limp JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 359 of 2199

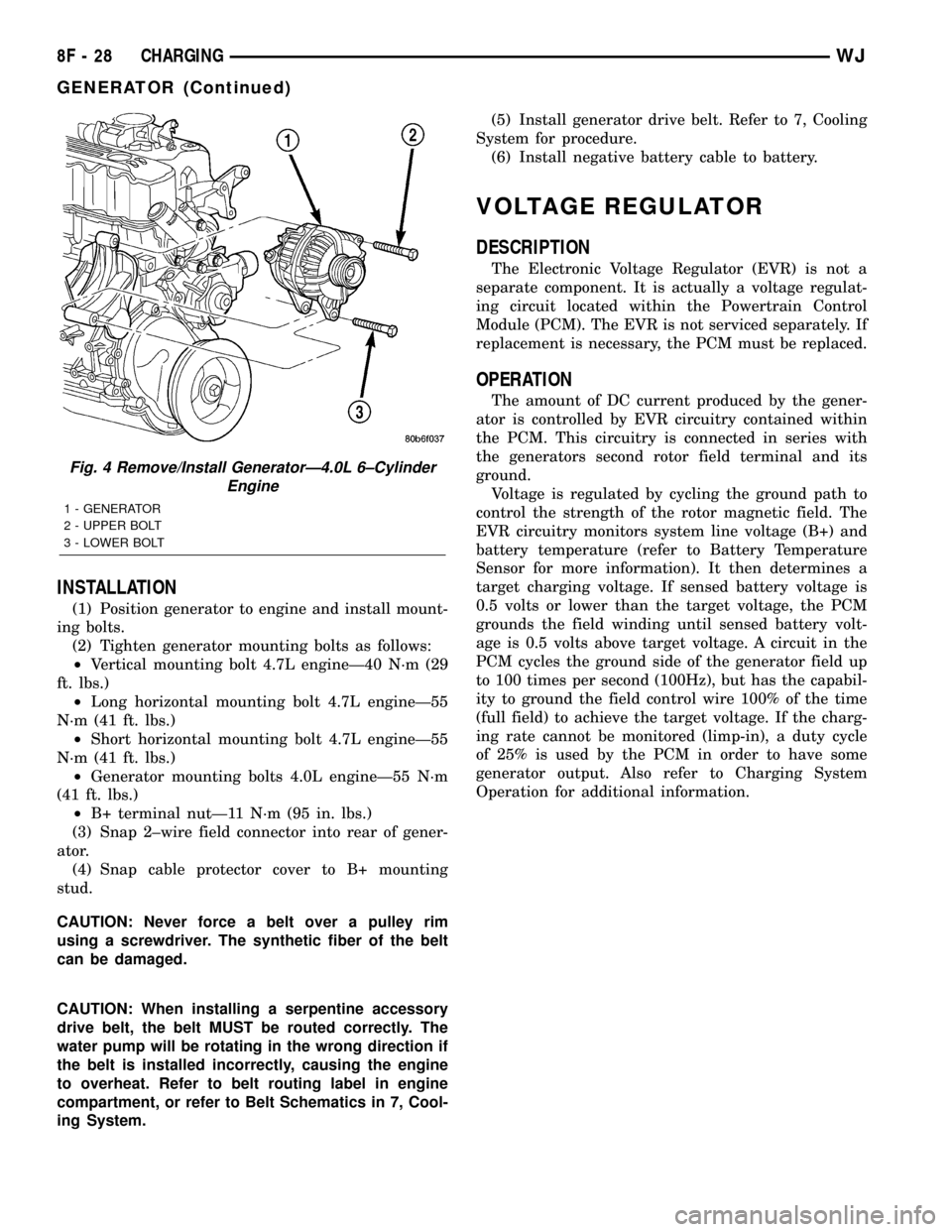

INSTALLATION

(1) Position generator to engine and install mount-

ing bolts.

(2) Tighten generator mounting bolts as follows:

²Vertical mounting bolt 4.7L engineÐ40 N´m (29

ft. lbs.)

²Long horizontal mounting bolt 4.7L engineÐ55

N´m (41 ft. lbs.)

²Short horizontal mounting bolt 4.7L engineÐ55

N´m (41 ft. lbs.)

