rear wiper JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1 of 2199

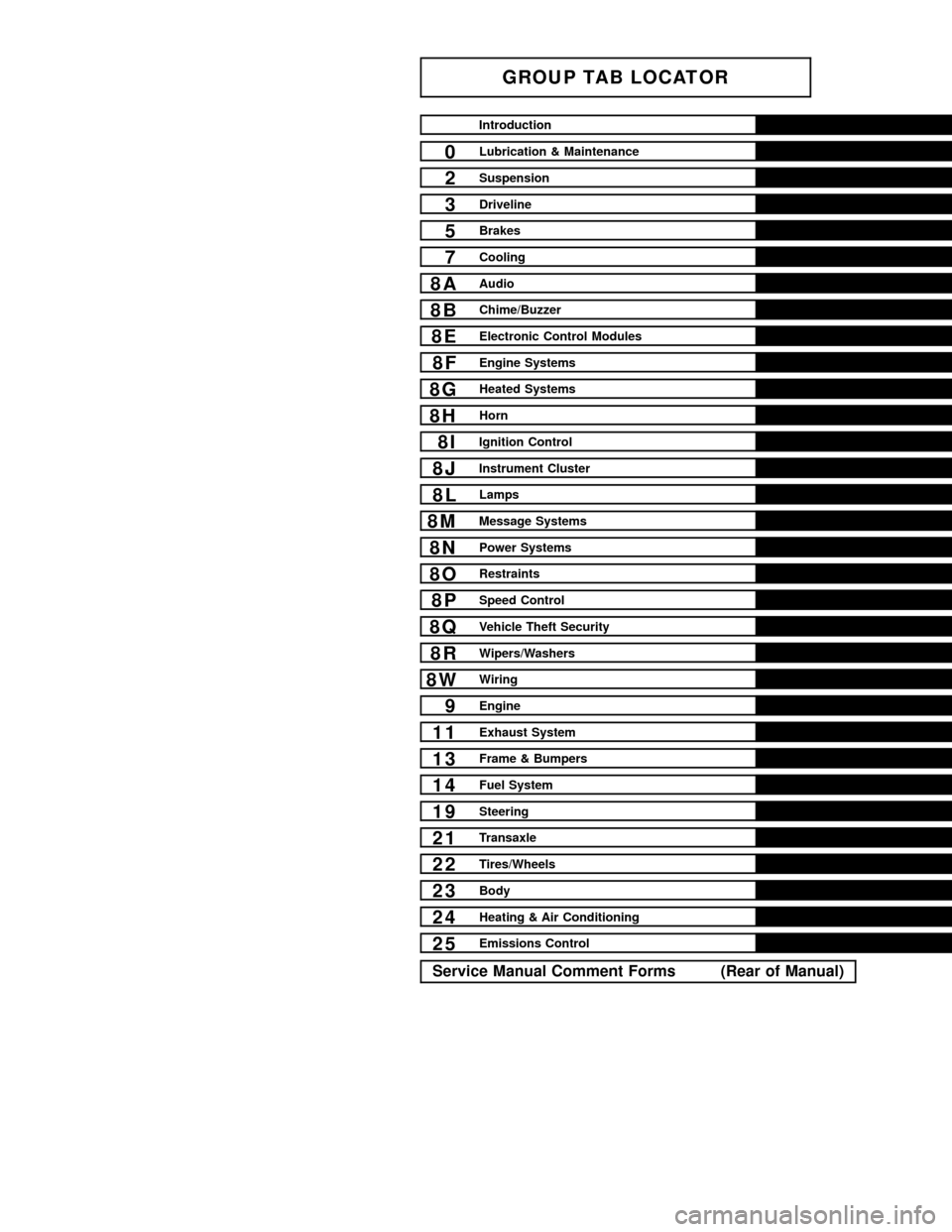

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Service Manual Comment Forms (Rear of Manual)

