tires JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1 of 2199

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Service Manual Comment Forms (Rear of Manual)

Page 22 of 2199

SUSPENSION

TABLE OF CONTENTS

page page

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING SYSTEM................1WHEEL ALIGNMENT......................3

FRONT.................................6

REAR.................................17

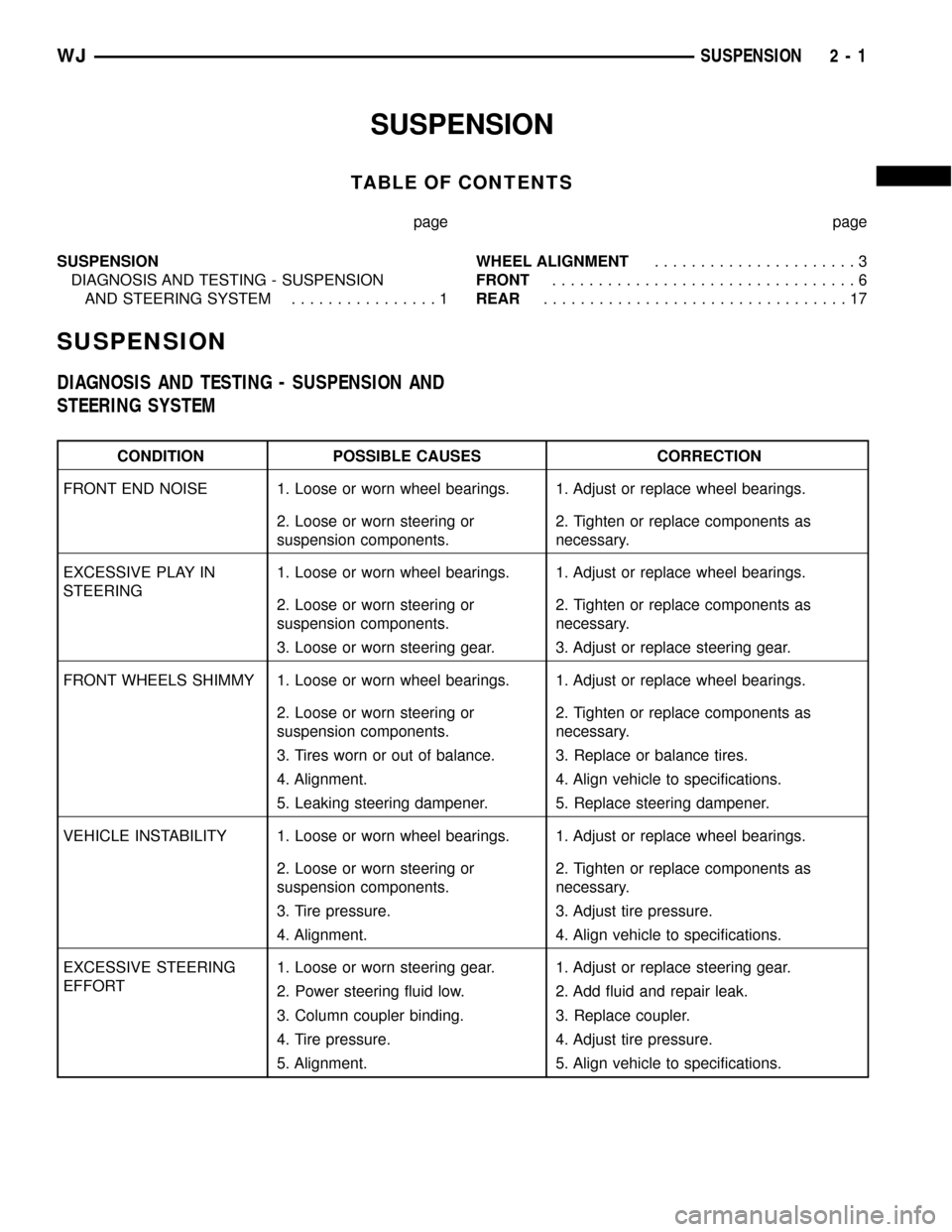

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION AND

STEERING SYSTEM

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Adjust or replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

5. Leaking steering dampener. 5. Replace steering dampener.

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Adjust or replace steering gear.

2. Power steering fluid low. 2. Add fluid and repair leak.

3. Column coupler binding. 3. Replace coupler.

4. Tire pressure. 4. Adjust tire pressure.

5. Alignment. 5. Align vehicle to specifications.

WJSUSPENSION 2 - 1

Page 23 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE PULLS TO ONE

SIDE DURING BRAKING1. Uneven tire pressure. 1. Adjust tire pressure.

2. Worn brake components. 2. Repair brakes as necessary.

3. Air in brake line. 3. Repair as necessary.

VEHICLE LEADS OR

DRIFTS FROM STRAIGHT

AHEAD DIRECTION ON

UNCROWNED ROAD1. Radial tire lead. 1. Cross front tires.

2. Brakes dragging. 2. Repair brake as necessary.

3. Weak or broken spring. 3. Replace spring.

4. Uneven tire pressure. 4. Adjust tire pressure.

5. Wheel Alignment. 5. Align vehicle.

6. Loose or worn steering or

suspension components.6. Repair as necessary.

