Sensor location JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1459 of 2199

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

DESCRIPTION - 4.0L

The Crankshaft Position Sensor (CKP) is mounted

to the transmission bellhousing at the left/rear side

of the engine block (Fig. 17).

DESCRIPTION - 4.7L

The Crankshaft Position Sensor (CKP) is mounted

into the engine block above the starter motor (Fig.

18).

OPERATION

OPERATION - 4.0L

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along withother inputs, to determine injector sequence and igni-

tion timing.

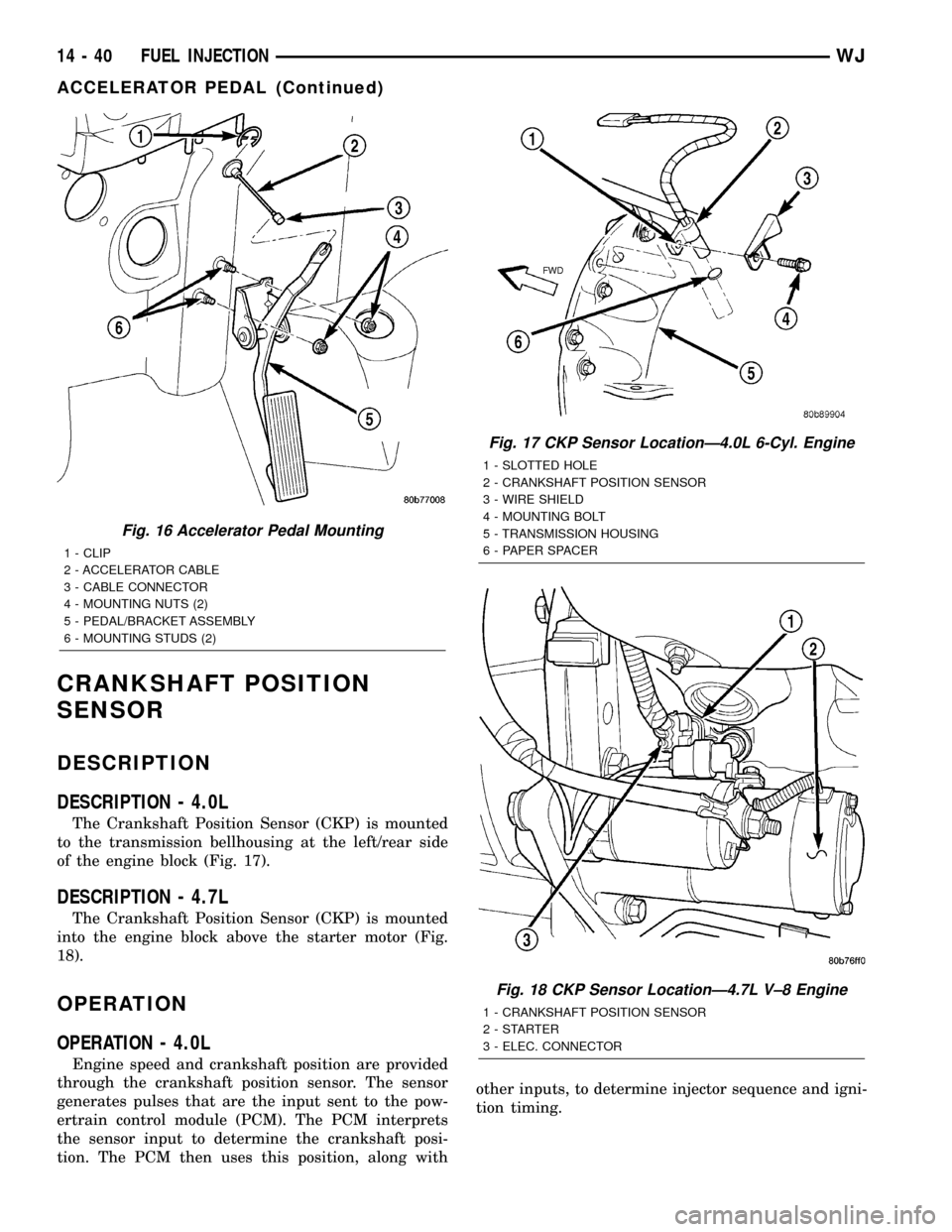

Fig. 16 Accelerator Pedal Mounting

1 - CLIP

2 - ACCELERATOR CABLE

3 - CABLE CONNECTOR

4 - MOUNTING NUTS (2)

5 - PEDAL/BRACKET ASSEMBLY

6 - MOUNTING STUDS (2)

Fig. 17 CKP Sensor LocationÐ4.0L 6-Cyl. Engine

1 - SLOTTED HOLE

2 - CRANKSHAFT POSITION SENSOR

3 - WIRE SHIELD

4 - MOUNTING BOLT

5 - TRANSMISSION HOUSING

6 - PAPER SPACER

Fig. 18 CKP Sensor LocationÐ4.7L V±8 Engine

1 - CRANKSHAFT POSITION SENSOR

2-STARTER

3 - ELEC. CONNECTOR

14 - 40 FUEL INJECTIONWJ

ACCELERATOR PEDAL (Continued)

