Band adjustment JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1520 of 2199

TRANSMISSION AND TRANSFER CASE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE..........1

AUTOMATIC TRANSMISSION - 545RFE......177TRANSFER CASE - NV242................280

TRANSFER CASE - NV247................315

AUTOMATIC TRANSMISSION - 42RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE

DESCRIPTION..........................3

OPERATION............................5

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION......................11

DIAGNOSIS AND TESTING - PRELIMINARY . 11

DIAGNOSIS AND TESTING - ROAD

TESTING............................11

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST.....................12

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH AND BAND

OPERATION.........................15

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK.................15

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS............................16

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR......................26

REMOVAL.............................27

DISASSEMBLY.........................29

CLEANING............................34

INSPECTION..........................34

ASSEMBLY............................34

INSTALLATION.........................41

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS..............43

SPECIFICATIONS

TRANSMISSION......................55

SPECIAL TOOLS

RE TRANSMISSIONS..................57

ACCUMULATOR

DESCRIPTION.........................60

OPERATION...........................60

INSPECTION..........................60BANDS

DESCRIPTION.........................61

OPERATION...........................61

ADJUSTMENTS

ADJUSTMENT - BANDS................62

BRAKE TRANSMISSION SHIFT INTERLOCK

MECHANISM

DESCRIPTION.........................63

OPERATION...........................63

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK.......63

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK....................64

ELECTRONIC GOVERNOR

DESCRIPTION.........................65

OPERATION...........................65

REMOVAL.............................67

INSTALLATION.........................67

EXTENSION HOUSING BUSHING

REMOVAL.............................68

INSTALLATION.........................68

EXTENSION HOUSING SEAL

REMOVAL.............................69

INSTALLATION.........................69

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL..............69

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID........................69

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION.....................70

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK.............................70

WJTRANSMISSION AND TRANSFER CASE 21 - 1

Page 1522 of 2199

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE........134

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................134

OPERATION..........................134

VALVE BODY

DESCRIPTION........................135

OPERATION..........................139REMOVAL............................154

DISASSEMBLY........................155

CLEANING...........................165

INSPECTION.........................166

ASSEMBLY...........................167

INSTALLATION........................175

ADJUSTMENTS - VALVE BODY...........175

AUTOMATIC TRANSMISSION -

42RE

DESCRIPTION

The 42RE is a four speed fully automatic transmis-

sion (Fig. 1) with an electronic governor. The 42RE is

equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and the

low/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 3

Page 1530 of 2199

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

overdrive control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

valve moves the overdrive piston into contact with

the overdrive clutch. The direct clutch is disengaged

before the overdrive clutch is engaged. The boost

valve provides increased fluid apply pressure to the

overdrive clutch during 3-4 upshifts, and when accel-

erating in fourth gear. The 3-4 accumulator cushions

overdrive clutch engagement to smooth 3-4 upshifts.

The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

Automatic transmission problems can be a result of

poor engine performance, incorrect fluid level, incor-

rect linkage or cable adjustment, band or hydraulic

control pressure adjustments, hydraulic system mal-

functions or electrical/mechanical component mal-

functions. Begin diagnosis by checking the easily

accessible items such as: fluid level and condition,

linkage adjustments and electrical connections. A

road test will determine if further diagnosis is neces-

sary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if com-

plaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart provides a basis for analyzing road test

