Oil feed tube JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 69 of 2199

DIFFERENTIAL

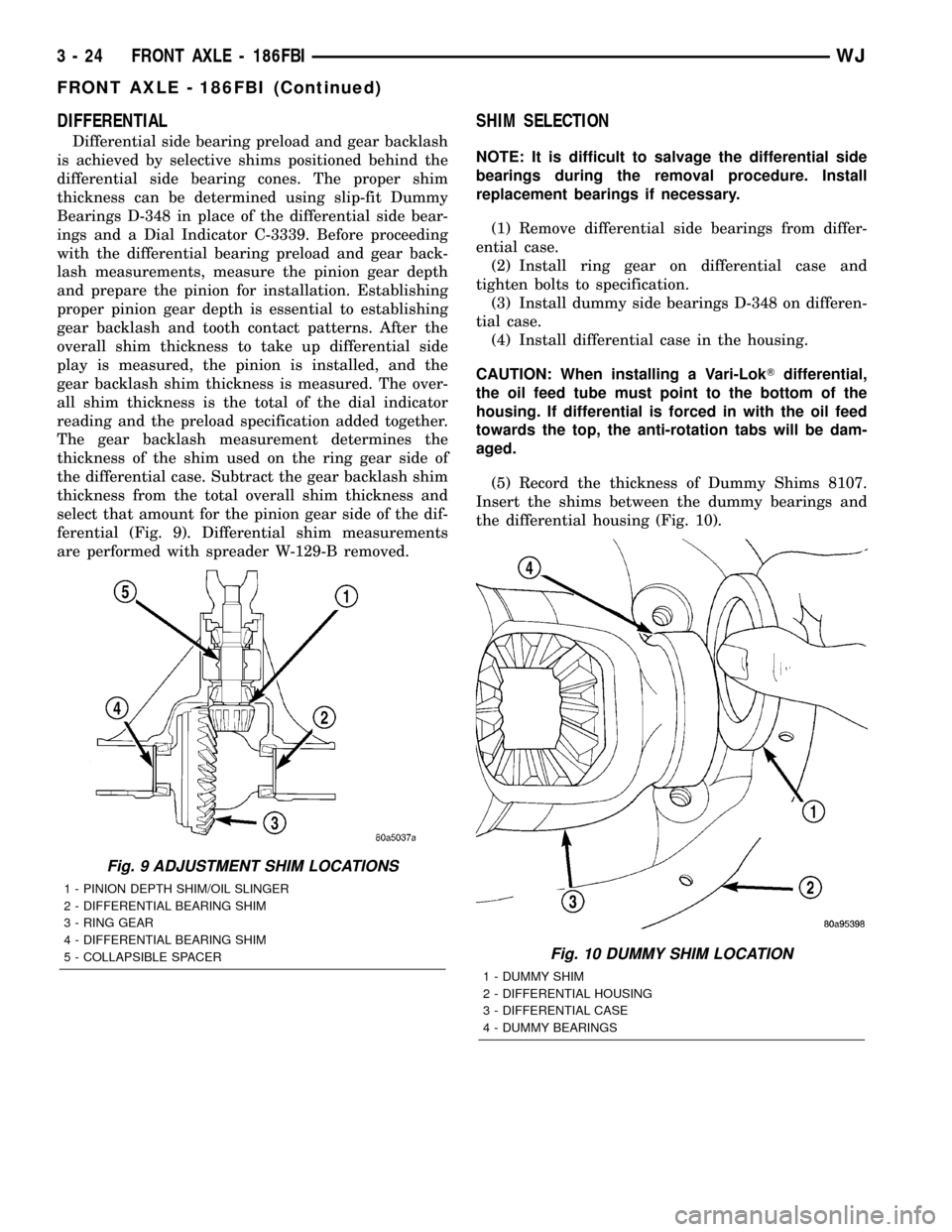

Differential side bearing preload and gear backlash

is achieved by selective shims positioned behind the

differential side bearing cones. The proper shim

thickness can be determined using slip-fit Dummy

Bearings D-348 in place of the differential side bear-

ings and a Dial Indicator C-3339. Before proceeding

with the differential bearing preload and gear back-

lash measurements, measure the pinion gear depth

and prepare the pinion for installation. Establishing

proper pinion gear depth is essential to establishing

gear backlash and tooth contact patterns. After the

overall shim thickness to take up differential side

play is measured, the pinion is installed, and the

gear backlash shim thickness is measured. The over-

all shim thickness is the total of the dial indicator

reading and the preload specification added together.

The gear backlash measurement determines the

thickness of the shim used on the ring gear side of

the differential case. Subtract the gear backlash shim

thickness from the total overall shim thickness and

select that amount for the pinion gear side of the dif-

ferential (Fig. 9). Differential shim measurements

are performed with spreader W-129-B removed.

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove differential side bearings from differ-

ential case.

(2) Install ring gear on differential case and

tighten bolts to specification.

(3) Install dummy side bearings D-348 on differen-

tial case.

(4) Install differential case in the housing.

CAUTION: When installing a Vari-LokTdifferential,

the oil feed tube must point to the bottom of the

housing. If differential is forced in with the oil feed

towards the top, the anti-rotation tabs will be dam-

aged.

(5) Record the thickness of Dummy Shims 8107.

Insert the shims between the dummy bearings and

the differential housing (Fig. 10).

