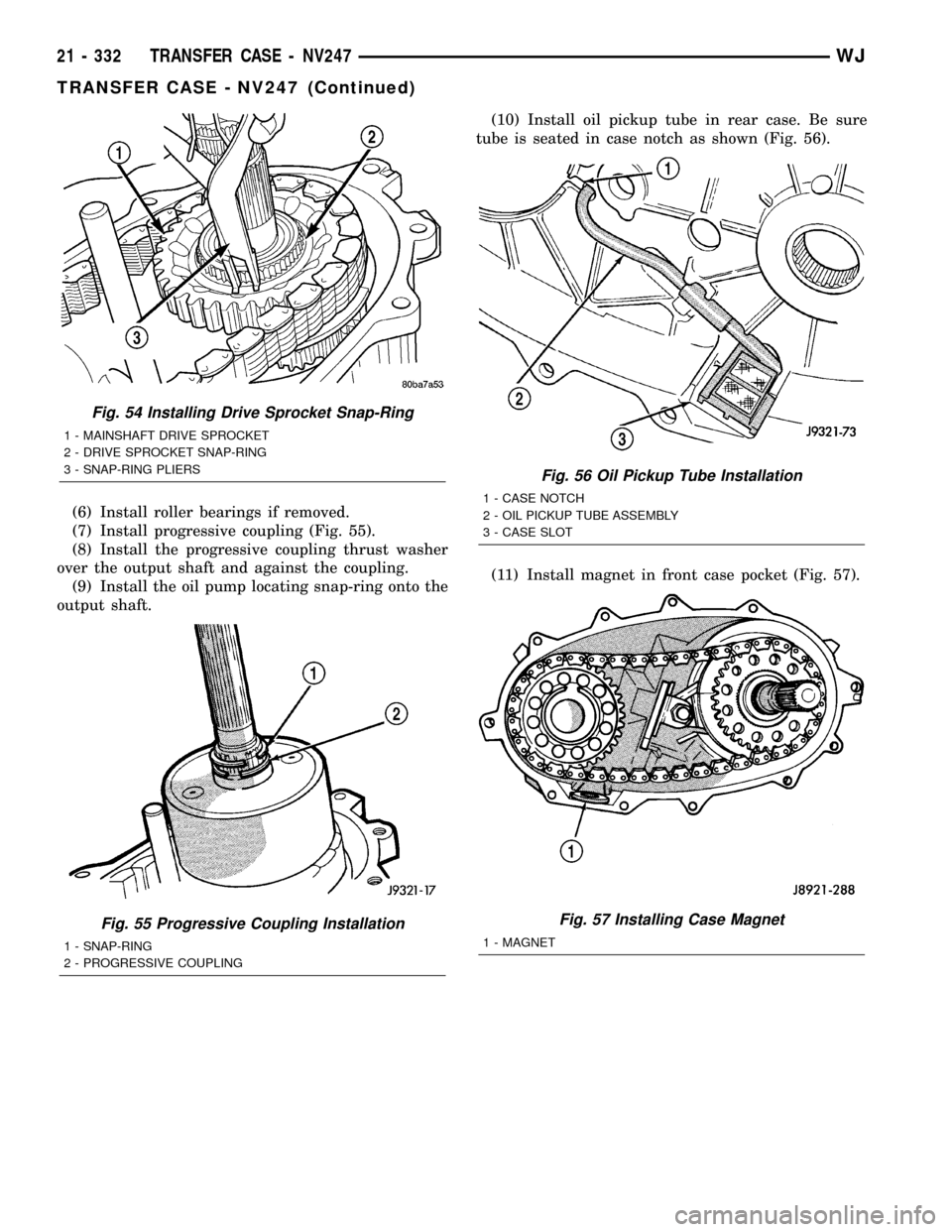

(6) Install roller bearings if removed.

(7) Install progressive coupling (Fig. 55).

(8) Install the progressive coupling thrust washer

over the output shaft and against the coupling.

(9) Install the oil pump locating snap-ring onto the

output shaft.(10) Install oil pickup tube in rear case. Be sure

tube is seated in case notch as shown (Fig. 56).

(11) Install magnet in front case pocket (Fig. 57).

