Starting system JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1910 of 2199

INSTRUMENT PANEL SYSTEM

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right and left A-pil-

lars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - REMOVAL).(3) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

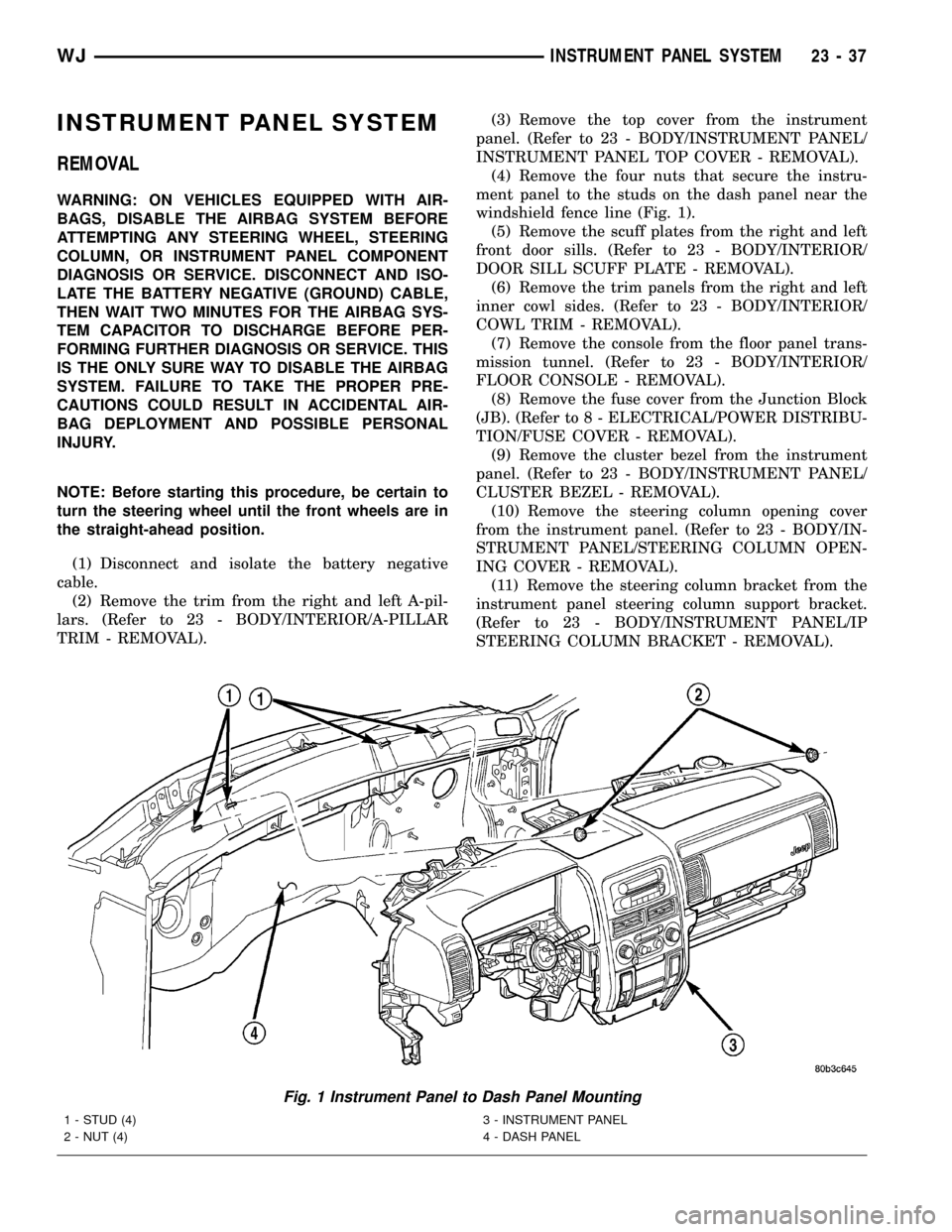

(4) Remove the four nuts that secure the instru-

ment panel to the studs on the dash panel near the

windshield fence line (Fig. 1).