7. Cross caster out of spec. 7. Align vehicle.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

3. Shock valve. 3. Replace shock.

IMPROPER TRACKING 1. Loose, worn or bent track bar. 1. Inspect, tighten or replace component as

necessary.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

2 - 2 SUSPENSIONWJ

SUSPENSION (Continued)

Page 24 of 2199

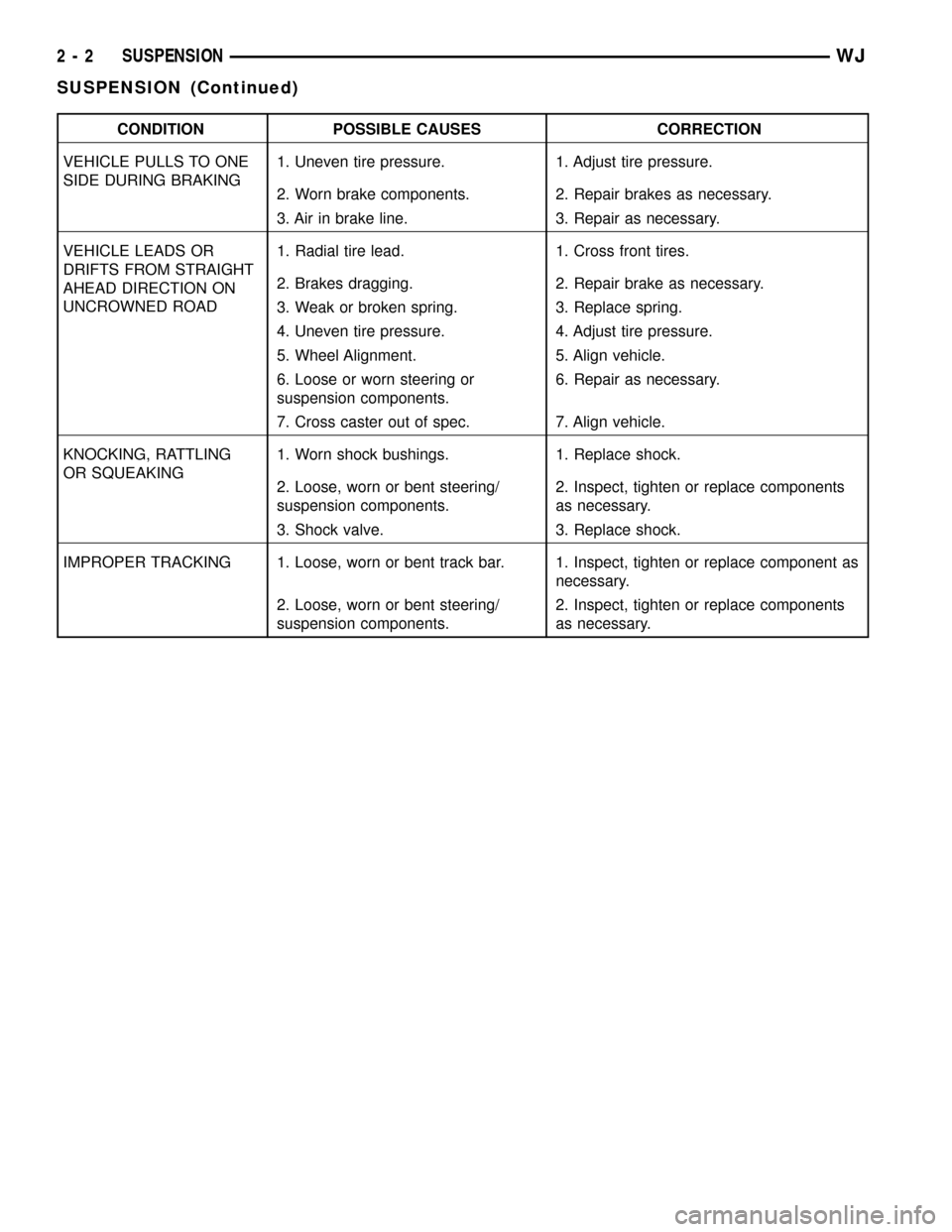

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE

STANDARD PROCEDURE - CAMBER.......3STANDARD PROCEDURE - CASTER.......4

STANDARD PROCEDURE - TOE POSITION . . 4

SPECIFICATIONS

ALIGNMENT..........................5

WHEEL ALIGNMENT

DESCRIPTION

Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stabil-

ity and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe position (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated, Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting the

top of the knuckle forward provides negative caster.

Caster is a directional stability angle. This angle

enables the front wheels to return to a straight

ahead position after turns (Fig. 1).

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on theinside or outside edge of the tire. The angle is not

adjustable, damaged component(s) must be replaced

to correct the camber angle (Fig. 1).

²WHEEL TOE POSITIONis the difference

between the leading inside edges and trailing inside

edges of the front tires. Incorrect wheel toe position

is the most common cause of unstable steering and

uneven tire wear. The wheel toe position is thefinal

front wheel alignment adjustment (Fig. 1).

²STEERING AXIS INCLINATION ANGLEis

measured in degrees and is the angle that the steer-

ing knuckles are tilted. The inclination angle has a

fixed relationship with the camber angle. It will not

change except when a spindle or ball stud is dam-

aged or bent. The angle is not adjustable, damaged

component(s) must be replaced to correct the steering

axis inclination angle.

²THRUST ANGLEis the angle of the rear axle

relative to the centerline of the vehicle. Incorrect

thrust angle can cause off-center steering and exces-

sive tire wear. This angle is not adjustable, damaged

component(s) must be replaced to correct the thrust

angle (Fig. 1).

STANDARD PROCEDURE

STANDARD PROCEDURE - CAMBER

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.

