Turn signal switch JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1137 of 2199

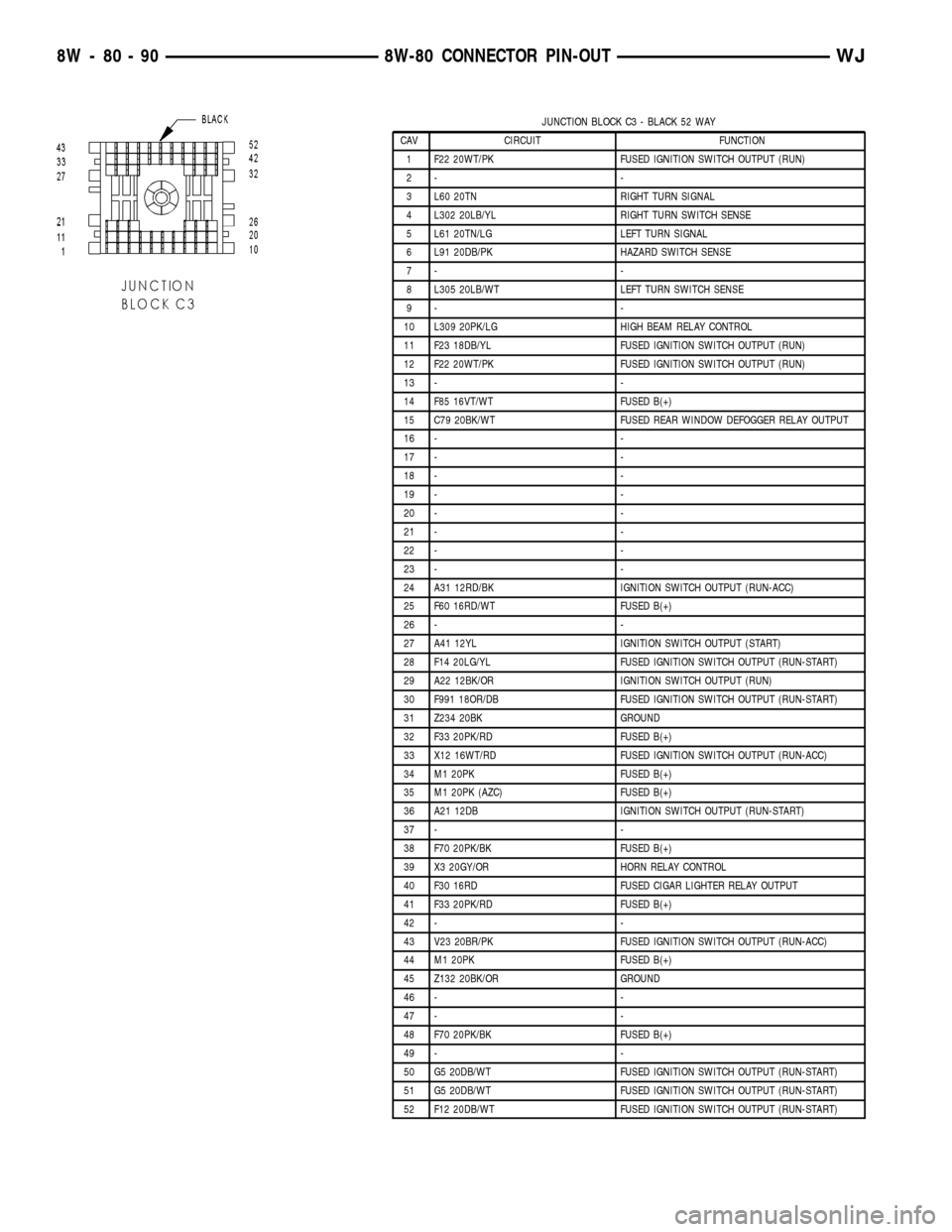

JUNCTION BLOCK C3 - BLACK 52 WAY

CAV CIRCUIT FUNCTION

1 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

2- -

3 L60 20TN RIGHT TURN SIGNAL

4 L302 20LB/YL RIGHT TURN SWITCH SENSE

5 L61 20TN/LG LEFT TURN SIGNAL

6 L91 20DB/PK HAZARD SWITCH SENSE

7- -

8 L305 20LB/WT LEFT TURN SWITCH SENSE

9- -

10 L309 20PK/LG HIGH BEAM RELAY CONTROL

11 F23 18DB/YL FUSED IGNITION SWITCH OUTPUT (RUN)

12 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

13 - -

14 F85 16VT/WT FUSED B(+)

15 C79 20BK/WT FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

16 - -

17 - -

18 - -

19 - -

20 - -

21 - -

22 - -

23 - -

24 A31 12RD/BK IGNITION SWITCH OUTPUT (RUN-ACC)

25 F60 16RD/WT FUSED B(+)

26 - -

27 A41 12YL IGNITION SWITCH OUTPUT (START)

28 F14 20LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

29 A22 12BK/OR IGNITION SWITCH OUTPUT (RUN)

30 F991 18OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

31 Z234 20BK GROUND

32 F33 20PK/RD FUSED B(+)

33 X12 16WT/RD FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

34 M1 20PK FUSED B(+)

35 M1 20PK (AZC) FUSED B(+)