Fig. 9 ADJUSTMENT SHIM LOCATIONS

1 - PINION DEPTH SHIM/OIL SLINGER

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

Fig. 10 DUMMY SHIM LOCATION

1 - DUMMY SHIM

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

3 - 24 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 72 of 2199

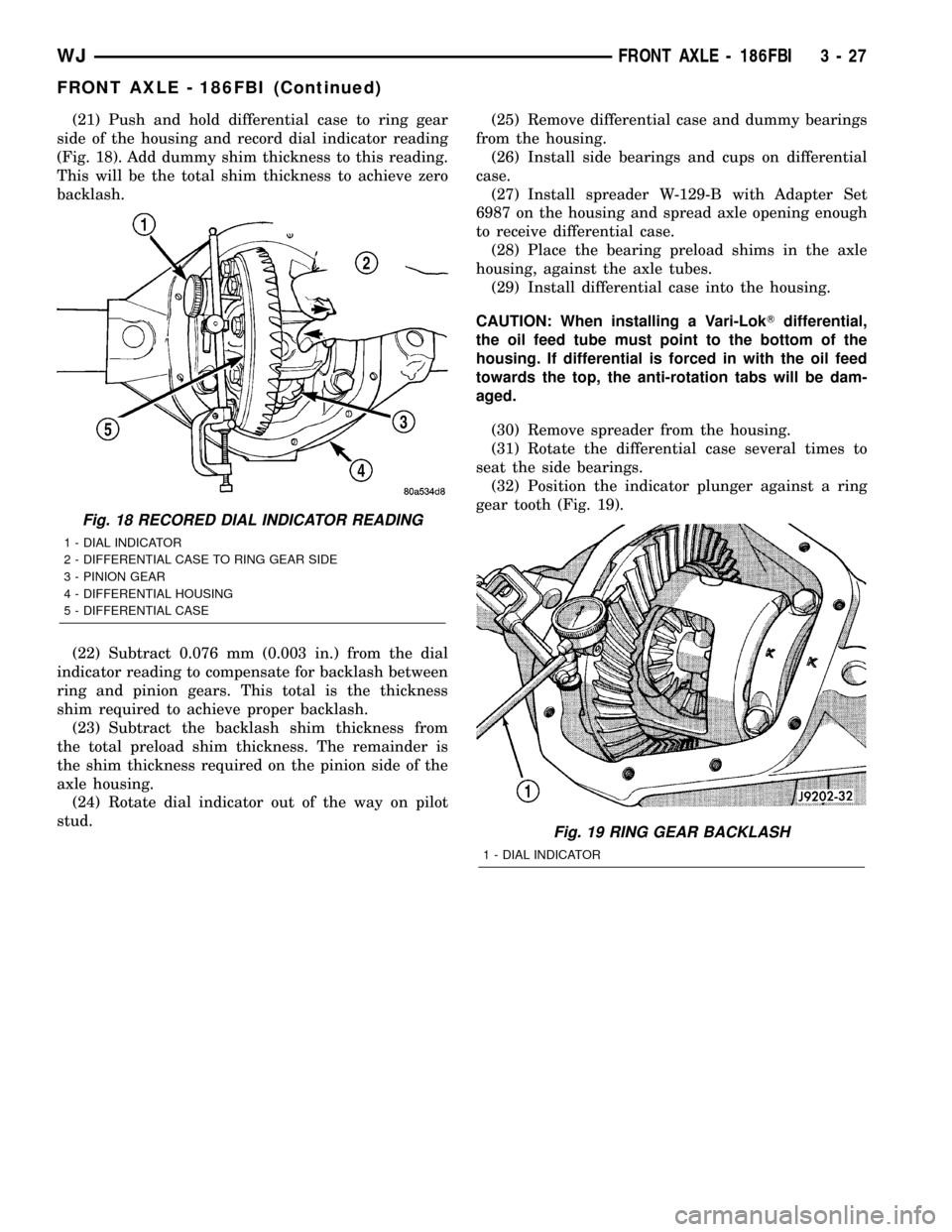

(21) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 18). Add dummy shim thickness to this reading.

This will be the total shim thickness to achieve zero

backlash.

(22) Subtract 0.076 mm (0.003 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. This total is the thickness

shim required to achieve proper backlash.

(23) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

axle housing.

(24) Rotate dial indicator out of the way on pilot

stud.(25) Remove differential case and dummy bearings

from the housing.

(26) Install side bearings and cups on differential

case.

(27) Install spreader W-129-B with Adapter Set

6987 on the housing and spread axle opening enough

to receive differential case.

(28) Place the bearing preload shims in the axle

housing, against the axle tubes.

(29) Install differential case into the housing.

CAUTION: When installing a Vari-LokTdifferential,

the oil feed tube must point to the bottom of the

housing. If differential is forced in with the oil feed

towards the top, the anti-rotation tabs will be dam-

aged.

(30) Remove spreader from the housing.

(31) Rotate the differential case several times to

seat the side bearings.

(32) Position the indicator plunger against a ring

gear tooth (Fig. 19).

Fig. 18 RECORED DIAL INDICATOR READING

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

Fig. 19 RING GEAR BACKLASH

1 - DIAL INDICATOR

WJFRONT AXLE - 186FBI 3 - 27

FRONT AXLE - 186FBI (Continued)