Fig. 54 Installing Drive Sprocket Snap-Ring

1 - MAINSHAFT DRIVE SPROCKET

2 - DRIVE SPROCKET SNAP-RING

3 - SNAP-RING PLIERS

Fig. 55 Progressive Coupling Installation

1 - SNAP-RING

2 - PROGRESSIVE COUPLING

Fig. 56 Oil Pickup Tube Installation

1 - CASE NOTCH

2 - OIL PICKUP TUBE ASSEMBLY

3 - CASE SLOT

Fig. 57 Installing Case Magnet

1 - MAGNET

21 - 332 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1852 of 2199

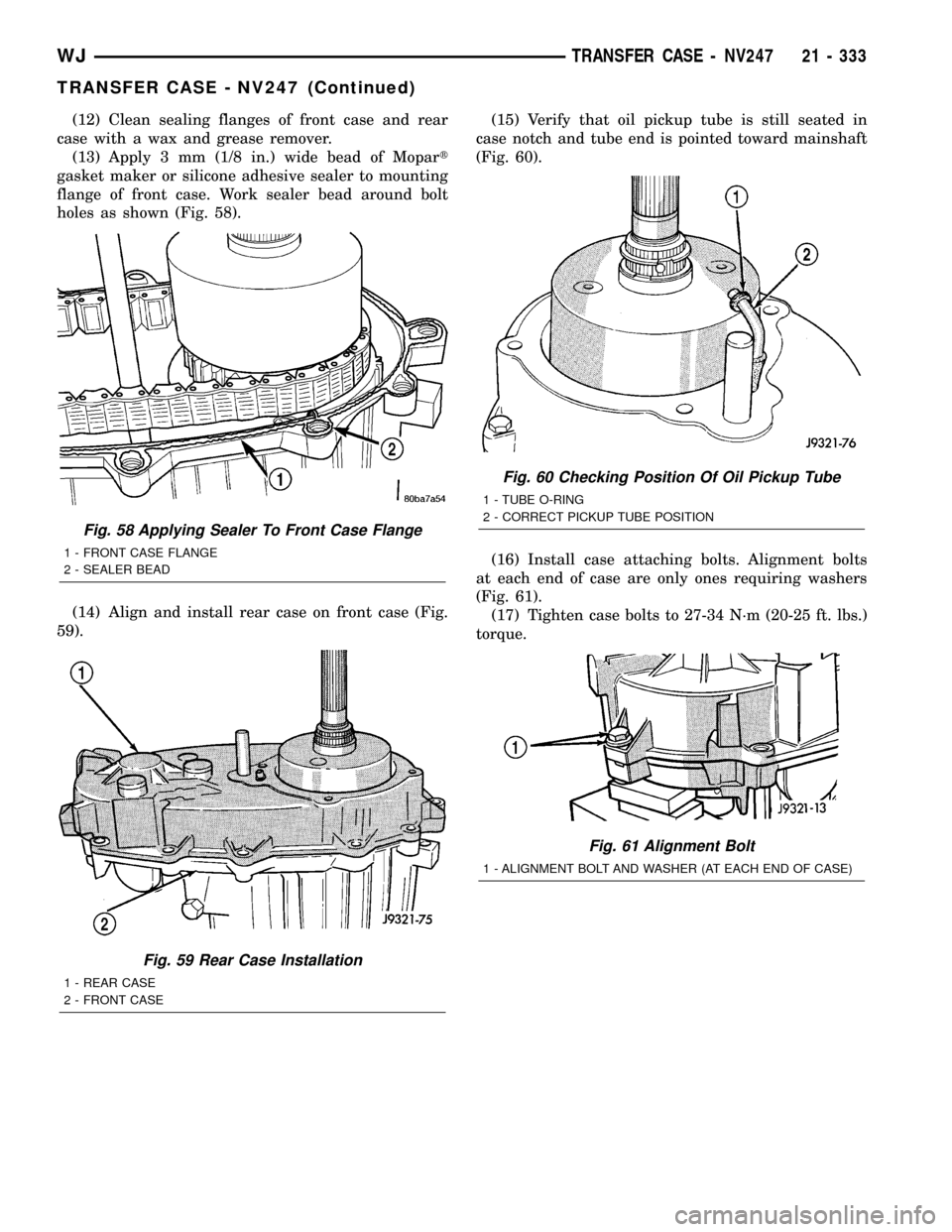

(12) Clean sealing flanges of front case and rear

case with a wax and grease remover.

(13) Apply 3 mm (1/8 in.) wide bead of Mopart

gasket maker or silicone adhesive sealer to mounting

flange of front case. Work sealer bead around bolt

holes as shown (Fig. 58).

(14) Align and install rear case on front case (Fig.

59).(15) Verify that oil pickup tube is still seated in

case notch and tube end is pointed toward mainshaft

(Fig. 60).

(16) Install case attaching bolts. Alignment bolts

at each end of case are only ones requiring washers

(Fig. 61).

(17) Tighten case bolts to 27-34 N´m (20-25 ft. lbs.)

torque.

Fig. 58 Applying Sealer To Front Case Flange

1 - FRONT CASE FLANGE

2 - SEALER BEAD

Fig. 59 Rear Case Installation

1 - REAR CASE

2 - FRONT CASE

Fig. 60 Checking Position Of Oil Pickup Tube

1 - TUBE O-RING

2 - CORRECT PICKUP TUBE POSITION

Fig. 61 Alignment Bolt

1 - ALIGNMENT BOLT AND WASHER (AT EACH END OF CASE)

WJTRANSFER CASE - NV247 21 - 333

TRANSFER CASE - NV247 (Continued)