To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

The wheel camber angle is preset. This angle is not

adjustable and cannot be altered.

WJWHEEL ALIGNMENT 2 - 3

Page 31 of 2199

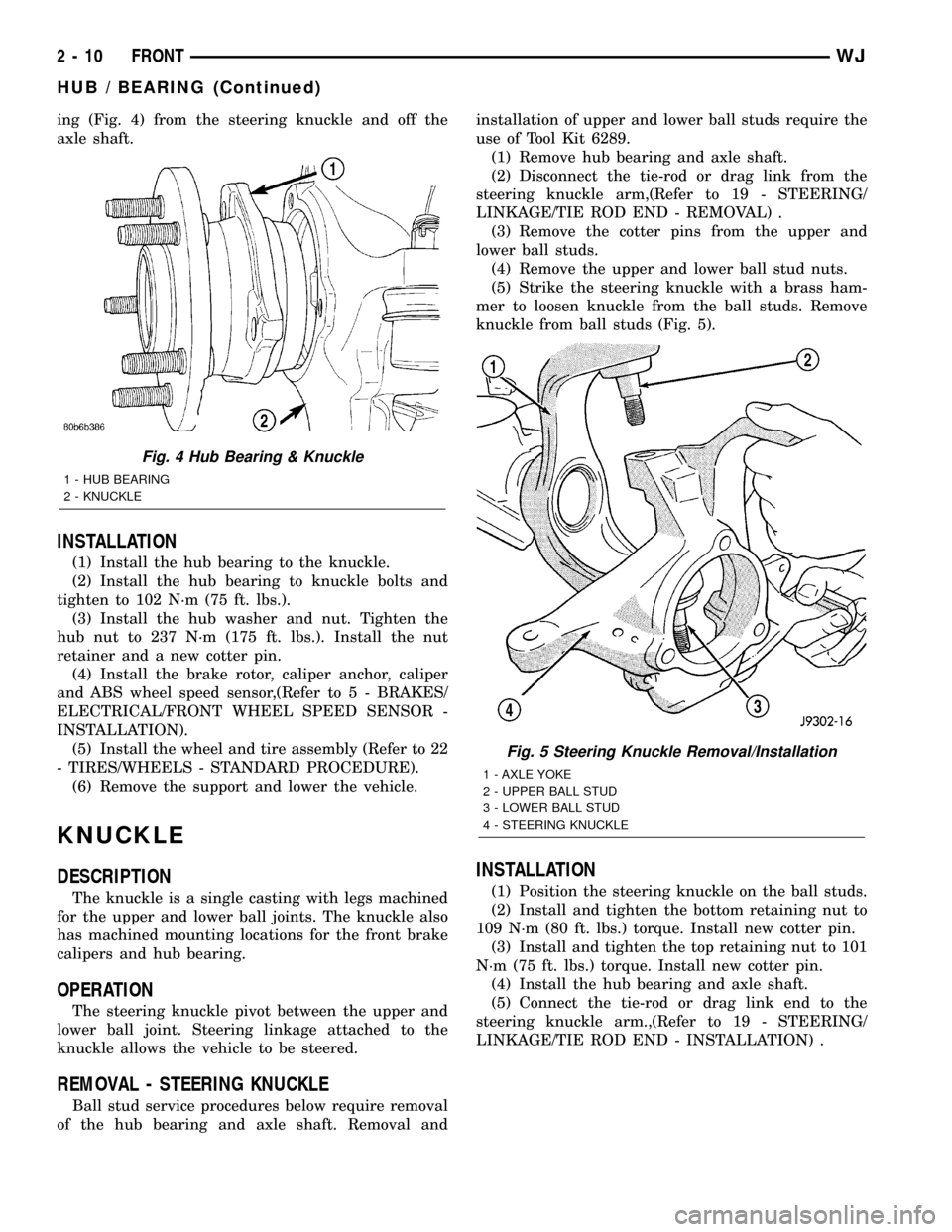

ing (Fig. 4) from the steering knuckle and off the

axle shaft.

INSTALLATION

(1) Install the hub bearing to the knuckle.

(2) Install the hub bearing to knuckle bolts and

tighten to 102 N´m (75 ft. lbs.).

(3) Install the hub washer and nut. Tighten the

hub nut to 237 N´m (175 ft. lbs.). Install the nut

retainer and a new cotter pin.

(4) Install the brake rotor, caliper anchor, caliper

and ABS wheel speed sensor,(Refer to 5 - BRAKES/

ELECTRICAL/FRONT WHEEL SPEED SENSOR -

INSTALLATION).

(5) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS - STANDARD PROCEDURE).

(6) Remove the support and lower the vehicle.

KNUCKLE

DESCRIPTION

The knuckle is a single casting with legs machined

for the upper and lower ball joints. The knuckle also

has machined mounting locations for the front brake

calipers and hub bearing.

OPERATION

The steering knuckle pivot between the upper and

lower ball joint. Steering linkage attached to the

knuckle allows the vehicle to be steered.

