air JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 649 of 2199

secured loosely to and pivots on the wiper arm hinge

pin to conceal the wiper arm retaining nut. The wide

end of a tapered, stamped steel channel is secured

with a hinge pin to the pivot end of the wiper arm.

One end of a long, rigid, stamped steel strap, with a

small hole near its pivot end, is riveted and crimped

within the narrow end of the stamped steel channel.

The tip of the wiper blade end of this strap is bent

back under itself to form a small hook. Concealed

within the stamped steel channel, one end of a long

spring is engaged with a wire hook on the underside

of the die cast pivot end, while the other end of the

spring is hooked through the small hole in the steel

strap. A molded plastic wiper arm support is snapped

onto the wiper arm strap where it exits the channel.

The entire wiper arm has a satin black finish applied

to all of its visible surfaces.

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

OPERATION

The rear wiper arm is designed to mechanically

transmit the motion from the rear wiper motor out-

put shaft to the rear wiper blade. The wiper arm

must be properly indexed to the motor output shaft

in order to maintain the proper wiper blade travel on

the glass. The wiper arm support is designed to lift

and support the rear wiper arm and blade off of the

glass when the rear wiper blade is parked. This sup-

port and the park ramp on the liftgate outer panel

below the glass also provide an alignment reference

to ensure accurate rear wiper arm and blade instal-

lation. The hole with internal serrations in the wiper

arm pivot end interlocks with the serrations on the

outer circumference of the motor output shaft, allow-

ing positive engagement and finite adjustment of this

connection. A hex nut secures the wiper arm pivot

end to the threads on the motor output shaft and the

pivot cover hinges and snaps over this connection for

a neat appearance. The spring-loaded wiper arm

hinge controls the down-force applied through the tip

of the wiper arm to the wiper blade on the glass. The

hook formation on the tip of the wiper arm provides

a cradle for securing and latching the wiper blade

pivot block to the wiper arm.

REMOVAL

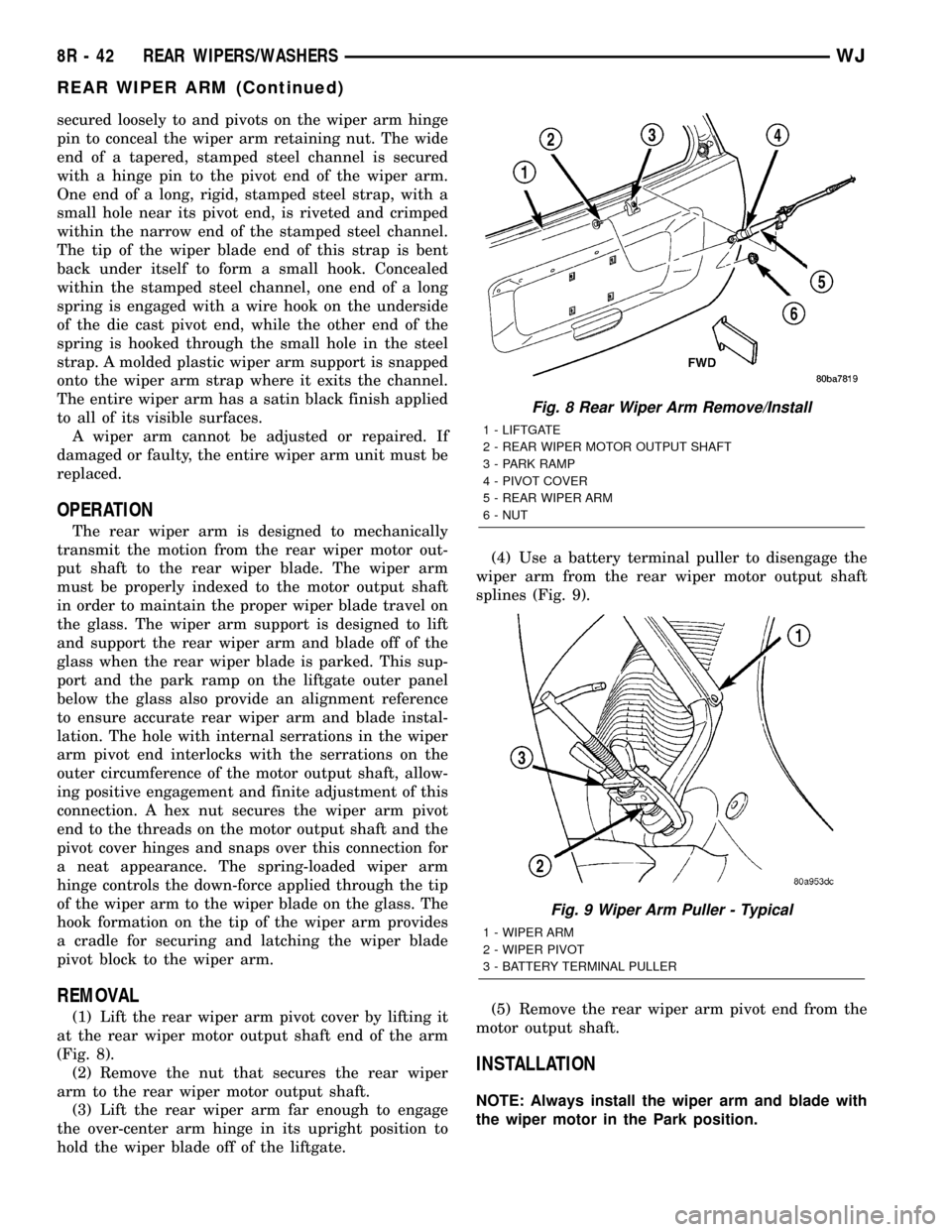

(1) Lift the rear wiper arm pivot cover by lifting it

at the rear wiper motor output shaft end of the arm

(Fig. 8).

(2) Remove the nut that secures the rear wiper

arm to the rear wiper motor output shaft.

