turn JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1949 of 2199

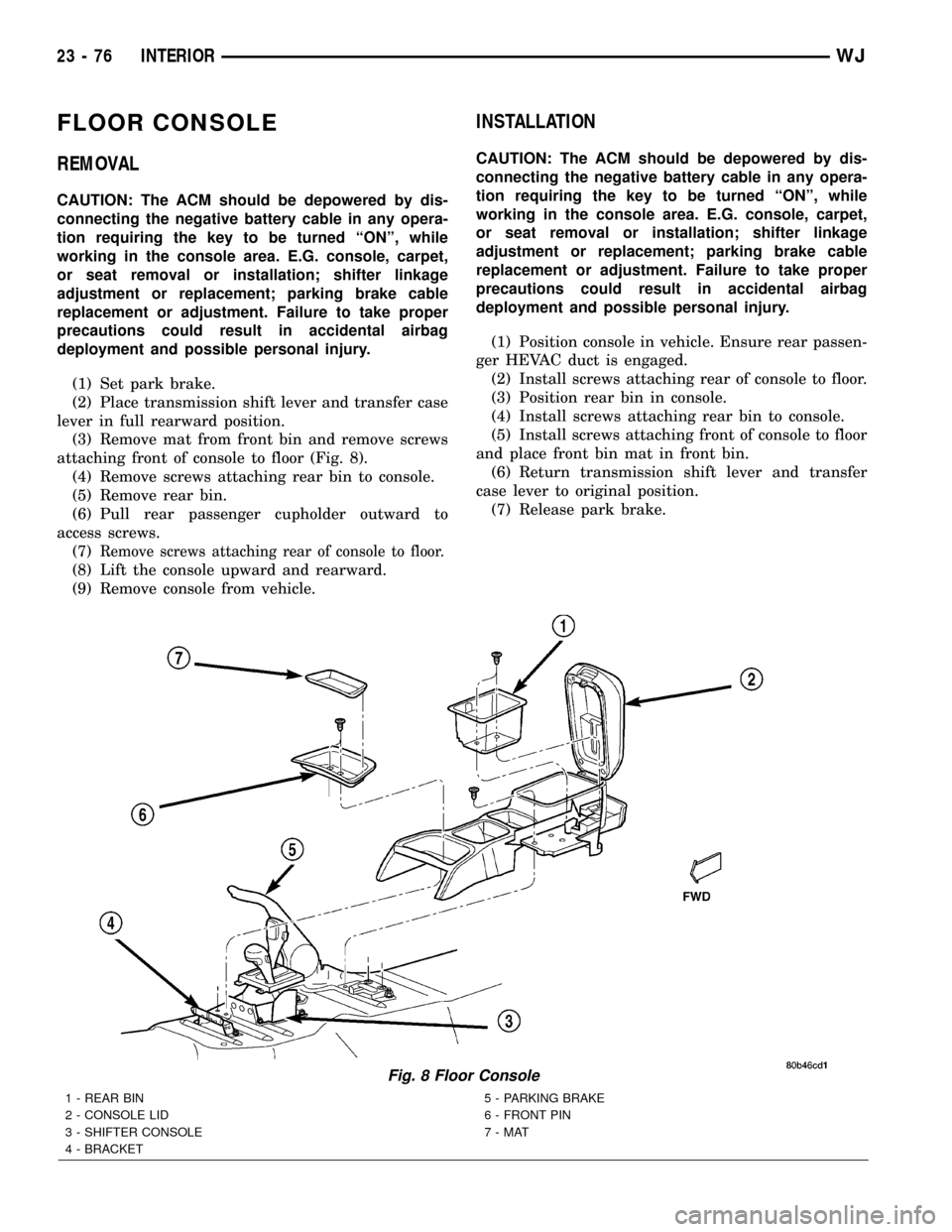

FLOOR CONSOLE

REMOVAL

CAUTION: The ACM should be depowered by dis-

connecting the negative battery cable in any opera-

tion requiring the key to be turned ªONº, while

working in the console area. E.G. console, carpet,

or seat removal or installation; shifter linkage

adjustment or replacement; parking brake cable

replacement or adjustment. Failure to take proper

precautions could result in accidental airbag

deployment and possible personal injury.

(1) Set park brake.

(2) Place transmission shift lever and transfer case

lever in full rearward position.

(3) Remove mat from front bin and remove screws

attaching front of console to floor (Fig. 8).

(4) Remove screws attaching rear bin to console.

(5) Remove rear bin.

(6) Pull rear passenger cupholder outward to

access screws.

(7)

Remove screws attaching rear of console to floor.

(8) Lift the console upward and rearward.

(9) Remove console from vehicle.

INSTALLATION

CAUTION: The ACM should be depowered by dis-

connecting the negative battery cable in any opera-

tion requiring the key to be turned ªONº, while

working in the console area. E.G. console, carpet,

or seat removal or installation; shifter linkage

adjustment or replacement; parking brake cable

replacement or adjustment. Failure to take proper

precautions could result in accidental airbag

deployment and possible personal injury.

(1) Position console in vehicle. Ensure rear passen-

ger HEVAC duct is engaged.

(2) Install screws attaching rear of console to floor.

(3) Position rear bin in console.

(4) Install screws attaching rear bin to console.

(5) Install screws attaching front of console to floor

and place front bin mat in front bin.

(6) Return transmission shift lever and transfer

case lever to original position.

(7) Release park brake.