36 A21 12DB IGNITION SWITCH OUTPUT (RUN-START)

37 - -

38 F70 20PK/BK FUSED B(+)

39 X3 20GY/OR HORN RELAY CONTROL

40 F30 16RD FUSED CIGAR LIGHTER RELAY OUTPUT

41 F33 20PK/RD FUSED B(+)

42 - -

43 V23 20BR/PK FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

44 M1 20PK FUSED B(+)

45 Z132 20BK/OR GROUND

46 - -

47 - -

48 F70 20PK/BK FUSED B(+)

49 - -

50 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

51 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

52 F12 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

8W - 80 - 90 8W-80 CONNECTOR PIN-OUTWJ

Page 1142 of 2199

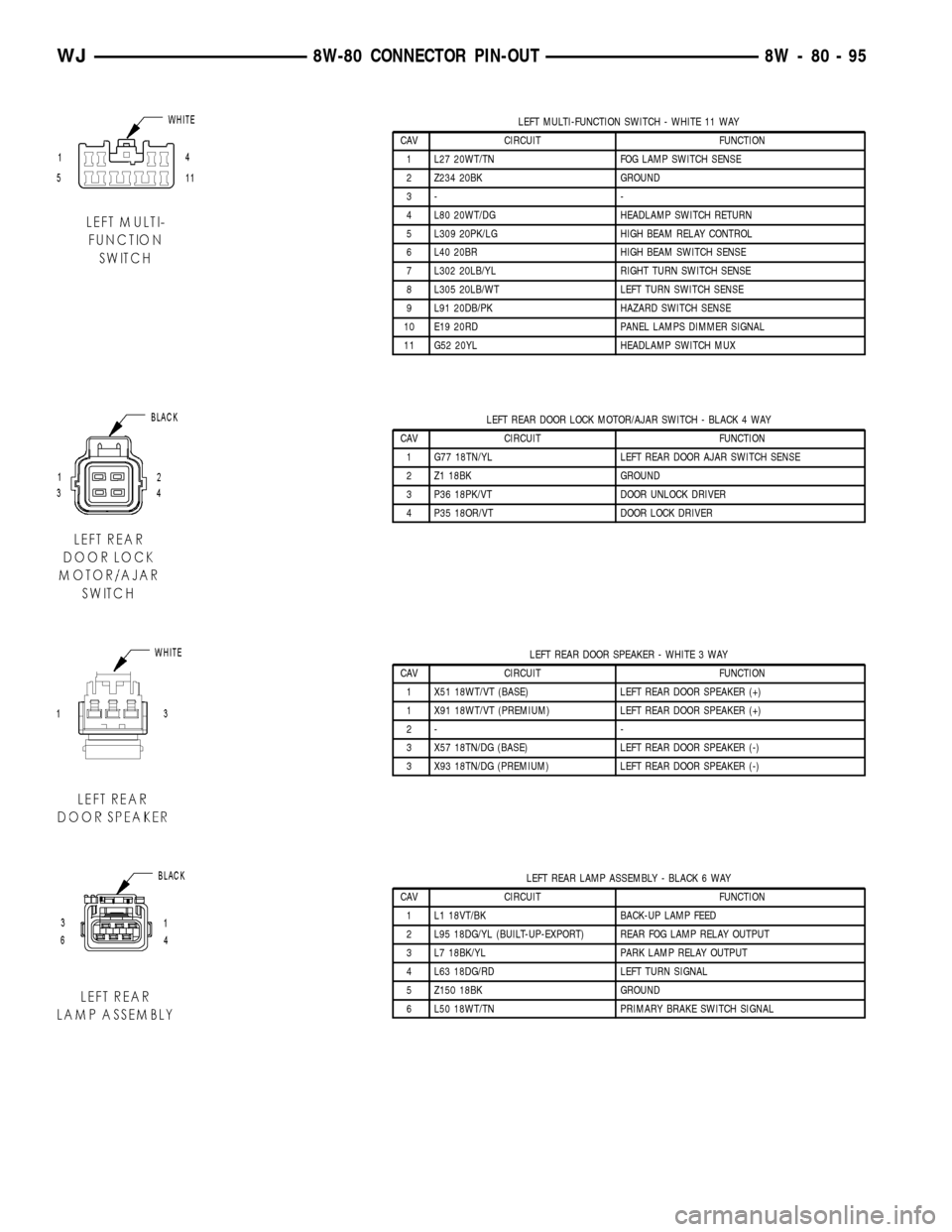

LEFT MULTI-FUNCTION SWITCH - WHITE 11 WAY

CAV CIRCUIT FUNCTION

1 L27 20WT/TN FOG LAMP SWITCH SENSE

2 Z234 20BK GROUND

3- -

4 L80 20WT/DG HEADLAMP SWITCH RETURN

5 L309 20PK/LG HIGH BEAM RELAY CONTROL

6 L40 20BR HIGH BEAM SWITCH SENSE

7 L302 20LB/YL RIGHT TURN SWITCH SENSE

8 L305 20LB/WT LEFT TURN SWITCH SENSE

9 L91 20DB/PK HAZARD SWITCH SENSE

10 E19 20RD PANEL LAMPS DIMMER SIGNAL

11 G52 20YL HEADLAMP SWITCH MUX

LEFT REAR DOOR LOCK MOTOR/AJAR SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 G77 18TN/YL LEFT REAR DOOR AJAR SWITCH SENSE

