Speed JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 323 of 2199

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

the injector pulse width by turning the ground circuit

to each individual injector on and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

8E - 14 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 324 of 2199

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

OPERATION

OPERATION - PCM

(1) Also refer to Modes of Operation.

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²A/C request

²Auto shutdown (ASD) sense

²Battery temperature

²Battery voltage

²Brake switch

²J1850 bus circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connections for DRB scan tool

²Engine coolant temperature sensor

²Five volts (primary)

²Five volts (secondary)

²Fuel level

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)

²Intake manifold air temperature sensor

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Overdrive/override switch

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed (from ABS module)

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 (+/-) circuits for: speedometer, voltmeter,

fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRBIIItscan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)

²Idle air control (IAC) motor

²Ignition coil

²Leak detection pump

WJELECTRONIC CONTROL MODULES 8E - 15

POWERTRAIN CONTROL MODULE (Continued)

Page 325 of 2199

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Overdrive indicator lamp (if equipped). Driven

through J1850 circuits.

²Oxygen sensor heater relays (if equipped).

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control source

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (if equipped with an RE auto-

matic transmission).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM.

REMOVAL

USE THE DRBIIItSCAN TOOL TO REPRO-

GRAM THE NEW POWERTRAIN CONTROL

MODULE (PCM) WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE, A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

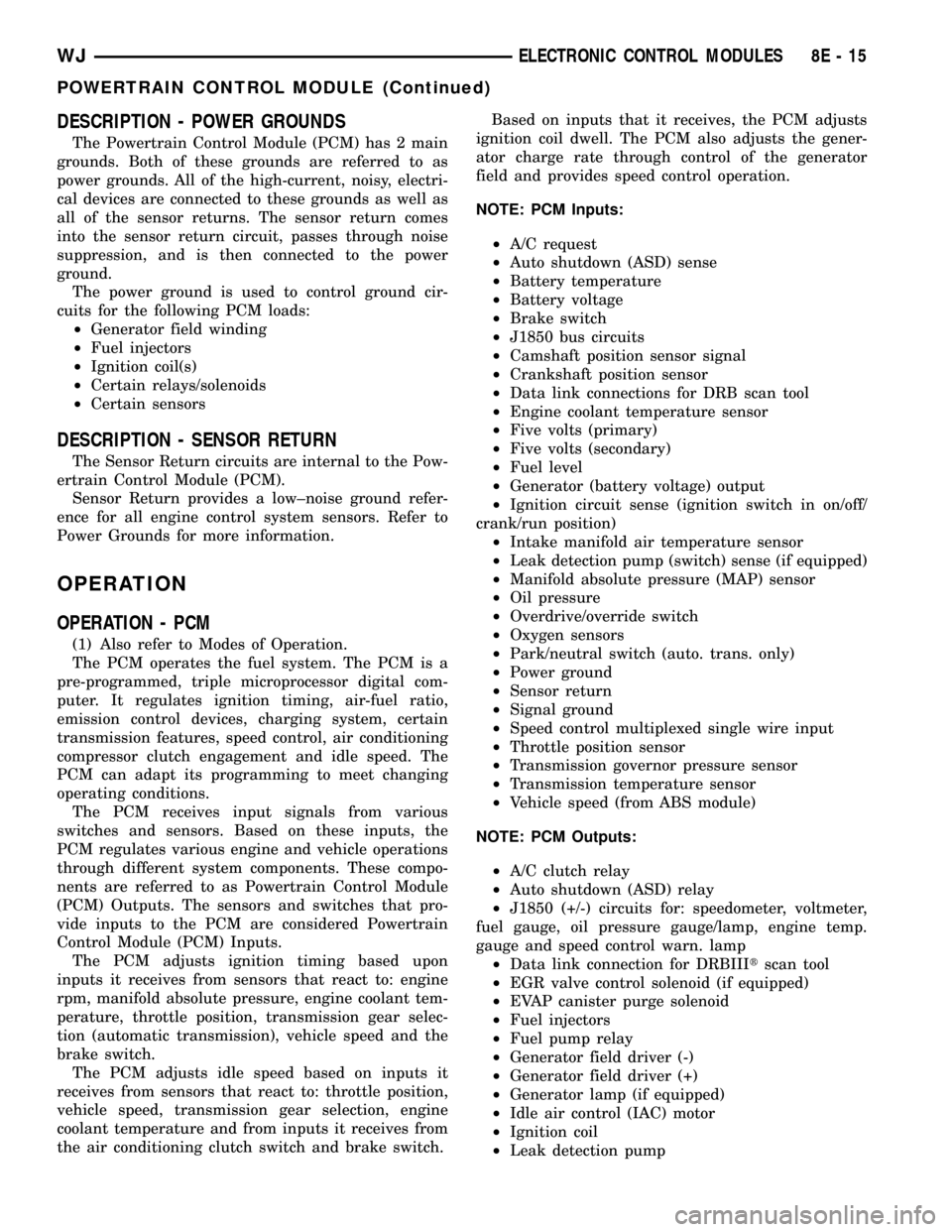

The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).

To avoid possible voltage spike damage to PCM,

ignition key must be off, and negative battery cable

must be disconnected before unplugging PCM connec-

tors.

(1) Disconnect negative battery cable at battery.

Fig. 12 Powertrain Control Module (PCM) Location

1 - PCM

2 - COOLANT TANK

Fig. 13 Powertrain Control Module (PCM) 32±Way

Connectors

1 - 3 32±WAY CONNECTORS

2 - PCM/BRACKET ASSEMBLY

3 - BRACKET NUTS (3)

8E - 16 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 329 of 2199

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM

are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBtScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

²Diagnostic capabilities (with DRBtscan tool)

NOTE: If the TCM has been replaced, the ªQuick

Learn Procedureº must be performed. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

BATTERY FEED

A fused, direct battery feed to the TCM is used for

continuous power. This battery voltage is necessary

to retain adaptive learn values in the TCM's RAM

(Random Access Memory). When the battery (B+) is

disconnected, this memory is lost. When the battery

(B+) is restored, this memory loss is detected by the

TCM and a Diagnostic Trouble Code (DTC) is set.

