cooling fan relay JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 226 of 2199

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan

or fan control solenoid circuit controling the hydrau-

lic fan, a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTINGÐPRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

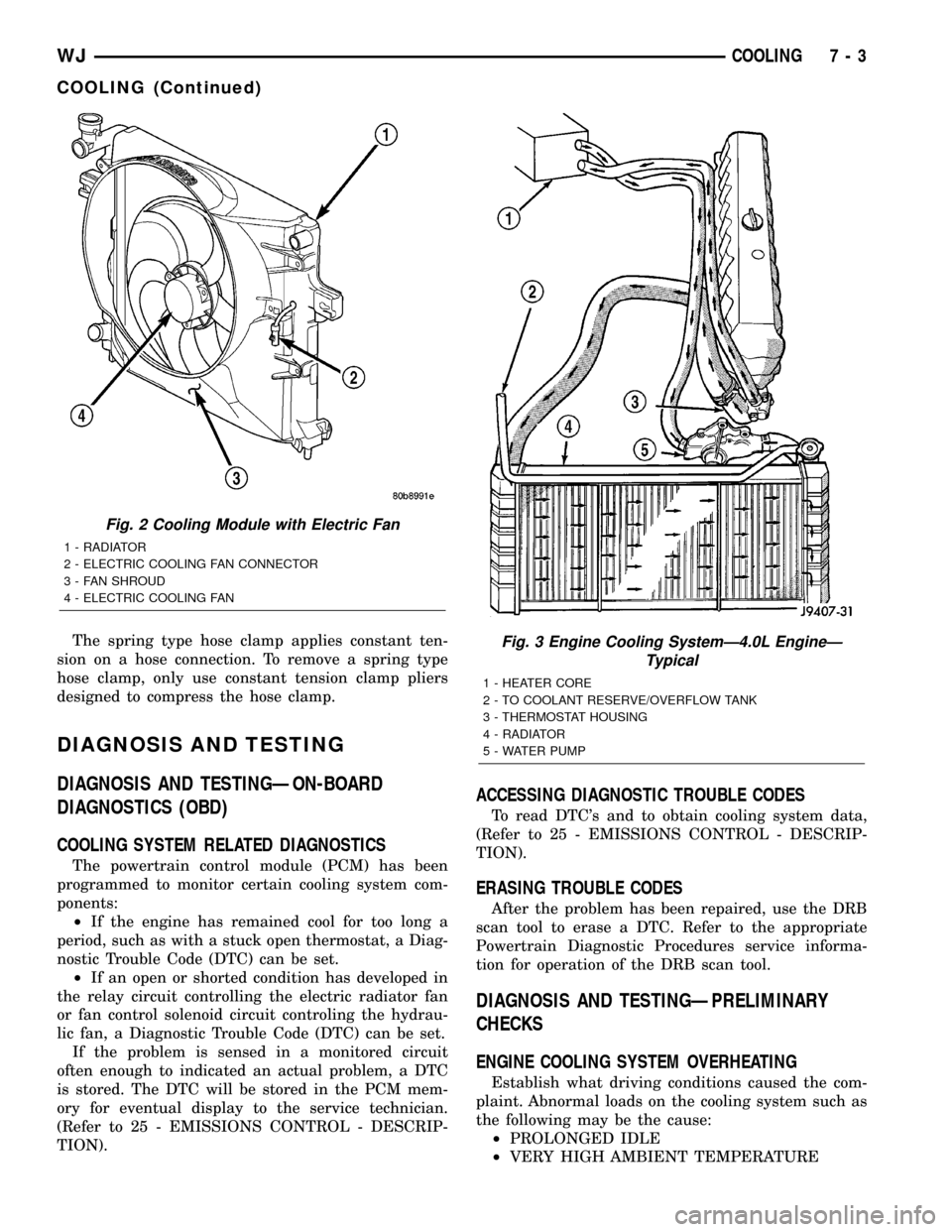

Fig. 2 Cooling Module with Electric Fan

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

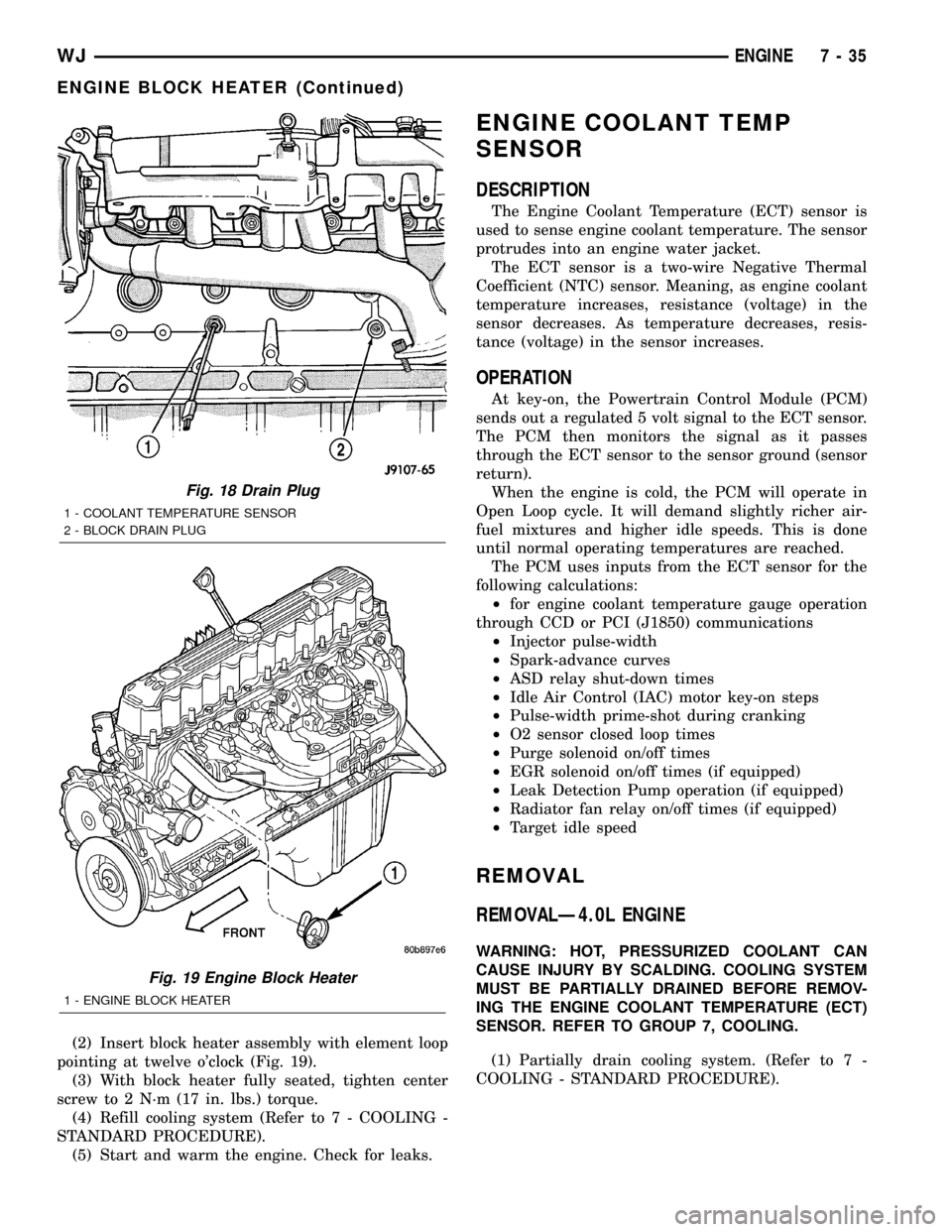

Fig. 3 Engine Cooling SystemÐ4.0L EngineÐ

Typical

1 - HEATER CORE

2 - TO COOLANT RESERVE/OVERFLOW TANK

3 - THERMOSTAT HOUSING

4 - RADIATOR

5 - WATER PUMP

WJCOOLING 7 - 3

COOLING (Continued)

Page 258 of 2199

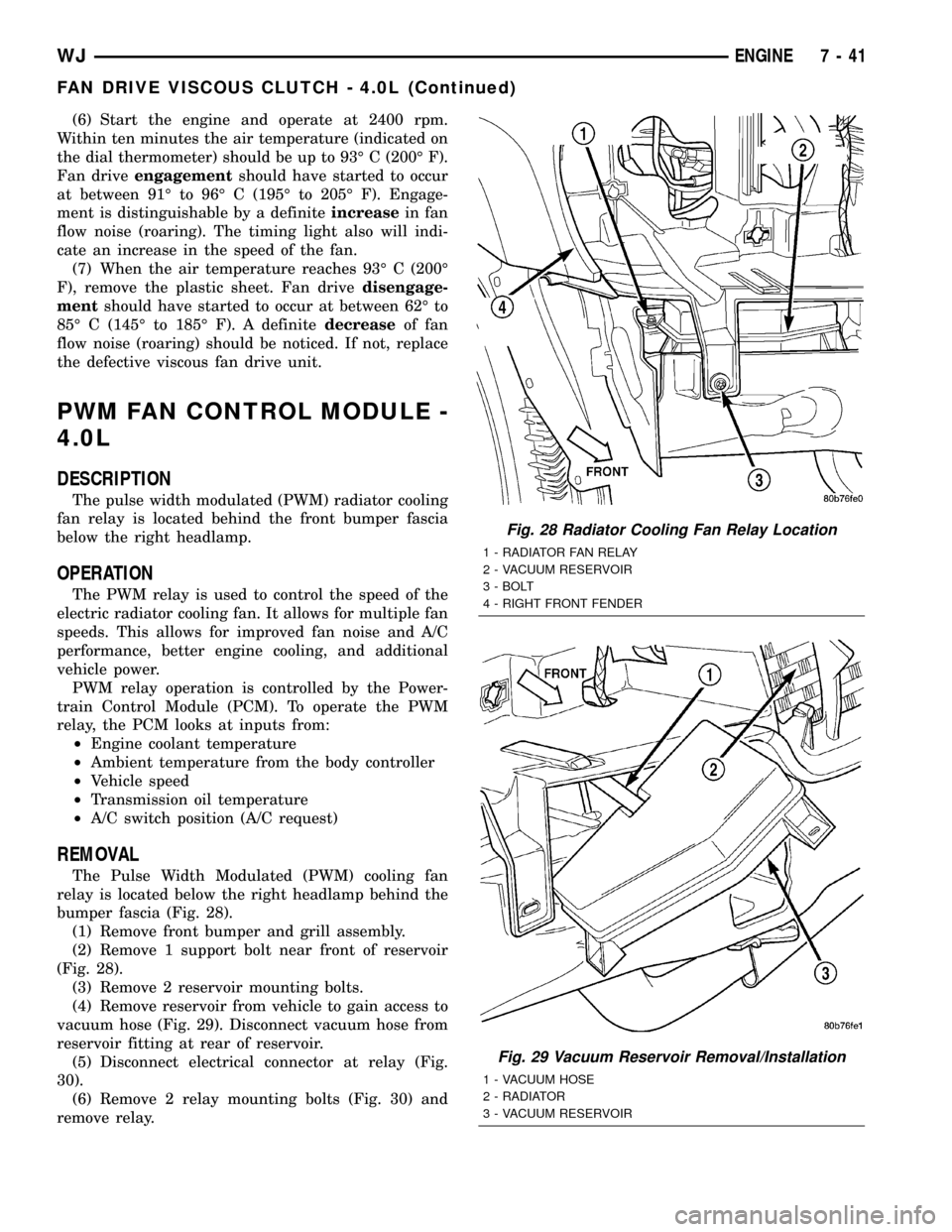

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 19).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

Fig. 18 Drain Plug

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

Fig. 19 Engine Block Heater

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 35

ENGINE BLOCK HEATER (Continued)

Page 264 of 2199

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 93É C (200É F).

Fan driveengagementshould have started to occur

at between 91É to 96É C (195É to 205É F). Engage-

ment is distinguishable by a definiteincreasein fan

flow noise (roaring). The timing light also will indi-

cate an increase in the speed of the fan.

(7) When the air temperature reaches 93É C (200É

F), remove the plastic sheet. Fan drivedisengage-

mentshould have started to occur at between 62É to

85É C (145É to 185É F). A definitedecreaseof fan

flow noise (roaring) should be noticed. If not, replace

the defective viscous fan drive unit.