results.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 11

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1539 of 2199

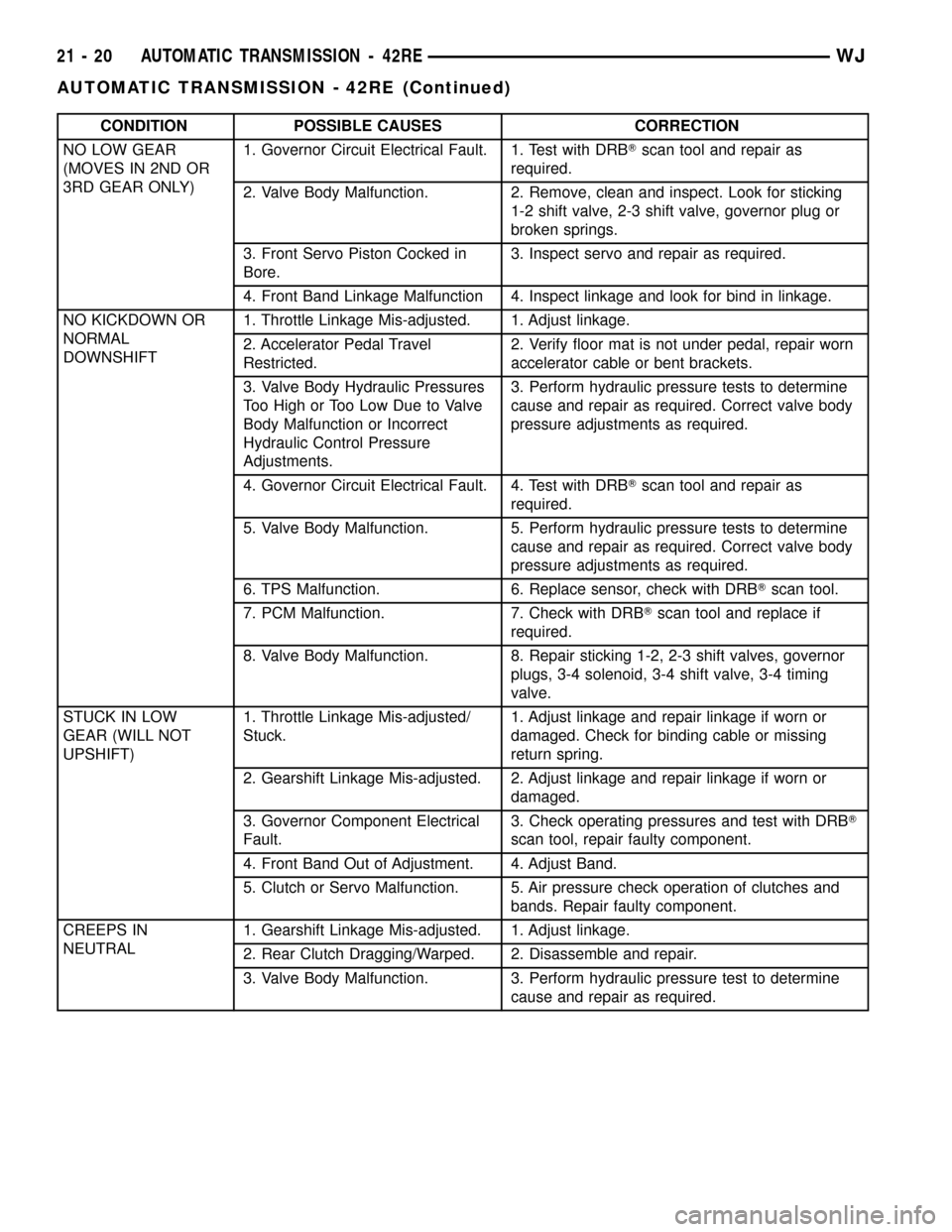

CONDITION POSSIBLE CAUSES CORRECTION

NO LOW GEAR

(MOVES IN 2ND OR

3RD GEAR ONLY)1. Governor Circuit Electrical Fault. 1. Test with DRBTscan tool and repair as

required.

2. Valve Body Malfunction. 2. Remove, clean and inspect. Look for sticking

1-2 shift valve, 2-3 shift valve, governor plug or

broken springs.

3. Front Servo Piston Cocked in

Bore.3. Inspect servo and repair as required.

4. Front Band Linkage Malfunction 4. Inspect linkage and look for bind in linkage.

NO KICKDOWN OR

NORMAL

DOWNSHIFT1. Throttle Linkage Mis-adjusted. 1. Adjust linkage.

2. Accelerator Pedal Travel

Restricted.2. Verify floor mat is not under pedal, repair worn

accelerator cable or bent brackets.

3. Valve Body Hydraulic Pressures

Too High or Too Low Due to Valve

Body Malfunction or Incorrect

Hydraulic Control Pressure

Adjustments.3. Perform hydraulic pressure tests to determine

cause and repair as required. Correct valve body

pressure adjustments as required.

4. Governor Circuit Electrical Fault. 4. Test with DRBTscan tool and repair as

required.

5. Valve Body Malfunction. 5. Perform hydraulic pressure tests to determine

cause and repair as required. Correct valve body

pressure adjustments as required.

6. TPS Malfunction. 6. Replace sensor, check with DRBTscan tool.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace if

required.