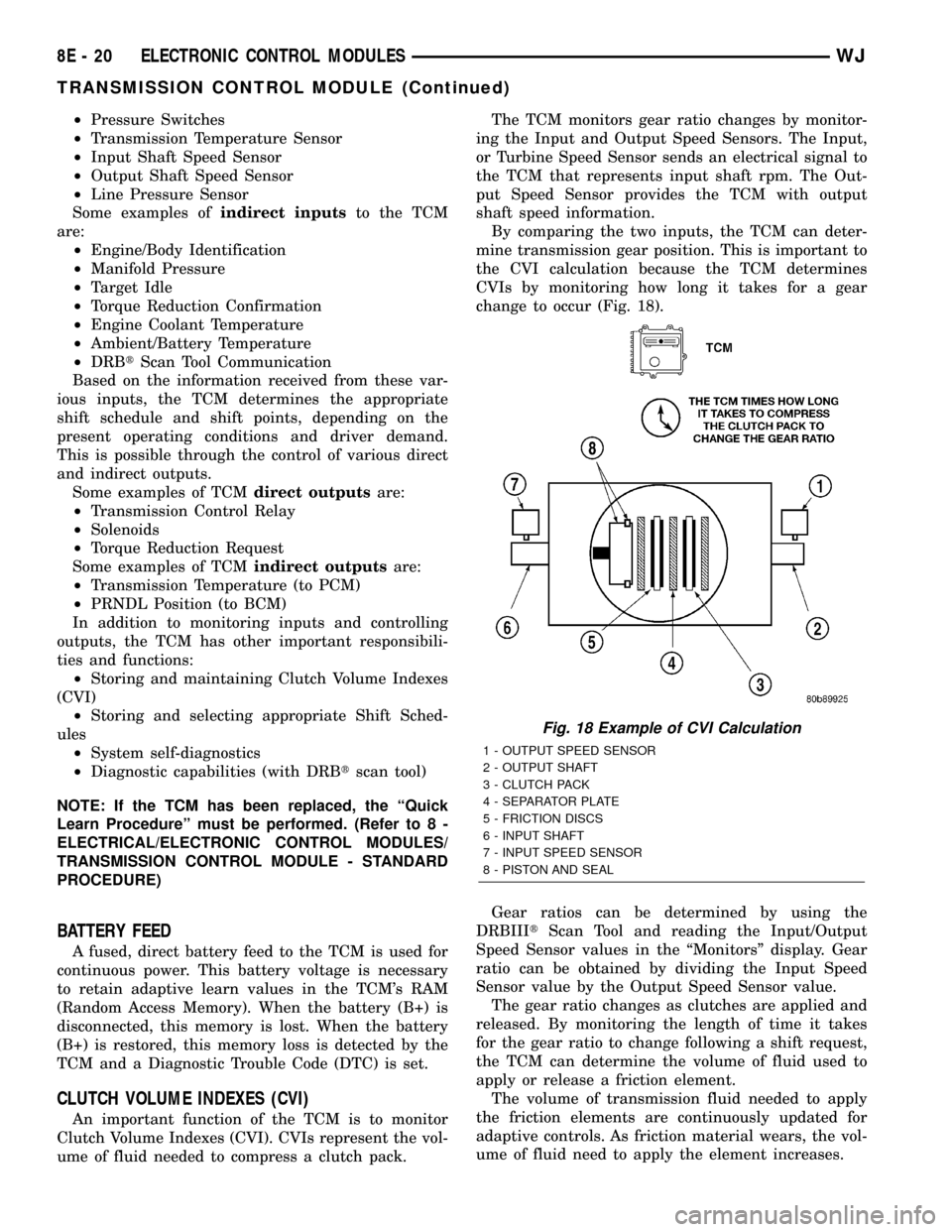

CLUTCH VOLUME INDEXES (CVI)

An important function of the TCM is to monitor

Clutch Volume Indexes (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-

put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transmission gear position. This is important to

the CVI calculation because the TCM determines

CVIs by monitoring how long it takes for a gear

change to occur (Fig. 18).

Gear ratios can be determined by using the

DRBIIItScan Tool and reading the Input/Output

Speed Sensor values in the ªMonitorsº display. Gear

ratio can be obtained by dividing the Input Speed

Sensor value by the Output Speed Sensor value.

The gear ratio changes as clutches are applied and

released. By monitoring the length of time it takes

for the gear ratio to change following a shift request,

the TCM can determine the volume of fluid used to

apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Fig. 18 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

8E - 20 ELECTRONIC CONTROL MODULESWJ

TRANSMISSION CONTROL MODULE (Continued)