PWM FAN CONTROL MODULE -

4.0L

DESCRIPTION

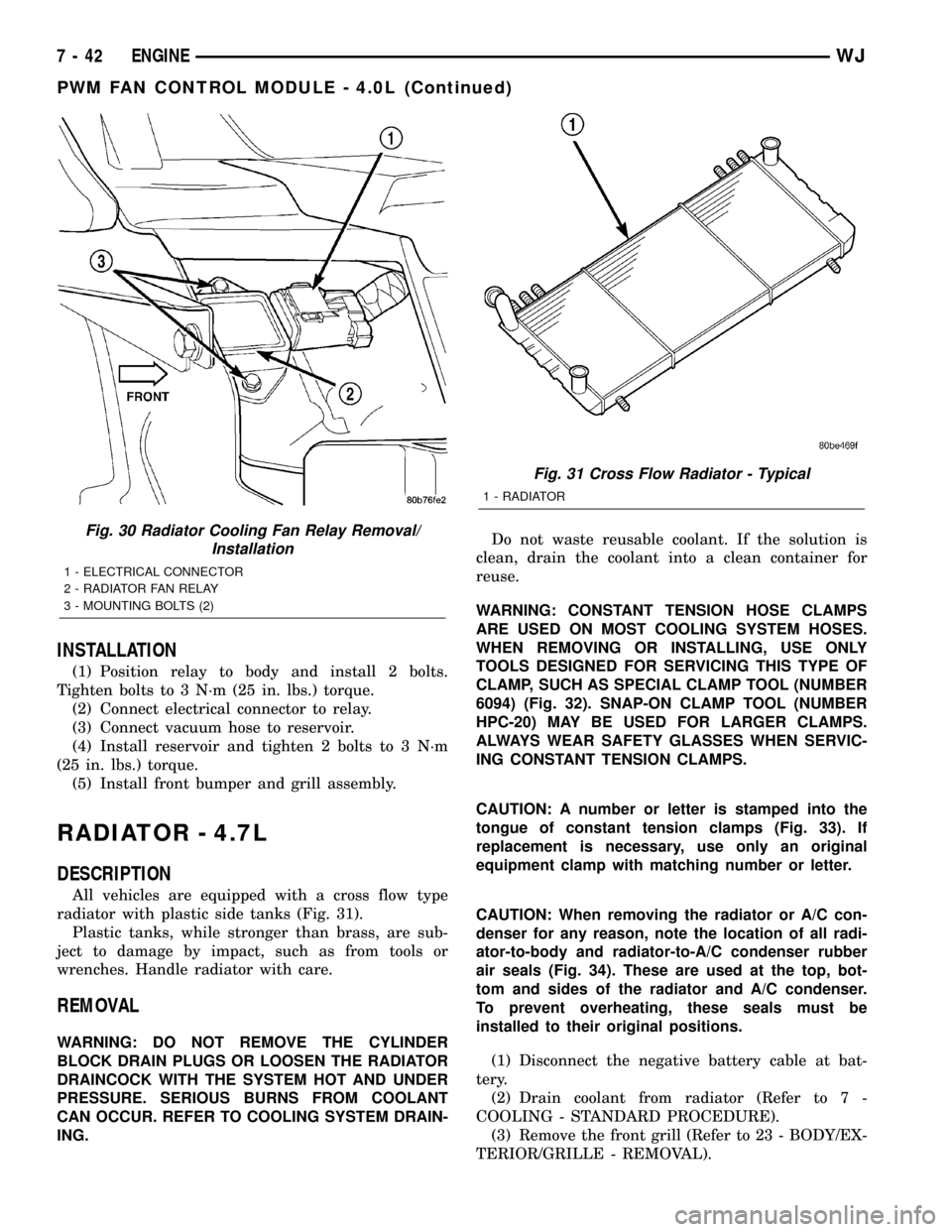

The pulse width modulated (PWM) radiator cooling

fan relay is located behind the front bumper fascia

below the right headlamp.

OPERATION

The PWM relay is used to control the speed of the

electric radiator cooling fan. It allows for multiple fan

speeds. This allows for improved fan noise and A/C

performance, better engine cooling, and additional

vehicle power.

PWM relay operation is controlled by the Power-

train Control Module (PCM). To operate the PWM

relay, the PCM looks at inputs from:

²Engine coolant temperature

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

²A/C switch position (A/C request)

REMOVAL

The Pulse Width Modulated (PWM) cooling fan

relay is located below the right headlamp behind the

bumper fascia (Fig. 28).

(1) Remove front bumper and grill assembly.

(2) Remove 1 support bolt near front of reservoir

(Fig. 28).

(3) Remove 2 reservoir mounting bolts.

(4) Remove reservoir from vehicle to gain access to

vacuum hose (Fig. 29). Disconnect vacuum hose from

reservoir fitting at rear of reservoir.

(5) Disconnect electrical connector at relay (Fig.

30).

(6) Remove 2 relay mounting bolts (Fig. 30) and

remove relay.

Fig. 28 Radiator Cooling Fan Relay Location

1 - RADIATOR FAN RELAY

2 - VACUUM RESERVOIR

3 - BOLT

4 - RIGHT FRONT FENDER

Fig. 29 Vacuum Reservoir Removal/Installation

1 - VACUUM HOSE

2 - RADIATOR

3 - VACUUM RESERVOIR

WJENGINE 7 - 41

FAN DRIVE VISCOUS CLUTCH - 4.0L (Continued)

Page 265 of 2199

INSTALLATION

(1) Position relay to body and install 2 bolts.

Tighten bolts to 3 N´m (25 in. lbs.) torque.

(2) Connect electrical connector to relay.

(3) Connect vacuum hose to reservoir.

(4) Install reservoir and tighten 2 bolts to 3 N´m

(25 in. lbs.) torque.

(5) Install front bumper and grill assembly.

RADIATOR - 4.7L

DESCRIPTION

All vehicles are equipped with a cross flow type

radiator with plastic side tanks (Fig. 31).

Plastic tanks, while stronger than brass, are sub-

ject to damage by impact, such as from tools or

wrenches. Handle radiator with care.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR. REFER TO COOLING SYSTEM DRAIN-

ING.Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 32). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 33). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

CAUTION: When removing the radiator or A/C con-

denser for any reason, note the location of all radi-

ator-to-body and radiator-to-A/C condenser rubber

air seals (Fig. 34). These are used at the top, bot-

tom and sides of the radiator and A/C condenser.

To prevent overheating, these seals must be

installed to their original positions.

(1) Disconnect the negative battery cable at bat-

tery.

(2) Drain coolant from radiator (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Remove the front grill (Refer to 23 - BODY/EX-

TERIOR/GRILLE - REMOVAL).

