track bar JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 23 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE PULLS TO ONE

SIDE DURING BRAKING1. Uneven tire pressure. 1. Adjust tire pressure.

2. Worn brake components. 2. Repair brakes as necessary.

3. Air in brake line. 3. Repair as necessary.

VEHICLE LEADS OR

DRIFTS FROM STRAIGHT

AHEAD DIRECTION ON

UNCROWNED ROAD1. Radial tire lead. 1. Cross front tires.

2. Brakes dragging. 2. Repair brake as necessary.

3. Weak or broken spring. 3. Replace spring.

4. Uneven tire pressure. 4. Adjust tire pressure.

5. Wheel Alignment. 5. Align vehicle.

6. Loose or worn steering or

suspension components.6. Repair as necessary.

7. Cross caster out of spec. 7. Align vehicle.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

3. Shock valve. 3. Replace shock.

IMPROPER TRACKING 1. Loose, worn or bent track bar. 1. Inspect, tighten or replace component as

necessary.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

2 - 2 SUSPENSIONWJ

SUSPENSION (Continued)

Page 27 of 2199

FRONT

TABLE OF CONTENTS

page page

FRONT

DESCRIPTION..........................6

STANDARD PROCEDURE - SERVICE

WARNINGS AND CAUTIONS..............6

SPECIFICATIONS

TORQUE CHART......................7

SPECIAL TOOLS

FRONT SUSPENSION...................8

BUSHINGS

REMOVAL.............................9

INSTALLATION..........................9

HUB / BEARING

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION.........................10

KNUCKLE

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL - STEERING KNUCKLE..........10

