Ecu JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2154 of 2199

(4) Unplug the clutch coil wire harness connector.

(5) Remove the bolts that secure the viscous

heater to the mounting bracket.

(6) Remove the viscous heater from the mounting

bracket. Support the viscous heater in the engine

compartment while servicing the clutch.

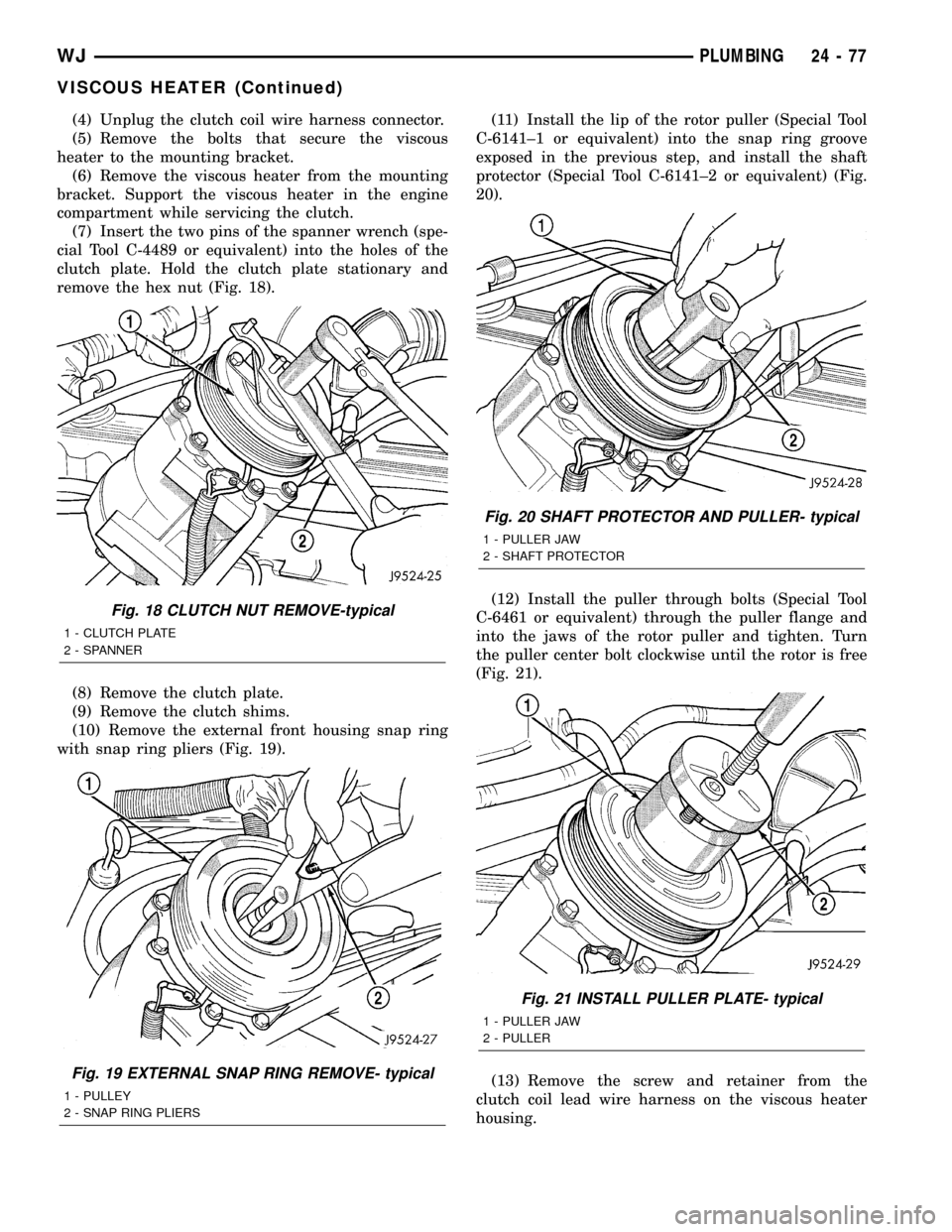

(7) Insert the two pins of the spanner wrench (spe-

cial Tool C-4489 or equivalent) into the holes of the

clutch plate. Hold the clutch plate stationary and

remove the hex nut (Fig. 18).

