radio controls JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 281 of 2199

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. The standard equipment

audio system includes an AM/FM/cassette (RBB sales

code) radio receiver, and speakers in six locations.

Several combinations of radio receivers and speaker

systems are offered as optional equipment on this

model. The audio system uses an ignition switched

control of battery current so that the system will only

operate when the ignition switch is in the On or

Accessory positions.

A Compact Disc (CD) changer with a ten disc mag-

azine, remote radio switches with six functions

mounted to the backs of the steering wheel spokes,

and a memory system that automatically stores and

recalls up to twenty radio station presets (ten AM

and ten FM) and the last station listened to for two

drivers are optional factory-installed equipment on

this model. Refer to Electrical, Power Seats for more

information on the memory system.

The audio system includes the following compo-

nents:

²Antenna

²Compact disc changer (available with RBP sales

code radio receivers only)

²Power amplifier (with premium speaker system

only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches

²Speakers

Certain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB scan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect audio

system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

The audio system includes the following major

components, which are described in further detail

elsewhere in this service information:

²Amplifier- On models equipped with the

optional premium speaker system, an audio power

amplifier is located on the rear floor panel under-

neath the right end of the rear seat cushion in the

passenger compartment.

²Antenna Body and Cable- The most visible

component of the antenna body and cable are the

antenna adapter and the antenna cap nut, which are

located on the top of the right front fender panel of

the vehicle, near the right end of the cowl plenum.

²Antenna Mast- The antenna mast is a metal

rod that extends upward from the antenna body and

cable on the top of the right front fender panel of the

vehicle, near the right end of the cowl plenum.

²Radio- The radio for this model is located in

the instrument panel center stack area, inboard of

the instrument cluster and above the heater and air

conditioner controls.

²Radio Noise Suppression Ground Strap-A

radio noise suppression ground strap is installed

between the rear of the engine cylinder head(s) and

the dash panel sheet metal in the engine compart-

ment.

²Speaker- The standard speaker system

includes six speakers in six locations, while the pre-

mium speaker system includes an amplifier for the

six speakers in six locations.

Hard wired circuitry connects the audio system

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

audio system components through the use of a com-

bination of soldered splices, splice block connectors

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information in this service manual for com-