(5) Remove the scuff plates from the right and left

front door sills. (Refer to 23 - BODY/INTERIOR/

DOOR SILL SCUFF PLATE - REMOVAL).

(6) Remove the trim panels from the right and left

inner cowl sides. (Refer to 23 - BODY/INTERIOR/

COWL TRIM - REMOVAL).

(7) Remove the console from the floor panel trans-

mission tunnel. (Refer to 23 - BODY/INTERIOR/

FLOOR CONSOLE - REMOVAL).

(8) Remove the fuse cover from the Junction Block

(JB). (Refer to 8 - ELECTRICAL/POWER DISTRIBU-

TION/FUSE COVER - REMOVAL).

(9) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(10) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(11) Remove the steering column bracket from the

instrument panel steering column support bracket.

(Refer to 23 - BODY/INSTRUMENT PANEL/IP

STEERING COLUMN BRACKET - REMOVAL).

Fig. 1 Instrument Panel to Dash Panel Mounting

1 - STUD (4)

2 - NUT (4)3 - INSTRUMENT PANEL

4 - DASH PANEL

WJINSTRUMENT PANEL SYSTEM 23 - 37

Page 2087 of 2199

VACUUM RESERVOIR

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................35

INSTALLATION.........................35EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL.............................35

INSTALLATION.........................35

CONTROLS

DIAGNOSIS AND TESTING - VACUUM SYSTEM

Vacuum control is used to operate the mode doors

in the standard equipment manual temperature con-

trol system HVAC housing. Testing of the A/C Heater

mode control switch operation will determine if the

vacuum and electrical controls are functioning. How-

ever, it is possible that a vacuum control system that

operates perfectly at engine idle (high engine vac-

uum) may not function properly at high engine

speeds or loads (low engine vacuum). This can be

caused by leaks in the vacuum system, or a faulty

vacuum check valve.

A vacuum system test will help to identify the

source of poor vacuum system performance or vac-

uum system leaks. Before starting this test, stop the

engine and make certain that the problem isn't a dis-

connected vacuum supply tube at the engine intake

manifold vacuum tap or the vacuum reservoir.