Page 5 of 2199

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

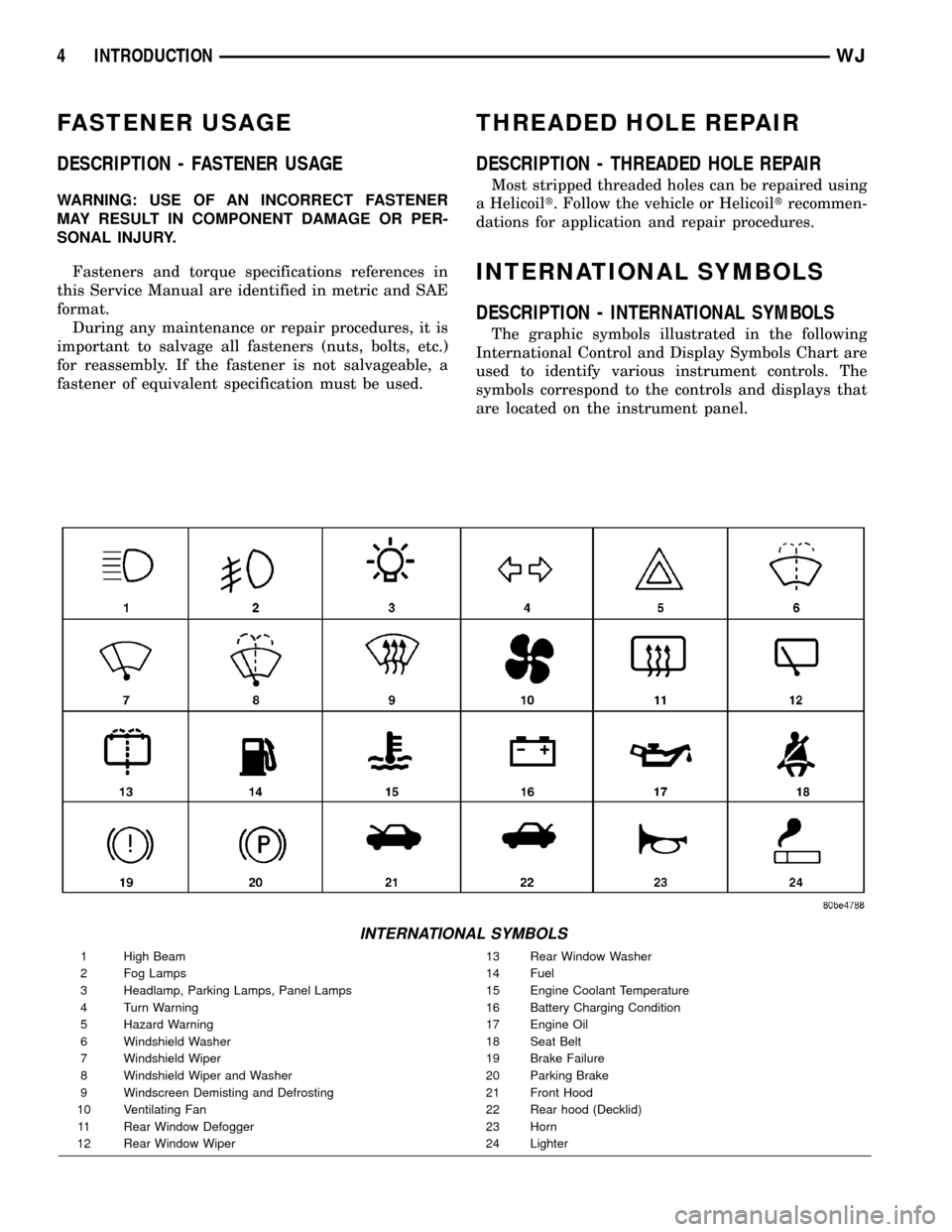

INTERNATIONAL SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONWJ

Page 313 of 2199

BCM programming then performs those tasks and

provides features through both PCI data bus commu-

nication with other electronic modules and hard

wired outputs to a number of relays. These relays

provide the BCM with the ability to control numer-

ous high current accessory systems in the vehicle.

The BCM circuitry operates on battery current

received through fuses in the Junction Block (JB) on a

non-switched fused B(+) circuit, a fused ignition switch

output (start-run) circuit, and a fused ignition switch

output (run-accessory) circuit. This arrangement allows

the BCM to provide some features regardless of the

ignition switch position. The BCM circuitry is grounded

through the chassis beneath the center console.

The BCM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the BCM include the fol-

lowing:

²A/C switch signal

²Ambient temperature sensor signal

²Body control module flash enable

²Coolant level switch sense

²Door ajar switch sense (two circuits - one left

rear, and one right rear)

²Driver seat heater switch mux

²Fog lamp switch sense

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (st-run)

²Ground (five circuits - two Z1, and three Z2)

²Hazard switch sense

²Headlamp switch mux

²High beam switch sense

²Hood ajar switch sense (export)

²Key-in ignition switch sense

²Liftgate ajar switch sense

²Liftgate courtesy disable

²Liftgate flip-up ajar switch sense

²Panel lamps dimmer signal

²Park lamp relay output

²Passenger seat heater switch mux

²PCI bus

²Radio control mux

²Rear window defogger switch sense

²Seat belt switch sense

²Ultralight sensor signal

²Washer fluid switch sense

²Washer pump switch sense

²Windshield wiper switch mux

²Wiper park switch sense

MESSAGING

The BCM uses the following messages received

from other electronic modules over the PCI data bus:

²Accessory Delay Control (DDM/PDM)

²Battery Temperature (PCM)

²Chime Request (EMIC, EVIC, SKIM)

²Cylinder Lock Switch Status (DDM)

²Door Ajar Status/Front Doors (DDM/PDM)

²Door Lock Status (DDM/PDM)

²Engine Model (PCM)

²Engine RPM (PCM)

²Engine Temperature (PCM)

²English/Metric Default (EMIC)

²Fuel Tank Level (PCM)

²Fuel Used/Injector Pulses (PCM)

²Panic Control (PDM)

²Programmable Features Preferences/Audible &

Optical Chirps/Headlamp Delay (EVIC)

²RKE Status (PDM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Switch Status (PCM)

²Ambient Temperature Data (AZC/EVIC/PCM)

²Average/Instantaneous Fuel Economy (EVIC)

²Country Code (EMIC)

²Courtesy Lamp Status (DDM/PDM)

²Distance To Empty (EVIC)

²Elapsed Ignition On Timer (EVIC)

²English/Metric Status (EMIC)

²Front & Rear Door Ajar Status (EVIC)

²Front & Rear Fog Lamp Status (EMIC)

²Heated Seat Switch Status (HSM/MHSM)

²High Beam Status (EMIC)

²Ignition Off Timer (EVIC)

²Ignition Switch Position (DDM/PDM)

²Key-In Ignition Status (DDM/PDM)

²Low Beam Status (EMIC)

²Panel Lamp Status (AZC/EMIC/Radio)

²Rear Window Defogger Relay Status (DDM/

PDM)

²Remote Radio Switch Status (Radio)

²Seatbelt Status (EMIC/MHSM/MSM)

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM) may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. Refer to the appropriate wiring information.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the BCM. In order to

obtain conclusive testing of the BCM, the Program-

mable Communications Interface (PCI) data bus net-

work and all of the electronic modules that provide

8E - 4 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 481 of 2199

wired between a body ground, the Body Control Mod-

ule (BCM) and the rear wiper motor module through

the liftgate and body wire harnesses.

The liftgate flip-up glass ajar switch cannot be

adjusted or repaired and, if faulty or damaged, the

liftgate flip-up glass latch unit must be replaced.

(Refer to 23 - BODY/DECKLID/HATCH/LIFTGATE/

TAILGATE/FLIP-UP GLASS LATCH - REMOVAL)

for the service procedures. For complete circuit dia-

grams, refer to the appropriate wiring information.

DESCRIPTION - LIFTGATE AJAR SWITCH

The two liftgate ajar switches are integral to the

two liftgate latch mechanisms. The two liftgate ajar

switches are actuated by the liftgate latch mecha-

nisms, and are hard wired with each other between a

body ground and the Body Control Module (BCM)

through the liftgate and body wire harnesses.

The liftgate ajar switches cannot be adjusted or

repaired and, if faulty or damaged, the liftgate latch

unit must be replaced. (Refer to 23 - BODY/DECK-

LID/HATCH/LIFTGATE/TAILGATE/LATCH -

REMOVAL) for the service procedures. For complete

circuit diagrams, refer to the appropriate wiring

information.

OPERATION

OPERATION - DOOR AJAR SWITCH

The front door ajar switches close a path to ground

for the DDM or the PDM when a front door is

opened, and opens the ground path when a front door

is closed. The rear door ajar switches close a path to

ground for the BCM when a rear door is opened, and

opens the ground path when a rear door is closed.

The DDM, PDM, or BCM read the switch status then

send the proper switch status messages to other

modules over the Programmable Communications

Interface (PCI) data bus network. The door ajar

switch status message is used by the BCM as an

input for Vehicle Theft Security System (VTSS) oper-

ation.