²Generator mounting bolts 4.0L engineÐ55 N´m

(41 ft. lbs.)

²B+ terminal nutÐ11 N´m (95 in. lbs.)

(3) Snap 2±wire field connector into rear of gener-

ator.

(4) Snap cable protector cover to B+ mounting

stud.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in 7, Cool-

ing System.(5) Install generator drive belt. Refer to 7, Cooling

System for procedure.

(6) Install negative battery cable to battery.

VOLTAGE REGULATOR

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

OPERATION

The amount of DC current produced by the gener-

ator is controlled by EVR circuitry contained within

the PCM. This circuitry is connected in series with

the generators second rotor field terminal and its

ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage (B+) and

battery temperature (refer to Battery Temperature

Sensor for more information). It then determines a

target charging voltage. If sensed battery voltage is

0.5 volts or lower than the target voltage, the PCM

grounds the field winding until sensed battery volt-

age is 0.5 volts above target voltage. A circuit in the

PCM cycles the ground side of the generator field up

to 100 times per second (100Hz), but has the capabil-

ity to ground the field control wire 100% of the time

(full field) to achieve the target voltage. If the charg-

ing rate cannot be monitored (limp-in), a duty cycle

of 25% is used by the PCM in order to have some

generator output. Also refer to Charging System

Operation for additional information.

Fig. 4 Remove/Install GeneratorÐ4.0L 6±Cylinder

Engine

1 - GENERATOR

2 - UPPER BOLT

3 - LOWER BOLT

8F - 28 CHARGINGWJ

GENERATOR (Continued)

