23 body JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1544 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

NO START IN PARK

OR NEUTRAL1. Gearshift Linkage/Cable

Mis-adjusted.1. Adjust linkage/cable.

2. Neutral Sense Wire Open/Cut. 2. Check continuity with test lamp. Repair as

required.

3. Park/Neutral Switch, or

Transmission Range Sensor Faulty.3. Refer to service section for test and

replacement procedure.

4. Park/Neutral Switch, or

Transmission Range Sensor

Connection Faulty.4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if damaged.

NO REVERSE (OR

SLIPS IN REVERSE)1. Direct Clutch Pack (front clutch)

Worn.1. Disassemble unit and rebuild clutch pack.

2. Rear Band Mis-adjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/

Burned.3. Air-pressure test clutch operation. Remove and

rebuild if necessary.

4. Overdrive Thrust Bearing

Failure.4. Disassemble geartrain and replace bearings.

5. Direct Clutch Spring Collapsed/

Broken.5. Remove and disassemble unit. Check clutch

position and replace spring.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 25

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1545 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS. 1. Fluid Lines and Fittings

Loose/Leaks/Damaged.1. Tighten fittings. If leaks persist, replace fittings

and lines if necessary.

2. Fill Tube (where tube enters

case) Leaks/Damaged.2. Replace tube seal. Inspect tube for cracks in fill

tube.

3. Pressure Port Plug Loose

Loose/Damaged.3. Tighten to correct torque. Replace plug or

reseal if leak persists.

4. Pan Gasket Leaks. 4. Tighten pan screws (150 in. lbs.). If leaks

persist, replace gasket.

5. Valve Body Manual Lever Shaft

Seal Leaks/Worn.5. Replace shaft seal.

6. Rear Bearing Access Plate

Leaks.6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are

Loose.7. Replace bolts or gasket or tighten both.

8. Adapter/Extension Gasket

Damaged Leaks/Damaged.8. Replace gasket.

9. Park/Neutral Switch, or

Transmission Range Sensor

Leaks/Damaged.9. Replace switch and gasket.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by worn seal

or burr on converter hub (cutting seal), worn

bushing, missing oil return, oil in front pump

housing or hole plugged. Check for leaks past

O-ring seal on pump or past pump-to-case bolts;

pump housing porous, oil coming out vent due to

overfill or leak past front band shaft access plug.

11. Pump Seal Leaks/Worn/

Damaged.11. Replace seal.

12. Torque Converter Weld

Leak/Cracked Hub.12. Replace converter.

13. Case Porosity Leaks. 13. Replace case.

NOISY OPERATION

IN FOURTH GEAR

ONLY1. Overdrive Clutch Discs, Plates

or Snap Rings Damaged.1. Remove unit and rebuild clutch pack.

2. Overdrive Piston or Planetary

Thrust Bearing Damaged.2. Remove and disassemble unit. Replace either

thrust bearing if damaged.

3. Output Shaft Bearings

Scored/Damaged.3. Remove and disassemble unit. Replace either

bearing if damaged.

4. Planetary Gears Worn/Chipped. 4. Remove and overhaul overdrive unit.

5. Overdrive Unit Overrunning

Clutch Rollers Worn/Scored.5. Remove and overhaul overdrive unit.

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, orequivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

21 - 26 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1547 of 2199

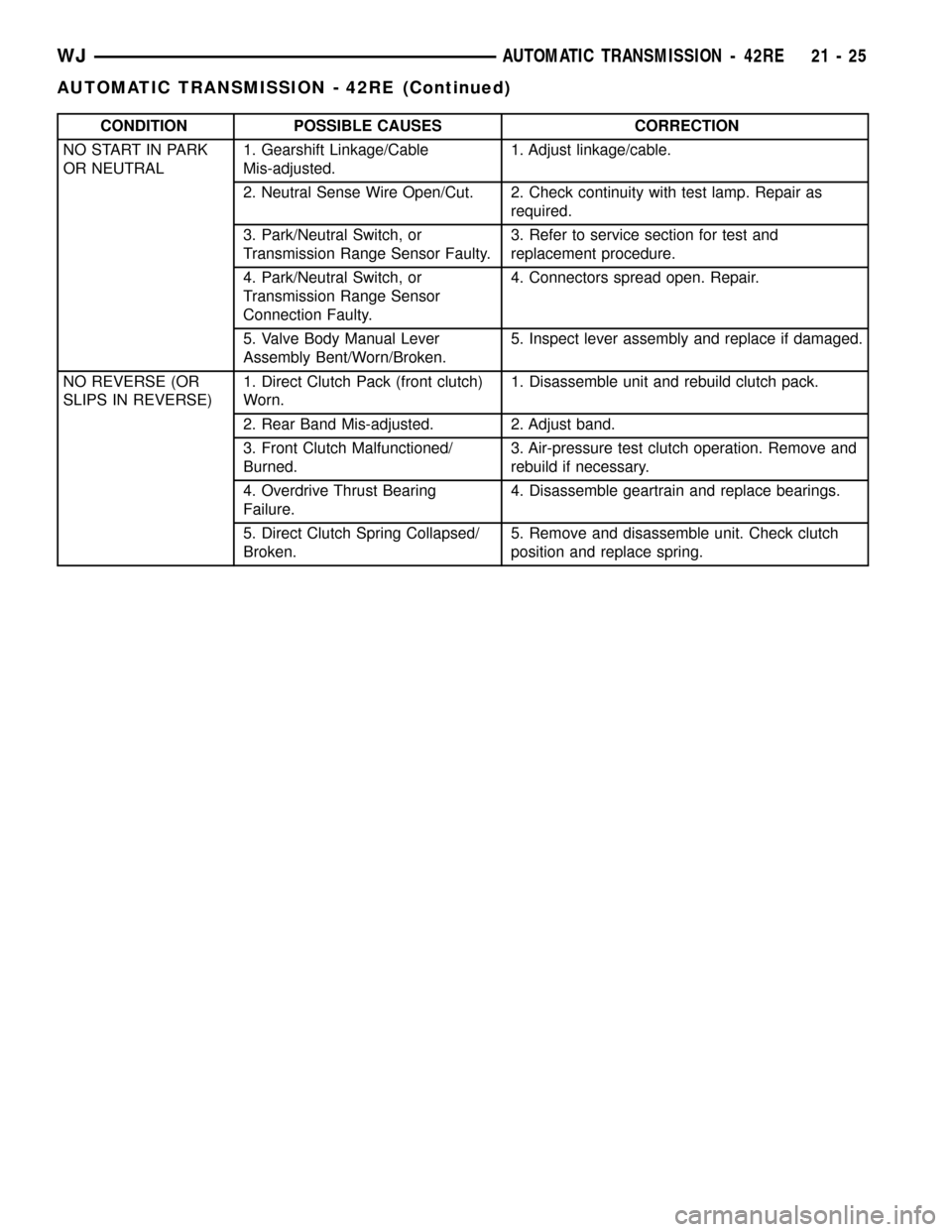

(17) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever (Fig. 15).