2 Z1 18BK GROUND

3 P36 18PK/VT DOOR UNLOCK DRIVER

4 P35 18OR/VT DOOR LOCK DRIVER

LEFT REAR DOOR SPEAKER - WHITE 3 WAY

CAV CIRCUIT FUNCTION

1 X51 18WT/VT (BASE) LEFT REAR DOOR SPEAKER (+)

1 X91 18WT/VT (PREMIUM) LEFT REAR DOOR SPEAKER (+)

2- -

3 X57 18TN/DG (BASE) LEFT REAR DOOR SPEAKER (-)

3 X93 18TN/DG (PREMIUM) LEFT REAR DOOR SPEAKER (-)

LEFT REAR LAMP ASSEMBLY - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L1 18VT/BK BACK-UP LAMP FEED

2 L95 18DG/YL (BUILT-UP-EXPORT) REAR FOG LAMP RELAY OUTPUT

3 L7 18BK/YL PARK LAMP RELAY OUTPUT

4 L63 18DG/RD LEFT TURN SIGNAL

5 Z150 18BK GROUND

6 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 95

Page 1143 of 2199

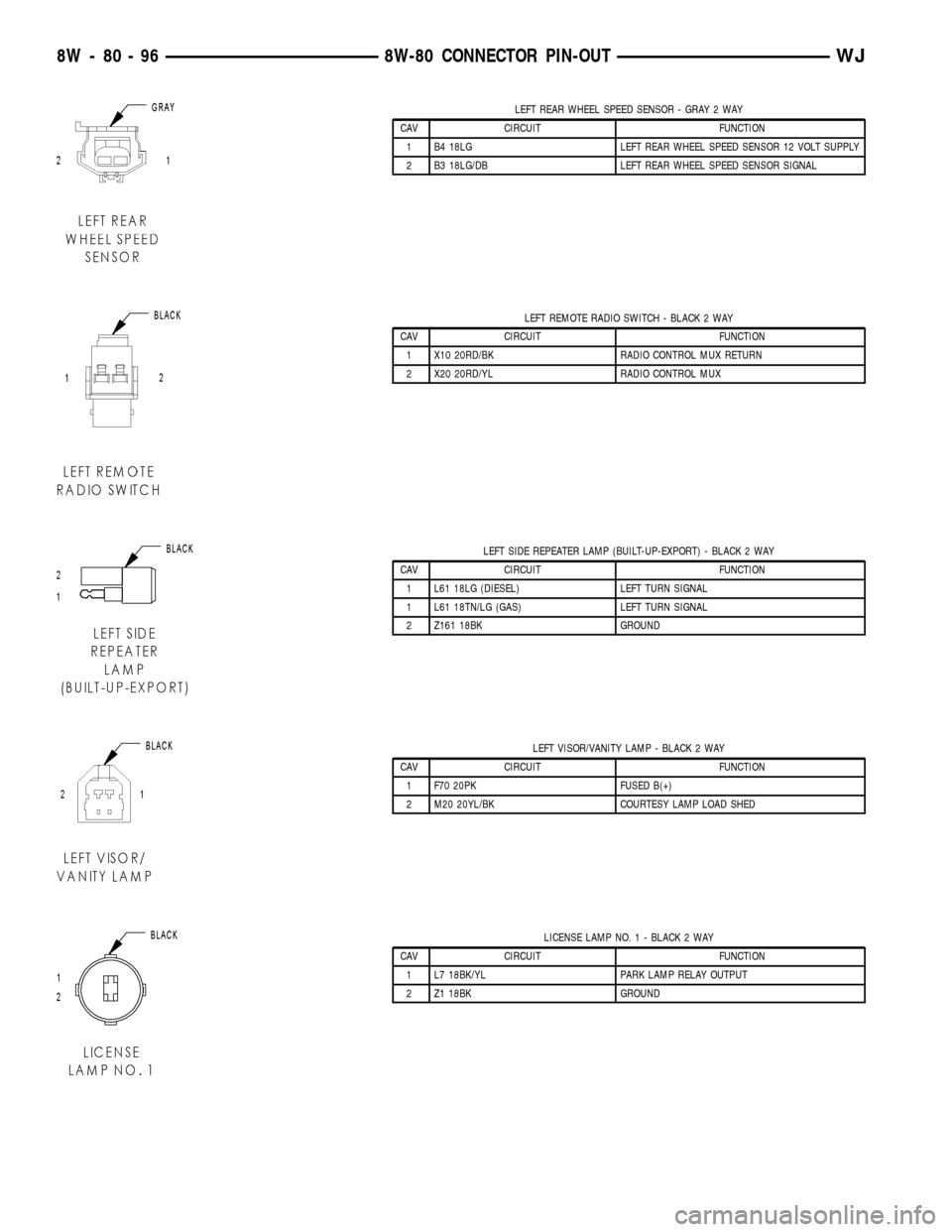

LEFT REAR WHEEL SPEED SENSOR - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 B4 18LG LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

2 B3 18LG/DB LEFT REAR WHEEL SPEED SENSOR SIGNAL

LEFT REMOTE RADIO SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X10 20RD/BK RADIO CONTROL MUX RETURN

2 X20 20RD/YL RADIO CONTROL MUX

LEFT SIDE REPEATER LAMP (BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L61 18LG (DIESEL) LEFT TURN SIGNAL

1 L61 18TN/LG (GAS) LEFT TURN SIGNAL

2 Z161 18BK GROUND

LEFT VISOR/VANITY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 F70 20PK FUSED B(+)

2 M20 20YL/BK COURTESY LAMP LOAD SHED

LICENSE LAMP NO. 1 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L7 18BK/YL PARK LAMP RELAY OUTPUT

2 Z1 18BK GROUND

8W - 80 - 96 8W-80 CONNECTOR PIN-OUTWJ

Page 1164 of 2199

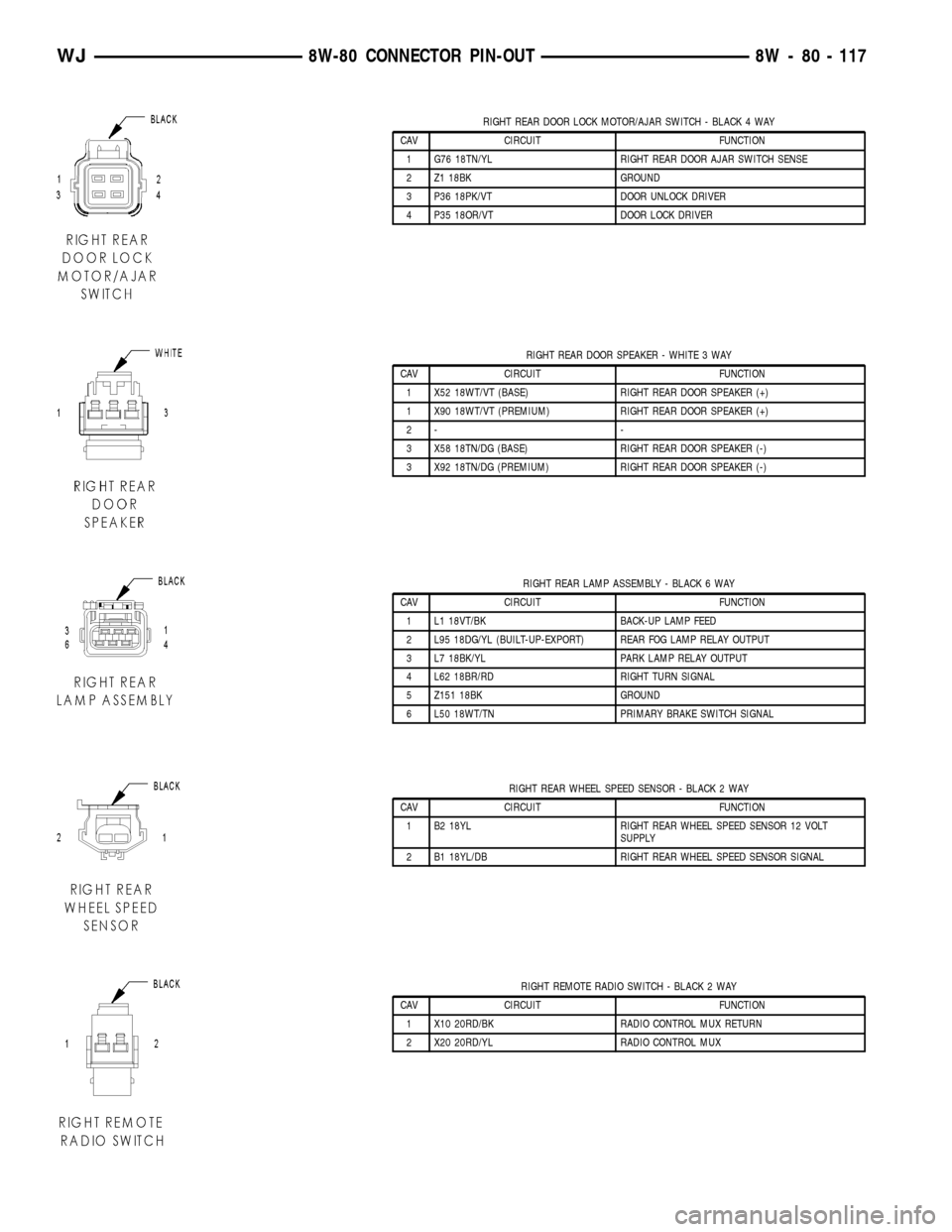

RIGHT REAR DOOR LOCK MOTOR/AJAR SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 G76 18TN/YL RIGHT REAR DOOR AJAR SWITCH SENSE