Page 1857 of 2199

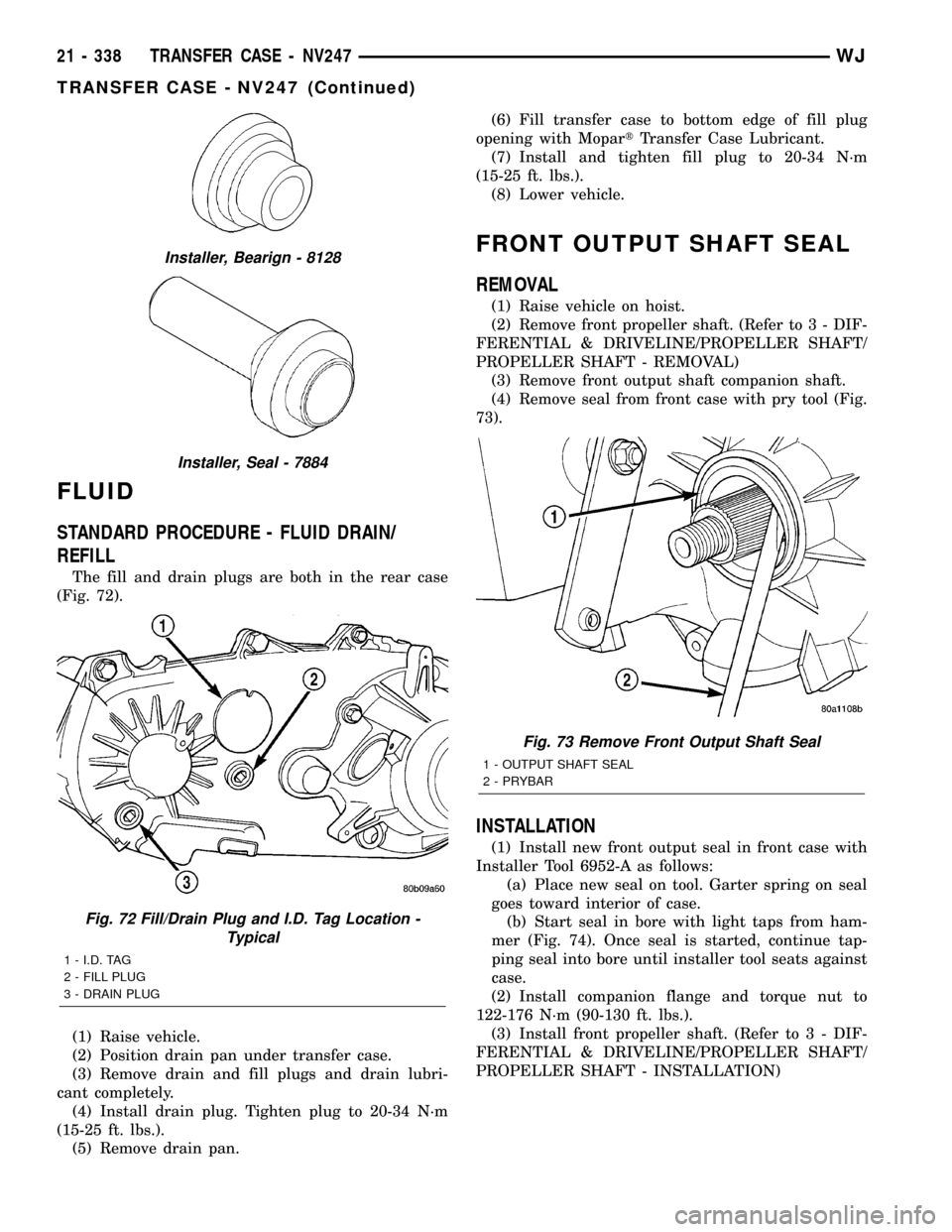

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

The fill and drain plugs are both in the rear case

(Fig. 72).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.(6) Fill transfer case to bottom edge of fill plug

opening with MopartTransfer Case Lubricant.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Remove front output shaft companion shaft.

(4) Remove seal from front case with pry tool (Fig.

73).