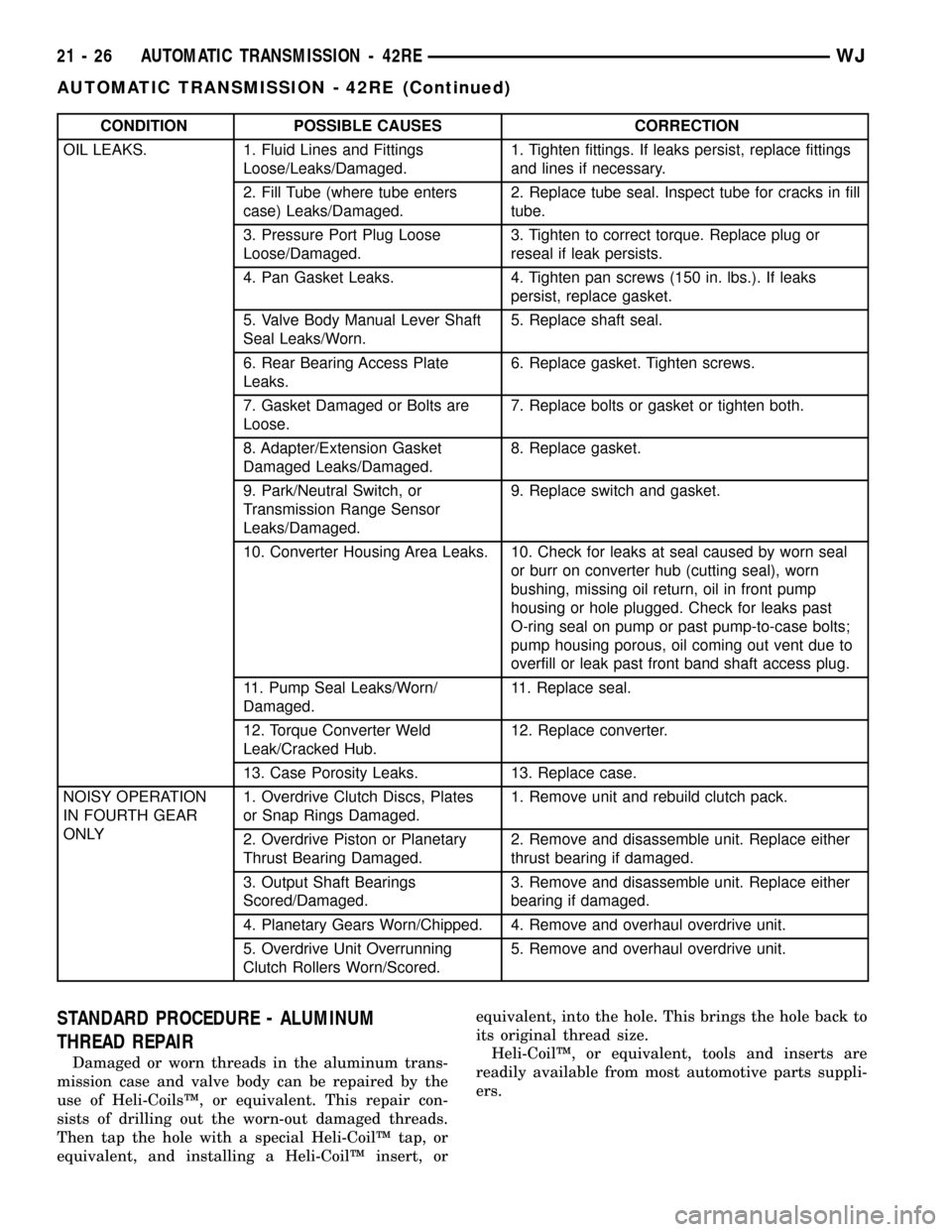

(18) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 16).

(19) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(20) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(21) Support rear of engine with safety stand or