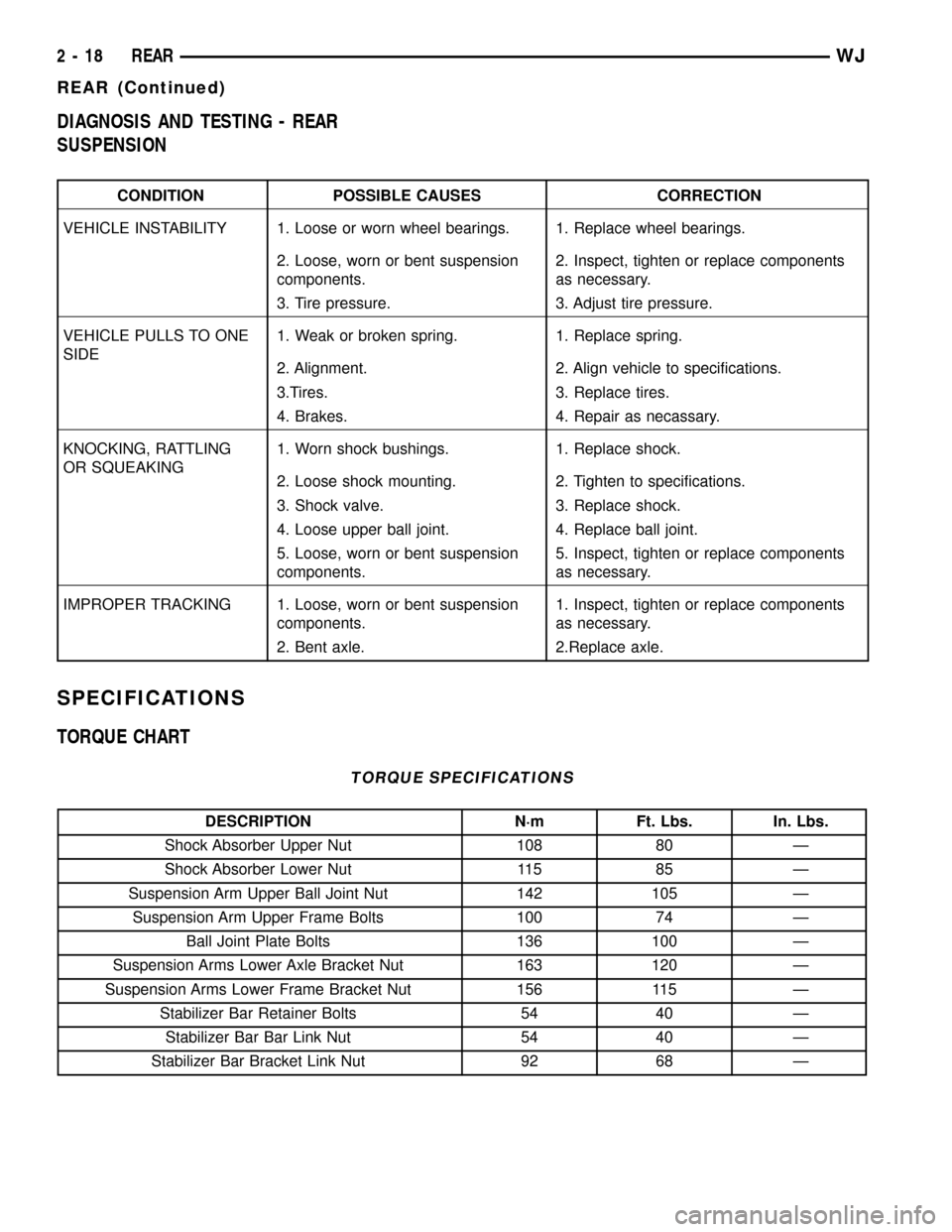

REMOVAL - STEERING KNUCKLE

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal andinstallation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Remove hub bearing and axle shaft.

(2) Disconnect the tie-rod or drag link from the

steering knuckle arm,(Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL) .

(3) Remove the cotter pins from the upper and

lower ball studs.

(4) Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen knuckle from the ball studs. Remove

knuckle from ball studs (Fig. 5).

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten the bottom retaining nut to

109 N´m (80 ft. lbs.) torque. Install new cotter pin.

(3) Install and tighten the top retaining nut to 101

N´m (75 ft. lbs.) torque. Install new cotter pin.

(4) Install the hub bearing and axle shaft.

(5) Connect the tie-rod or drag link end to the

steering knuckle arm.,(Refer to 19 - STEERING/

LINKAGE/TIE ROD END - INSTALLATION) .

Fig. 4 Hub Bearing & Knuckle

1 - HUB BEARING

2 - KNUCKLE

Fig. 5 Steering Knuckle Removal/Installation

1 - AXLE YOKE

2 - UPPER BALL STUD

3 - LOWER BALL STUD

4 - STEERING KNUCKLE

2 - 10 FRONTWJ

HUB / BEARING (Continued)