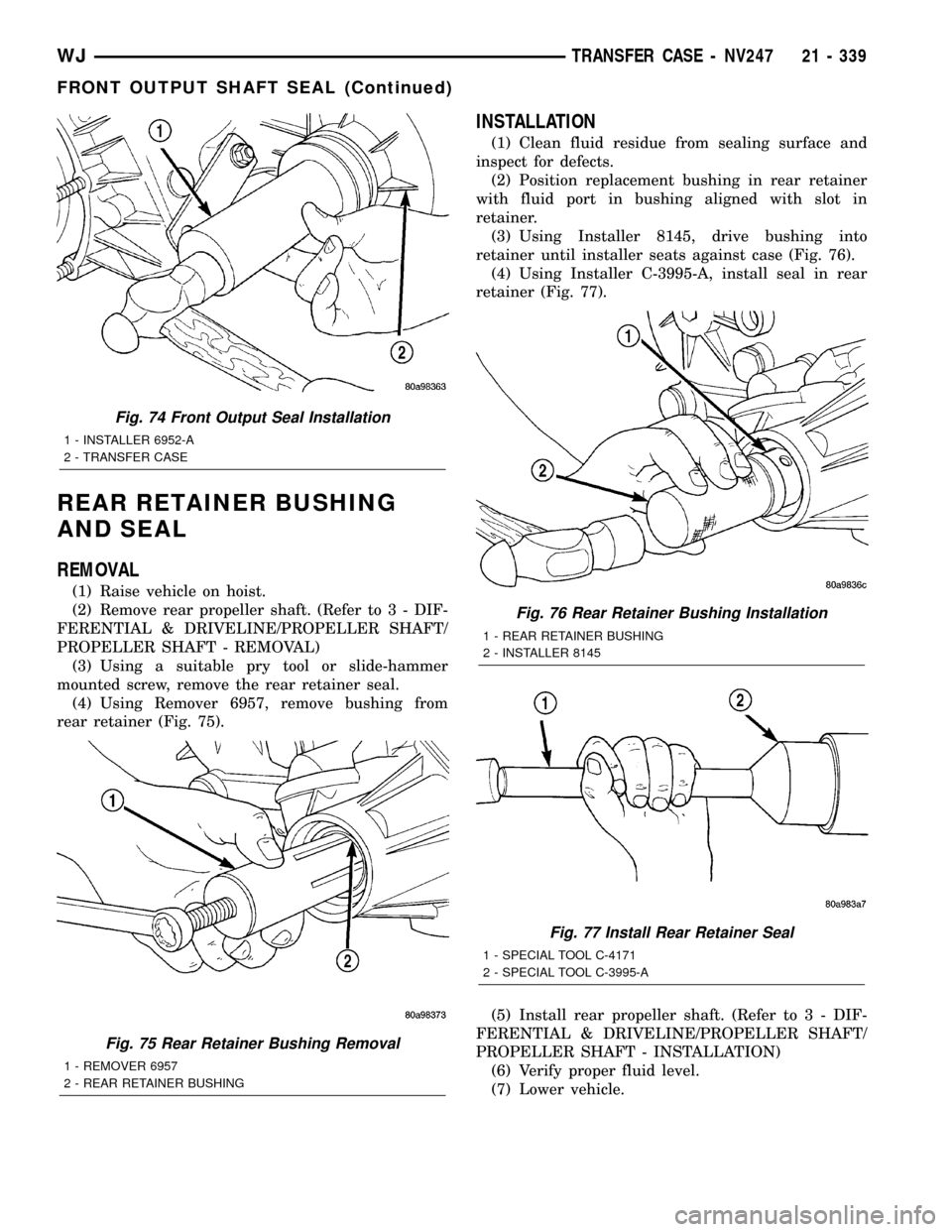

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6952-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 74). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange and torque nut to

122-176 N´m (90-130 ft. lbs.).

(3) Install front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

Installer, Bearign - 8128

Installer, Seal - 7884

Fig. 72 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 73 Remove Front Output Shaft Seal

