Cooling system JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 1384 of 2199

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners. DO

NOT tighten until all fasteners are in place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners. Tighten all manifold bolts starting at

center and working outward to 25 N´m (18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield. Tighten

fasteners to 8 N´m (72 in. lbs.), then loosen 45

degrees.

(5) Install starter and fasteners.

(6) Connect exhaust pipe to manifold.

(7) Connect heater hoses at engine.

(8) Install fastener attaching A/C accumulator.

(9) Install A/C compressor and fasteners.

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Install washer bottle and battery tray assem-

bly.

(12) Install PDC.

(13) Install battery and connect cables.

(14) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

VALVE TIMING

DESCRIPTION - TIMING DRIVE SYSTEM

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain and two second-

ary timing chain drives (Fig. 109).

OPERATION - TIMING DRIVE SYSTEM

The primary timing chain is a single inverted tooth

type. The primary chain drives the large fifty tooth

idler sprocket directly from a 25 tooth crankshaftsprocket. Primary chain motion is controlled by a

pivoting leaf spring tensioner arm and a fixed guide.

The arm and the guide both use nylon plastic wear

faces for low friction and long wear. The primary

chain receives oil splash lubrication from the second-

ary chain drive and oil pump leakage. The idler

sprocket assembly connects the primary and second-

ary chain drives. The idler sprocket assembly con-

sists of two integral thirty tooth sprockets and a fifty

tooth sprocket that is splined to the assembly. The

spline joint is a non ± serviceable press fit anti rattle

type. A spiral ring is installed on the outboard side of

the fifty tooth sprocket to prevent spline disengage-

ment. The idler sprocket assembly spins on a station-

ary idler shaft. The idler shaft is press-fit into the

cylinder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to con-

trol sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to pro-

vide lubrication for the two bushings used in the

idler sprocket assembly.

There are two secondary drive chains, both are

inverted tooth type, one to drive the camshaft in each

SOHC cylinder head. There are no shaft speed

changes in the secondary chain drive system. Each

secondary chain drives a thirty tooth cam sprocket

directly from the thirty tooth sprocket on the idler

sprocket assembly. A fixed chain guide and a hydrau-

lic oil damped tensioner are used to maintain tension

in each secondary chain system. The hydraulic ten-

sioners for the secondary chain systems are fed pres-

surized oil from oil reservoir pockets in the block.

Each tensioner also has a mechanical ratchet system

that limits chain slack if the tensioner piston bleeds

down after engine shut down. The tensioner arms

and guides also utilize nylon wear faces for low fric-

tion and long wear. The secondary timing chains

receive lubrication from a small orifice in the ten-

sioners. This orifice is protected from clogging by a

fine mesh screen which is located on the back of the

hydraulic tensioners.

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE TIMING -

VERIFICATION

CAUTION: The 4.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

WJENGINE - 4.7L 9 - 141

EXHAUST MANIFOLD - RIGHT (Continued)

Page 1389 of 2199

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Disconnect both heater hoses at timing cover.

(4) Disconnect lower radiator hose at engine.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

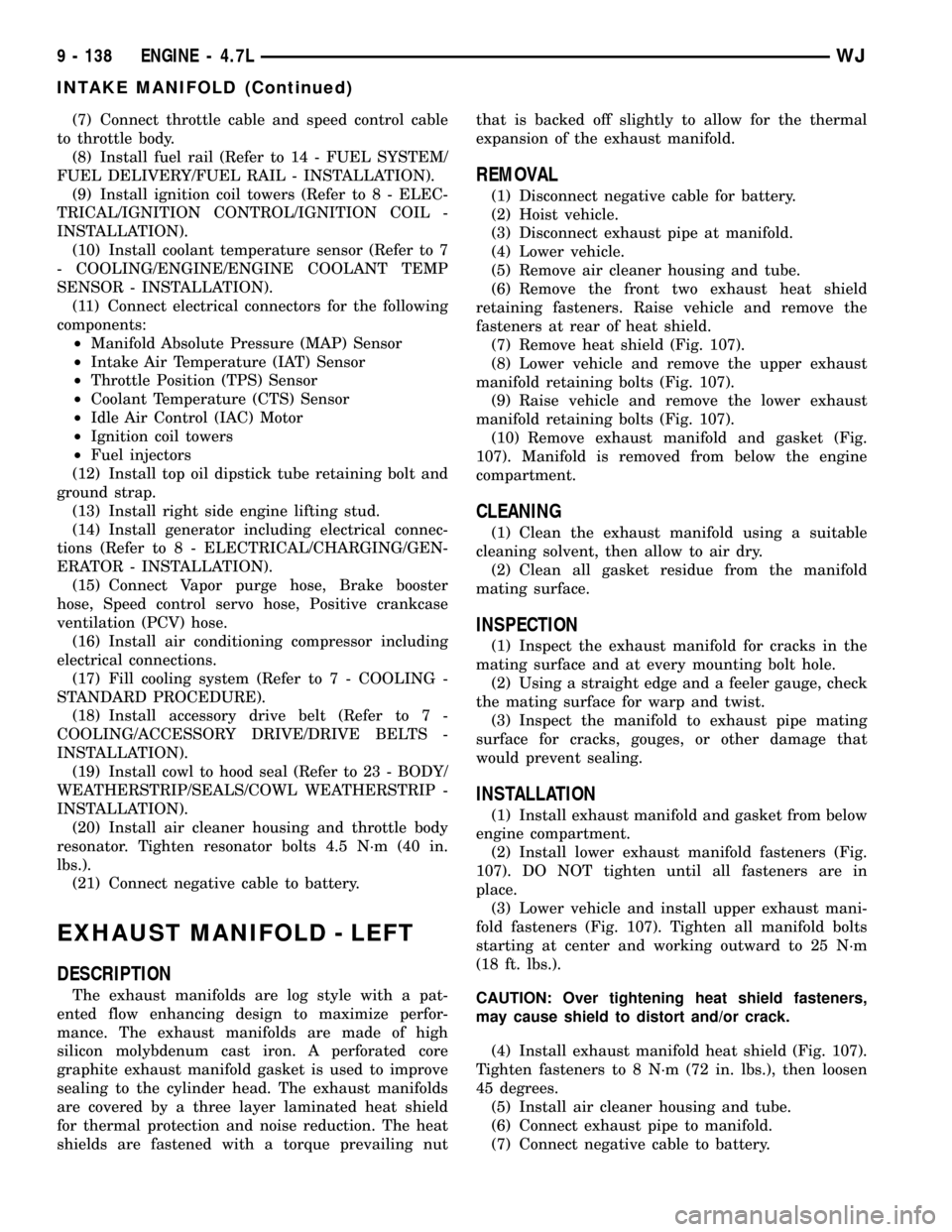

(6) Remove accessory drive belt tensioner assembly

(Fig. 117).