Page 88 of 2199

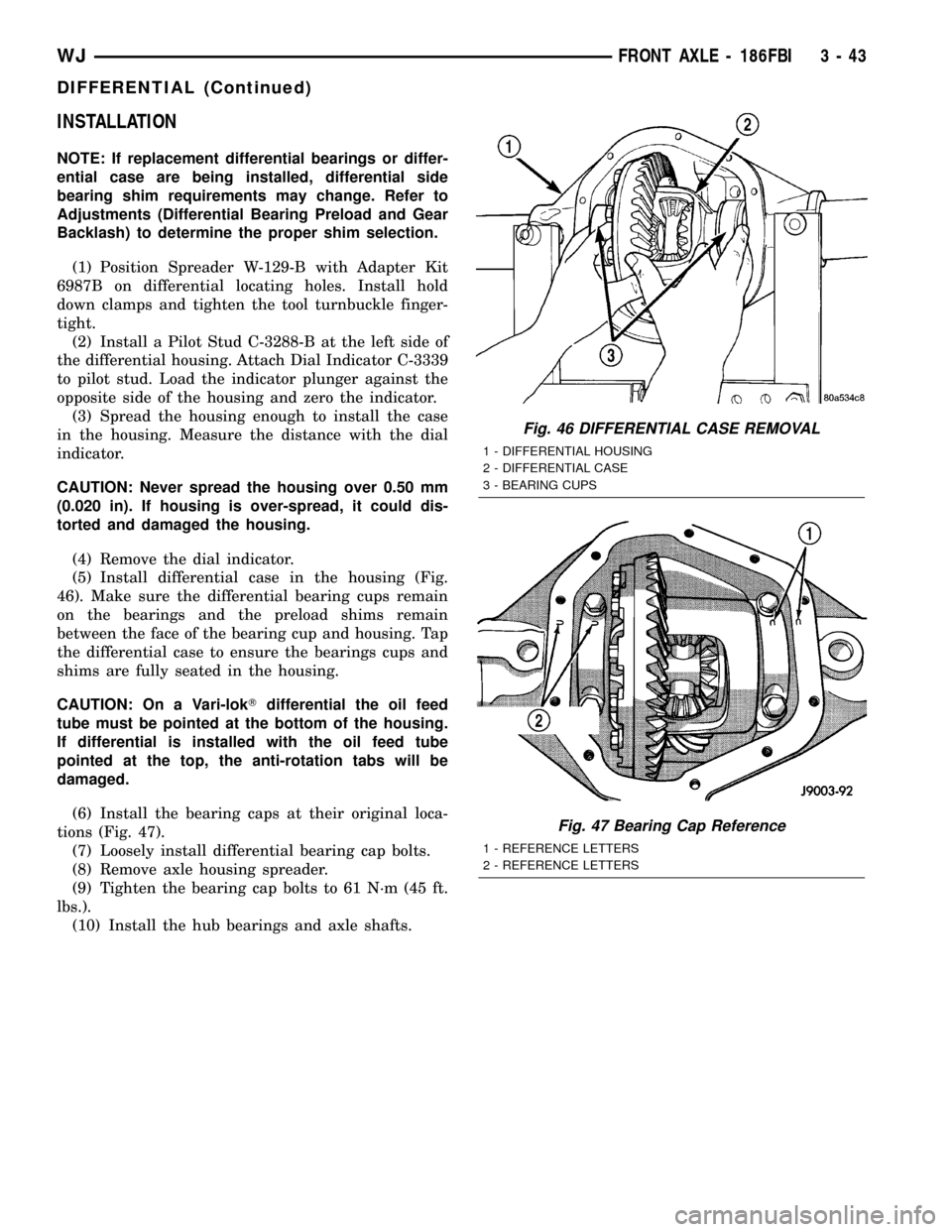

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes. Install hold

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could dis-

torted and damaged the housing.

(4) Remove the dial indicator.

(5) Install differential case in the housing (Fig.

46). Make sure the differential bearing cups remain

on the bearings and the preload shims remain

between the face of the bearing cup and housing. Tap

the differential case to ensure the bearings cups and

shims are fully seated in the housing.

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing.

If differential is installed with the oil feed tube

pointed at the top, the anti-rotation tabs will be

damaged.

(6) Install the bearing caps at their original loca-

tions (Fig. 47).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten the bearing cap bolts to 61 N´m (45 ft.

lbs.).

(10) Install the hub bearings and axle shafts.

Fig. 46 DIFFERENTIAL CASE REMOVAL

1 - DIFFERENTIAL HOUSING

2 - DIFFERENTIAL CASE

3 - BEARING CUPS

Fig. 47 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

WJFRONT AXLE - 186FBI 3 - 43

DIFFERENTIAL (Continued)