Page 330 of 2199

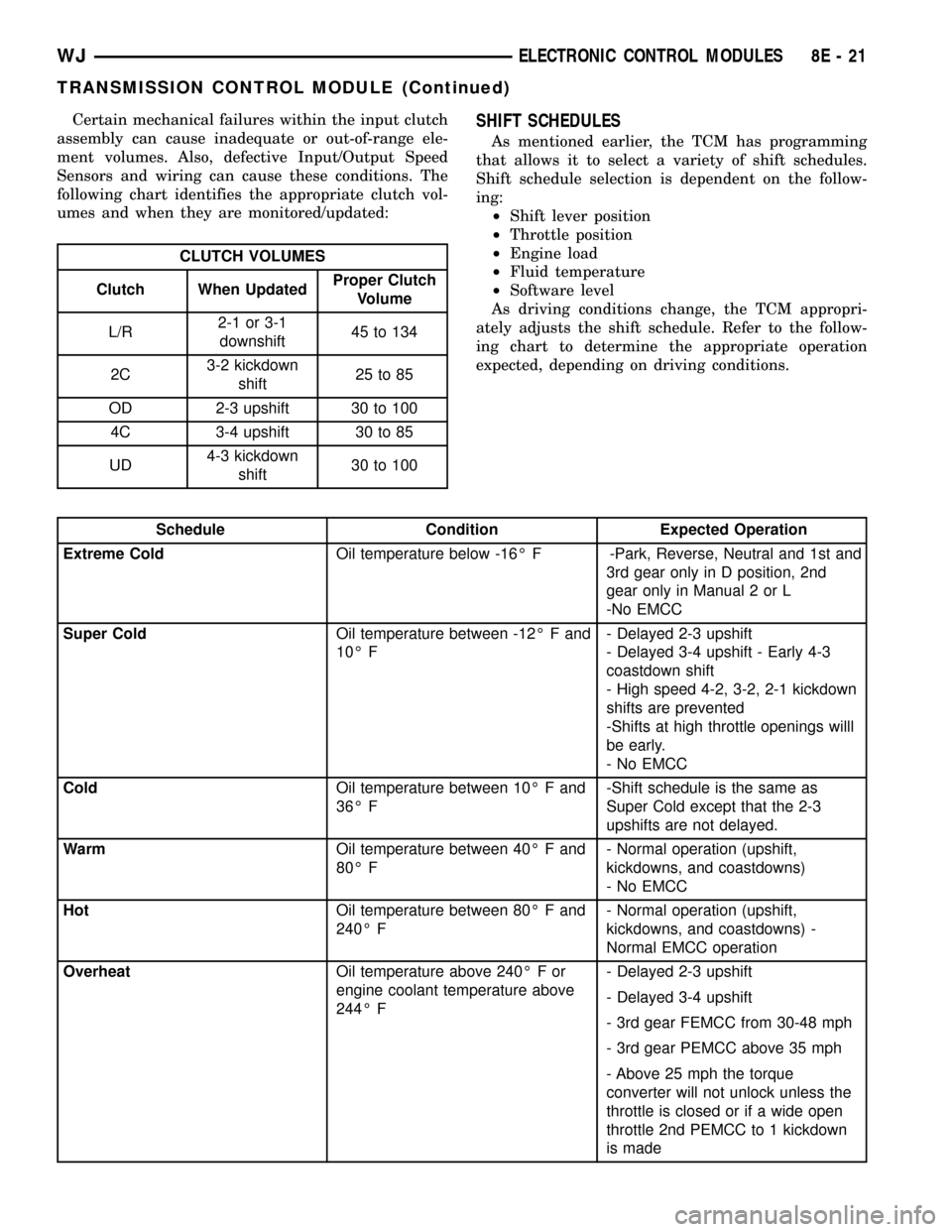

Certain mechanical failures within the input clutch

assembly can cause inadequate or out-of-range ele-

ment volumes. Also, defective Input/Output Speed

Sensors and wiring can cause these conditions. The

following chart identifies the appropriate clutch vol-

umes and when they are monitored/updated:

CLUTCH VOLUMES

Clutch When UpdatedProper Clutch

Volume

L/R2-1 or 3-1

downshift45 to 134

2C3-2 kickdown

shift25 to 85

OD 2-3 upshift 30 to 100

4C 3-4 upshift 30 to 85

UD4-3 kickdown

shift30 to 100

SHIFT SCHEDULES

As mentioned earlier, the TCM has programming

that allows it to select a variety of shift schedules.

Shift schedule selection is dependent on the follow-

ing:

²Shift lever position

²Throttle position

²Engine load

²Fluid temperature

²Software level

As driving conditions change, the TCM appropri-

ately adjusts the shift schedule. Refer to the follow-

ing chart to determine the appropriate operation

expected, depending on driving conditions.

Schedule Condition Expected Operation

Extreme ColdOil temperature below -16É F -Park, Reverse, Neutral and 1st and

3rd gear only in D position, 2nd

gear only in Manual 2 or L

-No EMCC

Super ColdOil temperature between -12É F and

10É F- Delayed 2-3 upshift

- Delayed 3-4 upshift - Early 4-3

coastdown shift

- High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

-Shifts at high throttle openings willl

be early.

- No EMCC

ColdOil temperature between 10É F and

36É F-Shift schedule is the same as

Super Cold except that the 2-3

upshifts are not delayed.

WarmOil temperature between 40É F and

80É F- Normal operation (upshift,

kickdowns, and coastdowns)

- No EMCC

HotOil temperature between 80É F and

240É F- Normal operation (upshift,

kickdowns, and coastdowns) -

Normal EMCC operation

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- 3rd gear FEMCC from 30-48 mph

- 3rd gear PEMCC above 35 mph

- Above 25 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

WJELECTRONIC CONTROL MODULES 8E - 21

TRANSMISSION CONTROL MODULE (Continued)