8. Valve Body Malfunction. 8. Repair sticking 1-2, 2-3 shift valves, governor

plugs, 3-4 solenoid, 3-4 shift valve, 3-4 timing

valve.

STUCK IN LOW

GEAR (WILL NOT

UPSHIFT)1. Throttle Linkage Mis-adjusted/

Stuck.1. Adjust linkage and repair linkage if worn or

damaged. Check for binding cable or missing

return spring.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage and repair linkage if worn or

damaged.

3. Governor Component Electrical

Fault.3. Check operating pressures and test with DRBT

scan tool, repair faulty component.

4. Front Band Out of Adjustment. 4. Adjust Band.

5. Clutch or Servo Malfunction. 5. Air pressure check operation of clutches and

bands. Repair faulty component.

CREEPS IN

NEUTRAL1. Gearshift Linkage Mis-adjusted. 1. Adjust linkage.

2. Rear Clutch Dragging/Warped. 2. Disassemble and repair.

3. Valve Body Malfunction. 3. Perform hydraulic pressure test to determine

cause and repair as required.

21 - 20 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1540 of 2199

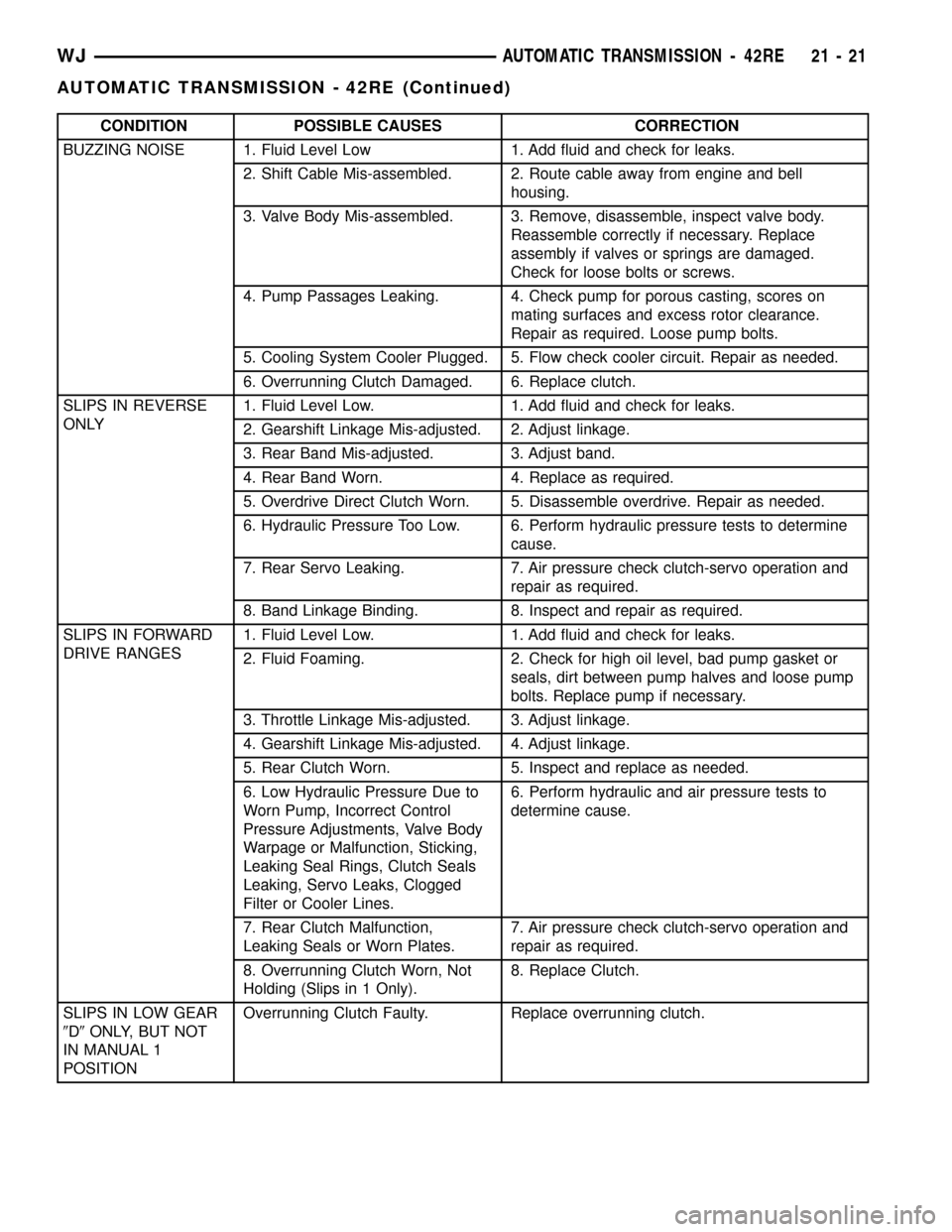

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Mis-assembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Mis-assembled. 3. Remove, disassemble, inspect valve body.