OPERATION - FLIP UP GLASS AJAR SWITCH

The liftgate flip-up glass ajar switch can close a

path to ground for the BCM and the rear wiper

motor module when the liftgate flip-up glass is

opened, and opens the ground path when the liftgate

flip-up glass is closed. The rear wiper motor module

uses the liftgate flip-up glass ajar switch input to

control the rear wiper operation, and will park the

rear wiper blade if this input indicates that the lift-

gate flip-up glass is ajar. The BCM reads the switch

status then sends the proper switch status message

to other modules over the Programmable Communi-cations Interface (PCI) data bus network. The liftgate

flip-up glass ajar switch status message is used by

the BCM as an input for Vehicle Theft Security Sys-

tem (VTSS) operation.

OPERATION - LIFTGATE AJAR SWITCH

Each of the liftgate ajar switches can close a path

to ground for the BCM when the liftgate is opened,

and opens the ground path when the liftgate is

closed. The BCM reads the switch status then sends

the proper switch status message to other modules

over the Programmable Communications Interface

(PCI) data bus network. The liftgate ajar switch sta-

tus message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation.

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH

The following diagnosis and testing is only

for the chime functions. For interior lamp diag-

nosis, refer to the appropriate wiring informa-

tion.The driver door ajar switch is hard wired to the

Driver Door Module (DDM). The DDM communicates

the switch status to the other modules in the vehicle

on the Programmable Communications Interface

(PCI) data bus network. The following test will diag-

nose a faulty driver door ajar switch and circuits. For

complete circuit diagrams, refer to the appropriate

wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Check that the interior lighting switch on the

control stalk of the left multi-function switch is not

in the dome lamp disable position. Open the driver

side front door and note whether the interior lamps

light. They should light. If OK, refer to Key-In Igni-

tion Switch in the Diagnosis and Testing section of

this group for further diagnosis of the chime warning

system. If not OK, go to Step 2.

(2) Disconnect and isolate the battery negative

cable. Remove the trim panel from the driver front

door and disconnect the 4-way door wire harness con-

nector from the front door latch connector. Check for

continuity between the ground circuit of the 4-way

door wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the ground circuit.

8L - 30 LAMPS/LIGHTING - INTERIORWJ

DOOR AJAR SWITCH (Continued)

Page 608 of 2199

WIPERS/WASHERS

TABLE OF CONTENTS

page page

FRONT WIPERS/WASHERS.................. 1REAR WIPERS/WASHERS.................. 33

FRONT WIPERS/WASHERS

TABLE OF CONTENTS

page page

FRONT WIPERS/WASHERS

DESCRIPTION..........................2

OPERATION............................4

DIAGNOSIS AND TESTING - FRONT WIPER &

WASHER SYSTEM.....................6

CLEANING - FRONT WIPER & WASHER

SYSTEM.............................8

INSPECTION - FRONT WIPER & WASHER

SYSTEM.............................8

FRONT CHECK VALVE

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION.........................10

FRONT WASHER HOSES/TUBES

DESCRIPTION.........................10

OPERATION...........................11

FRONT WASHER NOZZLE

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

FRONT WASHER PUMP/MOTOR

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................13

FRONT WIPER ARM

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................14

FRONT WIPER BLADE

DESCRIPTION.........................14

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

FRONT WIPER MODULE

DESCRIPTION.........................16OPERATION...........................16

REMOVAL.............................17

INSTALLATION.........................17

RAIN SENSOR MODULE

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................19

INSTALLATION.........................19

RIGHT MULTI-FUNCTION SWITCH

DESCRIPTION.........................20

OPERATION...........................21

DIAGNOSIS AND TESTING - RIGHT MULTI-

FUNCTION SWITCH...................22

REMOVAL.............................24

INSTALLATION.........................24

WASHER FLUID LEVEL SWITCH

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................26

INSTALLATION.........................26

WASHER RESERVOIR

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................28

WIPER HIGH/LOW RELAY

DESCRIPTION.........................29

OPERATION...........................29

DIAGNOSIS AND TESTING - WIPER HIGH/

LOW RELAY.........................30

REMOVAL.............................30

INSTALLATION.........................30

WIPER ON/OFF RELAY

DESCRIPTION.........................31

OPERATION...........................31

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY..............................32

REMOVAL.............................32

INSTALLATION.........................32

WJWIPERS/WASHERS 8R - 1

Page 610 of 2199

²Front Check Valve- The front washer system

check valve is integral to the wye fitting located in

the washer plumbing between the cowl plenum

washer hose and the front washer nozzles, and is

concealed beneath the cowl plenum cover/grille panel

at the base of the windshield.

²Front Washer Nozzle- Two fluidic front

washer nozzles are secured with integral snap fea-

tures to dedicated openings in the cowl plenum cover/

grille panel located near the base of the windshield.

²Front Washer Plumbing- The plumbing for

the front washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the left side of the engine compartment from the

washer reservoir, and through the dash panel into

the cowl plenum to the front washer nozzle fittings

beneath the cowl plenum cover/grille panel.

²Front Washer Pump/Motor- The front washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, behind

the inner fender liner ahead of the left front wheel.

The front washer pump is located ahead of and below

the rear washer pump.

²Front Wiper Arm- The two front wiper arms

are secured with nuts to the threaded studs on the

ends of the two wiper pivot shafts, which extend

through the cowl plenum cover/grille panel located

near the base of the windshield.

²Front Wiper Blade- The two front wiper

blades are secured to the two front wiper arms with

an integral latch, and are parked on the glass near

the bottom of the windshield when the front wiper

system is not in operation.

²Front Wiper Module- The front wiper pivot

shafts are the only visible components of the front

wiper module. The remainder of the module is con-

cealed within the cowl plenum beneath the cowl ple-

num cover/grille panel. The front wiper module

includes the module bracket, four rubber-isolated

wiper module mounts, the front wiper motor, the

wiper motor crank arm, the two wiper drive links,

and the two front wiper pivots.

²Rain Sensor Module- Models equipped with

the optional automatic wiper feature have a Rain

Sensor Module (RSM) located behind a trim cover on

a bracket bonded to the inside surface of the wind-

shield glass, just above the inside rear view mirror

mounting button.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column, just below the

steering wheel. Only the control stalk for the right

multi-function switch is visible, while the remainder

of the switch is concealed beneath the steering col-

umn shrouds. The right multi-function switch con-tains all of the switches and control circuitry for both

the front and rear wiper and washer systems.

²Washer Fluid Level Switch- The washer fluid

level switch is located in a dedicated hole near the

center of the forward surface of the washer reservoir,

behind the left front wheel house splash shield.