plete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

8A - 2 AUDIOWJ

Page 291 of 2199

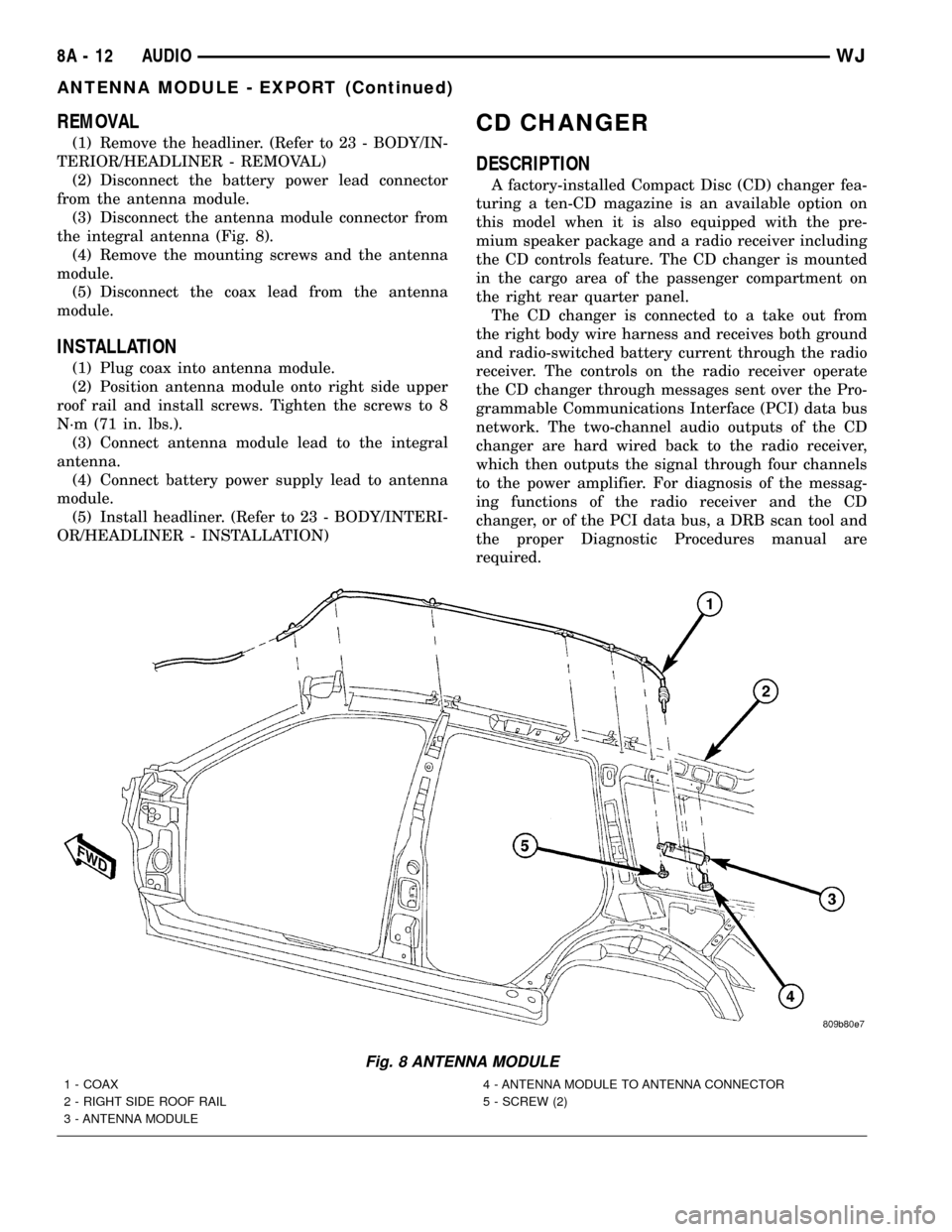

REMOVAL

(1) Remove the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - REMOVAL)

(2) Disconnect the battery power lead connector

from the antenna module.

(3) Disconnect the antenna module connector from

the integral antenna (Fig. 8).

(4) Remove the mounting screws and the antenna

module.

(5) Disconnect the coax lead from the antenna

module.

INSTALLATION

(1) Plug coax into antenna module.

(2) Position antenna module onto right side upper

roof rail and install screws. Tighten the screws to 8

N´m (71 in. lbs.).

(3) Connect antenna module lead to the integral

antenna.

(4) Connect battery power supply lead to antenna

module.

(5) Install headliner. (Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION)

CD CHANGER

DESCRIPTION

A factory-installed Compact Disc (CD) changer fea-

turing a ten-CD magazine is an available option on

this model when it is also equipped with the pre-

mium speaker package and a radio receiver including

the CD controls feature. The CD changer is mounted

in the cargo area of the passenger compartment on

the right rear quarter panel.

The CD changer is connected to a take out from

the right body wire harness and receives both ground

and radio-switched battery current through the radio

receiver. The controls on the radio receiver operate

the CD changer through messages sent over the Pro-

grammable Communications Interface (PCI) data bus

network. The two-channel audio outputs of the CD

changer are hard wired back to the radio receiver,

which then outputs the signal through four channels

to the power amplifier. For diagnosis of the messag-

ing functions of the radio receiver and the CD

changer, or of the PCI data bus, a DRB scan tool and

the proper Diagnostic Procedures manual are

required.

Fig. 8 ANTENNA MODULE

1 - COAX

2 - RIGHT SIDE ROOF RAIL

3 - ANTENNA MODULE4 - ANTENNA MODULE TO ANTENNA CONNECTOR

5 - SCREW (2)

8A - 12 AUDIOWJ

ANTENNA MODULE - EXPORT (Continued)

Page 302 of 2199

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Turn the ignition switch to the On position.