Page 1698 of 2199

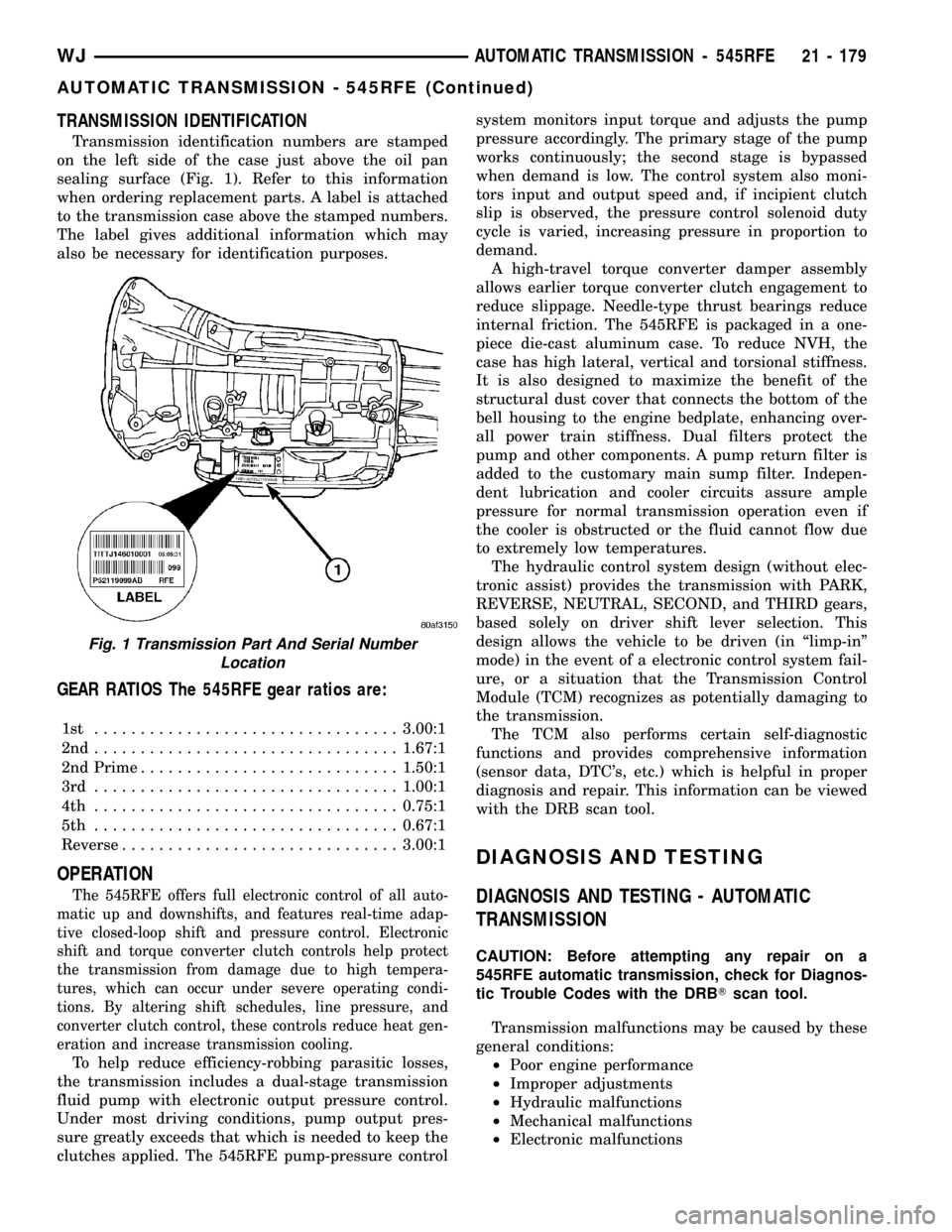

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime............................1.50:1

3rd .................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse..............................3.00:1

OPERATION

The 545RFE offers full electronic control of all auto-

matic up and downshifts, and features real-time adap-

tive closed-loop shift and pressure control. Electronic

shift and torque converter clutch controls help protect

the transmission from damage due to high tempera-

tures, which can occur under severe operating condi-

tions. By altering shift schedules, line pressure, and

converter clutch control, these controls reduce heat gen-

eration and increase transmission cooling.

To help reduce efficiency-robbing parasitic losses,

the transmission includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 545RFE pump-pressure controlsystem monitors input torque and adjusts the pump

pressure accordingly. The primary stage of the pump

works continuously; the second stage is bypassed

when demand is low. The control system also moni-

tors input and output speed and, if incipient clutch

slip is observed, the pressure control solenoid duty

cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 545RFE is packaged in a one-

piece die-cast aluminum case. To reduce NVH, the

case has high lateral, vertical and torsional stiffness.

It is also designed to maximize the benefit of the

structural dust cover that connects the bottom of the

bell housing to the engine bedplate, enhancing over-

all power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a

545RFE automatic transmission, check for Diagnos-

tic Trouble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Fig. 1 Transmission Part And Serial Number

Location

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 179

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1699 of 2199

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or if more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure for

vehicles that are drivable and an alternate procedure for

disabled vehicles (will not back up or move forward).

VEHICLE IS DRIVABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust gearshift cable if complaint was based

on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform stall test if complaint is based on slug-

gish acceleration. Or, if abnormal throttle opening is

needed to maintain normal speeds with a properly

tuned engine.

(6) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(7)

Perform air-pressure test to check clutch operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2)

Check for broken or disconnected gearshift cable.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged driveplate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that all diagnostic trou-

ble codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, overrunning clutch, or line presure problems.