Fig. 30 Radiator Cooling Fan Relay Removal/

Installation

1 - ELECTRICAL CONNECTOR

2 - RADIATOR FAN RELAY

3 - MOUNTING BOLTS (2)

Fig. 31 Cross Flow Radiator - Typical

1 - RADIATOR

7 - 42 ENGINEWJ

PWM FAN CONTROL MODULE - 4.0L (Continued)

Page 270 of 2199

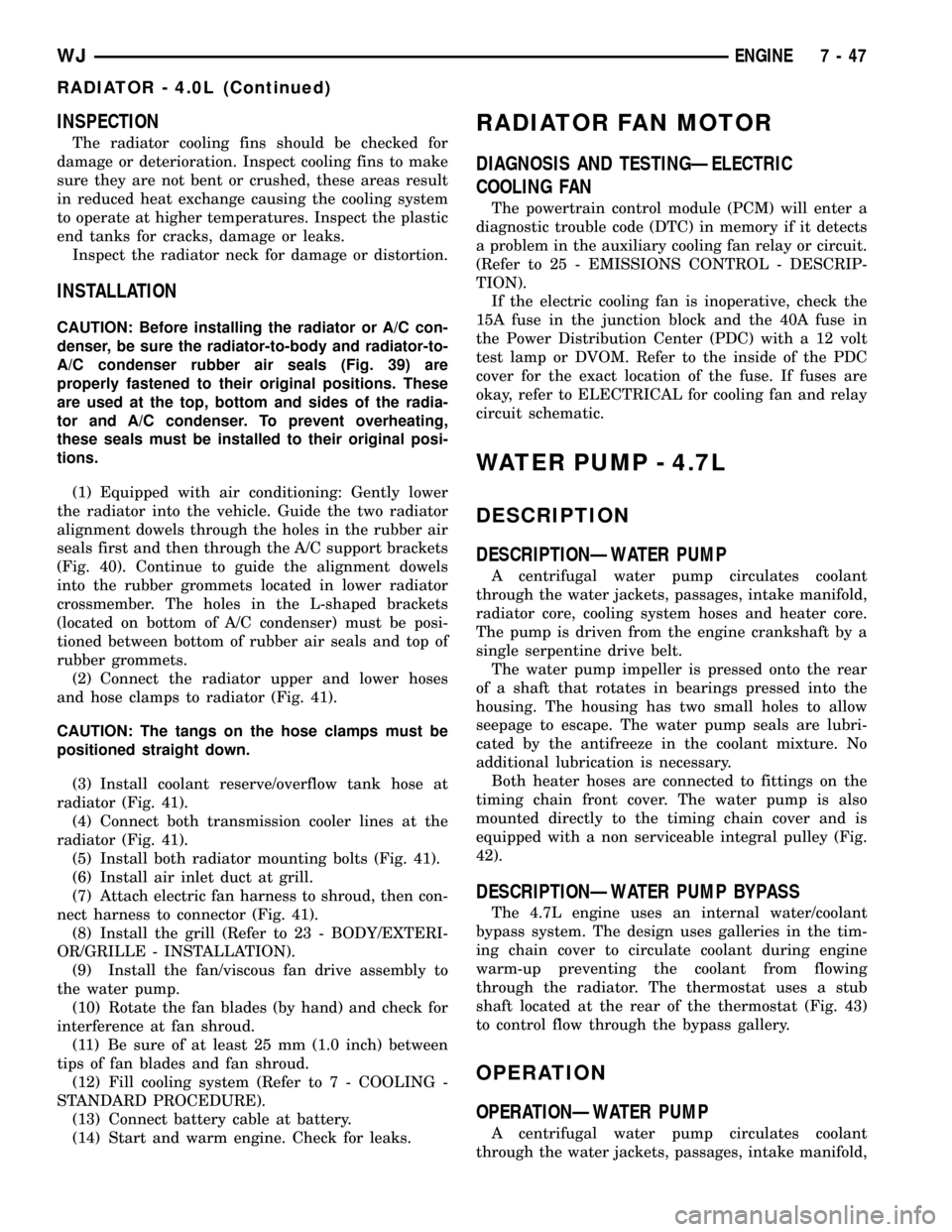

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator into the vehicle. Guide the two radiator

alignment dowels through the holes in the rubber air

seals first and then through the A/C support brackets

(Fig. 40). Continue to guide the alignment dowels

into the rubber grommets located in lower radiator

crossmember. The holes in the L-shaped brackets

(located on bottom of A/C condenser) must be posi-

tioned between bottom of rubber air seals and top of

rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator (Fig. 41).

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator (Fig. 41).

(4) Connect both transmission cooler lines at the

radiator (Fig. 41).

(5) Install both radiator mounting bolts (Fig. 41).

(6) Install air inlet duct at grill.

(7) Attach electric fan harness to shroud, then con-

nect harness to connector (Fig. 41).

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Install the fan/viscous fan drive assembly to

the water pump.

(10) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(11) Be sure of at least 25 mm (1.0 inch) between

tips of fan blades and fan shroud.

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery cable at battery.

(14) Start and warm engine. Check for leaks.

RADIATOR FAN MOTOR

DIAGNOSIS AND TESTINGÐELECTRIC

COOLING FAN

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) in memory if it detects

a problem in the auxiliary cooling fan relay or circuit.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

If the electric cooling fan is inoperative, check the

15A fuse in the junction block and the 40A fuse in

the Power Distribution Center (PDC) with a 12 volt

test lamp or DVOM. Refer to the inside of the PDC

cover for the exact location of the fuse. If fuses are

okay, refer to ELECTRICAL for cooling fan and relay

circuit schematic.

WATER PUMP - 4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

42).

DESCRIPTIONÐWATER PUMP BYPASS

The 4.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

through the radiator. The thermostat uses a stub

shaft located at the rear of the thermostat (Fig. 43)

to control flow through the bypass gallery.

OPERATION

OPERATIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

WJENGINE 7 - 47

RADIATOR - 4.0L (Continued)

Page 325 of 2199

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Overdrive indicator lamp (if equipped). Driven

through J1850 circuits.

²Oxygen sensor heater relays (if equipped).

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control source

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (if equipped with an RE auto-

matic transmission).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM.