Page 1461 of 2199

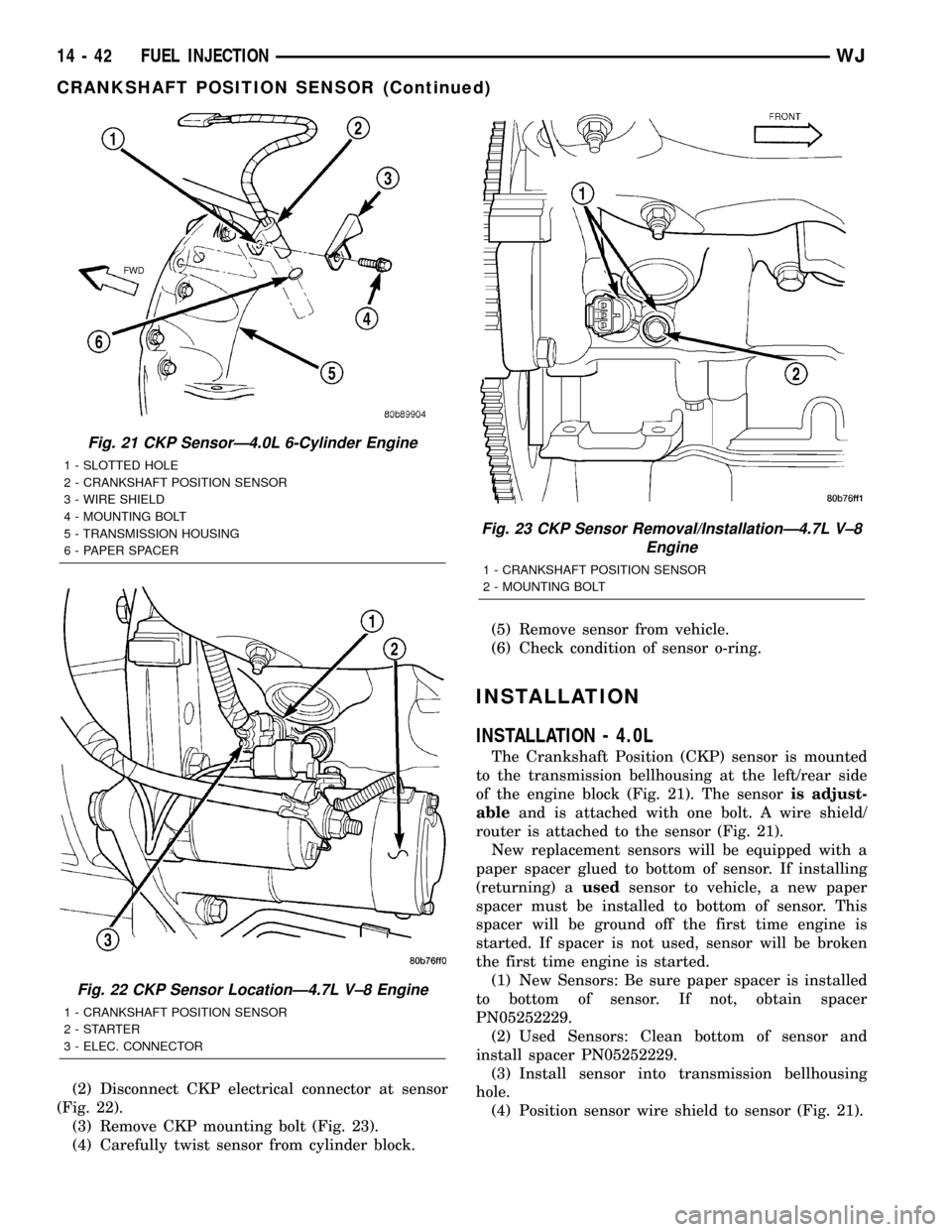

(2) Disconnect CKP electrical connector at sensor

(Fig. 22).

(3) Remove CKP mounting bolt (Fig. 23).

(4) Carefully twist sensor from cylinder block.(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

INSTALLATION

INSTALLATION - 4.0L

The Crankshaft Position (CKP) sensor is mounted

to the transmission bellhousing at the left/rear side

of the engine block (Fig. 21). The sensoris adjust-

ableand is attached with one bolt. A wire shield/

router is attached to the sensor (Fig. 21).

New replacement sensors will be equipped with a

paper spacer glued to bottom of sensor. If installing

(returning) ausedsensor to vehicle, a new paper

spacer must be installed to bottom of sensor. This

spacer will be ground off the first time engine is

started. If spacer is not used, sensor will be broken

the first time engine is started.

(1) New Sensors: Be sure paper spacer is installed

to bottom of sensor. If not, obtain spacer

PN05252229.

(2) Used Sensors: Clean bottom of sensor and

install spacer PN05252229.

(3) Install sensor into transmission bellhousing

hole.

(4) Position sensor wire shield to sensor (Fig. 21).

Fig. 21 CKP SensorÐ4.0L 6-Cylinder Engine

1 - SLOTTED HOLE

2 - CRANKSHAFT POSITION SENSOR

3 - WIRE SHIELD

4 - MOUNTING BOLT

5 - TRANSMISSION HOUSING

6 - PAPER SPACER

Fig. 22 CKP Sensor LocationÐ4.7L V±8 Engine

1 - CRANKSHAFT POSITION SENSOR

2-STARTER

3 - ELEC. CONNECTOR

Fig. 23 CKP Sensor Removal/InstallationÐ4.7L V±8

Engine

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

14 - 42 FUEL INJECTIONWJ

CRANKSHAFT POSITION SENSOR (Continued)

Page 1465 of 2199

INSTALLATION

INSTALLATION - 4.0L

The IAC motor is located on the throttle body.

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner duct/air box to throttle body.

INSTALLATION - 4.7L

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air duct/air box to throttle body.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:

