idle air control JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 226 of 2199

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan

or fan control solenoid circuit controling the hydrau-

lic fan, a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTINGÐPRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

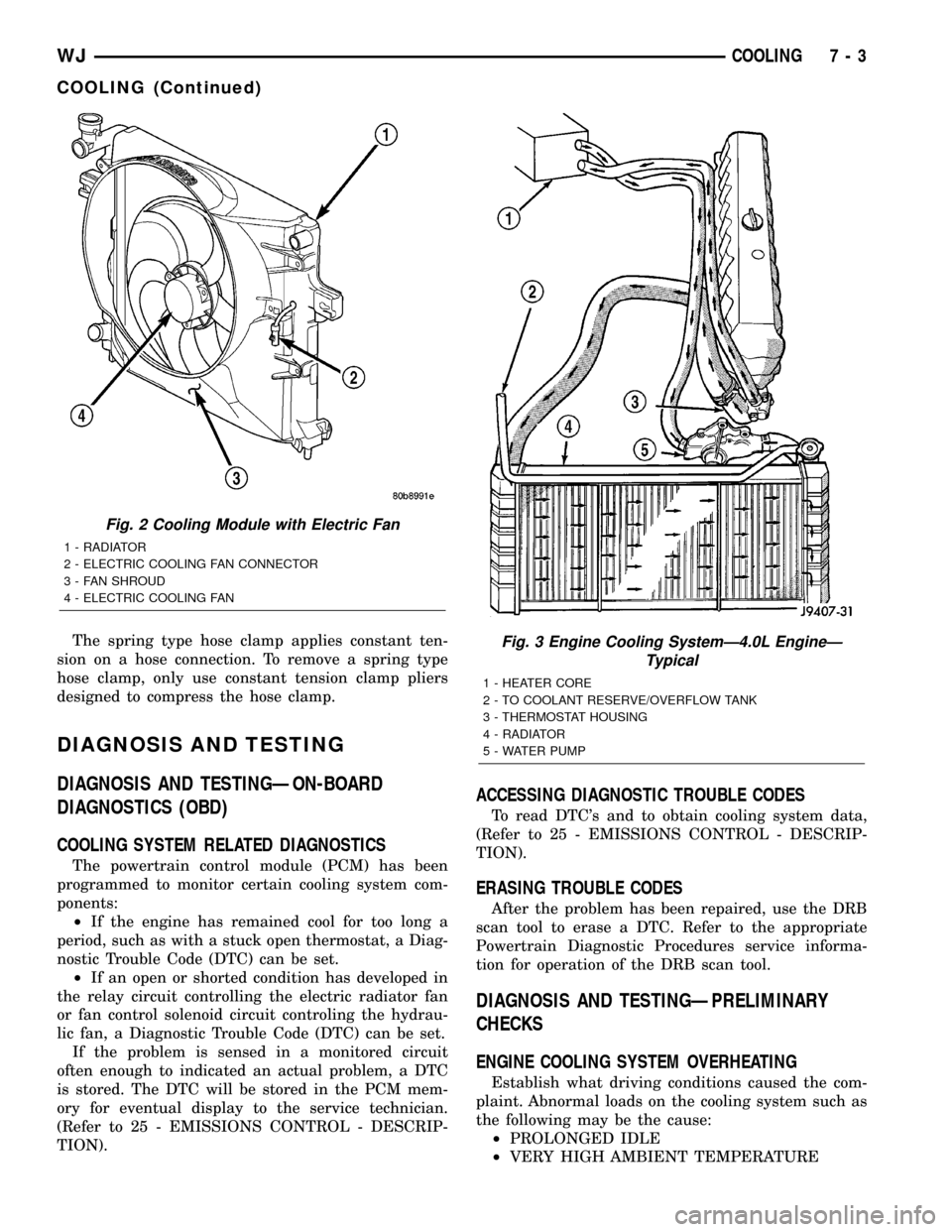

Fig. 2 Cooling Module with Electric Fan

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

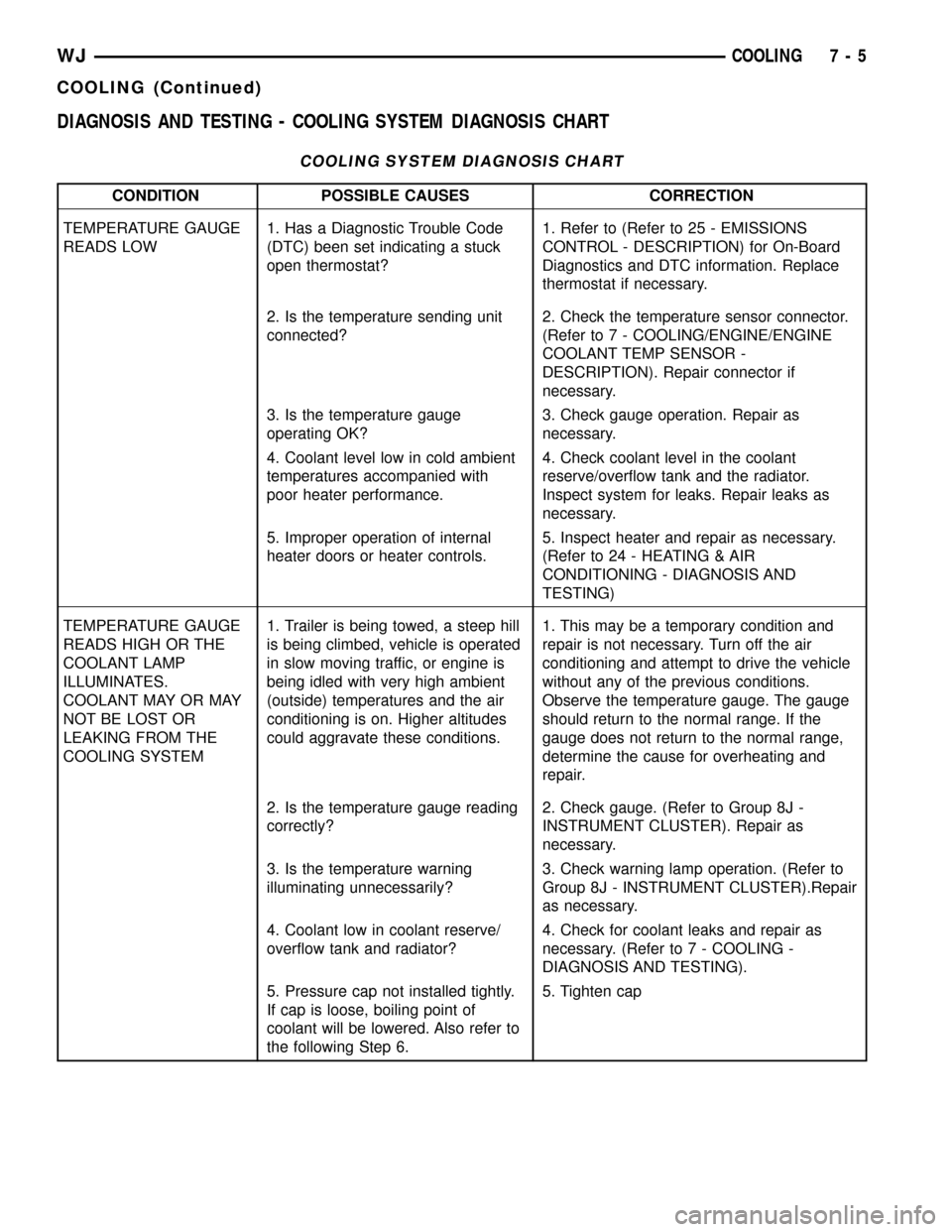

Fig. 3 Engine Cooling SystemÐ4.0L EngineÐ

Typical

1 - HEATER CORE

2 - TO COOLANT RESERVE/OVERFLOW TANK

3 - THERMOSTAT HOUSING

4 - RADIATOR

5 - WATER PUMP

WJCOOLING 7 - 3

COOLING (Continued)

Page 228 of 2199

DIAGNOSIS AND TESTING - COOLING SYSTEM DIAGNOSIS CHART

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open thermostat?1. Refer to (Refer to 25 - EMISSIONS

CONTROL - DESCRIPTION) for On-Board

Diagnostics and DTC information. Replace

thermostat if necessary.

2. Is the temperature sending unit

connected?2. Check the temperature sensor connector.

(Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT TEMP SENSOR -

DESCRIPTION). Repair connector if

necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. Repair as

necessary.

4. Coolant level low in cold ambient

temperatures accompanied with

poor heater performance.4. Check coolant level in the coolant

reserve/overflow tank and the radiator.

Inspect system for leaks. Repair leaks as

necessary.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as necessary.

(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND

TESTING)

TEMPERATURE GAUGE

READS HIGH OR THE

COOLANT LAMP

ILLUMINATES.

COOLANT MAY OR MAY

NOT BE LOST OR

LEAKING FROM THE

COOLING SYSTEM1. Trailer is being towed, a steep hill

is being climbed, vehicle is operated

in slow moving traffic, or engine is

being idled with very high ambient

(outside) temperatures and the air

conditioning is on. Higher altitudes

could aggravate these conditions.1. This may be a temporary condition and

repair is not necessary. Turn off the air

conditioning and attempt to drive the vehicle

without any of the previous conditions.

Observe the temperature gauge. The gauge

should return to the normal range. If the

gauge does not return to the normal range,

determine the cause for overheating and

repair.

2. Is the temperature gauge reading

correctly?2. Check gauge. (Refer to Group 8J -

INSTRUMENT CLUSTER). Repair as

necessary.