(7) Remove the generator and A/C compressor.

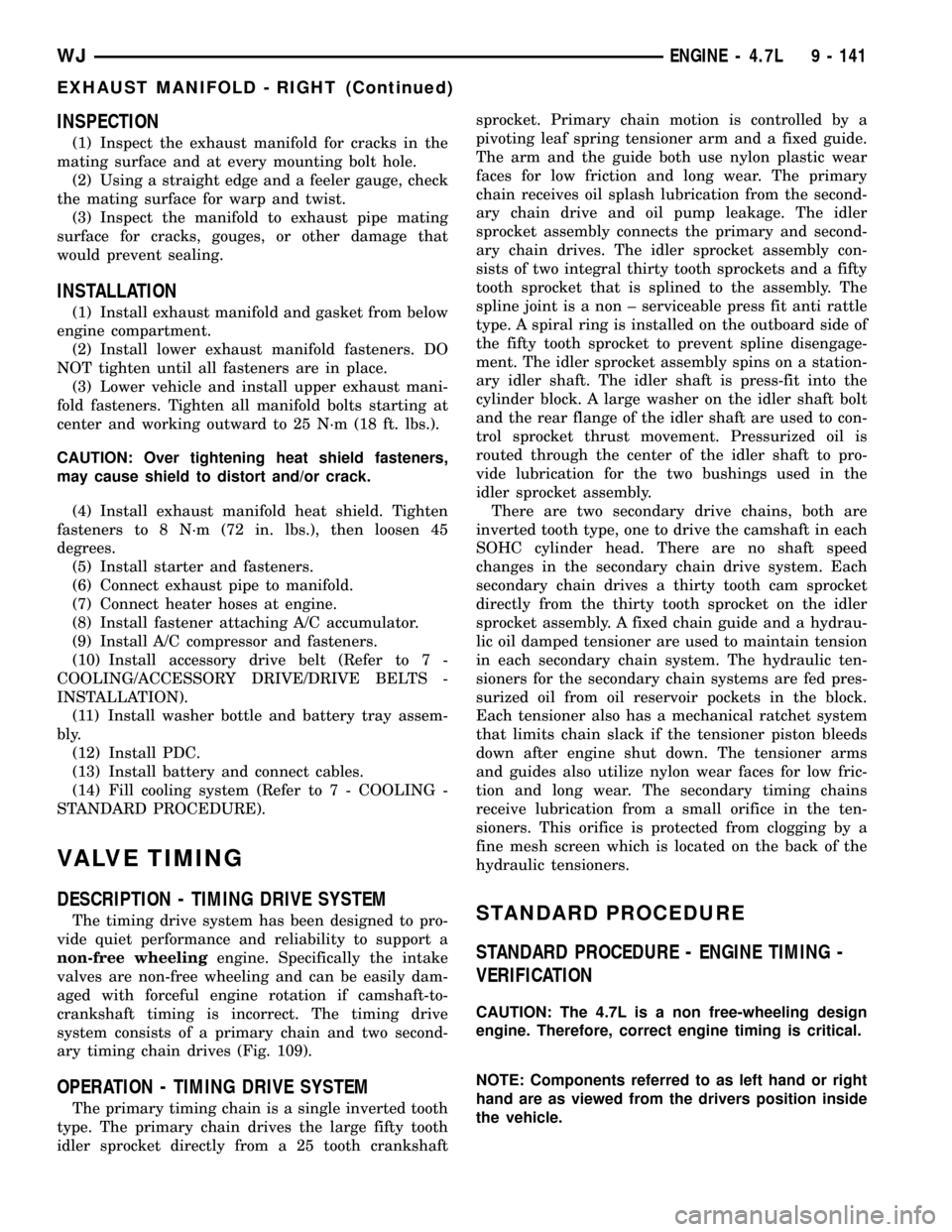

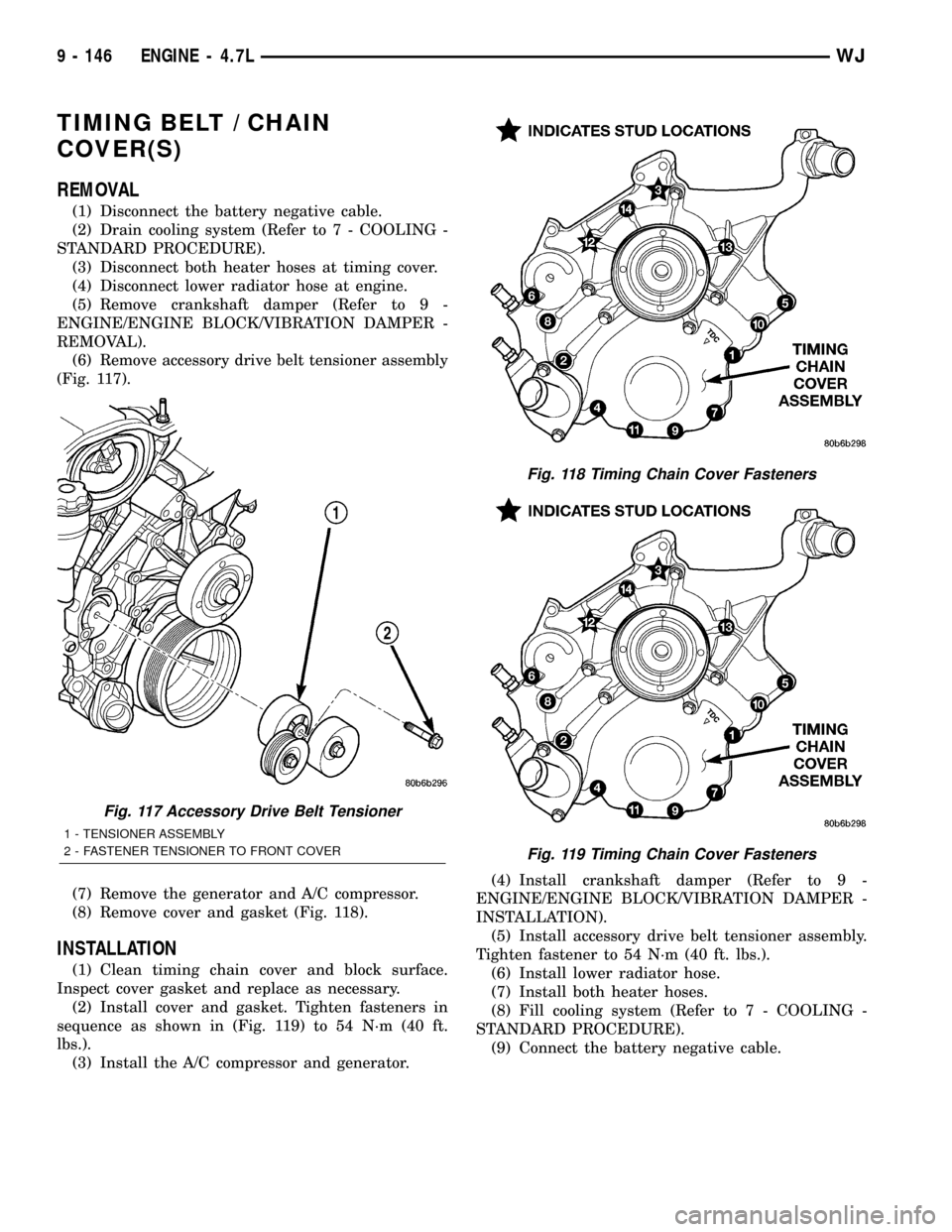

(8) Remove cover and gasket (Fig. 118).

INSTALLATION

(1) Clean timing chain cover and block surface.

Inspect cover gasket and replace as necessary.

(2) Install cover and gasket. Tighten fasteners in

sequence as shown in (Fig. 119) to 54 N´m (40 ft.

lbs.).

(3) Install the A/C compressor and generator.(4) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(5) Install accessory drive belt tensioner assembly.

Tighten fastener to 54 N´m (40 ft. lbs.).

(6) Install lower radiator hose.