2 Z1 18BK GROUND

3 P36 18PK/VT DOOR UNLOCK DRIVER

4 P35 18OR/VT DOOR LOCK DRIVER

RIGHT REAR DOOR SPEAKER - WHITE 3 WAY

CAV CIRCUIT FUNCTION

1 X52 18WT/VT (BASE) RIGHT REAR DOOR SPEAKER (+)

1 X90 18WT/VT (PREMIUM) RIGHT REAR DOOR SPEAKER (+)

2- -

3 X58 18TN/DG (BASE) RIGHT REAR DOOR SPEAKER (-)

3 X92 18TN/DG (PREMIUM) RIGHT REAR DOOR SPEAKER (-)

RIGHT REAR LAMP ASSEMBLY - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L1 18VT/BK BACK-UP LAMP FEED

2 L95 18DG/YL (BUILT-UP-EXPORT) REAR FOG LAMP RELAY OUTPUT

3 L7 18BK/YL PARK LAMP RELAY OUTPUT

4 L62 18BR/RD RIGHT TURN SIGNAL

5 Z151 18BK GROUND

6 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B2 18YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT

SUPPLY

2 B1 18YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

RIGHT REMOTE RADIO SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X10 20RD/BK RADIO CONTROL MUX RETURN

2 X20 20RD/YL RADIO CONTROL MUX

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 117

Page 1165 of 2199

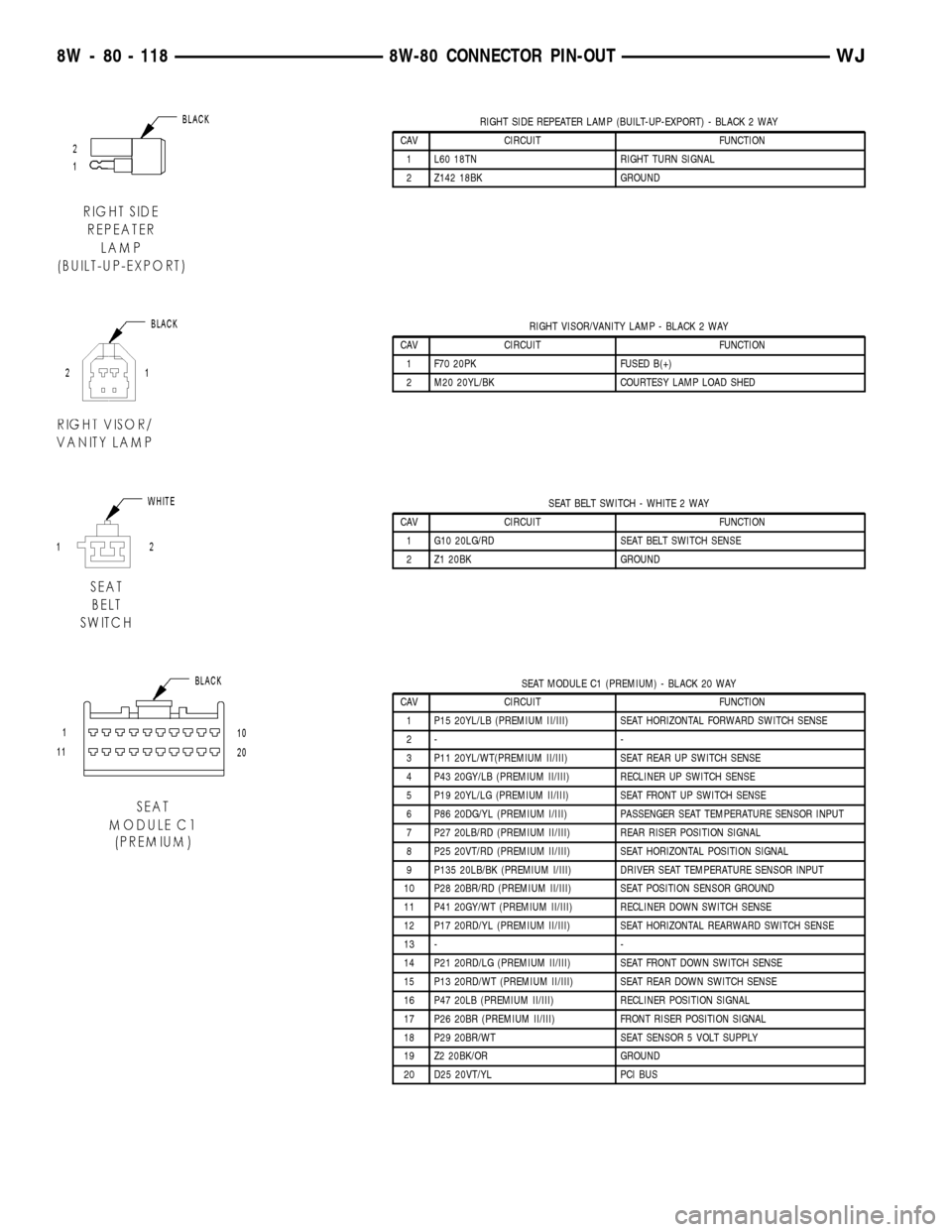

RIGHT SIDE REPEATER LAMP (BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L60 18TN RIGHT TURN SIGNAL

2 Z142 18BK GROUND

RIGHT VISOR/VANITY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 F70 20PK FUSED B(+)

2 M20 20YL/BK COURTESY LAMP LOAD SHED

SEAT BELT SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 G10 20LG/RD SEAT BELT SWITCH SENSE