Page 331 of 2199

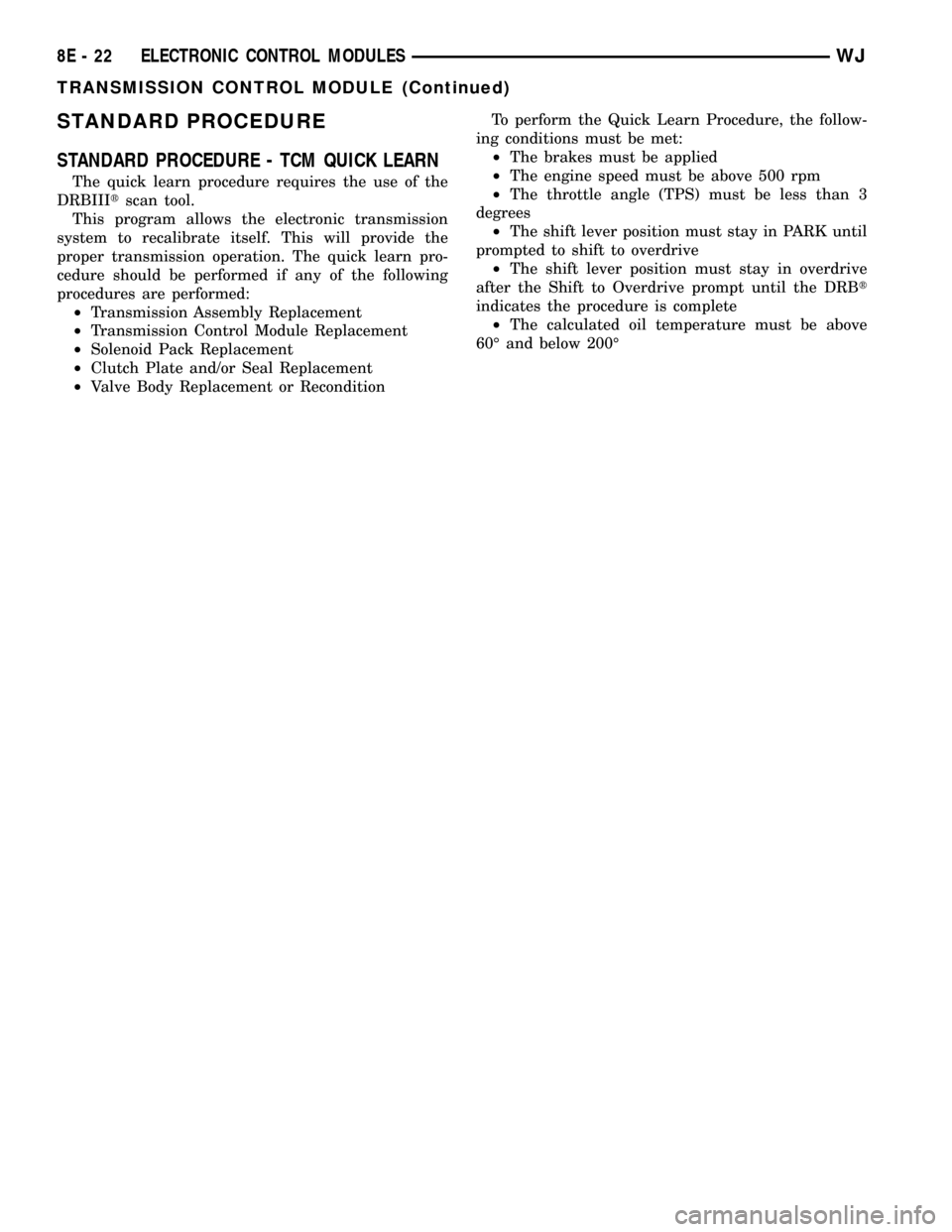

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK LEARN

The quick learn procedure requires the use of the

DRBIIItscan tool.

This program allows the electronic transmission

system to recalibrate itself. This will provide the

proper transmission operation. The quick learn pro-

cedure should be performed if any of the following

procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or ReconditionTo perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay in PARK until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBt

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

8E - 22 ELECTRONIC CONTROL MODULESWJ

TRANSMISSION CONTROL MODULE (Continued)