3. Is the temperature warning

illuminating unnecessarily?3. Check warning lamp operation. (Refer to

Group 8J - INSTRUMENT CLUSTER).Repair

as necessary.

4. Coolant low in coolant reserve/

overflow tank and radiator?4. Check for coolant leaks and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer to

the following Step 6.5. Tighten cap

WJCOOLING 7 - 5

COOLING (Continued)

Page 251 of 2199

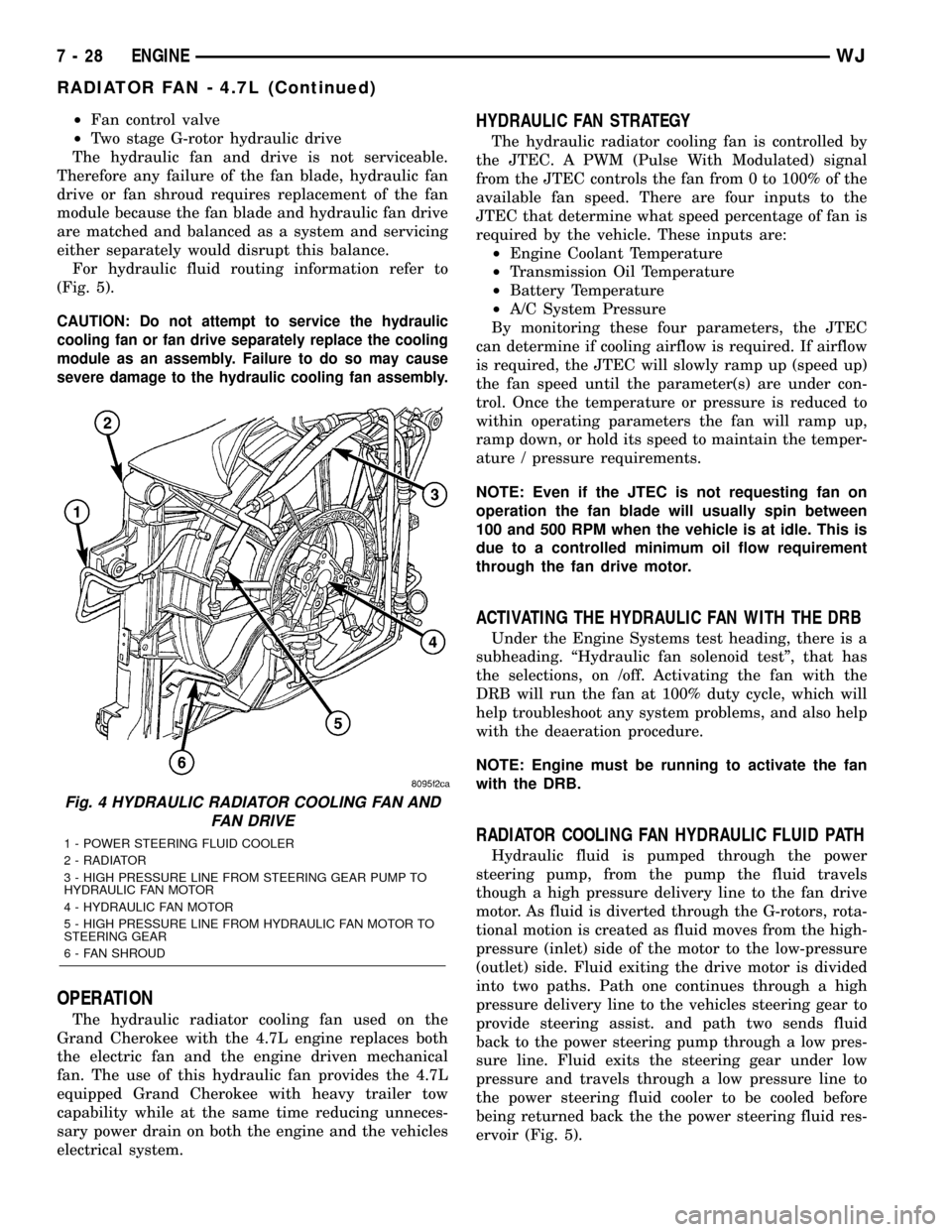

²Fan control valve

²Two stage G-rotor hydraulic drive

The hydraulic fan and drive is not serviceable.

Therefore any failure of the fan blade, hydraulic fan

drive or fan shroud requires replacement of the fan

module because the fan blade and hydraulic fan drive

are matched and balanced as a system and servicing

either separately would disrupt this balance.

For hydraulic fluid routing information refer to

(Fig. 5).

CAUTION: Do not attempt to service the hydraulic

cooling fan or fan drive separately replace the cooling

module as an assembly. Failure to do so may cause

severe damage to the hydraulic cooling fan assembly.