2 Z1 20BK GROUND

SEAT MODULE C1 (PREMIUM) - BLACK 20 WAY

CAV CIRCUIT FUNCTION

1 P15 20YL/LB (PREMIUM II/III) SEAT HORIZONTAL FORWARD SWITCH SENSE

2- -

3 P11 20YL/WT(PREMIUM II/III) SEAT REAR UP SWITCH SENSE

4 P43 20GY/LB (PREMIUM II/III) RECLINER UP SWITCH SENSE

5 P19 20YL/LG (PREMIUM II/III) SEAT FRONT UP SWITCH SENSE

6 P86 20DG/YL (PREMIUM I/III) PASSENGER SEAT TEMPERATURE SENSOR INPUT

7 P27 20LB/RD (PREMIUM II/III) REAR RISER POSITION SIGNAL

8 P25 20VT/RD (PREMIUM II/III) SEAT HORIZONTAL POSITION SIGNAL

9 P135 20LB/BK (PREMIUM I/III) DRIVER SEAT TEMPERATURE SENSOR INPUT

10 P28 20BR/RD (PREMIUM II/III) SEAT POSITION SENSOR GROUND

11 P41 20GY/WT (PREMIUM II/III) RECLINER DOWN SWITCH SENSE

12 P17 20RD/YL (PREMIUM II/III) SEAT HORIZONTAL REARWARD SWITCH SENSE

13 - -

14 P21 20RD/LG (PREMIUM II/III) SEAT FRONT DOWN SWITCH SENSE

15 P13 20RD/WT (PREMIUM II/III) SEAT REAR DOWN SWITCH SENSE

16 P47 20LB (PREMIUM II/III) RECLINER POSITION SIGNAL

17 P26 20BR (PREMIUM II/III) FRONT RISER POSITION SIGNAL

18 P29 20BR/WT SEAT SENSOR 5 VOLT SUPPLY

19 Z2 20BK/OR GROUND

20 D25 20VT/YL PCI BUS

8W - 80 - 118 8W-80 CONNECTOR PIN-OUTWJ

Page 1182 of 2199

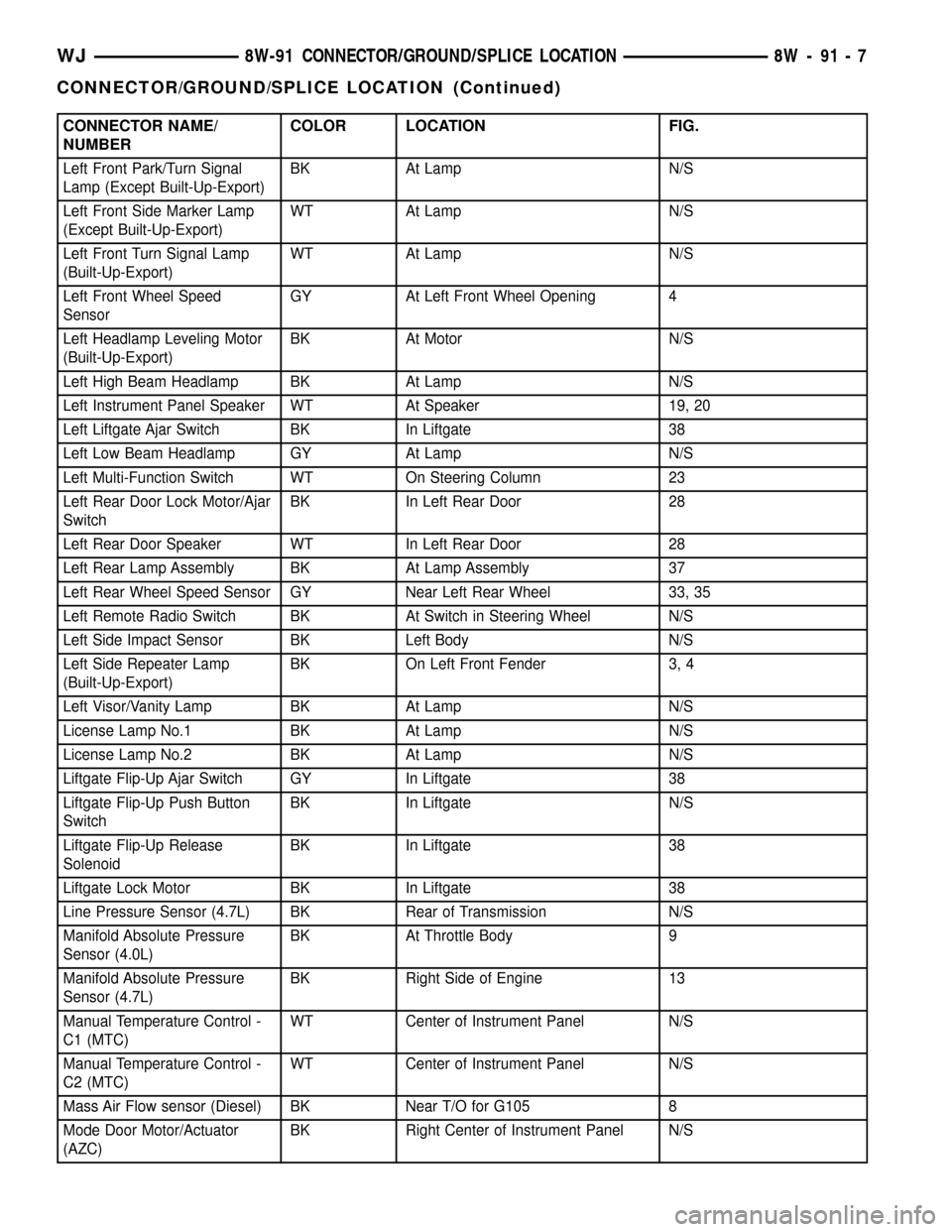

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Left Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Left Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Left Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Left Front Wheel Speed

SensorGY At Left Front Wheel Opening 4

Left Headlamp Leveling Motor

(Built-Up-Export)BK At Motor N/S

Left High Beam Headlamp BK At Lamp N/S

Left Instrument Panel Speaker WT At Speaker 19, 20

Left Liftgate Ajar Switch BK In Liftgate 38

Left Low Beam Headlamp GY At Lamp N/S

Left Multi-Function Switch WT On Steering Column 23

Left Rear Door Lock Motor/Ajar

SwitchBK In Left Rear Door 28

Left Rear Door Speaker WT In Left Rear Door 28

Left Rear Lamp Assembly BK At Lamp Assembly 37

Left Rear Wheel Speed Sensor GY Near Left Rear Wheel 33, 35

Left Remote Radio Switch BK At Switch in Steering Wheel N/S

Left Side Impact Sensor BK Left Body N/S

Left Side Repeater Lamp

(Built-Up-Export)BK On Left Front Fender 3, 4

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp No.1 BK At Lamp N/S

License Lamp No.2 BK At Lamp N/S

Liftgate Flip-Up Ajar Switch GY In Liftgate 38

Liftgate Flip-Up Push Button

SwitchBK In Liftgate N/S

Liftgate Flip-Up Release

SolenoidBK In Liftgate 38

Liftgate Lock Motor BK In Liftgate 38

Line Pressure Sensor (4.7L) BK Rear of Transmission N/S

Manifold Absolute Pressure

Sensor (4.0L)BK At Throttle Body 9

Manifold Absolute Pressure

Sensor (4.7L)BK Right Side of Engine 13

Manual Temperature Control -

C1 (MTC)WT Center of Instrument Panel N/S

Manual Temperature Control -

C2 (MTC)WT Center of Instrument Panel N/S

Mass Air Flow sensor (Diesel) BK Near T/O for G105 8

Mode Door Motor/Actuator

(AZC)BK Right Center of Instrument Panel N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1185 of 2199