(3) Lift the rear wiper arm far enough to engage

the over-center arm hinge in its upright position to

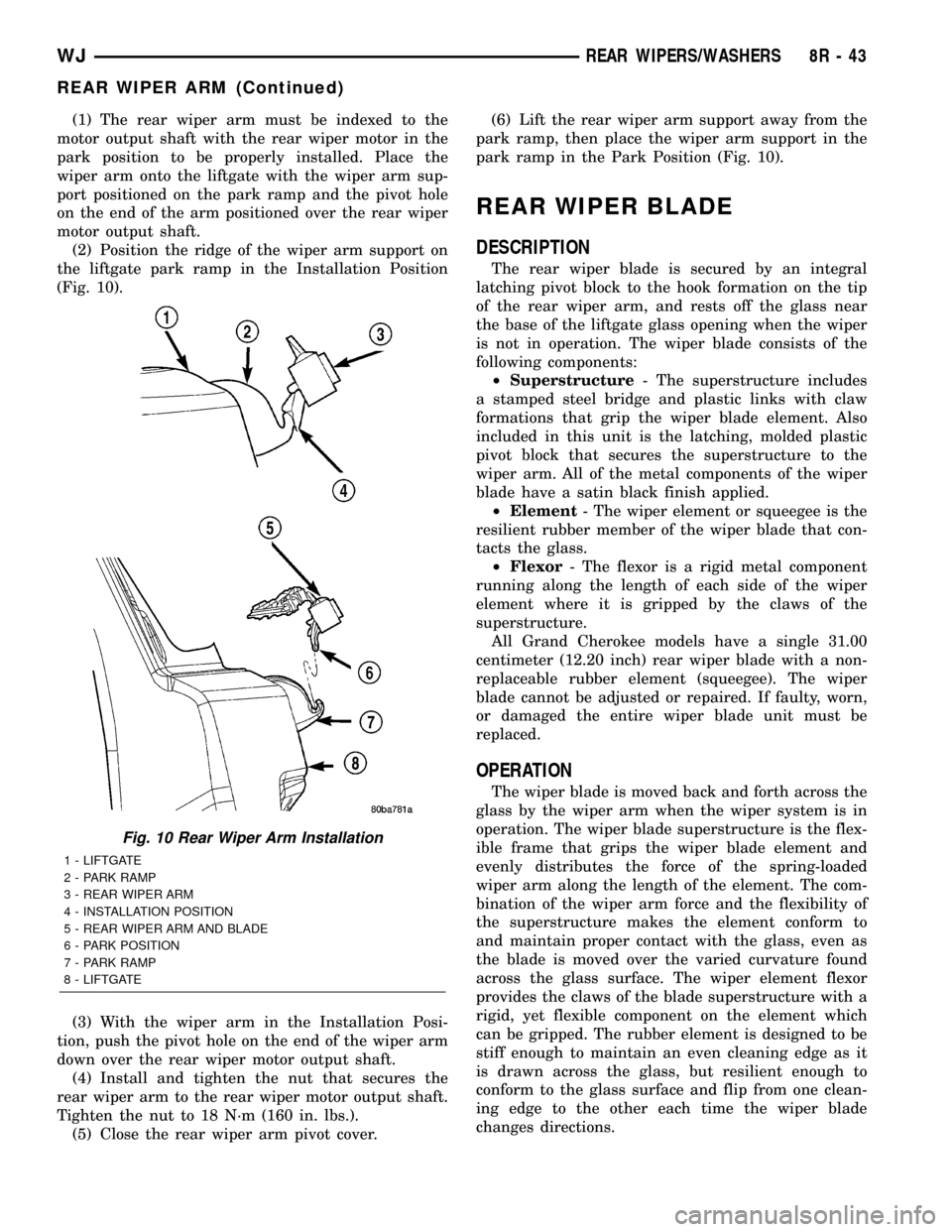

hold the wiper blade off of the liftgate.(4) Use a battery terminal puller to disengage the

wiper arm from the rear wiper motor output shaft

splines (Fig. 9).

(5) Remove the rear wiper arm pivot end from the

motor output shaft.

INSTALLATION

NOTE: Always install the wiper arm and blade with

the wiper motor in the Park position.

Fig. 8 Rear Wiper Arm Remove/Install

1 - LIFTGATE

2 - REAR WIPER MOTOR OUTPUT SHAFT

3 - PARK RAMP

4 - PIVOT COVER

5 - REAR WIPER ARM

6 - NUT

Fig. 9 Wiper Arm Puller - Typical

1 - WIPER ARM

2 - WIPER PIVOT

3 - BATTERY TERMINAL PULLER

8R - 42 REAR WIPERS/WASHERSWJ

REAR WIPER ARM (Continued)