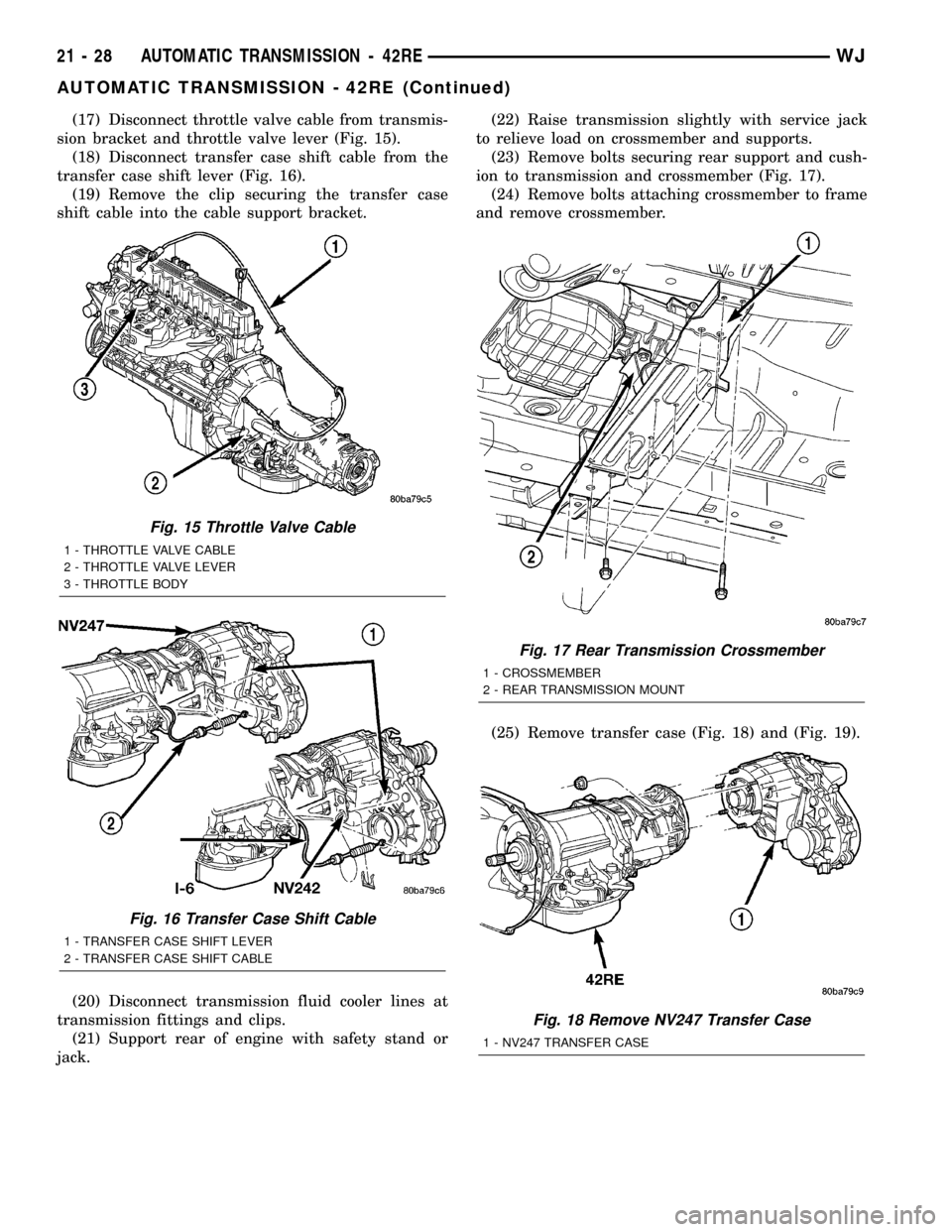

jack.(22) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(23) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 17).

(24) Remove bolts attaching crossmember to frame

and remove crossmember.

(25) Remove transfer case (Fig. 18) and (Fig. 19).

Fig. 15 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

Fig. 16 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 17 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 18 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 28 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1548 of 2199

(26) Remove bolts holding the upper transmission

bending braces to the torque converter housing and

the overdrive unit (Fig. 20).

(27) Remove all remaining converter housing bolts.

(28) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(29) Hold torque converter in place during trans-

mission removal.

(30) Lower transmission and remove assembly

from under the vehicle.

(31) To remove torque converter, carefully slide

torque converter out of the transmission.

DISASSEMBLY

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

operations.

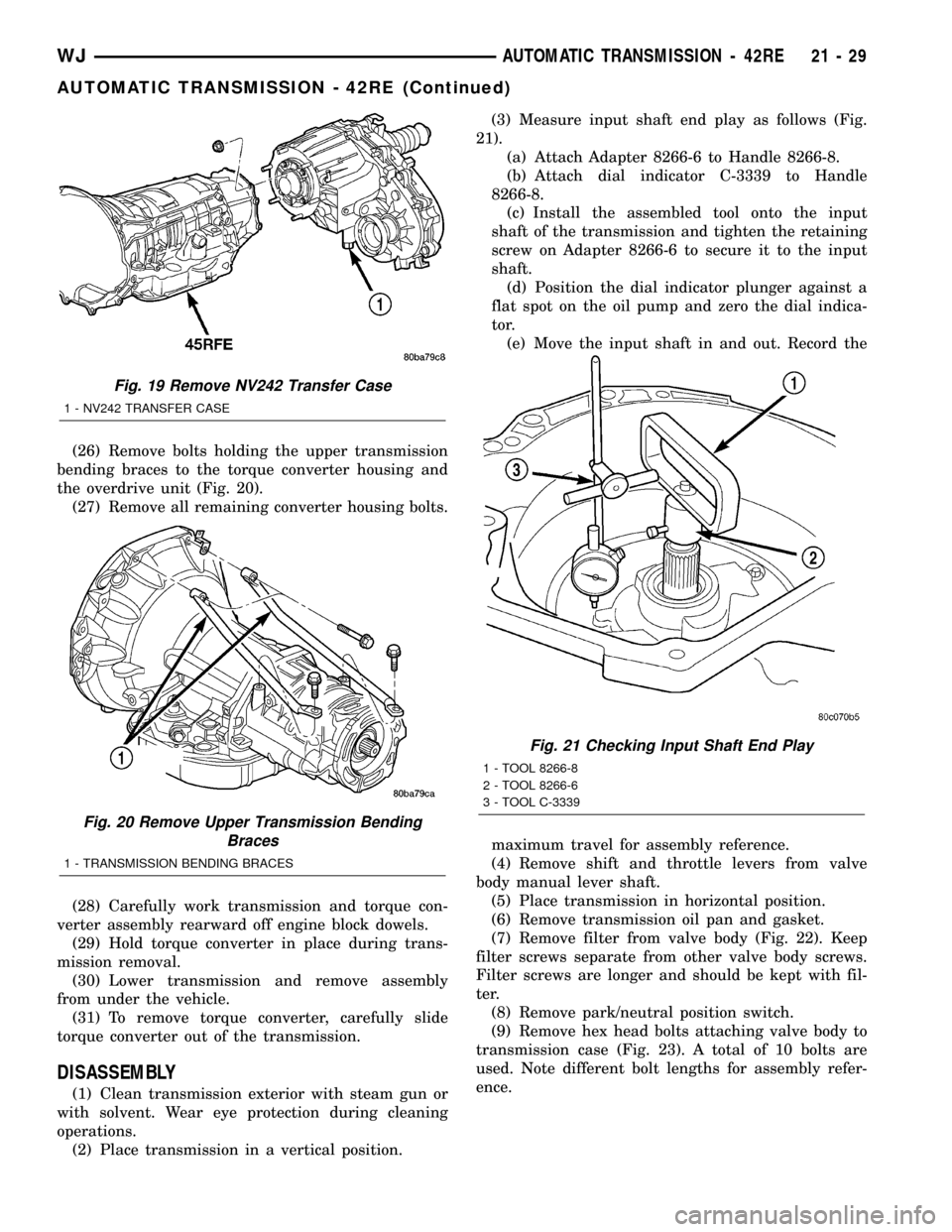

(2) Place transmission in a vertical position.(3) Measure input shaft end play as follows (Fig.

21).