Page 335 of 2199

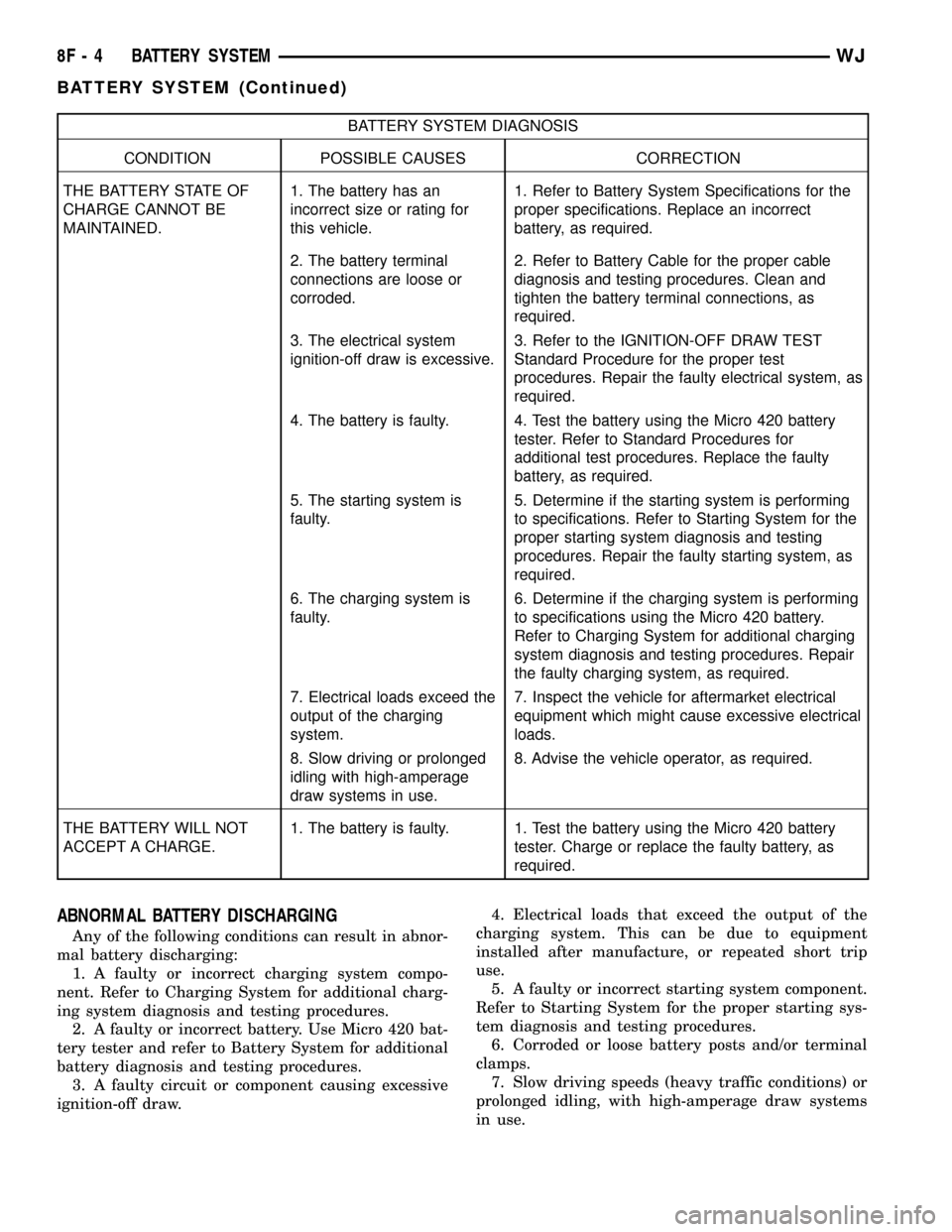

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED.1. The battery has an

incorrect size or rating for

this vehicle.1. Refer to Battery System Specifications for the

proper specifications. Replace an incorrect

battery, as required.

2. The battery terminal

connections are loose or

corroded.2. Refer to Battery Cable for the proper cable

diagnosis and testing procedures. Clean and

tighten the battery terminal connections, as

required.

3. The electrical system

ignition-off draw is excessive.3. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the faulty electrical system, as

required.

4. The battery is faulty. 4. Test the battery using the Micro 420 battery

tester. Refer to Standard Procedures for

additional test procedures. Replace the faulty

battery, as required.

5. The starting system is

faulty.5. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

6. The charging system is

faulty.6. Determine if the charging system is performing

to specifications using the Micro 420 battery.

Refer to Charging System for additional charging

system diagnosis and testing procedures. Repair

the faulty charging system, as required.

7. Electrical loads exceed the

output of the charging

system.7. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

8. Slow driving or prolonged

idling with high-amperage

draw systems in use.8. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE.1. The battery is faulty. 1. Test the battery using the Micro 420 battery

tester. Charge or replace the faulty battery, as

required.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

1. A faulty or incorrect charging system compo-

nent. Refer to Charging System for additional charg-

ing system diagnosis and testing procedures.

2. A faulty or incorrect battery. Use Micro 420 bat-

tery tester and refer to Battery System for additional

battery diagnosis and testing procedures.

3. A faulty circuit or component causing excessive

ignition-off draw.4. Electrical loads that exceed the output of the

charging system. This can be due to equipment

installed after manufacture, or repeated short trip

use.

5. A faulty or incorrect starting system component.

Refer to Starting System for the proper starting sys-

tem diagnosis and testing procedures.

6. Corroded or loose battery posts and/or terminal

clamps.

7. Slow driving speeds (heavy traffic conditions) or

prolonged idling, with high-amperage draw systems

in use.

8F - 4 BATTERY SYSTEMWJ

BATTERY SYSTEM (Continued)