(7) Install both heater hoses.

(8) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(9) Connect the battery negative cable.

Fig. 117 Accessory Drive Belt Tensioner

1 - TENSIONER ASSEMBLY

2 - FASTENER TENSIONER TO FRONT COVER

Fig. 118 Timing Chain Cover Fasteners

Fig. 119 Timing Chain Cover Fasteners

9 - 146 ENGINE - 4.7LWJ

Page 1390 of 2199

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

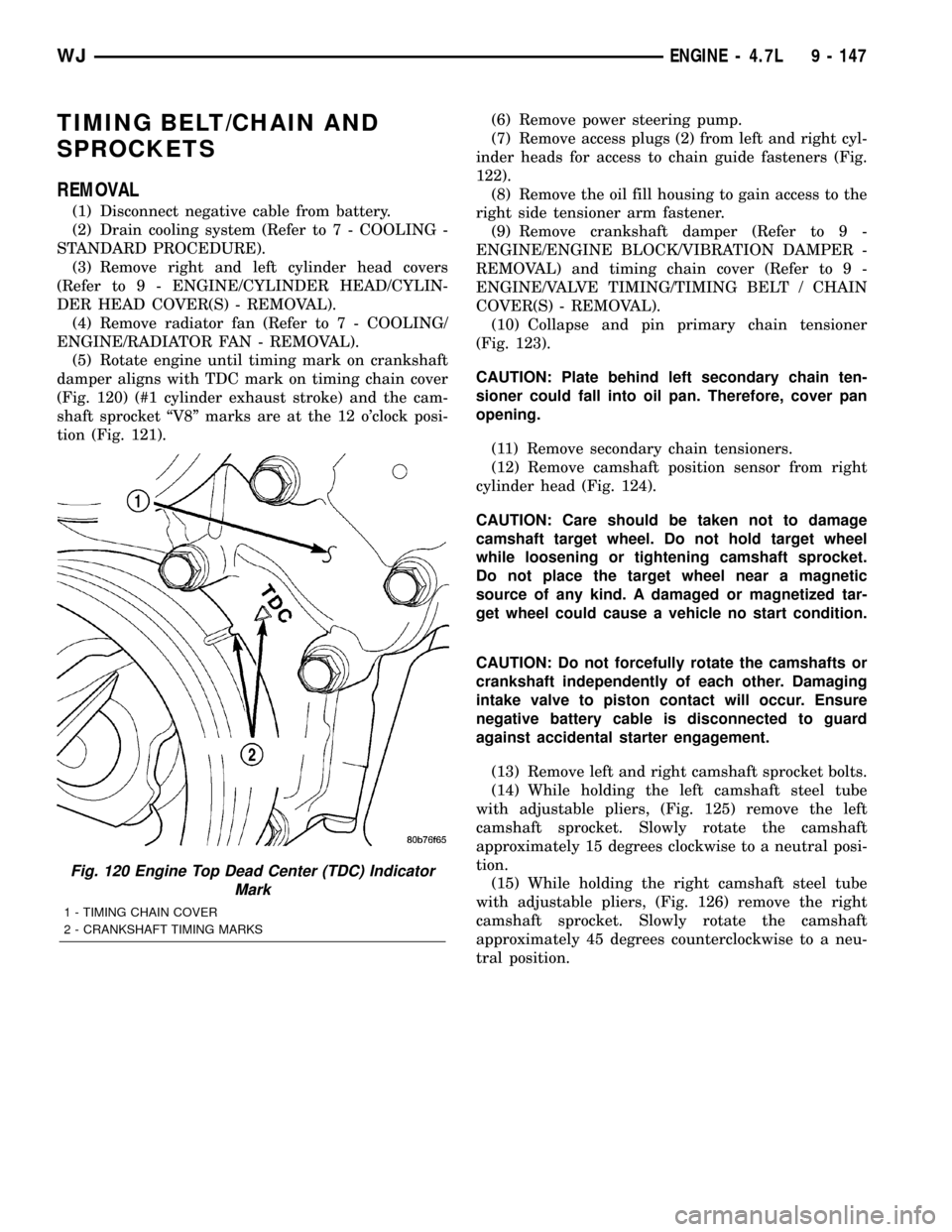

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 120) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 121).(6) Remove power steering pump.