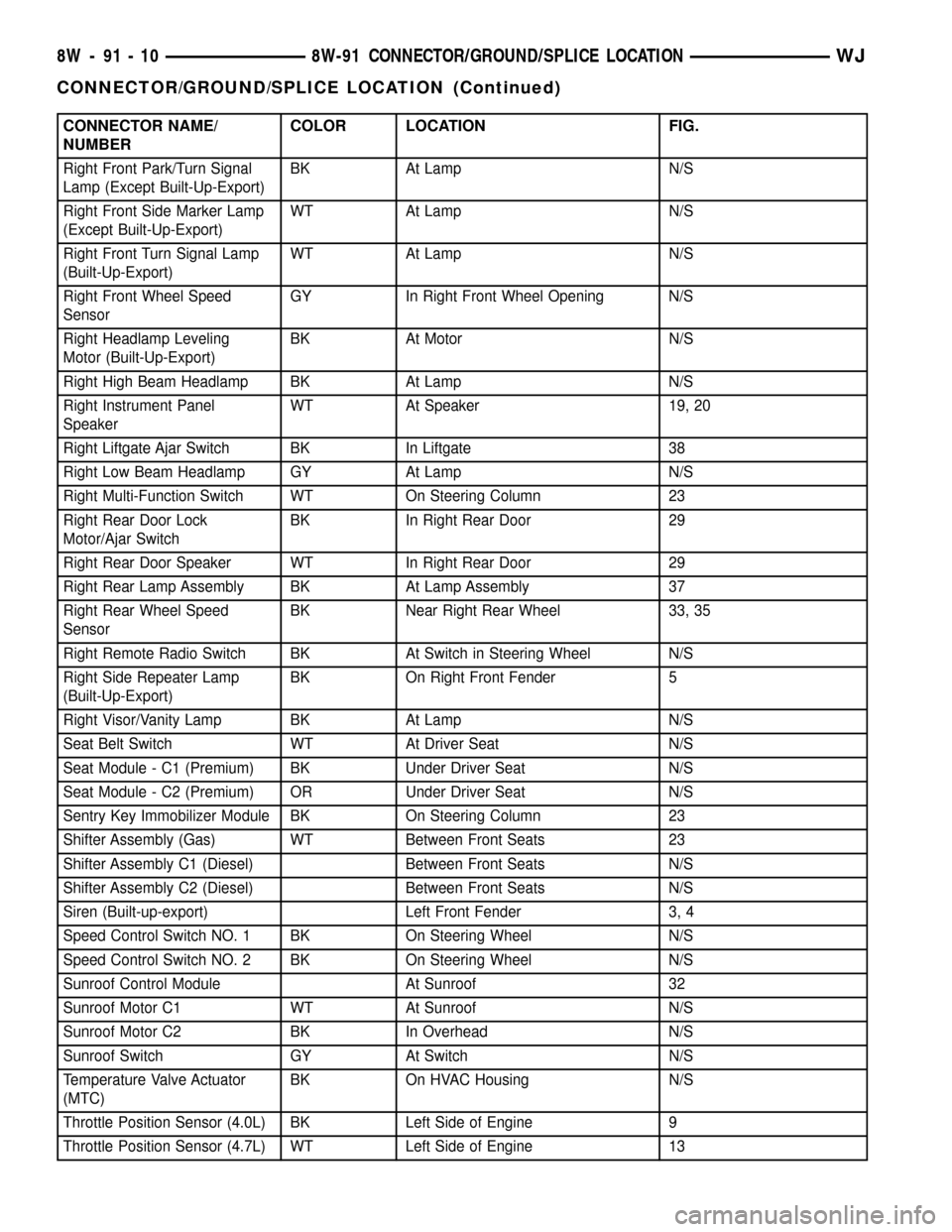

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Right Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Right Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Right Front Wheel Speed

SensorGY In Right Front Wheel Opening N/S

Right Headlamp Leveling

Motor (Built-Up-Export)BK At Motor N/S

Right High Beam Headlamp BK At Lamp N/S

Right Instrument Panel

SpeakerWT At Speaker 19, 20

Right Liftgate Ajar Switch BK In Liftgate 38

Right Low Beam Headlamp GY At Lamp N/S

Right Multi-Function Switch WT On Steering Column 23

Right Rear Door Lock

Motor/Ajar SwitchBK In Right Rear Door 29

Right Rear Door Speaker WT In Right Rear Door 29

Right Rear Lamp Assembly BK At Lamp Assembly 37

Right Rear Wheel Speed

SensorBK Near Right Rear Wheel 33, 35

Right Remote Radio Switch BK At Switch in Steering Wheel N/S

Right Side Repeater Lamp

(Built-Up-Export)BK On Right Front Fender 5

Right Visor/Vanity Lamp BK At Lamp N/S

Seat Belt Switch WT At Driver Seat N/S

Seat Module - C1 (Premium) BK Under Driver Seat N/S

Seat Module - C2 (Premium) OR Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 23

