Security wiring diagram JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 390 of 2199

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 2

HORN

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING - HORN..........3

REMOVAL.............................3

INSTALLATION..........................4

HORN RELAY

DESCRIPTION..........................4OPERATION............................4

DIAGNOSIS AND TESTING - HORN RELAY....4

REMOVAL.............................5

INSTALLATION..........................5

HORN SWITCH

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - HORN SWITCH . . . 6

REMOVAL.............................7

INSTALLATION..........................7

HORN SYSTEM

DESCRIPTION

A dual-note electric horn system is standard facto-

ry-installed equipment on this model. The standard

equipment horn system features one low-note horn

unit and one high-note horn unit. The horn system

allows the vehicle operator to provide an audible

warning of the presence or approach of the vehicle to

pedestrians and the drivers of other vehicles in near

proximity. The horn system uses a non-switched

source of battery current so that the system will

remain functional, regardless of the ignition switch

position.

The horn system can also be activated by the Body

Control Module (BCM). The BCM is programmed to

activate the horns in order to provide the following

features:

²Remote Keyless Entry (RKE) system lock

request audible verification (except export)

²RKE system panic mode audible alert

²Vehicle Theft Security System (VTSS) audible

alarm.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Refer to Overhead Console for more informa-

tion on the customer programmable feature options.

Customer programmable feature options affecting the

horn system include:

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.The horn system includes the following compo-

nents:

²Clockspring

²Horns

²Horn relay

²Horn switch

Certain functions and features of the horn system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB scan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect horn

system operation are as follows:

²Body Control Module (BCM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Electronic Vehicle Information Center

(EVIC)(Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DESCRIPTION) for more information.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - DESCRIPTION) for more information on

this component. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

WJHORN 8H - 1

Page 481 of 2199

wired between a body ground, the Body Control Mod-

ule (BCM) and the rear wiper motor module through

the liftgate and body wire harnesses.

The liftgate flip-up glass ajar switch cannot be

adjusted or repaired and, if faulty or damaged, the

liftgate flip-up glass latch unit must be replaced.

(Refer to 23 - BODY/DECKLID/HATCH/LIFTGATE/

TAILGATE/FLIP-UP GLASS LATCH - REMOVAL)

for the service procedures. For complete circuit dia-

grams, refer to the appropriate wiring information.

DESCRIPTION - LIFTGATE AJAR SWITCH

The two liftgate ajar switches are integral to the

two liftgate latch mechanisms. The two liftgate ajar

switches are actuated by the liftgate latch mecha-

nisms, and are hard wired with each other between a

body ground and the Body Control Module (BCM)

through the liftgate and body wire harnesses.

The liftgate ajar switches cannot be adjusted or

repaired and, if faulty or damaged, the liftgate latch

unit must be replaced. (Refer to 23 - BODY/DECK-

LID/HATCH/LIFTGATE/TAILGATE/LATCH -

REMOVAL) for the service procedures. For complete

circuit diagrams, refer to the appropriate wiring

information.

OPERATION

OPERATION - DOOR AJAR SWITCH

The front door ajar switches close a path to ground

for the DDM or the PDM when a front door is

opened, and opens the ground path when a front door

is closed. The rear door ajar switches close a path to

ground for the BCM when a rear door is opened, and

opens the ground path when a rear door is closed.

The DDM, PDM, or BCM read the switch status then

send the proper switch status messages to other

modules over the Programmable Communications

Interface (PCI) data bus network. The door ajar

switch status message is used by the BCM as an

input for Vehicle Theft Security System (VTSS) oper-

ation.

OPERATION - FLIP UP GLASS AJAR SWITCH

The liftgate flip-up glass ajar switch can close a

path to ground for the BCM and the rear wiper

motor module when the liftgate flip-up glass is

opened, and opens the ground path when the liftgate

flip-up glass is closed. The rear wiper motor module

uses the liftgate flip-up glass ajar switch input to

control the rear wiper operation, and will park the

rear wiper blade if this input indicates that the lift-

gate flip-up glass is ajar. The BCM reads the switch

status then sends the proper switch status message

to other modules over the Programmable Communi-cations Interface (PCI) data bus network. The liftgate

flip-up glass ajar switch status message is used by

the BCM as an input for Vehicle Theft Security Sys-

tem (VTSS) operation.