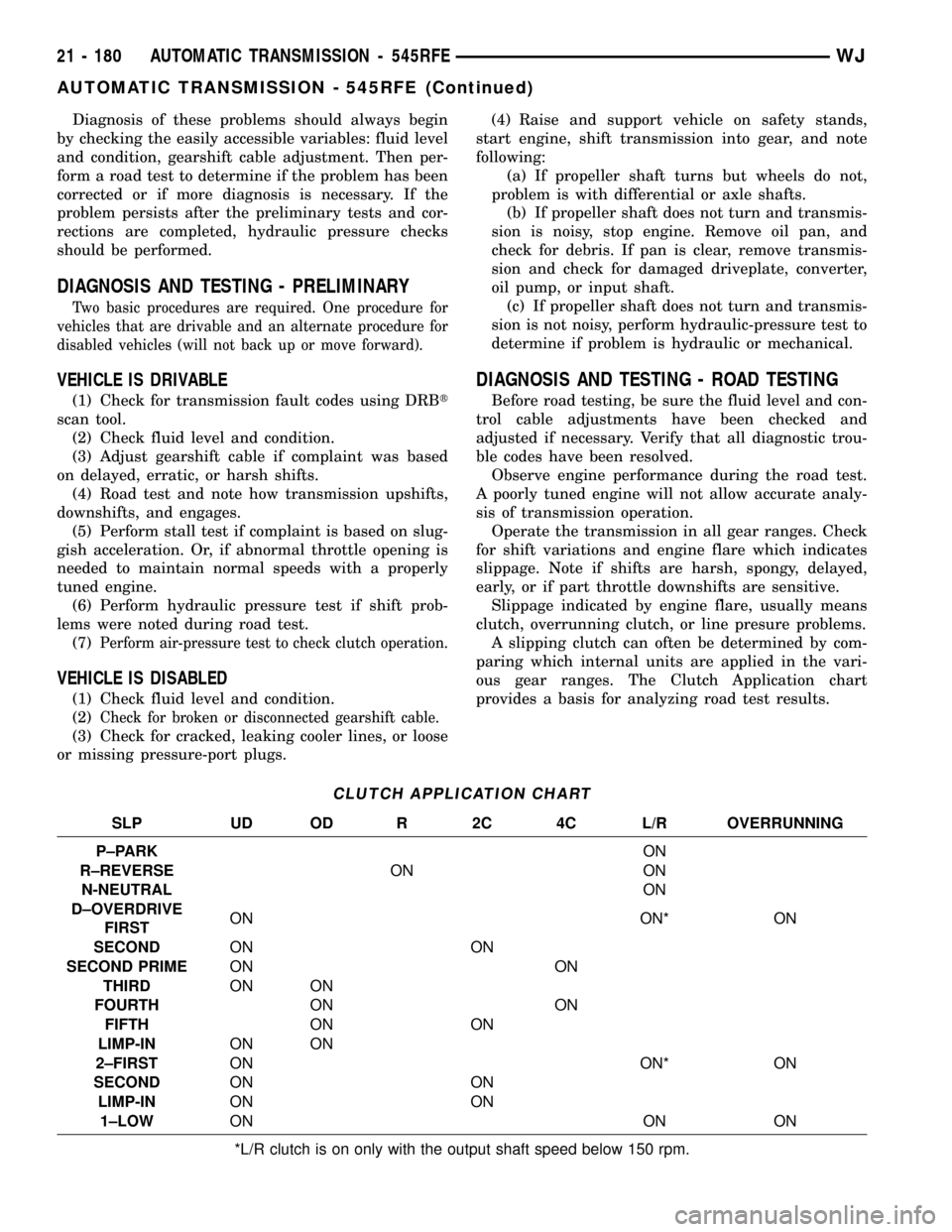

A slipping clutch can often be determined by com-

paring which internal units are applied in the vari-

ous gear ranges. The Clutch Application chart

provides a basis for analyzing road test results.

CLUTCH APPLICATION CHART

SLP UD OD R 2C 4C L/R OVERRUNNING

P±PARKON

R±REVERSEON ON

N-NEUTRALON

D±OVERDRIVE

FIRSTON ON* ON

SECONDON ON

SECOND PRIMEON ON

THIRDON ON

FOURTHON ON

FIFTHON ON

LIMP-INON ON

2±FIRSTON ON* ON

SECONDON ON

LIMP-INON ON

1±LOWON ON ON

*L/R clutch is on only with the output shaft speed below 150 rpm.