Page 650 of 2199

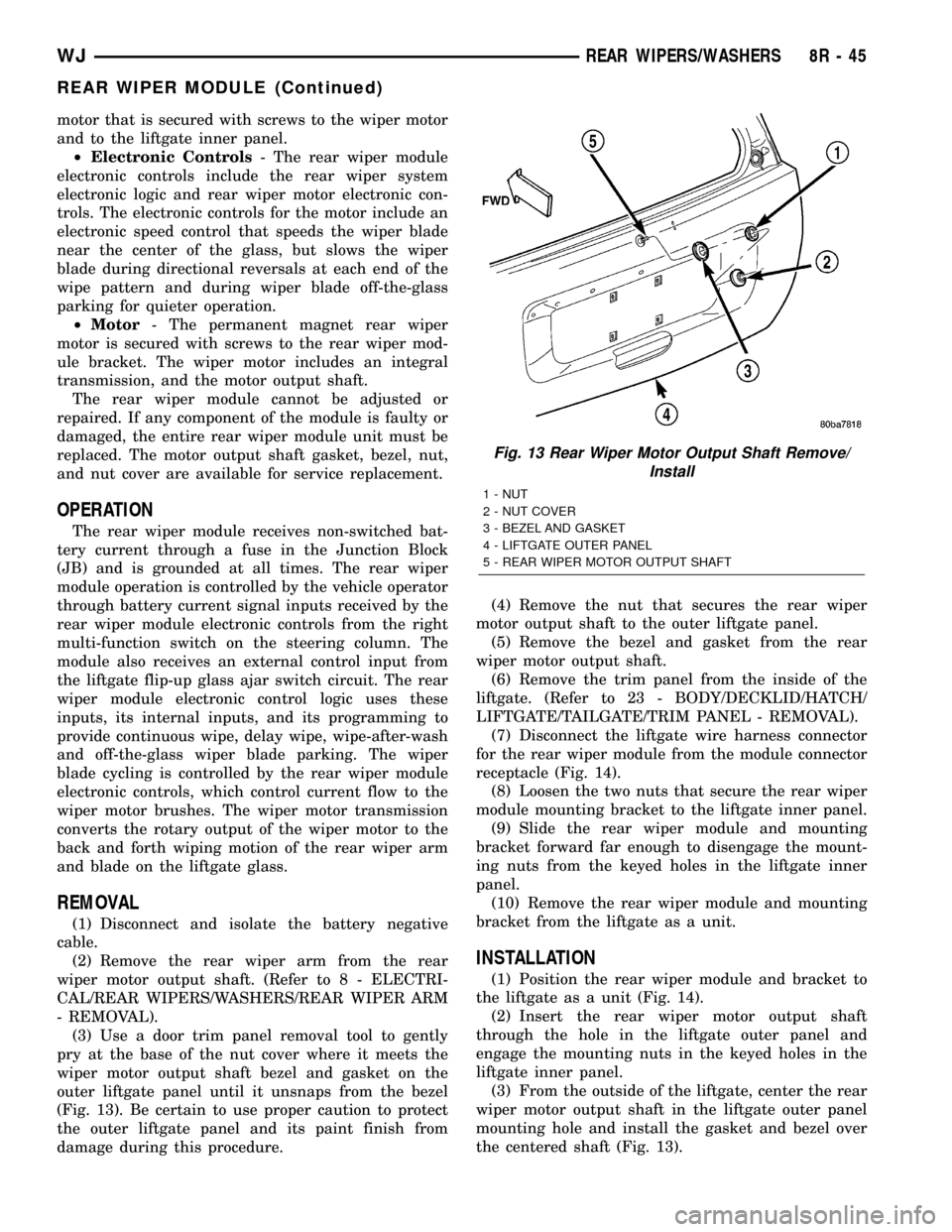

(1) The rear wiper arm must be indexed to the

motor output shaft with the rear wiper motor in the

park position to be properly installed. Place the

wiper arm onto the liftgate with the wiper arm sup-

port positioned on the park ramp and the pivot hole

on the end of the arm positioned over the rear wiper

motor output shaft.

(2) Position the ridge of the wiper arm support on

the liftgate park ramp in the Installation Position

(Fig. 10).

(3) With the wiper arm in the Installation Posi-

tion, push the pivot hole on the end of the wiper arm

down over the rear wiper motor output shaft.

(4) Install and tighten the nut that secures the

rear wiper arm to the rear wiper motor output shaft.

Tighten the nut to 18 N´m (160 in. lbs.).

(5) Close the rear wiper arm pivot cover.(6) Lift the rear wiper arm support away from the

park ramp, then place the wiper arm support in the

park ramp in the Park Position (Fig. 10).

REAR WIPER BLADE

DESCRIPTION

The rear wiper blade is secured by an integral

latching pivot block to the hook formation on the tip

of the rear wiper arm, and rests off the glass near

the base of the liftgate glass opening when the wiper

is not in operation. The wiper blade consists of the

following components:

²Superstructure- The superstructure includes

a stamped steel bridge and plastic links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.

²Flexor- The flexor is a rigid metal component

running along the length of each side of the wiper

element where it is gripped by the claws of the

superstructure.

All Grand Cherokee models have a single 31.00

centimeter (12.20 inch) rear wiper blade with a non-

replaceable rubber element (squeegee). The wiper

blade cannot be adjusted or repaired. If faulty, worn,

or damaged the entire wiper blade unit must be

replaced.

OPERATION

The wiper blade is moved back and forth across the

glass by the wiper arm when the wiper system is in

operation. The wiper blade superstructure is the flex-

ible frame that grips the wiper blade element and

evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature found

across the glass surface. The wiper element flexor

provides the claws of the blade superstructure with a

rigid, yet flexible component on the element which

can be gripped. The rubber element is designed to be

stiff enough to maintain an even cleaning edge as it

is drawn across the glass, but resilient enough to

conform to the glass surface and flip from one clean-

ing edge to the other each time the wiper blade

changes directions.

Fig. 10 Rear Wiper Arm Installation

1 - LIFTGATE

2 - PARK RAMP

3 - REAR WIPER ARM

4 - INSTALLATION POSITION

5 - REAR WIPER ARM AND BLADE

6 - PARK POSITION

7 - PARK RAMP

8 - LIFTGATE

WJREAR WIPERS/WASHERS 8R - 43

REAR WIPER ARM (Continued)

Page 652 of 2199

motor that is secured with screws to the wiper motor

and to the liftgate inner panel.

²Electronic Controls- The rear wiper module

electronic controls include the rear wiper system

electronic logic and rear wiper motor electronic con-

trols. The electronic controls for the motor include an

electronic speed control that speeds the wiper blade

near the center of the glass, but slows the wiper

blade during directional reversals at each end of the

wipe pattern and during wiper blade off-the-glass

parking for quieter operation.

²Motor- The permanent magnet rear wiper

motor is secured with screws to the rear wiper mod-

ule bracket. The wiper motor includes an integral

transmission, and the motor output shaft.

The rear wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire rear wiper module unit must be

replaced. The motor output shaft gasket, bezel, nut,

and nut cover are available for service replacement.