²Washer Reservoir- The washer reservoir is

concealed between the left inner fender shield and

the left outer fender panel, behind the inner fender

liner and ahead of the left front wheel. The washer

reservoir filler neck is the only visible portion of the

reservoir, and it is accessed from the left front corner

of the engine compartment.

²Wiper High-Low Relay- The wiper high-low

relay is an International Standards Organization

(ISO) micro relay located in the Power Distribution

Center (PDC) in the engine compartment near the

battery.

²Wiper On-Off Relay- The wiper on-off relay is

an International Standards Organization (ISO) micro

relay located in the Power Distribution Center (PDC)

in the engine compartment near the battery.

Hard wired circuitry connects the front wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the front wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATING MODES

The components of the front wiper and washer sys-

tem are designed to work in concert to provide the

following operating modes:

²Automatic Wiper- In models equipped with

the optional automatic wiper feature, the internal

circuitry of both the right (wiper) multi-function

switch, the rain sensor module, and the BCM work

in concert to provide an automatic wiper mode with

five sensitivity selections. The BCM tells the Rain

Sensor Module (RSM) when the automatic wiper

mode is selected and the manually selected sensitiv-

ity level, then the rain sensor module tells the BCM

each time enough water droplets have accumulated

within the wipe pattern on the windshield to require

front wiper operation. The BCM then automatically

WJFRONT WIPERS/WASHERS 8R - 3

FRONT WIPERS/WASHERS (Continued)

Page 619 of 2199

(4) Reinstall the washer hoses for the front washer

nozzle(s) into their routing clips on the underside of

the cowl grille cover.

(5) Position the cowl grille cover onto the cowl ple-

num and cowl top panels through the opening

between the hood and the base of the windshield

(Fig. 4).

(6) Lift the left end of the cowl grille cover off of

the cowl plenum panel far enough to access the front

washer plumbing.

(7) Reconnect the cowl grille cover washer hose to

the engine compartment washer hose at the elbow

connector.

(8) Install the six plastic nuts that secure the cowl

grille cover to the studs on the cowl top panel near

the base of the windshield. These nuts are to be

installed by pushing them onto the studs in the fol-

lowing sequence:

(a) First, install the short nuts to the third stud

from the right, then the second stud from the left.

(b) Next, install the long nuts to the right out-

board stud, then the left outboard stud.

(c) Finally, install the two remaining long nuts

to the third stud from the left, then the second

stud from the right.

(9) Starting at the ends and working toward the

center, push the hood to plenum seal onto the for-

ward flanges of the cowl grille cover and the plenum

panel.

(10) Close and latch the hood.

(11) Reinstall the wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/FRONT WIPERS/

WASHERS/FRONT WIPER ARMS -

INSTALLATION).

(12) Reconnect the battery negative cable.

FRONT WASHER PUMP/

MOTOR

DESCRIPTION

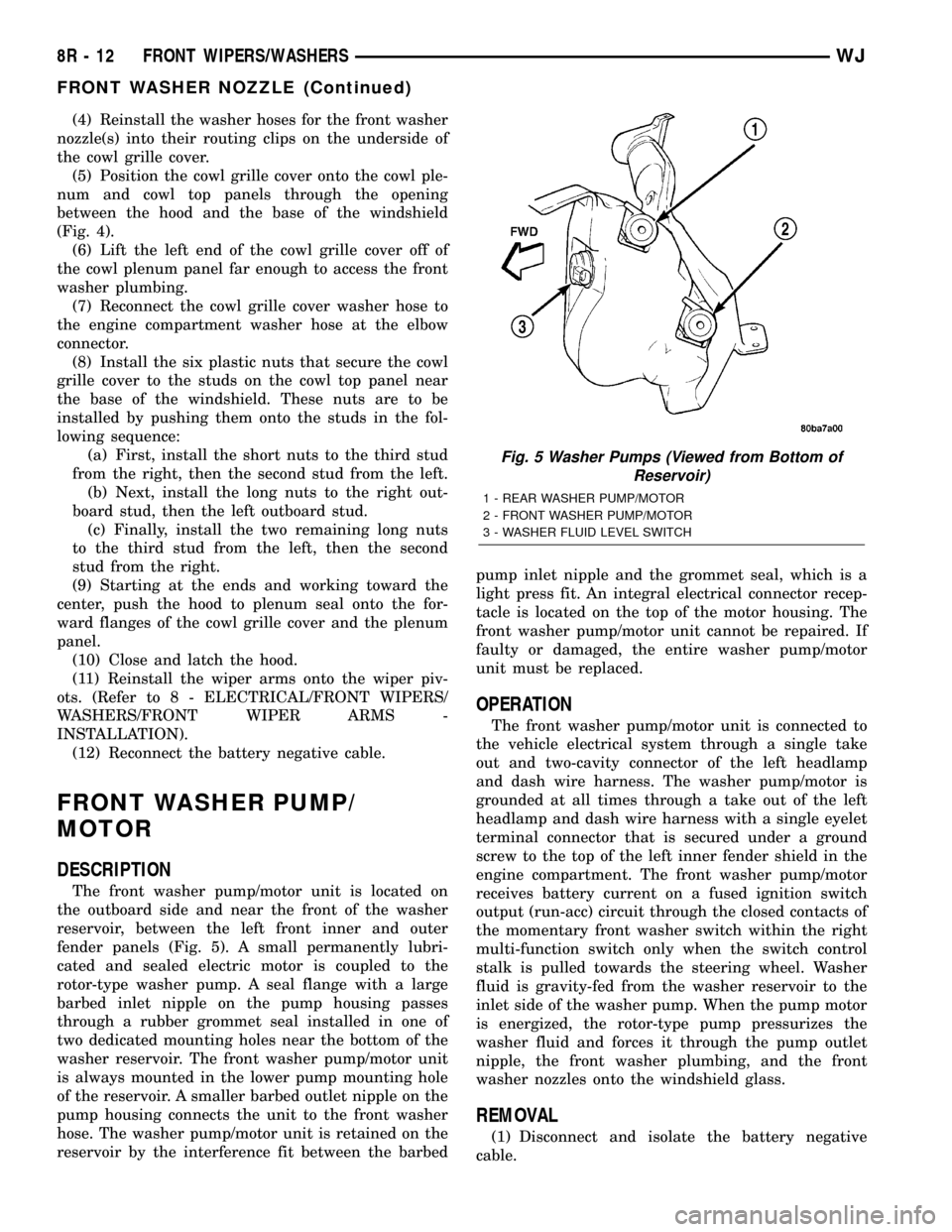

The front washer pump/motor unit is located on

the outboard side and near the front of the washer

reservoir, between the left front inner and outer

fender panels (Fig. 5). A small permanently lubri-

cated and sealed electric motor is coupled to the

rotor-type washer pump. A seal flange with a large

barbed inlet nipple on the pump housing passes

through a rubber grommet seal installed in one of

two dedicated mounting holes near the bottom of the

washer reservoir. The front washer pump/motor unit

is always mounted in the lower pump mounting hole

of the reservoir. A smaller barbed outlet nipple on the

pump housing connects the unit to the front washer

hose. The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbedpump inlet nipple and the grommet seal, which is a

light press fit. An integral electrical connector recep-

tacle is located on the top of the motor housing. The

front washer pump/motor unit cannot be repaired. If

faulty or damaged, the entire washer pump/motor

unit must be replaced.