1 - OUTPUT SHAFT SEAL

2 - PRYBAR

21 - 338 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1858 of 2199

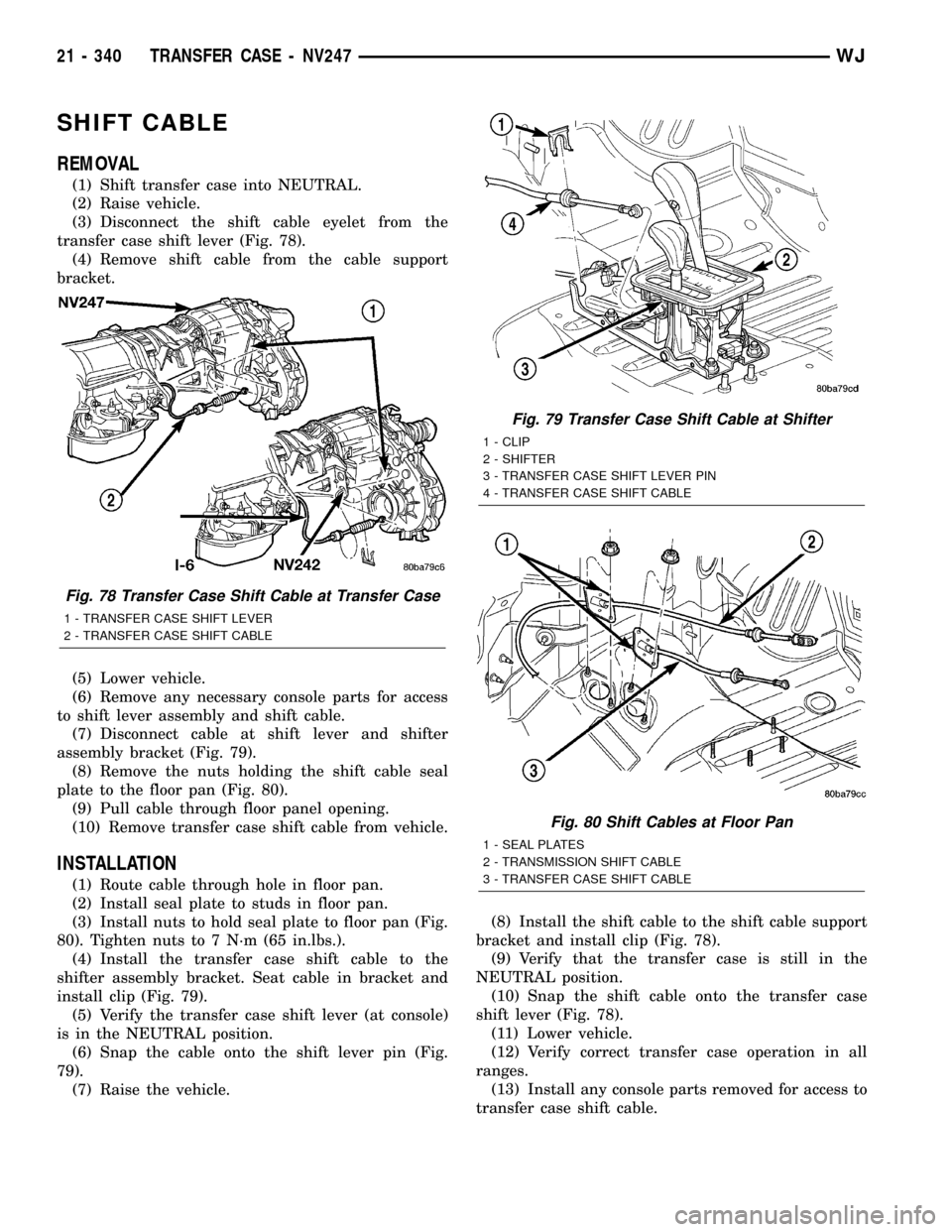

REAR RETAINER BUSHING

AND SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the rear retainer seal.

(4) Using Remover 6957, remove bushing from

rear retainer (Fig. 75).

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Position replacement bushing in rear retainer

with fluid port in bushing aligned with slot in

retainer.

(3) Using Installer 8145, drive bushing into

retainer until installer seats against case (Fig. 76).

(4) Using Installer C-3995-A, install seal in rear

retainer (Fig. 77).

(5) Install rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

(6) Verify proper fluid level.

(7) Lower vehicle.

Fig. 74 Front Output Seal Installation

1 - INSTALLER 6952-A

2 - TRANSFER CASE

Fig. 75 Rear Retainer Bushing Removal

1 - REMOVER 6957

2 - REAR RETAINER BUSHING

Fig. 76 Rear Retainer Bushing Installation

1 - REAR RETAINER BUSHING

2 - INSTALLER 8145

Fig. 77 Install Rear Retainer Seal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL C-3995-A

WJTRANSFER CASE - NV247 21 - 339

FRONT OUTPUT SHAFT SEAL (Continued)