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

122).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Collapse and pin primary chain tensioner

(Fig. 123).

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor from right

cylinder head (Fig. 124).

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with adjustable pliers, (Fig. 125) remove the left

camshaft sprocket. Slowly rotate the camshaft

approximately 15 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with adjustable pliers, (Fig. 126) remove the right

camshaft sprocket. Slowly rotate the camshaft

approximately 45 degrees counterclockwise to a neu-

tral position.

Fig. 120 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

WJENGINE - 4.7L 9 - 147

Page 1396 of 2199

(22) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and crankshaft

damper (Refer to 9 - ENGINE/ENGINE BLOCK/VI-

BRATION DAMPER - INSTALLATION).

(23) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(24) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.) (Fig. 122).

(25) Install the oil fill housing.

(26) Install access plug in left cylinder head (Fig.

122).

(27) Install power steering pump.

(28) Install radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(29) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(30) Connect negative cable to battery.

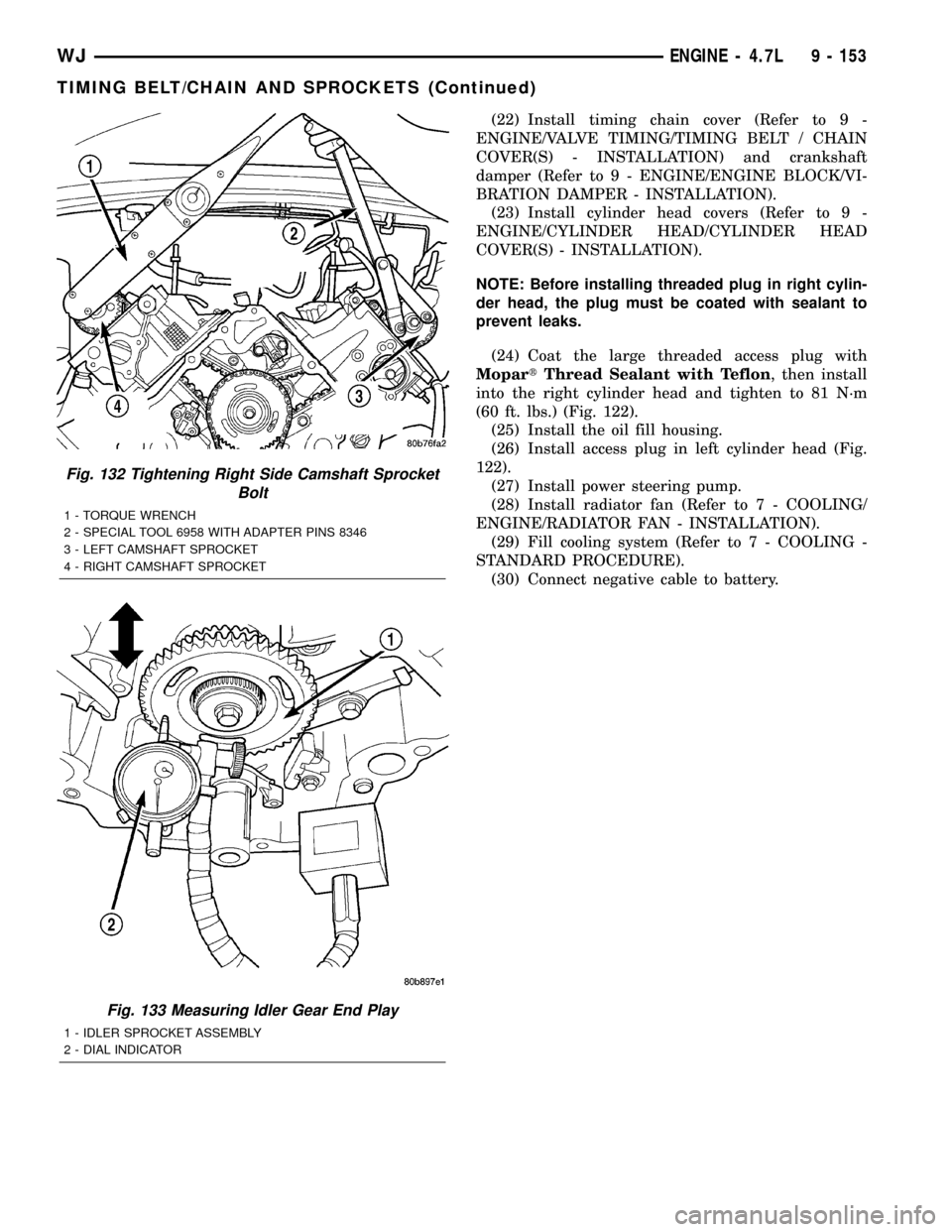

Fig. 132 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

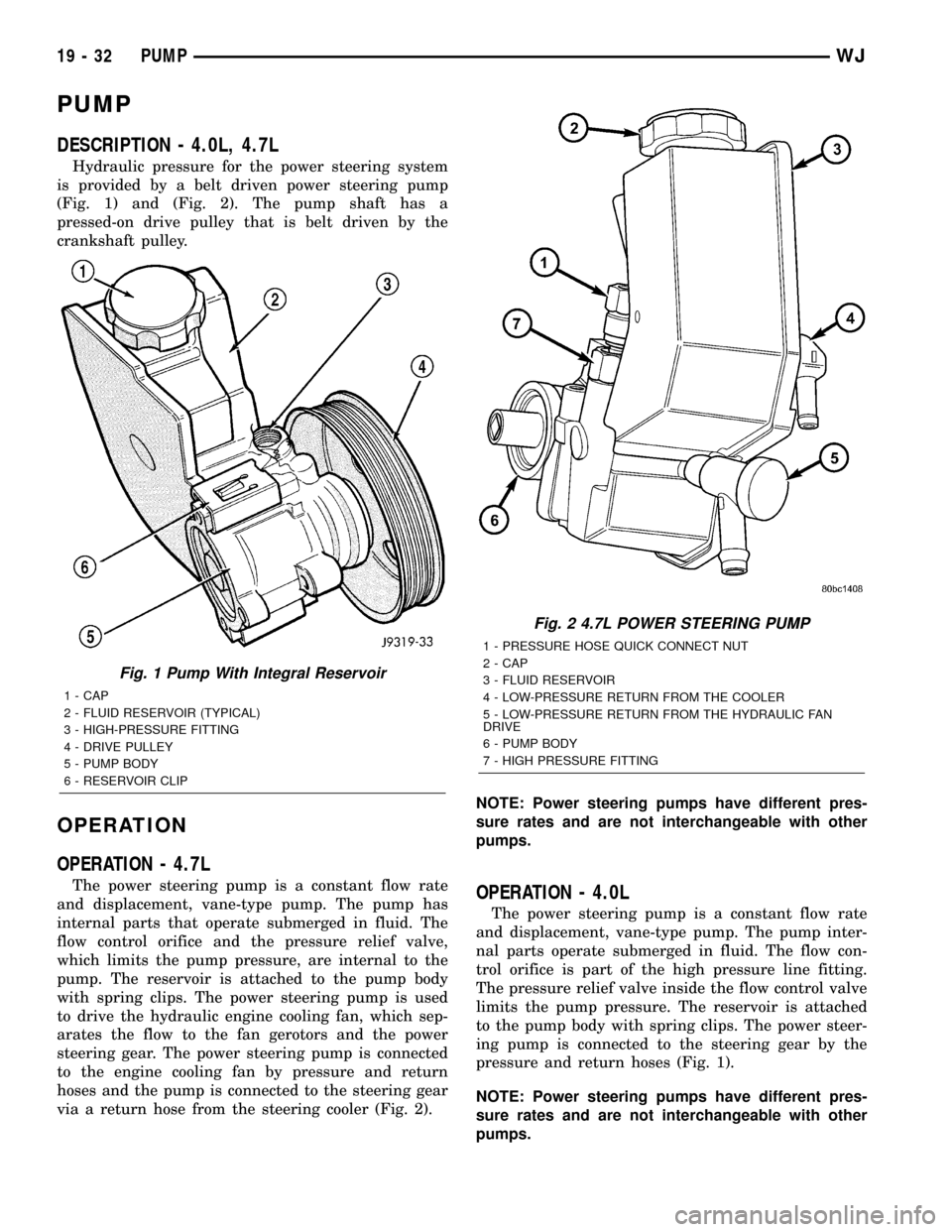

Fig. 133 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

WJENGINE - 4.7L 9 - 153

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1509 of 2199

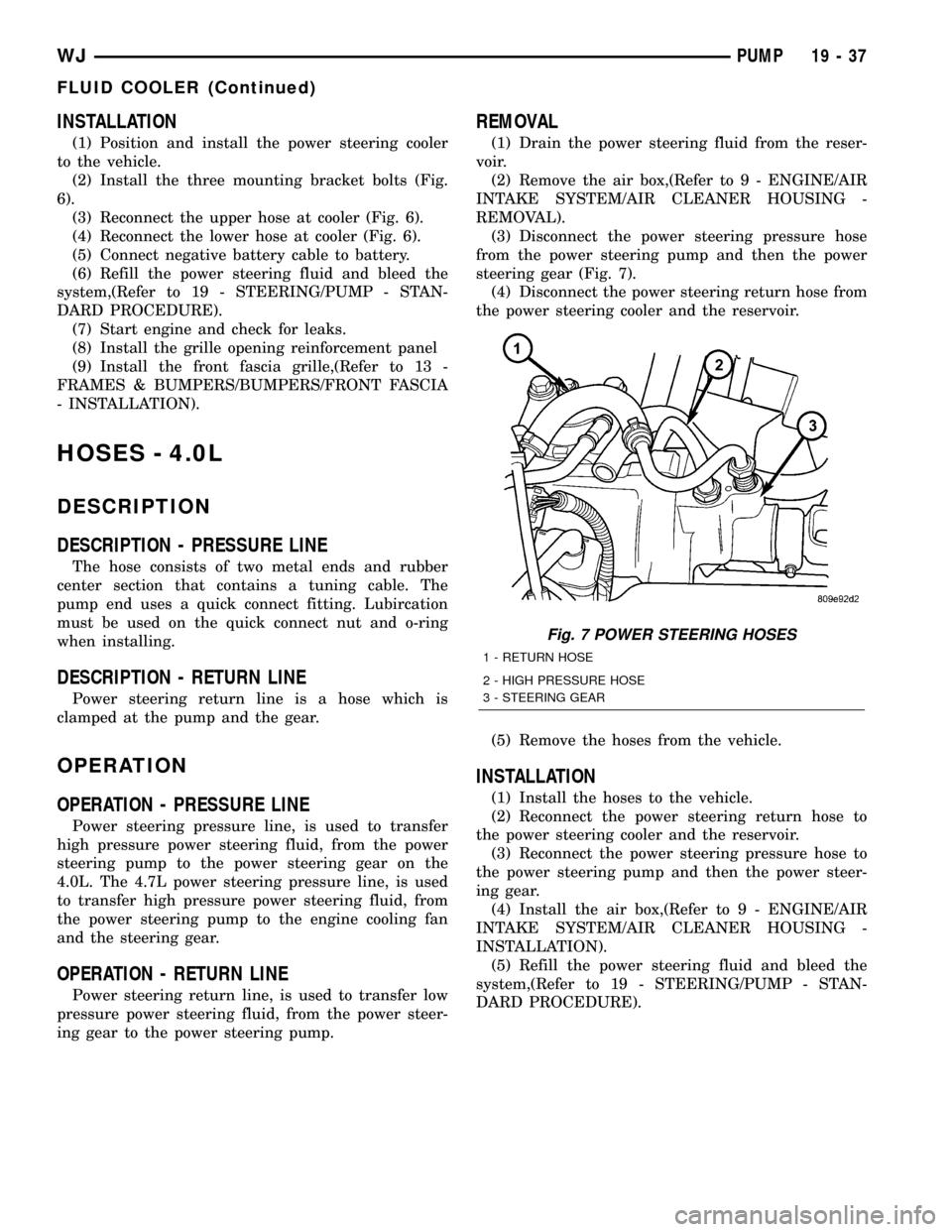

PUMP

DESCRIPTION - 4.0L, 4.7L

Hydraulic pressure for the power steering system

is provided by a belt driven power steering pump

(Fig. 1) and (Fig. 2). The pump shaft has a

pressed-on drive pulley that is belt driven by the

crankshaft pulley.