Page 366 of 2199

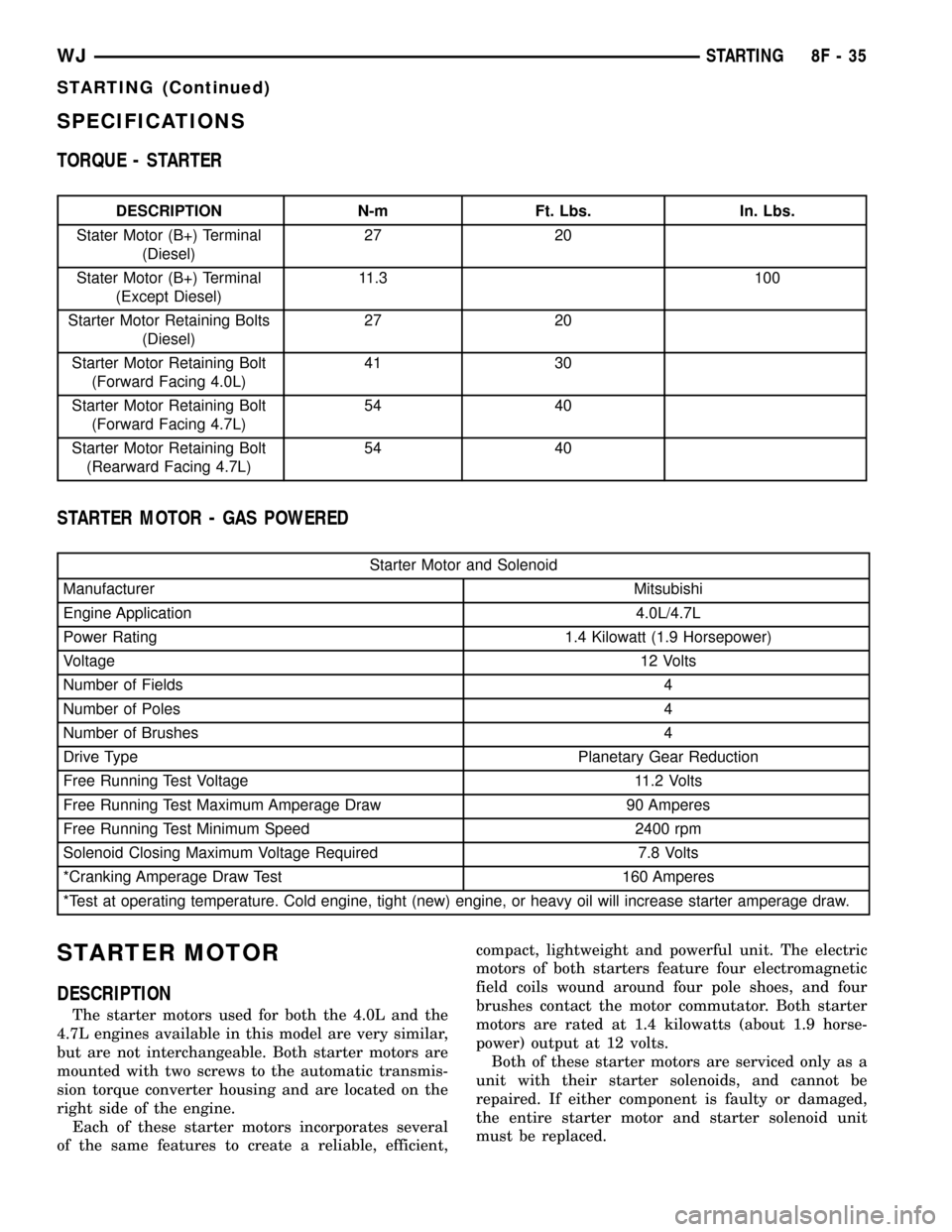

SPECIFICATIONS

TORQUE - STARTER

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Stater Motor (B+) Terminal

(Diesel)27 20

Stater Motor (B+) Terminal

(Except Diesel)11.3 100

Starter Motor Retaining Bolts

(Diesel)27 20

Starter Motor Retaining Bolt

(Forward Facing 4.0L)41 30

Starter Motor Retaining Bolt

(Forward Facing 4.7L)54 40

Starter Motor Retaining Bolt

(Rearward Facing 4.7L)54 40

STARTER MOTOR - GAS POWERED

Starter Motor and Solenoid

Manufacturer Mitsubishi

Engine Application 4.0L/4.7L

Power Rating 1.4 Kilowatt (1.9 Horsepower)

Voltage12 Volts

Number of Fields 4

Number of Poles 4

Number of Brushes 4

Drive Type Planetary Gear Reduction

Free Running Test Voltage 11.2 Volts

Free Running Test Maximum Amperage Draw 90 Amperes

Free Running Test Minimum Speed 2400 rpm

Solenoid Closing Maximum Voltage Required 7.8 Volts

*Cranking Amperage Draw Test 160 Amperes

*Test at operating temperature. Cold engine, tight (new) engine, or heavy oil will increase starter amperage draw.

STARTER MOTOR

DESCRIPTION

The starter motors used for both the 4.0L and the

4.7L engines available in this model are very similar,

but are not interchangeable. Both starter motors are

mounted with two screws to the automatic transmis-

sion torque converter housing and are located on the

right side of the engine.

Each of these starter motors incorporates several

of the same features to create a reliable, efficient,compact, lightweight and powerful unit. The electric

motors of both starters feature four electromagnetic

field coils wound around four pole shoes, and four

brushes contact the motor commutator. Both starter

motors are rated at 1.4 kilowatts (about 1.9 horse-

power) output at 12 volts.

Both of these starter motors are serviced only as a

unit with their starter solenoids, and cannot be

repaired. If either component is faulty or damaged,

the entire starter motor and starter solenoid unit

must be replaced.

WJSTARTING 8F - 35

STARTING (Continued)

Page 367 of 2199

OPERATION

These starter motors are equipped with a plane-

tary gear reduction (intermediate transmission) sys-

tem. The planetary gear reduction system consists of

a gear that is integral to the output end of the elec-

tric motor armature shaft that is in continual

engagement with a larger gear that is splined to the

input end of the starter pinion gear shaft. This fea-

ture makes it possible to reduce the dimensions of

the starter. At the same time, it allows higher arma-

ture rotational speed and delivers increased torque

through the starter pinion gear to the starter ring

gear.

The starter motors for both engines are activated

by an integral heavy duty starter solenoid switch

mounted to the overrunning clutch housing. This

electromechanical switch connects and disconnects

the feed of battery voltage to the starter motor and

actuates a shift fork that engages and disengages the

starter pinion gear with the starter ring gear.

Both starter motors use an overrunning clutch and

starter pinion gear unit to engage and drive a starter

ring gear that is integral to the torque converter

drive plate mounted on the rear crankshaft flange.

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with the starter

motor removed from the vehicle. Refer toStarting

Systemin the Specifications section of this group for

the starter motor specifications.

(1) Remove the starter motor from the vehicle.

Refer toStarter Motorin the Removal and Instal-

lation section of this group for the procedures.

(2) Mount the starter motor securely in a soft-

jawed bench vise. The vise jaws should be clamped

on the mounting flange of the starter motor. Never

clamp on the starter motor by the field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to the starter motor in series, and set

the ammeter to the 100 ampere scale. See the

instructions provided by the manufacturer of the

volt-ampere tester being used.

(4) Install a jumper wire from the solenoid termi-

nal to the solenoid battery terminal. The starter

motor should operate. If the starter motor fails to

operate, replace the faulty starter motor assembly.

(5) Adjust the carbon pile load of the tester to

obtain the free running test voltage. Refer toStart-

ing Systemin the Specifications section of this

group for the starter motor free running test voltage

specifications.

(6) Note the reading on the ammeter and compare

this reading to the free running test maximum

amperage draw. Refer toStarting Systemin theSpecifications section of this group for the starter

motor free running test maximum amperage draw

specifications.

(7) If the ammeter reading exceeds the maximum

amperage draw specification, replace the faulty

starter motor assembly.