²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

REMOVAL

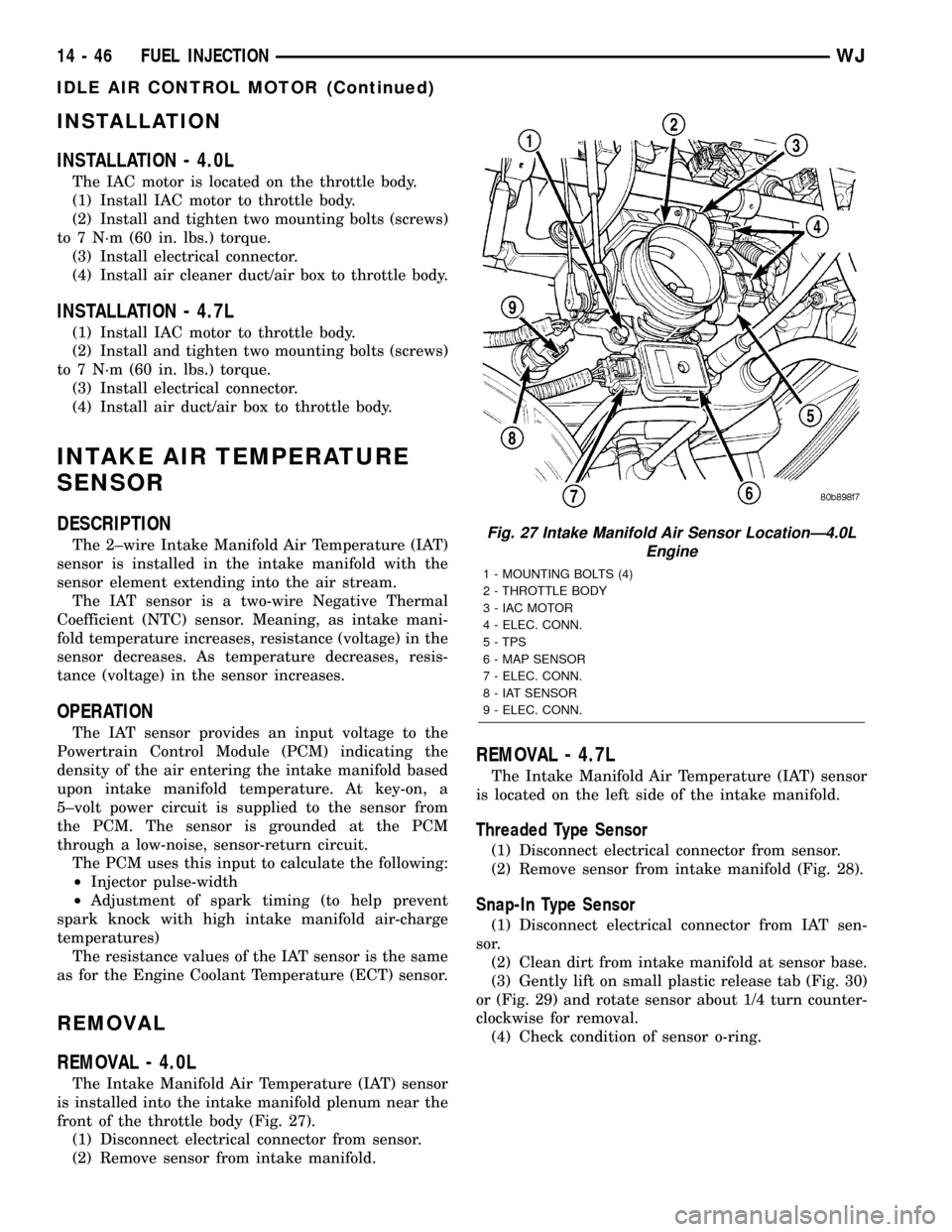

REMOVAL - 4.0L

The Intake Manifold Air Temperature (IAT) sensor

is installed into the intake manifold plenum near the

front of the throttle body (Fig. 27).

(1) Disconnect electrical connector from sensor.

(2) Remove sensor from intake manifold.

REMOVAL - 4.7L

The Intake Manifold Air Temperature (IAT) sensor

is located on the left side of the intake manifold.

Threaded Type Sensor

(1) Disconnect electrical connector from sensor.

(2) Remove sensor from intake manifold (Fig. 28).

Snap-In Type Sensor

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 30)

or (Fig. 29) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

Fig. 27 Intake Manifold Air Sensor LocationÐ4.0L

Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

14 - 46 FUEL INJECTIONWJ

IDLE AIR CONTROL MOTOR (Continued)

Page 1468 of 2199

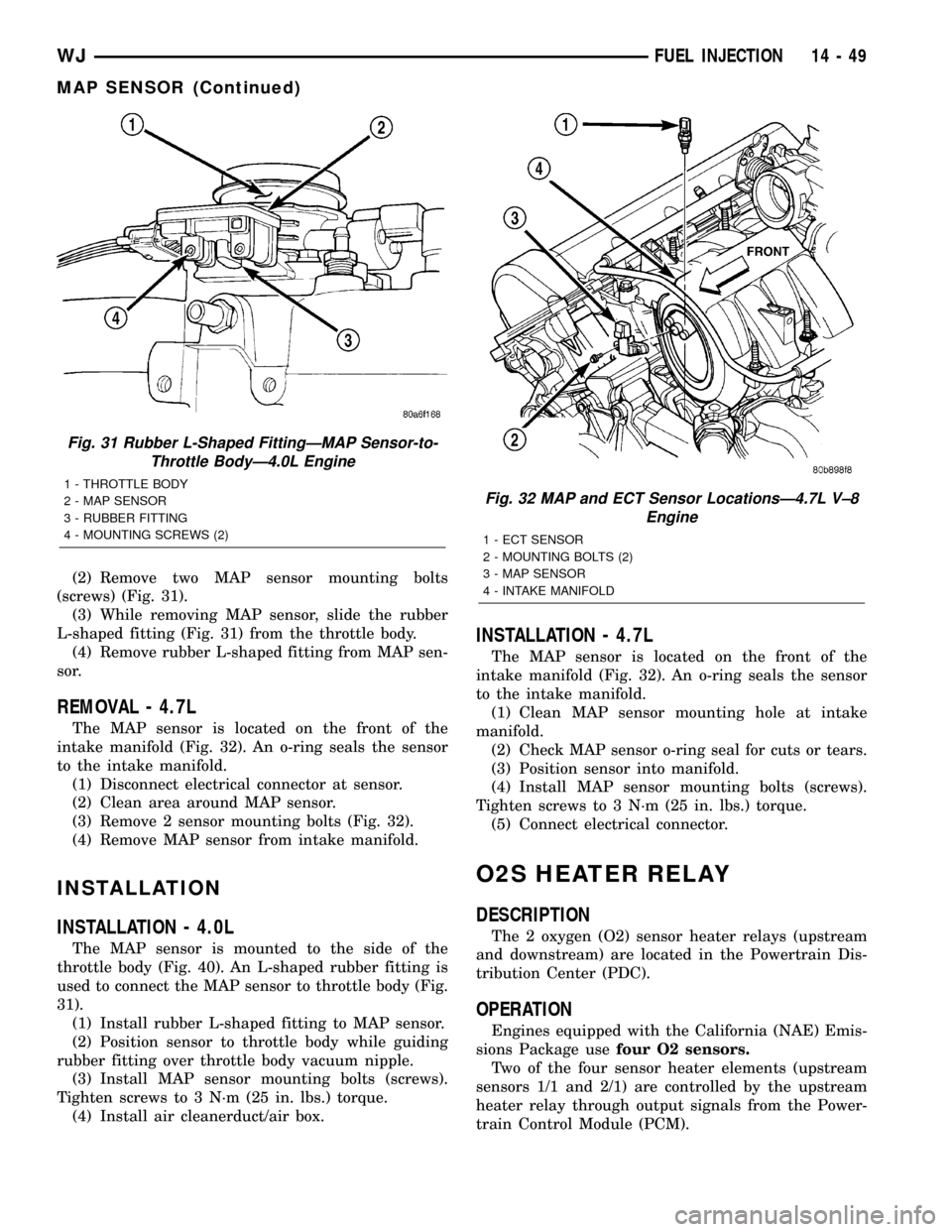

(2) Remove two MAP sensor mounting bolts

(screws) (Fig. 31).

(3) While removing MAP sensor, slide the rubber

L-shaped fitting (Fig. 31) from the throttle body.