(8) Remove the clutch plate.

(9) Remove the clutch shims.

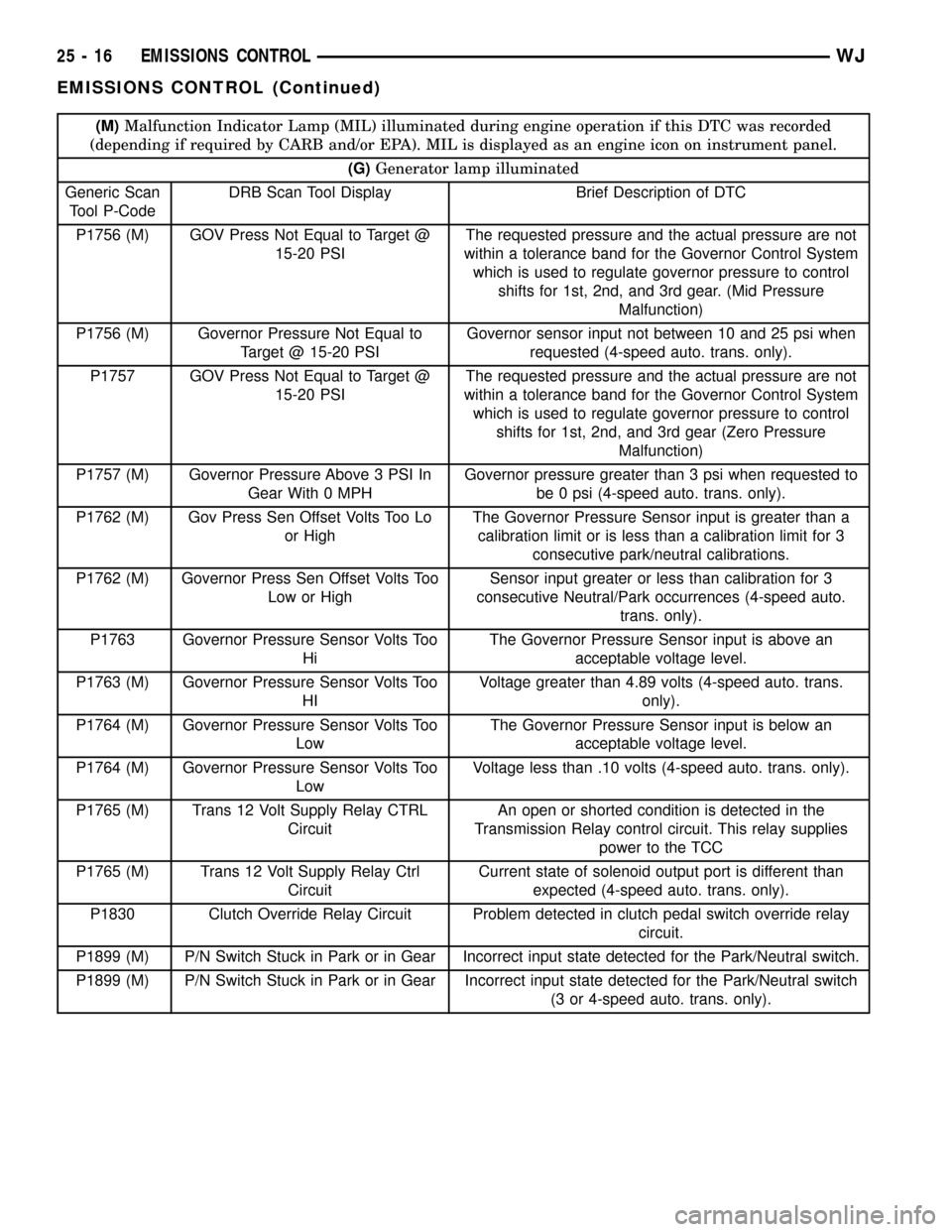

(10) Remove the external front housing snap ring

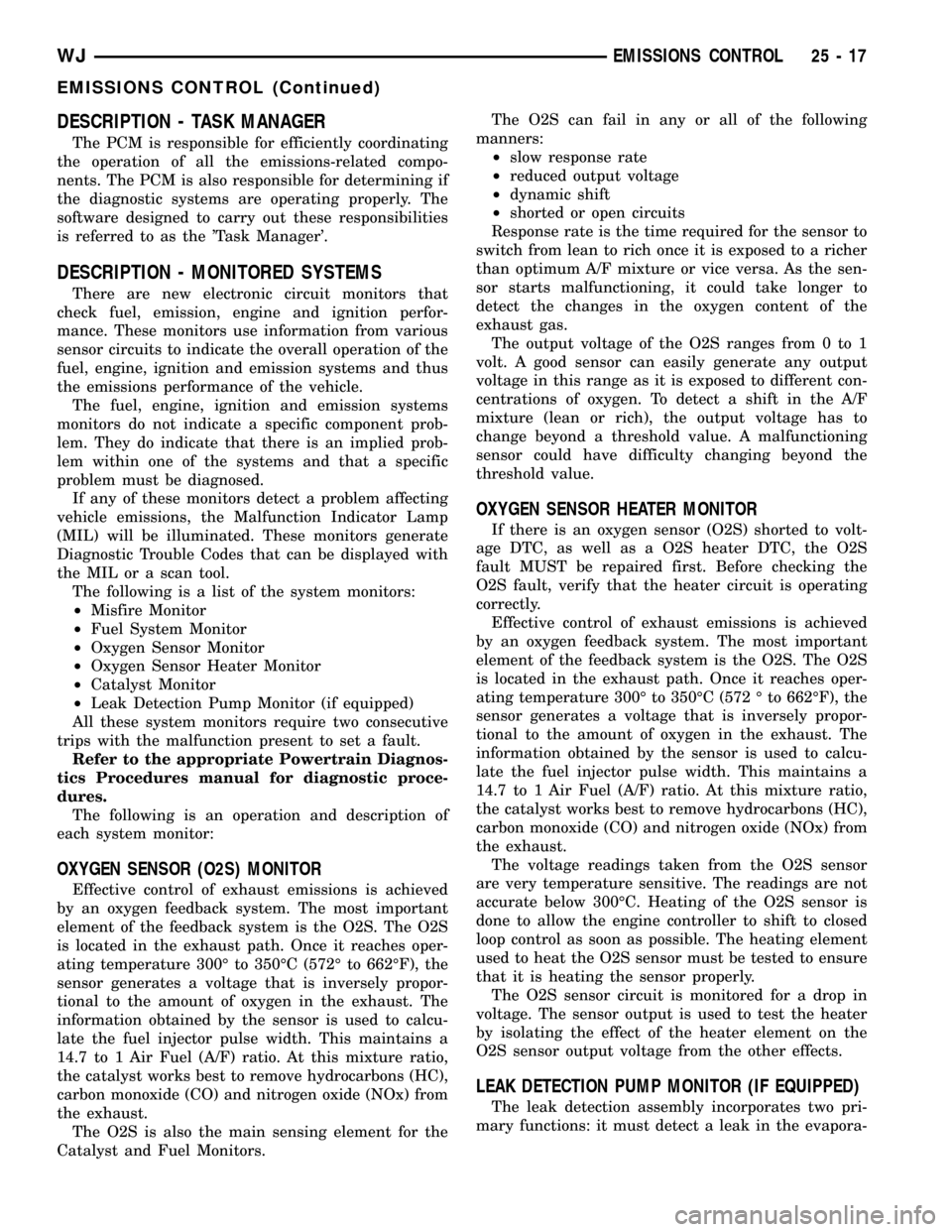

with snap ring pliers (Fig. 19).(11) Install the lip of the rotor puller (Special Tool

C-6141±1 or equivalent) into the snap ring groove

exposed in the previous step, and install the shaft

protector (Special Tool C-6141±2 or equivalent) (Fig.