(a) Attach Adapter 8266-6 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-6 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move the input shaft in and out. Record the

maximum travel for assembly reference.

(4) Remove shift and throttle levers from valve

body manual lever shaft.

(5) Place transmission in horizontal position.

(6) Remove transmission oil pan and gasket.

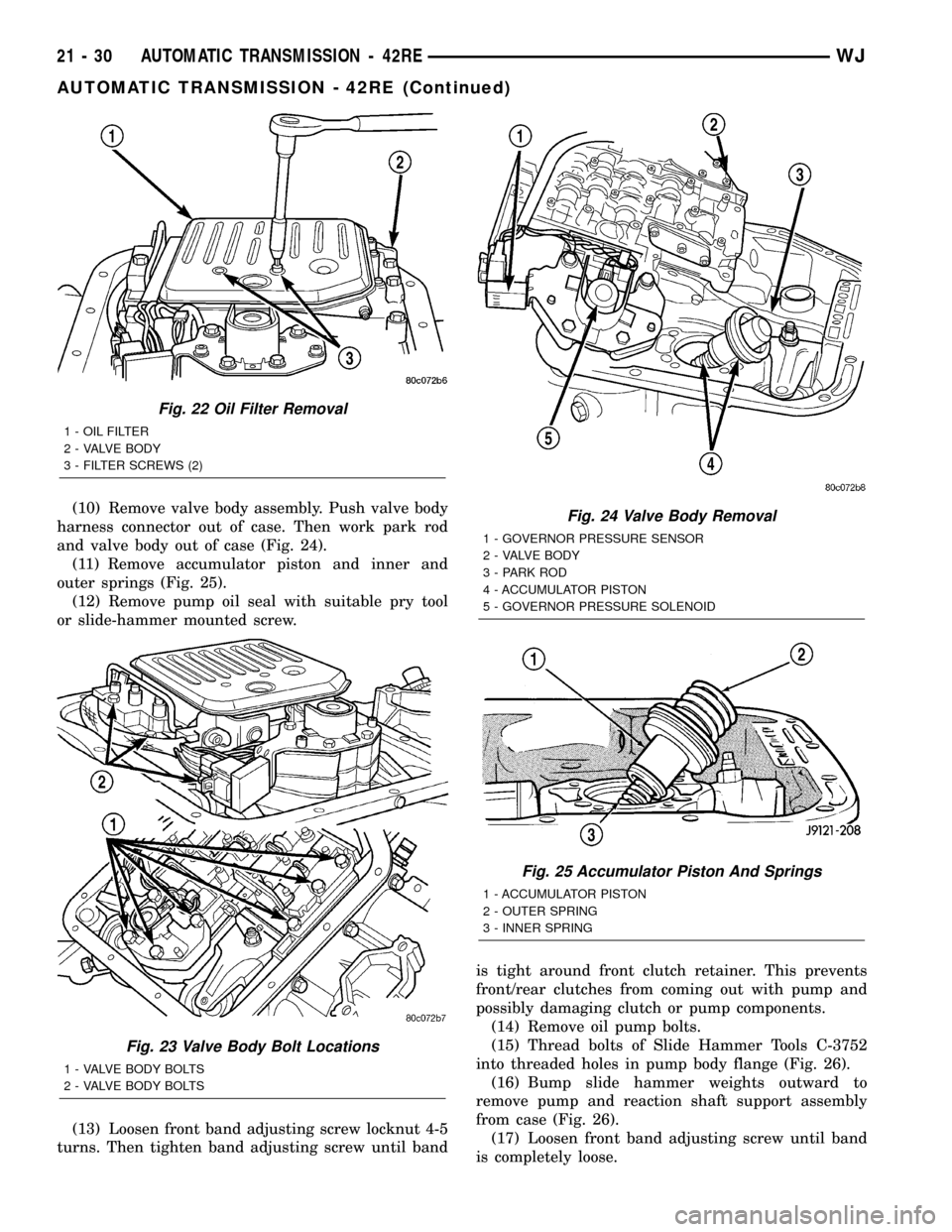

(7) Remove filter from valve body (Fig. 22). Keep

filter screws separate from other valve body screws.

Filter screws are longer and should be kept with fil-

ter.

(8) Remove park/neutral position switch.

(9) Remove hex head bolts attaching valve body to

transmission case (Fig. 23). A total of 10 bolts are

used. Note different bolt lengths for assembly refer-

ence.

Fig. 19 Remove NV242 Transfer Case

1 - NV242 TRANSFER CASE

Fig. 20 Remove Upper Transmission Bending

Braces

1 - TRANSMISSION BENDING BRACES

Fig. 21 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-6

3 - TOOL C-3339

WJAUTOMATIC TRANSMISSION - 42RE 21 - 29

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1549 of 2199

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 24).

(11) Remove accumulator piston and inner and

outer springs (Fig. 25).

(12) Remove pump oil seal with suitable pry tool

or slide-hammer mounted screw.

(13) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until bandis tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

(14) Remove oil pump bolts.

(15) Thread bolts of Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 26).

(16) Bump slide hammer weights outward to

remove pump and reaction shaft support assembly

from case (Fig. 26).

(17) Loosen front band adjusting screw until band

is completely loose.

Fig. 22 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 23 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 24 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