Page 122 of 2199

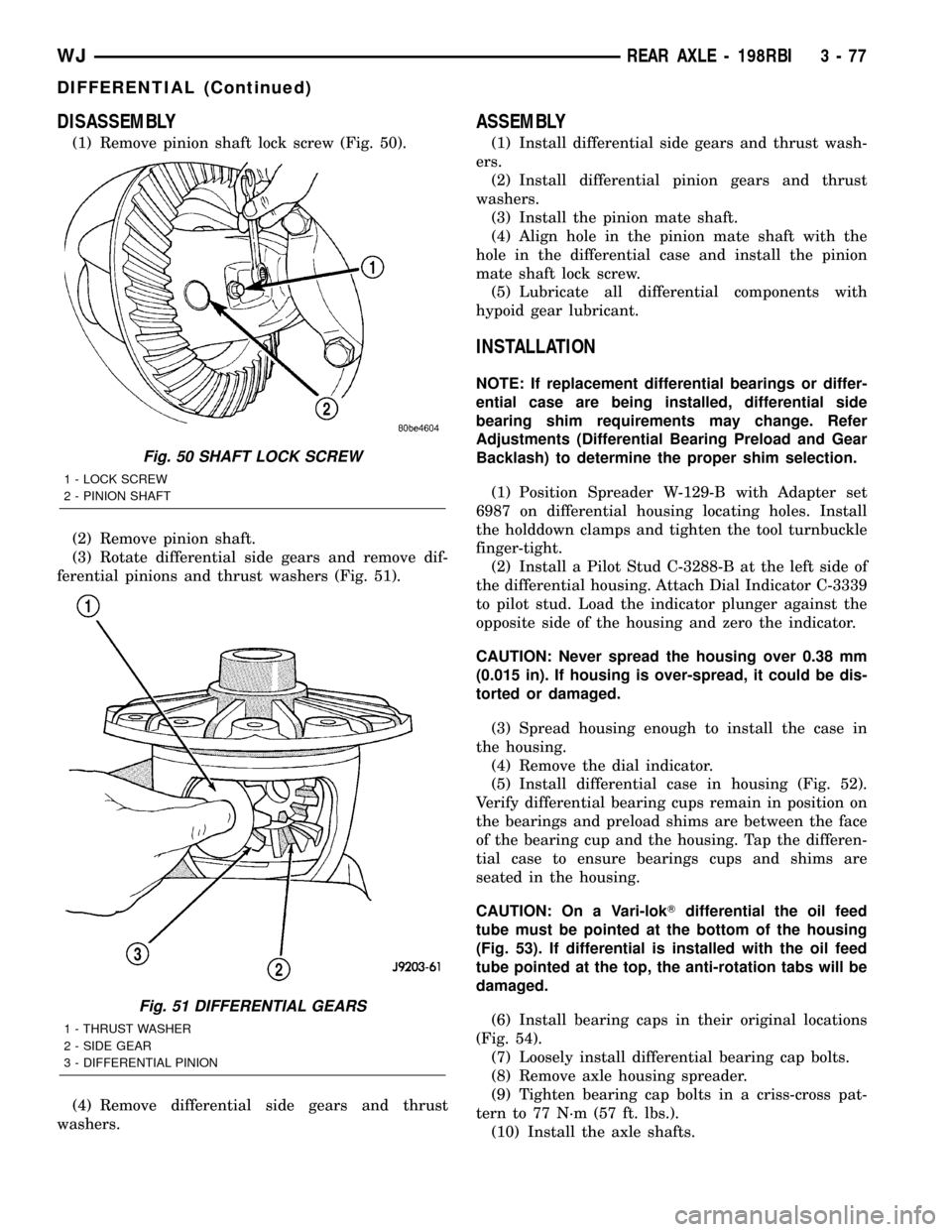

DISASSEMBLY

(1) Remove pinion shaft lock screw (Fig. 50).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 51).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion gears and thrust

washers.

(3) Install the pinion mate shaft.

(4) Align hole in the pinion mate shaft with the

hole in the differential case and install the pinion

mate shaft lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter set

6987 on differential housing locating holes. Install

the holddown clamps and tighten the tool turnbuckle

finger-tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

CAUTION: Never spread the housing over 0.38 mm

(0.015 in). If housing is over-spread, it could be dis-

torted or damaged.

(3) Spread housing enough to install the case in

the housing.

(4) Remove the dial indicator.

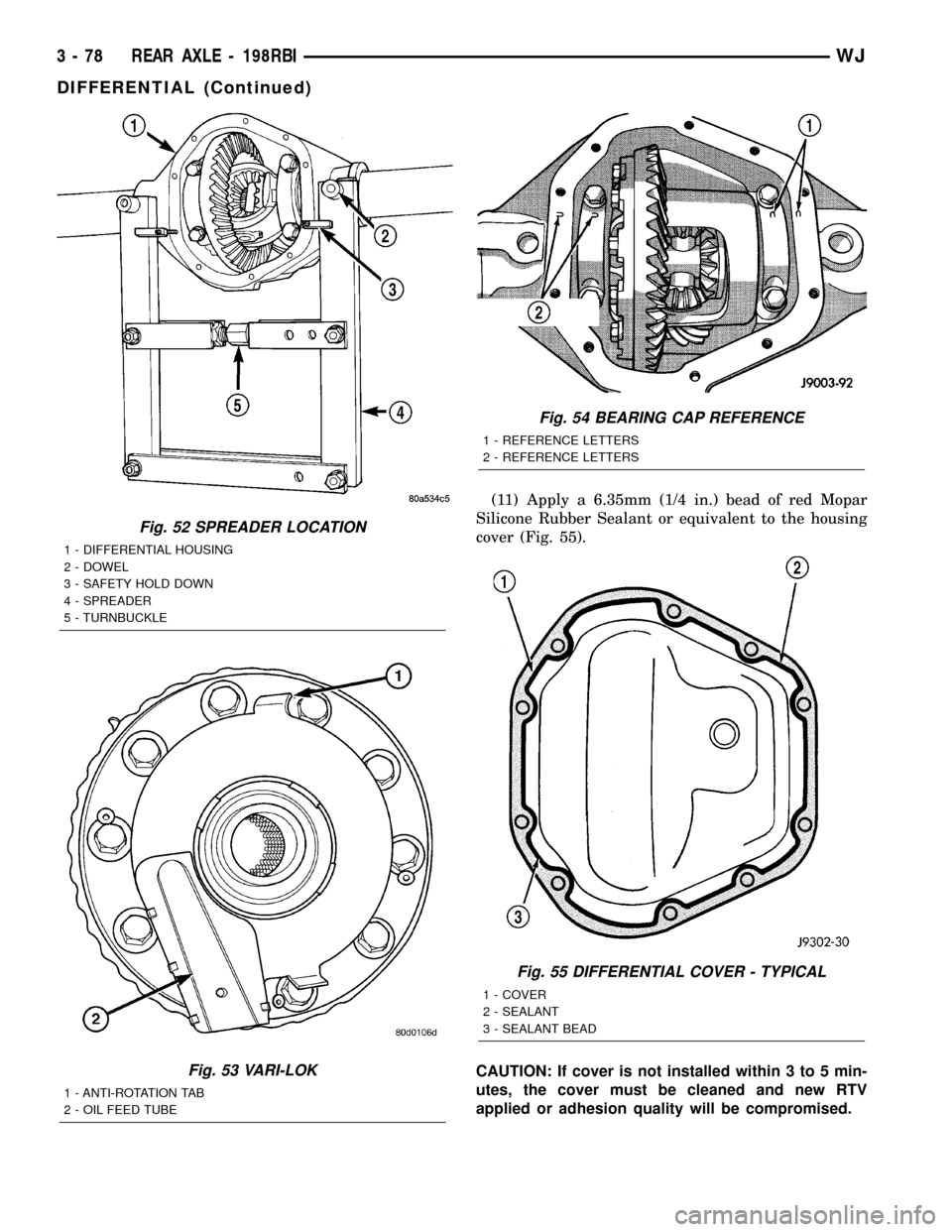

(5) Install differential case in housing (Fig. 52).

Verify differential bearing cups remain in position on

the bearings and preload shims are between the face

of the bearing cup and the housing. Tap the differen-

tial case to ensure bearings cups and shims are

seated in the housing.