20).

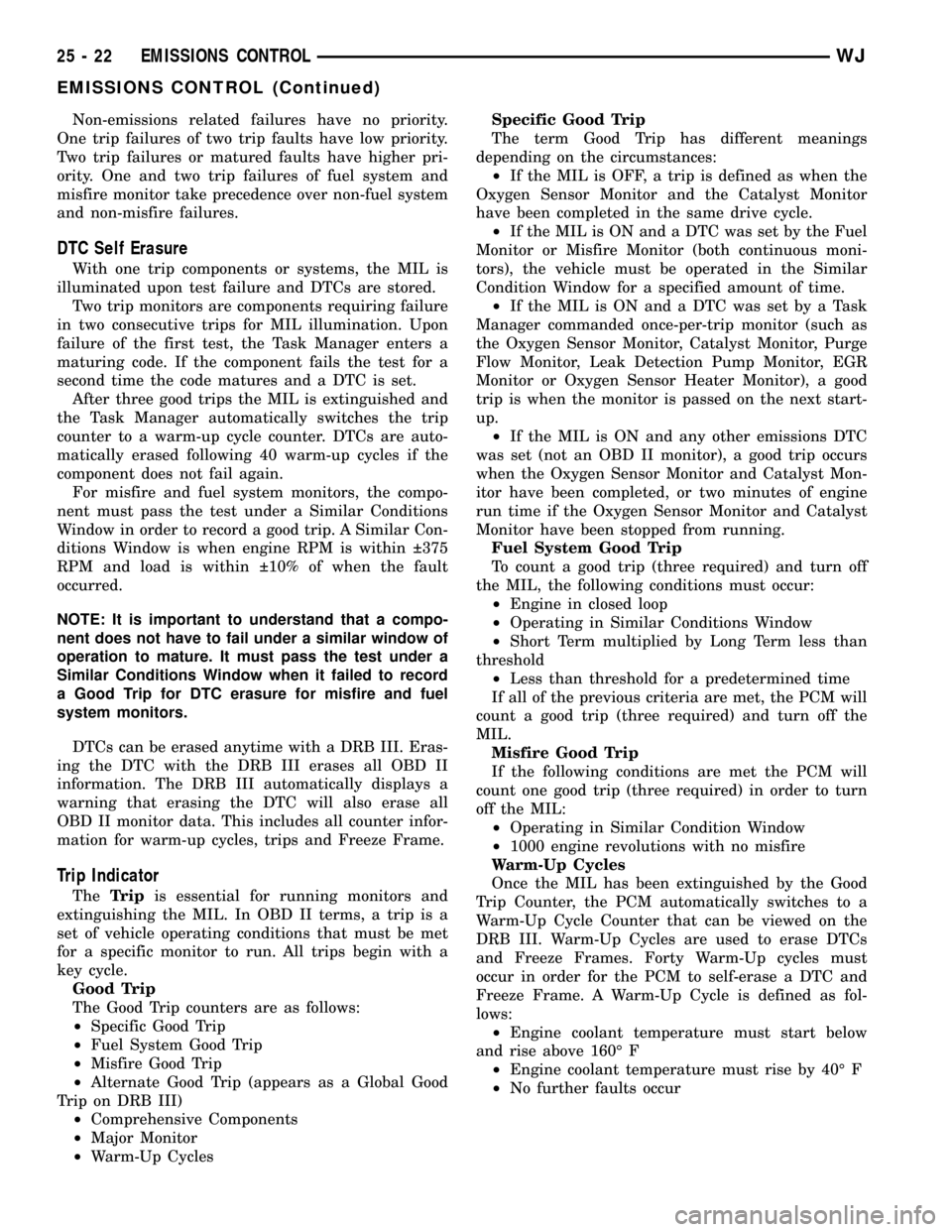

(12) Install the puller through bolts (Special Tool

C-6461 or equivalent) through the puller flange and

into the jaws of the rotor puller and tighten. Turn

the puller center bolt clockwise until the rotor is free

(Fig. 21).

(13) Remove the screw and retainer from the

clutch coil lead wire harness on the viscous heater

housing.