Page 39 of 2199

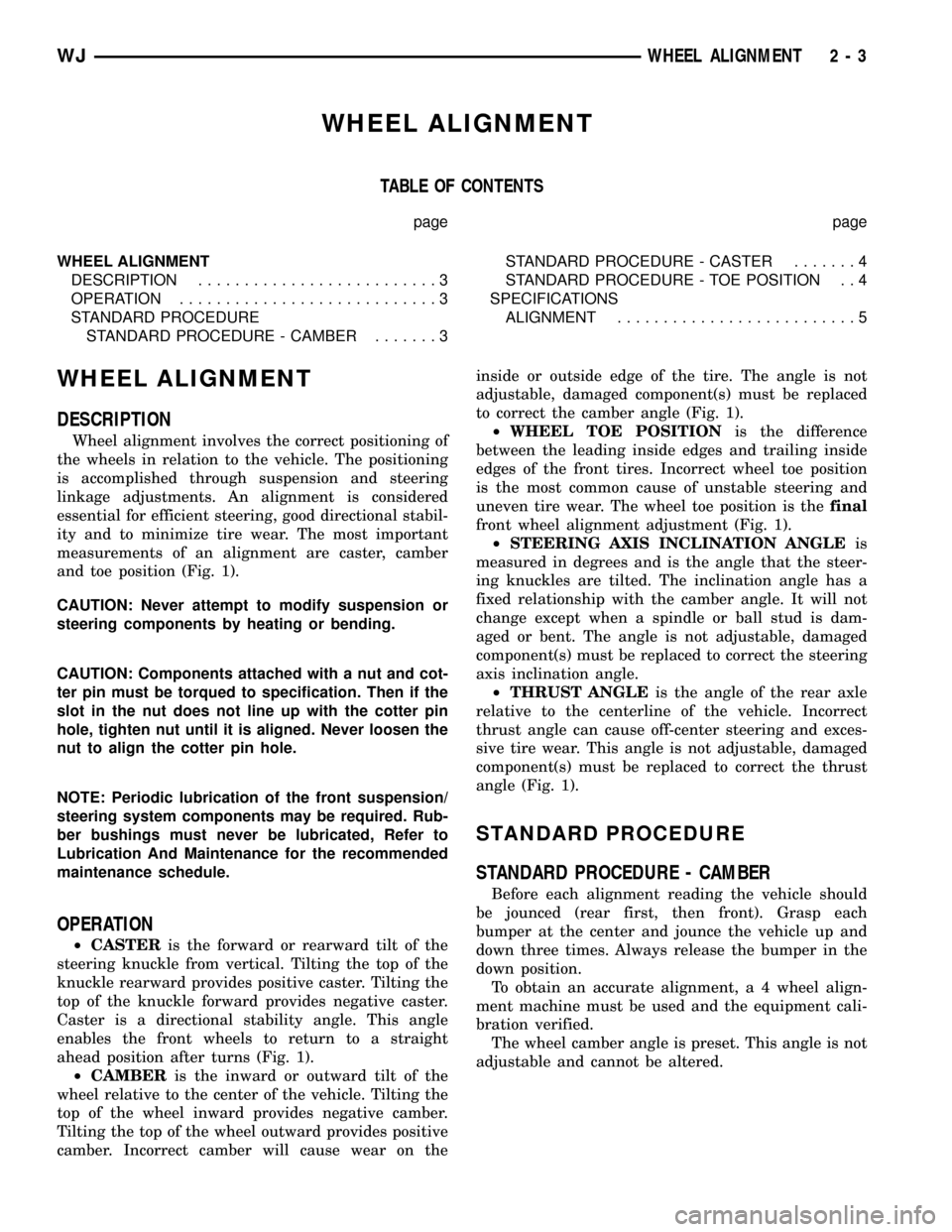

DIAGNOSIS AND TESTING - REAR

SUSPENSION

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose, worn or bent suspension

components.2. Inspect, tighten or replace components

as necessary.

3. Tire pressure. 3. Adjust tire pressure.

VEHICLE PULLS TO ONE

SIDE1. Weak or broken spring. 1. Replace spring.

2. Alignment. 2. Align vehicle to specifications.

3.Tires. 3. Replace tires.

4. Brakes. 4. Repair as necassary.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose shock mounting. 2. Tighten to specifications.

3. Shock valve. 3. Replace shock.

4. Loose upper ball joint. 4. Replace ball joint.

5. Loose, worn or bent suspension

components.5. Inspect, tighten or replace components

as necessary.

IMPROPER TRACKING 1. Loose, worn or bent suspension

components.1. Inspect, tighten or replace components

as necessary.