Fig. 8 Floor Console

1 - REAR BIN

2 - CONSOLE LID

3 - SHIFTER CONSOLE

4 - BRACKET5 - PARKING BRAKE

6 - FRONT PIN

7-MAT

23 - 76 INTERIORWJ

Page 1957 of 2199

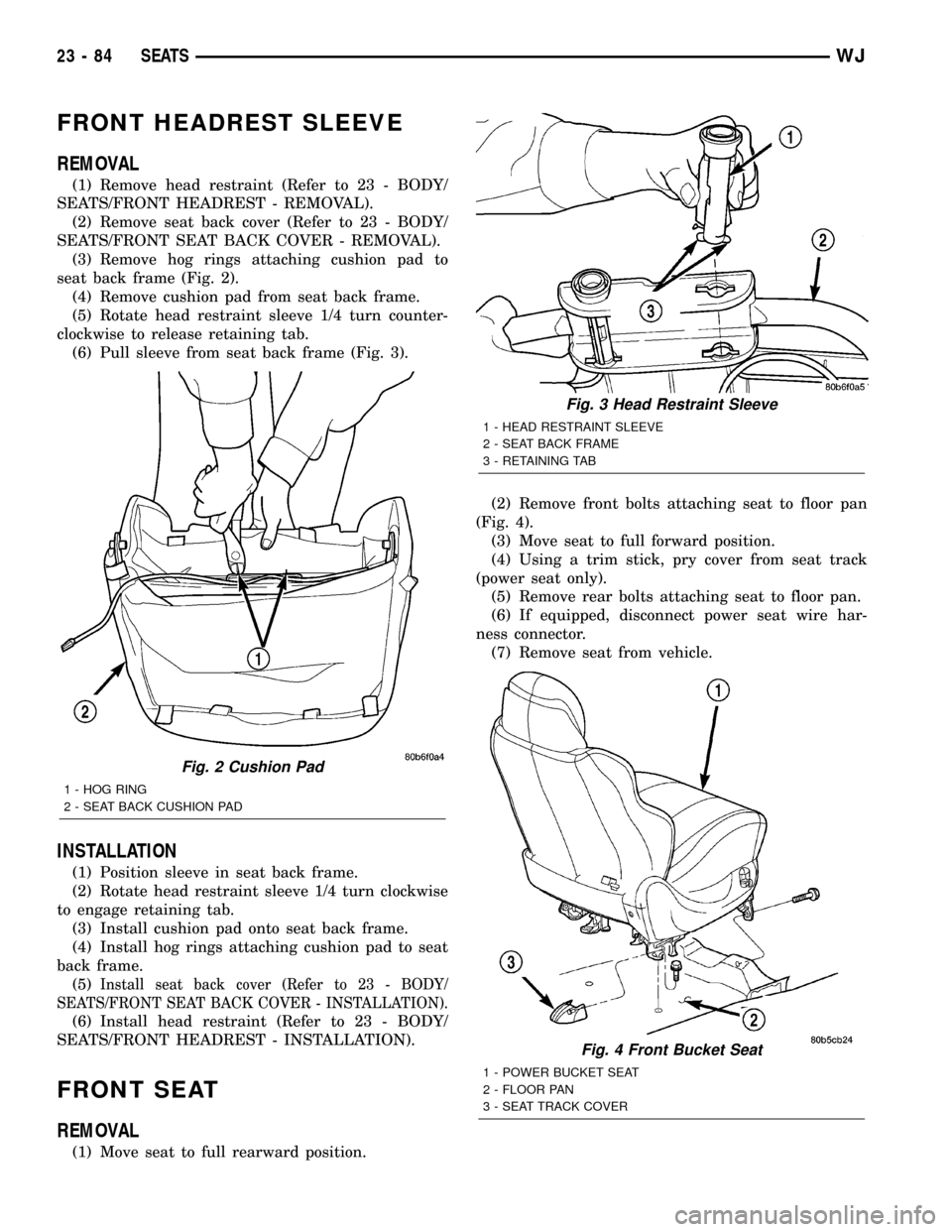

FRONT HEADREST SLEEVE

REMOVAL

(1) Remove head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - REMOVAL).

(2) Remove seat back cover (Refer to 23 - BODY/

SEATS/FRONT SEAT BACK COVER - REMOVAL).

(3) Remove hog rings attaching cushion pad to

seat back frame (Fig. 2).

(4) Remove cushion pad from seat back frame.

(5) Rotate head restraint sleeve 1/4 turn counter-

clockwise to release retaining tab.

(6) Pull sleeve from seat back frame (Fig. 3).

INSTALLATION

(1) Position sleeve in seat back frame.

(2) Rotate head restraint sleeve 1/4 turn clockwise

to engage retaining tab.

(3) Install cushion pad onto seat back frame.

(4) Install hog rings attaching cushion pad to seat

back frame.

(5)

Install seat back cover (Refer to 23 - BODY/

SEATS/FRONT SEAT BACK COVER - INSTALLATION).

(6) Install head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - INSTALLATION).

FRONT SEAT

REMOVAL

(1) Move seat to full rearward position.(2) Remove front bolts attaching seat to floor pan

(Fig. 4).

(3) Move seat to full forward position.

(4) Using a trim stick, pry cover from seat track

(power seat only).

(5) Remove rear bolts attaching seat to floor pan.

(6) If equipped, disconnect power seat wire har-

ness connector.

(7) Remove seat from vehicle.

Fig. 2 Cushion Pad

1 - HOG RING

2 - SEAT BACK CUSHION PAD

Fig. 3 Head Restraint Sleeve

1 - HEAD RESTRAINT SLEEVE

2 - SEAT BACK FRAME

3 - RETAINING TAB

Fig. 4 Front Bucket Seat

1 - POWER BUCKET SEAT

2 - FLOOR PAN

3 - SEAT TRACK COVER

23 - 84 SEATSWJ

Page 1962 of 2199

REAR HEADREST SLEEVE

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Remove head rest (Refer to 23 - BODY/SEATS/

REAR HEADREST - REMOVAL).

(3) Remove head rest caps.

(4) Remove seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - REMOVAL).

(5) Rotate head rest sleeve 1/4 turn counter-clock-

wise to release retaining tab.

(6) Pull sleeve from seat back frame.

INSTALLATION

(1) Position sleeve in seat back frame.

(2) Rotate head rest sleeve 1/4 turn clockwise to

engage retaining tab.

(3) Install seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - INSTALLA-

TION).

(4) Install head rest caps.

NOTE: The head rest cap with the taller button is

always on the inboard side of the seat back.

(5) Install the head rest (Refer to 23 - BODY/

SEATS/REAR HEADREST - INSTALLATION).

NOTE: The folding head rest release knob is always

on the outboard side.

(6) Install the seat back (Refer to 23 - BODY/

SEATS/REAR SEAT BACK - INSTALLATION).

REAR SEAT BACK

REMOVAL

(1) Move rear seat cushions to forward cargo posi-

tion.

(2) Remove bolts attaching seatback side support

bracket to floor pan (right side) (Fig. 11).

(3) Tilt seatback forward, and slide it outboard to

detach it from pin on center pivot bracket.

(4) Remove right side (60%) seatback from vehicle.

(5) Remove bolts attaching seatback side support

bracket and center pivot bracket to floor pan (left

side).

(6) Remove left side (40%) seatback from vehicle.

INSTALLATION

(1) Position left side (40%) seatback in vehicle.

(2) Position left side support bracket and center

pivot bracket with bolt holes aligned and install

bolts. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Position right side (60%) seatback in vehicle.

(4) Install seatback onto center pivot bracket pin.

Ensure seat back is properly engaged on the center

pivot pin.

(5) Position right side support bracket with bolt

holes aligned and install bolts. Tighten bolts to 28

N´m (20 ft. lbs.) torque.

(6) Return seat cushions to seating position.