OPERATION

The rear wiper module receives non-switched bat-

tery current through a fuse in the Junction Block

(JB) and is grounded at all times. The rear wiper

module operation is controlled by the vehicle operator

through battery current signal inputs received by the

rear wiper module electronic controls from the right

multi-function switch on the steering column. The

module also receives an external control input from

the liftgate flip-up glass ajar switch circuit. The rear

wiper module electronic control logic uses these

inputs, its internal inputs, and its programming to

provide continuous wipe, delay wipe, wipe-after-wash

and off-the-glass wiper blade parking. The wiper

blade cycling is controlled by the rear wiper module

electronic controls, which control current flow to the

wiper motor brushes. The wiper motor transmission

converts the rotary output of the wiper motor to the

back and forth wiping motion of the rear wiper arm

and blade on the liftgate glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear wiper arm from the rear

wiper motor output shaft. (Refer to 8 - ELECTRI-

CAL/REAR WIPERS/WASHERS/REAR WIPER ARM

- REMOVAL).

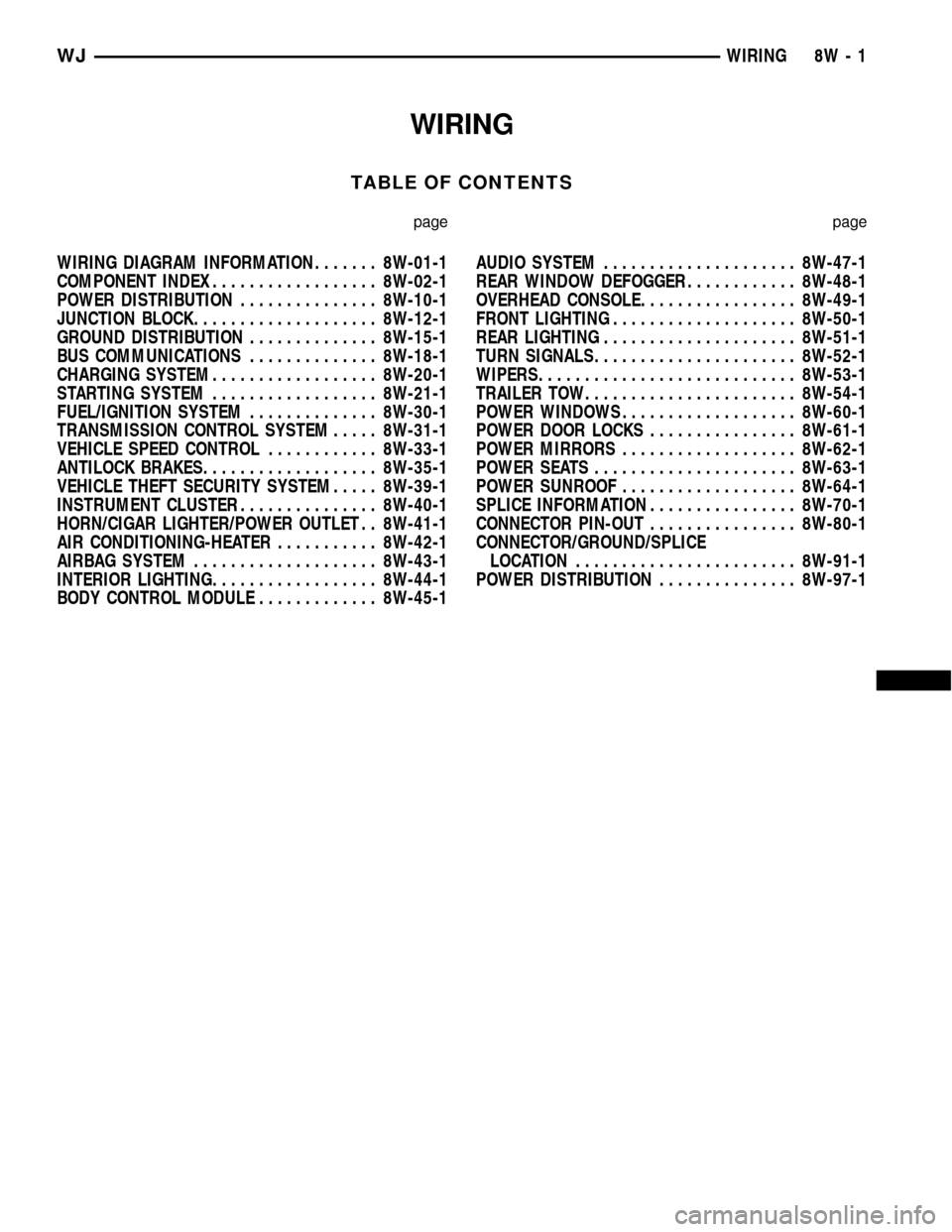

(3) Use a door trim panel removal tool to gently

pry at the base of the nut cover where it meets the

wiper motor output shaft bezel and gasket on the

outer liftgate panel until it unsnaps from the bezel

(Fig. 13). Be certain to use proper caution to protect

the outer liftgate panel and its paint finish from

damage during this procedure.(4) Remove the nut that secures the rear wiper

motor output shaft to the outer liftgate panel.

(5) Remove the bezel and gasket from the rear

wiper motor output shaft.

(6) Remove the trim panel from the inside of the

liftgate. (Refer to 23 - BODY/DECKLID/HATCH/

LIFTGATE/TAILGATE/TRIM PANEL - REMOVAL).

(7) Disconnect the liftgate wire harness connector

for the rear wiper module from the module connector

receptacle (Fig. 14).

(8) Loosen the two nuts that secure the rear wiper

module mounting bracket to the liftgate inner panel.

(9) Slide the rear wiper module and mounting

bracket forward far enough to disengage the mount-

ing nuts from the keyed holes in the liftgate inner

panel.

(10) Remove the rear wiper module and mounting

bracket from the liftgate as a unit.

INSTALLATION

(1) Position the rear wiper module and bracket to

the liftgate as a unit (Fig. 14).

(2) Insert the rear wiper motor output shaft

through the hole in the liftgate outer panel and

engage the mounting nuts in the keyed holes in the

liftgate inner panel.

(3) From the outside of the liftgate, center the rear

wiper motor output shaft in the liftgate outer panel

mounting hole and install the gasket and bezel over

the centered shaft (Fig. 13).