2. Bent axle. 2.Replace axle.

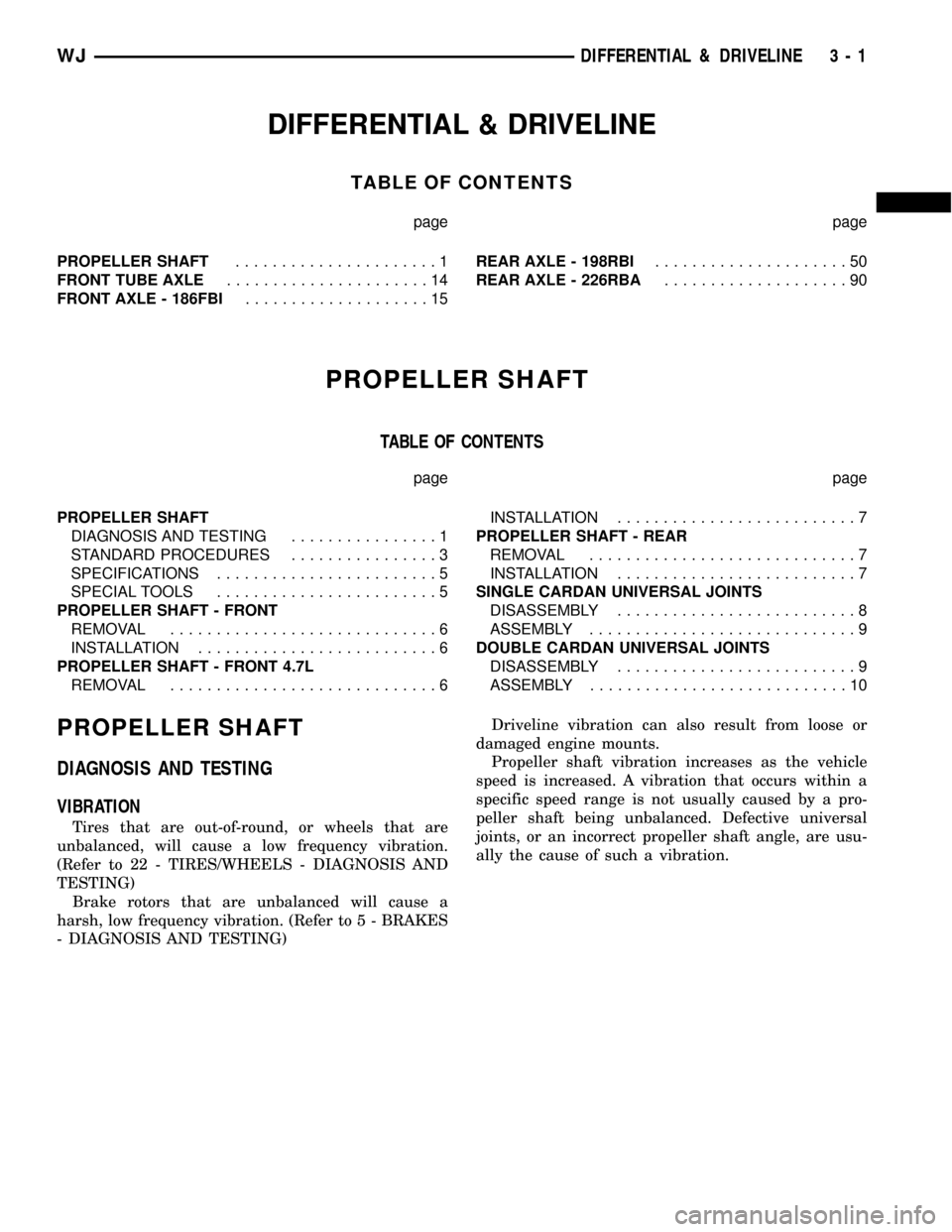

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 108 80 Ð

Shock Absorber Lower Nut 115 85 Ð

Suspension Arm Upper Ball Joint Nut 142 105 Ð

Suspension Arm Upper Frame Bolts 100 74 Ð

Ball Joint Plate Bolts 136 100 Ð

Suspension Arms Lower Axle Bracket Nut 163 120 Ð

Suspension Arms Lower Frame Bracket Nut 156 115 Ð

Stabilizer Bar Retainer Bolts 54 40 Ð

Stabilizer Bar Bar Link Nut 54 40 Ð

Stabilizer Bar Bracket Link Nut 92 68 Ð

2 - 18 REARWJ

REAR (Continued)

Page 46 of 2199

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

PROPELLER SHAFT......................1

FRONT TUBE AXLE......................14

FRONT AXLE - 186FBI....................15REAR AXLE - 198RBI.....................50

REAR AXLE - 226RBA....................90

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DIAGNOSIS AND TESTING................1

STANDARD PROCEDURES................3

SPECIFICATIONS........................5

SPECIAL TOOLS........................5

PROPELLER SHAFT - FRONT

REMOVAL.............................6

INSTALLATION..........................6

PROPELLER SHAFT - FRONT 4.7L

REMOVAL.............................6INSTALLATION..........................7

PROPELLER SHAFT - REAR

REMOVAL.............................7

INSTALLATION..........................7

SINGLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY..........................8

ASSEMBLY.............................9

DOUBLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY..........................9

ASSEMBLY............................10

PROPELLER SHAFT

DIAGNOSIS AND TESTING

VIBRATION

Tires that are out-of-round, or wheels that are

unbalanced, will cause a low frequency vibration.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

Brake rotors that are unbalanced will cause a

harsh, low frequency vibration. (Refer to 5 - BRAKES

- DIAGNOSIS AND TESTING)Driveline vibration can also result from loose or

damaged engine mounts.

Propeller shaft vibration increases as the vehicle

speed is increased. A vibration that occurs within a

specific speed range is not usually caused by a pro-

peller shaft being unbalanced. Defective universal

joints, or an incorrect propeller shaft angle, are usu-

ally the cause of such a vibration.

WJDIFFERENTIAL & DRIVELINE 3 - 1

Page 47 of 2199

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign material

on shaft.1) Clean exterior of shaft and wash with

solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws and

tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline angles.

5) Rear spring center bolt not in seat. 5) Loosen spring u-bolts and seat center

bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out of

balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test, and

evaluate.

10) Excessive drive pinion gear shaft

runout.10) Re-index propeller shaft and evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws and

tighten to proper torque.

2) Lack of lubrication. 2) Replace U-joints as necessary.

