clock JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1245 of 2199

REMOVAL

REMOVAL - CAMSHAFT BEARINGS.......31

REMOVAL - CAMSHAFT................31

INSPECTION

INSPECTION - CAMSHAFT BEARINGS.....31

INSPECTION - CAMSHAFT..............31

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . . 32

INSTALLATION - CAMSHAFT............32

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - FITTING

CONNECTING ROD BEARINGS..........33

CRANKSHAFT

DESCRIPTION.........................35

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - FITTING

CRANKSHAFT MAIN BEARINGS..........36

REMOVAL.............................39

INSPECTION..........................40

INSTALLATION.........................40

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................41

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................42

INSTALLATION.........................42

HYDRAULIC LIFTERS

DESCRIPTION.........................43

REMOVAL.............................43

CLEANING............................43

INSPECTION..........................43

INSTALLATION.........................43

PISTON & CONNECTING ROD

DESCRIPTION.........................44

STANDARD PROCEDURE - PISTON FITTING . 44

REMOVAL.............................45

INSTALLATION.........................46

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................47

VIBRATION DAMPER

REMOVAL.............................49

INSTALLATION.........................49STRUCTURAL SUPPORT

REMOVAL.............................49

INSTALLATION.........................50

LUBRICATION

DESCRIPTION.........................50

OPERATION...........................50

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE..........................51

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK...............................51

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE............................53

OIL FILTER

REMOVAL.............................53

INSTALLATION.........................54

OIL PAN

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................55

ENGINE OIL PRESSURE SENSOR

DESCRIPTION.........................56

OPERATION...........................56

OIL PUMP

REMOVAL.............................56

INSTALLATION.........................57

INTAKE MANIFOLD

DESCRIPTION.........................57

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE..................57

REMOVAL.............................57

INSTALLATION.........................57

EXHAUST MANIFOLD

DESCRIPTION.........................58

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL.............................60

INSTALLATION.........................60

ENGINE - 4.0L

DESCRIPTION

The 4.0 Liter (242 CID) six-cylinder engine is an

In-line, lightweight, overhead valve engine. This

engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in better

fuel economy.

The cylinders are numbered 1 through 6 from front

to rear. The firing order is 1-5-3-6-2-4 (Fig. 1).The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within seven main bearings. The camshaft rotates

within four bearings.

The engine Build Date Code is located on a

machined surface on the right side of the cylinder

block between the No.2 and No.3 cylinders (Fig. 2).

The digits of the code identify:

²1st DigitÐThe year (8 = 1998).

²2nd & 3rd DigitsÐThe month (01 - 12).

²4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (MX = A 4.0 Liter (242 CID) 8.7:1

compression ratio engine with a multi-point fuel

injection system).

9 - 2 ENGINE - 4.0LWJ

Page 1286 of 2199

HYDRAULIC LIFTERS

DESCRIPTION

Valve lash is controlled by hydraulic tappets

located inside the cylinder block, in tappet bores

above the camshaft.

REMOVAL

NOTE: Retain all the components in the same order

as removed.

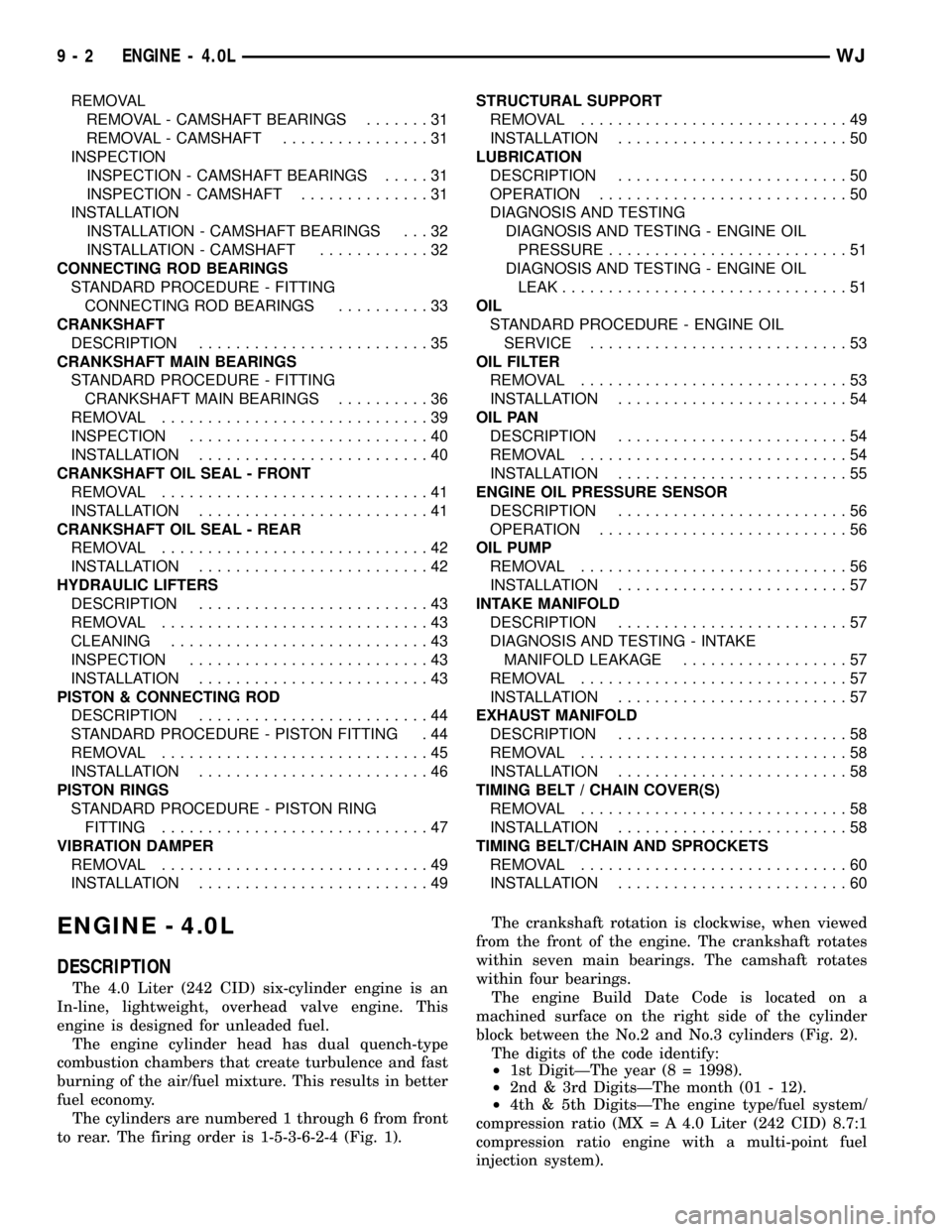

(1) Remove the engine cylinder head(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Remove the push rods.