OPERATION - LIFTGATE AJAR SWITCH

Each of the liftgate ajar switches can close a path

to ground for the BCM when the liftgate is opened,

and opens the ground path when the liftgate is

closed. The BCM reads the switch status then sends

the proper switch status message to other modules

over the Programmable Communications Interface

(PCI) data bus network. The liftgate ajar switch sta-

tus message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation.

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH

The following diagnosis and testing is only

for the chime functions. For interior lamp diag-

nosis, refer to the appropriate wiring informa-

tion.The driver door ajar switch is hard wired to the

Driver Door Module (DDM). The DDM communicates

the switch status to the other modules in the vehicle

on the Programmable Communications Interface

(PCI) data bus network. The following test will diag-

nose a faulty driver door ajar switch and circuits. For

complete circuit diagrams, refer to the appropriate

wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Check that the interior lighting switch on the

control stalk of the left multi-function switch is not

in the dome lamp disable position. Open the driver

side front door and note whether the interior lamps

light. They should light. If OK, refer to Key-In Igni-

tion Switch in the Diagnosis and Testing section of

this group for further diagnosis of the chime warning

system. If not OK, go to Step 2.

(2) Disconnect and isolate the battery negative

cable. Remove the trim panel from the driver front

door and disconnect the 4-way door wire harness con-

nector from the front door latch connector. Check for

continuity between the ground circuit of the 4-way

door wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the ground circuit.

8L - 30 LAMPS/LIGHTING - INTERIORWJ

DOOR AJAR SWITCH (Continued)