Reassemble correctly if necessary. Replace

assembly if valves or springs are damaged.

Check for loose bolts or screws.

4. Pump Passages Leaking. 4. Check pump for porous casting, scores on

mating surfaces and excess rotor clearance.

Repair as required. Loose pump bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as needed.

6. Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE

ONLY1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage.

3. Rear Band Mis-adjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Overdrive Direct Clutch Worn. 5. Disassemble overdrive. Repair as needed.

6. Hydraulic Pressure Too Low. 6. Perform hydraulic pressure tests to determine

cause.

7. Rear Servo Leaking. 7. Air pressure check clutch-servo operation and

repair as required.

8. Band Linkage Binding. 8. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump gasket or

seals, dirt between pump halves and loose pump

bolts. Replace pump if necessary.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage.

4. Gearshift Linkage Mis-adjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking,

Leaking Seal Rings, Clutch Seals

Leaking, Servo Leaks, Clogged

Filter or Cooler Lines.6. Perform hydraulic and air pressure tests to

determine cause.

7. Rear Clutch Malfunction,

Leaking Seals or Worn Plates.7. Air pressure check clutch-servo operation and

repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR

9D9ONLY, BUT NOT

IN MANUAL 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 21

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1574 of 2199

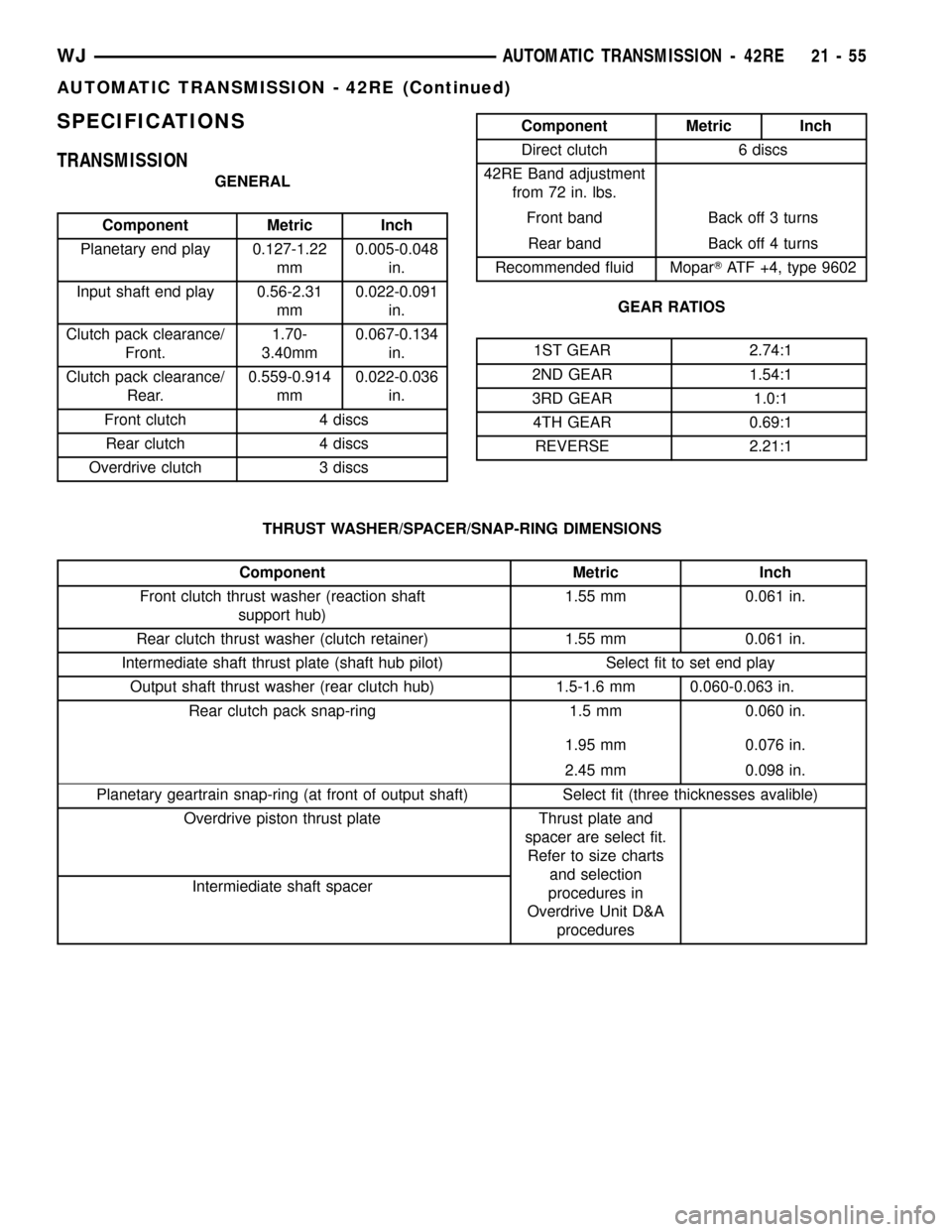

SPECIFICATIONS

TRANSMISSION

GENERAL

Component Metric Inch

Planetary end play 0.127-1.22

mm0.005-0.048

in.

Input shaft end play 0.56-2.31

mm0.022-0.091

in.

Clutch pack clearance/

Front.1.70-

3.40mm0.067-0.134

in.

Clutch pack clearance/

Rear.0.559-0.914

mm0.022-0.036

in.

Front clutch 4 discs

Rear clutch 4 discs

Overdrive clutch 3 discs

Component Metric Inch

Direct clutch 6 discs

42RE Band adjustment

from 72 in. lbs.

Front band Back off 3 turns

Rear band Back off 4 turns

Recommended fluid MoparTATF +4, type 9602

GEAR RATIOS

1ST GEAR 2.74:1

2ND GEAR 1.54:1

3RD GEAR 1.0:1

4TH GEAR 0.69:1

REVERSE 2.21:1

THRUST WASHER/SPACER/SNAP-RING DIMENSIONS

Component Metric Inch

Front clutch thrust washer (reaction shaft

support hub)1.55 mm 0.061 in.

Rear clutch thrust washer (clutch retainer) 1.55 mm 0.061 in.

Intermediate shaft thrust plate (shaft hub pilot) Select fit to set end play

Output shaft thrust washer (rear clutch hub) 1.5-1.6 mm 0.060-0.063 in.

Rear clutch pack snap-ring 1.5 mm 0.060 in.

1.95 mm 0.076 in.

2.45 mm 0.098 in.

Planetary geartrain snap-ring (at front of output shaft) Select fit (three thicknesses avalible)

Overdrive piston thrust plate Thrust plate and

spacer are select fit.