Fig. 11 Rear Seat Back

1 - SEAT BACK

2 - FLOOR PAN

3 - CENTER PIVOT BRACKET

4 - SIDE SUPPORT BRACKET

WJSEATS 23 - 89

Page 2083 of 2199

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the radiator coolant

level, serpentine drive belt tension, radiator air flow

and the radiator fan operation. Also be certain that

the accessory vacuum supply line is connected at the

engine intake manifold for the manual temperature

control system.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling at

normal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor heat position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

OBSTRUCTED COOLANT FLOW

Possible locations or causes of obstructed coolant

flow:

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible locations or causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A blend door not functioning properly.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob(s) on the

A/C Heater control panel, the following could require

service:

²The A/C heater control.

²The blend door actuator(s).

²The wire harness circuits for the A/C heater con-

trol or the blend door actuator(s).²The blend door(s).

²Improper engine coolant temperature.

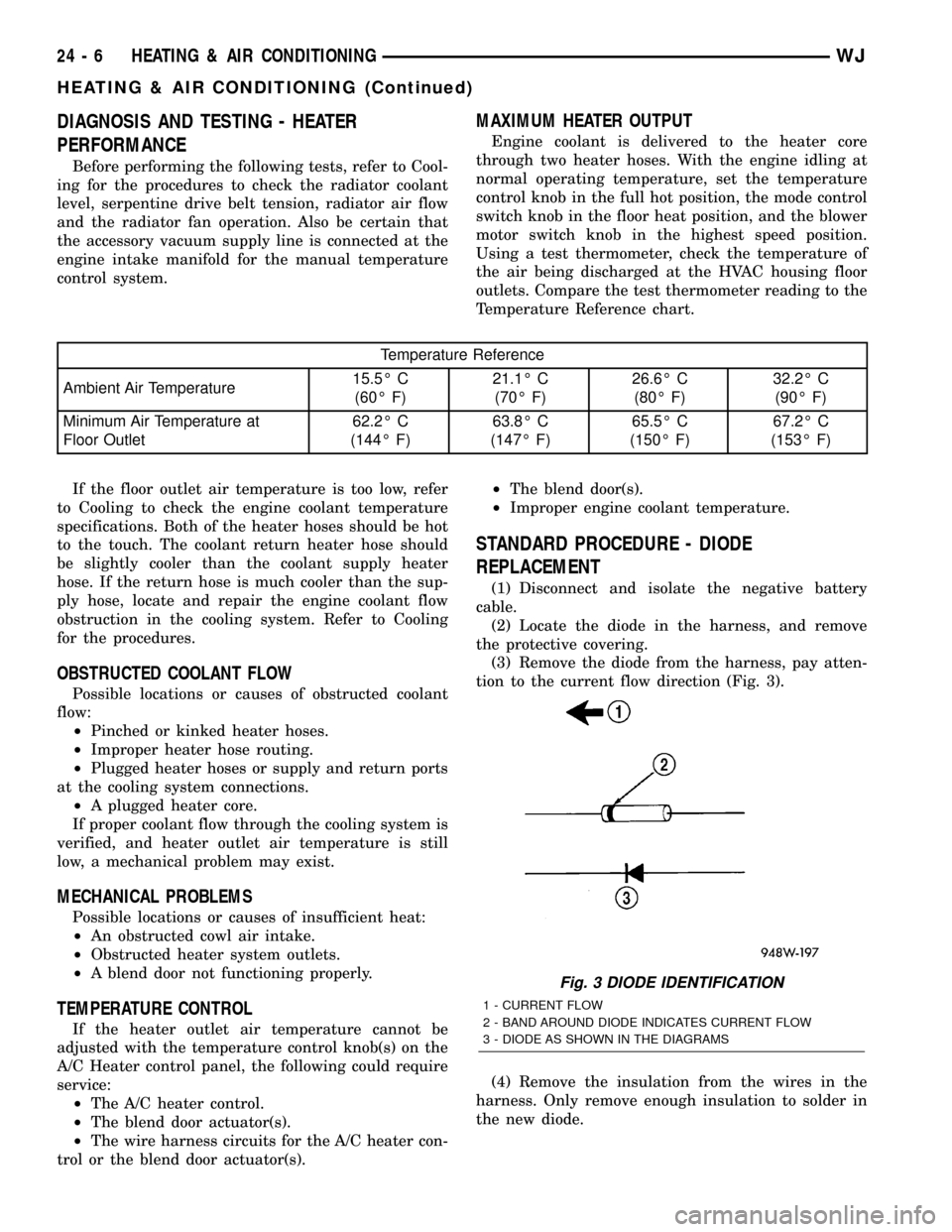

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the negative battery

cable.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 3).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

Fig. 3 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

24 - 6 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2087 of 2199

VACUUM RESERVOIR

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................35

INSTALLATION.........................35EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL.............................35

INSTALLATION.........................35

CONTROLS

DIAGNOSIS AND TESTING - VACUUM SYSTEM

Vacuum control is used to operate the mode doors

in the standard equipment manual temperature con-

trol system HVAC housing. Testing of the A/C Heater

mode control switch operation will determine if the

vacuum and electrical controls are functioning. How-

ever, it is possible that a vacuum control system that

operates perfectly at engine idle (high engine vac-

uum) may not function properly at high engine

speeds or loads (low engine vacuum). This can be

caused by leaks in the vacuum system, or a faulty

vacuum check valve.

A vacuum system test will help to identify the

source of poor vacuum system performance or vac-

uum system leaks. Before starting this test, stop the

engine and make certain that the problem isn't a dis-

connected vacuum supply tube at the engine intake

manifold vacuum tap or the vacuum reservoir.