(4) Remove rubber L-shaped fitting from MAP sen-

sor.

REMOVAL - 4.7L

The MAP sensor is located on the front of the

intake manifold (Fig. 32). An o-ring seals the sensor

to the intake manifold.

(1) Disconnect electrical connector at sensor.

(2) Clean area around MAP sensor.

(3) Remove 2 sensor mounting bolts (Fig. 32).

(4) Remove MAP sensor from intake manifold.

INSTALLATION

INSTALLATION - 4.0L

The MAP sensor is mounted to the side of the

throttle body (Fig. 40). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

31).

(1) Install rubber L-shaped fitting to MAP sensor.

(2) Position sensor to throttle body while guiding

rubber fitting over throttle body vacuum nipple.

(3) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(4) Install air cleanerduct/air box.

INSTALLATION - 4.7L

The MAP sensor is located on the front of the

intake manifold (Fig. 32). An o-ring seals the sensor

to the intake manifold.

(1) Clean MAP sensor mounting hole at intake

manifold.

(2) Check MAP sensor o-ring seal for cuts or tears.

(3) Position sensor into manifold.

(4) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(5) Connect electrical connector.

O2S HEATER RELAY

DESCRIPTION

The 2 oxygen (O2) sensor heater relays (upstream

and downstream) are located in the Powertrain Dis-

tribution Center (PDC).

OPERATION

Engines equipped with the California (NAE) Emis-

sions Package usefour O2 sensors.

Two of the four sensor heater elements (upstream

sensors 1/1 and 2/1) are controlled by the upstream

heater relay through output signals from the Power-

train Control Module (PCM).

Fig. 31 Rubber L-Shaped FittingÐMAP Sensor-to-

Throttle BodyÐ4.0L Engine

1 - THROTTLE BODY

2 - MAP SENSOR

3 - RUBBER FITTING

4 - MOUNTING SCREWS (2)Fig. 32 MAP and ECT Sensor LocationsÐ4.7L V±8

Engine

1 - ECT SENSOR

2 - MOUNTING BOLTS (2)

3 - MAP SENSOR

4 - INTAKE MANIFOLD

WJFUEL INJECTION 14 - 49

MAP SENSOR (Continued)

Page 1470 of 2199

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

on preprogrammed (fixed) values and inputs from

other sensors.

Upstream Sensor (Non-California Emissions):

The upstream sensor (1/1) provides an input voltage

to the PCM. The input tells the PCM the oxygen con-

tent of the exhaust gas. The PCM uses this informa-

tion to fine tune fuel delivery to maintain the correct

oxygen content at the downstream oxygen sensor.

The PCM will change the air/fuel ratio until the

upstream sensor inputs a voltage that the PCM has

determined will make the downstream sensor output

(oxygen content) correct.

The upstream oxygen sensor also provides an input

to determine catalytic convertor efficiency.

Downstream Sensor (Non-California Emis-

sions):The downstream oxygen sensor (1/2) is also

used to determine the correct air-fuel ratio. As the

oxygen content changes at the downstream sensor,

the PCM calculates how much air-fuel ratio change is

required. The PCM then looks at the upstream oxy-

gen sensor voltage and changes fuel delivery until

the upstream sensor voltage changes enough to cor-

rect the downstream sensor voltage (oxygen content).

The downstream oxygen sensor also provides an

input to determine catalytic convertor efficiency.

Upstream Sensors (California Engines):Tw o

upstream sensors are used (1/1 and 2/1). The 1/1 sen-

sor is the first sensor to receive exhaust gases from

the #1 cylinder. They provide an input voltage to the

PCM. The input tells the PCM the oxygen content of

the exhaust gas. The PCM uses this information to

fine tune fuel delivery to maintain the correct oxygen

content at the downstream oxygen sensors. The PCM

will change the air/fuel ratio until the upstream sen-

sors input a voltage that the PCM has determined

will make the downstream sensors output (oxygen

content) correct.

The upstream oxygen sensors also provide an input

to determine mini-catalyst efficiency. Main catalytic

convertor efficiency is not calculated with this pack-

age.

Downstream Sensors (California Engines):

Two downstream sensors are used (1/2 and 2/2). The

downstream sensors are used to determine the cor-

rect air-fuel ratio. As the oxygen content changes at

the downstream sensor, the PCM calculates how

much air-fuel ratio change is required. The PCM

then looks at the upstream oxygen sensor voltage,

and changes fuel delivery until the upstream sensor

voltage changes enough to correct the downstream

sensor voltage (oxygen content).The downstream oxygen sensors also provide an

input to determine mini-catalyst efficiency. Main cat-

alytic convertor efficiency is not calculated with this

package.

Engines equipped with either a downstream sen-

sor(s), or a post-catalytic sensor, will monitor cata-

lytic convertor efficiency. If efficiency is below

emission standards, the Malfunction Indicator Lamp

(MIL) will be illuminated and a Diagnostic Trouble

Code (DTC) will be set. Refer to Monitored Systems

in Emission Control Systems for additional informa-

tion.

REMOVAL

Never apply any type of grease to the oxygen

sensor electrical connector, or attempt any sol-

dering of the sensor wiring harness.

