warning light JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1955 of 2199

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

OPERATION

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISHING

DESCRIPTION

CAUTION: Do not remove more than .5 mils of

clearcoat finish, if equipped. Base coat paint must

retain clear coat for durability.

Use a Paint Thickness Gauge #PR-ETG-2X or equiv-

alent to determine film thickness before and after

the repair.

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

23 - 82 PAINTWJ

Page 1969 of 2199

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION.........................96

DIAGNOSIS AND TESTING - SUNROOF......96

DRAIN TUBE

REMOVAL............................100

INSTALLATION........................100

CONTROL MODULE

REMOVAL............................101

INSTALLATION........................101

DRIVE MOTOR

REMOVAL............................101

INSTALLATION........................101

WIND DEFLECTOR

REMOVAL............................102INSTALLATION........................102

GLASS PANEL

REMOVAL............................102

INSTALLATION........................103

ADJUSTMENTS

ADJUSTMENTS - FIT.................103

ADJUSTMENT - TIMING...............103

SUNSHADE

REMOVAL............................103

INSTALLATION........................103

HOUSING ASSEMBLY

REMOVAL............................104

INSTALLATION........................104

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sunroof features a power sliding glass panel

and a sunshade which can be manually positioned

anywhere along its travel, rearward of glass panel

front edge.

The sunroof is electrically operated from a switch

located on the mini overhead console. To operate the

sunroof the ignition switch must be in the On/Run

position. The sunroof has both manual and Express

Open modes of operation when opening. To open the

sunroof in the Express Open mode, the switch is

pressed rearward for less than1 second.This causes

the sunroof glass to automatically retract and stop at

a position slightly forward of full open that reduces

low speed wind buffeting. The sunroof can also be

opened manually by pressing and holding the switch

rearward. Once the switch is held reward for more

than1 second,the glass will retract in the manual

mode. Releasing the switch at any time during travel

will cause the sunroof to stop at the current position.

To close the sunroof from an open position, the

switch must be pushed forward and held until the

sunroof glass comes to a complete stop. Releasing the

switch at any time in this mode will cause the sun-

roof to stop at the current position.

To vent the sunroof from the closed position, the

switch is pushed forward and held. Releasing theswitch at any time during travel will cause the sun-

roof to stop at the current vent position. To reach the

fully vented position, continue to hold the switch for-

ward until vent motion stops. To close the sunroof

from the vent position, push and hold the switch

rearward until the glass comes to a complete stop.

DIAGNOSIS AND TESTING - SUNROOF

CAUTION: The sunroof motor is only to be powered

through the vehicle battery and vehicle wire har-

ness. Applying power to the sunroof motor leads

will cause failure of the sunroof control unit.

Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating con-

dition. Refer to Sunroof Diagnostic Chart for possible

causes. If not, a common electrical problem may

exist. Refer to Group 8W, Wiring Diagrams, of this

publication for circuit, splice and component descrip-

tions. Check the condition of the circuit protection

(20 amp high current fuse (battery feed) located in

the Power Distribution Center (PDC). Check the

cover of the PDC for location of the fuse. Check for

correct operation of the sunroof delay relay. Inspect

all wiring connector pins for proper engagement and

continuity. Check for battery voltage at battery and

ignition pins of the power sunroof express module

wiring connector. Refer to Group 8W, Wiring Dia-

grams, for circuit information. The controller will not

operate at less than 10 volts. Check the ground at

the sunroof express module.

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

23 - 96 SUNROOFWJ

Page 2129 of 2199

VISCOUS HEATER

DESCRIPTION

DESCRIPTION........................76

DESCRIPTION - VISCOUS HEATER

CLUTCH............................76

OPERATION

OPERATION - VISCOUS HEATER.........76

OPERATION - VISCOUS HEATER CLUTCH . . 76REMOVAL

REMOVAL - VISCOUS HEATER...........76

REMOVAL - VISCOUS HEATER CLUTCH . . . 76

INSTALLATION

INSTALLATION.......................78

INSTALLATION - VISCOUS HEATER

CLUTCH............................78

PLUMBING

DESCRIPTION - REFRIGERANT LINE

The refrigerant lines and hoses are used to carry

the refrigerant between the various air conditioning

system components. A barrier hose design with a

nylon tube, which is sandwiched between rubber lay-

ers, is used for the R-134a air conditioning system on

this vehicle. This nylon tube helps to further contain

the R-134a refrigerant, which has a smaller molecu-

lar structure than R-12 refrigerant. The ends of the

refrigerant hoses are made from lightweight alumi-

num or steel, and commonly use braze-less fittings.