21 - 180 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1789 of 2199

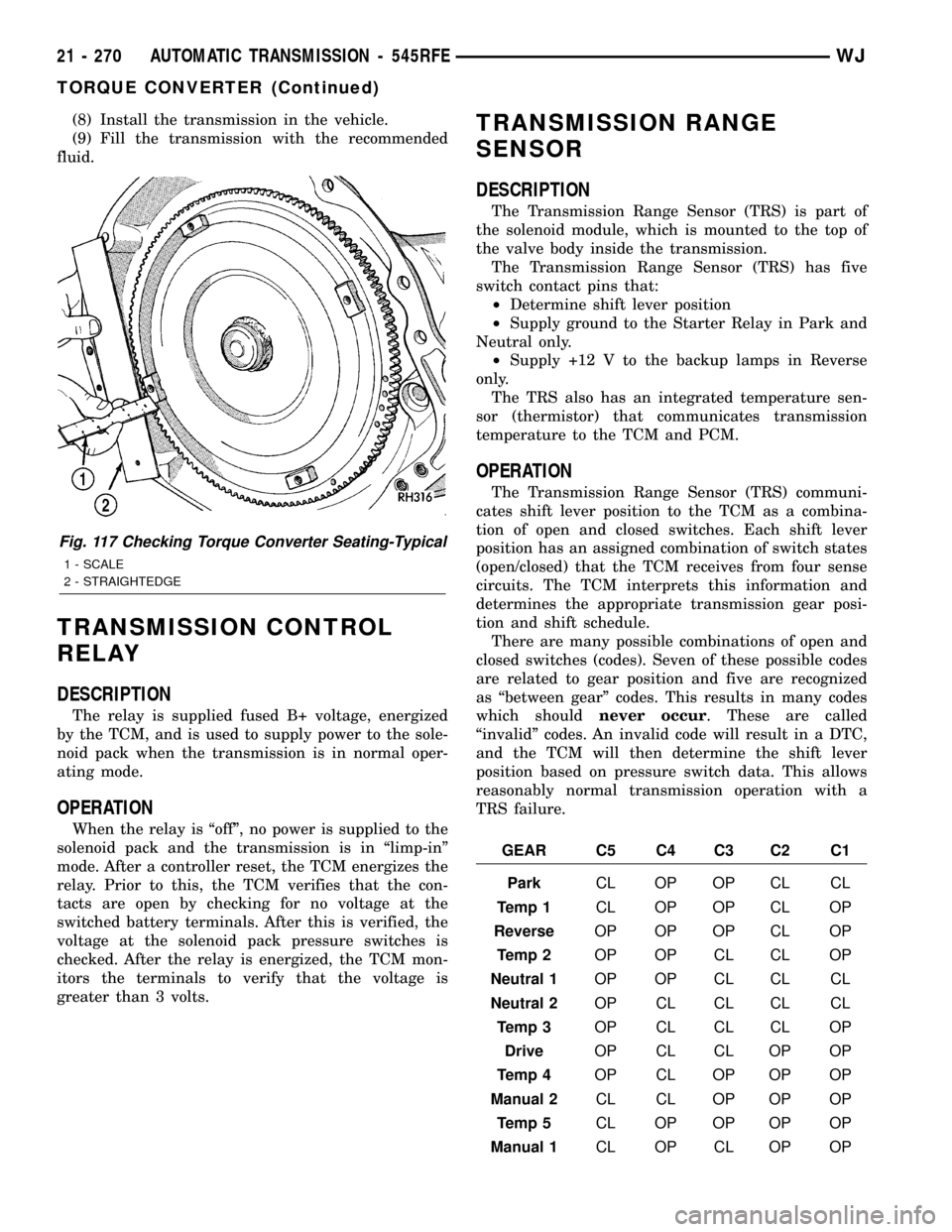

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The relay is supplied fused B+ voltage, energized

by the TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal oper-

ating mode.

OPERATION

When the relay is ªoffº, no power is supplied to the

solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset, the TCM energizes the

relay. Prior to this, the TCM verifies that the con-

tacts are open by checking for no voltage at the

switched battery terminals. After this is verified, the

voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the TCM mon-

itors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is part of

the solenoid module, which is mounted to the top of

the valve body inside the transmission.

The Transmission Range Sensor (TRS) has five

switch contact pins that:

²Determine shift lever position

²Supply ground to the Starter Relay in Park and

Neutral only.

²Supply +12 V to the backup lamps in Reverse

only.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transmission

temperature to the TCM and PCM.

OPERATION

The Transmission Range Sensor (TRS) communi-

cates shift lever position to the TCM as a combina-

tion of open and closed switches. Each shift lever

position has an assigned combination of switch states

(open/closed) that the TCM receives from four sense

circuits. The TCM interprets this information and

determines the appropriate transmission gear posi-

tion and shift schedule.

There are many possible combinations of open and

closed switches (codes). Seven of these possible codes

are related to gear position and five are recognized

as ªbetween gearº codes. This results in many codes

which shouldnever occur. These are called

ªinvalidº codes. An invalid code will result in a DTC,

and the TCM will then determine the shift lever

position based on pressure switch data. This allows

reasonably normal transmission operation with a

TRS failure.