Fig. 25 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

21 - 30 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1553 of 2199

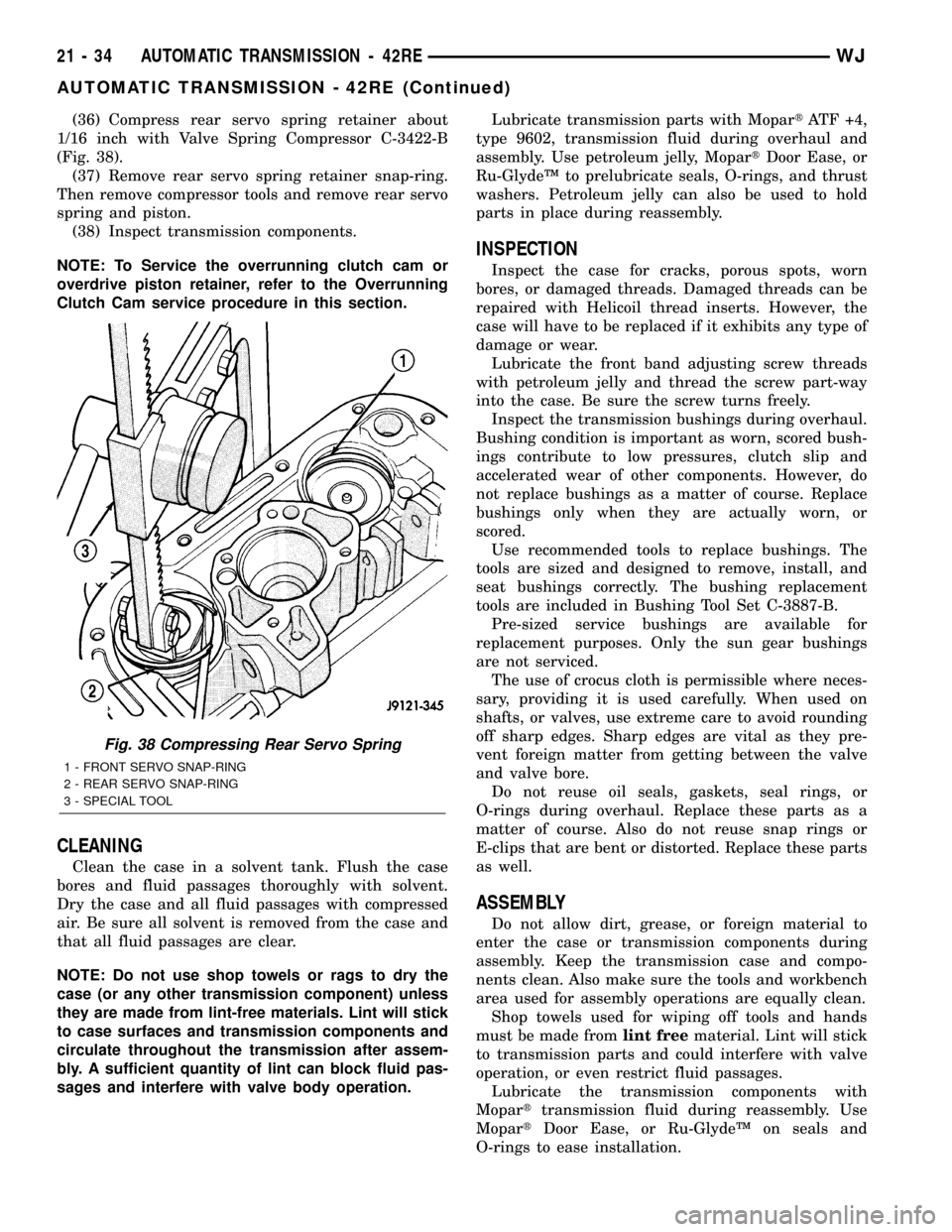

(36) Compress rear servo spring retainer about

1/16 inch with Valve Spring Compressor C-3422-B

(Fig. 38).

(37) Remove rear servo spring retainer snap-ring.

Then remove compressor tools and remove rear servo

spring and piston.

(38) Inspect transmission components.

NOTE: To Service the overrunning clutch cam or

overdrive piston retainer, refer to the Overrunning

Clutch Cam service procedure in this section.

CLEANING

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.Lubricate transmission parts with MopartATF +4,

type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-GlydeŸ to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Inspect the transmission bushings during overhaul.

Bushing condition is important as worn, scored bush-

ings contribute to low pressures, clutch slip and

accelerated wear of other components. However, do

not replace bushings as a matter of course. Replace

bushings only when they are actually worn, or

scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install, and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B.

Pre-sized service bushings are available for

replacement purposes. Only the sun gear bushings

are not serviced.

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

ASSEMBLY

Do not allow dirt, grease, or foreign material to

enter the case or transmission components during

assembly. Keep the transmission case and compo-

nents clean. Also make sure the tools and workbench

area used for assembly operations are equally clean.

Shop towels used for wiping off tools and hands

must be made fromlint freematerial. Lint will stick

to transmission parts and could interfere with valve

operation, or even restrict fluid passages.

Lubricate the transmission components with

Moparttransmission fluid during reassembly. Use

MopartDoor Ease, or Ru-GlydeŸ on seals and

O-rings to ease installation.