Turn the radio receiver on. Adjust the balance and

fader controls to check the performance of each indi-

vidual speaker. Note the speaker locations that are

not performing correctly. Go to Step 2.

(2) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. Remove the radio receiver

from the instrument panel. If the vehicle is equipped

with the Infinity speaker package, also disconnect

the wire harness connectors at the power amplifier.

Check both the speaker feed (+) circuit and return (±)

circuit cavities for the inoperative speaker location(s)

at the radio receiver wire harness connectors for con-

tinuity to ground. In each case, there should be no

continuity. If OK, go to Step 3. If not OK, repair the

shorted speaker feed (+) and/or return (±) circuit(s) to

the speaker as required.

(3) If the vehicle is equipped with the Infinity

speaker package, go to Step 6. If the vehicle is

equipped with the standard speaker system, check

the resistance between the speaker feed (+) circuit

and return (±) circuit cavities of the radio receiverwire harness connectors for the inoperative speaker

location(s). The meter should read between 2 and 3

ohms (speaker resistance). If OK, go to Step 4. If not

OK, go to Step 5.

(4) Install a known good radio receiver. Connect

the battery negative cable. Turn the ignition switch

to the On position. Turn on the radio receiver and

test the speaker operation. If OK, replace the faulty

radio receiver. If not OK, turn the radio receiver off,

turn the ignition switch to the Off position, discon-

nect and isolate the battery negative cable, remove

the test radio receiver, and go to Step 5.

(5) Disconnect the wire harness connector at the

inoperative speaker. Check for continuity between

the speaker feed (+) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. Repeat the check between the

speaker return (±) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. In each case, there should be con-

tinuity. If OK, replace the faulty speaker. If not OK,

repair the open speaker feed (+) and/or return (±) cir-

cuit(s) as required.

(6) For each inoperative speaker location, check for

continuity between the speaker feed (+) circuit cavi-

ties of the radio receiver wire harness connectors and

the power amplifier wire harness connectors. Repeat

the check for each inoperative speaker location

between the speaker return (±) circuit cavities of the

radio receiver wire harness connectors and the power

amplifier wire harness connectors. In each case,

there should be continuity. If OK, go to Step 7. If not

OK, repair the open speaker feed (+) and/or return

(±) circuit(s) as required.

(7) Check for continuity between the two ground

circuit cavities of the power amplifier wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 8. If not OK, repair the open

ground circuit(s) to ground as required.

(8) Check the fused B(+) fuse for the power ampli-

fier in the junction block. If OK, go to Step 9. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(9) Install the radio receiver. Connect the battery

negative cable. Check for battery voltage at the fused

B(+) fuse for the power amplifier in the junction

block. If OK, go to Step 10. If not OK, repair the

open fused B(+) circuit to the Power Distribution

Center (PDC) fuse as required.

(10) Check for battery voltage at the two fused

B(+) circuit cavities of the power amplifier wire har-

ness connector. If OK, go to Step 11. If not OK, repair

the open fused B(+) circuit(s) to the power amplifier

fuse in the junction block as required.

(11) Turn the ignition switch to the On position.

Turn the radio receiver on. Check for battery voltage

WJAUDIO 8A - 23

SPEAKER (Continued)