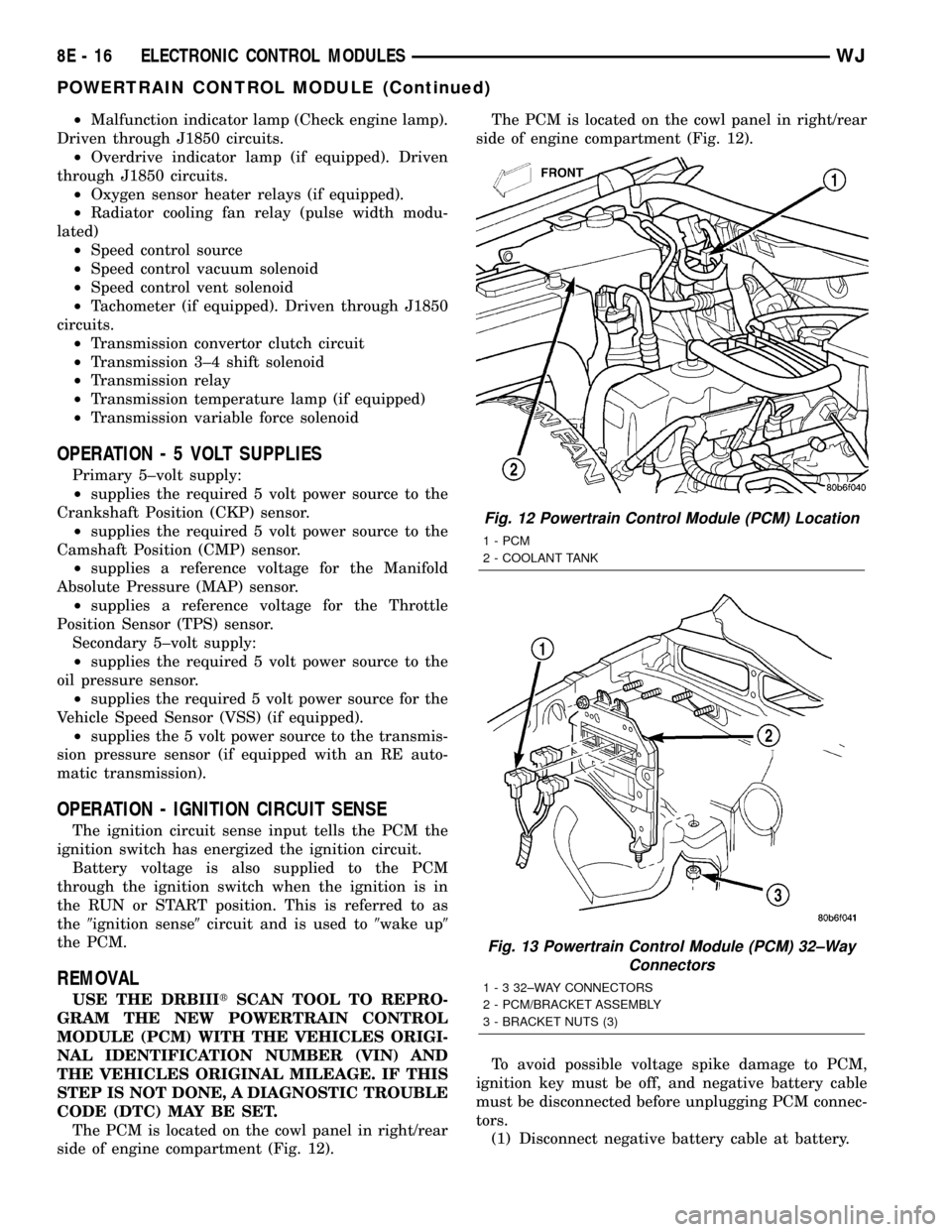

REMOVAL

USE THE DRBIIItSCAN TOOL TO REPRO-

GRAM THE NEW POWERTRAIN CONTROL

MODULE (PCM) WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE, A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).

To avoid possible voltage spike damage to PCM,

ignition key must be off, and negative battery cable

must be disconnected before unplugging PCM connec-

tors.

(1) Disconnect negative battery cable at battery.

Fig. 12 Powertrain Control Module (PCM) Location

1 - PCM

2 - COOLANT TANK

Fig. 13 Powertrain Control Module (PCM) 32±Way

Connectors

1 - 3 32±WAY CONNECTORS

2 - PCM/BRACKET ASSEMBLY

3 - BRACKET NUTS (3)