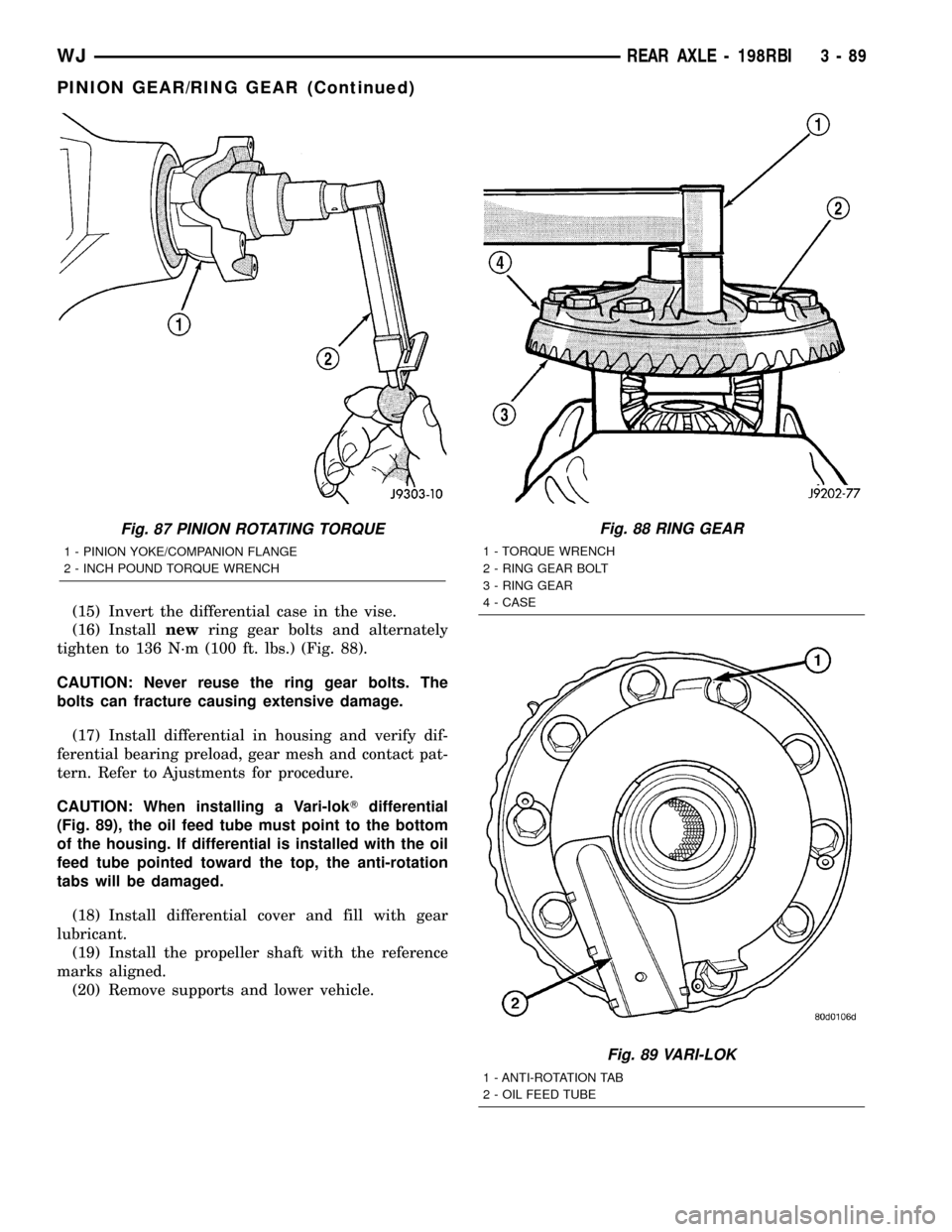

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing

(Fig. 53). If differential is installed with the oil feed

tube pointed at the top, the anti-rotation tabs will be

damaged.