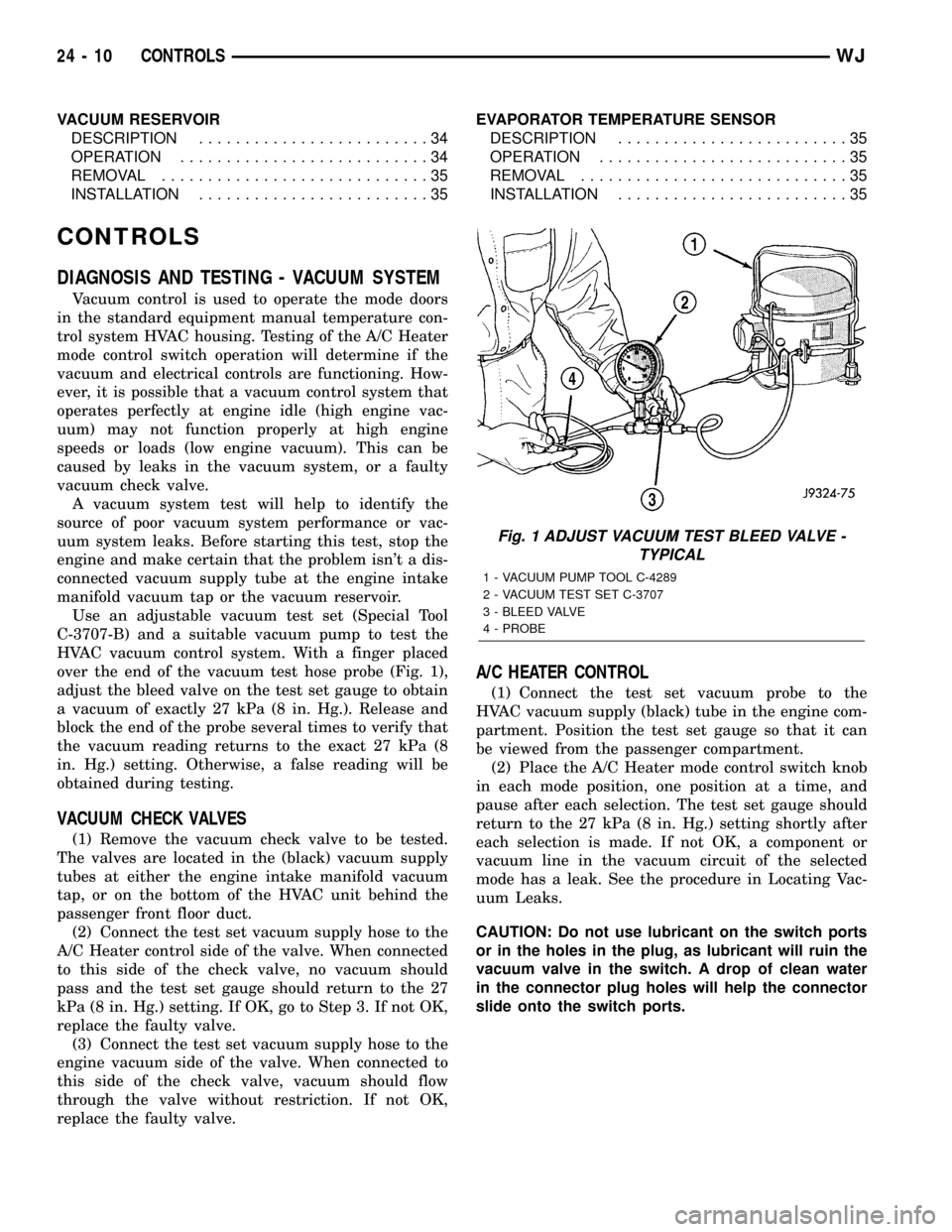

Use an adjustable vacuum test set (Special Tool

C-3707-B) and a suitable vacuum pump to test the

HVAC vacuum control system. With a finger placed

over the end of the vacuum test hose probe (Fig. 1),

adjust the bleed valve on the test set gauge to obtain

a vacuum of exactly 27 kPa (8 in. Hg.). Release and

block the end of the probe several times to verify that

the vacuum reading returns to the exact 27 kPa (8

in. Hg.) setting. Otherwise, a false reading will be

obtained during testing.

VACUUM CHECK VALVES

(1) Remove the vacuum check valve to be tested.

The valves are located in the (black) vacuum supply

tubes at either the engine intake manifold vacuum

tap, or on the bottom of the HVAC unit behind the

passenger front floor duct.

(2) Connect the test set vacuum supply hose to the

A/C Heater control side of the valve. When connected

to this side of the check valve, no vacuum should

pass and the test set gauge should return to the 27

kPa (8 in. Hg.) setting. If OK, go to Step 3. If not OK,

replace the faulty valve.

(3) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

A/C HEATER CONTROL

(1) Connect the test set vacuum probe to the

HVAC vacuum supply (black) tube in the engine com-

partment. Position the test set gauge so that it can

be viewed from the passenger compartment.

(2) Place the A/C Heater mode control switch knob

in each mode position, one position at a time, and

pause after each selection. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each selection is made. If not OK, a component or

vacuum line in the vacuum circuit of the selected

mode has a leak. See the procedure in Locating Vac-

uum Leaks.

CAUTION: Do not use lubricant on the switch ports

or in the holes in the plug, as lubricant will ruin the

vacuum valve in the switch. A drop of clean water

in the connector plug holes will help the connector

slide onto the switch ports.