Page 494 of 2199

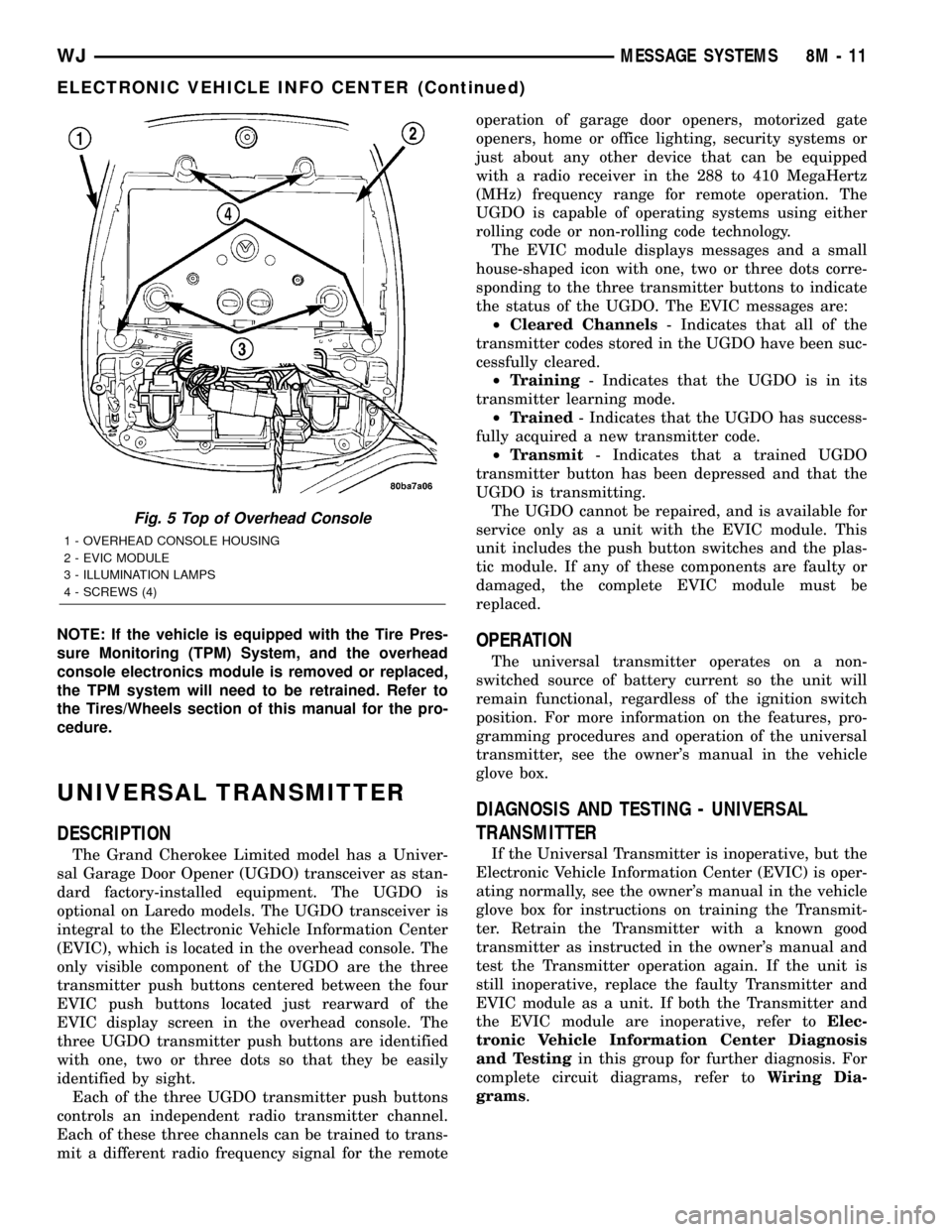

NOTE: If the vehicle is equipped with the Tire Pres-

sure Monitoring (TPM) System, and the overhead

console electronics module is removed or replaced,

the TPM system will need to be retrained. Refer to

the Tires/Wheels section of this manual for the pro-

cedure.

UNIVERSAL TRANSMITTER

DESCRIPTION

The Grand Cherokee Limited model has a Univer-

sal Garage Door Opener (UGDO) transceiver as stan-

dard factory-installed equipment. The UGDO is

optional on Laredo models. The UGDO transceiver is

integral to the Electronic Vehicle Information Center

(EVIC), which is located in the overhead console. The

only visible component of the UGDO are the three

transmitter push buttons centered between the four

EVIC push buttons located just rearward of the

EVIC display screen in the overhead console. The

three UGDO transmitter push buttons are identified

with one, two or three dots so that they be easily

identified by sight.

Each of the three UGDO transmitter push buttons

controls an independent radio transmitter channel.