Fig. 13 Rear Wiper Motor Output Shaft Remove/

Install

1 - NUT

2 - NUT COVER

3 - BEZEL AND GASKET

4 - LIFTGATE OUTER PANEL

5 - REAR WIPER MOTOR OUTPUT SHAFT

WJREAR WIPERS/WASHERS 8R - 45

REAR WIPER MODULE (Continued)

Page 654 of 2199

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUT................ 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 WJWIRING 8W - 1

Page 656 of 2199

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - CIRCUIT FUNCTIONS......6

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............7

WARNING

WARNINGS - GENERAL.................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................9

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS...........10

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP......................10

SPECIAL TOOLS

WIRING/TERMINAL....................10

CONNECTOR

REMOVAL.............................11

INSTALLATION.........................11

DIODE

REMOVAL.............................14

INSTALLATION.........................14

TERMINAL

REMOVAL.............................14

INSTALLATION.........................14

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 15

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 662 of 2199

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 663 of 2199

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

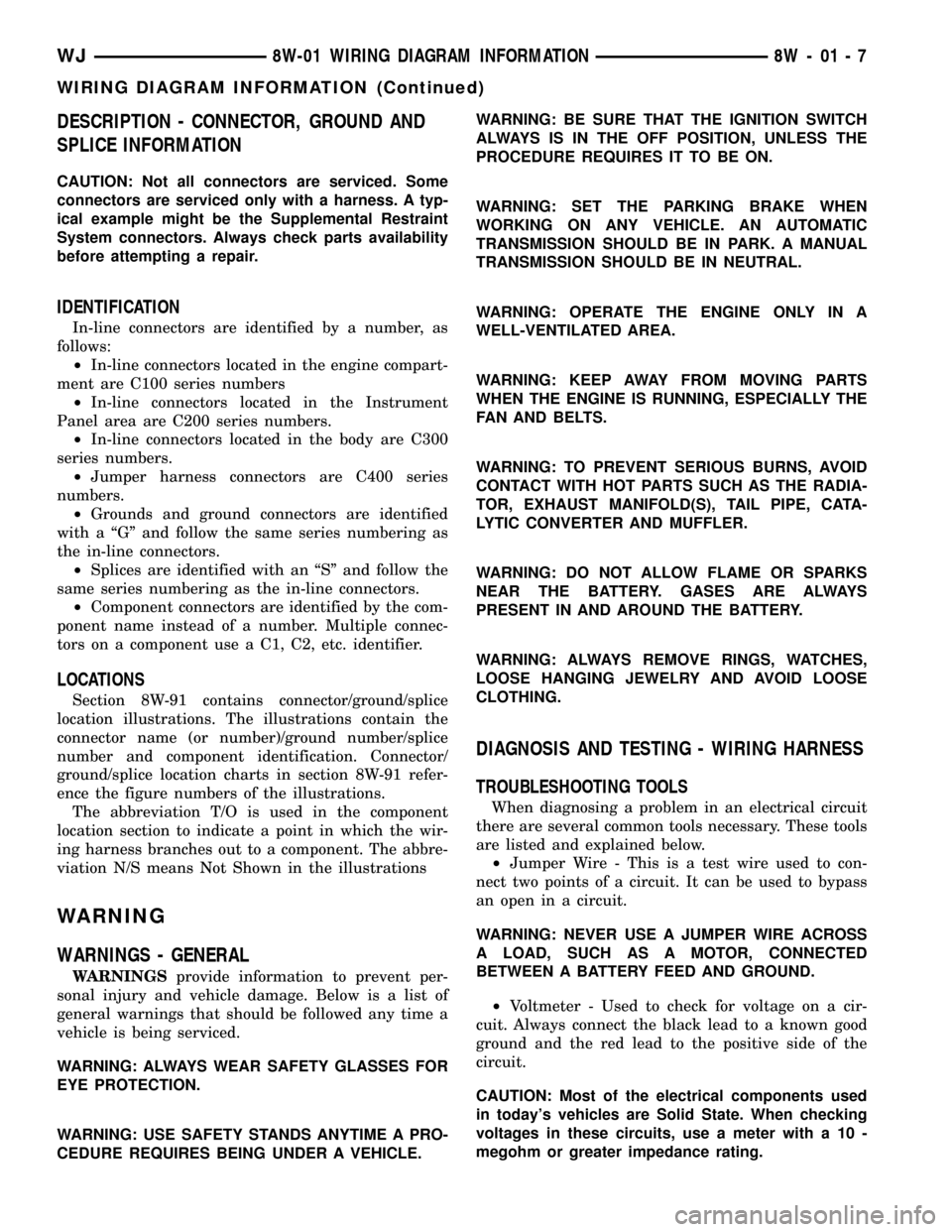

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked into

position

²

Dirt or corrosion on the terminals. Any amount of

corrosion or dirt could cause an intermittent problem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The stepsare listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem area.

(6) Verify the proper operation. For this step,

check for proper operation of all items on the

repaired circuit. Refer to the wiring diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ELECTROSTATIC