GEAR C5 C4 C3 C2 C1

ParkCL OP OP CL CL

Temp 1CL OP OP CL OP

ReverseOP OP OP CL OP

Temp 2OP OP CL CL OP

Neutral 1OP OP CL CL CL

Neutral 2OP CL CL CL CL

Temp 3OP CL CL CL OP

DriveOP CL CL OP OP

Temp 4OP CL OP OP OP

Manual 2CL CL OP OP OP

Temp 5CL OP OP OP OP

Manual 1CL OP CL OP OP

Fig. 117 Checking Torque Converter Seating-Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 270 AUTOMATIC TRANSMISSION - 545RFEWJ

TORQUE CONVERTER (Continued)

Page 1790 of 2199

TRANSMISSION SOLENOID/

TRS ASSEMBLY

DESCRIPTION

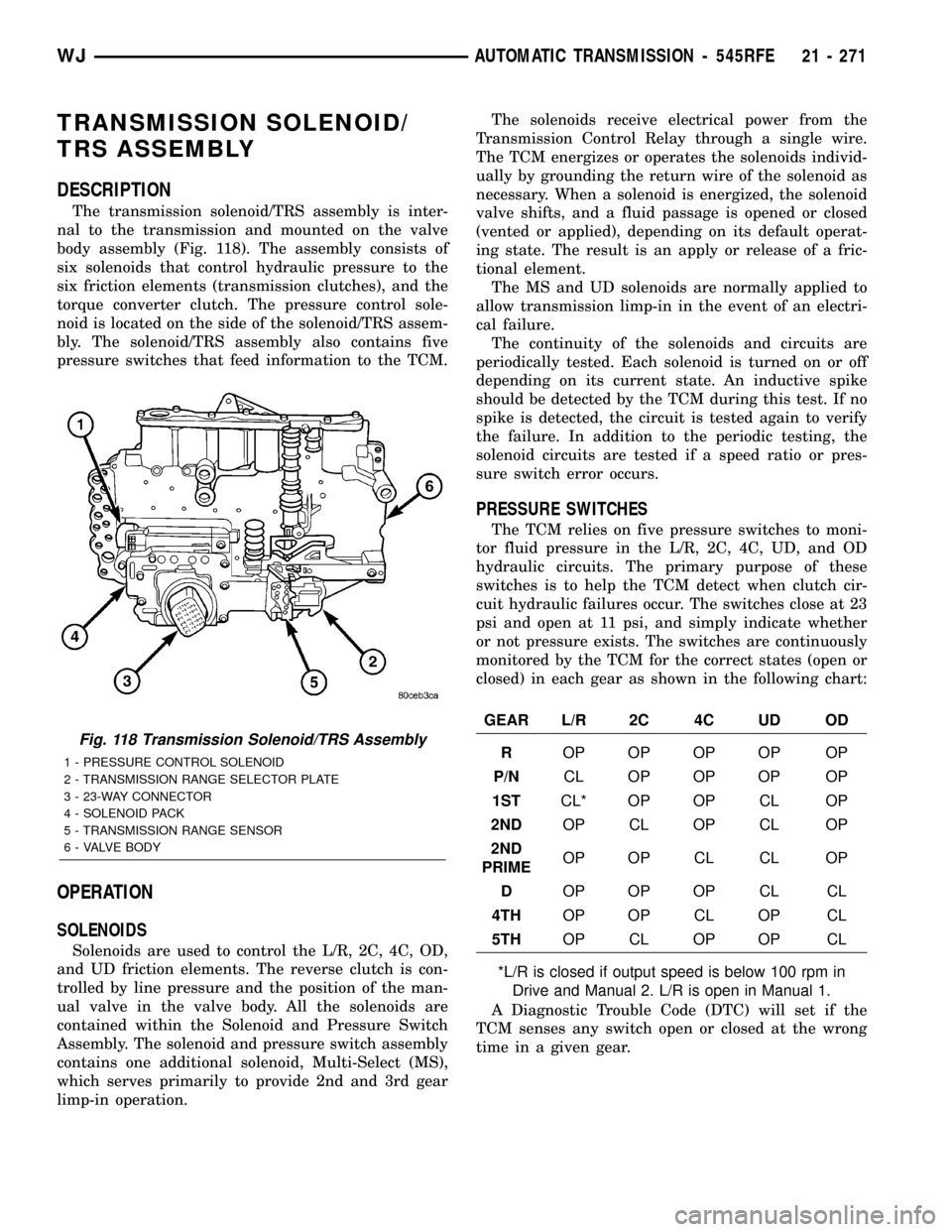

The transmission solenoid/TRS assembly is inter-

nal to the transmission and mounted on the valve

body assembly (Fig. 118). The assembly consists of

six solenoids that control hydraulic pressure to the

six friction elements (transmission clutches), and the

torque converter clutch. The pressure control sole-

noid is located on the side of the solenoid/TRS assem-

bly. The solenoid/TRS assembly also contains five

pressure switches that feed information to the TCM.