Page 1859 of 2199

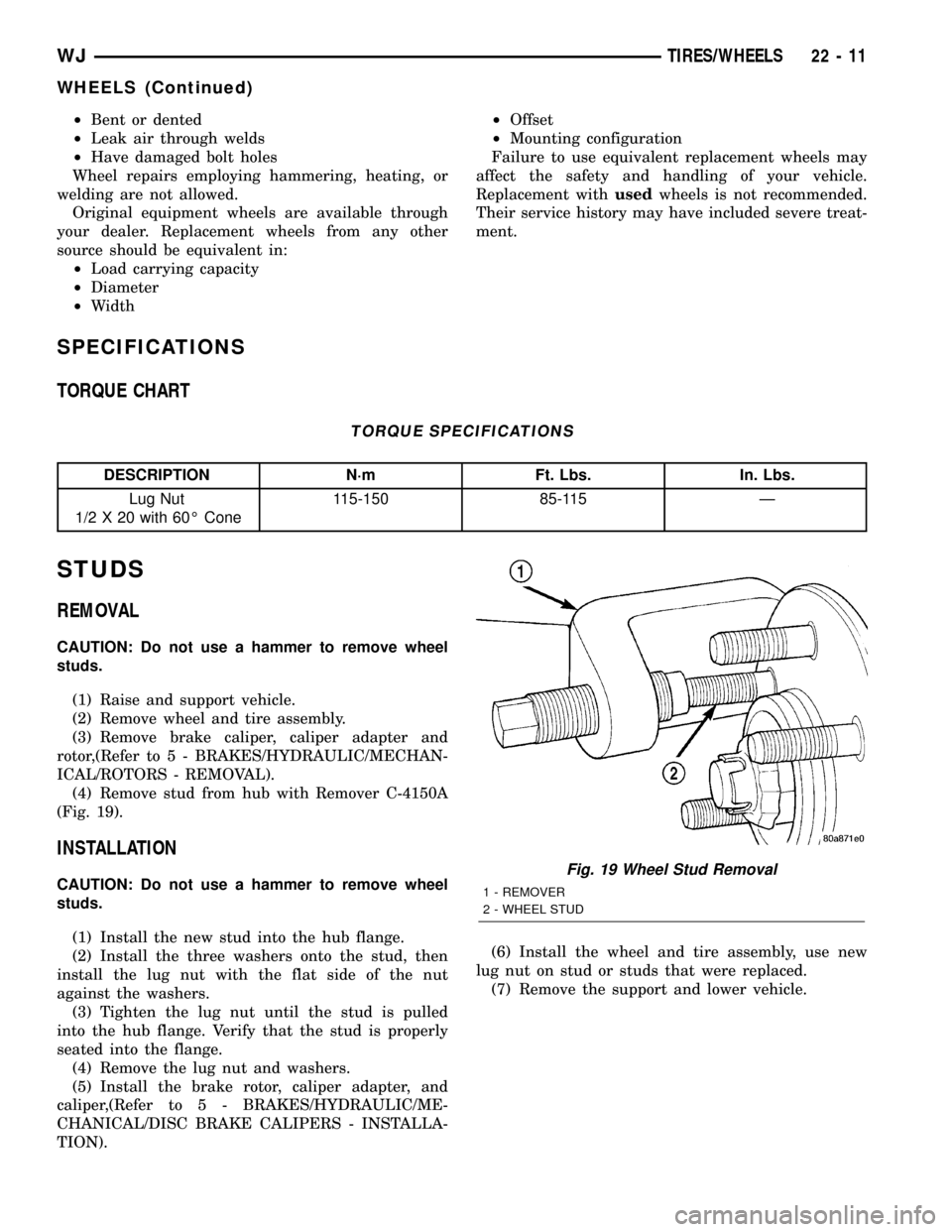

SHIFT CABLE

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Disconnect the shift cable eyelet from the

transfer case shift lever (Fig. 78).

(4) Remove shift cable from the cable support

bracket.

(5) Lower vehicle.

(6) Remove any necessary console parts for access

to shift lever assembly and shift cable.

(7) Disconnect cable at shift lever and shifter

assembly bracket (Fig. 79).

(8) Remove the nuts holding the shift cable seal

plate to the floor pan (Fig. 80).

(9) Pull cable through floor panel opening.

(10) Remove transfer case shift cable from vehicle.

INSTALLATION

(1) Route cable through hole in floor pan.

(2) Install seal plate to studs in floor pan.

(3) Install nuts to hold seal plate to floor pan (Fig.

80). Tighten nuts to 7 N´m (65 in.lbs.).

(4) Install the transfer case shift cable to the

shifter assembly bracket. Seat cable in bracket and

install clip (Fig. 79).

(5) Verify the transfer case shift lever (at console)

is in the NEUTRAL position.

(6) Snap the cable onto the shift lever pin (Fig.

79).

(7) Raise the vehicle.(8) Install the shift cable to the shift cable support

bracket and install clip (Fig. 78).

(9) Verify that the transfer case is still in the

NEUTRAL position.

(10) Snap the shift cable onto the transfer case

shift lever (Fig. 78).

(11) Lower vehicle.

(12) Verify correct transfer case operation in all

ranges.

(13) Install any console parts removed for access to

transfer case shift cable.

Fig. 78 Transfer Case Shift Cable at Transfer Case

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 79 Transfer Case Shift Cable at Shifter