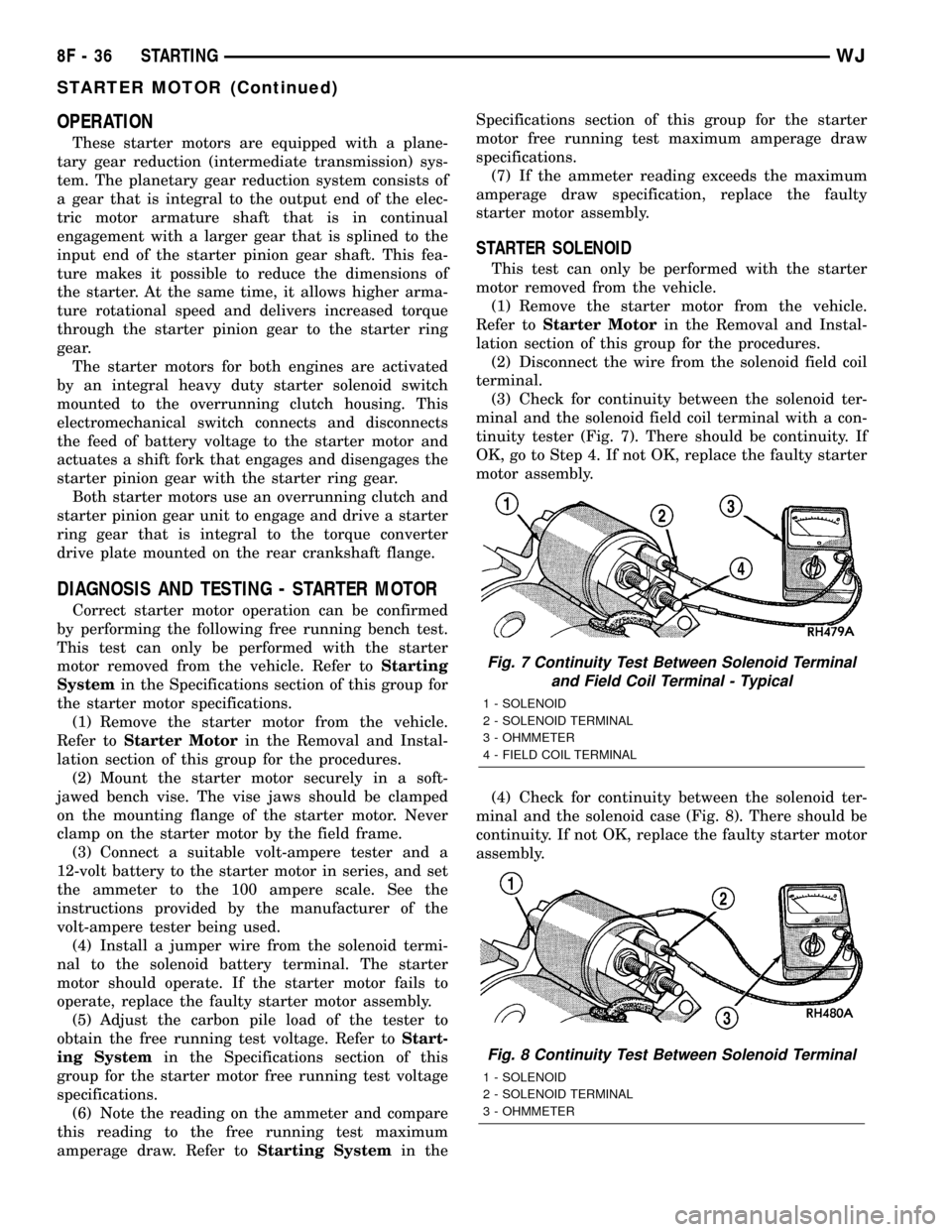

STARTER SOLENOID

This test can only be performed with the starter

motor removed from the vehicle.

(1) Remove the starter motor from the vehicle.

Refer toStarter Motorin the Removal and Instal-

lation section of this group for the procedures.

(2) Disconnect the wire from the solenoid field coil

terminal.

(3) Check for continuity between the solenoid ter-

minal and the solenoid field coil terminal with a con-

tinuity tester (Fig. 7). There should be continuity. If

OK, go to Step 4. If not OK, replace the faulty starter

motor assembly.

(4) Check for continuity between the solenoid ter-

minal and the solenoid case (Fig. 8). There should be

continuity. If not OK, replace the faulty starter motor

assembly.

Fig. 7 Continuity Test Between Solenoid Terminal

and Field Coil Terminal - Typical

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER

4 - FIELD COIL TERMINAL

Fig. 8 Continuity Test Between Solenoid Terminal

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER

8F - 36 STARTINGWJ

STARTER MOTOR (Continued)