INSTALLATION.........................10

LOWER BALL JOINT

REMOVAL.............................11

LOWER CONTROL ARM

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11SHOCK

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................12

SPRING

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

STABILIZER BAR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

TRACK BAR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

UPPER BALL JOINT

REMOVAL.............................15

UPPER CONTROL ARM

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

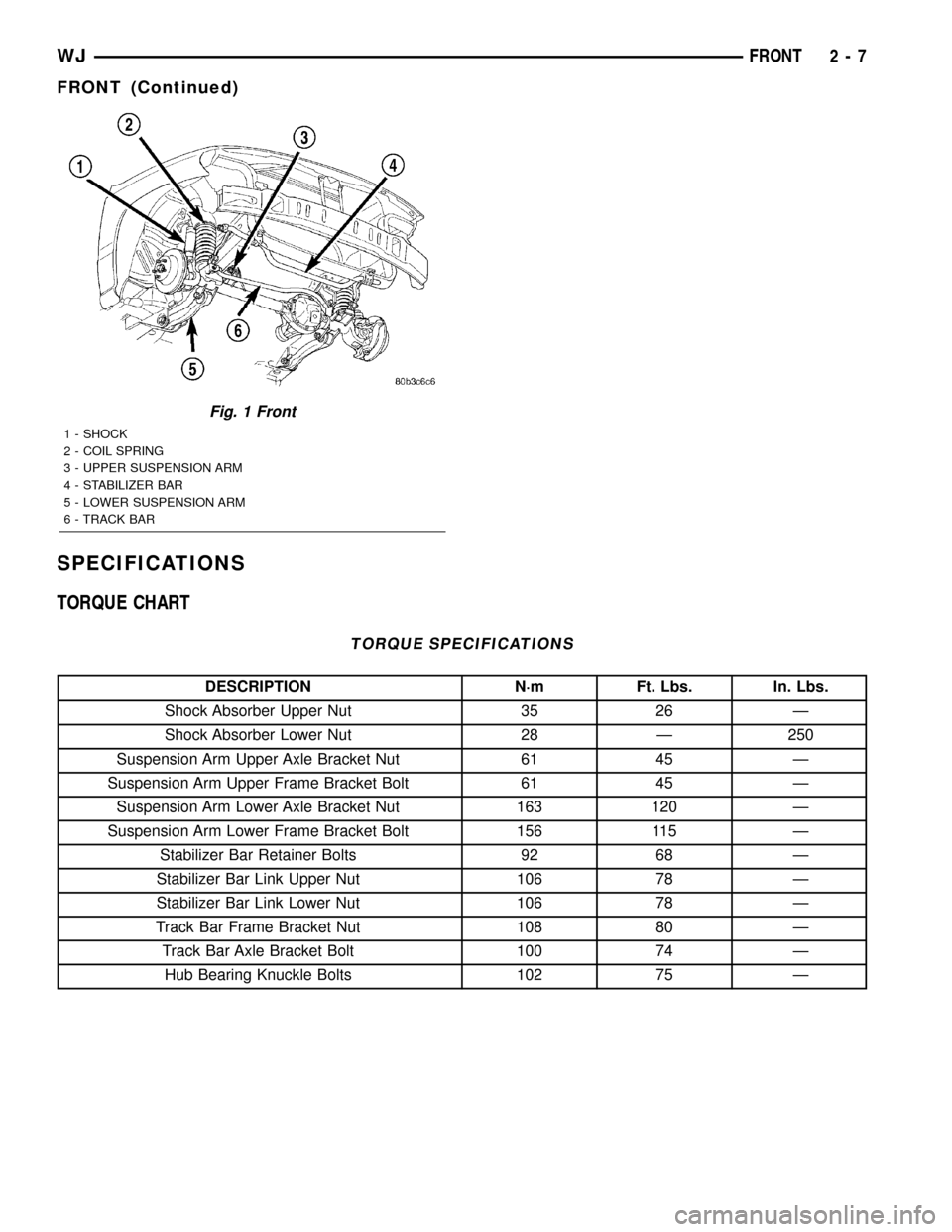

FRONT

DESCRIPTION

The front suspension (Fig. 1) is a link/coil design

comprised of :

²Drive axle

²Shock absorbers

²Coil springs

²Upper and lower suspension arms

²Stabilizer bar

²Track bar

²Jounce bumpers

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.CAUTION: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

STANDARD PROCEDURE - SERVICE

WARNINGS AND CAUTIONS

CAUTION: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

2 - 6 FRONTWJ

Page 28 of 2199

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 35 26 Ð

Shock Absorber Lower Nut 28 Ð 250

Suspension Arm Upper Axle Bracket Nut 61 45 Ð

Suspension Arm Upper Frame Bracket Bolt 61 45 Ð

Suspension Arm Lower Axle Bracket Nut 163 120 Ð

Suspension Arm Lower Frame Bracket Bolt 156 115 Ð

Stabilizer Bar Retainer Bolts 92 68 Ð

Stabilizer Bar Link Upper Nut 106 78 Ð

Stabilizer Bar Link Lower Nut 106 78 Ð

Track Bar Frame Bracket Nut 108 80 Ð

Track Bar Axle Bracket Bolt 100 74 Ð

Hub Bearing Knuckle Bolts 102 75 Ð

Fig. 1 Front

1 - SHOCK

2 - COIL SPRING

3 - UPPER SUSPENSION ARM

4 - STABILIZER BAR

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

WJFRONT 2 - 7

FRONT (Continued)