Page 494 of 2199

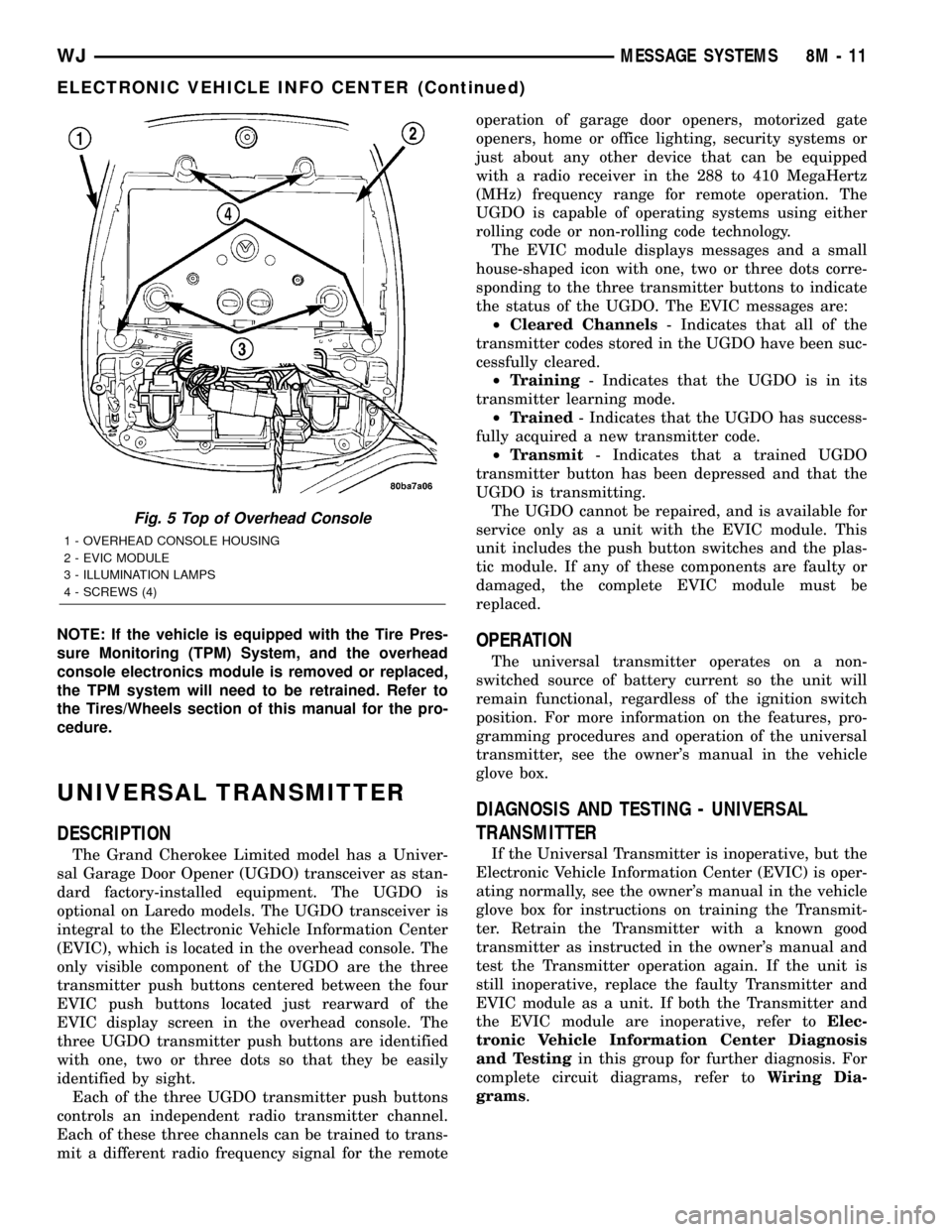

NOTE: If the vehicle is equipped with the Tire Pres-

sure Monitoring (TPM) System, and the overhead

console electronics module is removed or replaced,

the TPM system will need to be retrained. Refer to

the Tires/Wheels section of this manual for the pro-

cedure.

UNIVERSAL TRANSMITTER

DESCRIPTION

The Grand Cherokee Limited model has a Univer-

sal Garage Door Opener (UGDO) transceiver as stan-

dard factory-installed equipment. The UGDO is

optional on Laredo models. The UGDO transceiver is

integral to the Electronic Vehicle Information Center

(EVIC), which is located in the overhead console. The

only visible component of the UGDO are the three

transmitter push buttons centered between the four

EVIC push buttons located just rearward of the

EVIC display screen in the overhead console. The

three UGDO transmitter push buttons are identified

with one, two or three dots so that they be easily

identified by sight.

Each of the three UGDO transmitter push buttons

controls an independent radio transmitter channel.

Each of these three channels can be trained to trans-

mit a different radio frequency signal for the remoteoperation of garage door openers, motorized gate

openers, home or office lighting, security systems or

just about any other device that can be equipped

with a radio receiver in the 288 to 410 MegaHertz

(MHz) frequency range for remote operation. The

UGDO is capable of operating systems using either

rolling code or non-rolling code technology.

The EVIC module displays messages and a small

house-shaped icon with one, two or three dots corre-

sponding to the three transmitter buttons to indicate

the status of the UGDO. The EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the UGDO have been suc-

cessfully cleared.

²Training- Indicates that the UGDO is in its

transmitter learning mode.

²Trained- Indicates that the UGDO has success-

fully acquired a new transmitter code.

²Transmit- Indicates that a trained UGDO

transmitter button has been depressed and that the

UGDO is transmitting.

The UGDO cannot be repaired, and is available for

service only as a unit with the EVIC module. This

unit includes the push button switches and the plas-

tic module. If any of these components are faulty or

damaged, the complete EVIC module must be

replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, replace the faulty Transmitter and

EVIC module as a unit. If both the Transmitter and

the EVIC module are inoperative, refer toElec-

tronic Vehicle Information Center Diagnosis

and Testingin this group for further diagnosis. For

complete circuit diagrams, refer toWiring Dia-

grams.

Fig. 5 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC MODULE

3 - ILLUMINATION LAMPS

4 - SCREWS (4)

WJMESSAGE SYSTEMS 8M - 11

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 502 of 2199

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power lock system.

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM

The Passenger Door Module (PDM) contains the

RKE system control logic and the RKE receiver.

When the RKE receiver recognizes a Lock, Unlock or

Panic message from a valid RKE transmitter, the

RKE receiver provides that input to the PDM. The

PDM circuitry and programming responds by sending

the proper messages to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus.