OPERATION

SOLENOIDS

Solenoids are used to control the L/R, 2C, 4C, OD,

and UD friction elements. The reverse clutch is con-

trolled by line pressure and the position of the man-

ual valve in the valve body. All the solenoids are

contained within the Solenoid and Pressure Switch

Assembly. The solenoid and pressure switch assembly

contains one additional solenoid, Multi-Select (MS),

which serves primarily to provide 2nd and 3rd gear

limp-in operation.The solenoids receive electrical power from the

Transmission Control Relay through a single wire.

The TCM energizes or operates the solenoids individ-

ually by grounding the return wire of the solenoid as

necessary. When a solenoid is energized, the solenoid

valve shifts, and a fluid passage is opened or closed

(vented or applied), depending on its default operat-

ing state. The result is an apply or release of a fric-

tional element.

The MS and UD solenoids are normally applied to

allow transmission limp-in in the event of an electri-

cal failure.

The continuity of the solenoids and circuits are

periodically tested. Each solenoid is turned on or off

depending on its current state. An inductive spike

should be detected by the TCM during this test. If no

spike is detected, the circuit is tested again to verify

the failure. In addition to the periodic testing, the

solenoid circuits are tested if a speed ratio or pres-

sure switch error occurs.

PRESSURE SWITCHES

The TCM relies on five pressure switches to moni-

tor fluid pressure in the L/R, 2C, 4C, UD, and OD

hydraulic circuits. The primary purpose of these

switches is to help the TCM detect when clutch cir-

cuit hydraulic failures occur. The switches close at 23

psi and open at 11 psi, and simply indicate whether

or not pressure exists. The switches are continuously

monitored by the TCM for the correct states (open or

closed) in each gear as shown in the following chart:

GEAR L/R 2C 4C UD OD

ROP OP OP OP OP

P/NCL OP OP OP OP

1STCL* OP OP CL OP

2NDOP CL OP CL OP

2ND

PRIMEOP OP CL CL OP

DOP OP OP CL CL

4THOP OP CL OP CL

5THOP CL OP OP CL

*L/R is closed if output speed is below 100 rpm in

Drive and Manual 2. L/R is open in Manual 1.

A Diagnostic Trouble Code (DTC) will set if the

TCM senses any switch open or closed at the wrong

time in a given gear.

Fig. 118 Transmission Solenoid/TRS Assembly

1 - PRESSURE CONTROL SOLENOID

2 - TRANSMISSION RANGE SELECTOR PLATE

3 - 23-WAY CONNECTOR

4 - SOLENOID PACK

5 - TRANSMISSION RANGE SENSOR

6 - VALVE BODY

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 271

Page 2174 of 2199

and deteriorate engine performance, driveability and

fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, itdepends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks or any component that

has an associated limp in will set a fault after 1 trip

with the malfunction present. Components without

WJEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)

Page 2175 of 2199

an associated limp in will take two trips to illumi-

nate the MIL.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

DESCRIPTION - NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems and conditions that could have malfunctions

causing driveability problems. The PCM might not

store diagnostic trouble codes for these conditions.

However, problems with these systems may cause the

PCM to store diagnostic trouble codes for other sys-

tems or components. For example, a fuel pressure

problem will not register a fault directly, but could

cause a rich/lean condition or misfire. This could

cause the PCM to store an oxygen sensor or misfire

diagnostic trouble code

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system, although it may set a fuel

system fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injectoris installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIRFLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

DESCRIPTION - LOAD VALUE

ENGINE IDLE/NEUTRAL 2500 RPM/NEUTRAL

All Engines 2% to 8% of Maximum Load 9% to 17% of Maximum Load

25 - 20 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)