(3) Remove the tappets through the push rod open-

ings in the cylinder block with a Hydraulic Valve

Tappet Removal/Installation Tool (Fig. 53).

CLEANING

Clean each tappet assembly in cleaning solvent to

remove all varnish, gum and sludge deposits.

INSPECTION

Inspect for indications of scuffing on the side and

base of each tappet body.

Inspect each tappet base for concave wear with a

straightedge positioned across the base. If the base is

concave, the corresponding lobe on the camshaft is

also worn. Replace the camshaft and tappets.

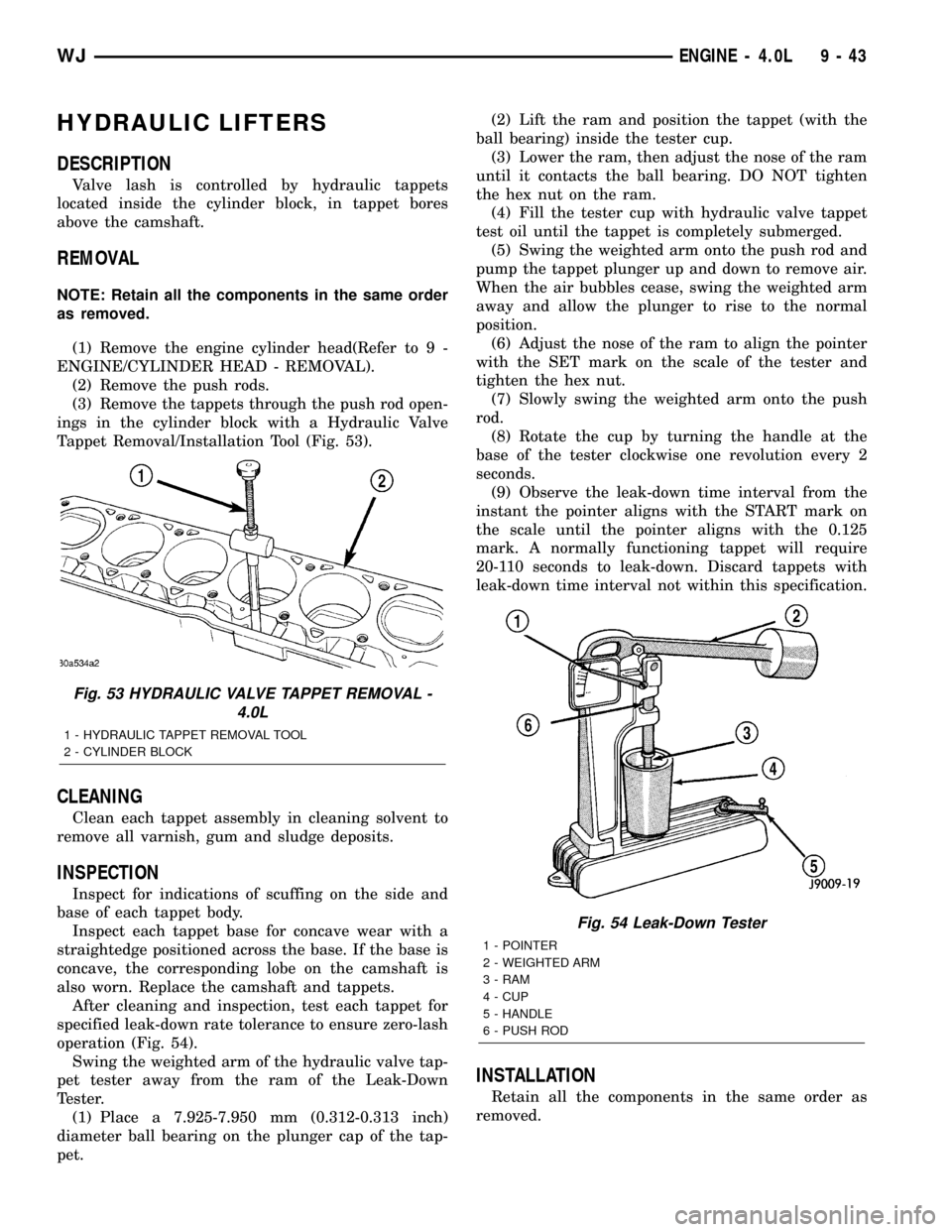

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 54).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Leak-Down

Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

INSTALLATION

Retain all the components in the same order as

removed.