Page 405 of 2199

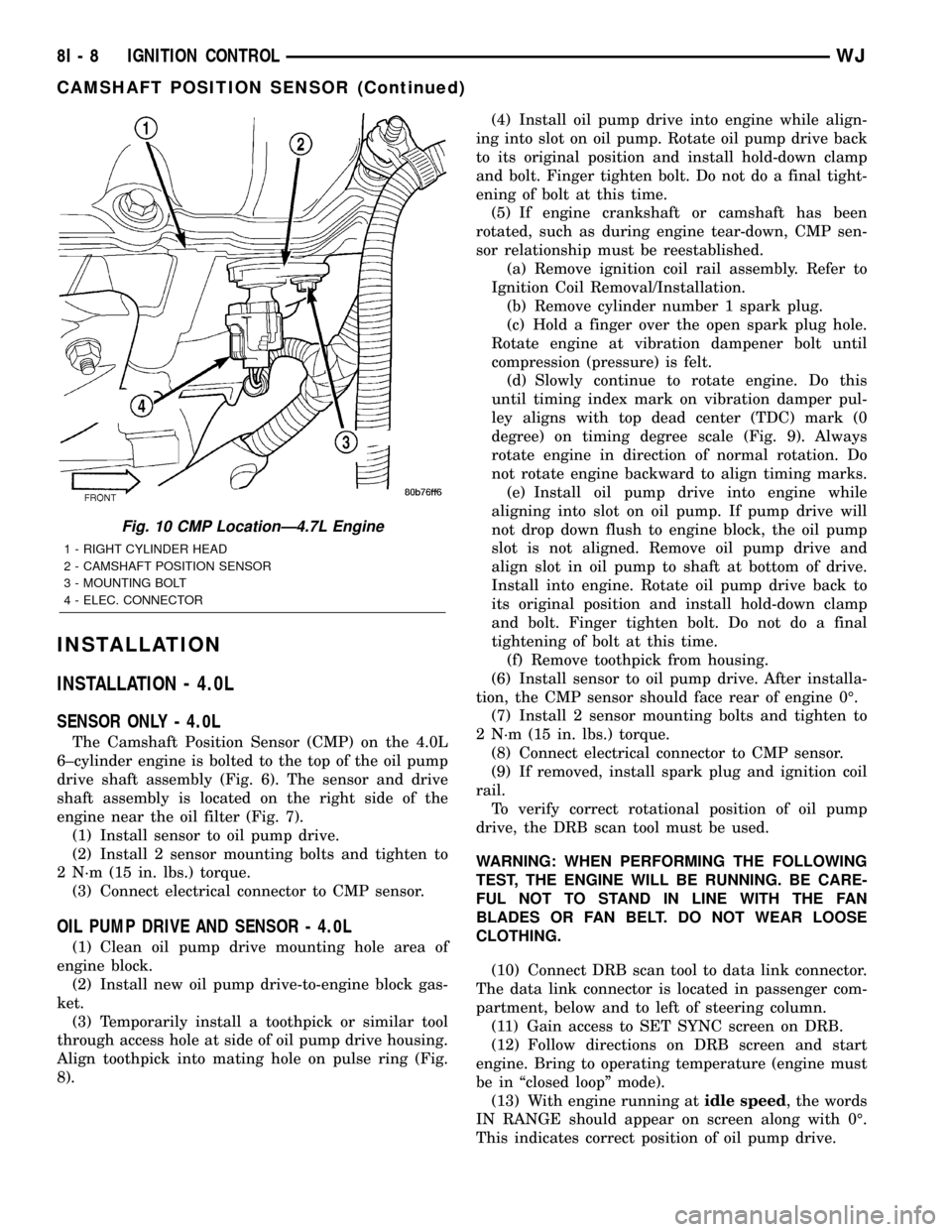

INSTALLATION

INSTALLATION - 4.0L

SENSOR ONLY - 4.0L

The Camshaft Position Sensor (CMP) on the 4.0L

6±cylinder engine is bolted to the top of the oil pump

drive shaft assembly (Fig. 6). The sensor and drive

shaft assembly is located on the right side of the

engine near the oil filter (Fig. 7).

(1) Install sensor to oil pump drive.

(2) Install 2 sensor mounting bolts and tighten to

2 N´m (15 in. lbs.) torque.

(3) Connect electrical connector to CMP sensor.

OIL PUMP DRIVE AND SENSOR - 4.0L

(1) Clean oil pump drive mounting hole area of

engine block.

(2) Install new oil pump drive-to-engine block gas-

ket.

(3) Temporarily install a toothpick or similar tool

through access hole at side of oil pump drive housing.

Align toothpick into mating hole on pulse ring (Fig.

8).(4) Install oil pump drive into engine while align-

ing into slot on oil pump. Rotate oil pump drive back

to its original position and install hold-down clamp

and bolt. Finger tighten bolt. Do not do a final tight-

ening of bolt at this time.

(5) If engine crankshaft or camshaft has been

rotated, such as during engine tear-down, CMP sen-

sor relationship must be reestablished.

(a) Remove ignition coil rail assembly. Refer to

Ignition Coil Removal/Installation.

(b) Remove cylinder number 1 spark plug.

(c) Hold a finger over the open spark plug hole.

Rotate engine at vibration dampener bolt until

compression (pressure) is felt.

(d) Slowly continue to rotate engine. Do this

until timing index mark on vibration damper pul-

ley aligns with top dead center (TDC) mark (0

degree) on timing degree scale (Fig. 9). Always

rotate engine in direction of normal rotation. Do

not rotate engine backward to align timing marks.

(e) Install oil pump drive into engine while

aligning into slot on oil pump. If pump drive will

not drop down flush to engine block, the oil pump

slot is not aligned. Remove oil pump drive and

align slot in oil pump to shaft at bottom of drive.

Install into engine. Rotate oil pump drive back to

its original position and install hold-down clamp

and bolt. Finger tighten bolt. Do not do a final

tightening of bolt at this time.

(f) Remove toothpick from housing.

(6) Install sensor to oil pump drive. After installa-

tion, the CMP sensor should face rear of engine 0É.

(7) Install 2 sensor mounting bolts and tighten to

2 N´m (15 in. lbs.) torque.

(8) Connect electrical connector to CMP sensor.

(9) If removed, install spark plug and ignition coil

rail.

To verify correct rotational position of oil pump

drive, the DRB scan tool must be used.

WARNING: WHEN PERFORMING THE FOLLOWING

TEST, THE ENGINE WILL BE RUNNING. BE CARE-

FUL NOT TO STAND IN LINE WITH THE FAN

BLADES OR FAN BELT. DO NOT WEAR LOOSE

CLOTHING.

(10) Connect DRB scan tool to data link connector.

The data link connector is located in passenger com-

partment, below and to left of steering column.

(11) Gain access to SET SYNC screen on DRB.

(12) Follow directions on DRB screen and start

engine. Bring to operating temperature (engine must

be in ªclosed loopº mode).

(13) With engine running atidle speed, the words

IN RANGE should appear on screen along with 0É.

This indicates correct position of oil pump drive.

Fig. 10 CMP LocationÐ4.7L Engine

1 - RIGHT CYLINDER HEAD

2 - CAMSHAFT POSITION SENSOR

3 - MOUNTING BOLT

4 - ELEC. CONNECTOR

8I - 8 IGNITION CONTROLWJ

CAMSHAFT POSITION SENSOR (Continued)