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

OPERATION - REFRIGERANT LINE

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

The refrigerant lines and hoses cannot be repaired

and, if faulty or damaged, they must be replaced.

WARNING

WARNING: THE AIR CONDITIONING SYSTEM CON-

TAINS REFRIGERANT UNDER HIGH PRESSURE.

SEVERE PERSONAL INJURY MAY RESULT FROM

IMPROPER SERVICE PROCEDURES. REPAIRS

SHOULD ONLY BE PERFORMED BY QUALIFIED

SERVICE PERSONNEL.

AVOID BREATHING THE REFRIGERANT AND

REFRIGERANT OIL VAPOR OR MIST. EXPOSURE

MAY IRRITATE THE EYES, NOSE, AND/OR THROAT.

WEAR EYE PROTECTION WHEN SERVICING THE

AIR CONDITIONING REFRIGERANT SYSTEM. SERI-

OUS EYE INJURY CAN RESULT FROM DIRECT

CONTACT WITH THE REFRIGERANT. IF EYE CON-

TACT OCCURS, SEEK MEDICAL ATTENTION IMME-

DIATELY.

DO NOT EXPOSE THE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN

REFRIGERANT IS BURNED. AN ELECTRONIC LEAK

DETECTOR IS RECOMMENDED.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE THE WORK AREA BEFORE RESUMING

SERVICE. LARGE AMOUNTS OF REFRIGERANT

RELEASED IN A CLOSED WORK AREA WILL DIS-

PLACE THE OXYGEN AND CAUSE SUFFOCATION.

THE EVAPORATION RATE OF R-134a REFRIGER-

ANT AT AVERAGE TEMPERATURE AND ALTITUDE

IS EXTREMELY HIGH. AS A RESULT, ANYTHING

THAT COMES IN CONTACT WITH THE REFRIGER-

ANT WILL FREEZE. ALWAYS PROTECT THE SKIN

OR DELICATE OBJECTS FROM DIRECT CONTACT

WITH THE REFRIGERANT.

THE R-134a SERVICE EQUIPMENT OR THE VEHI-

CLE REFRIGERANT SYSTEM SHOULD NOT BE

PRESSURE TESTED OR LEAK TESTED WITH COM-

PRESSED AIR. SOME MIXTURES OF AIR AND

R-134a HAVE BEEN SHOWN TO BE COMBUSTIBLE

AT ELEVATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS, AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

24 - 52 PLUMBINGWJ

Page 2140 of 2199

(11) Remove the bolts that secure the upper con-

denser and transmission cooler.

(12) Carefully lift the condenser out of the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

CAUTION: Before removing the condenser, note the

location of each of the radiator and condenser air

seals. These seals are used to direct air through the

condenser and radiator. The air seals must be rein-

stalled in their proper locations in order for the air

conditioning and engine cooling systems to per-

form as designed.

(1) Carefully position the condenser in the vehicle.

(2) Install the bolts that secure the upper con-

denser and transmission cooler.

(3) Remove the tape or plugs from the refrigerant

line fittings on the condenser inlet and the discharge

line. Connect the discharge line to the condenser

inlet. Tighten the retaining nut to 28 N´m (250 in.

lbs.).

(4) Remove the tape or plugs from the refrigerant

line fittings on the condenser outlet and the liquid

line. Connect the liquid line to the condenser outlet.

Tighten the retaining nut to 28 N´m (250 in. lbs.).

(5) Install the headlamp mounting module and

front fascia. Refer to Body for the procedure.

(6) Install the engine air filter inlet duct.

(7) Install the bolts that secure the radiator to the

upper crossmember.(8) Install the nuts that secure the hood latch and

brace to the upper crossmember.

(9) Install the headlamps in their mounts.

(10) Install the screws attaching the grille and

headlamp mounting module to the upper crossmem-

ber of the vehicle. Refer to Body for this and further

steps in the procedure.

(11) Evacuate and Recharge the refrigerant sys-

tem. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM EVACUATE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(12) Connect the battery negative cable.

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - DESCRIPTION)

A/C DISCHARGE LINE

REMOVAL

REMOVAL - 2.7L TURBO DIESEL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the negative battery

cable.