Fig. 38 Compressing Rear Servo Spring

1 - FRONT SERVO SNAP-RING

2 - REAR SERVO SNAP-RING

3 - SPECIAL TOOL

21 - 34 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1558 of 2199

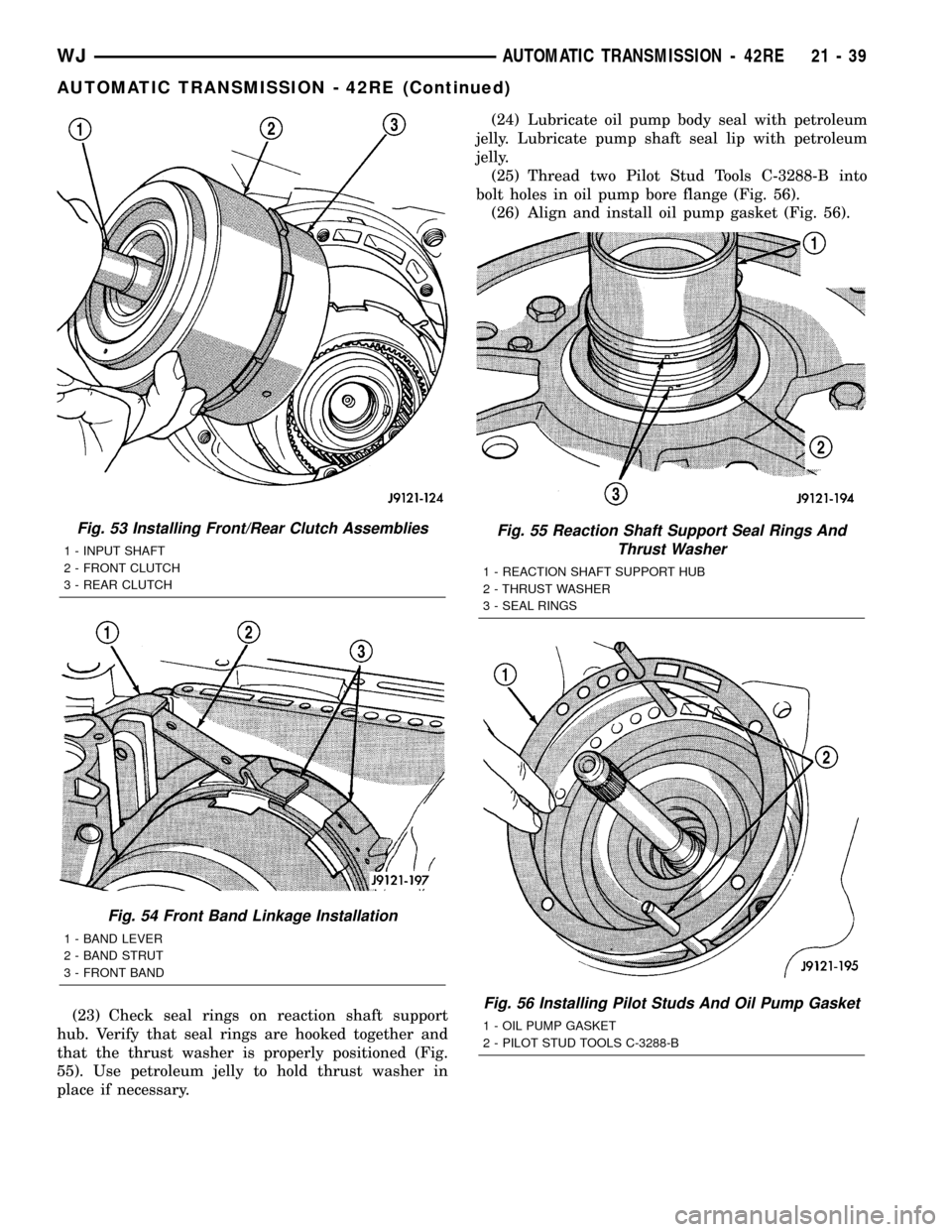

(23) Check seal rings on reaction shaft support

hub. Verify that seal rings are hooked together and

that the thrust washer is properly positioned (Fig.

55). Use petroleum jelly to hold thrust washer in

place if necessary.(24) Lubricate oil pump body seal with petroleum

jelly. Lubricate pump shaft seal lip with petroleum

jelly.

(25) Thread two Pilot Stud Tools C-3288-B into

bolt holes in oil pump bore flange (Fig. 56).

(26) Align and install oil pump gasket (Fig. 56).

Fig. 53 Installing Front/Rear Clutch Assemblies

1 - INPUT SHAFT

2 - FRONT CLUTCH

3 - REAR CLUTCH

Fig. 54 Front Band Linkage Installation

1 - BAND LEVER

2 - BAND STRUT

3 - FRONT BAND

Fig. 55 Reaction Shaft Support Seal Rings And

Thrust Washer

1 - REACTION SHAFT SUPPORT HUB

2 - THRUST WASHER

3 - SEAL RINGS

Fig. 56 Installing Pilot Studs And Oil Pump Gasket

1 - OIL PUMP GASKET

2 - PILOT STUD TOOLS C-3288-B

WJAUTOMATIC TRANSMISSION - 42RE 21 - 39

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1559 of 2199

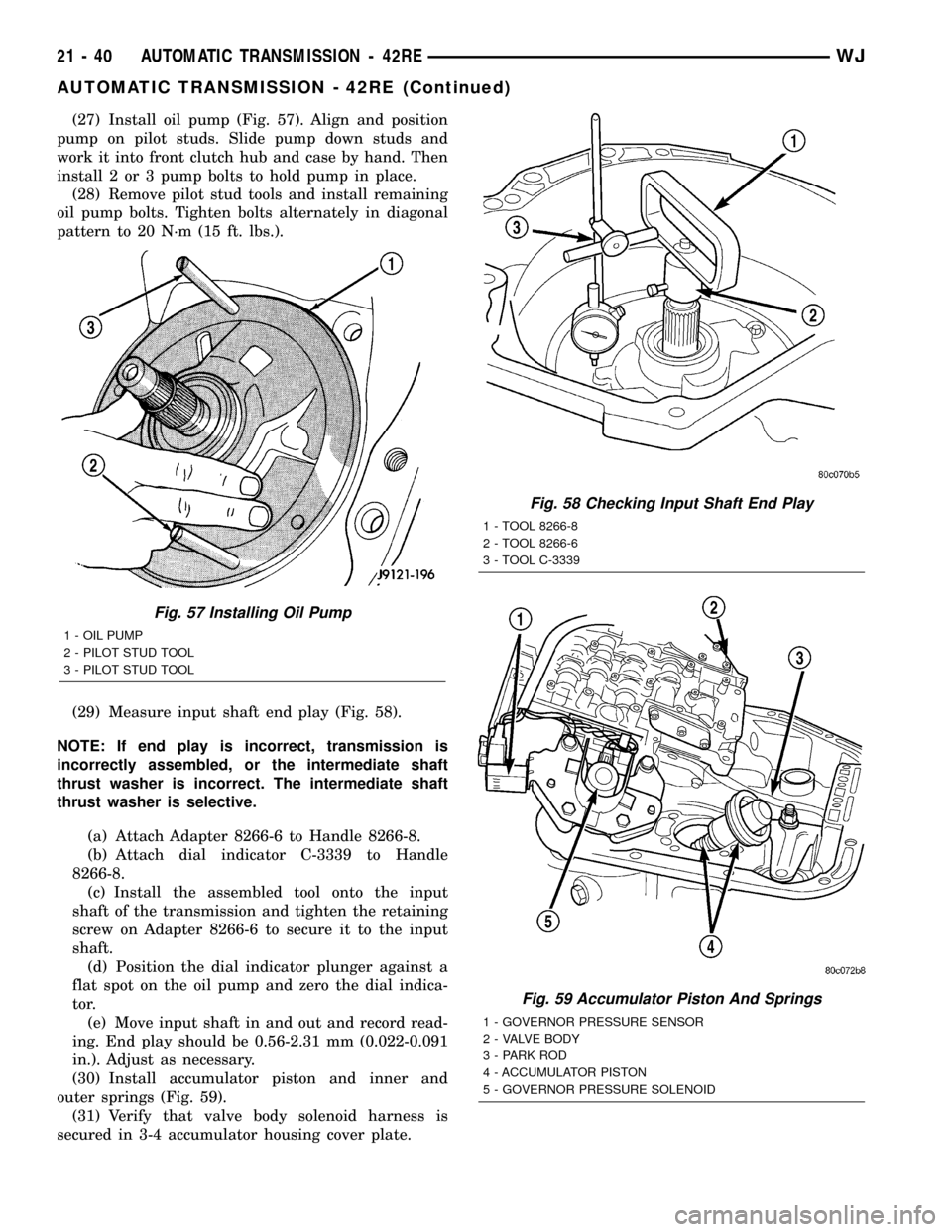

(27) Install oil pump (Fig. 57). Align and position

pump on pilot studs. Slide pump down studs and

work it into front clutch hub and case by hand. Then

install 2 or 3 pump bolts to hold pump in place.