OPERATION

The front washer pump/motor unit is connected to

the vehicle electrical system through a single take

out and two-cavity connector of the left headlamp

and dash wire harness. The washer pump/motor is

grounded at all times through a take out of the left

headlamp and dash wire harness with a single eyelet

terminal connector that is secured under a ground

screw to the top of the left inner fender shield in the

engine compartment. The front washer pump/motor

receives battery current on a fused ignition switch

output (run-acc) circuit through the closed contacts of

the momentary front washer switch within the right

multi-function switch only when the switch control

stalk is pulled towards the steering wheel. Washer

fluid is gravity-fed from the washer reservoir to the

inlet side of the washer pump. When the pump motor

is energized, the rotor-type pump pressurizes the

washer fluid and forces it through the pump outlet

nipple, the front washer plumbing, and the front

washer nozzles onto the windshield glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 5 Washer Pumps (Viewed from Bottom of

Reservoir)

1 - REAR WASHER PUMP/MOTOR

2 - FRONT WASHER PUMP/MOTOR

3 - WASHER FLUID LEVEL SWITCH

8R - 12 FRONT WIPERS/WASHERSWJ

FRONT WASHER NOZZLE (Continued)

Page 620 of 2199

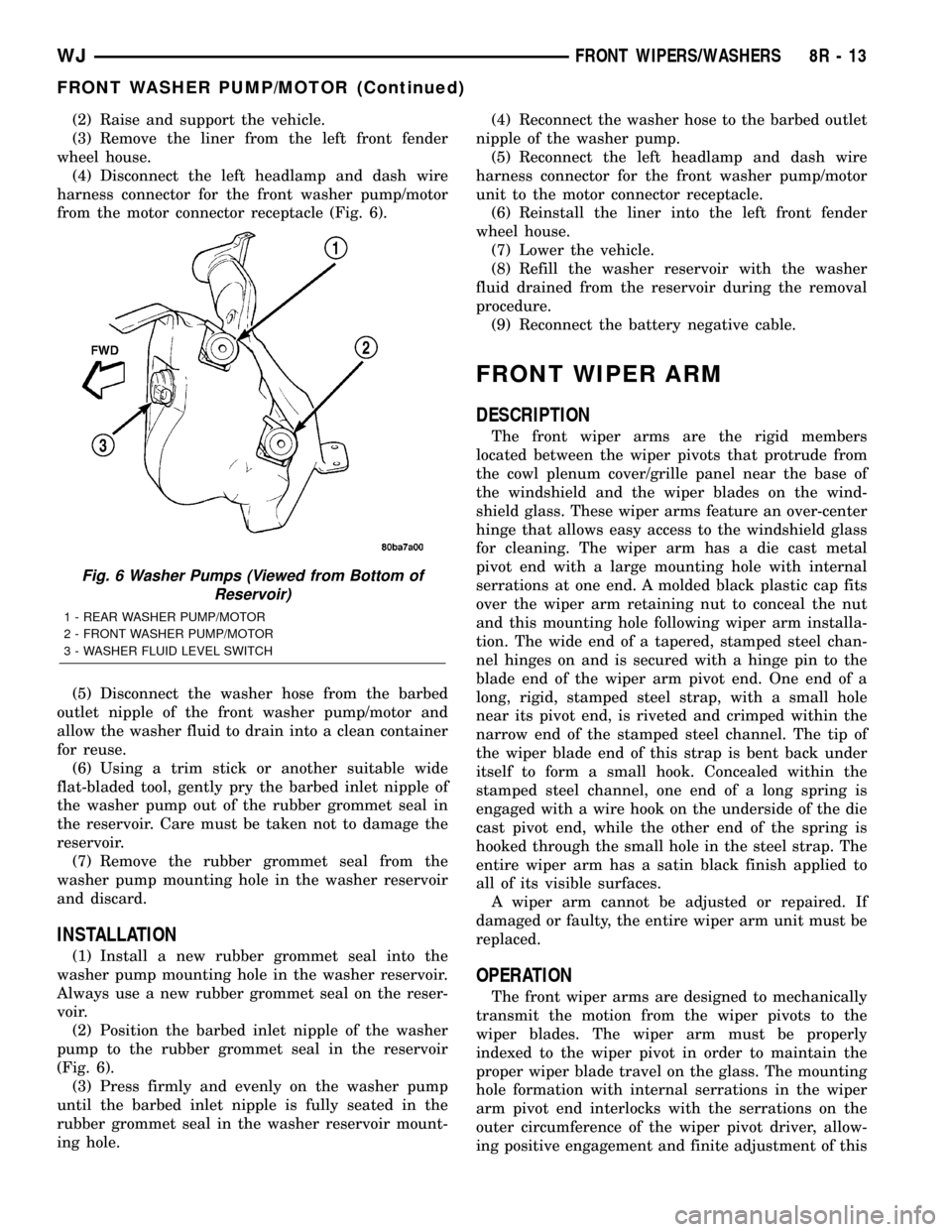

(2) Raise and support the vehicle.

(3) Remove the liner from the left front fender

wheel house.

(4) Disconnect the left headlamp and dash wire

harness connector for the front washer pump/motor

from the motor connector receptacle (Fig. 6).

(5) Disconnect the washer hose from the barbed

outlet nipple of the front washer pump/motor and

allow the washer fluid to drain into a clean container

for reuse.

(6) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed inlet nipple of

the washer pump out of the rubber grommet seal in

the reservoir. Care must be taken not to damage the

reservoir.

(7) Remove the rubber grommet seal from the

washer pump mounting hole in the washer reservoir

and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.