Refer to size charts

and selection

procedures in

Overdrive Unit D&A

procedures Intermiediate shaft spacer

WJAUTOMATIC TRANSMISSION - 42RE 21 - 55

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1581 of 2199

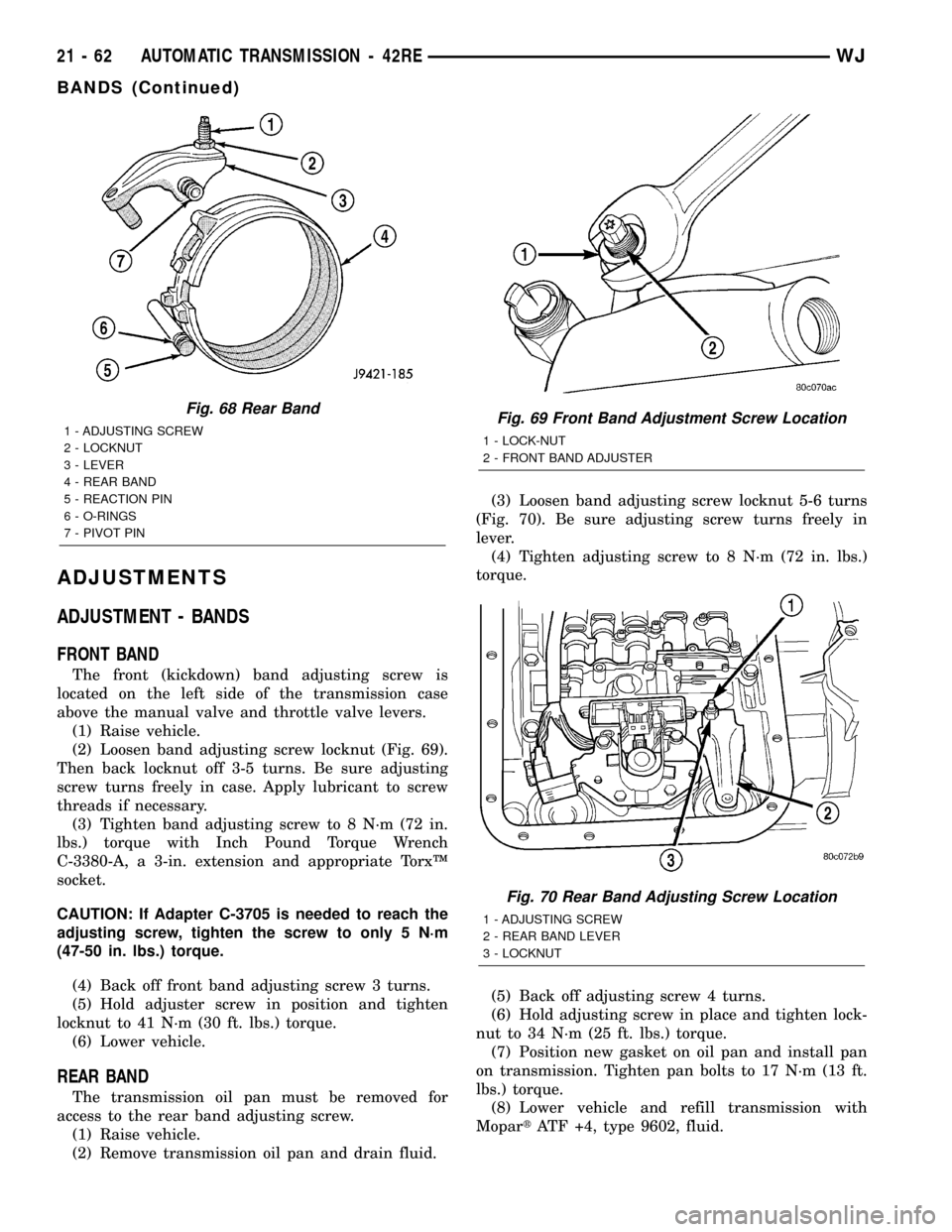

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 69).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and appropriate TorxŸ

socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4) Back off front band adjusting screw 3 turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

REAR BAND

The transmission oil pan must be removed for

access to the rear band adjusting screw.

(1) Raise vehicle.

(2) Remove transmission oil pan and drain fluid.(3) Loosen band adjusting screw locknut 5-6 turns

(Fig. 70). Be sure adjusting screw turns freely in

lever.

(4) Tighten adjusting screw to 8 N´m (72 in. lbs.)

torque.

(5) Back off adjusting screw 4 turns.

(6) Hold adjusting screw in place and tighten lock-

nut to 34 N´m (25 ft. lbs.) torque.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 17 N´m (13 ft.

lbs.) torque.

(8) Lower vehicle and refill transmission with

MopartATF +4, type 9602, fluid.

Fig. 68 Rear Band

1 - ADJUSTING SCREW

2 - LOCKNUT

3 - LEVER

4 - REAR BAND

5 - REACTION PIN

6 - O-RINGS

7 - PIVOT PINFig. 69 Front Band Adjustment Screw Location

1 - LOCK-NUT

2 - FRONT BAND ADJUSTER

Fig. 70 Rear Band Adjusting Screw Location

1 - ADJUSTING SCREW

2 - REAR BAND LEVER

3 - LOCKNUT

21 - 62 AUTOMATIC TRANSMISSION - 42REWJ

BANDS (Continued)