DISCHARGE (ESD) SENSITIVE DEVICES

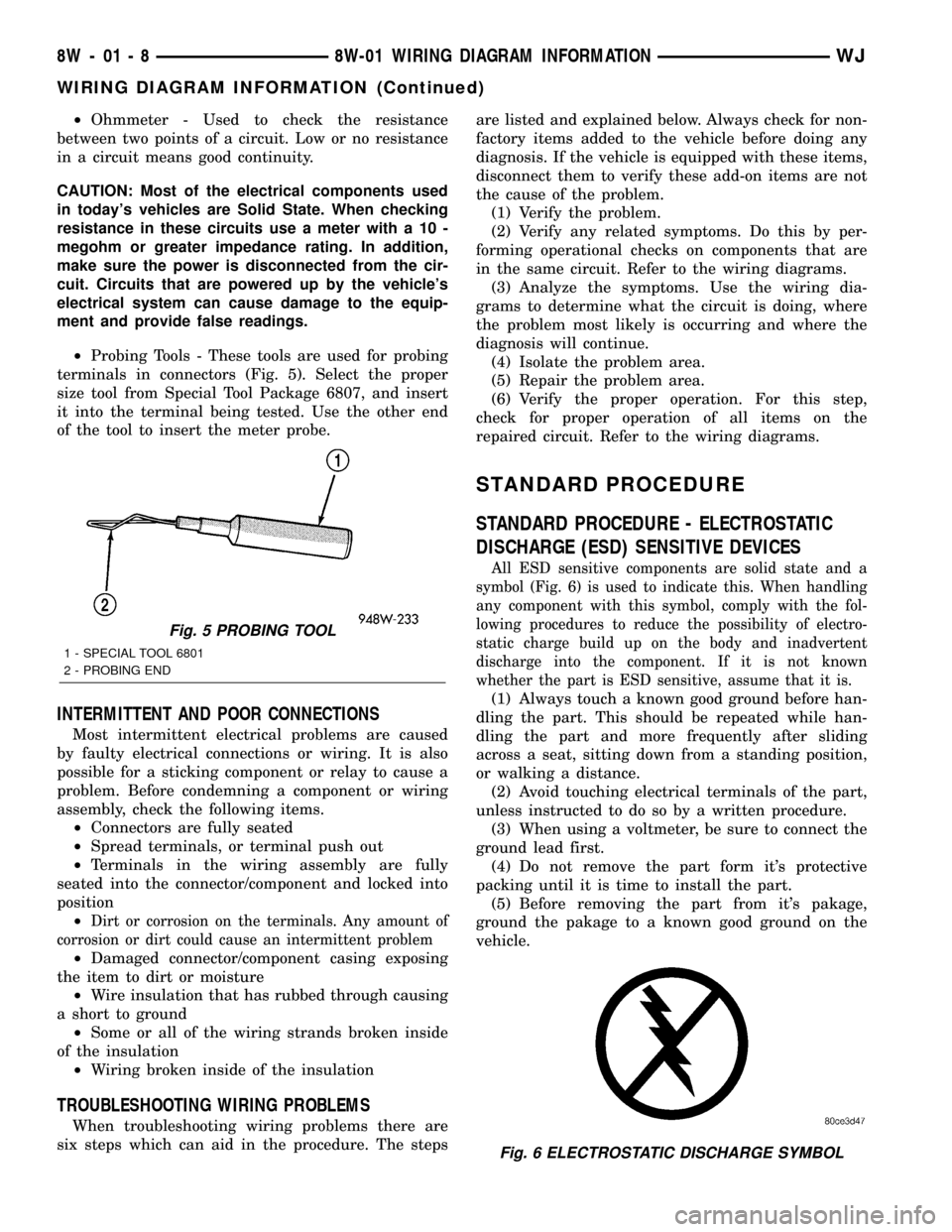

All ESD sensitive components are solid state and a

symbol (Fig. 6) is used to indicate this. When handling

any component with this symbol, comply with the fol-

lowing procedures to reduce the possibility of electro-

static charge build up on the body and inadvertent

discharge into the component. If it is not known

whether the part is ESD sensitive, assume that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part form it's protective

packing until it is time to install the part.

(5) Before removing the part from it's pakage,

ground the pakage to a known good ground on the

vehicle.

Fig. 5 PROBING TOOL

1 - SPECIAL TOOL 6801

2 - PROBING END

Fig. 6 ELECTROSTATIC DISCHARGE SYMBOL

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONWJ

WIRING DIAGRAM INFORMATION (Continued)