(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the reservoir

(Fig. 6).

(3) Press firmly and evenly on the washer pump

until the barbed inlet nipple is fully seated in the

rubber grommet seal in the washer reservoir mount-

ing hole.(4) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.

(5) Reconnect the left headlamp and dash wire

harness connector for the front washer pump/motor

unit to the motor connector receptacle.

(6) Reinstall the liner into the left front fender

wheel house.

(7) Lower the vehicle.

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

FRONT WIPER ARM

DESCRIPTION

The front wiper arms are the rigid members

located between the wiper pivots that protrude from

the cowl plenum cover/grille panel near the base of

the windshield and the wiper blades on the wind-

shield glass. These wiper arms feature an over-center

hinge that allows easy access to the windshield glass

for cleaning. The wiper arm has a die cast metal

pivot end with a large mounting hole with internal

serrations at one end. A molded black plastic cap fits

over the wiper arm retaining nut to conceal the nut

and this mounting hole following wiper arm installa-

tion. The wide end of a tapered, stamped steel chan-

nel hinges on and is secured with a hinge pin to the

blade end of the wiper arm pivot end. One end of a

long, rigid, stamped steel strap, with a small hole

near its pivot end, is riveted and crimped within the

narrow end of the stamped steel channel. The tip of

the wiper blade end of this strap is bent back under

itself to form a small hook. Concealed within the

stamped steel channel, one end of a long spring is

engaged with a wire hook on the underside of the die

cast pivot end, while the other end of the spring is

hooked through the small hole in the steel strap. The

entire wiper arm has a satin black finish applied to

all of its visible surfaces.

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

OPERATION

The front wiper arms are designed to mechanically

transmit the motion from the wiper pivots to the

wiper blades. The wiper arm must be properly

indexed to the wiper pivot in order to maintain the

proper wiper blade travel on the glass. The mounting

hole formation with internal serrations in the wiper

arm pivot end interlocks with the serrations on the

outer circumference of the wiper pivot driver, allow-

ing positive engagement and finite adjustment of this

Fig. 6 Washer Pumps (Viewed from Bottom of

Reservoir)

1 - REAR WASHER PUMP/MOTOR

2 - FRONT WASHER PUMP/MOTOR

3 - WASHER FLUID LEVEL SWITCH

WJFRONT WIPERS/WASHERS 8R - 13

FRONT WASHER PUMP/MOTOR (Continued)

Page 625 of 2199

(9) Install the six plastic nuts that secure the cowl

grille cover to the studs on the cowl top panel near

the base of the windshield. These nuts are to be

installed by pushing them onto the studs in the fol-

lowing sequence:

(a) First, install the short nuts to the third stud

from the right, then the second stud from the left.

(b) Next, install long nuts to the right outboard

stud, then the left outboard stud.

(c) Finally, install the two remaining long nuts

to the third stud from the left, then the second

stud from the right.

(10) Starting at the ends and working toward the

center, push the hood to plenum seal onto the for-

ward flanges of the cowl grille cover and the plenum

panel.

(11) Close and latch the hood.

(12) Reinstall the wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/FRONT WIPERS/

WASHERS/FRONT WIPER ARMS -

INSTALLATION).

(13) Reconnect the battery negative cable.