OPERATION

The hydraulic radiator cooling fan used on the

Grand Cherokee with the 4.7L engine replaces both

the electric fan and the engine driven mechanical

fan. The use of this hydraulic fan provides the 4.7L

equipped Grand Cherokee with heavy trailer tow

capability while at the same time reducing unneces-

sary power drain on both the engine and the vehicles

electrical system.

HYDRAULIC FAN STRATEGY

The hydraulic radiator cooling fan is controlled by

the JTEC. A PWM (Pulse With Modulated) signal

from the JTEC controls the fan from 0 to 100% of the

available fan speed. There are four inputs to the

JTEC that determine what speed percentage of fan is

required by the vehicle. These inputs are:

²Engine Coolant Temperature

²Transmission Oil Temperature

²Battery Temperature

²A/C System Pressure

By monitoring these four parameters, the JTEC

can determine if cooling airflow is required. If airflow

is required, the JTEC will slowly ramp up (speed up)

the fan speed until the parameter(s) are under con-

trol. Once the temperature or pressure is reduced to

within operating parameters the fan will ramp up,

ramp down, or hold its speed to maintain the temper-

ature / pressure requirements.

NOTE: Even if the JTEC is not requesting fan on

operation the fan blade will usually spin between

100 and 500 RPM when the vehicle is at idle. This is

due to a controlled minimum oil flow requirement

through the fan drive motor.

ACTIVATING THE HYDRAULIC FAN WITH THE DRB

Under the Engine Systems test heading, there is a

subheading. ªHydraulic fan solenoid testº, that has

the selections, on /off. Activating the fan with the

DRB will run the fan at 100% duty cycle, which will

help troubleshoot any system problems, and also help

with the deaeration procedure.

NOTE: Engine must be running to activate the fan

with the DRB.

RADIATOR COOLING FAN HYDRAULIC FLUID PATH

Hydraulic fluid is pumped through the power

steering pump, from the pump the fluid travels

though a high pressure delivery line to the fan drive

motor. As fluid is diverted through the G-rotors, rota-

tional motion is created as fluid moves from the high-

pressure (inlet) side of the motor to the low-pressure

(outlet) side. Fluid exiting the drive motor is divided

into two paths. Path one continues through a high

pressure delivery line to the vehicles steering gear to

provide steering assist. and path two sends fluid

back to the power steering pump through a low pres-

sure line. Fluid exits the steering gear under low

pressure and travels through a low pressure line to

the power steering fluid cooler to be cooled before

being returned back the the power steering fluid res-

ervoir (Fig. 5).

Fig. 4 HYDRAULIC RADIATOR COOLING FAN AND

FAN DRIVE

1 - POWER STEERING FLUID COOLER

2 - RADIATOR

3 - HIGH PRESSURE LINE FROM STEERING GEAR PUMP TO

HYDRAULIC FAN MOTOR

4 - HYDRAULIC FAN MOTOR

5 - HIGH PRESSURE LINE FROM HYDRAULIC FAN MOTOR TO

STEERING GEAR

6 - FAN SHROUD

7 - 28 ENGINEWJ

RADIATOR FAN - 4.7L (Continued)