OPERATION

OPERATION - 4.7L

The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump has

internal parts that operate submerged in fluid. The

flow control orifice and the pressure relief valve,

which limits the pump pressure, are internal to the

pump. The reservoir is attached to the pump body

with spring clips. The power steering pump is used

to drive the hydraulic engine cooling fan, which sep-

arates the flow to the fan gerotors and the power

steering gear. The power steering pump is connected

to the engine cooling fan by pressure and return

hoses and the pump is connected to the steering gear

via a return hose from the steering cooler (Fig. 2).NOTE: Power steering pumps have different pres-

sure rates and are not interchangeable with other

pumps.OPERATION - 4.0L

The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump inter-

nal parts operate submerged in fluid. The flow con-

trol orifice is part of the high pressure line fitting.

The pressure relief valve inside the flow control valve

limits the pump pressure. The reservoir is attached

to the pump body with spring clips. The power steer-

ing pump is connected to the steering gear by the

pressure and return hoses (Fig. 1).

NOTE: Power steering pumps have different pres-

sure rates and are not interchangeable with other

pumps.

Fig. 1 Pump With Integral Reservoir

1 - CAP

2 - FLUID RESERVOIR (TYPICAL)

3 - HIGH-PRESSURE FITTING

4 - DRIVE PULLEY

5 - PUMP BODY

6 - RESERVOIR CLIP

Fig. 2 4.7L POWER STEERING PUMP

1 - PRESSURE HOSE QUICK CONNECT NUT

2 - CAP

3 - FLUID RESERVOIR

4 - LOW-PRESSURE RETURN FROM THE COOLER

5 - LOW-PRESSURE RETURN FROM THE HYDRAULIC FAN

DRIVE

6 - PUMP BODY

7 - HIGH PRESSURE FITTING

19 - 32 PUMPWJ

Page 1514 of 2199

INSTALLATION

(1) Position and install the power steering cooler

to the vehicle.

(2) Install the three mounting bracket bolts (Fig.

6).

(3) Reconnect the upper hose at cooler (Fig. 6).

(4) Reconnect the lower hose at cooler (Fig. 6).

(5) Connect negative battery cable to battery.

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(7) Start engine and check for leaks.

(8) Install the grille opening reinforcement panel

(9) Install the front fascia grille,(Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT FASCIA

- INSTALLATION).

HOSES - 4.0L

DESCRIPTION

DESCRIPTION - PRESSURE LINE

The hose consists of two metal ends and rubber

center section that contains a tuning cable. The

pump end uses a quick connect fitting. Lubircation

must be used on the quick connect nut and o-ring

when installing.

DESCRIPTION - RETURN LINE

Power steering return line is a hose which is

clamped at the pump and the gear.

OPERATION

OPERATION - PRESSURE LINE

Power steering pressure line, is used to transfer

high pressure power steering fluid, from the power

steering pump to the power steering gear on the

4.0L. The 4.7L power steering pressure line, is used

to transfer high pressure power steering fluid, from

the power steering pump to the engine cooling fan

and the steering gear.

OPERATION - RETURN LINE

Power steering return line, is used to transfer low

pressure power steering fluid, from the power steer-

ing gear to the power steering pump.

REMOVAL

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the power steering pressure hose

from the power steering pump and then the power

steering gear (Fig. 7).

(4) Disconnect the power steering return hose from

the power steering cooler and the reservoir.

(5) Remove the hoses from the vehicle.

INSTALLATION

(1) Install the hoses to the vehicle.

(2) Reconnect the power steering return hose to

the power steering cooler and the reservoir.

(3) Reconnect the power steering pressure hose to

the power steering pump and then the power steer-

ing gear.

(4) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(5) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