When an RKE lock message is received, the doors

and the liftgate lock, the interior lighting fades to off,

the horn chirps (if this feature is enabled), the exte-

rior lamps flash (if this feature is enabled) and, if the

vehicle is so equipped, the Vehicle Theft Security

System (VTSS) is armed. When an RKE unlock mes-

sage is received, the driver side front door (or all

doors and the liftgate if this feature is enabled)

unlock, the interior lighting is turned on and, if the

vehicle is so equipped, the VTSS is disarmed. If the

vehicle is equipped with the Memory System and the

RKE Linked to Memory feature is enabled, the RKE

unlock message also recalls the driver seat, outside

mirror and radio settings assigned to the RKE trans-

mitter that sent the unlock signal.

When an RKE panic message is received, it causes

the exterior lamps (including the headlights) to flash,

and the horn to pulse for about three minutes, or

until a second panic message is received. A vehicle

speed of about 24 kilometers-per-hour (15 miles-per-

hour) will also cancel the panic event.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the RKE system.

OPERATION - LIFTGATE FLIP-UP GLASS

POWER RELEASE SYSTEM

When the liftgate mounted flip-up glass release

switch is depressed, battery current is directed to the

electric release motor that is integral to the flip-up

glass latch located inside the liftgate. When the

release motor is energized the latch releases and the

flip-up glass can be opened. A liftgate flip-up glass

limit switch is integral to the liftgate latch actuator

mechanism. The limit switch automatically enables

or disables the liftgate flip-up glass power release cir-

cuitry, depending upon the position of the liftgate

latch lock mechanism. When the liftgate latch is

unlocked, the limit switch closes and battery current

is available at the release switch. When the liftgatelatch is locked , the limit switch opens, and the

release switch is disabled.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the liftgate flip-up glass power release system.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER LOCK

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the power lock motors are being sent the proper

hard wired outputs by the door modules for them to

perform their power lock system functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the Power

Distribution Center. If the fuse is OK, proceed to

diagnosis of the door modules. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

DOOR MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS - DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY SYSTEM).

WJPOWER LOCKS 8N - 5

POWER LOCKS (Continued)

Page 504 of 2199

If not OK, replace the faulty liftgate latch actuator

(brainplate) unit.

(5) Disconnect the liftgate wire harness connector

for the liftgate flip-up glass release switch from the

switch connector receptacle. With the liftgate latch

unlocked, check for battery voltage at the liftgate

flip-up glass limit switch output circuit cavity of the

liftgate wire harness connector for the release switch.

If OK, go to Step 6. If not OK, repair the open lift-

gate flip-up glass limit switch output circuit between

the release switch and the limit switch as required.

(6) Check for continuity between the two terminals

of the liftgate flip-up glass release switch. There

should be no continuity. Depress the switch, there

should now be continuity. If OK, go to Step 7. If not

OK, replace the faulty liftgate flip-up glass release

switch.

(7) Disconnect the liftgate wire harness connector

for the liftgate flip-up glass latch motor from the

motor connector receptacle. Check for continuity

between the ground circuit cavity of the liftgate wire

harness connector for the latch motor and a good

ground. There should be continuity. If OK, go to Step

8. If not OK, repair the open ground circuit to ground

as required.

(8) With the liftgate latch unlocked and the flip-up

glass release switch depressed, check for battery volt-

age at the liftgate flip-up glass release switch output

circuit cavity of the liftgate wire harness connector

for the latch motor. If OK, replace the faulty liftgate

flip-up glass latch unit. If not OK, repair the open

liftgate flip-up glass release switch output circuit

between the latch motor and the release switch as

required.

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The driver cylinder lock switch is integral to the

key lock cylinder inside the driver side front door.

The driver cylinder lock switch is a resistive multi-

plexed switch that is hard wired between a body

ground and the Driver Door Module (DDM) through

the front door wire harness. It maintains a path to

ground, and changes voltages through an internal

resistor when the lock cylinder is rotated to the lock

or unlock position.