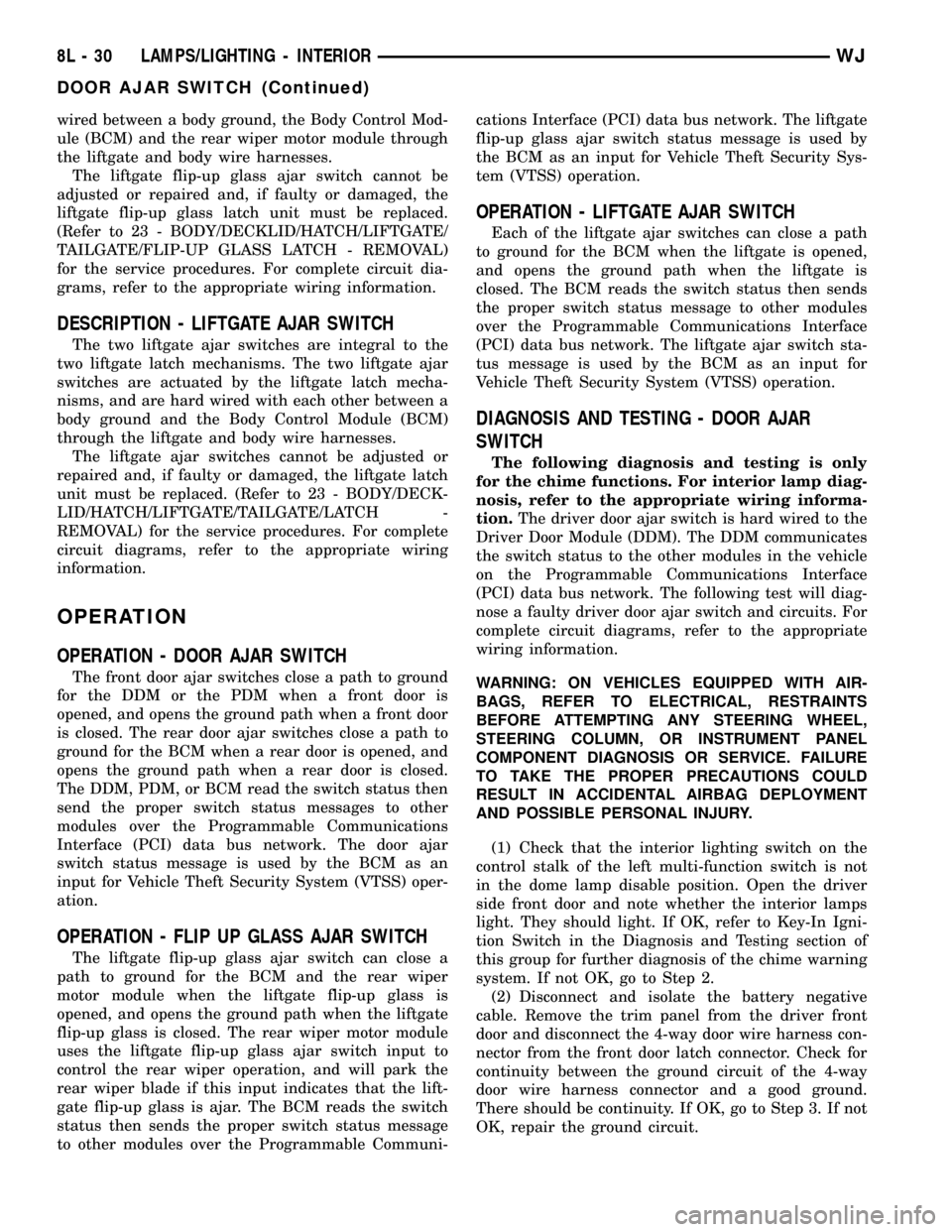

RAIN SENSOR MODULE

DESCRIPTION

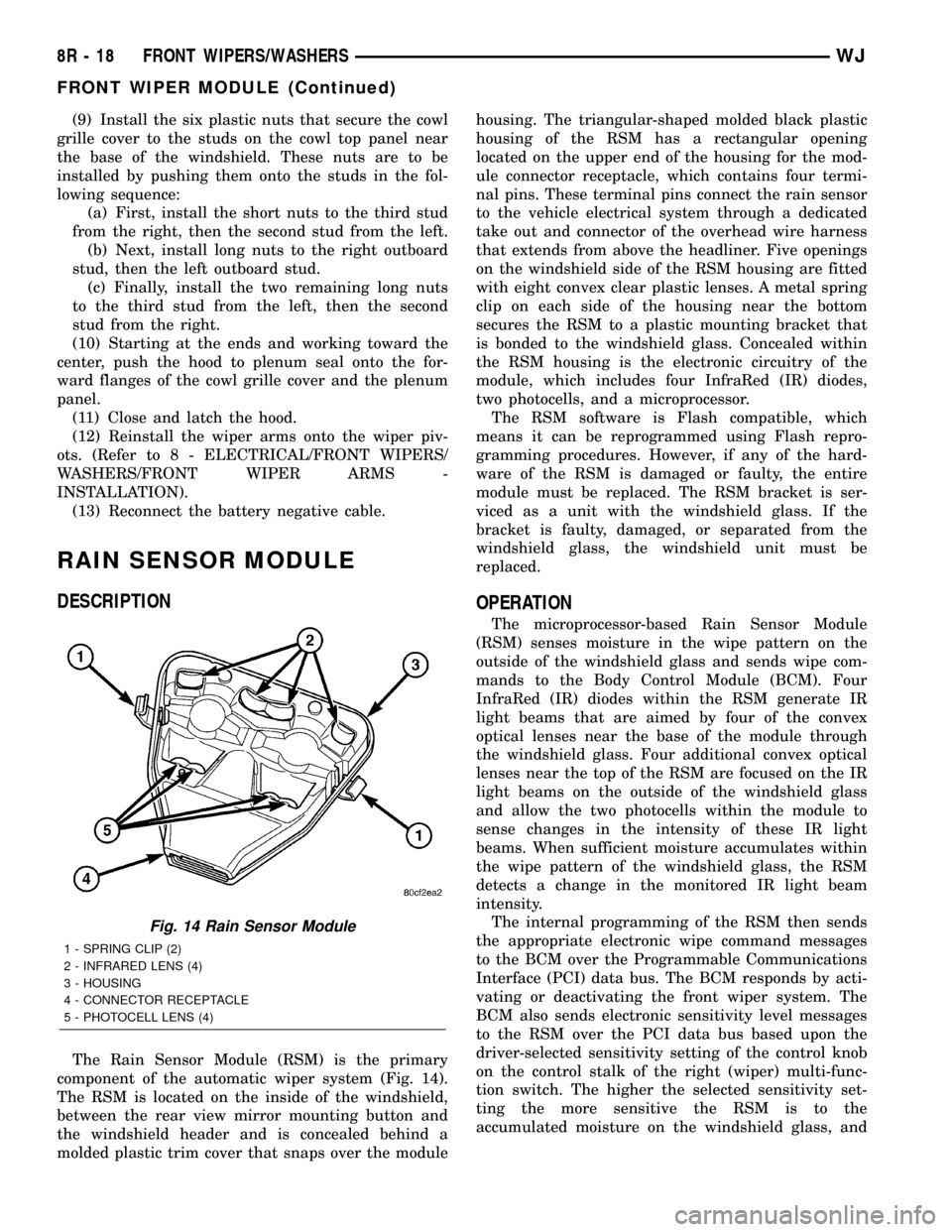

The Rain Sensor Module (RSM) is the primary

component of the automatic wiper system (Fig. 14).

The RSM is located on the inside of the windshield,

between the rear view mirror mounting button and

the windshield header and is concealed behind a

molded plastic trim cover that snaps over the modulehousing. The triangular-shaped molded black plastic

housing of the RSM has a rectangular opening

located on the upper end of the housing for the mod-

ule connector receptacle, which contains four termi-

nal pins. These terminal pins connect the rain sensor

to the vehicle electrical system through a dedicated

take out and connector of the overhead wire harness

that extends from above the headliner. Five openings

on the windshield side of the RSM housing are fitted

with eight convex clear plastic lenses. A metal spring

clip on each side of the housing near the bottom

secures the RSM to a plastic mounting bracket that

is bonded to the windshield glass. Concealed within

the RSM housing is the electronic circuitry of the

module, which includes four InfraRed (IR) diodes,

two photocells, and a microprocessor.

The RSM software is Flash compatible, which

means it can be reprogrammed using Flash repro-

gramming procedures. However, if any of the hard-

ware of the RSM is damaged or faulty, the entire

module must be replaced. The RSM bracket is ser-

viced as a unit with the windshield glass. If the

bracket is faulty, damaged, or separated from the

windshield glass, the windshield unit must be

replaced.

OPERATION

The microprocessor-based Rain Sensor Module

(RSM) senses moisture in the wipe pattern on the

outside of the windshield glass and sends wipe com-

mands to the Body Control Module (BCM). Four

InfraRed (IR) diodes within the RSM generate IR

light beams that are aimed by four of the convex

optical lenses near the base of the module through

the windshield glass. Four additional convex optical

lenses near the top of the RSM are focused on the IR

light beams on the outside of the windshield glass

and allow the two photocells within the module to

sense changes in the intensity of these IR light

beams. When sufficient moisture accumulates within

the wipe pattern of the windshield glass, the RSM

detects a change in the monitored IR light beam

intensity.