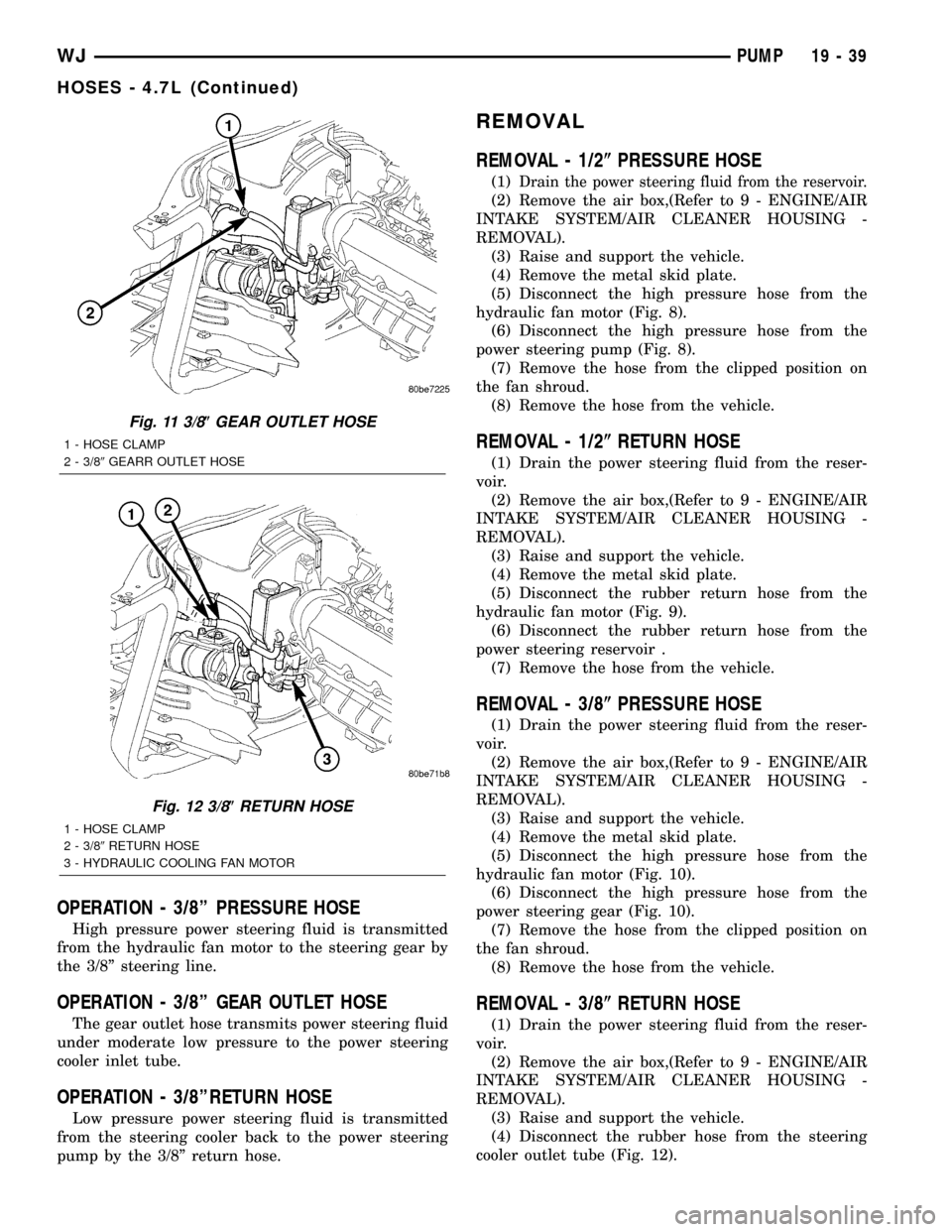

Fig. 7 POWER STEERING HOSES

1 - RETURN HOSE

2 - HIGH PRESSURE HOSE

3 - STEERING GEAR

WJPUMP 19 - 37

FLUID COOLER (Continued)

Page 1516 of 2199

OPERATION - 3/8º PRESSURE HOSE

High pressure power steering fluid is transmitted

from the hydraulic fan motor to the steering gear by

the 3/8º steering line.

OPERATION - 3/8º GEAR OUTLET HOSE

The gear outlet hose transmits power steering fluid

under moderate low pressure to the power steering

cooler inlet tube.

OPERATION - 3/8ºRETURN HOSE

Low pressure power steering fluid is transmitted

from the steering cooler back to the power steering

pump by the 3/8º return hose.

REMOVAL

REMOVAL - 1/2(PRESSURE HOSE

(1)Drain the power steering fluid from the reservoir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 8).

(6) Disconnect the high pressure hose from the

power steering pump (Fig. 8).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 1/2(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the rubber return hose from the

hydraulic fan motor (Fig. 9).

(6) Disconnect the rubber return hose from the

power steering reservoir .

(7) Remove the hose from the vehicle.

REMOVAL - 3/8(PRESSURE HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 10).

(6) Disconnect the high pressure hose from the

power steering gear (Fig. 10).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 3/8(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler outlet tube (Fig. 12).

Fig. 11 3/8(GEAR OUTLET HOSE

1 - HOSE CLAMP

2 - 3/89GEARR OUTLET HOSE

Fig. 12 3/8(RETURN HOSE

1 - HOSE CLAMP

2 - 3/89RETURN HOSE

3 - HYDRAULIC COOLING FAN MOTOR

WJPUMP 19 - 39

HOSES - 4.7L (Continued)

Page 1540 of 2199

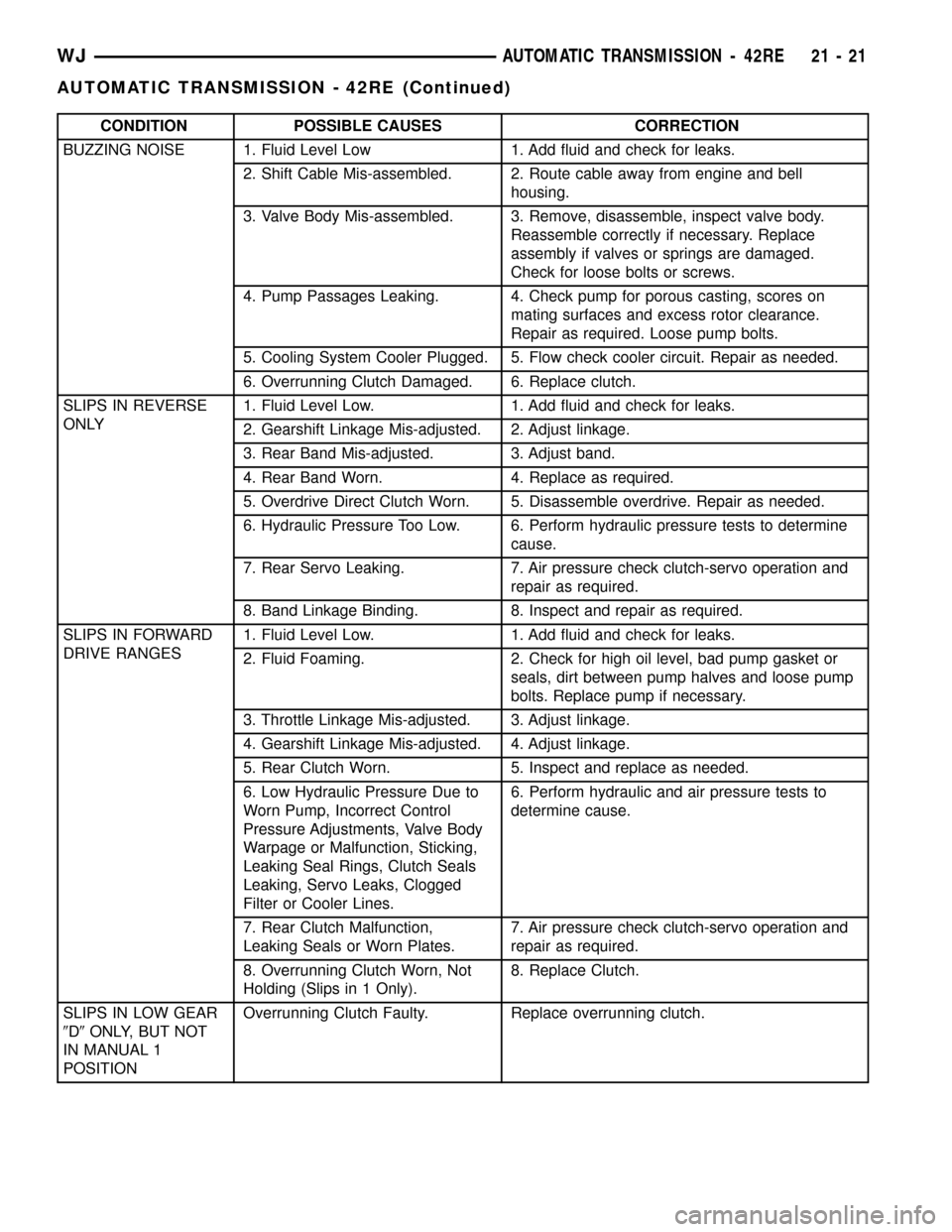

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Mis-assembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Mis-assembled. 3. Remove, disassemble, inspect valve body.