Each of these three channels can be trained to trans-

mit a different radio frequency signal for the remoteoperation of garage door openers, motorized gate

openers, home or office lighting, security systems or

just about any other device that can be equipped

with a radio receiver in the 288 to 410 MegaHertz

(MHz) frequency range for remote operation. The

UGDO is capable of operating systems using either

rolling code or non-rolling code technology.

The EVIC module displays messages and a small

house-shaped icon with one, two or three dots corre-

sponding to the three transmitter buttons to indicate

the status of the UGDO. The EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the UGDO have been suc-

cessfully cleared.

²Training- Indicates that the UGDO is in its

transmitter learning mode.

²Trained- Indicates that the UGDO has success-

fully acquired a new transmitter code.

²Transmit- Indicates that a trained UGDO

transmitter button has been depressed and that the

UGDO is transmitting.

The UGDO cannot be repaired, and is available for

service only as a unit with the EVIC module. This

unit includes the push button switches and the plas-

tic module. If any of these components are faulty or

damaged, the complete EVIC module must be

replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, replace the faulty Transmitter and

EVIC module as a unit. If both the Transmitter and

the EVIC module are inoperative, refer toElec-

tronic Vehicle Information Center Diagnosis

and Testingin this group for further diagnosis. For

complete circuit diagrams, refer toWiring Dia-

grams.

Fig. 5 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC MODULE

3 - ILLUMINATION LAMPS

4 - SCREWS (4)

WJMESSAGE SYSTEMS 8M - 11

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 516 of 2199

²Ten-way power drivers and passenger seats

with Memory- This power seat option is standard

on Overland models and optional on Limited models.

This option includes a six-way adjustable seat cush-

ion track with power seat back recliners and power

lumbar supports. Heated Seats are standard with

this option.

Refer toHeated Seat Systemfor more informa-

tion on the heated seat option. Refer toMemory

Systemin the Memory System section of this group

for more information on the memory system.

The power seat system includes the following com-

ponents:

²Power lumbar adjuster (ten-way power seat

only)

²Power lumbar switch (ten-way power seat only)

²Power seat recliner (ten-way power seat only)

²Power seat switch

²Power seat track.

Refer toPower Seatin Wiring Diagrams for com-

plete circuit diagrams. Following are general descrip-

tions of the major components in the power seat/

memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is standard equip-

ment on the Limited model. The memory system is

able to store and recall the driver side power seat

positions (including the power recliner position), and

both outside power mirror positions for two drivers.

For vehicles with a radio connected to the Program-

mable Communications Interface (PCI) data bus net-

work, the memory system is also able to store and

recall up to twenty - ten AM and ten FM - radio sta-

tion presets for two drivers. The memory system also

will store and recall the last station listened to for

each driver, even if it is not one of the twenty preset

stations.

The memory system will automatically return to

all of these settings when the corresponding num-

bered and color-coded button (Driver 1 - Black, or

Driver 2 - Gray) of the memory switch on the driver

side front door trim panel is depressed, or when the

doors are unlocked using the corresponding num-

bered and color-coded (Driver 1 - Black, or Driver 2 -

Gray) Remote Keyless Entry (RKE) transmitter. A

customer programmable feature of the memory sys-

tem allows the RKE recall of memory features to be

disabled in cases where there are more than two

drivers of the vehicle.

The memory system also has a customer program-

mable easy exit feature that will move the driver

seat rearward 55 millimeters (two inches) or to the

end of its travel, whichever occurs first, when the key

is removed from the ignition switch lock cylinder.A Memory Seat Module (MSM) or Memory Heated

Seat Module (MHSM) are used on this model to con-

trol and integrate the many electronic functions and

features included in the memory system. On vehicles

equipped with the heated seat system option, the

MHSM also controls the functions and features of

that system.

The memory system includes the following compo-

nents:

²Memory seat module (or memory heated seat

module)

²Memory switch

²Position potentiometers on both outside power

mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Radio receiver (if PCI data bus capable).