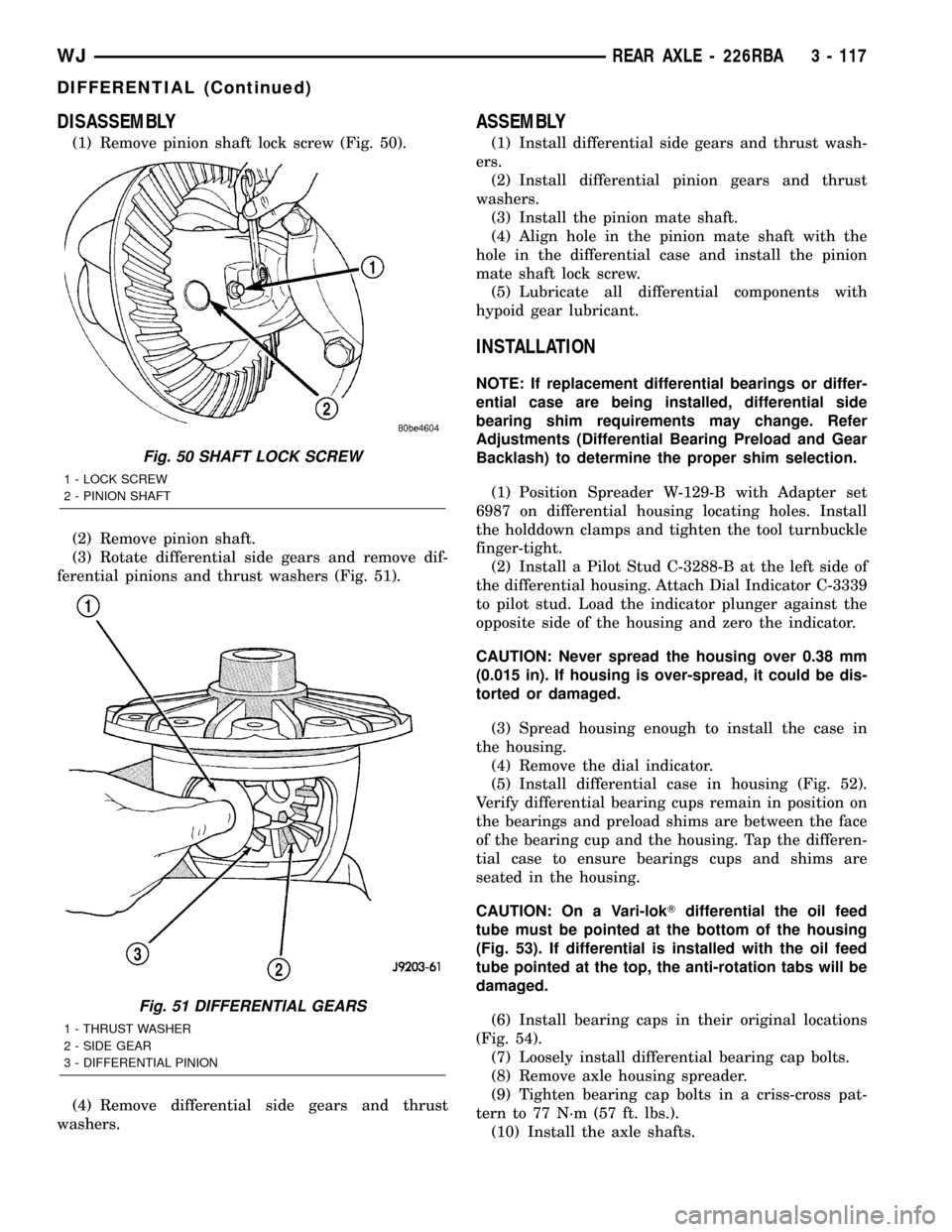

(6) Install bearing caps in their original locations

(Fig. 54).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten bearing cap bolts in a criss-cross pat-

tern to 77 N´m (57 ft. lbs.).

(10) Install the axle shafts.

Fig. 50 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 51 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

WJREAR AXLE - 198RBI 3 - 77

DIFFERENTIAL (Continued)

Page 123 of 2199

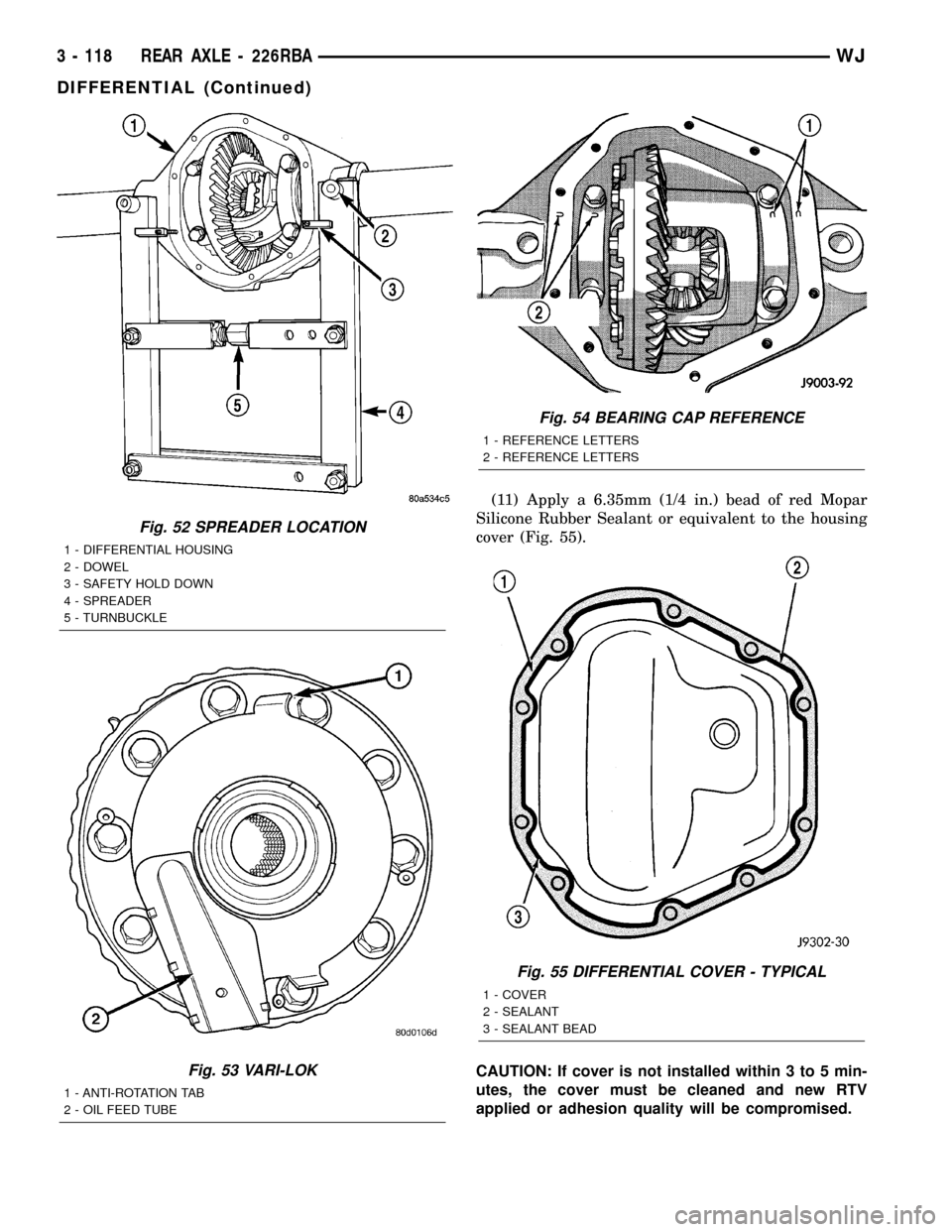

(11) Apply a 6.35mm (1/4 in.) bead of red Mopar

Silicone Rubber Sealant or equivalent to the housing

cover (Fig. 55).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

Fig. 52 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

Fig. 53 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

Fig. 54 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 55 DIFFERENTIAL COVER - TYPICAL

1 - COVER

2 - SEALANT

3 - SEALANT BEAD

3 - 78 REAR AXLE - 198RBIWJ

DIFFERENTIAL (Continued)

Page 134 of 2199

(15) Invert the differential case in the vise.

(16) Installnewring gear bolts and alternately

tighten to 136 N´m (100 ft. lbs.) (Fig. 88).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

(17) Install differential in housing and verify dif-

ferential bearing preload, gear mesh and contact pat-

tern. Refer to Ajustments for procedure.

CAUTION: When installing a Vari-lokTdifferential

(Fig. 89), the oil feed tube must point to the bottom

of the housing. If differential is installed with the oil

feed tube pointed toward the top, the anti-rotation

tabs will be damaged.