Fig. 1 ADJUST VACUUM TEST BLEED VALVE -

TYPICAL

1 - VACUUM PUMP TOOL C-4289

2 - VACUUM TEST SET C-3707

3 - BLEED VALVE

4 - PROBE

24 - 10 CONTROLSWJ

Page 2088 of 2199

LOCATING VACUUM LEAKS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

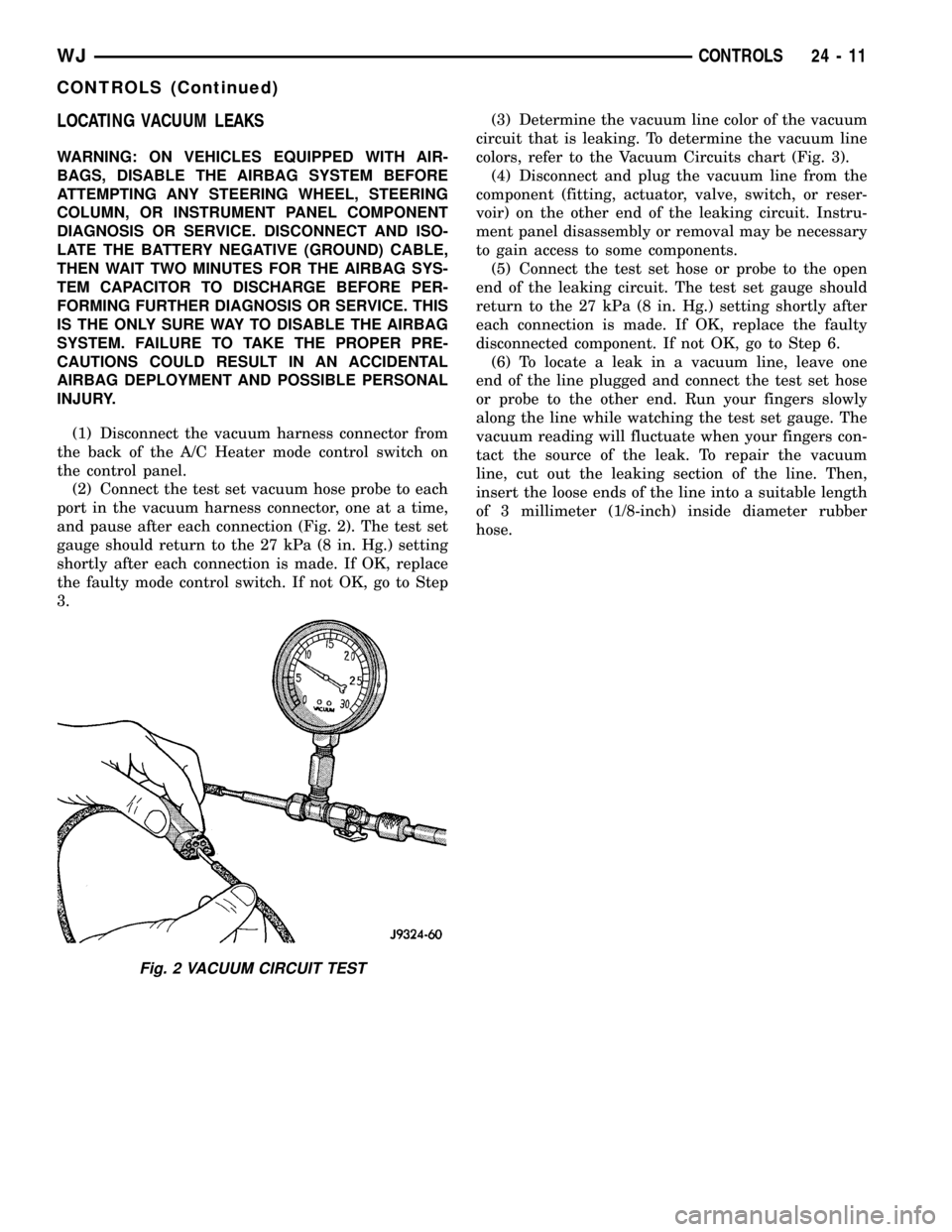

(1) Disconnect the vacuum harness connector from

the back of the A/C Heater mode control switch on

the control panel.

(2) Connect the test set vacuum hose probe to each

port in the vacuum harness connector, one at a time,

and pause after each connection (Fig. 2). The test set

gauge should return to the 27 kPa (8 in. Hg.) setting

shortly after each connection is made. If OK, replace

the faulty mode control switch. If not OK, go to Step

3.(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, refer to the Vacuum Circuits chart (Fig. 3).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reser-

voir) on the other end of the leaking circuit. Instru-

ment panel disassembly or removal may be necessary

to gain access to some components.

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6) To locate a leak in a vacuum line, leave one

end of the line plugged and connect the test set hose

or probe to the other end. Run your fingers slowly

along the line while watching the test set gauge. The

vacuum reading will fluctuate when your fingers con-

tact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then,

insert the loose ends of the line into a suitable length

of 3 millimeter (1/8-inch) inside diameter rubber

hose.

Fig. 2 VACUUM CIRCUIT TEST

WJCONTROLS 24 - 11

CONTROLS (Continued)

Page 2090 of 2199

A/C COMPRESSOR CLUTCH

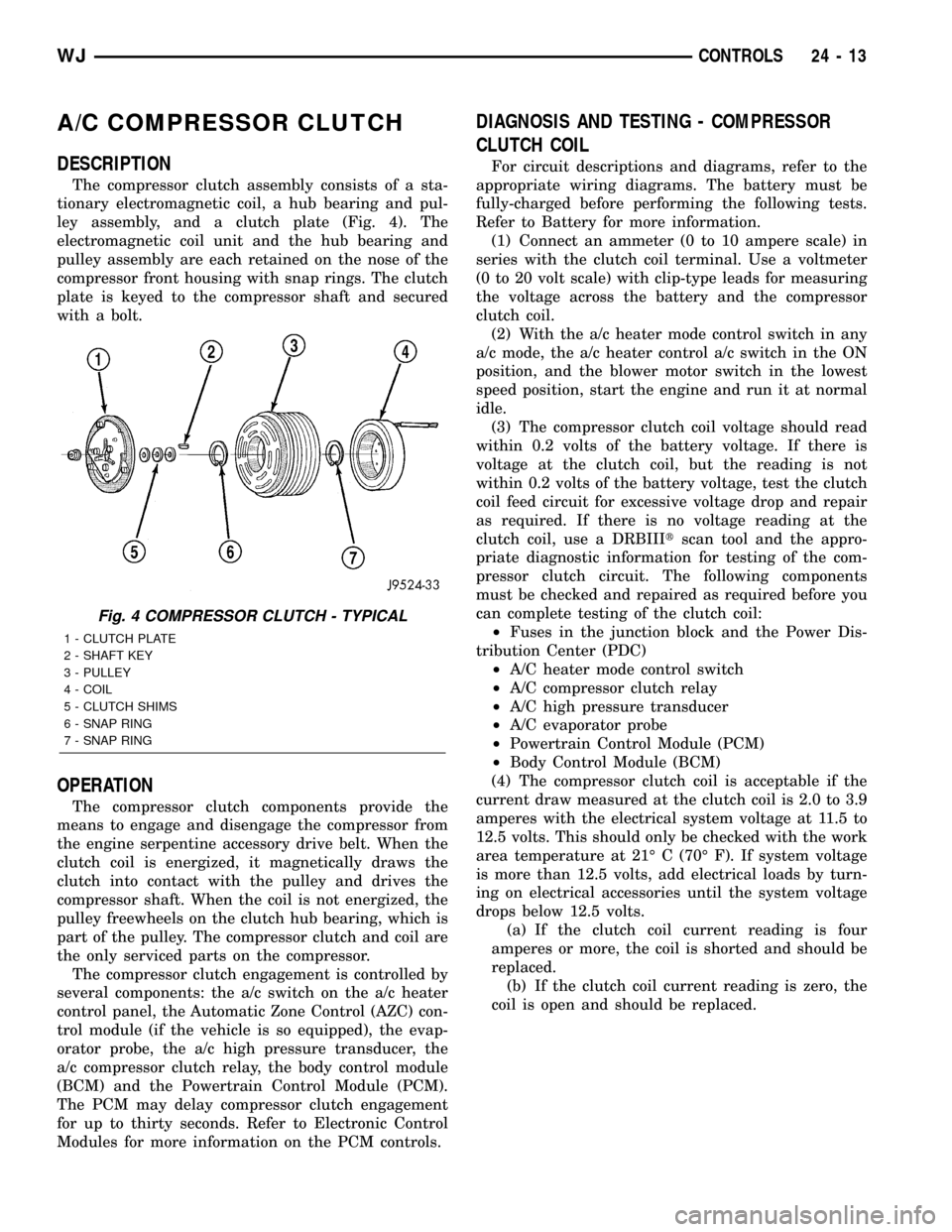

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c switch on the a/c heater

control panel, the Automatic Zone Control (AZC) con-

trol module (if the vehicle is so equipped), the evap-

orator probe, the a/c high pressure transducer, the

a/c compressor clutch relay, the body control module

(BCM) and the Powertrain Control Module (PCM).