Page 258 of 2199

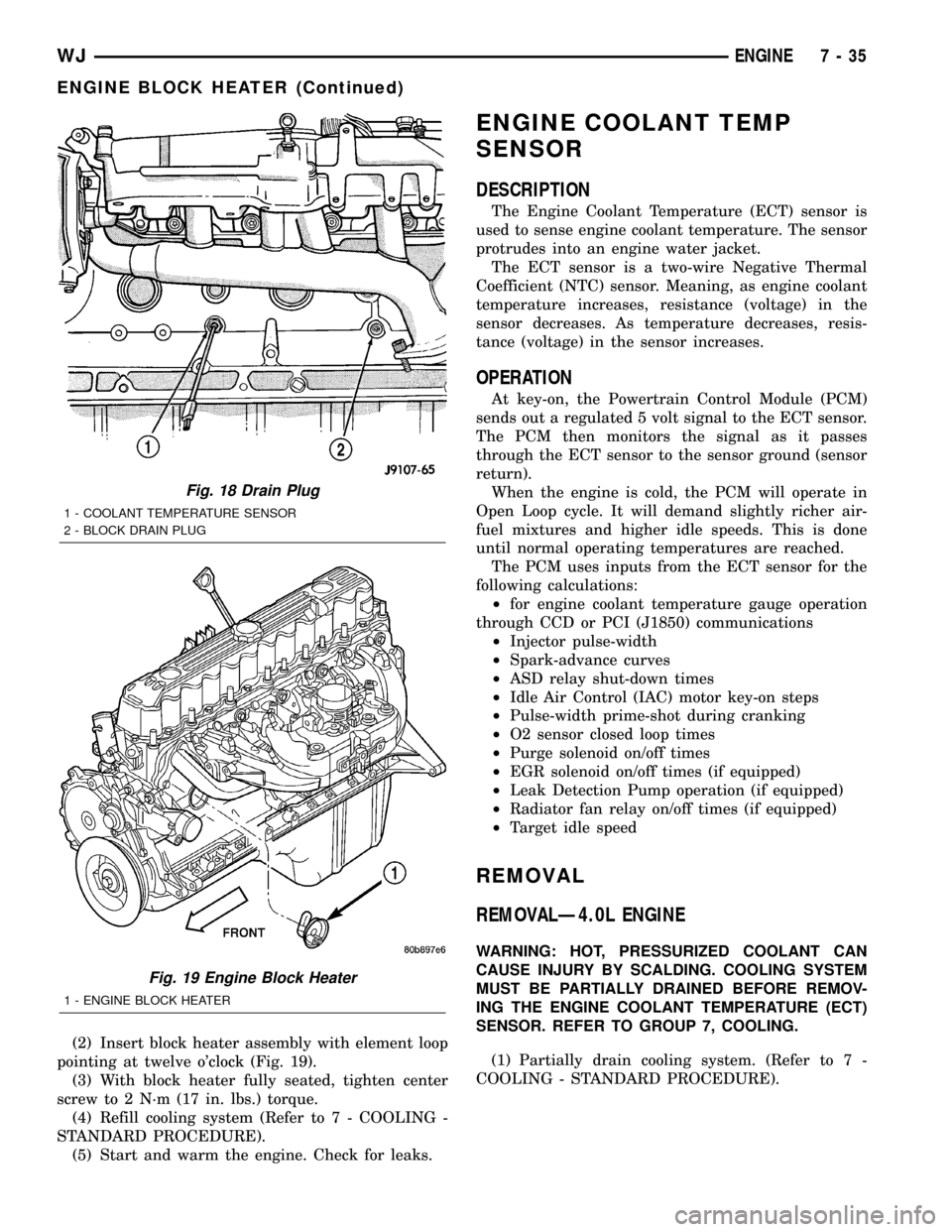

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 19).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

Fig. 18 Drain Plug

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

Fig. 19 Engine Block Heater

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 35

ENGINE BLOCK HEATER (Continued)

Page 321 of 2199

INSTALLATION

(1) Install the MHSM,HSM into the bracket.

(2) Position the heated seat module and mounting

bracket onto the power seat track.

(3) Reconnect the power seat wiring harness con-

nectors to the heated seat module.

(4) Install the driver side front bucket seat onto

the power seat track unit (Refer to 23 - BODY/

SEATS/SEAT TRACK ADJUSTER - INSTALLA-

TION).

(5) Reconnect the battery negative cable.

NOTE: If the vehicle is equipped with the optional

Memory System, following installation, it will be

necessary to initialize the Memory Heated Seat

Module (MHSM). In order to function properly, the

MHSM must ªlearnº the sensor values of each of

the power seat motor position transducers in each

of the adjuster hard stop positions. This is done by

performing the ªReset Guard Bandº procedure

using a DRBIIITscan tool and the proper Diagnostic

Procedures manual.

WARNING: THE ªRESET GUARD BANDº PROCE-

DURE WILL CAUSE THE DRIVER SIDE FRONT

SEAT TO AUTOMATICALLY ADJUST TO EACH OF

ITS TRAVEL LIMITS. BE CERTAIN THAT NO ONE IS

SEATED IN THE VEHICLE AND THAT THERE IS

NOTHING IN THE VEHICLE THAT WILL OBSTRUCT

SEAT MOVEMENT. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN PERSONAL INJURIES