Reassemble correctly if necessary. Replace

assembly if valves or springs are damaged.

Check for loose bolts or screws.

4. Pump Passages Leaking. 4. Check pump for porous casting, scores on

mating surfaces and excess rotor clearance.

Repair as required. Loose pump bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as needed.

6. Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE

ONLY1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage.

3. Rear Band Mis-adjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Overdrive Direct Clutch Worn. 5. Disassemble overdrive. Repair as needed.

6. Hydraulic Pressure Too Low. 6. Perform hydraulic pressure tests to determine

cause.

7. Rear Servo Leaking. 7. Air pressure check clutch-servo operation and

repair as required.

8. Band Linkage Binding. 8. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump gasket or

seals, dirt between pump halves and loose pump

bolts. Replace pump if necessary.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage.

4. Gearshift Linkage Mis-adjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking,

Leaking Seal Rings, Clutch Seals

Leaking, Servo Leaks, Clogged

Filter or Cooler Lines.6. Perform hydraulic and air pressure tests to

determine cause.

7. Rear Clutch Malfunction,

Leaking Seals or Worn Plates.7. Air pressure check clutch-servo operation and

repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR

9D9ONLY, BUT NOT

IN MANUAL 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 21

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1589 of 2199

(1) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to reverse flush cooler and lines after

repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This

is necessary because normal converter flushing proce-

dures will not remove all contaminants.

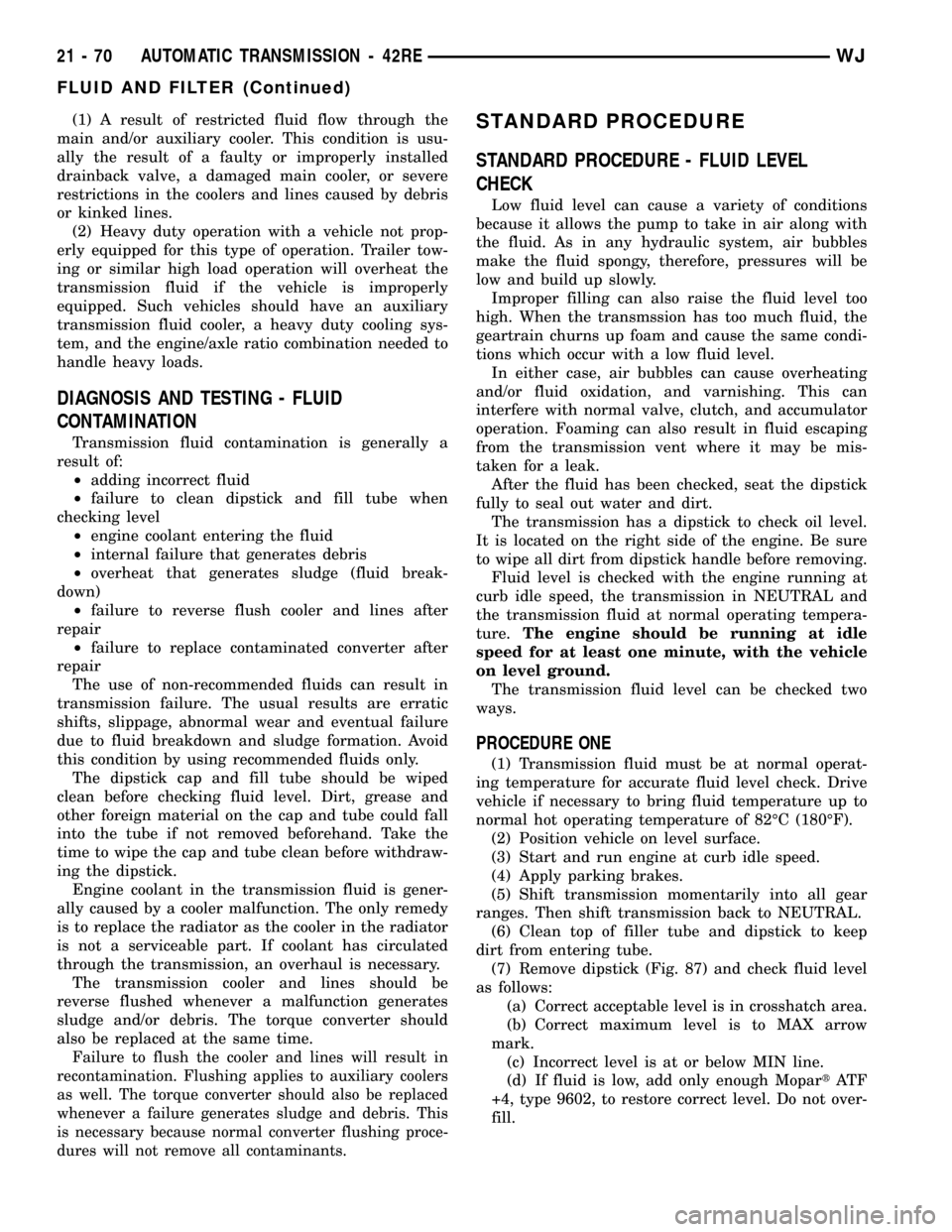

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and

the transmission fluid at normal operating tempera-

ture.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.

The transmission fluid level can be checked two

ways.

PROCEDURE ONE

(1) Transmission fluid must be at normal operat-

ing temperature for accurate fluid level check. Drive

vehicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to NEUTRAL.

(6) Clean top of filler tube and dipstick to keep

dirt from entering tube.

(7) Remove dipstick (Fig. 87) and check fluid level

as follows:

(a) Correct acceptable level is in crosshatch area.

(b) Correct maximum level is to MAX arrow

mark.

(c) Incorrect level is at or below MIN line.

(d) If fluid is low, add only enough MopartAT F

+4, type 9602, to restore correct level. Do not over-

fill.

21 - 70 AUTOMATIC TRANSMISSION - 42REWJ

FLUID AND FILTER (Continued)