Fig. 53 HYDRAULIC VALVE TAPPET REMOVAL -

4.0L

1 - HYDRAULIC TAPPET REMOVAL TOOL

2 - CYLINDER BLOCK

Fig. 54 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

WJENGINE - 4.0L 9 - 43

Page 1297 of 2199

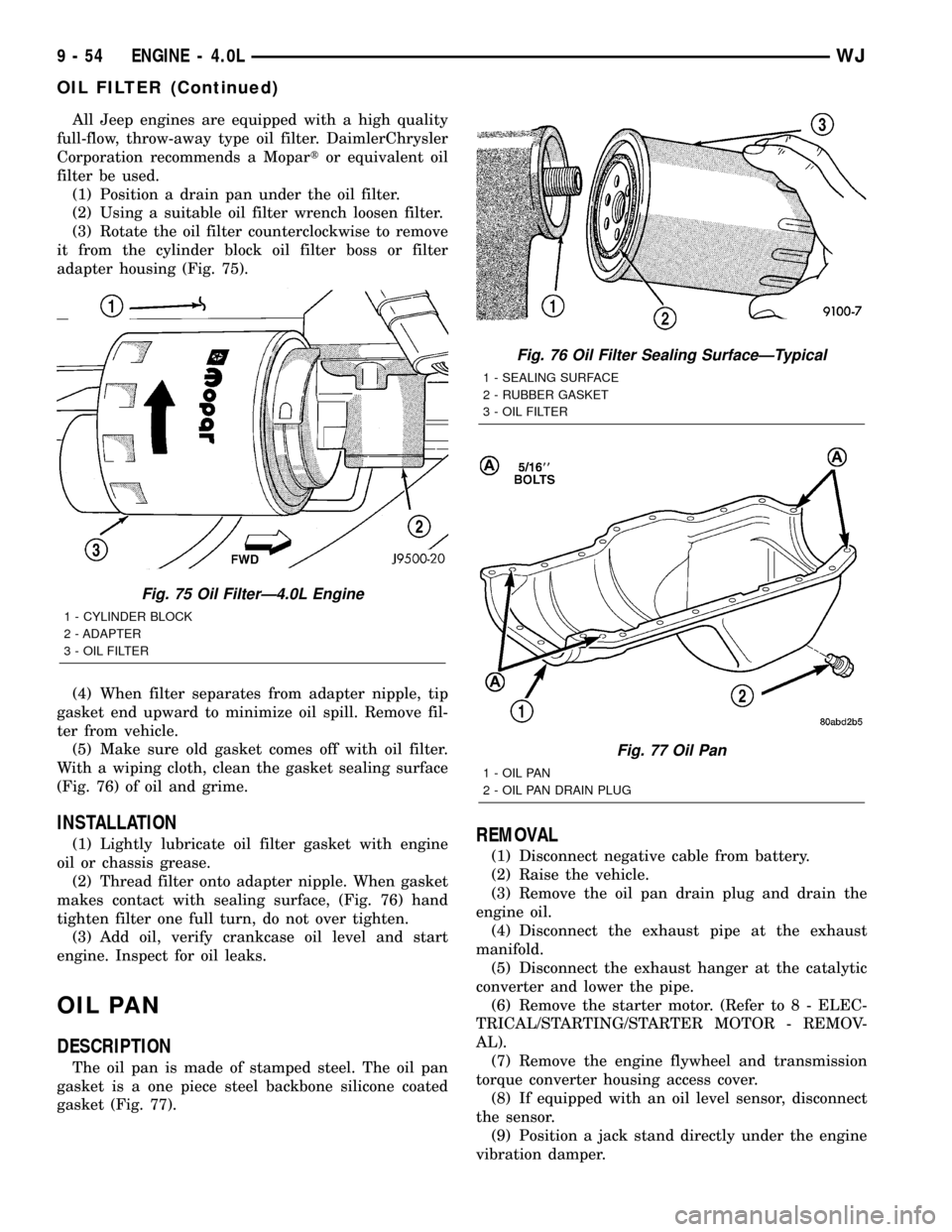

All Jeep engines are equipped with a high quality

full-flow, throw-away type oil filter. DaimlerChrysler

Corporation recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss or filter

adapter housing (Fig. 75).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) Make sure old gasket comes off with oil filter.

With a wiping cloth, clean the gasket sealing surface

(Fig. 76) of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 76) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

DESCRIPTION

The oil pan is made of stamped steel. The oil pan

gasket is a one piece steel backbone silicone coated

gasket (Fig. 77).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Remove the oil pan drain plug and drain the

engine oil.

(4) Disconnect the exhaust pipe at the exhaust

manifold.

(5) Disconnect the exhaust hanger at the catalytic

converter and lower the pipe.

(6) Remove the starter motor. (Refer to 8 - ELEC-

TRICAL/STARTING/STARTER MOTOR - REMOV-

AL).

(7) Remove the engine flywheel and transmission

torque converter housing access cover.

(8) If equipped with an oil level sensor, disconnect

the sensor.

(9) Position a jack stand directly under the engine

vibration damper.

Fig. 75 Oil FilterÐ4.0L Engine

1 - CYLINDER BLOCK

2 - ADAPTER

3 - OIL FILTER

Fig. 76 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 77 Oil Pan

1 - OIL PAN

2 - OIL PAN DRAIN PLUG

9 - 54 ENGINE - 4.0LWJ

OIL FILTER (Continued)