Page 666 of 2199

CONNECTOR

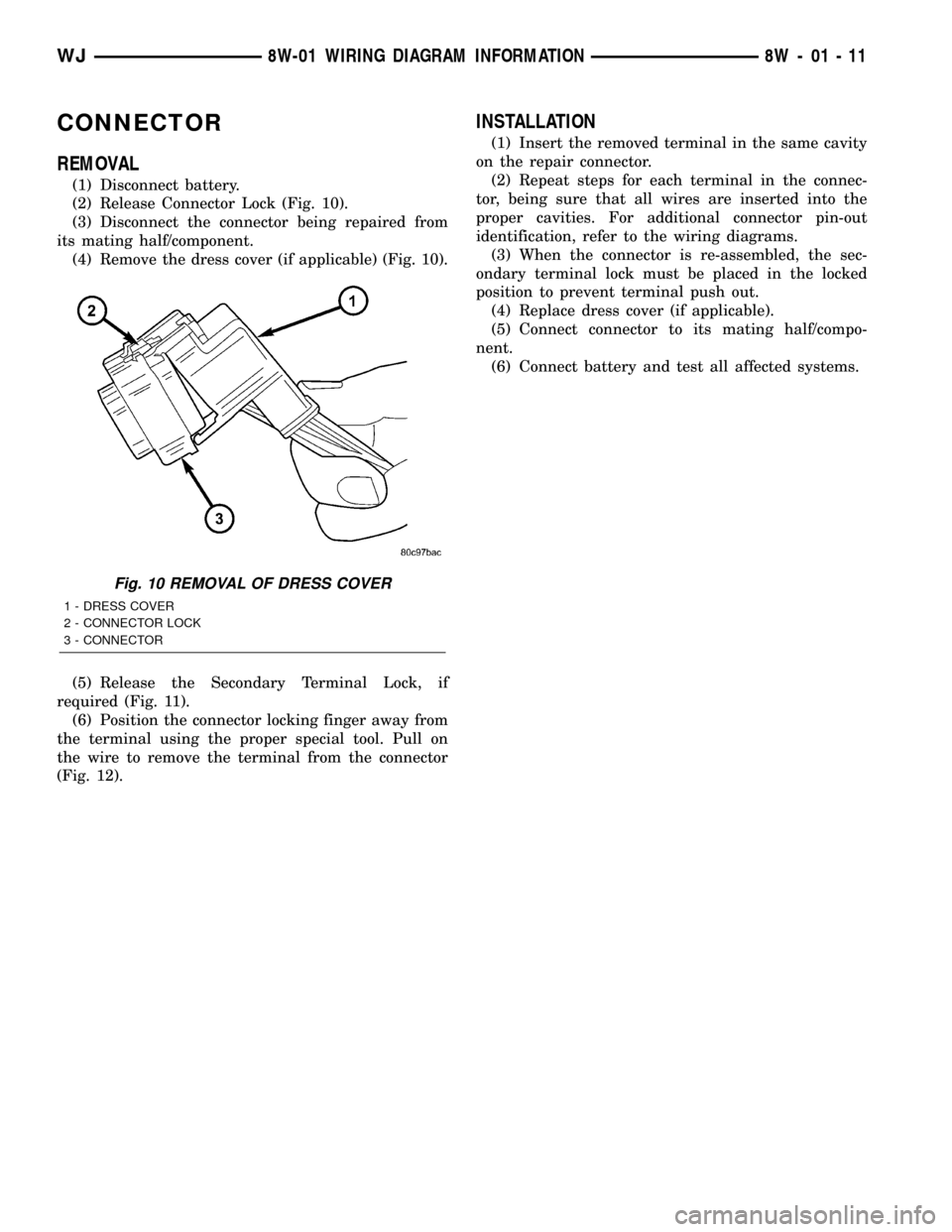

REMOVAL

(1) Disconnect battery.

(2) Release Connector Lock (Fig. 10).

(3) Disconnect the connector being repaired from

its mating half/component.

(4) Remove the dress cover (if applicable) (Fig. 10).

(5) Release the Secondary Terminal Lock, if

required (Fig. 11).

(6) Position the connector locking finger away from

the terminal using the proper special tool. Pull on

the wire to remove the terminal from the connector

(Fig. 12).

INSTALLATION

(1) Insert the removed terminal in the same cavity

on the repair connector.

(2) Repeat steps for each terminal in the connec-

tor, being sure that all wires are inserted into the

proper cavities. For additional connector pin-out

identification, refer to the wiring diagrams.

(3) When the connector is re-assembled, the sec-

ondary terminal lock must be placed in the locked

position to prevent terminal push out.

(4) Replace dress cover (if applicable).

(5) Connect connector to its mating half/compo-

nent.

(6) Connect battery and test all affected systems.

Fig. 10 REMOVAL OF DRESS COVER

1 - DRESS COVER

2 - CONNECTOR LOCK

3 - CONNECTOR

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 11

Page 669 of 2199

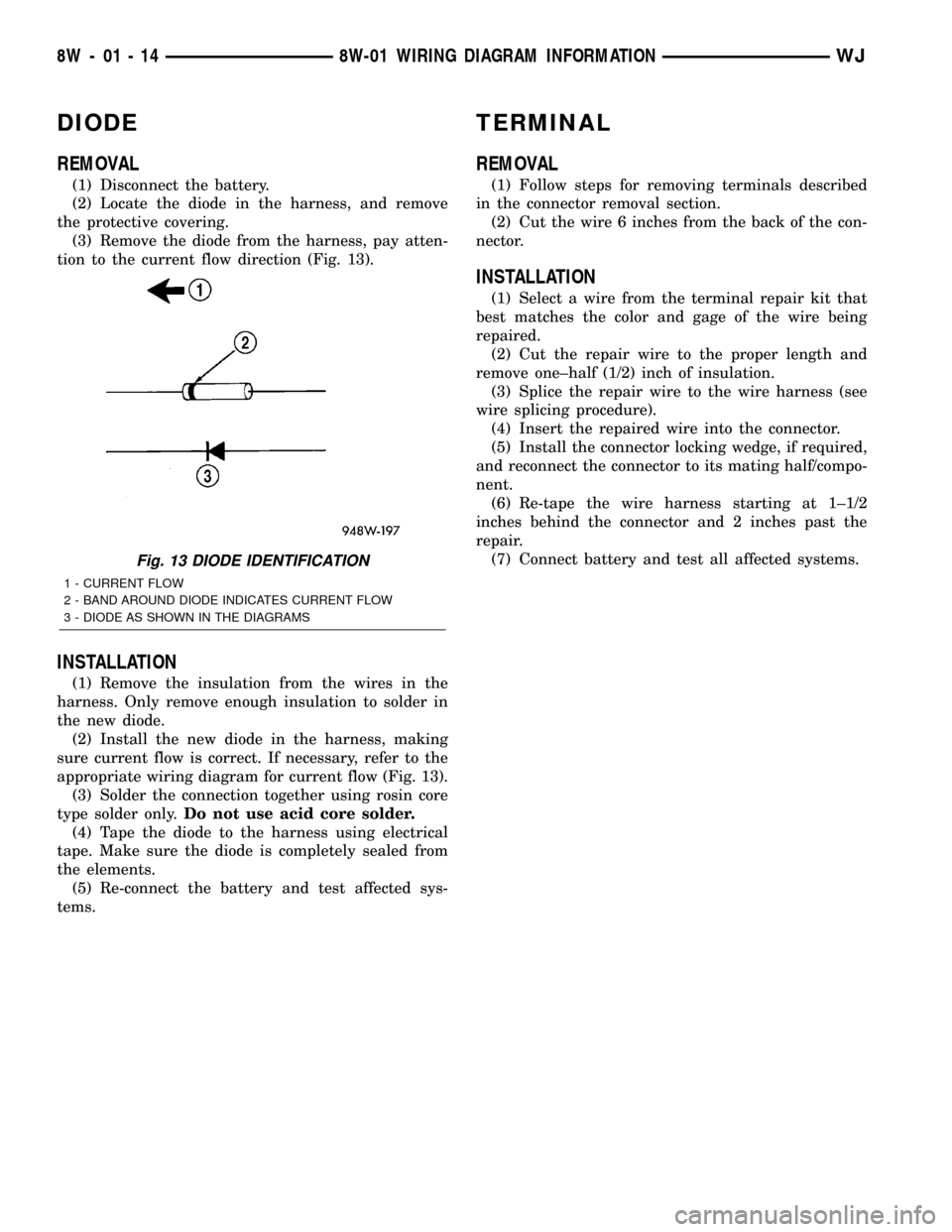

DIODE

REMOVAL

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 13).