The PCM may delay compressor clutch engagement

for up to thirty seconds. Refer to Electronic Control

Modules for more information on the PCM controls.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, refer to the

appropriate wiring diagrams. The battery must be

fully-charged before performing the following tests.

Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

a/c mode, the a/c heater control a/c switch in the ON

position, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRBIIItscan tool and the appro-

priate diagnostic information for testing of the com-

pressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²A/C compressor clutch relay

²A/C high pressure transducer

²A/C evaporator probe

²Powertrain Control Module (PCM)

²Body Control Module (BCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

WJCONTROLS 24 - 13

Page 2095 of 2199

Both the manual A/C Heater control panel and the

AZC control panel are serviced only as complete

units and cannot be repaired. If faulty or damaged,

the entire control panel unit must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC ZONE

CONTROL SYSTEM

The Automatic Zone Control (AZC) control module

has a system self-diagnostic mode which continuously

monitors various parameters during normal system

operation. If a system fault is detected, a current and

historical fault is recorded. When the current fault is

cleared, the historical fault remains until reset (man-

ually or automatically). Both the current and histor-

ical fault codes can be accessed through either the

front panel, or over the Programmable Communica-

tions Interface (PCI) bus using a DRBIIItscan tool,

and the appropriate diagnostic information.

The AZC control module is capable of three differ-

ent types of self-diagnostic tests, as follows:

²Fault Code Tests

²Input Circuit Tests

²Output Circuit/Actuator Tests

The information that follows describes:

²How to read the self-diagnostic display

²How to enter the AZC control module self-diag-

nostic test mode

²How to select the self-diagnostic test types

²How to perform the different tests

ENTERING THE AZC SELF-DIAGNOSTIC MODE

To enter the AZC self-diagnostic mode, perform the

following:

(1) Depress the a/c and recirc buttons at the same

time and hold. Rotate the left temperature control

knob clockwise (CW) one detent.

(2) If you continue to keep the a/c and recirc but-

tons depressed, the AZC control module will perform

a Segment Test of the Vacuum Fluorescent (VF) dis-

play. In the Segment Test you should see all of the

display segments illuminate as long as both buttons

are held. If a display segment fails to illuminate, the

vacuum fluorescent display is faulty and the a/c

heater control must be replaced.

(3) After viewing the Segment Test, release the

A/C and Recirc buttons and the display will clear

momentarily.Ifa0isdisplayed, then no faults

are set in the system.Should there be any faults,

either9current9or9historical9, all fault codes will be

displayed in ascending numerical sequence (note no

effort is made to display fault codes in chronological

order). Each fault code is displayed for one second

before the next code is displayed. Once all fault codes

have been displayed, the system will then repeat the

fault code numbers. This will continue until the left

side set temperature control is moved at least onedetent position in the CW direction or the ignition is

turned9OFF9.

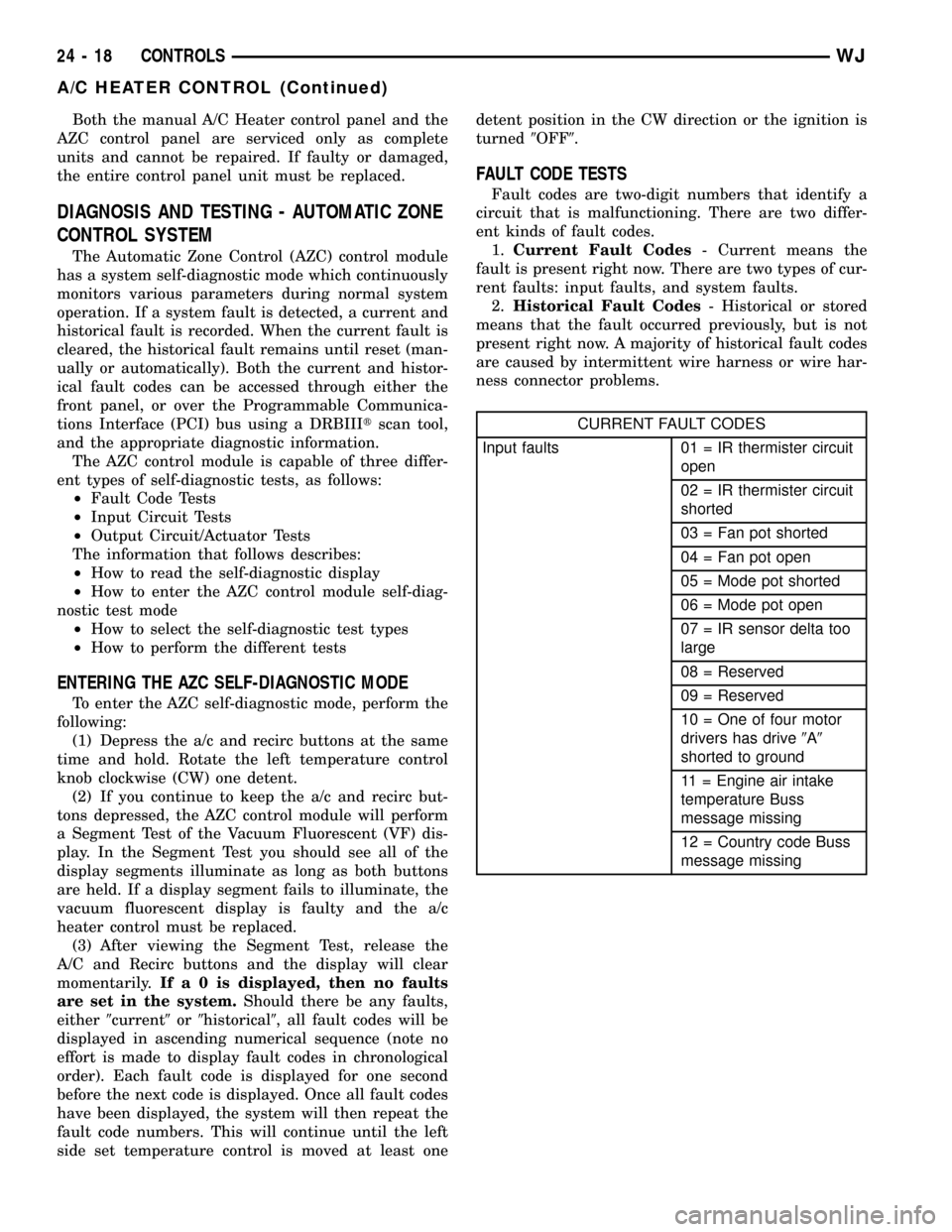

FAULT CODE TESTS

Fault codes are two-digit numbers that identify a

circuit that is malfunctioning. There are two differ-

ent kinds of fault codes.