Page 1329 of 2199

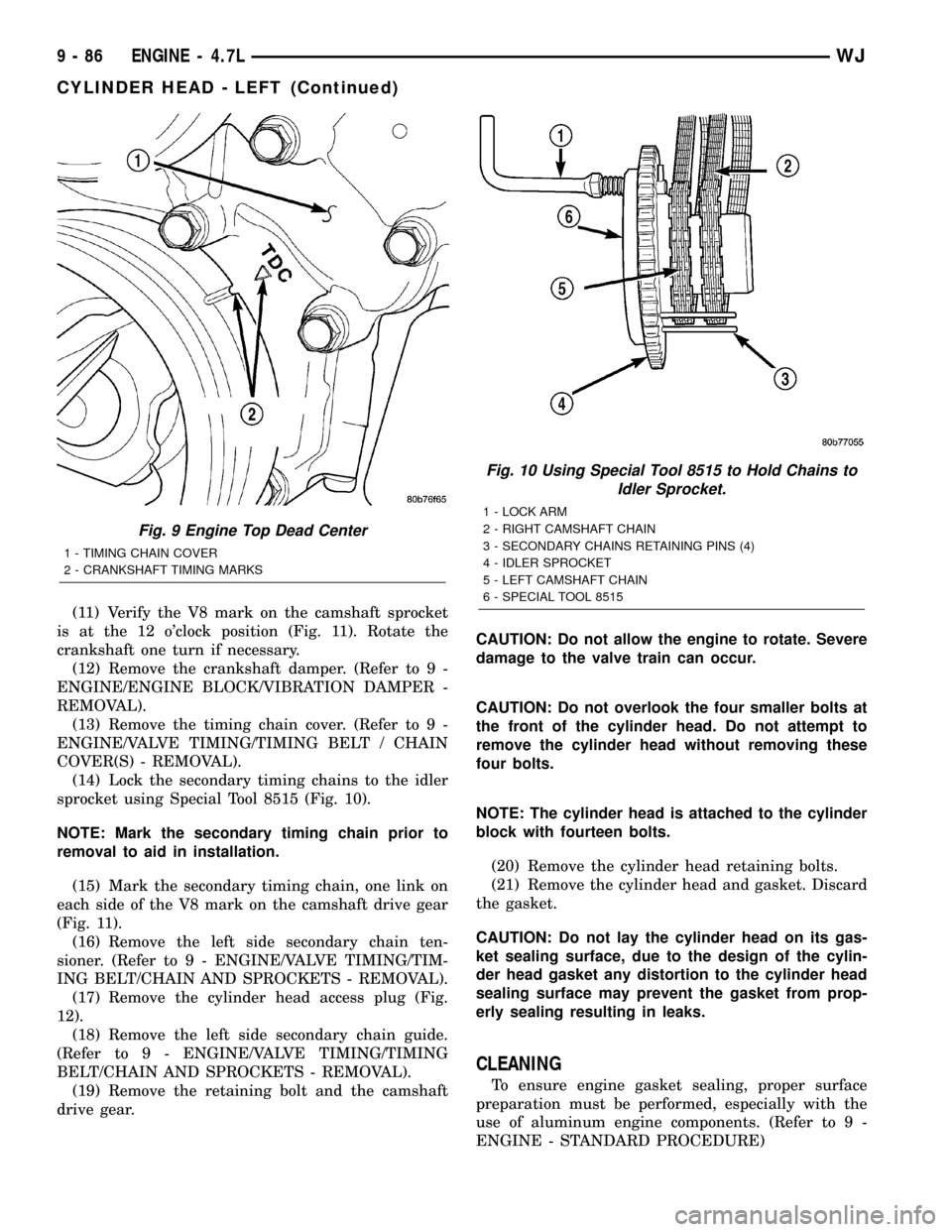

(11) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 11). Rotate the

crankshaft one turn if necessary.

(12) Remove the crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(13) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 10).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(15) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 11).

(16) Remove the left side secondary chain ten-

sioner. (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(17) Remove the cylinder head access plug (Fig.

12).

(18) Remove the left side secondary chain guide.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(19) Remove the retaining bolt and the camshaft

drive gear.CAUTION: Do not allow the engine to rotate. Severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

NOTE: The cylinder head is attached to the cylinder

block with fourteen bolts.

(20) Remove the cylinder head retaining bolts.

(21) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, due to the design of the cylin-

der head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

Fig. 9 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

Fig. 10 Using Special Tool 8515 to Hold Chains to

Idler Sprocket.

1 - LOCK ARM

2 - RIGHT CAMSHAFT CHAIN

3 - SECONDARY CHAINS RETAINING PINS (4)

4 - IDLER SPROCKET

5 - LEFT CAMSHAFT CHAIN

6 - SPECIAL TOOL 8515

9 - 86 ENGINE - 4.7LWJ

CYLINDER HEAD - LEFT (Continued)

Page 1332 of 2199

REMOVAL

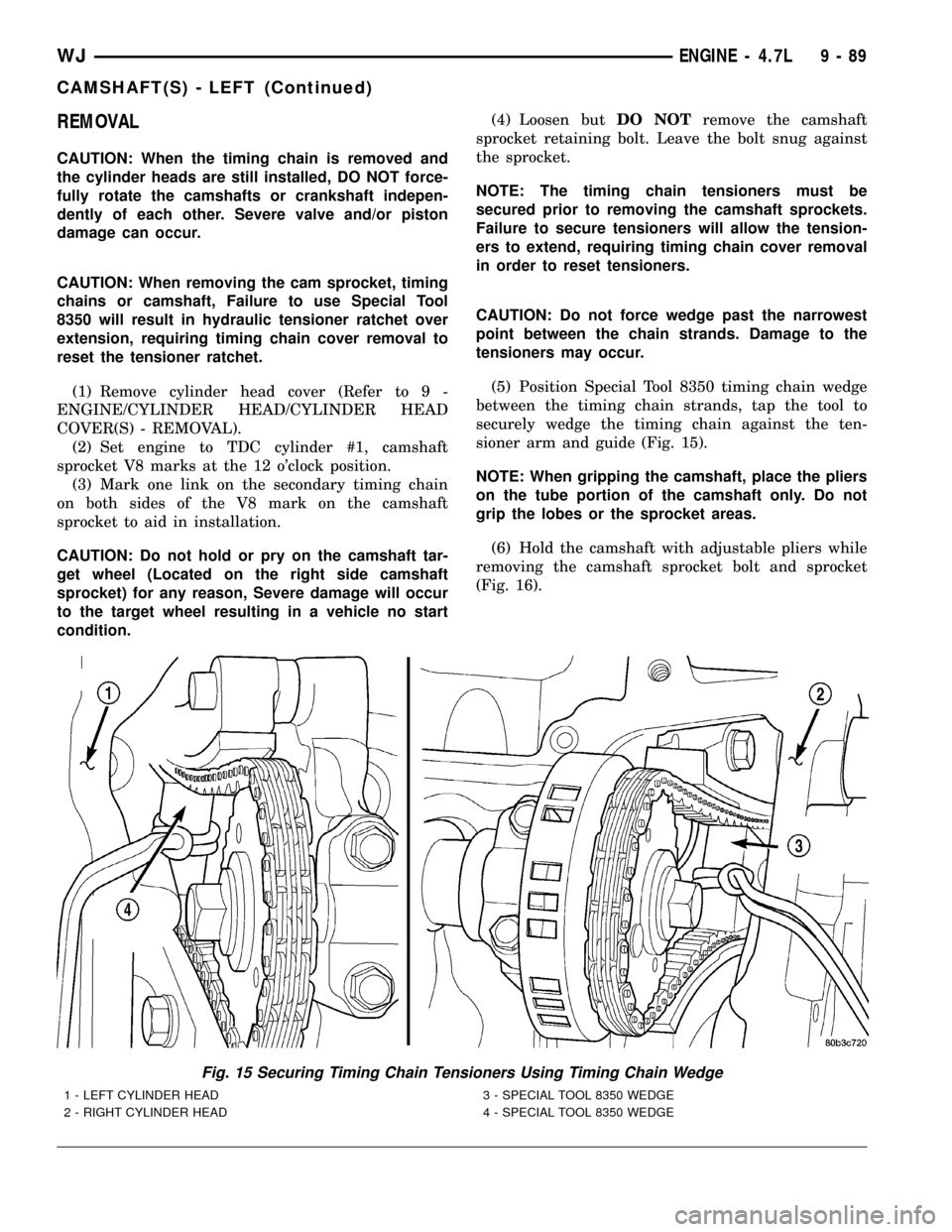

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use Special Tool

8350 will result in hydraulic tensioner ratchet over

extension, requiring timing chain cover removal to

reset the tensioner ratchet.