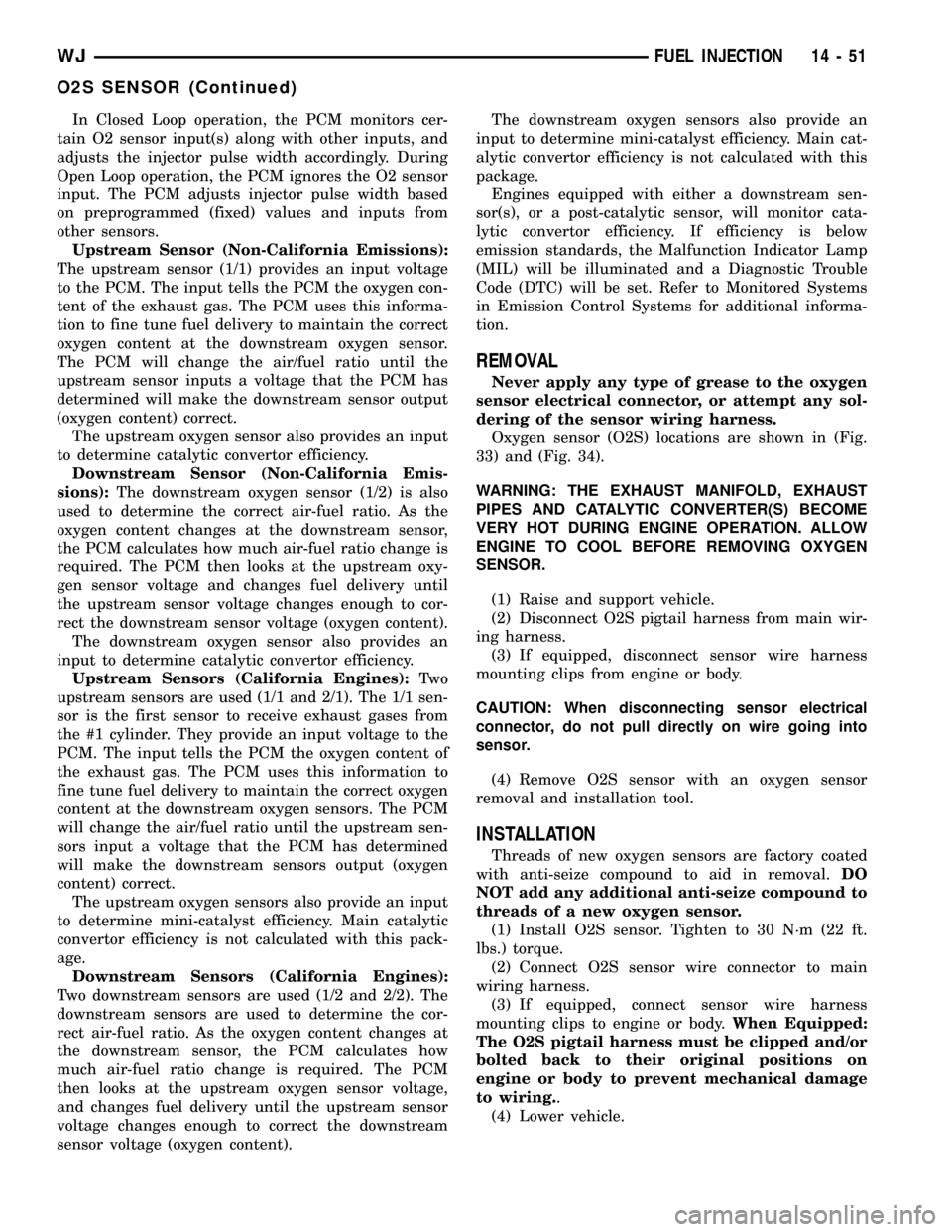

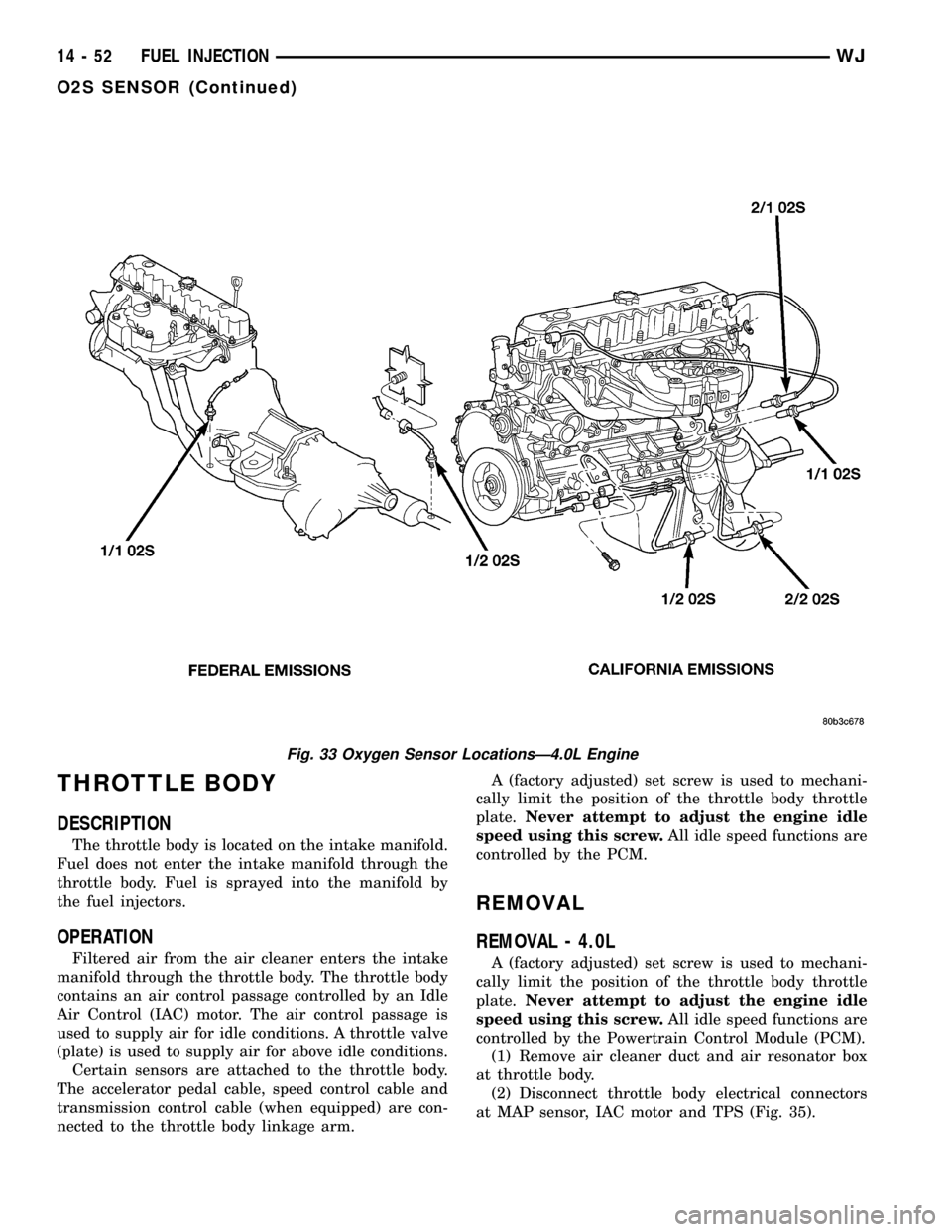

Oxygen sensor (O2S) locations are shown in (Fig.

33) and (Fig. 34).

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER(S) BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support vehicle.

(2) Disconnect O2S pigtail harness from main wir-

ing harness.

(3) If equipped, disconnect sensor wire harness

mounting clips from engine or body.

CAUTION: When disconnecting sensor electrical

connector, do not pull directly on wire going into

sensor.