Fig. 18 CLUTCH NUT REMOVE-typical

1 - CLUTCH PLATE

2 - SPANNER

Fig. 19 EXTERNAL SNAP RING REMOVE- typical

1 - PULLEY

2 - SNAP RING PLIERS

Fig. 20 SHAFT PROTECTOR AND PULLER- typical

1 - PULLER JAW

2 - SHAFT PROTECTOR

Fig. 21 INSTALL PULLER PLATE- typical

1 - PULLER JAW

2 - PULLER

WJPLUMBING 24 - 77

VISCOUS HEATER (Continued)

Page 2171 of 2199

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1756 (M) GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control

shifts for 1st, 2nd, and 3rd gear. (Mid Pressure

Malfunction)

P1756 (M) Governor Pressure Not Equal to

Target @ 15-20 PSIGovernor sensor input not between 10 and 25 psi when

requested (4-speed auto. trans. only).

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control

shifts for 1st, 2nd, and 3rd gear (Zero Pressure

Malfunction)

P1757 (M) Governor Pressure Above 3 PSI In

Gear With 0 MPHGovernor pressure greater than 3 psi when requested to

be 0 psi (4-speed auto. trans. only).

P1762 (M) Gov Press Sen Offset Volts Too Lo

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1762 (M) Governor Press Sen Offset Volts Too

Low or HighSensor input greater or less than calibration for 3

consecutive Neutral/Park occurrences (4-speed auto.

trans. only).

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an

acceptable voltage level.

P1763 (M) Governor Pressure Sensor Volts Too

HIVoltage greater than 4.89 volts (4-speed auto. trans.

only).

P1764 (M) Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an

acceptable voltage level.

P1764 (M) Governor Pressure Sensor Volts Too

LowVoltage less than .10 volts (4-speed auto. trans. only).

P1765 (M) Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the

Transmission Relay control circuit. This relay supplies

power to the TCC

P1765 (M) Trans 12 Volt Supply Relay Ctrl

CircuitCurrent state of solenoid output port is different than

expected (4-speed auto. trans. only).

P1830 Clutch Override Relay Circuit Problem detected in clutch pedal switch override relay

circuit.

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch

(3 or 4-speed auto. trans. only).

25 - 16 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)

Page 2172 of 2199

DESCRIPTION - TASK MANAGER

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is referred to as the 'Task Manager'.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator Lamp

(MIL) will be illuminated. These monitors generate

Diagnostic Trouble Codes that can be displayed with

the MIL or a scan tool.

The following is a list of the system monitors:

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive

trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

The following is an operation and description of

each system monitor:

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to volt-

age DTC, as well as a O2S heater DTC, the O2S

fault MUST be repaired first. Before checking the

O2S fault, verify that the heater circuit is operating

correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.

The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

WJEMISSIONS CONTROL 25 - 17

EMISSIONS CONTROL (Continued)

Page 2177 of 2199

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up CyclesSpecific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

25 - 22 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)

Page 2184 of 2199

INSTALLATION - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Connect fitting to CCV breather tube.

(2) Return fixed orifice fitting to valve cover grom-

met.