(2) Recover the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY)

(3) Remove both headlamps from the vehicle. Refer

to Lamps/Lighting for the procedure.

(4) Remove the a/c high pressure transducer(Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C PRESSURE TRANSDUCER - REMOV-

AL).

(5) Remove the front fascia from the vehicle. Refer

to Front Fascia for the procedure (Fig. 7).

(6) Remove the refrigerant line retaining fastener

from the condenser inlet fitting. Remove the line and

cap the condenser inlet tube to prevent contamina-

tion of the system.

WJPLUMBING 24 - 63

A/C CONDENSER (Continued)

Page 2141 of 2199

(7) Raise the vehicle on a hoist.

(8) Remove the front splash shield (if equipped).

(9) Remove the refrigerant line retaining fastener

from the compressor outlet fitting. Remove the line

and cap the compressor outlet opening to prevent

contamination of the system.

(10) Unclip and remove the discharge line from the

vehicle.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS GROUP BEFORE

PERFORMING THE FOLLOWING OPERATION.

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the a/c high pressure transducer(Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C PRESSURE TRANSDUCER - REMOV-

AL).(4) Disconnect the discharge line from the con-

denser inlet. Install plugs in, or tape over all of the

opened refrigerant line fittings.

(5) Remove the bolt that secures the discharge line

fitting to compressor. Install plugs in, or tape over all

of the opened refrigerant line fittings.

(6) Remove the discharge line assembly from the

vehicle.

INSTALLATION

INSTALLATION - 2.7L TURBO DIESEL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Carefully position the discharge line in the

vehicle.

(2) Remove the cap and install the discharge line

on the compressor. Be certain the sealing o-ring is

well lubricated with PAG oil and free of tears. Torque

the retaining fastener to 22 N´m (200 in. lbs.).

(3) Install the front splash shield (if equipped).

(4) Lower the vehicle from the hoist.

(5) Remove the cap and install the discharge line

on the condenser. Be certain the sealing o-ring is well

lubricated with PAG oil and free of tears. Torque the

retaining fastener to 28 N´m (21 ft. lbs.).

(6) Install the front fascia on the vehicle. Refer to

Front Fascia for the procedure.

(7) Install both headlamps in the vehicle. Refer to

Lamps/Lighting for the procedure.