Certain functions and features of the memory sys-

tem rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRBtscan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²Driver Door Module (DDM)- Refer toDoor

Modulein Electronic Control Modules for more

information.

²Electronic Vehicle Information Center

(EVIC)- Refer toElectronic Vehicle Information

Centerin Overhead Console Systems for more infor-

mation.

²Passenger Door Module (PDM)- Refer to

Door Modulein Electronic Control Modules for

more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Radio Receiver- Refer toRadio Receiverin

Audio Systems for more information.

Refer toHeated Seat Systemfor more informa-

tion on this system. Refer toRemote Keyless Entry

Systemin Power Lock Systems for more information

on the RKE system. Refer toPower Mirrorin

Power Mirror Systems for more information on the

WJPOWER SEAT SYSTEM 8N - 19

POWER SEAT SYSTEM (Continued)

Page 606 of 2199

cluster circuitry that controls the lamp, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). If the instrument cluster turns

on the SKIS indicator lamp after the bulb test, either

solid or flashing, it indicates that a SKIS malfunction

has occurred or that the SKIS is inoperative. For

proper diagnosis of the SKIS, the PCI data bus, or

the message inputs to the instrument cluster that

control the SKIS indicator lamp, a DRBIIItscan tool

and the appropriate diagnostic information are

required.