The driver cylinder lock switch cannot be adjusted

or repaired and, if faulty or damaged, the driver side

front door lock cylinder unit must be replaced. (Refer

to 23 - BODY/DOOR - FRONT/LOCK CYLINDER -

REMOVAL) and (Refer to 23 - BODY/DOOR -

FRONT/LOCK CYLINDER - INSTALLATION). Refer

to the appropriate wiring information. The wiringinformation includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

OPERATION

The driver cylinder lock switch is actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the unlock position. The

driver cylinder lock switch maintains a path to

ground and changes voltages through an internal

resistor for the DDM when the driver door key lock

cylinder is in the lock or unlock position. The DDM

reads the switch status through an internal pull-up,

then sends the proper switch status messages to

other electronic modules over the Programmable

Communications Interface (PCI) data bus network.

The driver cylinder lock switch unlock status mes-

sage is used by the BCM as an input for Vehicle

Theft Security System (VTSS) operation and interior

lighting.

POWER LOCK MOTOR

DESCRIPTION

Power operated front door, rear door, and liftgate

locking mechanisms are standard equipment on this

model. The lock mechanisms are actuated by a

reversible electric motor mounted within each door

and the liftgate. The power lock motors for the doors

are integral to the door latch units. The liftgate

power lock motor is a separate unit secured to the

latch brainplate near the center of the liftgate and

operates the liftgate latch lock mechanism through a

connecting linkage rod.

The power lock motors for the four doors cannot be

adjusted or repaired and, if faulty or damaged, the

entire door latch unit must be replaced. The liftgate

power lock motor cannot be adjusted or repaired and,

if faulty or damaged, the entire liftgate latch actua-

tor (brainplate) unit must be replaced.

OPERATION

The driver side front door power lock motor is con-

trolled by the Driver Door Module (DDM). The

remaining power door lock motors and the liftgate

power lock motor are controlled by the Passenger

Door Module (PDM). A positive and negative battery

connection to the two motor terminals will cause the

power lock motor plunger to move in one direction.

Reversing the current through these same two con-

nections will cause the power lock motor plunger to

move in the opposite direction.

WJPOWER LOCKS 8N - 7

POWER LOCKS (Continued)

Page 599 of 2199

cylinder lock switches are driven by the key lock cyl-

inders and contain two internal resistors. One resis-

tor value is used for the Lock position, and one for

the Unlock position.

The door cylinder lock switches cannot be adjusted

or repaired and, if faulty or damaged, they must be

replaced.

OPERATION

The door cylinder lock switches are actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the lock or unlock positions.

The door cylinder lock switch close a circuit between

the door lock switch ground circuit and the left or

right cylinder lock switch mux circuits through one of

two internal resistors for the Driver Door Module

(DDM) when either front door key lock cylinder is in

the Lock, or Unlock positions. The DDM reads the

switch status through an internal pull-up, then uses

this information as an input for the Vehicle Theft

Security System (VTSS) operation.