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Set engine to TDC cylinder #1, camshaft

sprocket V8 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V8 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel (Located on the right side camshaft

sprocket) for any reason, Severe damage will occur

to the target wheel resulting in a vehicle no start

condition.(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave the bolt snug against

the sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

(5) Position Special Tool 8350 timing chain wedge

between the timing chain strands, tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide (Fig. 15).

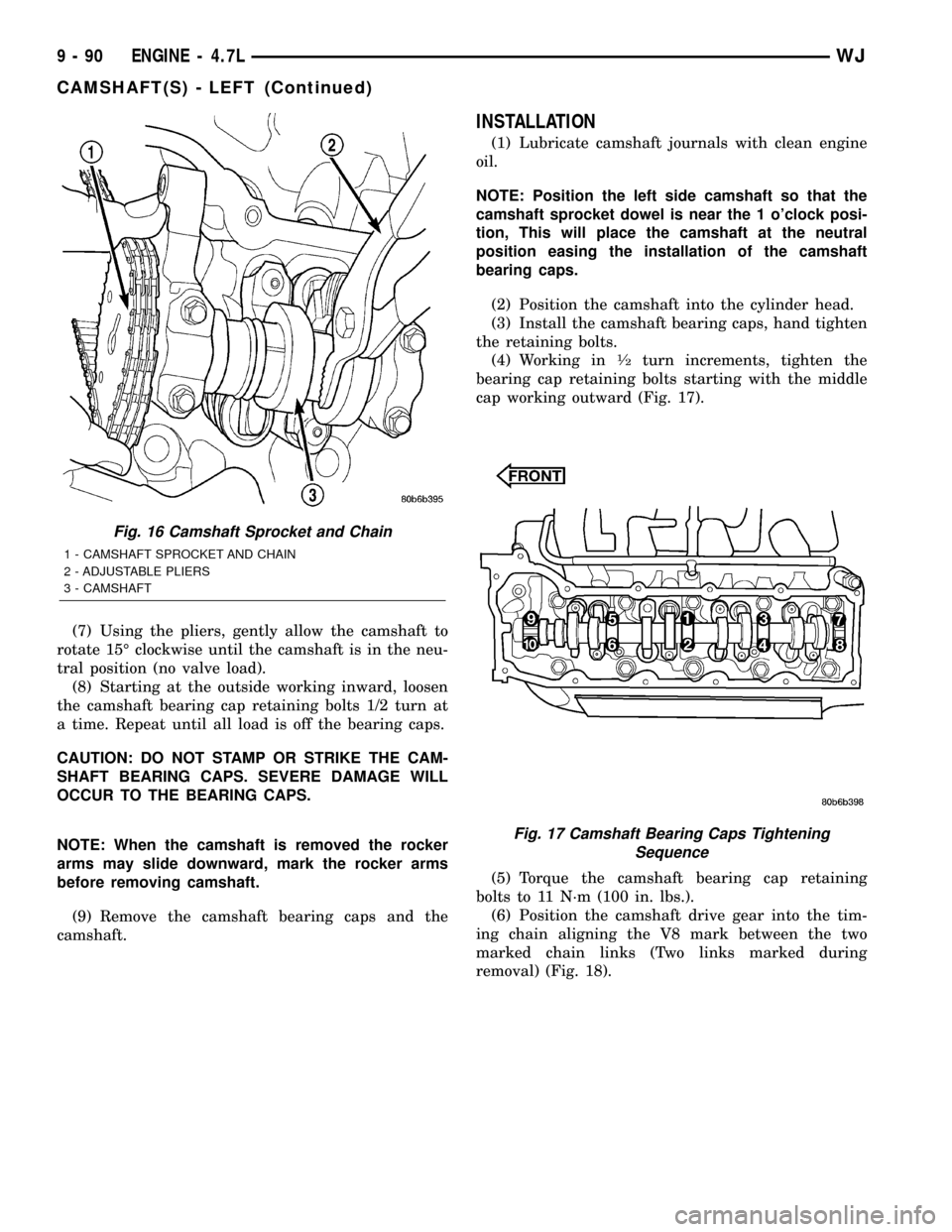

NOTE: When gripping the camshaft, place the pliers

on the tube portion of the camshaft only. Do not

grip the lobes or the sprocket areas.

(6) Hold the camshaft with adjustable pliers while

removing the camshaft sprocket bolt and sprocket

(Fig. 16).

Fig. 15 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD3 - SPECIAL TOOL 8350 WEDGE

4 - SPECIAL TOOL 8350 WEDGE

WJENGINE - 4.7L 9 - 89

CAMSHAFT(S) - LEFT (Continued)

Page 1333 of 2199

(7) Using the pliers, gently allow the camshaft to

rotate 15É clockwise until the camshaft is in the neu-

tral position (no valve load).

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(9) Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the left side camshaft so that the

camshaft sprocket dowel is near the 1 o'clock posi-

tion, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

(4) Working in

1¤2turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 17).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V8 mark between the two

marked chain links (Two links marked during

removal) (Fig. 18).

Fig. 16 Camshaft Sprocket and Chain

1 - CAMSHAFT SPROCKET AND CHAIN

2 - ADJUSTABLE PLIERS

3 - CAMSHAFT

Fig. 17 Camshaft Bearing Caps Tightening

Sequence

9 - 90 ENGINE - 4.7LWJ

CAMSHAFT(S) - LEFT (Continued)

Page 1338 of 2199

NOTE: All eight valve springs and valves are

removed in the same manner; this procedure only

covers one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.

NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

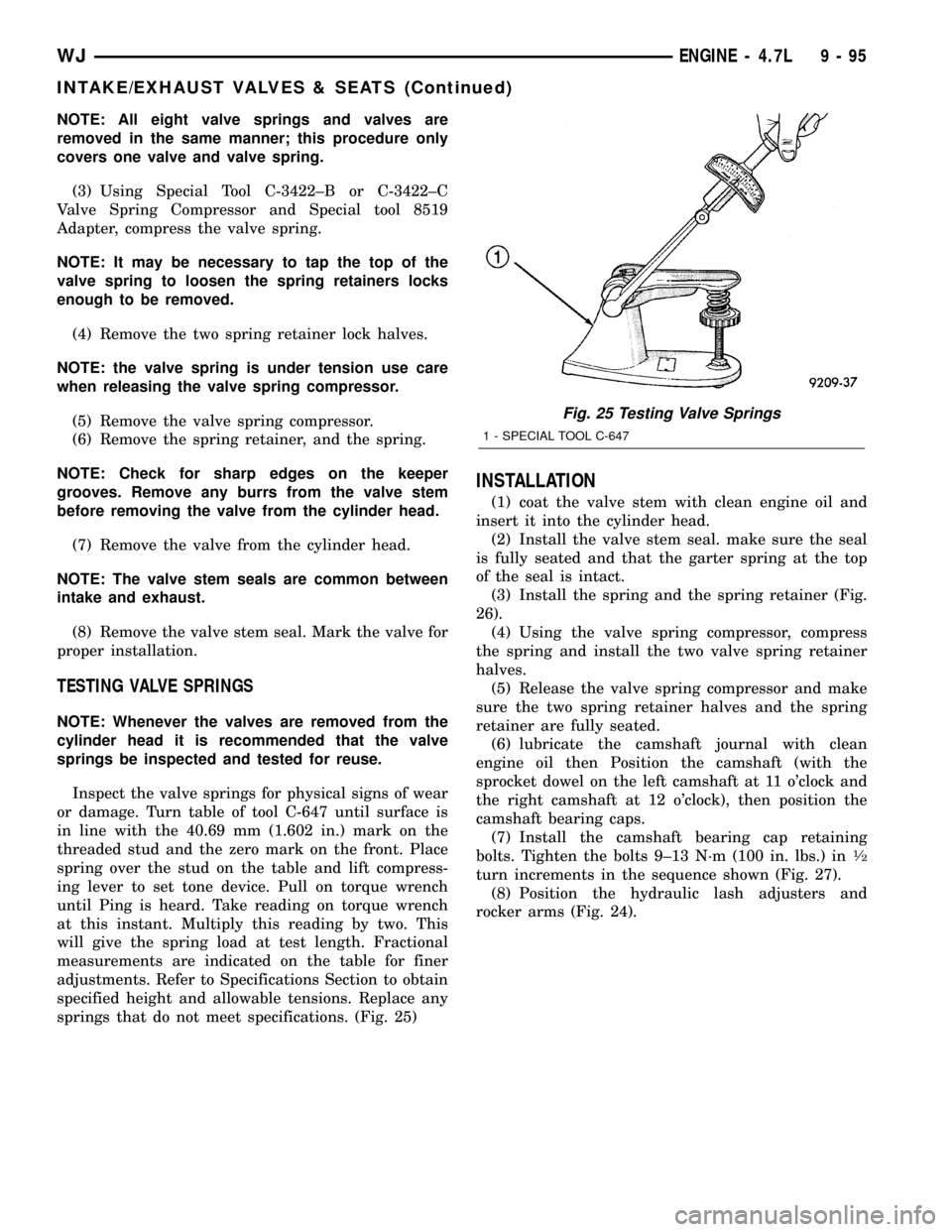

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.69 mm (1.602 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications. (Fig. 25)

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer (Fig.

26).

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves.

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.

(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9±13 N´m (100 in. lbs.) in

1¤2

turn increments in the sequence shown (Fig. 27).

(8) Position the hydraulic lash adjusters and

rocker arms (Fig. 24).