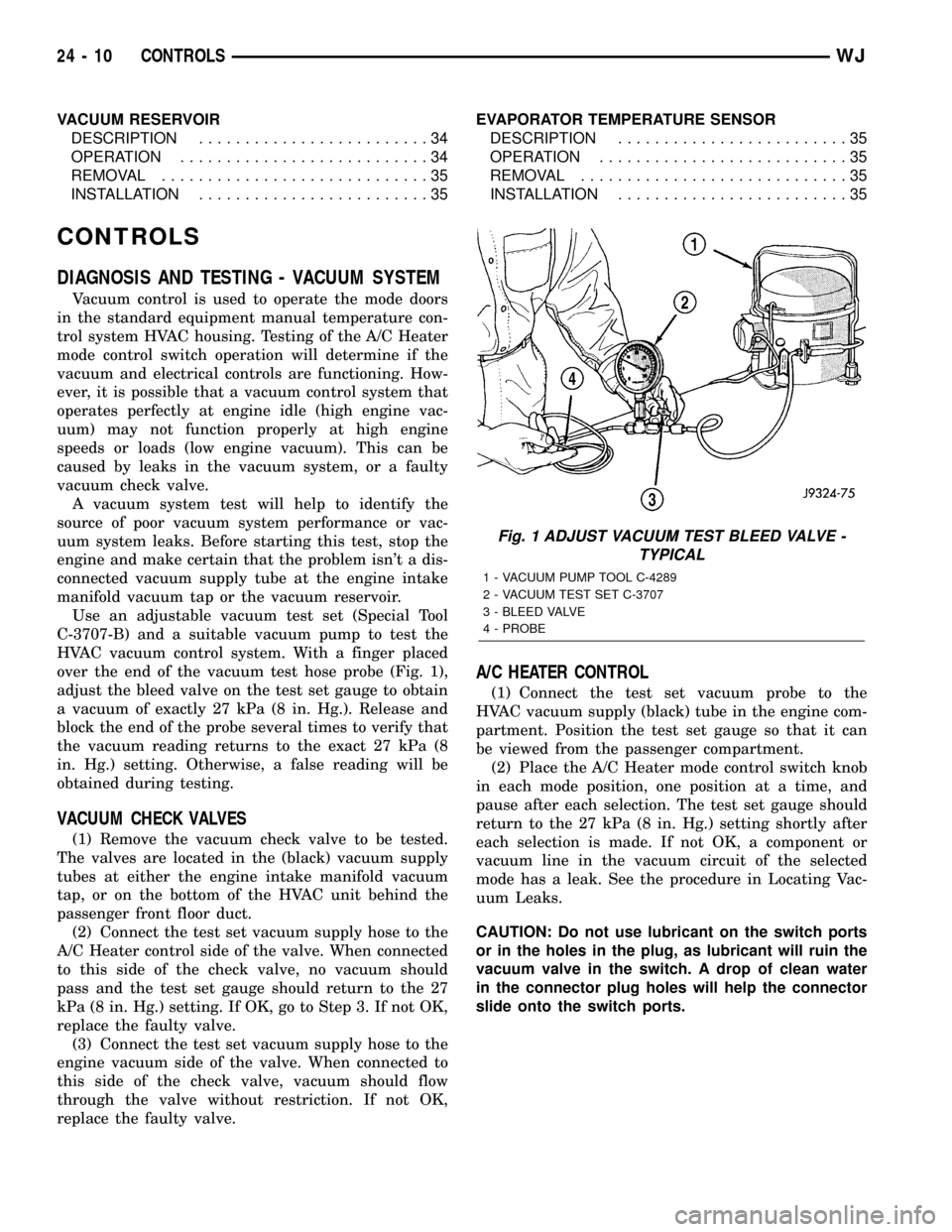

Use an adjustable vacuum test set (Special Tool

C-3707-B) and a suitable vacuum pump to test the

HVAC vacuum control system. With a finger placed

over the end of the vacuum test hose probe (Fig. 1),

adjust the bleed valve on the test set gauge to obtain

a vacuum of exactly 27 kPa (8 in. Hg.). Release and

block the end of the probe several times to verify that

the vacuum reading returns to the exact 27 kPa (8

in. Hg.) setting. Otherwise, a false reading will be

obtained during testing.

VACUUM CHECK VALVES

(1) Remove the vacuum check valve to be tested.

The valves are located in the (black) vacuum supply

tubes at either the engine intake manifold vacuum

tap, or on the bottom of the HVAC unit behind the

passenger front floor duct.

(2) Connect the test set vacuum supply hose to the

A/C Heater control side of the valve. When connected

to this side of the check valve, no vacuum should

pass and the test set gauge should return to the 27

kPa (8 in. Hg.) setting. If OK, go to Step 3. If not OK,

replace the faulty valve.

(3) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

A/C HEATER CONTROL

(1) Connect the test set vacuum probe to the

HVAC vacuum supply (black) tube in the engine com-

partment. Position the test set gauge so that it can

be viewed from the passenger compartment.

(2) Place the A/C Heater mode control switch knob

in each mode position, one position at a time, and

pause after each selection. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each selection is made. If not OK, a component or

vacuum line in the vacuum circuit of the selected

mode has a leak. See the procedure in Locating Vac-

uum Leaks.

CAUTION: Do not use lubricant on the switch ports

or in the holes in the plug, as lubricant will ruin the

vacuum valve in the switch. A drop of clean water

in the connector plug holes will help the connector

slide onto the switch ports.

Fig. 1 ADJUST VACUUM TEST BLEED VALVE -

TYPICAL

1 - VACUUM PUMP TOOL C-4289

2 - VACUUM TEST SET C-3707

3 - BLEED VALVE

4 - PROBE

24 - 10 CONTROLSWJ