AND/OR VEHICLE DAMAGE.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

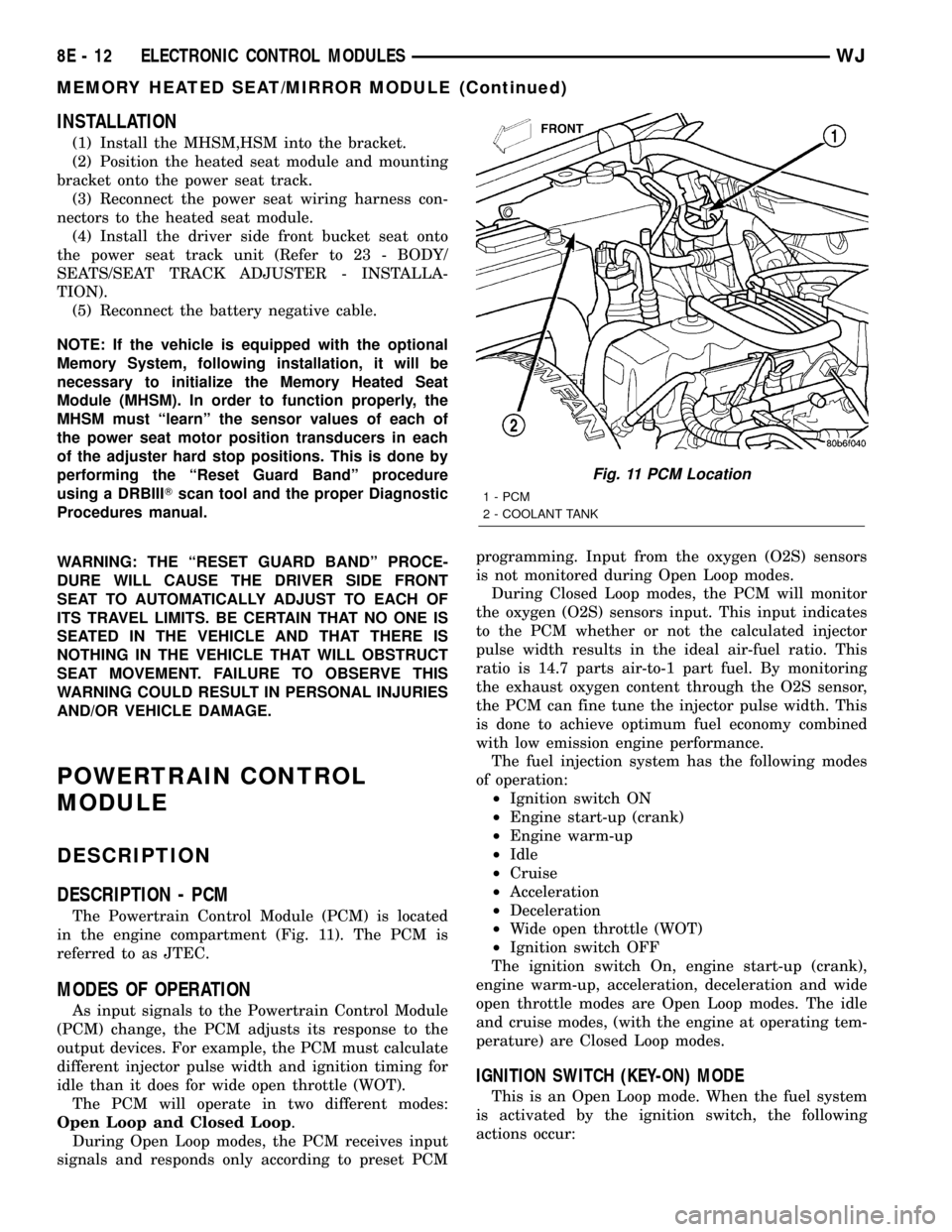

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 11). The PCM is

referred to as JTEC.

MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCMprogramming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

Fig. 11 PCM Location

1 - PCM

2 - COOLANT TANK

8E - 12 ELECTRONIC CONTROL MODULESWJ

MEMORY HEATED SEAT/MIRROR MODULE (Continued)

Page 322 of 2199

²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the O2S relays. The O2S sensor input is not used by

the PCM to calibrate air-fuel ratio during this mode

of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within approximately 3 seconds of

cranking the engine, it will shut down the fuel injec-

tion system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the clutch relay. This is done if A/C has been

selected by the vehicle operator and requested by the

A/C thermostat.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

WJELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 323 of 2199

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

the injector pulse width by turning the ground circuit

to each individual injector on and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

8E - 14 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 324 of 2199

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

OPERATION

OPERATION - PCM

(1) Also refer to Modes of Operation.

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²A/C request

²Auto shutdown (ASD) sense

²Battery temperature

²Battery voltage

²Brake switch

²J1850 bus circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connections for DRB scan tool

²Engine coolant temperature sensor

²Five volts (primary)

²Five volts (secondary)

²Fuel level

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)

²Intake manifold air temperature sensor

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Overdrive/override switch

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed (from ABS module)

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 (+/-) circuits for: speedometer, voltmeter,

fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRBIIItscan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)

²Idle air control (IAC) motor

²Ignition coil

²Leak detection pump

WJELECTRONIC CONTROL MODULES 8E - 15

POWERTRAIN CONTROL MODULE (Continued)

Page 458 of 2199

INSTALLATION - CHMSL

(1) Connect the wire harness connector.

(2) Position the CHMSL on liftgate.

(3) Install the screws attaching the CHMSL to the

liftgate.