Fig. 25 Testing Valve Springs

1 - SPECIAL TOOL C-647

WJENGINE - 4.7L 9 - 95

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1341 of 2199

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

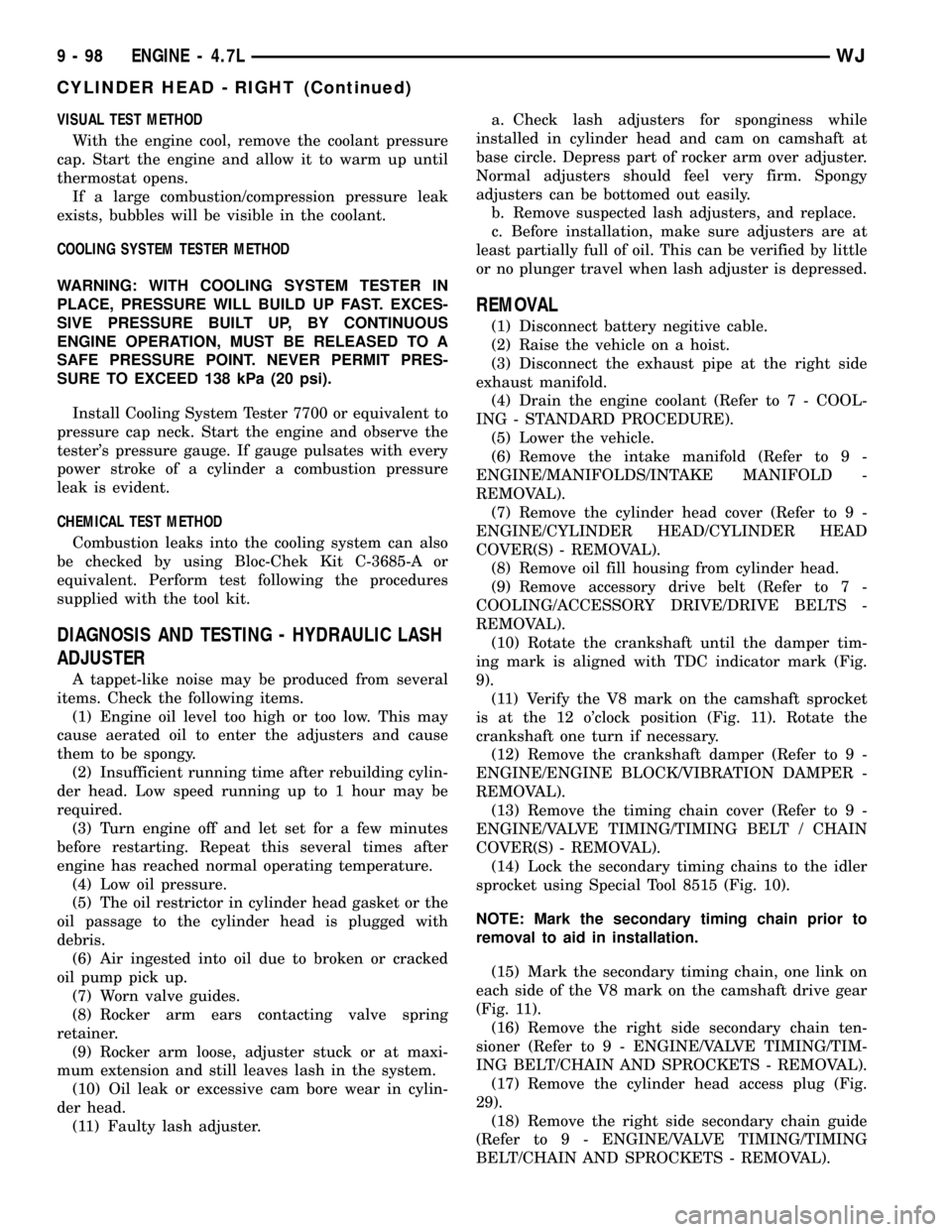

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

(1) Disconnect battery negitive cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(8) Remove oil fill housing from cylinder head.

(9) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

9).

(11) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 11). Rotate the

crankshaft one turn if necessary.

(12) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(13) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 10).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(15) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 11).

(16) Remove the right side secondary chain ten-

sioner (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(17) Remove the cylinder head access plug (Fig.

29).

(18) Remove the right side secondary chain guide

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

9 - 98 ENGINE - 4.7LWJ

CYLINDER HEAD - RIGHT (Continued)

Page 1343 of 2199

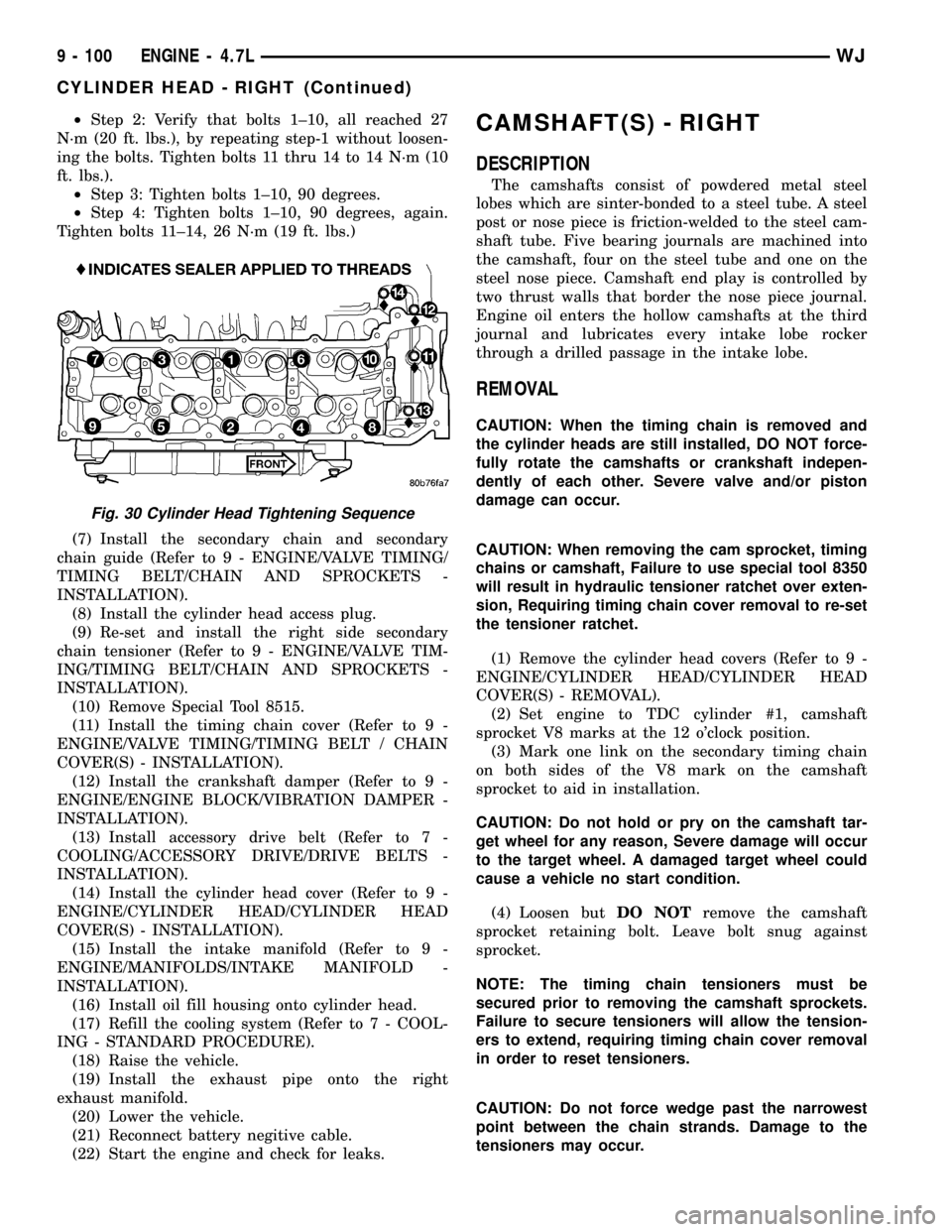

²Step 2: Verify that bolts 1±10, all reached 27

N´m (20 ft. lbs.), by repeating step-1 without loosen-

ing the bolts. Tighten bolts 11 thru 14 to 14 N´m (10

ft. lbs.).

²Step 3: Tighten bolts 1±10, 90 degrees.

²Step 4: Tighten bolts 1±10, 90 degrees, again.