(28) Remove pilot stud tools and install remaining

oil pump bolts. Tighten bolts alternately in diagonal

pattern to 20 N´m (15 ft. lbs.).

(29) Measure input shaft end play (Fig. 58).

NOTE: If end play is incorrect, transmission is

incorrectly assembled, or the intermediate shaft

thrust washer is incorrect. The intermediate shaft

thrust washer is selective.

(a) Attach Adapter 8266-6 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-6 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. End play should be 0.56-2.31 mm (0.022-0.091

in.). Adjust as necessary.

(30) Install accumulator piston and inner and

outer springs (Fig. 59).

(31) Verify that valve body solenoid harness is

secured in 3-4 accumulator housing cover plate.

Fig. 57 Installing Oil Pump

1 - OIL PUMP

2 - PILOT STUD TOOL

3 - PILOT STUD TOOL

Fig. 58 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-6

3 - TOOL C-3339

Fig. 59 Accumulator Piston And Springs

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

21 - 40 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1560 of 2199

(32) Install valve body as follows:

(a) Align and carefully insert park rod into pawl.

Rod will make click noise as it enters pawl. Move

rod slightly to check engagement.

(b) Align and seat valve body on case. Be sure

manual lever shaft and overdrive connector are

fully seated in case. Also be sure valve body wiring

is not pinched or kinked.

(c) Install and start all valve body attaching

bolts by hand. Then tighten bolts evenly, in a diag-

onal pattern to 12 N´m (105 in. lbs.) torque. Do not

overtighten valve body bolts. This could result in

distortion and cross leakage after installation.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into the cavity.

(33) Install new filter on valve body. Tighten filter

screws to 4 N´m (35 in. lbs.).

(34) Adjust front and rear bands.

(35) Install seal on park/neutral position switch.

Then install and tighten switch to 34 N´m (25 ft.

lbs.).

(36) Install magnet in oil pan. Magnet goes on

small protrusion at corner of pan.

(37) Position new oil pan gasket on case and

install oil pan. Tighten pan bolts to 17 N´m (13 ft.

lbs.).

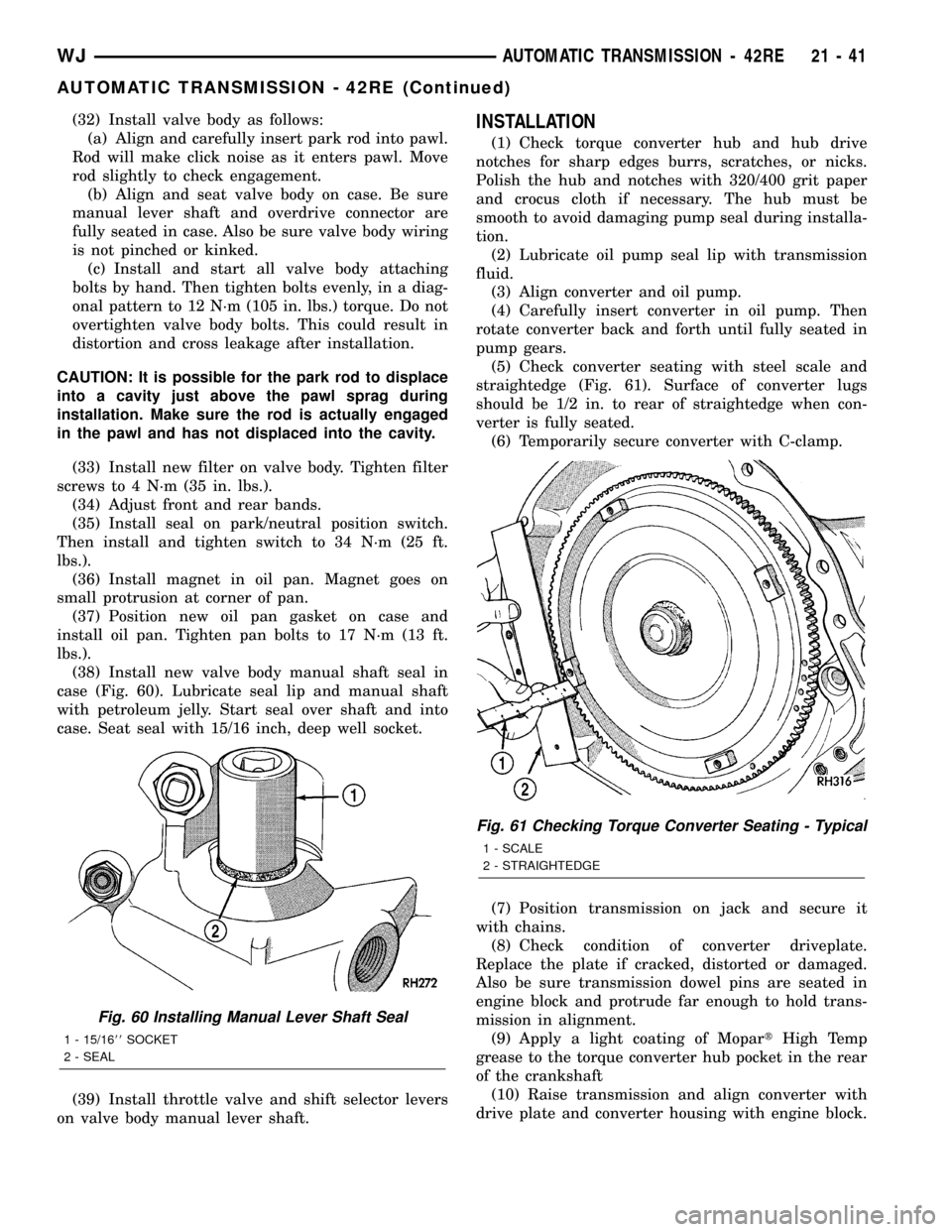

(38) Install new valve body manual shaft seal in

case (Fig. 60). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case. Seat seal with 15/16 inch, deep well socket.