INSTALLATION

(1) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(2) Install the new diode in the harness, making

sure current flow is correct. If necessary, refer to the

appropriate wiring diagram for current flow (Fig. 13).

(3) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(4) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(5) Re-connect the battery and test affected sys-

tems.

TERMINAL

REMOVAL

(1) Follow steps for removing terminals described

in the connector removal section.

(2) Cut the wire 6 inches from the back of the con-

nector.

INSTALLATION

(1) Select a wire from the terminal repair kit that

best matches the color and gage of the wire being

repaired.

(2) Cut the repair wire to the proper length and

remove one±half (1/2) inch of insulation.

(3) Splice the repair wire to the wire harness (see

wire splicing procedure).

(4) Insert the repaired wire into the connector.

(5) Install the connector locking wedge, if required,

and reconnect the connector to its mating half/compo-

nent.

(6) Re-tape the wire harness starting at 1±1/2

inches behind the connector and 2 inches past the

repair.

(7) Connect battery and test all affected systems.

Fig. 13 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

8W - 01 - 14 8W-01 WIRING DIAGRAM INFORMATIONWJ

Page 670 of 2199

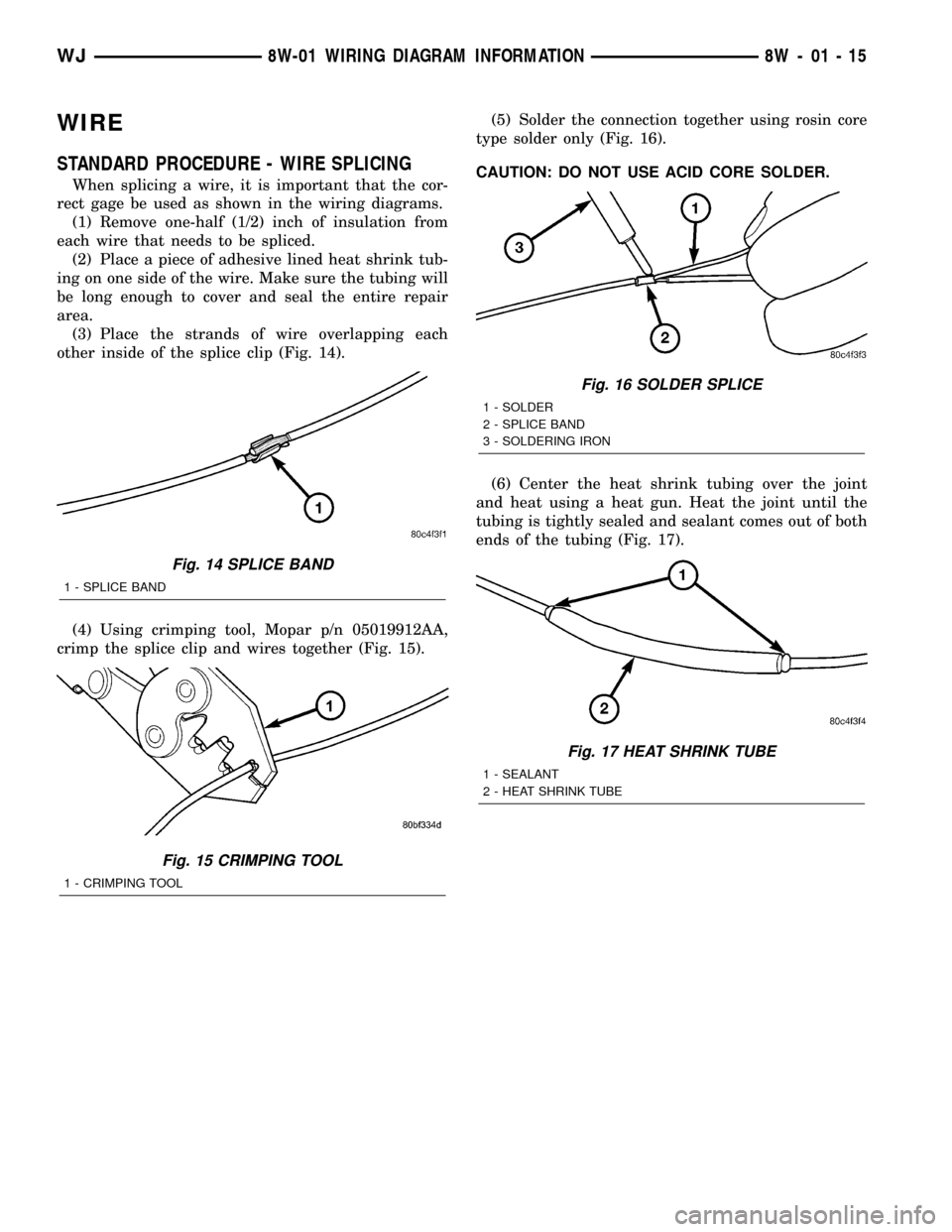

WIRE

STANDARD PROCEDURE - WIRE SPLICING

When splicing a wire, it is important that the cor-

rect gage be used as shown in the wiring diagrams.

(1) Remove one-half (1/2) inch of insulation from

each wire that needs to be spliced.

(2) Place a piece of adhesive lined heat shrink tub-

ing on one side of the wire. Make sure the tubing will

be long enough to cover and seal the entire repair

area.

(3) Place the strands of wire overlapping each

other inside of the splice clip (Fig. 14).

(4) Using crimping tool, Mopar p/n 05019912AA,

crimp the splice clip and wires together (Fig. 15).(5) Solder the connection together using rosin core

type solder only (Fig. 16).

CAUTION: DO NOT USE ACID CORE SOLDER.

(6) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing (Fig. 17).

Fig. 14 SPLICE BAND

1 - SPLICE BAND

Fig. 15 CRIMPING TOOL

1 - CRIMPING TOOL

Fig. 16 SOLDER SPLICE

1 - SOLDER

2 - SPLICE BAND

3 - SOLDERING IRON

Fig. 17 HEAT SHRINK TUBE

1 - SEALANT

2 - HEAT SHRINK TUBE

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 15