Tighten bolts 11±14, 26 N´m (19 ft. lbs.)

(7) Install the secondary chain and secondary

chain guide (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(8) Install the cylinder head access plug.

(9) Re-set and install the right side secondary

chain tensioner (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(10) Remove Special Tool 8515.

(11) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(13) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(14) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(15) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(16) Install oil fill housing onto cylinder head.

(17) Refill the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(18) Raise the vehicle.

(19) Install the exhaust pipe onto the right

exhaust manifold.

(20) Lower the vehicle.

(21) Reconnect battery negitive cable.

(22) Start the engine and check for leaks.CAMSHAFT(S) - RIGHT

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. A steel

post or nose piece is friction-welded to the steel cam-

shaft tube. Five bearing journals are machined into

the camshaft, four on the steel tube and one on the

steel nose piece. Camshaft end play is controlled by

two thrust walls that border the nose piece journal.

Engine oil enters the hollow camshafts at the third

journal and lubricates every intake lobe rocker

through a drilled passage in the intake lobe.

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use special tool 8350

will result in hydraulic tensioner ratchet over exten-

sion, Requiring timing chain cover removal to re-set

the tensioner ratchet.

(1) Remove the cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Set engine to TDC cylinder #1, camshaft

sprocket V8 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V8 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will occur

to the target wheel. A damaged target wheel could

cause a vehicle no start condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave bolt snug against

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

Fig. 30 Cylinder Head Tightening Sequence

9 - 100 ENGINE - 4.7LWJ

CYLINDER HEAD - RIGHT (Continued)

Page 1344 of 2199

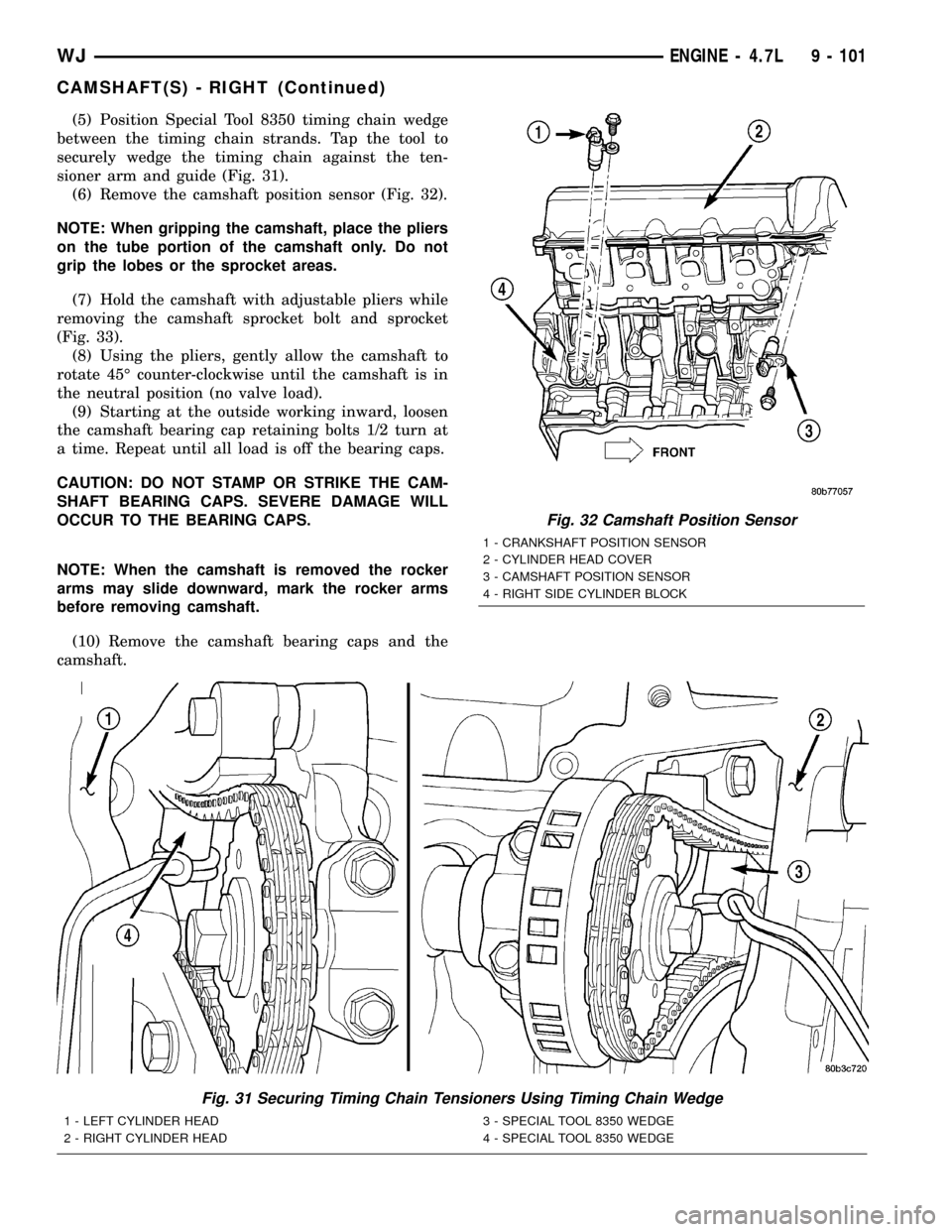

(5) Position Special Tool 8350 timing chain wedge

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide (Fig. 31).

(6) Remove the camshaft position sensor (Fig. 32).

NOTE: When gripping the camshaft, place the pliers

on the tube portion of the camshaft only. Do not

grip the lobes or the sprocket areas.

(7) Hold the camshaft with adjustable pliers while

removing the camshaft sprocket bolt and sprocket

(Fig. 33).

(8) Using the pliers, gently allow the camshaft to

rotate 45É counter-clockwise until the camshaft is in

the neutral position (no valve load).

(9) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(10) Remove the camshaft bearing caps and the

camshaft.

Fig. 31 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD3 - SPECIAL TOOL 8350 WEDGE

4 - SPECIAL TOOL 8350 WEDGE

Fig. 32 Camshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

WJENGINE - 4.7L 9 - 101

CAMSHAFT(S) - RIGHT (Continued)