Shifter Assembly (Gas) WT Between Front Seats 23

Shifter Assembly C1 (Diesel) Between Front Seats N/S

Shifter Assembly C2 (Diesel) Between Front Seats N/S

Siren (Built-up-export) Left Front Fender 3, 4

Speed Control Switch NO. 1 BK On Steering Wheel N/S

Speed Control Switch NO. 2 BK On Steering Wheel N/S

Sunroof Control Module At Sunroof 32

Sunroof Motor C1 WT At Sunroof N/S

Sunroof Motor C2 BK In Overhead N/S

Sunroof Switch GY At Switch N/S

Temperature Valve Actuator

(MTC)BK On HVAC Housing N/S

Throttle Position Sensor (4.0L) BK Left Side of Engine 9

Throttle Position Sensor (4.7L) WT Left Side of Engine 13

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1376 of 2199

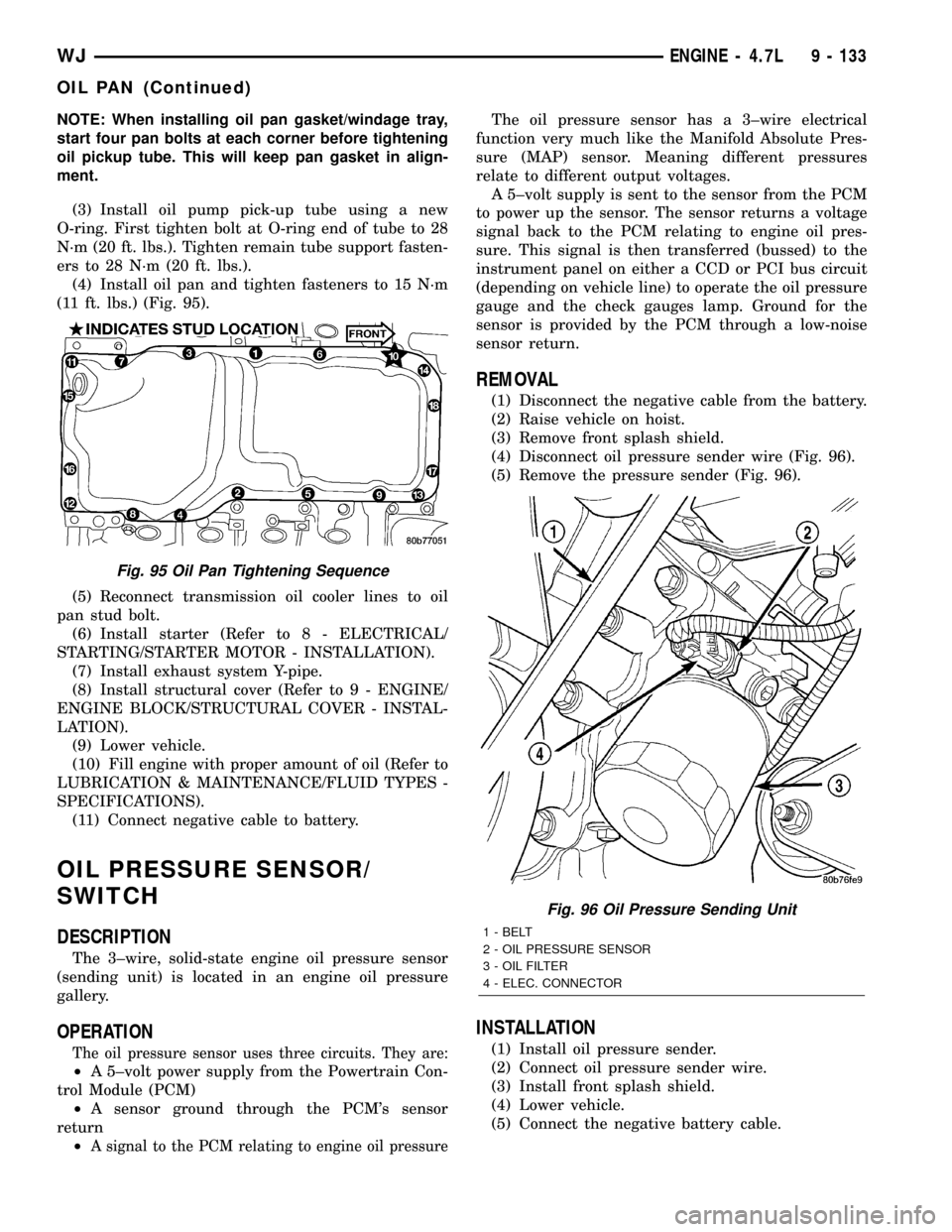

NOTE: When installing oil pan gasket/windage tray,

start four pan bolts at each corner before tightening

oil pickup tube. This will keep pan gasket in align-

ment.

(3) Install oil pump pick-up tube using a new

O-ring. First tighten bolt at O-ring end of tube to 28

N´m (20 ft. lbs.). Tighten remain tube support fasten-

ers to 28 N´m (20 ft. lbs.).

(4) Install oil pan and tighten fasteners to 15 N´m

(11 ft. lbs.) (Fig. 95).

(5) Reconnect transmission oil cooler lines to oil

pan stud bolt.

(6) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

(7) Install exhaust system Y-pipe.

(8) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(9) Lower vehicle.

(10) Fill engine with proper amount of oil (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

(11) Connect negative cable to battery.

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²

A signal to the PCM relating to engine oil pressure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 96).

(5) Remove the pressure sender (Fig. 96).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

Fig. 95 Oil Pan Tightening Sequence

Fig. 96 Oil Pressure Sending Unit

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

WJENGINE - 4.7L 9 - 133

OIL PAN (Continued)

Page 1605 of 2199

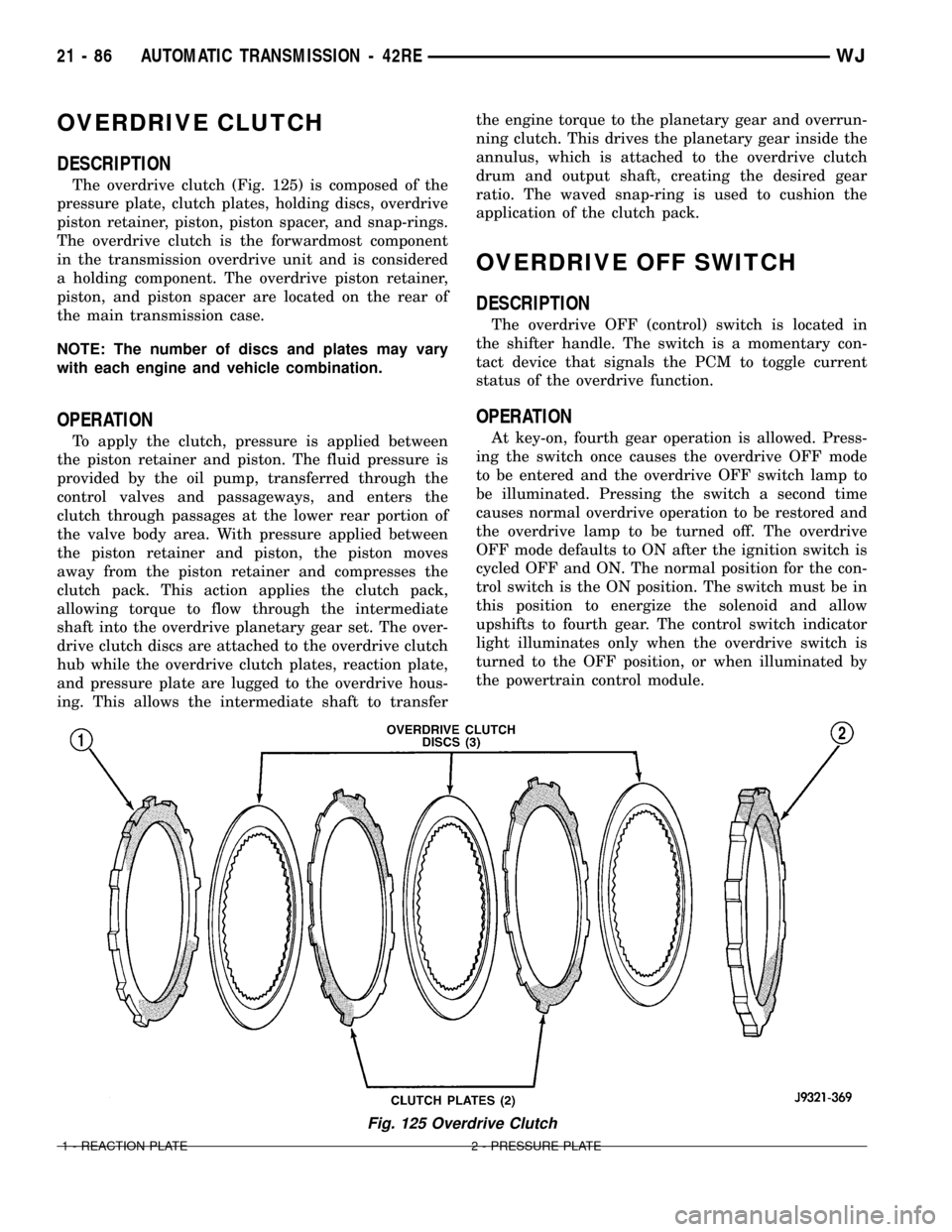

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 125) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the piston retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through passages at the lower rear portion of

the valve body area. With pressure applied between

the piston retainer and piston, the piston moves

away from the piston retainer and compresses the

clutch pack. This action applies the clutch pack,

allowing torque to flow through the intermediate

shaft into the overdrive planetary gear set. The over-

drive clutch discs are attached to the overdrive clutch

hub while the overdrive clutch plates, reaction plate,

and pressure plate are lugged to the overdrive hous-

ing. This allows the intermediate shaft to transferthe engine torque to the planetary gear and overrun-

ning clutch. This drives the planetary gear inside the

annulus, which is attached to the overdrive clutch

drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the

application of the clutch pack.