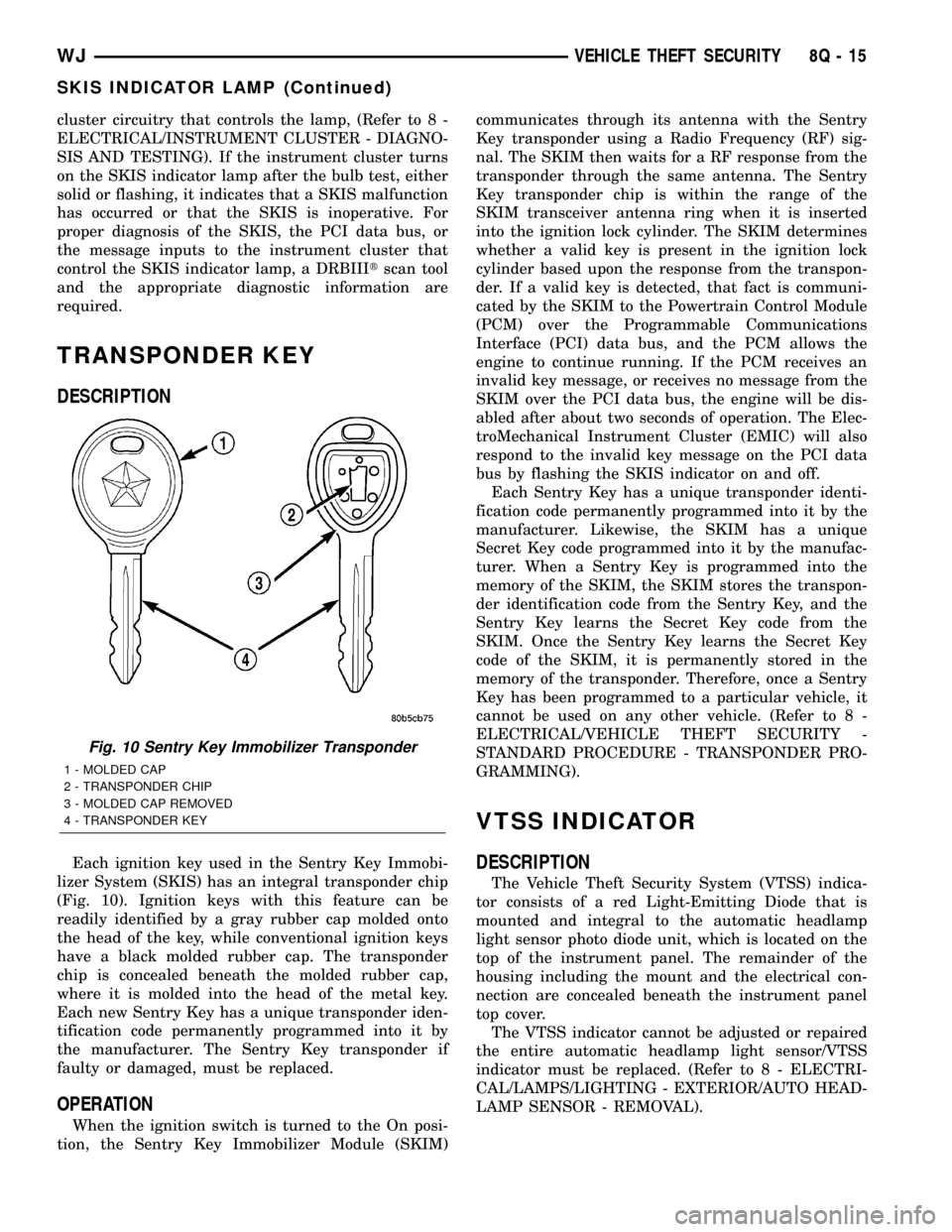

TRANSPONDER KEY

DESCRIPTION

Each ignition key used in the Sentry Key Immobi-

lizer System (SKIS) has an integral transponder chip

(Fig. 10). Ignition keys with this feature can be

readily identified by a gray rubber cap molded onto

the head of the key, while conventional ignition keys

have a black molded rubber cap. The transponder

chip is concealed beneath the molded rubber cap,

where it is molded into the head of the metal key.

Each new Sentry Key has a unique transponder iden-

tification code permanently programmed into it by

the manufacturer. The Sentry Key transponder if

faulty or damaged, must be replaced.

OPERATION

When the ignition switch is turned to the On posi-

tion, the Sentry Key Immobilizer Module (SKIM)communicates through its antenna with the Sentry

Key transponder using a Radio Frequency (RF) sig-

nal. The SKIM then waits for a RF response from the

transponder through the same antenna. The Sentry

Key transponder chip is within the range of the

SKIM transceiver antenna ring when it is inserted

into the ignition lock cylinder. The SKIM determines

whether a valid key is present in the ignition lock

cylinder based upon the response from the transpon-

der. If a valid key is detected, that fact is communi-

cated by the SKIM to the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus, and the PCM allows the

engine to continue running. If the PCM receives an

invalid key message, or receives no message from the

SKIM over the PCI data bus, the engine will be dis-

abled after about two seconds of operation. The Elec-

troMechanical Instrument Cluster (EMIC) will also

respond to the invalid key message on the PCI data

bus by flashing the SKIS indicator on and off.

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

Secret Key code programmed into it by the manufac-

turer. When a Sentry Key is programmed into the

memory of the SKIM, the SKIM stores the transpon-

der identification code from the Sentry Key, and the

Sentry Key learns the Secret Key code from the

SKIM. Once the Sentry Key learns the Secret Key

code of the SKIM, it is permanently stored in the

memory of the transponder. Therefore, once a Sentry

Key has been programmed to a particular vehicle, it

cannot be used on any other vehicle. (Refer to 8 -

ELECTRICAL/VEHICLE THEFT SECURITY -

STANDARD PROCEDURE - TRANSPONDER PRO-

GRAMMING).

VTSS INDICATOR

DESCRIPTION

The Vehicle Theft Security System (VTSS) indica-

tor consists of a red Light-Emitting Diode that is

mounted and integral to the automatic headlamp

light sensor photo diode unit, which is located on the

top of the instrument panel. The remainder of the

housing including the mount and the electrical con-

nection are concealed beneath the instrument panel

top cover.

The VTSS indicator cannot be adjusted or repaired

the entire automatic headlamp light sensor/VTSS

indicator must be replaced. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/AUTO HEAD-

LAMP SENSOR - REMOVAL).