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

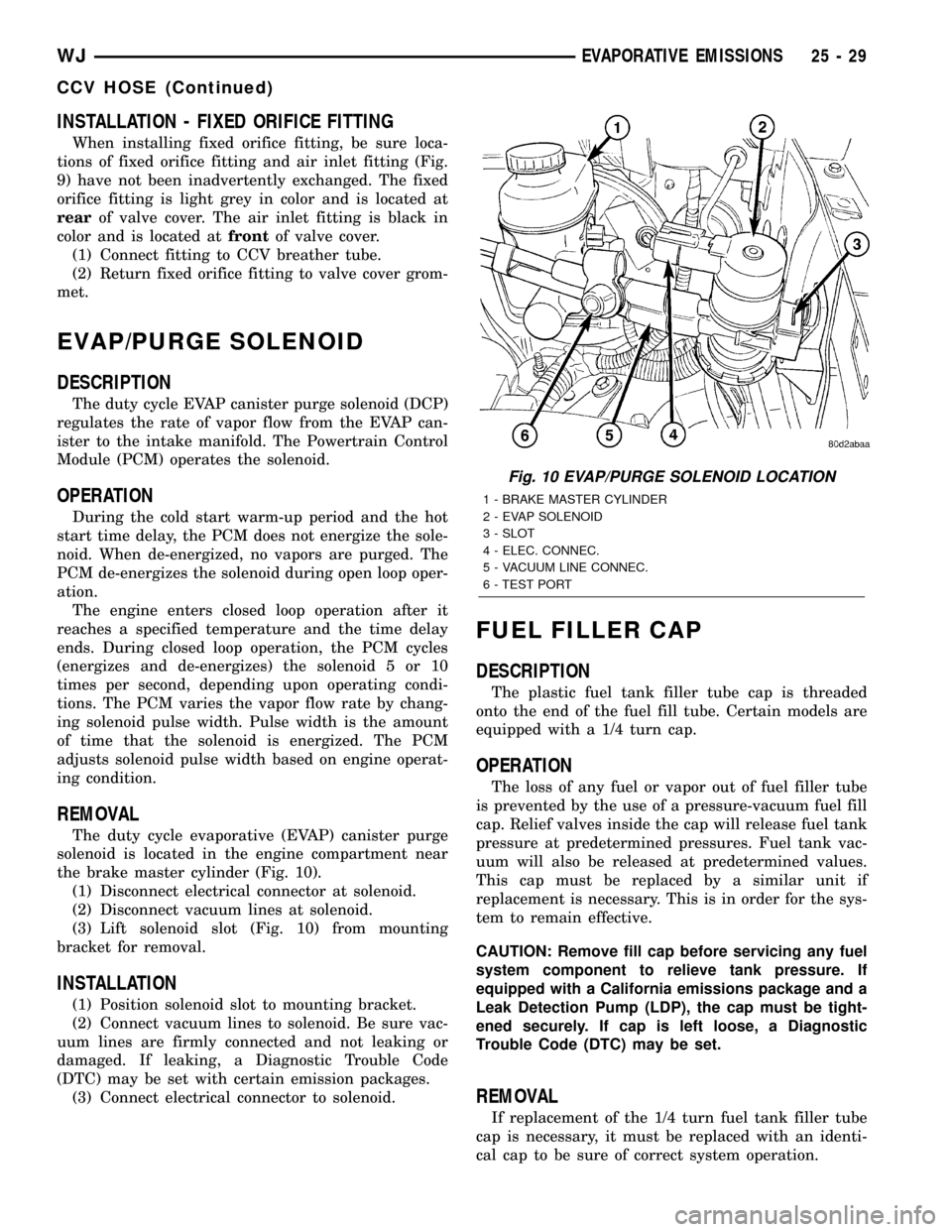

REMOVAL

The duty cycle evaporative (EVAP) canister purge

solenoid is located in the engine compartment near

the brake master cylinder (Fig. 10).

(1) Disconnect electrical connector at solenoid.

(2) Disconnect vacuum lines at solenoid.

(3) Lift solenoid slot (Fig. 10) from mounting

bracket for removal.

INSTALLATION

(1) Position solenoid slot to mounting bracket.

(2) Connect vacuum lines to solenoid. Be sure vac-

uum lines are firmly connected and not leaking or

damaged. If leaking, a Diagnostic Trouble Code

(DTC) may be set with certain emission packages.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a California emissions package and a

Leak Detection Pump (LDP), the cap must be tight-

ened securely. If cap is left loose, a Diagnostic

Trouble Code (DTC) may be set.

REMOVAL

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

Fig. 10 EVAP/PURGE SOLENOID LOCATION

1 - BRAKE MASTER CYLINDER

2 - EVAP SOLENOID

3 - SLOT

4 - ELEC. CONNEC.

5 - VACUUM LINE CONNEC.

6 - TEST PORT

WJEVAPORATIVE EMISSIONS 25 - 29

CCV HOSE (Continued)