(18) Install differential cover and fill with gear

lubricant.

(19) Install the propeller shaft with the reference

marks aligned.

(20) Remove supports and lower vehicle.

Fig. 87 PINION ROTATING TORQUE

1 - PINION YOKE/COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

Fig. 88 RING GEAR

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

Fig. 89 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

WJREAR AXLE - 198RBI 3 - 89

PINION GEAR/RING GEAR (Continued)

Page 162 of 2199

DISASSEMBLY

(1) Remove pinion shaft lock screw (Fig. 50).

(2) Remove pinion shaft.

(3) Rotate differential side gears and remove dif-

ferential pinions and thrust washers (Fig. 51).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install differential pinion gears and thrust

washers.

(3) Install the pinion mate shaft.

(4) Align hole in the pinion mate shaft with the

hole in the differential case and install the pinion

mate shaft lock screw.

(5) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer

Adjustments (Differential Bearing Preload and Gear

Backlash) to determine the proper shim selection.

(1) Position Spreader W-129-B with Adapter set

6987 on differential housing locating holes. Install

the holddown clamps and tighten the tool turnbuckle

finger-tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

CAUTION: Never spread the housing over 0.38 mm

(0.015 in). If housing is over-spread, it could be dis-

torted or damaged.

(3) Spread housing enough to install the case in

the housing.

(4) Remove the dial indicator.

(5) Install differential case in housing (Fig. 52).

Verify differential bearing cups remain in position on

the bearings and preload shims are between the face

of the bearing cup and the housing. Tap the differen-

tial case to ensure bearings cups and shims are

seated in the housing.

CAUTION: On a Vari-lokTdifferential the oil feed

tube must be pointed at the bottom of the housing

(Fig. 53). If differential is installed with the oil feed

tube pointed at the top, the anti-rotation tabs will be

damaged.

(6) Install bearing caps in their original locations

(Fig. 54).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten bearing cap bolts in a criss-cross pat-

tern to 77 N´m (57 ft. lbs.).

(10) Install the axle shafts.

Fig. 50 SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 51 DIFFERENTIAL GEARS

1 - THRUST WASHER

2 - SIDE GEAR

3 - DIFFERENTIAL PINION

WJREAR AXLE - 226RBA 3 - 117

DIFFERENTIAL (Continued)

Page 163 of 2199

(11) Apply a 6.35mm (1/4 in.) bead of red Mopar

Silicone Rubber Sealant or equivalent to the housing

cover (Fig. 55).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

Fig. 52 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

Fig. 53 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

Fig. 54 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 55 DIFFERENTIAL COVER - TYPICAL

1 - COVER

2 - SEALANT

3 - SEALANT BEAD

3 - 118 REAR AXLE - 226RBAWJ

DIFFERENTIAL (Continued)

Page 174 of 2199

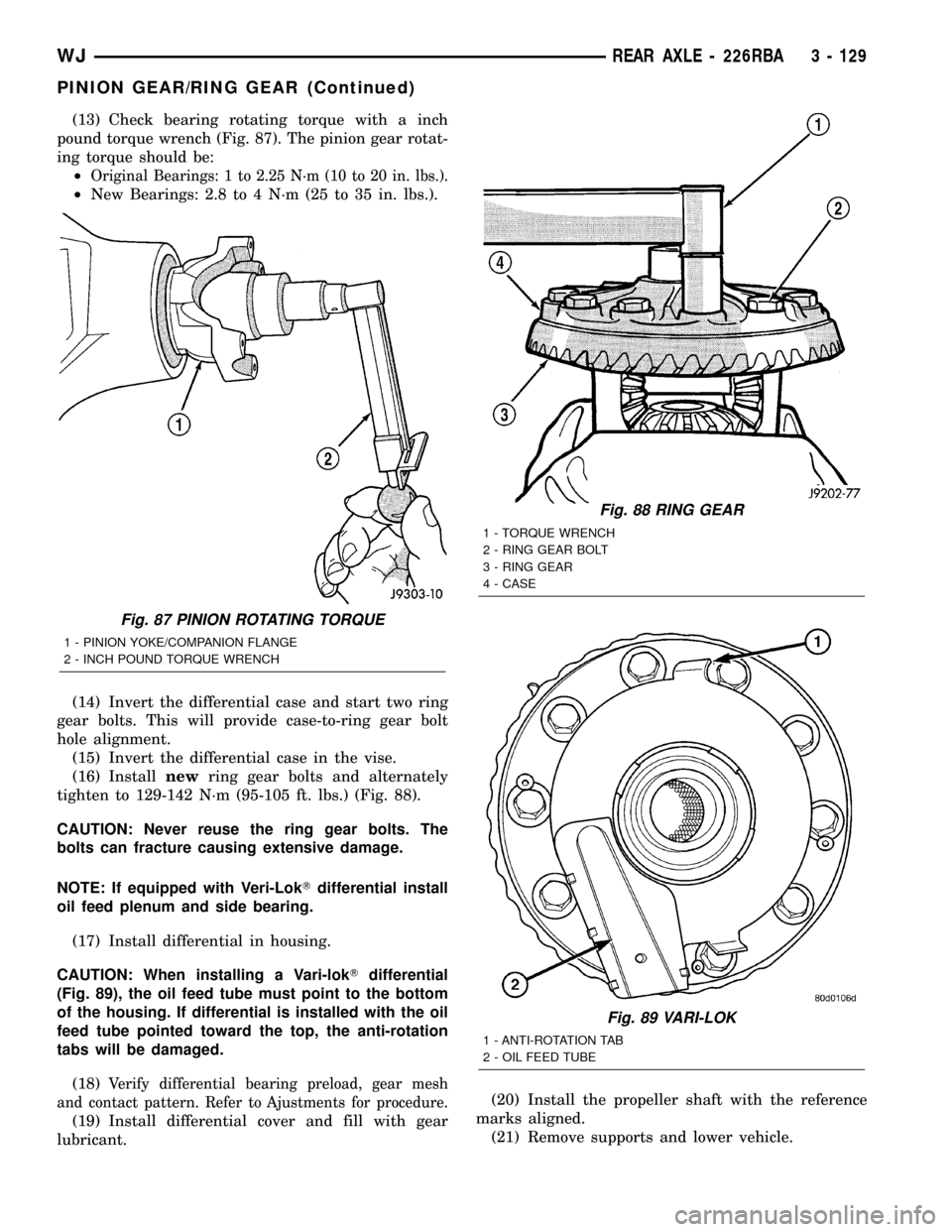

(13) Check bearing rotating torque with a inch

pound torque wrench (Fig. 87). The pinion gear rotat-

ing torque should be:

²

Original Bearings: 1 to 2.25 N´m (10 to 20 in. lbs.).