1.Current Fault Codes- Current means the

fault is present right now. There are two types of cur-

rent faults: input faults, and system faults.

2.Historical Fault Codes- Historical or stored

means that the fault occurred previously, but is not

present right now. A majority of historical fault codes

are caused by intermittent wire harness or wire har-

ness connector problems.

CURRENT FAULT CODES

Input faults 01 = IR thermister circuit

open

02 = IR thermister circuit

shorted

03 = Fan pot shorted

04 = Fan pot open

05 = Mode pot shorted

06 = Mode pot open

07 = IR sensor delta too

large

08 = Reserved

09 = Reserved

10 = One of four motor

drivers has drive9A9

shorted to ground

11 = Engine air intake

temperature Buss

message missing

12 = Country code Buss

message missing

24 - 18 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2098 of 2199

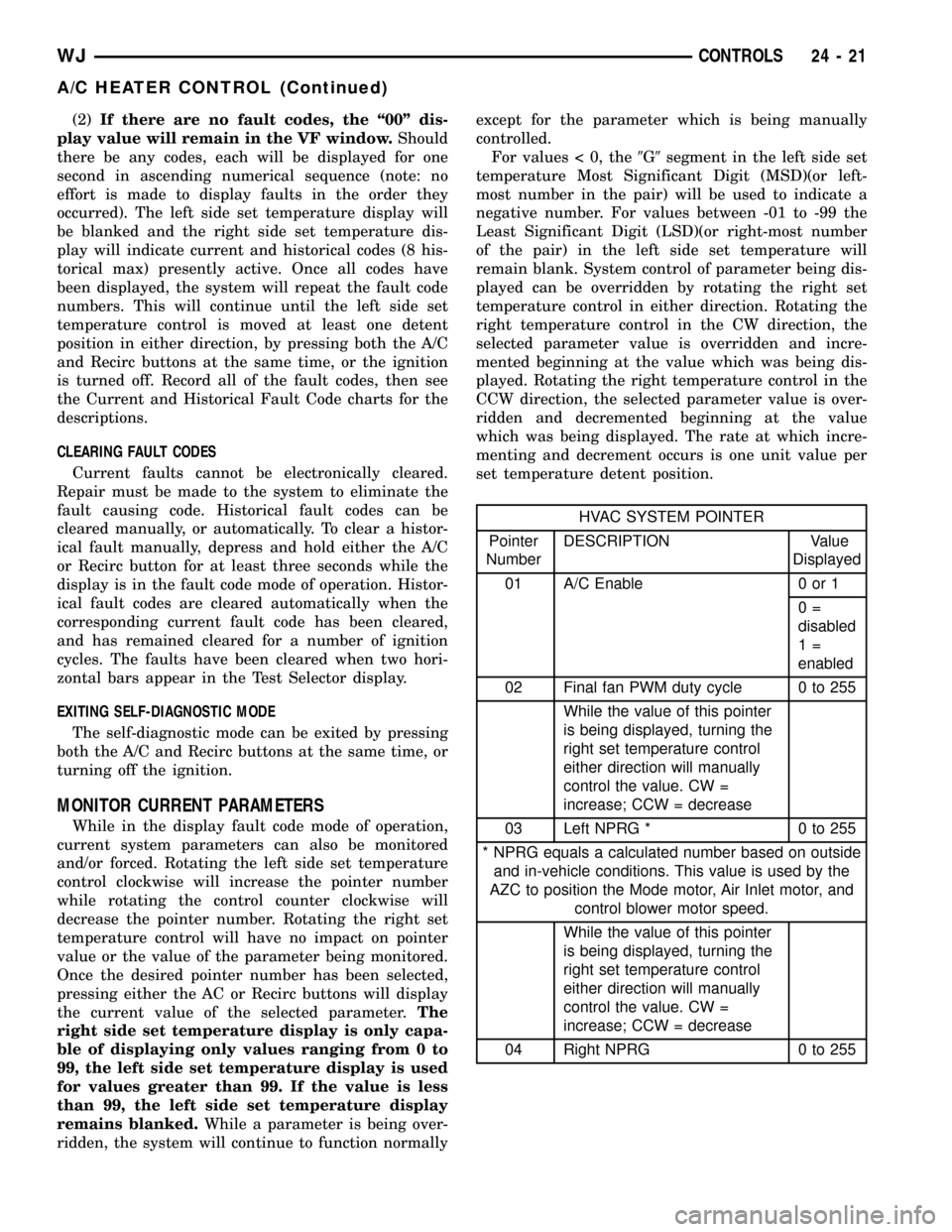

(2)If there are no fault codes, the ª00º dis-

play value will remain in the VF window.Should

there be any codes, each will be displayed for one

second in ascending numerical sequence (note: no

effort is made to display faults in the order they

occurred). The left side set temperature display will

be blanked and the right side set temperature dis-

play will indicate current and historical codes (8 his-

torical max) presently active. Once all codes have

been displayed, the system will repeat the fault code

numbers. This will continue until the left side set

temperature control is moved at least one detent

position in either direction, by pressing both the A/C

and Recirc buttons at the same time, or the ignition

is turned off. Record all of the fault codes, then see

the Current and Historical Fault Code charts for the

descriptions.

CLEARING FAULT CODES

Current faults cannot be electronically cleared.

Repair must be made to the system to eliminate the

fault causing code. Historical fault codes can be

cleared manually, or automatically. To clear a histor-

ical fault manually, depress and hold either the A/C

or Recirc button for at least three seconds while the

display is in the fault code mode of operation. Histor-

ical fault codes are cleared automatically when the

corresponding current fault code has been cleared,

and has remained cleared for a number of ignition

cycles. The faults have been cleared when two hori-

zontal bars appear in the Test Selector display.

EXITING SELF-DIAGNOSTIC MODE

The self-diagnostic mode can be exited by pressing

both the A/C and Recirc buttons at the same time, or

turning off the ignition.

MONITOR CURRENT PARAMETERS

While in the display fault code mode of operation,

current system parameters can also be monitored

and/or forced. Rotating the left side set temperature

control clockwise will increase the pointer number

while rotating the control counter clockwise will

decrease the pointer number. Rotating the right set

temperature control will have no impact on pointer

value or the value of the parameter being monitored.

Once the desired pointer number has been selected,

pressing either the AC or Recirc buttons will display

the current value of the selected parameter.The

right side set temperature display is only capa-

ble of displaying only values ranging from 0 to

99, the left side set temperature display is used

for values greater than 99. If the value is less

than 99, the left side set temperature display

remains blanked.While a parameter is being over-

ridden, the system will continue to function normallyexcept for the parameter which is being manually

controlled.