1 - CLIP

2 - SHIFTER

3 - TRANSFER CASE SHIFT LEVER PIN

4 - TRANSFER CASE SHIFT CABLE

Fig. 80 Shift Cables at Floor Pan

1 - SEAL PLATES

2 - TRANSMISSION SHIFT CABLE

3 - TRANSFER CASE SHIFT CABLE

21 - 340 TRANSFER CASE - NV247WJ

Page 1870 of 2199

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

1/2 X 20 with 60É Cone115-150 85-115 Ð

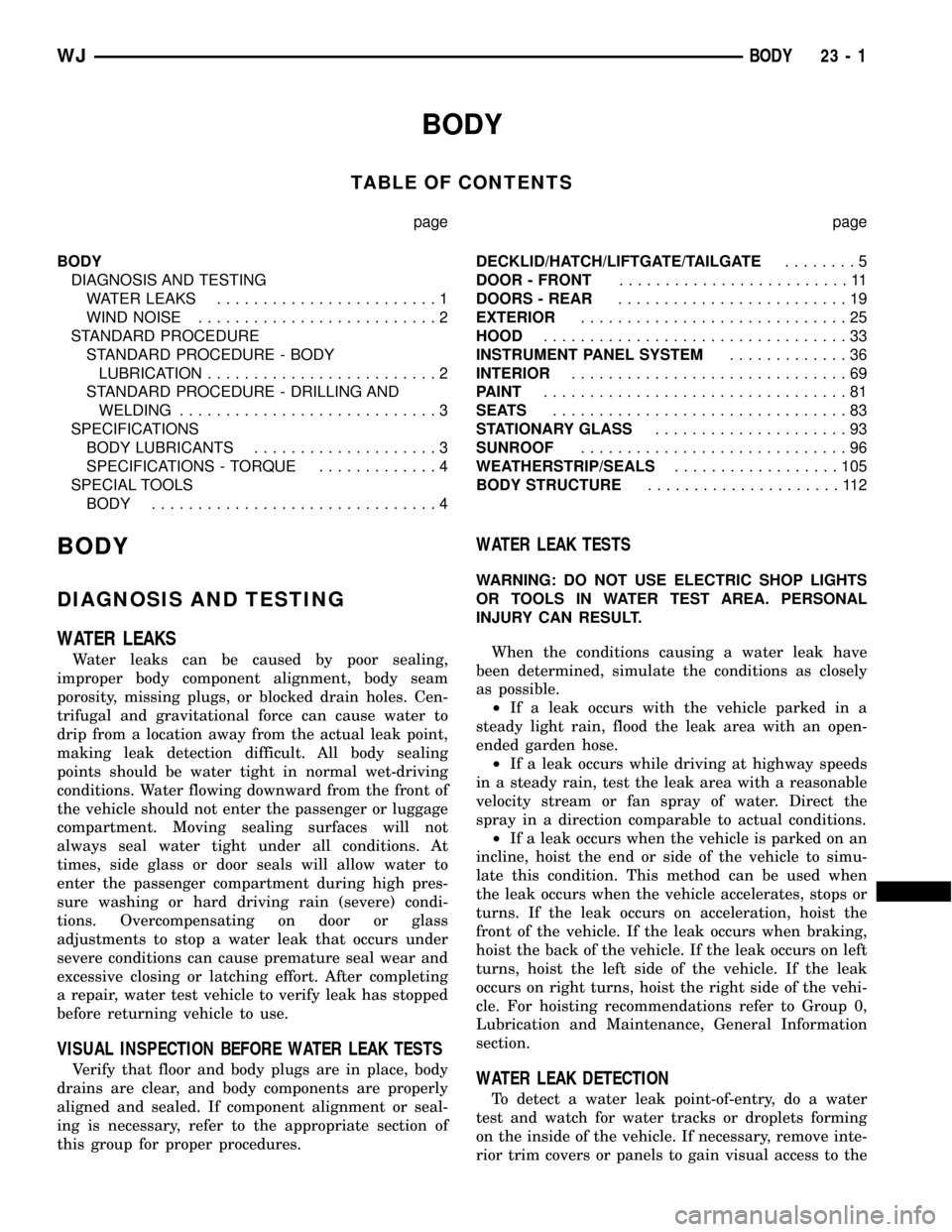

STUDS

REMOVAL

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, caliper adapter and

rotor,(Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove stud from hub with Remover C-4150A

(Fig. 19).

INSTALLATION

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and

caliper,(Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).(6) Install the wheel and tire assembly, use new

lug nut on stud or studs that were replaced.

(7) Remove the support and lower vehicle.Fig. 19 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

WJTIRES/WHEELS 22 - 11

WHEELS (Continued)

Page 1874 of 2199

BODY

TABLE OF CONTENTS

page page

BODY

DIAGNOSIS AND TESTING

WATER LEAKS........................1

WIND NOISE..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................2

STANDARD PROCEDURE - DRILLING AND

WELDING............................3

SPECIFICATIONS

BODY LUBRICANTS....................3

SPECIFICATIONS - TORQUE.............4

SPECIAL TOOLS

BODY...............................4DECKLID/HATCH/LIFTGATE/TAILGATE........5

DOOR - FRONT.........................11

DOORS - REAR.........................19

EXTERIOR.............................25

HOOD.................................33

INSTRUMENT PANEL SYSTEM.............36

INTERIOR..............................69

PAINT.................................81

SEATS................................83

STATIONARY GLASS.....................93

SUNROOF.............................96

WEATHERSTRIP/SEALS..................105

BODY STRUCTURE.....................112

BODY

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

WJBODY 23 - 1

Page 1876 of 2199

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas-

senger's clothing.

(3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker, and safety latch should be lubricated period-

ically.

(5) The door lock cylinders should be lubricated

twice each year (preferably autumn and spring).

(a) Spray a small amount of lock cylinder lubri-

cant directly into the lock cylinder.

(b) Apply a small amount to the key and insert

it into the lock cylinder.

(c) Rotate it to the locked position and then back

to the unlocked position several times.(d) Remove the key. Wipe the lubricant from it

with a clean cloth to avoid soiling of clothing.