(4) Remove O2S sensor with an oxygen sensor

removal and installation tool.

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector to main

wiring harness.

(3) If equipped, connect sensor wire harness

mounting clips to engine or body.When Equipped:

The O2S pigtail harness must be clipped and/or

bolted back to their original positions on

engine or body to prevent mechanical damage

to wiring..

(4) Lower vehicle.

WJFUEL INJECTION 14 - 51

O2S SENSOR (Continued)

Page 1471 of 2199

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

REMOVAL - 4.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

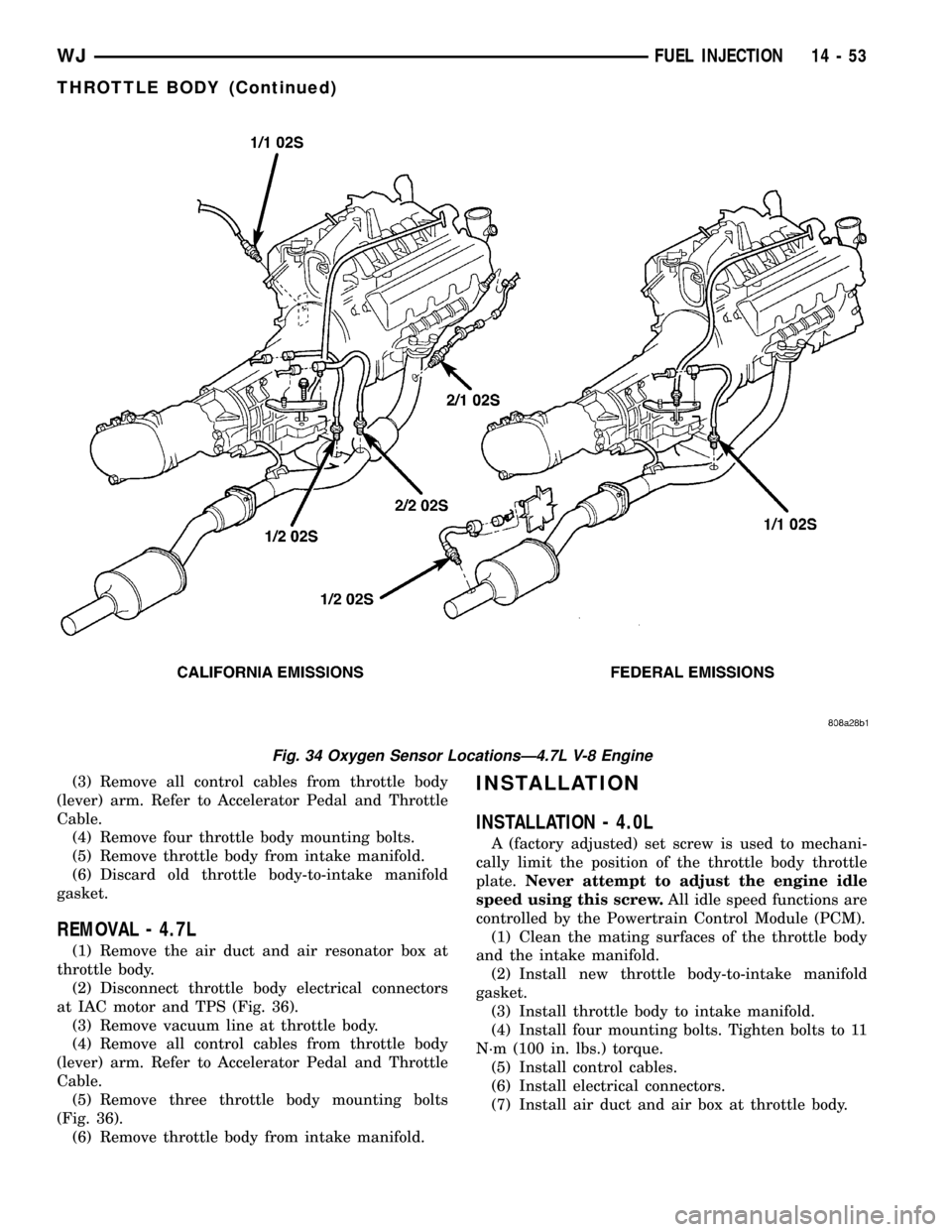

(1) Remove air cleaner duct and air resonator box

at throttle body.

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 35).

Fig. 33 Oxygen Sensor LocationsÐ4.0L Engine

14 - 52 FUEL INJECTIONWJ

O2S SENSOR (Continued)

Page 1472 of 2199

(3) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(4) Remove four throttle body mounting bolts.

(5) Remove throttle body from intake manifold.

(6) Discard old throttle body-to-intake manifold

gasket.

REMOVAL - 4.7L

(1) Remove the air duct and air resonator box at

throttle body.