The internal programming of the RSM then sends

the appropriate electronic wipe command messages

to the BCM over the Programmable Communications

Interface (PCI) data bus. The BCM responds by acti-

vating or deactivating the front wiper system. The

BCM also sends electronic sensitivity level messages

to the RSM over the PCI data bus based upon the

driver-selected sensitivity setting of the control knob

on the control stalk of the right (wiper) multi-func-

tion switch. The higher the selected sensitivity set-

ting the more sensitive the RSM is to the

accumulated moisture on the windshield glass, and

Fig. 14 Rain Sensor Module

1 - SPRING CLIP (2)

2 - INFRARED LENS (4)

3 - HOUSING

4 - CONNECTOR RECEPTACLE

5 - PHOTOCELL LENS (4)

8R - 18 FRONT WIPERS/WASHERSWJ

FRONT WIPER MODULE (Continued)

Page 626 of 2199

the more frequently the RSM will send wipe com-

mands to the BCM to operate the front wiper system.

The RSM operates on battery current received

through a fuse in the Junction Block (JB) on a fused

B(+) circuit. This circuit is switched by the power

accessory (sunroof) delay relay in the JB so that the

RSM will operate whenever the relay is energized by

the BCM. The RSM receives ground at all times

through a take out of the left body wire harness with

an eyelet terminal that is secured by a ground screw

to the front seat crossmember on the floor panel

under the left front seat. It is important to note that

the default condition for the wiper system is auto-

matic wipers Off; therefore, if no message is received

from the RSM by the BCM for more than about five

seconds, the automatic wipers will be disabled and

the BCM will default the front wiper system opera-

tion to the low speed continuous wipe mode.

The RSM ground and battery current inputs can be

diagnosed using conventional diagnostic tools and

methods. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the RSM

internal circuitry, the BCM, the PCI data bus net-

work, or the electronic messages received and trans-

mitted by the RSM over the PCI data bus. The most

reliable, efficient, and accurate means to diagnose

the RSM requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

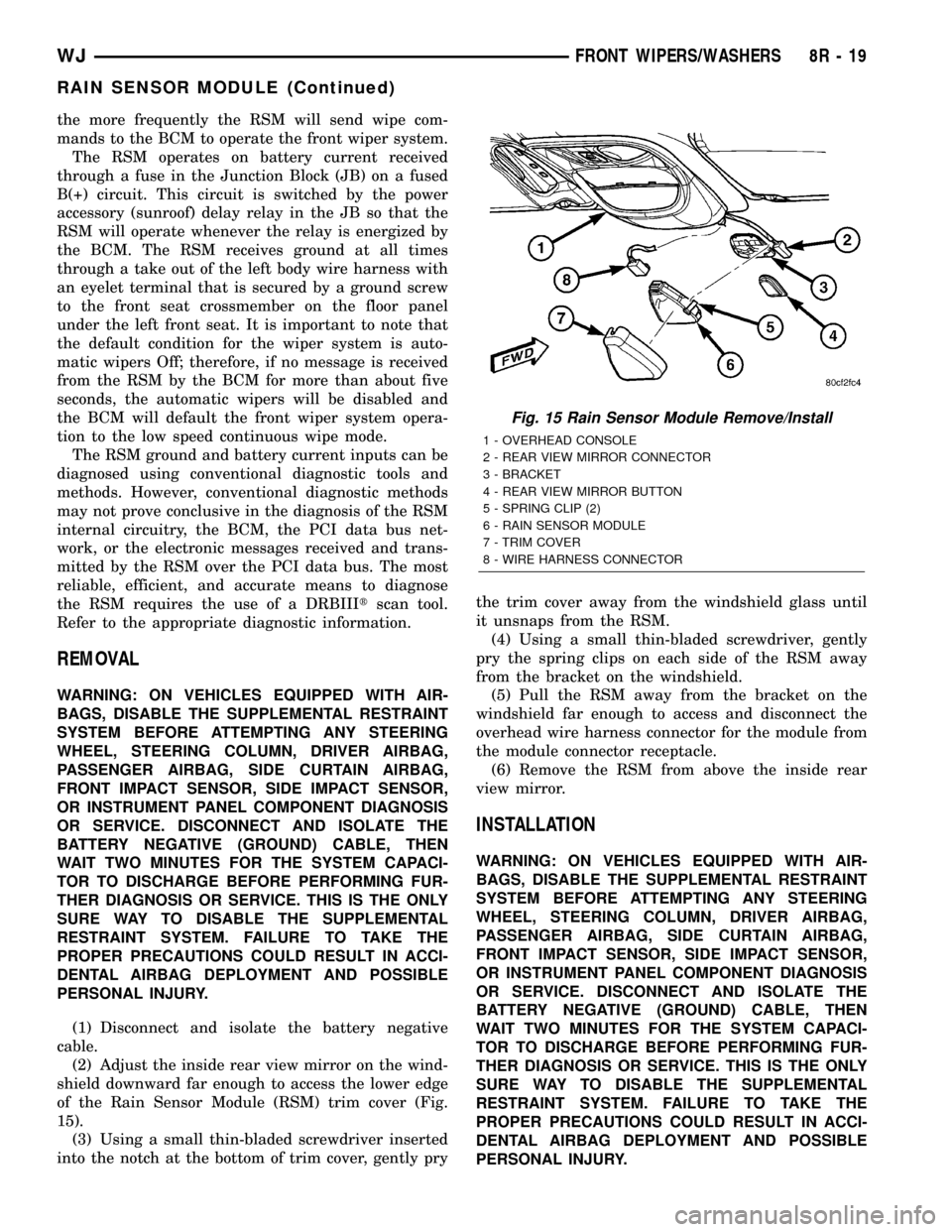

(2) Adjust the inside rear view mirror on the wind-

shield downward far enough to access the lower edge

of the Rain Sensor Module (RSM) trim cover (Fig.

15).

(3) Using a small thin-bladed screwdriver inserted

into the notch at the bottom of trim cover, gently prythe trim cover away from the windshield glass until

it unsnaps from the RSM.

(4) Using a small thin-bladed screwdriver, gently

pry the spring clips on each side of the RSM away

from the bracket on the windshield.

(5) Pull the RSM away from the bracket on the

windshield far enough to access and disconnect the

overhead wire harness connector for the module from

the module connector receptacle.

(6) Remove the RSM from above the inside rear

view mirror.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 15 Rain Sensor Module Remove/Install

1 - OVERHEAD CONSOLE

2 - REAR VIEW MIRROR CONNECTOR

3 - BRACKET

4 - REAR VIEW MIRROR BUTTON

5 - SPRING CLIP (2)

6 - RAIN SENSOR MODULE

7 - TRIM COVER

8 - WIRE HARNESS CONNECTOR

WJFRONT WIPERS/WASHERS 8R - 19

RAIN SENSOR MODULE (Continued)