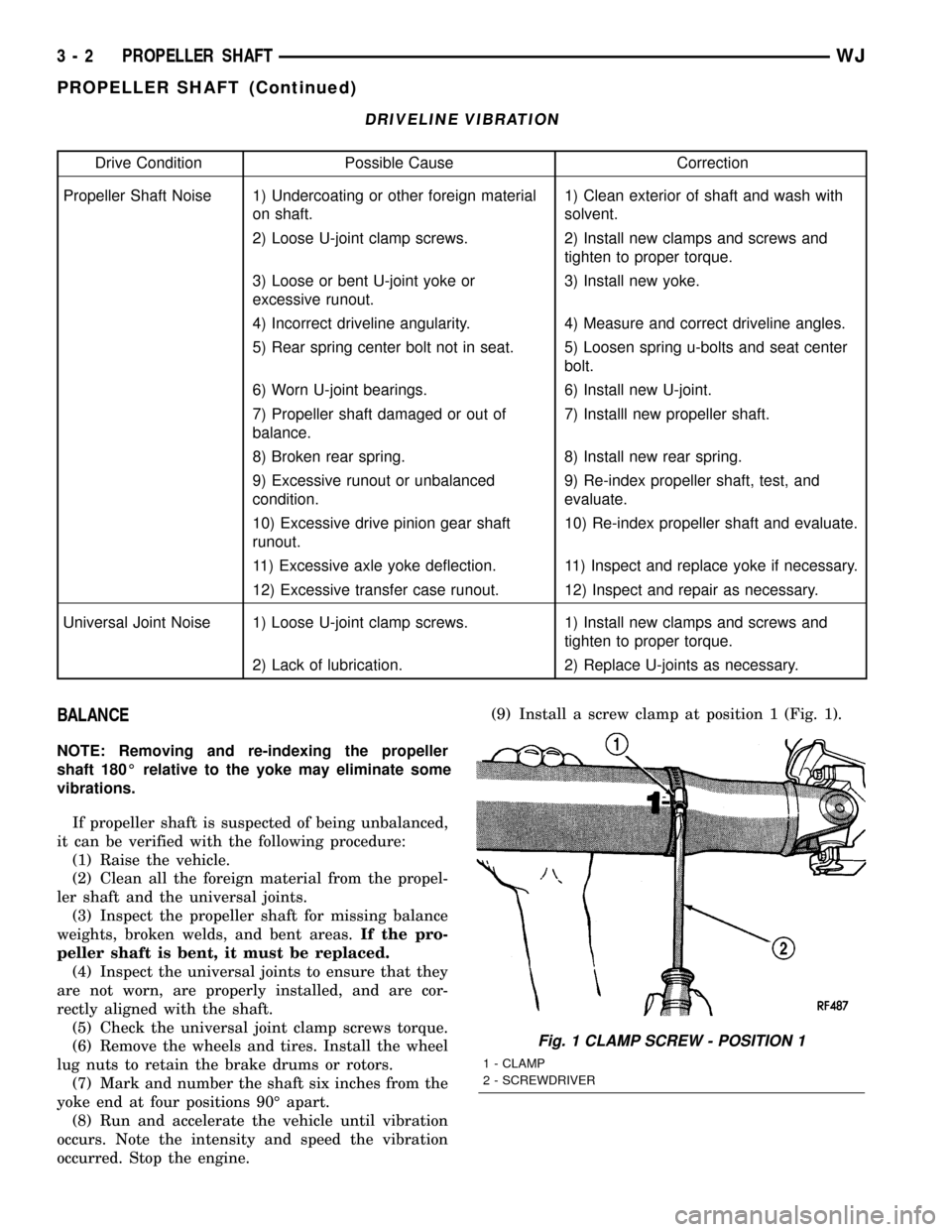

BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180É relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, are properly installed, and are cor-

rectly aligned with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.

(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.(9) Install a screw clamp at position 1 (Fig. 1).

Fig. 1 CLAMP SCREW - POSITION 1

1 - CLAMP

2 - SCREWDRIVER

3 - 2 PROPELLER SHAFTWJ

PROPELLER SHAFT (Continued)