(8) Install the a/c high pressure transducer, and

connect the electrical connector(Refer to 24 - HEAT-

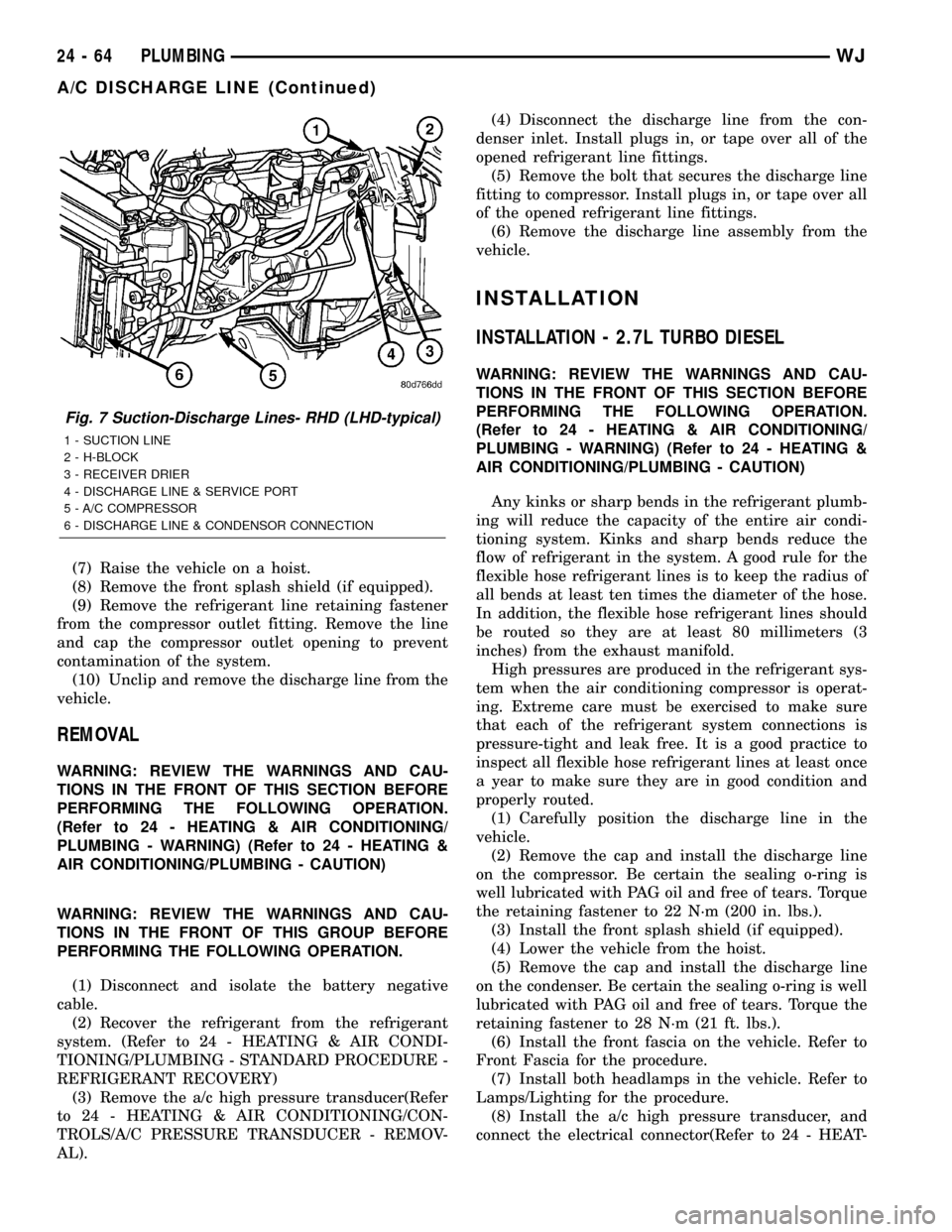

Fig. 7 Suction-Discharge Lines- RHD (LHD-typical)

1 - SUCTION LINE

2 - H-BLOCK

3 - RECEIVER DRIER

4 - DISCHARGE LINE & SERVICE PORT

5 - A/C COMPRESSOR

6 - DISCHARGE LINE & CONDENSOR CONNECTION

24 - 64 PLUMBINGWJ

A/C DISCHARGE LINE (Continued)