Fig. 10 Sentry Key Immobilizer Transponder

1 - MOLDED CAP

2 - TRANSPONDER CHIP

3 - MOLDED CAP REMOVED

4 - TRANSPONDER KEY

WJVEHICLE THEFT SECURITY 8Q - 15

SKIS INDICATOR LAMP (Continued)

Page 2094 of 2199

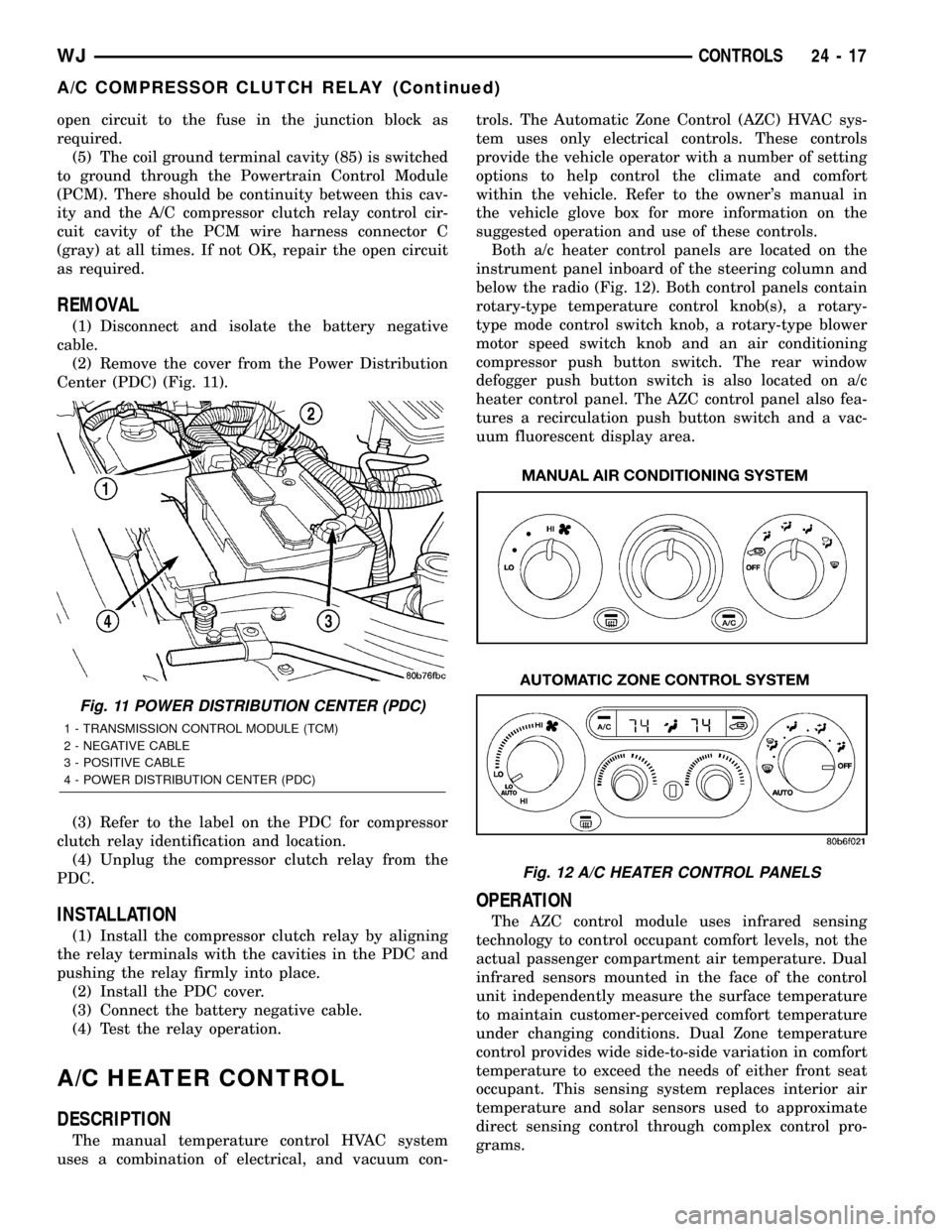

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)