COMBINATION FLASHER

DESCRIPTION

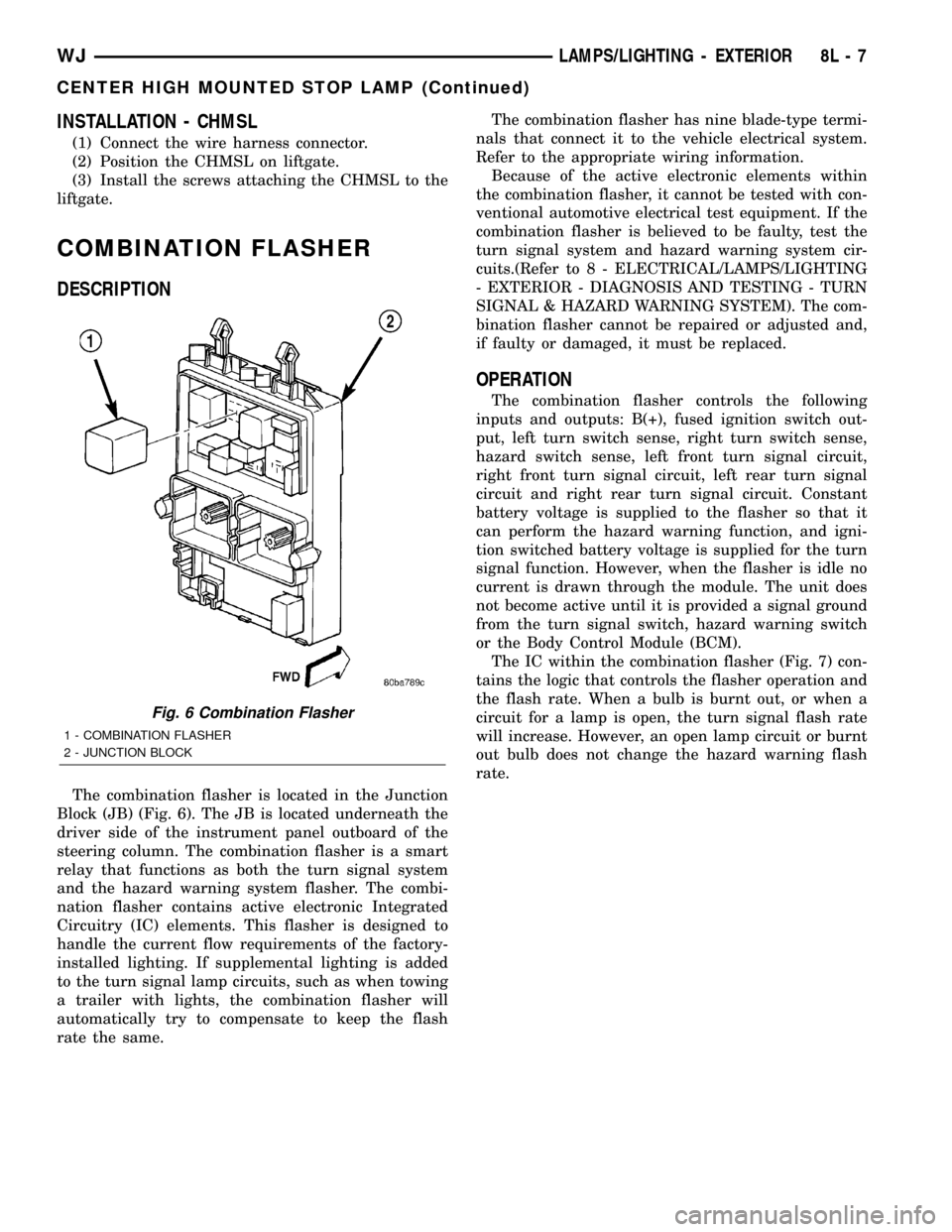

The combination flasher is located in the Junction

Block (JB) (Fig. 6). The JB is located underneath the

driver side of the instrument panel outboard of the

steering column. The combination flasher is a smart

relay that functions as both the turn signal system

and the hazard warning system flasher. The combi-

nation flasher contains active electronic Integrated

Circuitry (IC) elements. This flasher is designed to

handle the current flow requirements of the factory-

installed lighting. If supplemental lighting is added

to the turn signal lamp circuits, such as when towing

a trailer with lights, the combination flasher will

automatically try to compensate to keep the flash

rate the same.The combination flasher has nine blade-type termi-

nals that connect it to the vehicle electrical system.

Refer to the appropriate wiring information.

Because of the active electronic elements within

the combination flasher, it cannot be tested with con-

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the

turn signal system and hazard warning system cir-

cuits.(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING

- EXTERIOR - DIAGNOSIS AND TESTING - TURN

SIGNAL & HAZARD WARNING SYSTEM). The com-

bination flasher cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The combination flasher controls the following

inputs and outputs: B(+), fused ignition switch out-

put, left turn switch sense, right turn switch sense,

hazard switch sense, left front turn signal circuit,

right front turn signal circuit, left rear turn signal

circuit and right rear turn signal circuit. Constant

battery voltage is supplied to the flasher so that it

can perform the hazard warning function, and igni-

tion switched battery voltage is supplied for the turn

signal function. However, when the flasher is idle no

current is drawn through the module. The unit does

not become active until it is provided a signal ground

from the turn signal switch, hazard warning switch

or the Body Control Module (BCM).