Page 48 of 2199

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

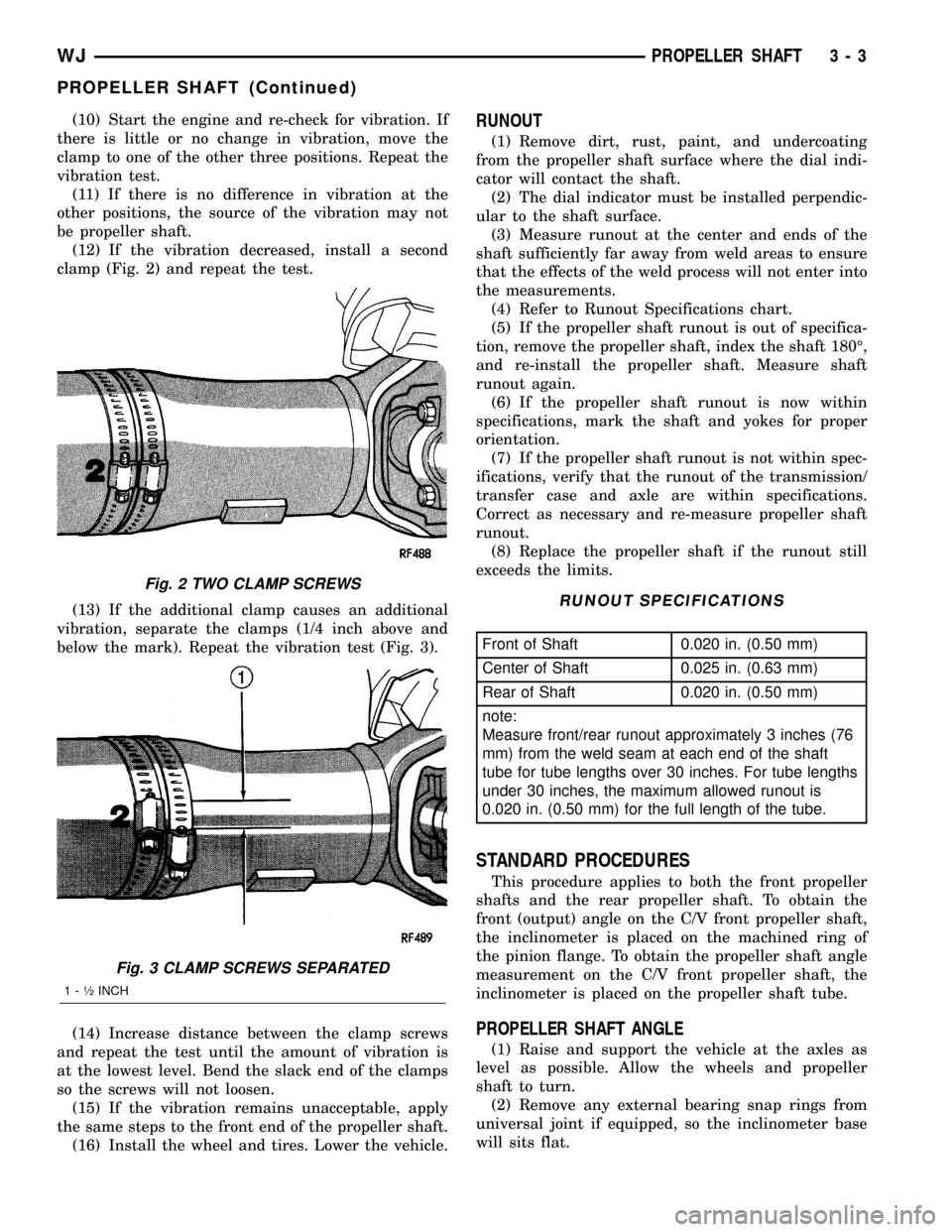

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/4 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

(15) If the vibration remains unacceptable, apply

the same steps to the front end of the propeller shaft.

(16) Install the wheel and tires. Lower the vehicle.RUNOUT

(1) Remove dirt, rust, paint, and undercoating

from the propeller shaft surface where the dial indi-

cator will contact the shaft.

(2) The dial indicator must be installed perpendic-

ular to the shaft surface.

(3) Measure runout at the center and ends of the

shaft sufficiently far away from weld areas to ensure

that the effects of the weld process will not enter into

the measurements.

(4) Refer to Runout Specifications chart.

(5) If the propeller shaft runout is out of specifica-

tion, remove the propeller shaft, index the shaft 180É,

and re-install the propeller shaft. Measure shaft

runout again.

(6) If the propeller shaft runout is now within

specifications, mark the shaft and yokes for proper

orientation.

(7) If the propeller shaft runout is not within spec-

ifications, verify that the runout of the transmission/

transfer case and axle are within specifications.

Correct as necessary and re-measure propeller shaft

runout.

(8) Replace the propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURES

This procedure applies to both the front propeller

shafts and the rear propeller shaft. To obtain the

front (output) angle on the C/V front propeller shaft,

the inclinometer is placed on the machined ring of

the pinion flange. To obtain the propeller shaft angle

measurement on the C/V front propeller shaft, the

inclinometer is placed on the propeller shaft tube.

PROPELLER SHAFT ANGLE

(1) Raise and support the vehicle at the axles as

level as possible. Allow the wheels and propeller

shaft to turn.

(2) Remove any external bearing snap rings from

universal joint if equipped, so the inclinometer base

will sits flat.

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

1 - ó INCH

WJPROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

Page 59 of 2199

FRONT TUBE AXLE

TABLE OF CONTENTS

page page

FRONT TUBE AXLE

REMOVAL.............................14INSTALLATION.........................14

FRONT TUBE AXLE

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle to lift.

(3) Remove the wheels and tires.

(4) Remove the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - REMOVAL)

and calipers.

(5) Disconnect wheel sensor wiring harness from

the vehicle wiring harness.

(6) Remove stabilizer bar links at the axle.

(7) Remove shock absorbers from axle brackets.

(8) Removet track bar.

(9) Remove tie rod and drag link from the steering

knuckle.

(10) Remove steering damper from the axle

bracket.

(11) Remove upper and lower suspension arms

from the axle brackets.

(12) Lower the lift enough to remove the axle. The

coil springs will drop with the axle.

(13) Remove the coil springs from the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If not at their nor-mal ride position, ride height and handling could be

affected.

(1) Install springs and retainer clips and tighten

retainer bolts to 21 N´m (16 ft. lbs.).

(2) Lift and position axle under the vehicle and

align it with the spring pads.

(3) Position upper and lower suspension arms in

the axle brackets and loosely install bolts and nuts.

(4) Install track bar to the axle bracket and loosely

install bolt.

(5) Install shock absorbers and tighten bolts to 23

N´m (17 ft. lbs.).

(6) Install stabilizer bar links to the axle brackets

and tighten nuts to 95 N´m (70 ft. lbs.).

(7) Install drag link and tie rod to the steering

knuckles.

(8) Install steering damper to the axle bracket and

tighten nut to 75 N´m (55 ft. lbs.).

(9) Install the brake rotors and calipers.

(10) Connect wheel speed sensor wiring harness, if

equipped.

(11) Install the wheel and tire assemblies.

(12) Remove lift from the axle and lower the vehi-

cle.

(13) Tighten upper suspension arm nuts to 75 N´m

(55 ft. lbs.). Tighten lower suspension arm nuts to

115 N´m (85 ft. lbs.).

(14) Tighten track bar bolt at the axle bracket to

100 N´m (74 ft. lbs.).

(15) Check the front wheel alignment.

3 - 14 FRONT TUBE AXLEWJ