²New Bearings: 2.8 to 4 N´m (25 to 35 in. lbs.).

(14) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(15) Invert the differential case in the vise.

(16) Installnewring gear bolts and alternately

tighten to 129-142 N´m (95-105 ft. lbs.) (Fig. 88).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

NOTE: If equipped with Veri-LokTdifferential install

oil feed plenum and side bearing.

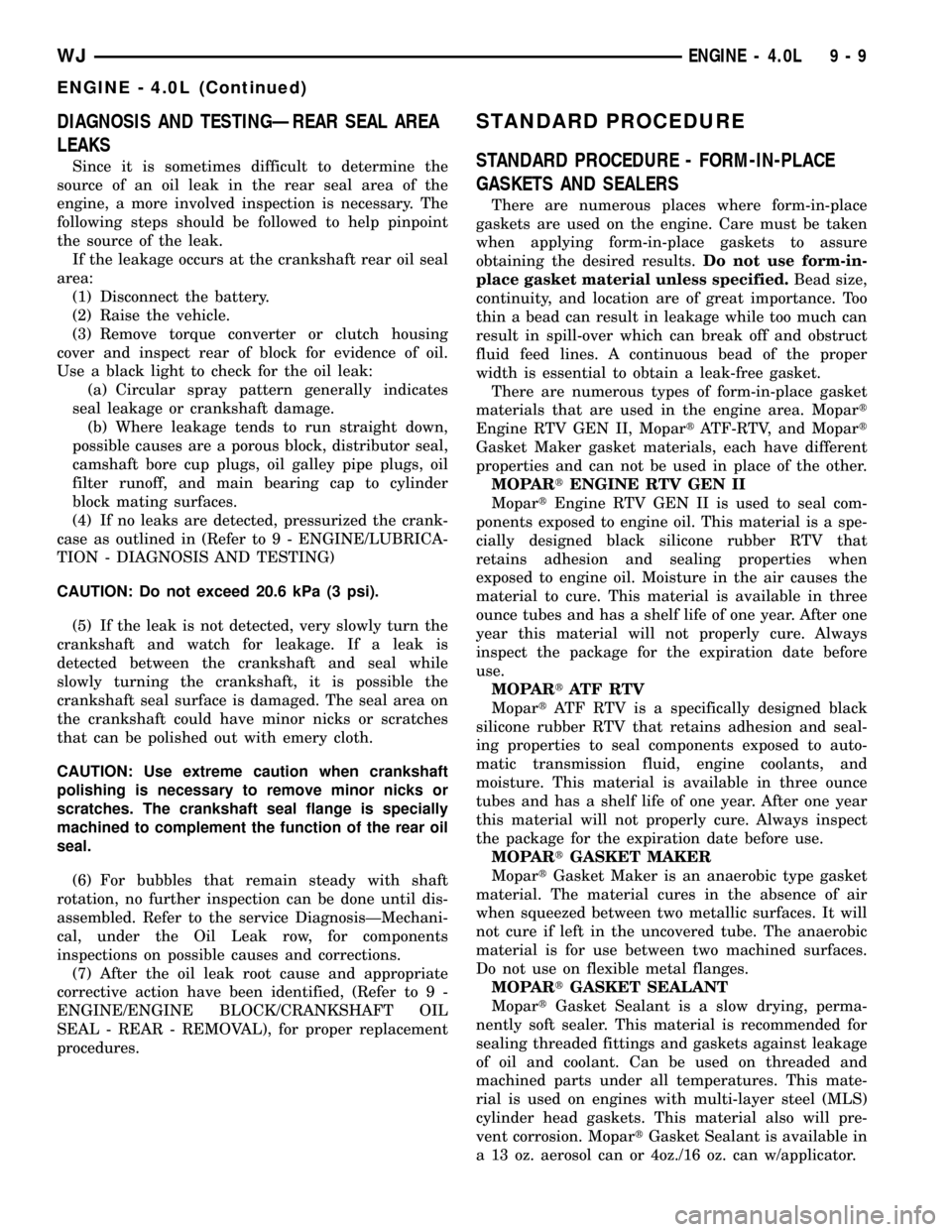

(17) Install differential in housing.

CAUTION: When installing a Vari-lokTdifferential

(Fig. 89), the oil feed tube must point to the bottom

of the housing. If differential is installed with the oil

feed tube pointed toward the top, the anti-rotation

tabs will be damaged.

(18)

Verify differential bearing preload, gear mesh

and contact pattern. Refer to Ajustments for procedure.

(19) Install differential cover and fill with gear

lubricant.(20) Install the propeller shaft with the reference

marks aligned.

(21) Remove supports and lower vehicle.

Fig. 87 PINION ROTATING TORQUE

1 - PINION YOKE/COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

Fig. 88 RING GEAR

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

Fig. 89 VARI-LOK

1 - ANTI-ROTATION TAB

2 - OIL FEED TUBE

WJREAR AXLE - 226RBA 3 - 129

PINION GEAR/RING GEAR (Continued)

Page 1252 of 2199

DIAGNOSIS AND TESTINGÐREAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurized the crank-

case as outlined in (Refer to 9 - ENGINE/LUBRICA-

TION - DIAGNOSIS AND TESTING)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL), for proper replacement

procedures.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

WJENGINE - 4.0L 9 - 9

ENGINE - 4.0L (Continued)