8E - 16 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 1131 of 2199

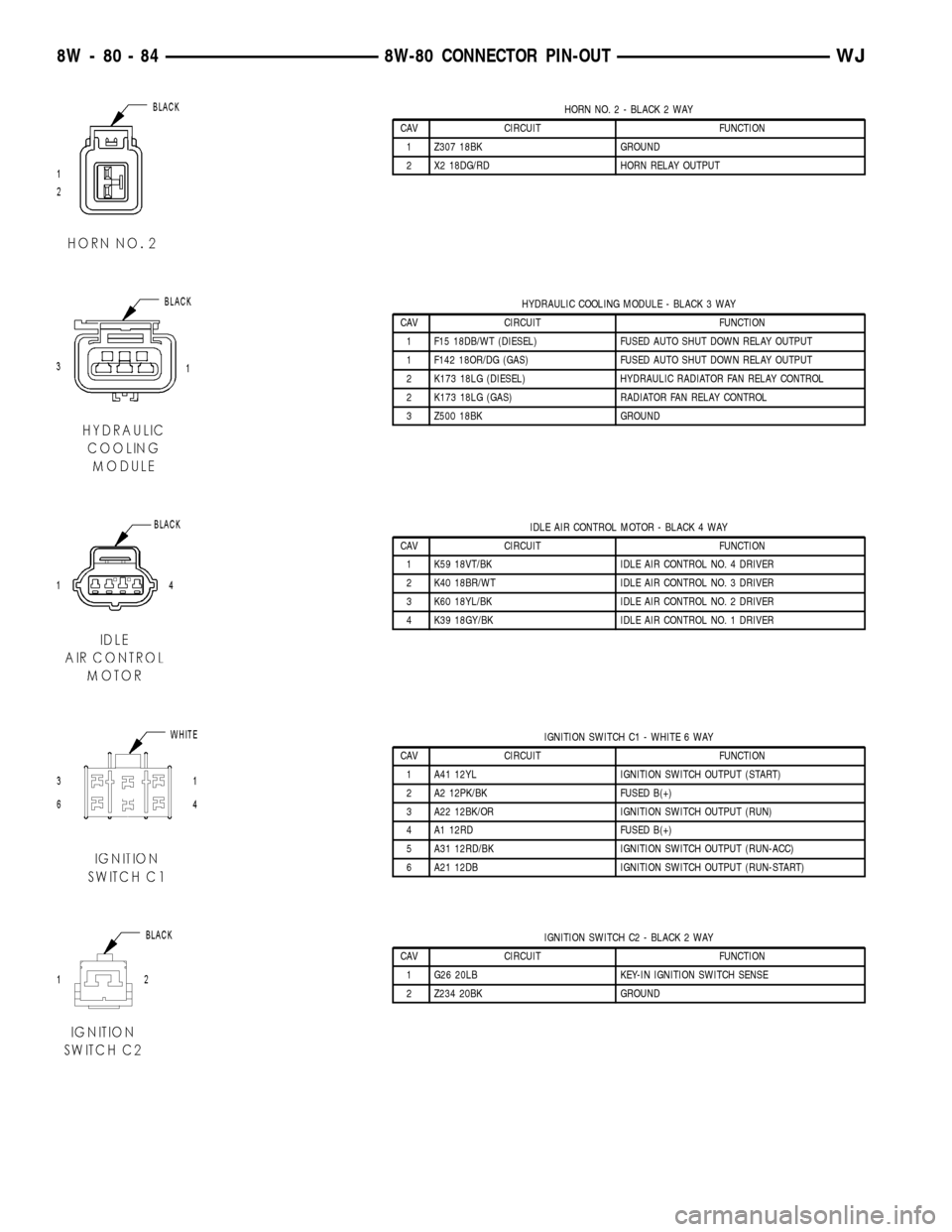

HORN NO. 2 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z307 18BK GROUND

2 X2 18DG/RD HORN RELAY OUTPUT

HYDRAULIC COOLING MODULE - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F15 18DB/WT (DIESEL) FUSED AUTO SHUT DOWN RELAY OUTPUT

1 F142 18OR/DG (GAS) FUSED AUTO SHUT DOWN RELAY OUTPUT

2 K173 18LG (DIESEL) HYDRAULIC RADIATOR FAN RELAY CONTROL

2 K173 18LG (GAS) RADIATOR FAN RELAY CONTROL

3 Z500 18BK GROUND

IDLE AIR CONTROL MOTOR - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 K59 18VT/BK IDLE AIR CONTROL NO. 4 DRIVER

2 K40 18BR/WT IDLE AIR CONTROL NO. 3 DRIVER

3 K60 18YL/BK IDLE AIR CONTROL NO. 2 DRIVER

4 K39 18GY/BK IDLE AIR CONTROL NO. 1 DRIVER

IGNITION SWITCH C1 - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1 A41 12YL IGNITION SWITCH OUTPUT (START)

2 A2 12PK/BK FUSED B(+)

3 A22 12BK/OR IGNITION SWITCH OUTPUT (RUN)

4 A1 12RD FUSED B(+)

5 A31 12RD/BK IGNITION SWITCH OUTPUT (RUN-ACC)

6 A21 12DB IGNITION SWITCH OUTPUT (RUN-START)

IGNITION SWITCH C2 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 G26 20LB KEY-IN IGNITION SWITCH SENSE

2 Z234 20BK GROUND

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTWJ

Page 1458 of 2199

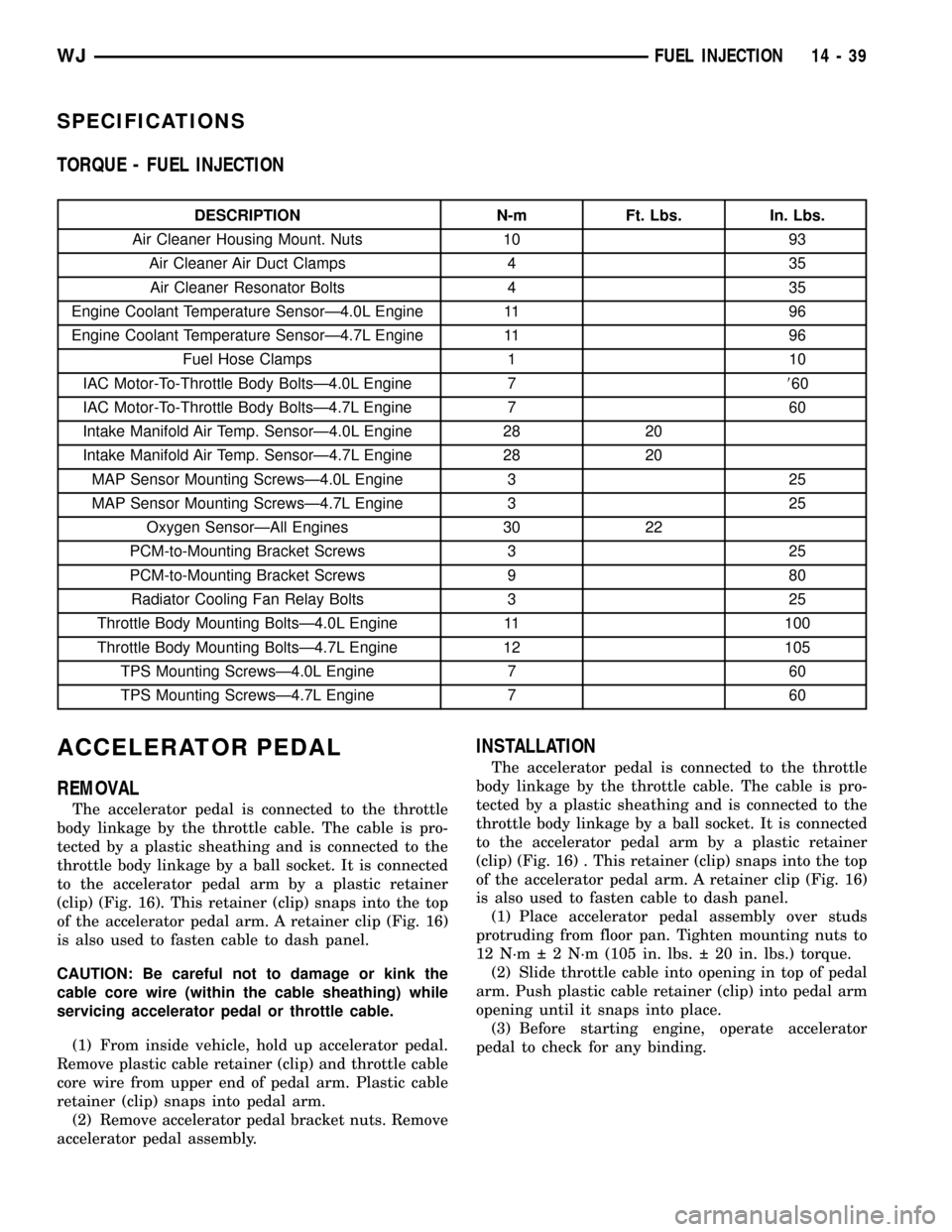

SPECIFICATIONS

TORQUE - FUEL INJECTION

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Air Cleaner Housing Mount. Nuts 10 93