The IC within the combination flasher (Fig. 7) con-

tains the logic that controls the flasher operation and

the flash rate. When a bulb is burnt out, or when a

circuit for a lamp is open, the turn signal flash rate

will increase. However, an open lamp circuit or burnt

out bulb does not change the hazard warning flash

rate.

Fig. 6 Combination Flasher

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

WJLAMPS/LIGHTING - EXTERIOR 8L - 7

CENTER HIGH MOUNTED STOP LAMP (Continued)

Page 464 of 2199

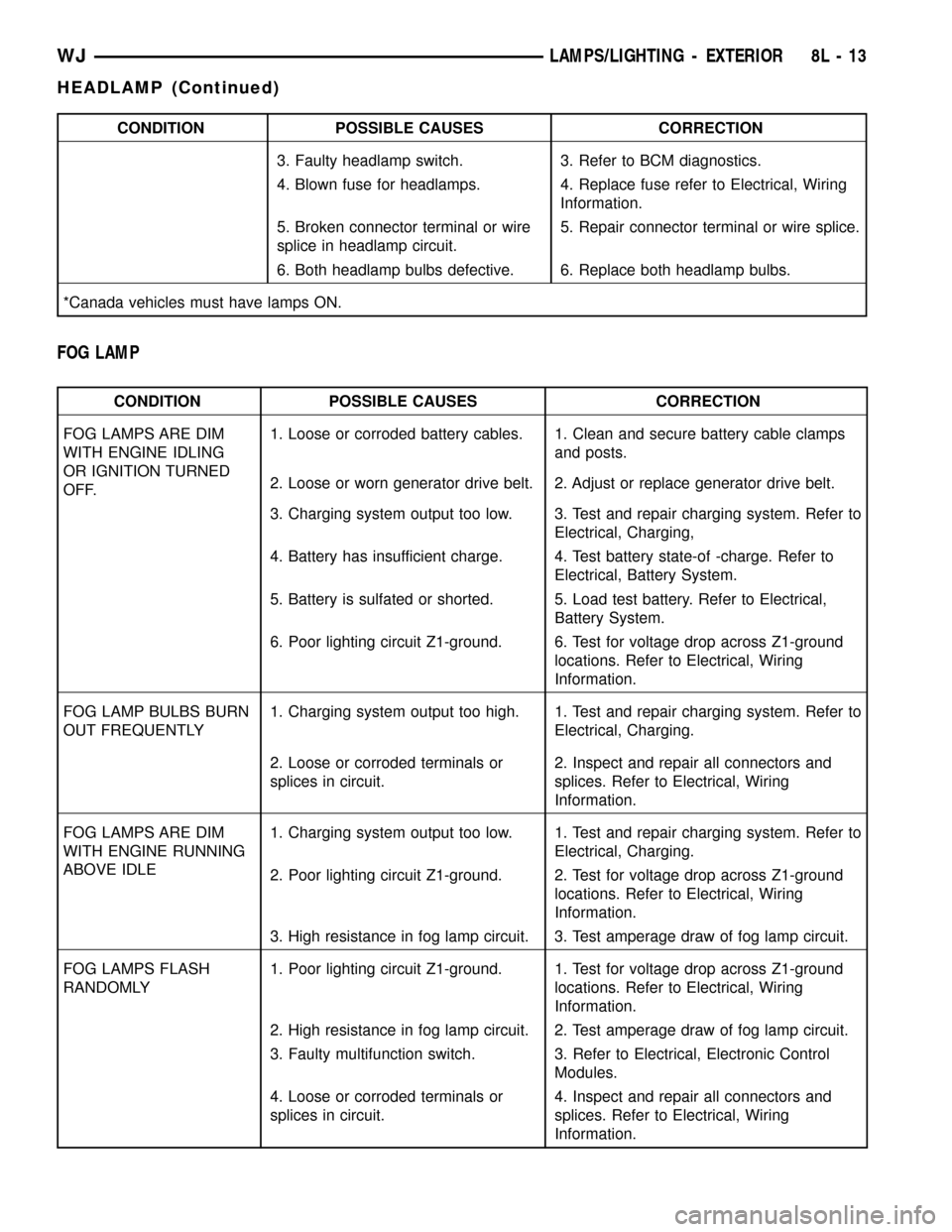

CONDITION POSSIBLE CAUSES CORRECTION

3. Faulty headlamp switch. 3. Refer to BCM diagnostics.

4. Blown fuse for headlamps. 4. Replace fuse refer to Electrical, Wiring

Information.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

6. Both headlamp bulbs defective. 6. Replace both headlamp bulbs.

*Canada vehicles must have lamps ON.

FOG LAMP

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of -charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical,

Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS BURN

OUT FREQUENTLY1. Charging system output too high. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

FOG LAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty multifunction switch. 3. Refer to Electrical, Electronic Control

Modules.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

WJLAMPS/LIGHTING - EXTERIOR 8L - 13

HEADLAMP (Continued)