STANDARD PROCEDURE - DRILLING AND

WELDING

When holes must be drilled or punched in an inner

body panel, verify depth of space to the outer body

panel, electrical wiring, or other components. Dam-

age to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

SPECIFICATIONS

BODY LUBRICANTS

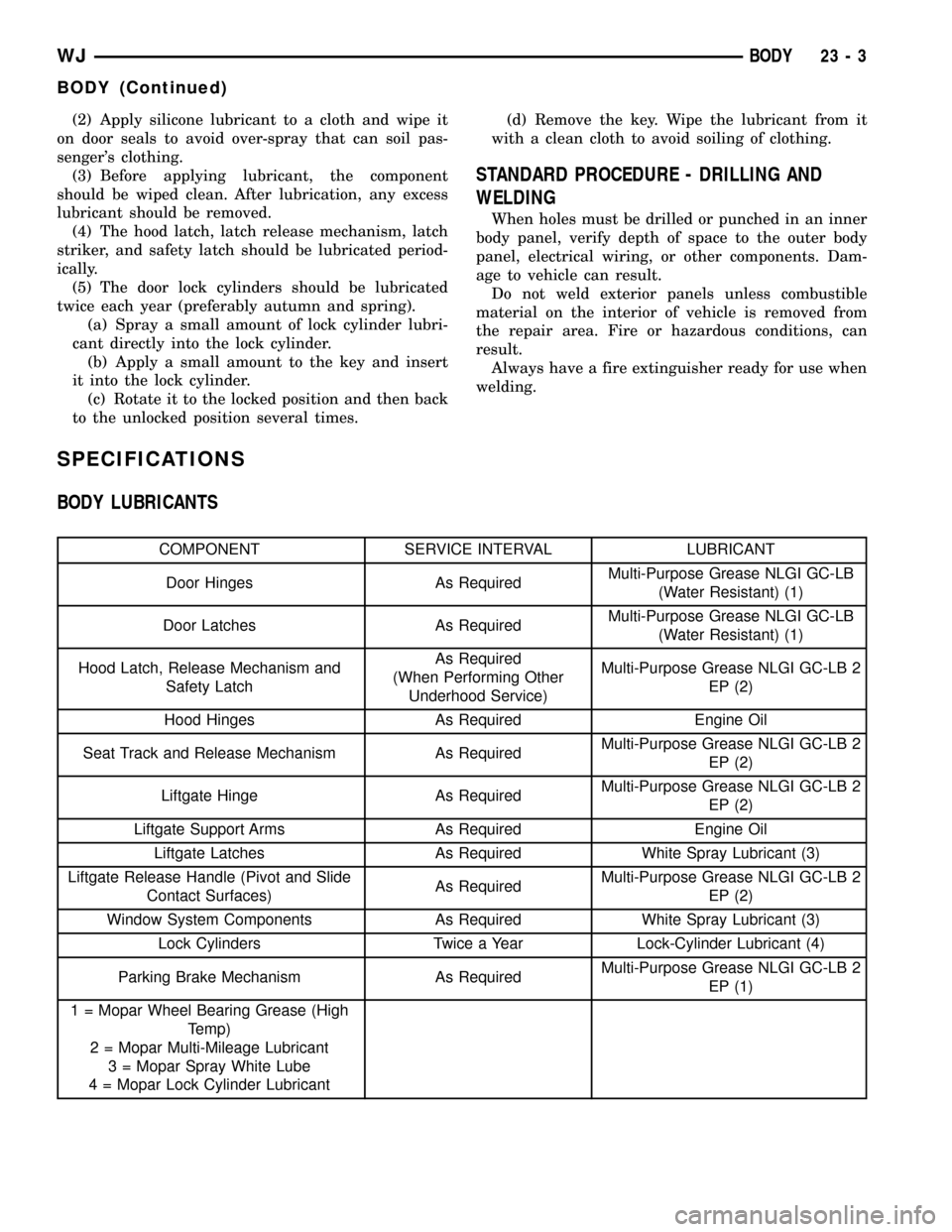

COMPONENT SERVICE INTERVAL LUBRICANT

Door Hinges As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Door Latches As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Hood Latch, Release Mechanism and

Safety LatchAs Required

(When Performing Other

Underhood Service)Multi-Purpose Grease NLGI GC-LB 2

EP (2)

Hood Hinges As Required Engine Oil

Seat Track and Release Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Hinge As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Support Arms As Required Engine Oil

Liftgate Latches As Required White Spray Lubricant (3)

Liftgate Release Handle (Pivot and Slide

Contact Surfaces)As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Window System Components As Required White Spray Lubricant (3)

Lock Cylinders Twice a Year Lock-Cylinder Lubricant (4)

Parking Brake Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (1)

1 = Mopar Wheel Bearing Grease (High

Temp)

2 = Mopar Multi-Mileage Lubricant

3 = Mopar Spray White Lube

4 = Mopar Lock Cylinder Lubricant

WJBODY 23 - 3

BODY (Continued)

Page 1877 of 2199

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

BUCKET SEAT BACK FRAME RECLINER BOLTS TO SEAT CUSHION

FRAME28 20 Ð

BUCKET SEAT RECLINER TO SEAT BACK FRAME BOLTS 28 20 Ð

BUCKET SEAT TRACK ADJUSTER NUTS TO SEAT CUSHION FRAME 28 20 Ð

FRONT BUCKET SEAT TO FLOOR PAN BOLTS 40 30 Ð

FRONT BUCKET SEAT TO FLOOR PAN FRONT BOLTS 40 30 Ð

FRONT DOOR HINGE BOLTS 35 26 Ð

FRONT DOOR LATCH TO DOOR SCREWS 10 Ð 89

FRONT DOOR STRIKER TO B-PILLAR 28 20 Ð

HOOD LATCH TO RADIATOR CROSSMEMBER 11 8 Ð

LIFT GATE LATCH STRIKER TO D-PILLAR NUTS 10 Ð 89

REAR DOOR LATCH TO DOOR SCREWS 10 Ð 89

REAR DOOR STRIKER TO C-PILLAR SCREWS 28 20 Ð

REAR SEAT BACK LATCH/HINGE TO SEAT BACK FRAME 28 20 Ð

REAR SEAT BACK LEFT SIDE SUPPORT BRACKET TO CENTER PIVOT

BRACKET28 20 Ð

REAR SEAT BACK RIGHT SIDE SUPPORT BRACKET 28 20 Ð

REAR SEAT CUSHION LATCH BASE PANEL SCREWS 8 Ð 75

REAR SEAT CUSHION TO FLOOR PAN BOLTS 11 8 Ð

SUNROOF MODULE TO ROOF PANEL NUTS 11 8 Ð

SPECIAL TOOLS

BODY

Remover, Moldings C-4829

23 - 4 BODYWJ

BODY (Continued)