Air Cleaner Air Duct Clamps 4 35

Air Cleaner Resonator Bolts 4 35

Engine Coolant Temperature SensorÐ4.0L Engine 11 96

Engine Coolant Temperature SensorÐ4.7L Engine 11 96

Fuel Hose Clamps 1 10

IAC Motor-To-Throttle Body BoltsÐ4.0L Engine 7860

IAC Motor-To-Throttle Body BoltsÐ4.7L Engine 7 60

Intake Manifold Air Temp. SensorÐ4.0L Engine 28 20

Intake Manifold Air Temp. SensorÐ4.7L Engine 28 20

MAP Sensor Mounting ScrewsÐ4.0L Engine 3 25

MAP Sensor Mounting ScrewsÐ4.7L Engine 3 25

Oxygen SensorÐAll Engines 30 22

PCM-to-Mounting Bracket Screws 3 25

PCM-to-Mounting Bracket Screws 9 80

Radiator Cooling Fan Relay Bolts 3 25

Throttle Body Mounting BoltsÐ4.0L Engine 11 100

Throttle Body Mounting BoltsÐ4.7L Engine 12 105

TPS Mounting ScrewsÐ4.0L Engine 7 60

TPS Mounting ScrewsÐ4.7L Engine 7 60

ACCELERATOR PEDAL

REMOVAL

The accelerator pedal is connected to the throttle

body linkage by the throttle cable. The cable is pro-

tected by a plastic sheathing and is connected to the

throttle body linkage by a ball socket. It is connected

to the accelerator pedal arm by a plastic retainer

(clip) (Fig. 16). This retainer (clip) snaps into the top

of the accelerator pedal arm. A retainer clip (Fig. 16)

is also used to fasten cable to dash panel.

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm. Plastic cable

retainer (clip) snaps into pedal arm.

(2) Remove accelerator pedal bracket nuts. Remove

accelerator pedal assembly.

INSTALLATION

The accelerator pedal is connected to the throttle

body linkage by the throttle cable. The cable is pro-

tected by a plastic sheathing and is connected to the

throttle body linkage by a ball socket. It is connected

to the accelerator pedal arm by a plastic retainer

(clip) (Fig. 16) . This retainer (clip) snaps into the top

of the accelerator pedal arm. A retainer clip (Fig. 16)

is also used to fasten cable to dash panel.

(1) Place accelerator pedal assembly over studs

protruding from floor pan. Tighten mounting nuts to

12 N´m 2 N´m (105 in. lbs. 20 in. lbs.) torque.

(2) Slide throttle cable into opening in top of pedal

arm. Push plastic cable retainer (clip) into pedal arm

opening until it snaps into place.

(3) Before starting engine, operate accelerator

pedal to check for any binding.

WJFUEL INJECTION 14 - 39

Page 2084 of 2199

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

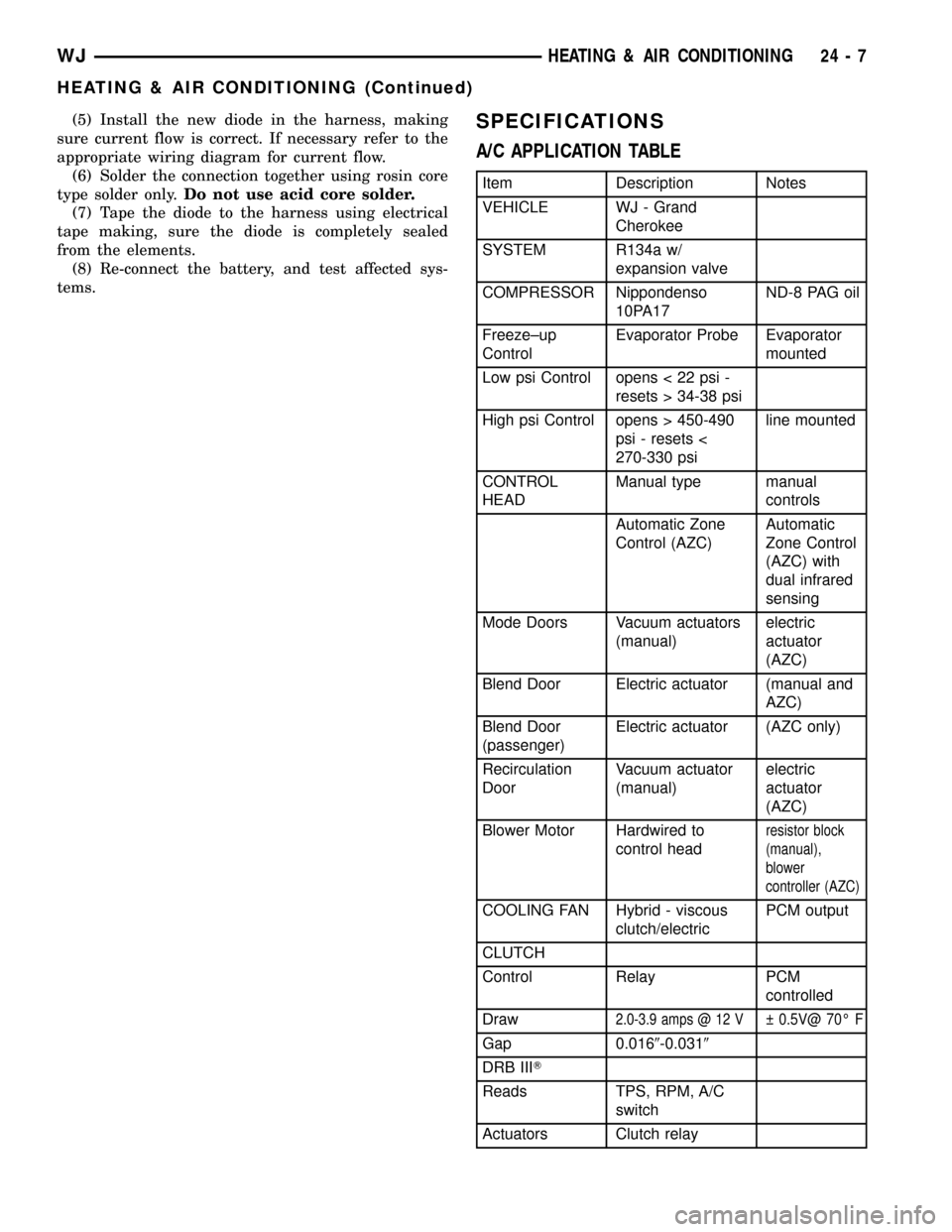

tems.SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

VEHICLE WJ - Grand

Cherokee

SYSTEM R134a w/

expansion valve

COMPRESSOR Nippondenso

10PA17ND-8 PAG oil

Freeze±up

ControlEvaporator Probe Evaporator

mounted

Low psi Control opens < 22 psi -

resets > 34-38 psi

High psi Control opens > 450-490

psi - resets <

270-330 psiline mounted

CONTROL

HEADManual type manual

controls

Automatic Zone

Control (AZC)Automatic

Zone Control

(AZC) with

dual infrared

sensing

Mode Doors Vacuum actuators

(manual)electric

actuator

(AZC)