The door cylinder lock switches and circuits can be

diagnosed using conventional diagnostic tools and

methods.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

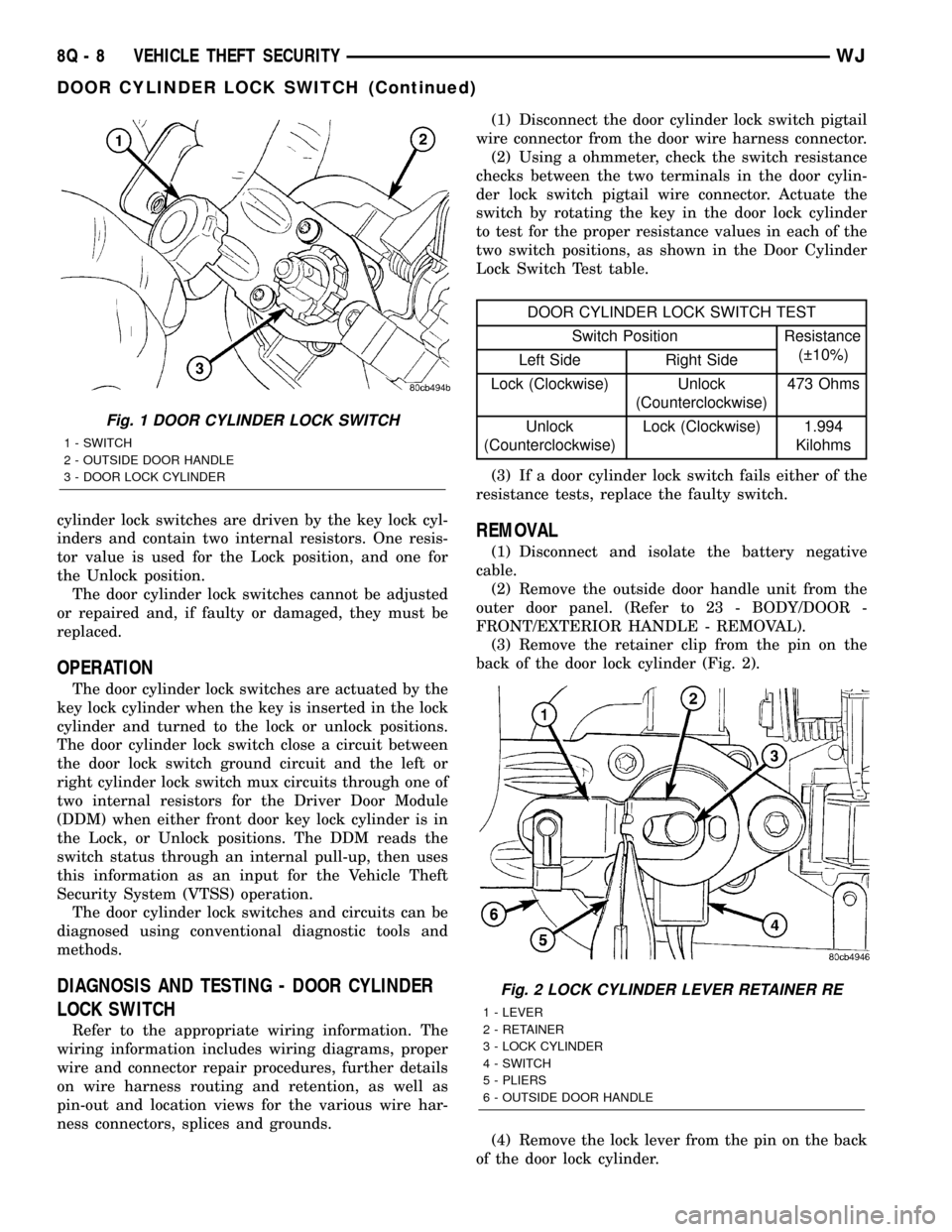

ness connectors, splices and grounds.(1) Disconnect the door cylinder lock switch pigtail

wire connector from the door wire harness connector.

(2) Using a ohmmeter, check the switch resistance

checks between the two terminals in the door cylin-

der lock switch pigtail wire connector. Actuate the

switch by rotating the key in the door lock cylinder

to test for the proper resistance values in each of the

two switch positions, as shown in the Door Cylinder

Lock Switch Test table.

DOOR CYLINDER LOCK SWITCH TEST

Switch Position Resistance

( 10%)

Left Side Right Side

Lock (Clockwise) Unlock

(Counterclockwise)473 Ohms

Unlock

(Counterclockwise)Lock (Clockwise) 1.994

Kilohms

(3) If a door cylinder lock switch fails either of the

resistance tests, replace the faulty switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the outside door handle unit from the

outer door panel. (Refer to 23 - BODY/DOOR -

FRONT/EXTERIOR HANDLE - REMOVAL).

(3) Remove the retainer clip from the pin on the

back of the door lock cylinder (Fig. 2).

(4) Remove the lock lever from the pin on the back

of the door lock cylinder.

Fig. 1 DOOR CYLINDER LOCK SWITCH

1 - SWITCH

2 - OUTSIDE DOOR HANDLE

3 - DOOR LOCK CYLINDER

Fig. 2 LOCK CYLINDER LEVER RETAINER RE

1 - LEVER

2 - RETAINER

3 - LOCK CYLINDER

4 - SWITCH

5 - PLIERS

6 - OUTSIDE DOOR HANDLE

8Q - 8 VEHICLE THEFT SECURITYWJ

DOOR CYLINDER LOCK SWITCH (Continued)

Page 654 of 2199

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

JUNCTION BLOCK.................... 8W-12-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUT................ 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 WJWIRING 8W - 1