For values < 0, the9G9segment in the left side set

temperature Most Significant Digit (MSD)(or left-

most number in the pair) will be used to indicate a

negative number. For values between -01 to -99 the

Least Significant Digit (LSD)(or right-most number

of the pair) in the left side set temperature will

remain blank. System control of parameter being dis-

played can be overridden by rotating the right set

temperature control in either direction. Rotating the

right temperature control in the CW direction, the

selected parameter value is overridden and incre-

mented beginning at the value which was being dis-

played. Rotating the right temperature control in the

CCW direction, the selected parameter value is over-

ridden and decremented beginning at the value

which was being displayed. The rate at which incre-

menting and decrement occurs is one unit value per

set temperature detent position.

HVAC SYSTEM POINTER

Pointer

NumberDESCRIPTION Value

Displayed

01 A/C Enable 0 or 1

0=

disabled

1=

enabled

02 Final fan PWM duty cycle 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

03 Left NPRG * 0 to 255

* NPRG equals a calculated number based on outside

and in-vehicle conditions. This value is used by the

AZC to position the Mode motor, Air Inlet motor, and

control blower motor speed.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

04 Right NPRG 0 to 255

WJCONTROLS 24 - 21

A/C HEATER CONTROL (Continued)

Page 2099 of 2199

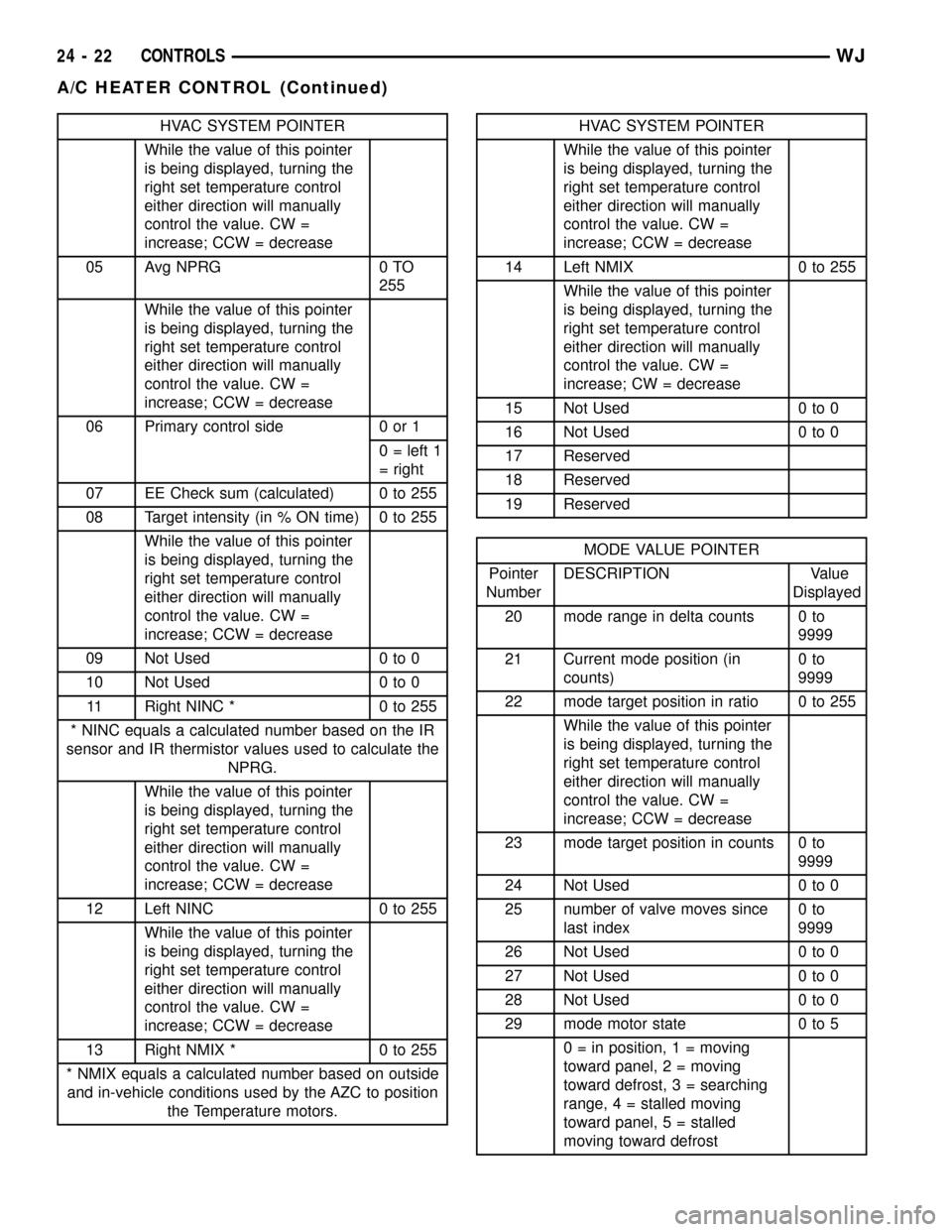

HVAC SYSTEM POINTER

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

05 Avg NPRG 0 TO

255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

06 Primary control side 0 or 1

0 = left 1

= right

07 EE Check sum (calculated) 0 to 255

08 Target intensity (in % ON time) 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

09 Not Used 0 to 0

10 Not Used 0 to 0

11 Right NINC * 0 to 255

* NINC equals a calculated number based on the IR

sensor and IR thermistor values used to calculate the

NPRG.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

12 Left NINC 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

13 Right NMIX * 0 to 255

* NMIX equals a calculated number based on outside

and in-vehicle conditions used by the AZC to position

the Temperature motors.HVAC SYSTEM POINTER

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

14 Left NMIX 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CW = decrease

15 Not Used 0 to 0

16 Not Used 0 to 0

17 Reserved

18 Reserved

19 Reserved

MODE VALUE POINTER

Pointer

NumberDESCRIPTION Value

Displayed

20 mode range in delta counts 0 to

9999

21 Current mode position (in

counts)0to

9999

22 mode target position in ratio 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

23 mode target position in counts 0 to

9999

24 Not Used 0 to 0

25 number of valve moves since

last index0to

9999

26 Not Used 0 to 0

27 Not Used 0 to 0

28 Not Used 0 to 0

29 mode motor state 0 to 5

0 = in position, 1 = moving

toward panel, 2 = moving

toward defrost, 3 = searching

range, 4 = stalled moving

toward panel, 5 = stalled

moving toward defrost

24 - 22 CONTROLSWJ

A/C HEATER CONTROL (Continued)