Page 2187 of 2199

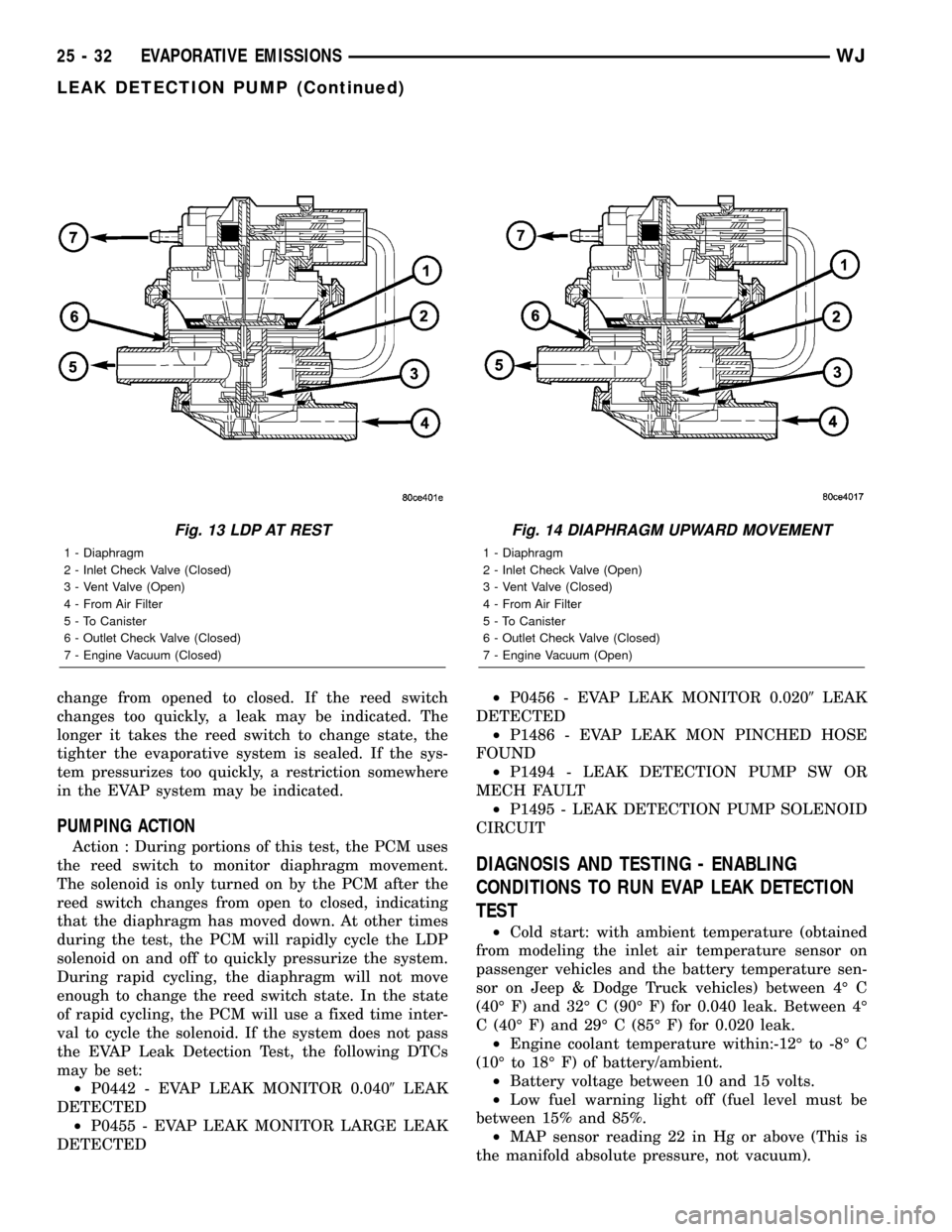

change from opened to closed. If the reed switch

changes too quickly, a leak may be indicated. The

longer it takes the reed switch to change state, the

tighter the evaporative system is sealed. If the sys-

tem pressurizes too quickly, a restriction somewhere

in the EVAP system may be indicated.

PUMPING ACTION

Action : During portions of this test, the PCM uses

the reed switch to monitor diaphragm movement.

The solenoid is only turned on by the PCM after the

reed switch changes from open to closed, indicating

that the diaphragm has moved down. At other times

during the test, the PCM will rapidly cycle the LDP

solenoid on and off to quickly pressurize the system.

During rapid cycling, the diaphragm will not move

enough to change the reed switch state. In the state

of rapid cycling, the PCM will use a fixed time inter-

val to cycle the solenoid. If the system does not pass

the EVAP Leak Detection Test, the following DTCs

may be set:

²P0442 - EVAP LEAK MONITOR 0.0409LEAK

DETECTED

²P0455 - EVAP LEAK MONITOR LARGE LEAK

DETECTED²P0456 - EVAP LEAK MONITOR 0.0209LEAK

DETECTED

²P1486 - EVAP LEAK MON PINCHED HOSE

FOUND

²P1494 - LEAK DETECTION PUMP SW OR

MECH FAULT

²P1495 - LEAK DETECTION PUMP SOLENOID

CIRCUIT

DIAGNOSIS AND TESTING - ENABLING

CONDITIONS TO RUN EVAP LEAK DETECTION

TEST

²Cold start: with ambient temperature (obtained

from modeling the inlet air temperature sensor on

passenger vehicles and the battery temperature sen-

sor on Jeep & Dodge Truck vehicles) between 4É C

(40É F) and 32É C (90É F) for 0.040 leak. Between 4É

C (40É F) and 29É C (85É F) for 0.020 leak.

²Engine coolant temperature within:-12É to -8É C

(10É to 18É F) of battery/ambient.

²Battery voltage between 10 and 15 volts.

²Low fuel warning light off (fuel level must be

between 15% and 85%.

²MAP sensor reading 22 in Hg or above (This is

the manifold absolute pressure, not vacuum).

Fig. 13 LDP AT REST

1 - Diaphragm

2 - Inlet Check Valve (Closed)

3 - Vent Valve (Open)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Closed)

Fig. 14 DIAPHRAGM UPWARD MOVEMENT

1 - Diaphragm

2 - Inlet Check Valve (Open)

3 - Vent Valve (Closed)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Open)

25 - 32 EVAPORATIVE EMISSIONSWJ

LEAK DETECTION PUMP (Continued)