(39) Install throttle valve and shift selector levers

on valve body manual lever shaft.INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal during installa-

tion.

(2) Lubricate oil pump seal lip with transmission

fluid.

(3) Align converter and oil pump.

(4) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(5) Check converter seating with steel scale and

straightedge (Fig. 61). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(6) Temporarily secure converter with C-clamp.

(7) Position transmission on jack and secure it

with chains.

(8) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated in

engine block and protrude far enough to hold trans-

mission in alignment.

(9) Apply a light coating of MopartHigh Temp

grease to the torque converter hub pocket in the rear

of the crankshaft

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

Fig. 60 Installing Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 61 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 41

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1575 of 2199

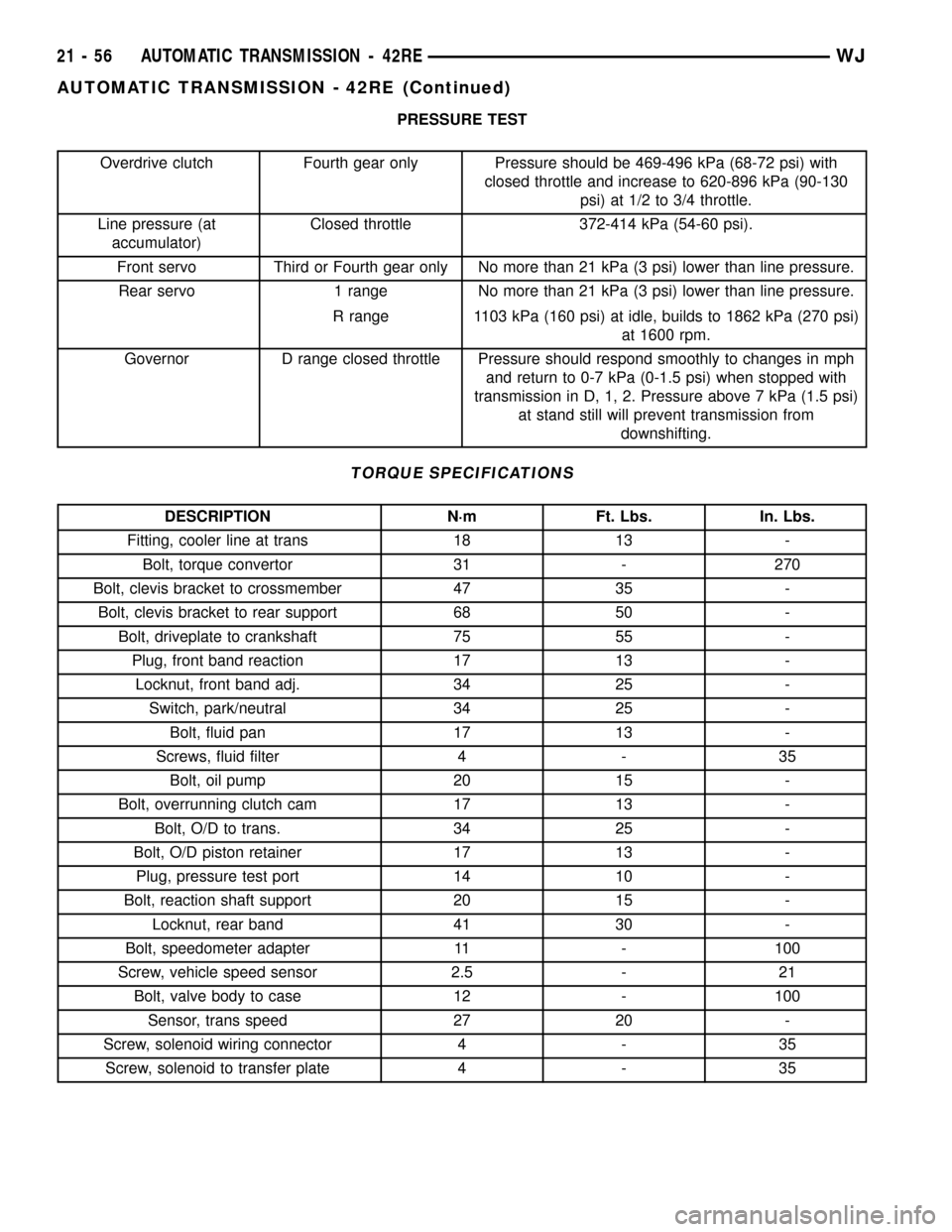

PRESSURE TEST

Overdrive clutch Fourth gear only Pressure should be 469-496 kPa (68-72 psi) with

closed throttle and increase to 620-896 kPa (90-130

psi) at 1/2 to 3/4 throttle.

Line pressure (at

accumulator)Closed throttle 372-414 kPa (54-60 psi).

Front servo Third or Fourth gear only No more than 21 kPa (3 psi) lower than line pressure.

Rear servo 1 range No more than 21 kPa (3 psi) lower than line pressure.

R range 1103 kPa (160 psi) at idle, builds to 1862 kPa (270 psi)

at 1600 rpm.

Governor D range closed throttle Pressure should respond smoothly to changes in mph

and return to 0-7 kPa (0-1.5 psi) when stopped with

transmission in D, 1, 2. Pressure above 7 kPa (1.5 psi)

at stand still will prevent transmission from

downshifting.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fitting, cooler line at trans 18 13 -

Bolt, torque convertor 31 - 270

Bolt, clevis bracket to crossmember 47 35 -

Bolt, clevis bracket to rear support 68 50 -

Bolt, driveplate to crankshaft 75 55 -

Plug, front band reaction 17 13 -

Locknut, front band adj. 34 25 -

Switch, park/neutral 34 25 -

Bolt, fluid pan 17 13 -

Screws, fluid filter 4 - 35

Bolt, oil pump 20 15 -

Bolt, overrunning clutch cam 17 13 -

Bolt, O/D to trans. 34 25 -

Bolt, O/D piston retainer 17 13 -

Plug, pressure test port 14 10 -

Bolt, reaction shaft support 20 15 -

Locknut, rear band 41 30 -

Bolt, speedometer adapter 11 - 100

Screw, vehicle speed sensor 2.5 - 21

Bolt, valve body to case 12 - 100

Sensor, trans speed 27 20 -

Screw, solenoid wiring connector 4 - 35

Screw, solenoid to transfer plate 4 - 35

21 - 56 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)