Blend Door Electric actuator (manual and

AZC)

Blend Door

(passenger)Electric actuator (AZC only)

Recirculation

DoorVacuum actuator

(manual)electric

actuator

(AZC)

Blower Motor Hardwired to

control head

resistor block

(manual),

blower

controller (AZC)

COOLING FAN Hybrid - viscous

clutch/electricPCM output

CLUTCH

Control Relay PCM

controlled

Draw

2.0-3.9 amps @ 12 V 0.5V@ 70É F

Gap 0.0169-0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch

Actuators Clutch relay

WJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2169 of 2199

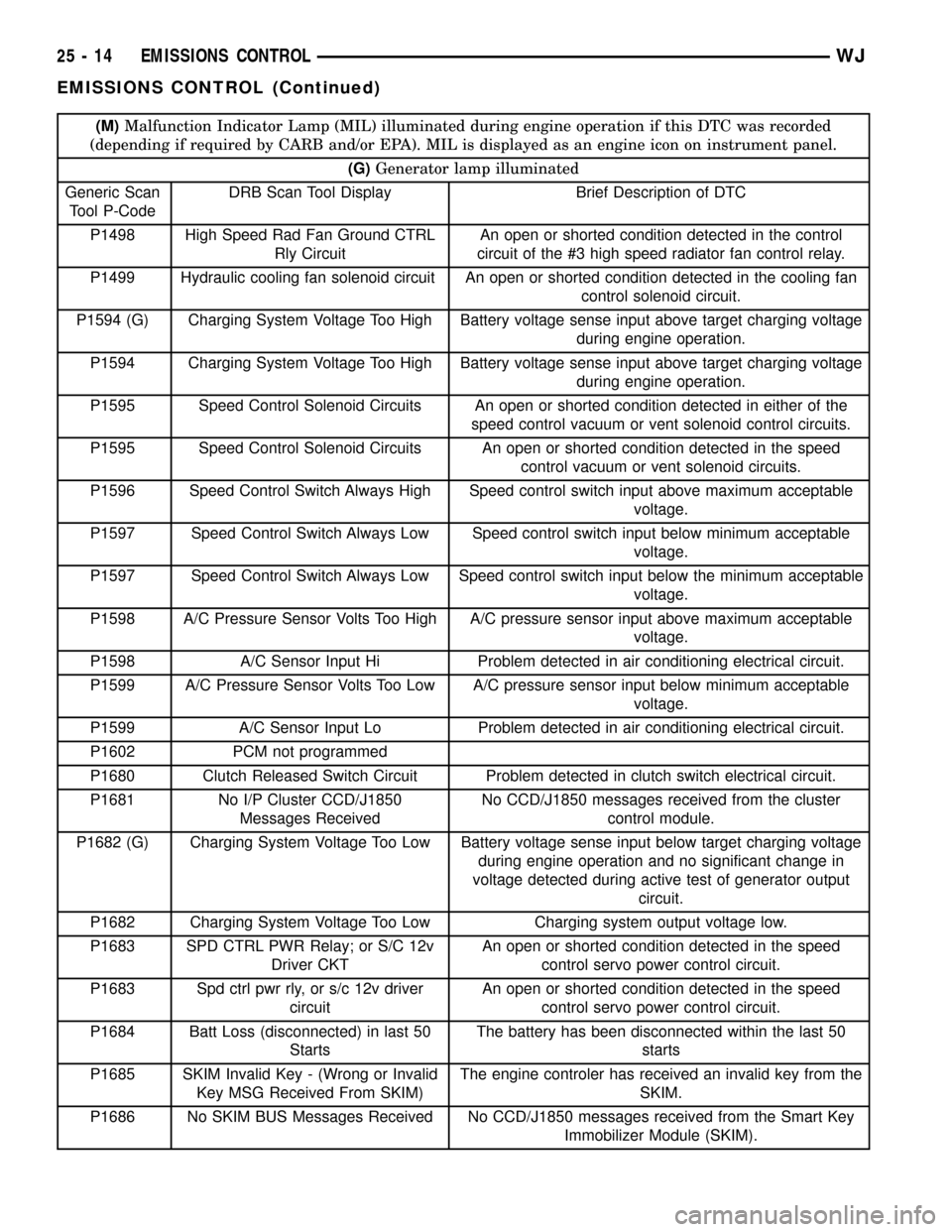

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1498 High Speed Rad Fan Ground CTRL

Rly CircuitAn open or shorted condition detected in the control

circuit of the #3 high speed radiator fan control relay.

P1499 Hydraulic cooling fan solenoid circuit An open or shorted condition detected in the cooling fan

control solenoid circuit.

P1594 (G) Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1594 Charging System Voltage Too High Battery voltage sense input above target charging voltage

during engine operation.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in either of the

speed control vacuum or vent solenoid control circuits.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in the speed

control vacuum or vent solenoid circuits.

P1596 Speed Control Switch Always High Speed control switch input above maximum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below minimum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below the minimum acceptable

voltage.

P1598 A/C Pressure Sensor Volts Too High A/C pressure sensor input above maximum acceptable

voltage.

P1598 A/C Sensor Input Hi Problem detected in air conditioning electrical circuit.

P1599 A/C Pressure Sensor Volts Too Low A/C pressure sensor input below minimum acceptable

voltage.

P1599 A/C Sensor Input Lo Problem detected in air conditioning electrical circuit.

P1602 PCM not programmed

P1680 Clutch Released Switch Circuit Problem detected in clutch switch electrical circuit.

P1681 No I/P Cluster CCD/J1850

Messages ReceivedNo CCD/J1850 messages received from the cluster

control module.

P1682 (G) Charging System Voltage Too Low Battery voltage sense input below target charging voltage

during engine operation and no significant change in

voltage detected during active test of generator output

circuit.

P1682 Charging System Voltage Too Low Charging system output voltage low.

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed

control servo power control circuit.

P1683 Spd ctrl pwr rly, or s/c 12v driver

circuitAn open or shorted condition detected in the speed

control servo power control circuit.

P1684 Batt Loss (disconnected) in last 50

StartsThe battery has been disconnected within the last 50

starts

P1685 SKIM Invalid Key - (Wrong or Invalid

Key MSG Received From SKIM)The engine controler has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

25 - 14 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)