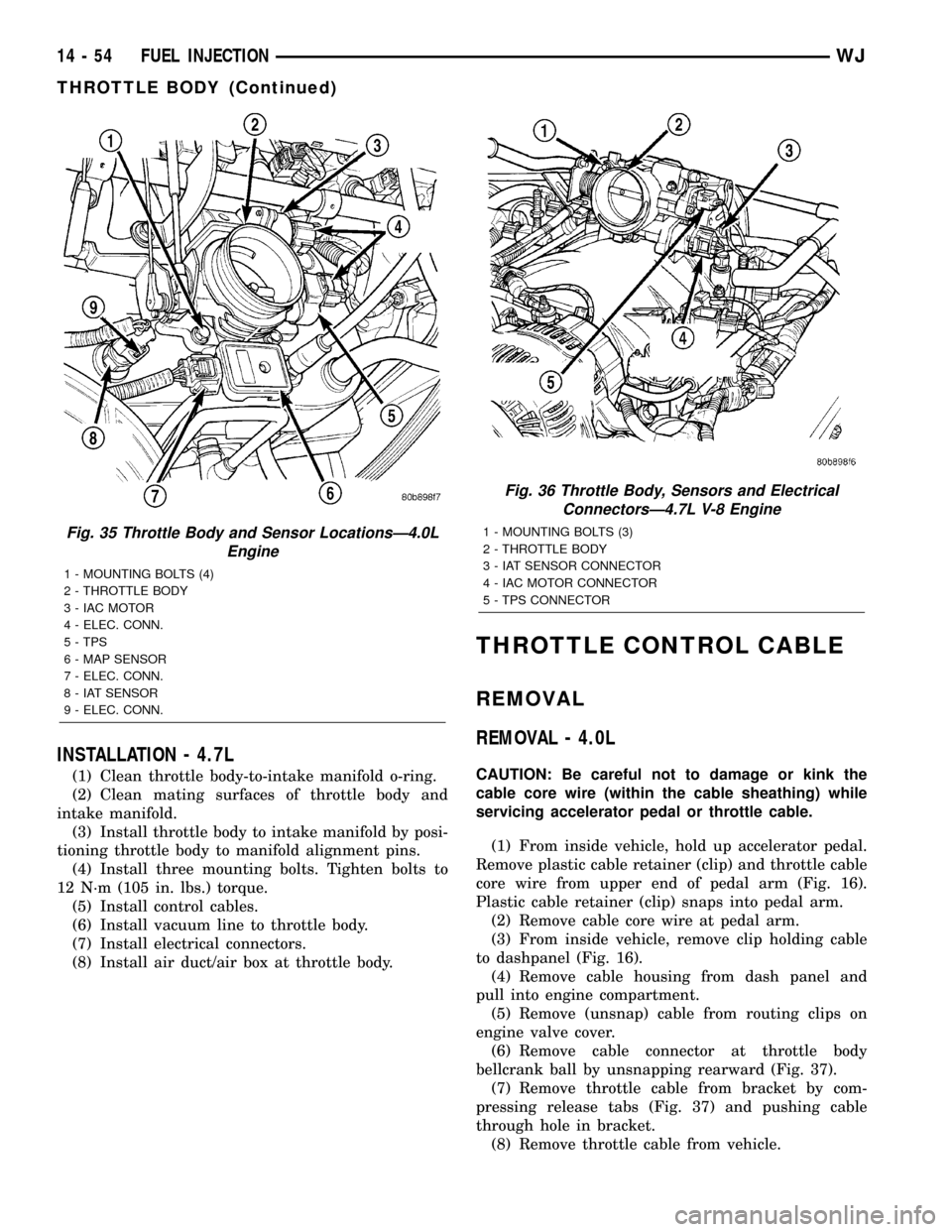

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 36).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 36).

(6) Remove throttle body from intake manifold.

INSTALLATION

INSTALLATION - 4.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 11

N´m (100 in. lbs.) torque.

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air duct and air box at throttle body.

Fig. 34 Oxygen Sensor LocationsÐ4.7L V-8 Engine

WJFUEL INJECTION 14 - 53

THROTTLE BODY (Continued)

Page 1473 of 2199

INSTALLATION - 4.7L

(1) Clean throttle body-to-intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install three mounting bolts. Tighten bolts to

12 N´m (105 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air duct/air box at throttle body.

THROTTLE CONTROL CABLE

REMOVAL

REMOVAL - 4.0L

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 16).

Plastic cable retainer (clip) snaps into pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove clip holding cable

to dashpanel (Fig. 16).

(4) Remove cable housing from dash panel and

pull into engine compartment.

(5) Remove (unsnap) cable from routing clips on

engine valve cover.

(6) Remove cable connector at throttle body

bellcrank ball by unsnapping rearward (Fig. 37).

(7) Remove throttle cable from bracket by com-

pressing release tabs (Fig. 37) and pushing cable

through hole in bracket.

(8) Remove throttle cable from vehicle.

Fig. 35 Throttle Body and Sensor LocationsÐ4.0L

Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

Fig. 36 Throttle Body, Sensors and Electrical

ConnectorsÐ4.7L V-8 Engine

1 - MOUNTING BOLTS (3)

2 - THROTTLE BODY

3 - IAT SENSOR CONNECTOR

4 - IAC MOTOR CONNECTOR

5 - TPS CONNECTOR

14 - 54 FUEL INJECTIONWJ

THROTTLE BODY (Continued)