OVERDRIVE OFF SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth gear operation is allowed. Press-

ing the switch once causes the overdrive OFF mode

to be entered and the overdrive OFF switch lamp to

be illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow

upshifts to fourth gear. The control switch indicator

light illuminates only when the overdrive switch is

turned to the OFF position, or when illuminated by

the powertrain control module.

Fig. 125 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 86 AUTOMATIC TRANSMISSION - 42REWJ

Page 1773 of 2199

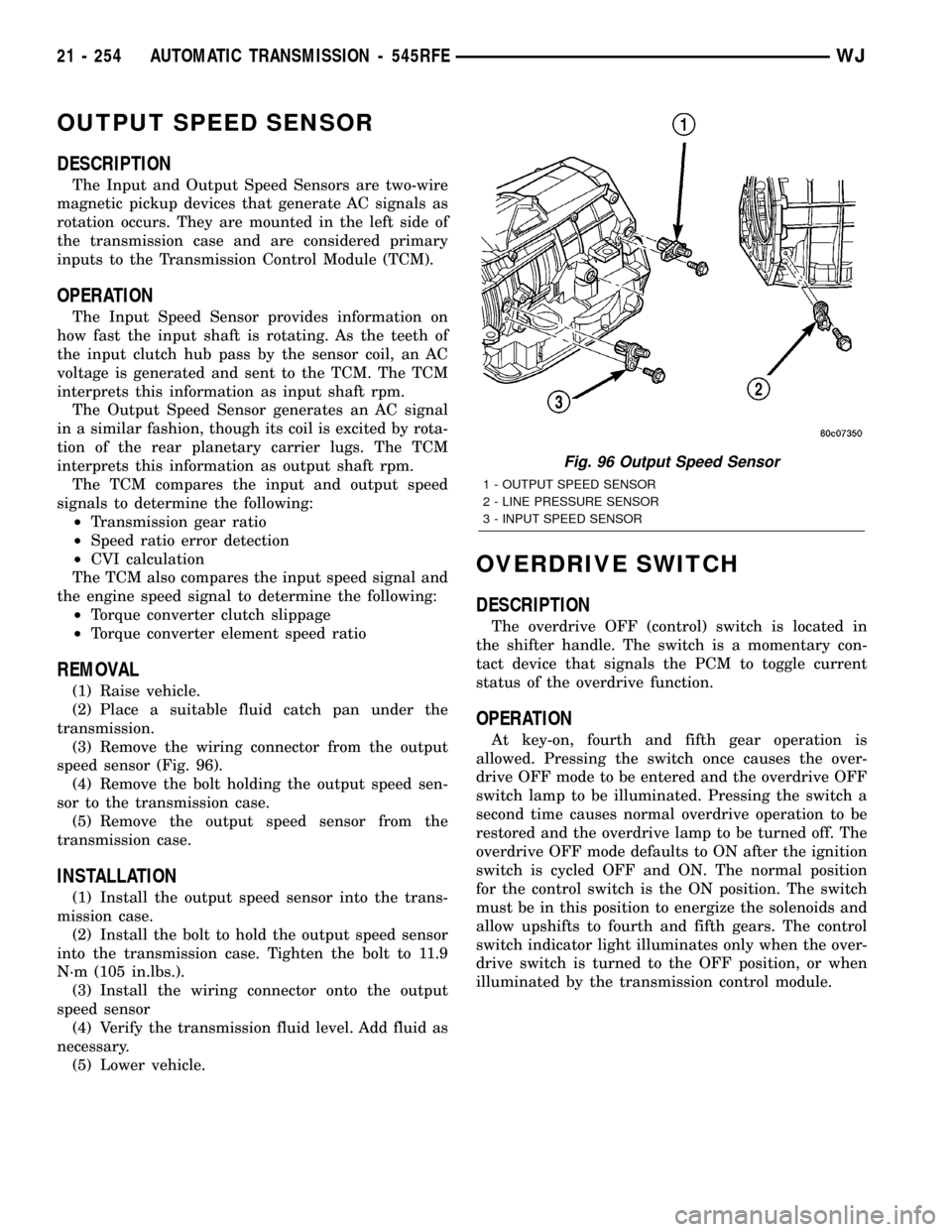

OUTPUT SPEED SENSOR

DESCRIPTION

The Input and Output Speed Sensors are two-wire

magnetic pickup devices that generate AC signals as

rotation occurs. They are mounted in the left side of

the transmission case and are considered primary

inputs to the Transmission Control Module (TCM).

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil, an AC

voltage is generated and sent to the TCM. The TCM

interprets this information as input shaft rpm.

The Output Speed Sensor generates an AC signal

in a similar fashion, though its coil is excited by rota-

tion of the rear planetary carrier lugs. The TCM

interprets this information as output shaft rpm.

The TCM compares the input and output speed

signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The TCM also compares the input speed signal and

the engine speed signal to determine the following:

²Torque converter clutch slippage

²Torque converter element speed ratio

REMOVAL

(1) Raise vehicle.

(2) Place a suitable fluid catch pan under the

transmission.

(3) Remove the wiring connector from the output

speed sensor (Fig. 96).

(4) Remove the bolt holding the output speed sen-

sor to the transmission case.

(5) Remove the output speed sensor from the

transmission case.

INSTALLATION

(1) Install the output speed sensor into the trans-

mission case.

(2) Install the bolt to hold the output speed sensor

into the transmission case. Tighten the bolt to 11.9

N´m (105 in.lbs.).

(3) Install the wiring connector onto the output

speed sensor

(4) Verify the transmission fluid level. Add fluid as

necessary.

(5) Lower vehicle.

OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth and fifth gear operation is

allowed. Pressing the switch once causes the over-

drive OFF mode to be entered and the overdrive OFF

switch lamp to be illuminated. Pressing the switch a

second time causes normal overdrive operation to be

restored and the overdrive lamp to be turned off. The

overdrive OFF mode defaults to ON after the ignition

switch is cycled OFF and ON. The normal position

for the control switch is the ON position. The switch

must be in this position to energize the solenoids and

allow upshifts to fourth and fifth gears. The control

switch indicator light illuminates only when the over-

drive switch is turned to the OFF position, or when

illuminated by the transmission control module.

Fig. 96 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

21 - 254 AUTOMATIC TRANSMISSION - 545RFEWJ