Page 1694 of 2199

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

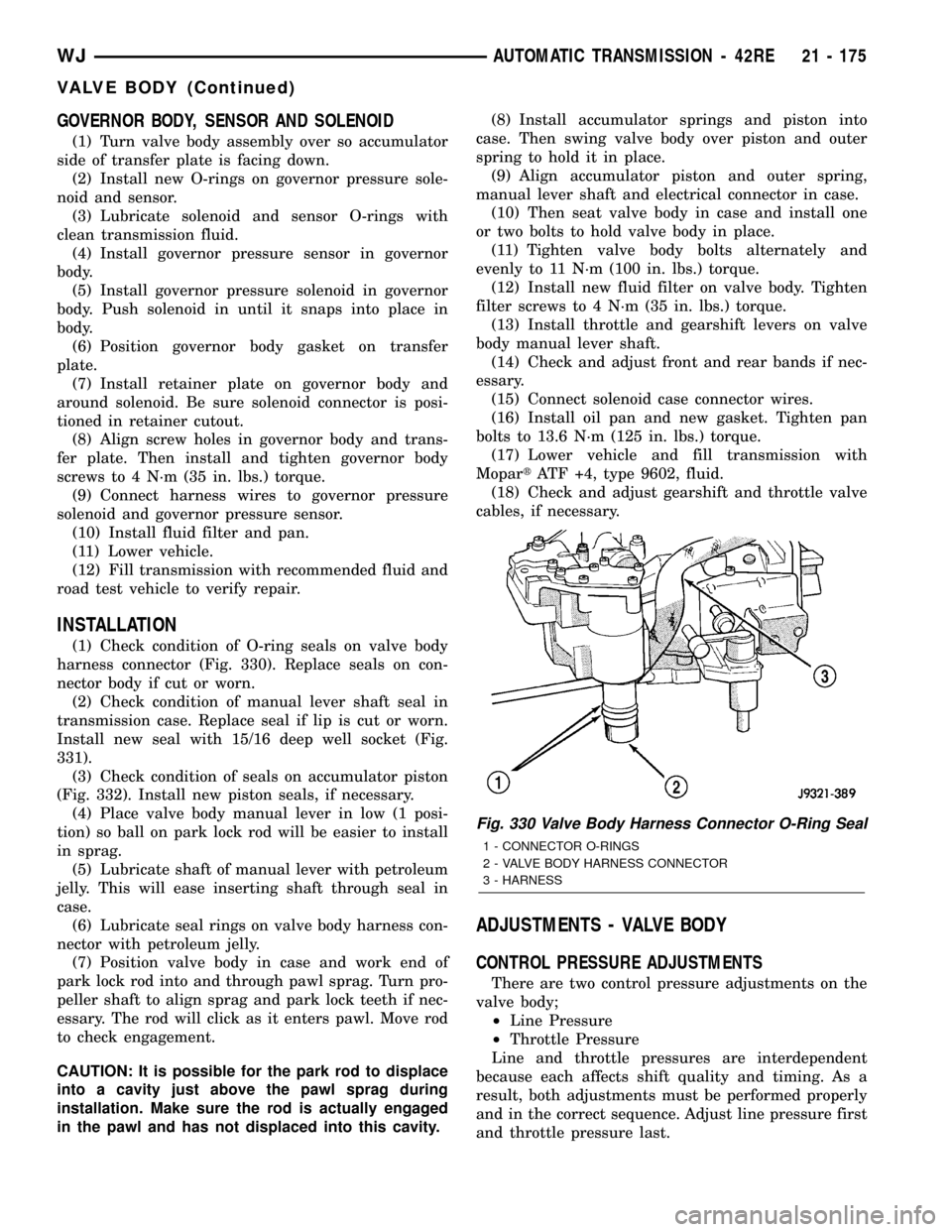

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 330). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

331).

(3) Check condition of seals on accumulator piston

(Fig. 332). Install new piston seals, if necessary.

(4) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(5) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(6) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(7) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.(8) Install accumulator springs and piston into

case. Then swing valve body over piston and outer

spring to hold it in place.

(9) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(10) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(11) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(12) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(13) Install throttle and gearshift levers on valve

body manual lever shaft.

(14) Check and adjust front and rear bands if nec-

essary.

(15) Connect solenoid case connector wires.

(16) Install oil pan and new gasket. Tighten pan

bolts to 13.6 N´m (125 in. lbs.) torque.

(17) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(18) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

Fig. 330 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

WJAUTOMATIC TRANSMISSION - 42RE 21 - 175

VALVE BODY (Continued)