Page 1549 of 2199

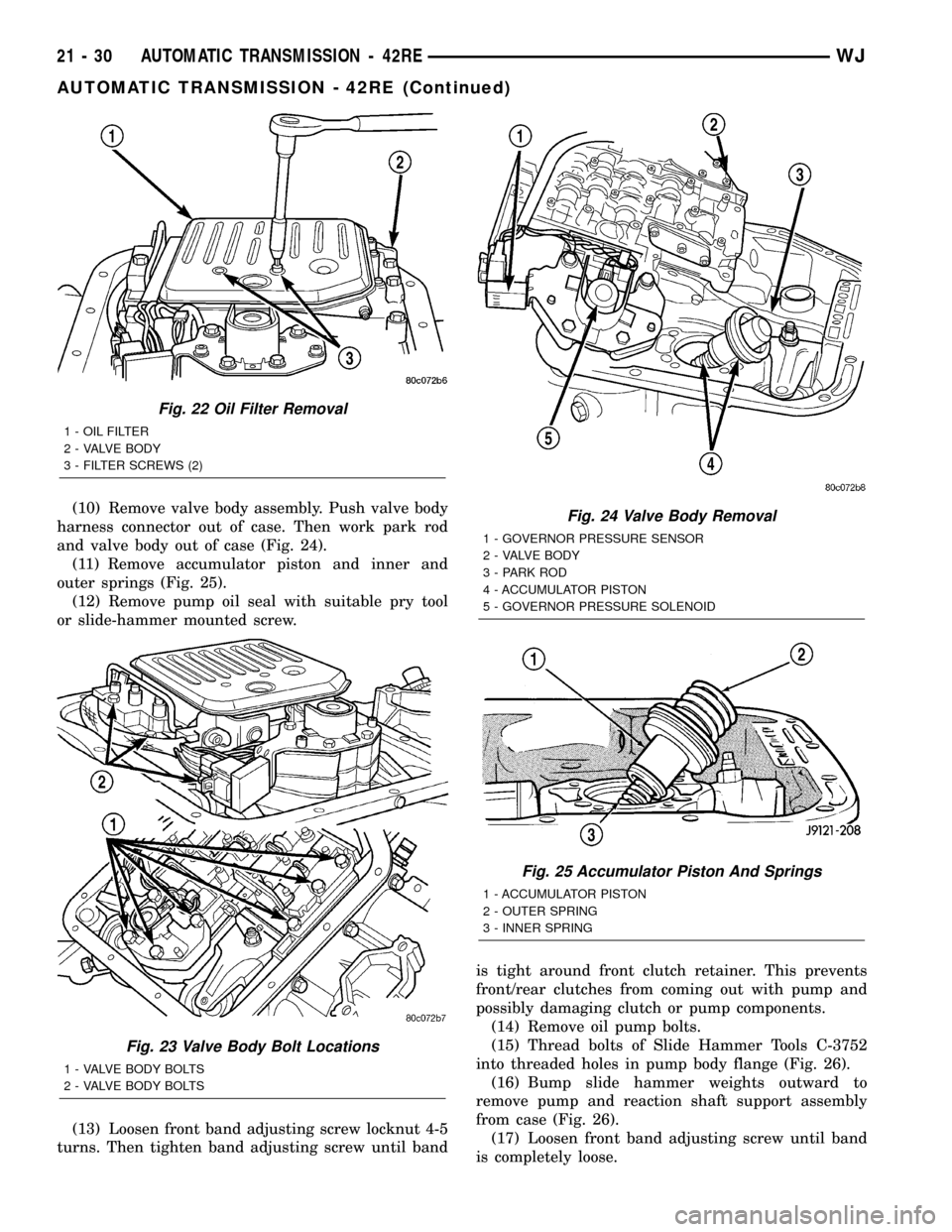

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 24).

(11) Remove accumulator piston and inner and

outer springs (Fig. 25).

(12) Remove pump oil seal with suitable pry tool

or slide-hammer mounted screw.

(13) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until bandis tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

(14) Remove oil pump bolts.

(15) Thread bolts of Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 26).

(16) Bump slide hammer weights outward to

remove pump and reaction shaft support assembly

from case (Fig. 26).

(17) Loosen front band adjusting screw until band

is completely loose.

Fig. 22 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 23 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 24 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

Fig. 25 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

21 - 30 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1607 of 2199

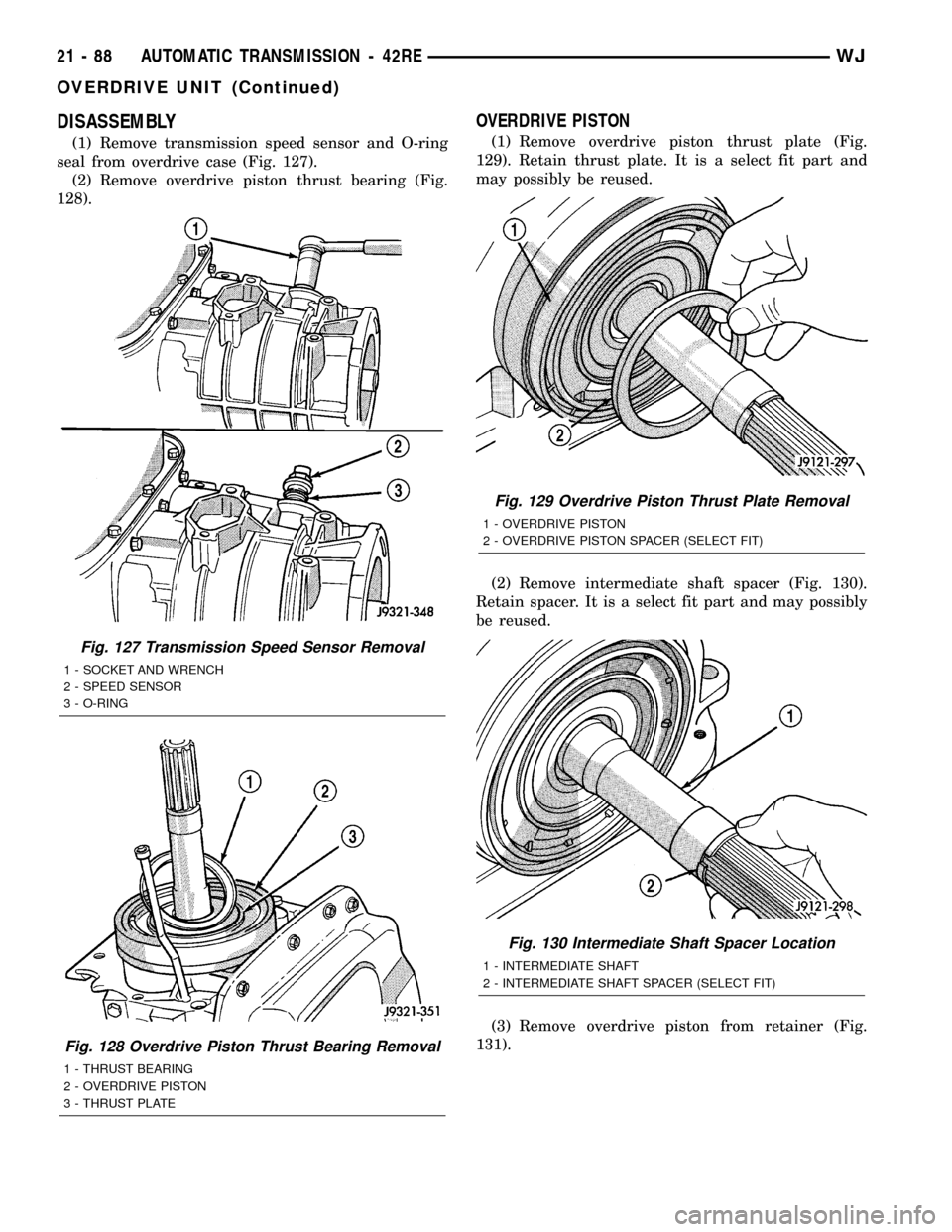

DISASSEMBLY

(1) Remove transmission speed sensor and O-ring

seal from overdrive case (Fig. 127).

(2) Remove overdrive piston thrust bearing (Fig.

128).

OVERDRIVE PISTON

(1) Remove overdrive piston thrust plate (Fig.

129). Retain thrust plate. It is a select fit part and

may possibly be reused.

(2) Remove intermediate shaft spacer (Fig. 130).

Retain spacer. It is a select fit part and may possibly

be reused.

(3) Remove overdrive piston from retainer (Fig.

131).

Fig. 127 Transmission Speed Sensor Removal

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

Fig. 128 Overdrive Piston Thrust Bearing Removal

1 - THRUST BEARING

2 - OVERDRIVE PISTON

3 - THRUST PLATE

Fig. 129 Overdrive Piston Thrust Plate Removal

1 - OVERDRIVE PISTON

2 - OVERDRIVE PISTON SPACER (SELECT FIT)

Fig. 130 Intermediate Shaft Spacer Location

1 - INTERMEDIATE SHAFT

2 - INTERMEDIATE SHAFT SPACER (SELECT FIT)

21 - 88 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)