Page 34 of 2199

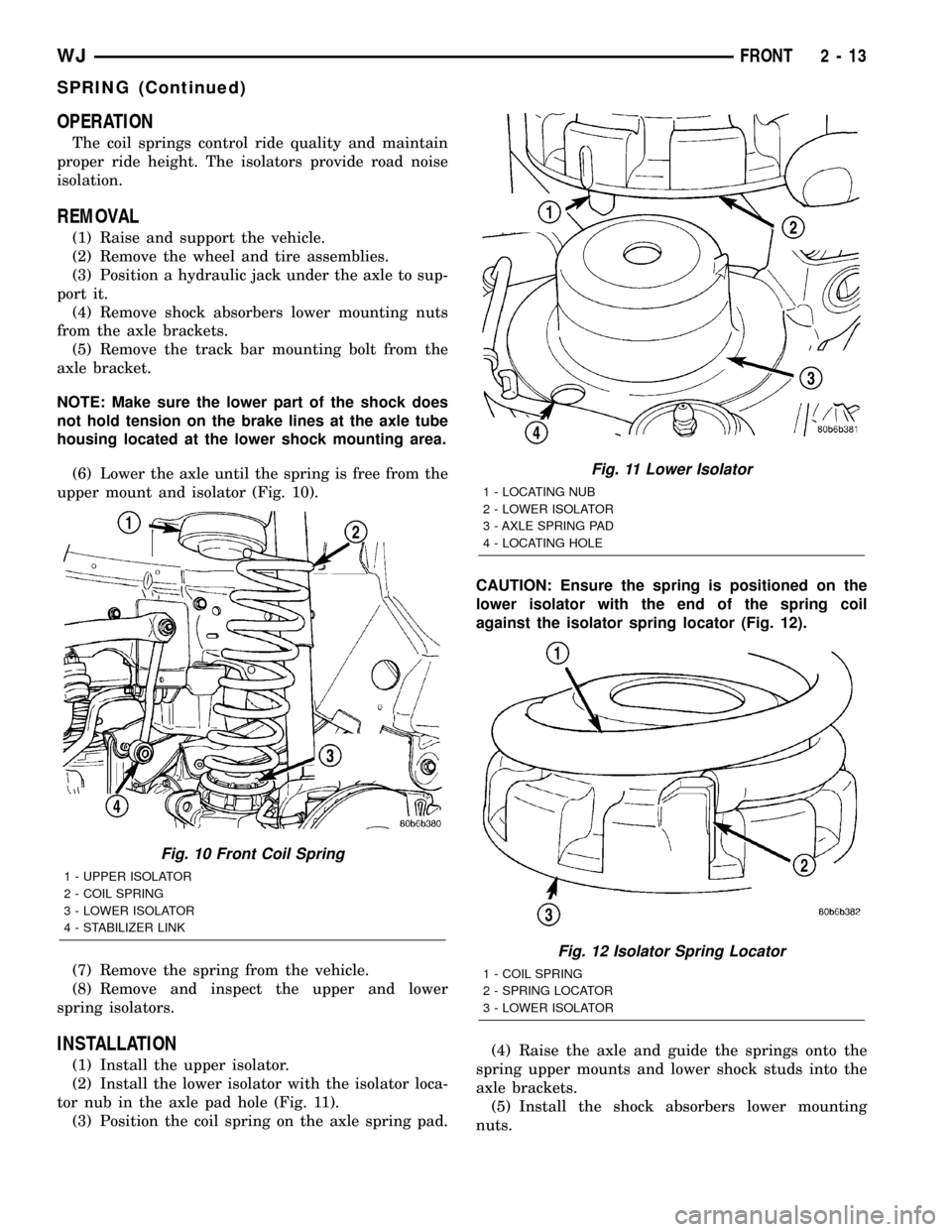

OPERATION

The coil springs control ride quality and maintain

proper ride height. The isolators provide road noise

isolation.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assemblies.

(3) Position a hydraulic jack under the axle to sup-

port it.

(4) Remove shock absorbers lower mounting nuts

from the axle brackets.

(5) Remove the track bar mounting bolt from the

axle bracket.

NOTE: Make sure the lower part of the shock does

not hold tension on the brake lines at the axle tube

housing located at the lower shock mounting area.

(6) Lower the axle until the spring is free from the

upper mount and isolator (Fig. 10).

(7) Remove the spring from the vehicle.

(8) Remove and inspect the upper and lower

spring isolators.

INSTALLATION

(1) Install the upper isolator.

(2) Install the lower isolator with the isolator loca-

tor nub in the axle pad hole (Fig. 11).

(3) Position the coil spring on the axle spring pad.CAUTION: Ensure the spring is positioned on the

lower isolator with the end of the spring coil

against the isolator spring locator (Fig. 12).

(4) Raise the axle and guide the springs onto the

spring upper mounts and lower shock studs into the

axle brackets.

(5) Install the shock absorbers lower mounting

nuts.

Fig. 10 Front Coil Spring

1 - UPPER ISOLATOR

2 - COIL SPRING

3 - LOWER ISOLATOR

4 - STABILIZER LINK

Fig. 11 Lower Isolator

1 - LOCATING NUB

2 - LOWER ISOLATOR

3 - AXLE SPRING PAD

4 - LOCATING HOLE

Fig. 12 Isolator Spring Locator

1 - COIL SPRING

2 - SPRING LOCATOR

3 - LOWER ISOLATOR

WJFRONT 2 - 13

SPRING (Continued)

Page 35 of 2199

(6) Install the track bar to the axle bracket and

install the mounting bolt.

NOTE: It may be necessary to pry the axle assem-

bly over to install the track bar bolt.

(7) Remove the hydraulic jack from under the

vehicle.

(8) Tighten all suspension components to proper

torque.

(9) Install the wheel and tire assemblies.

(10) Remove support and lower vehicle.

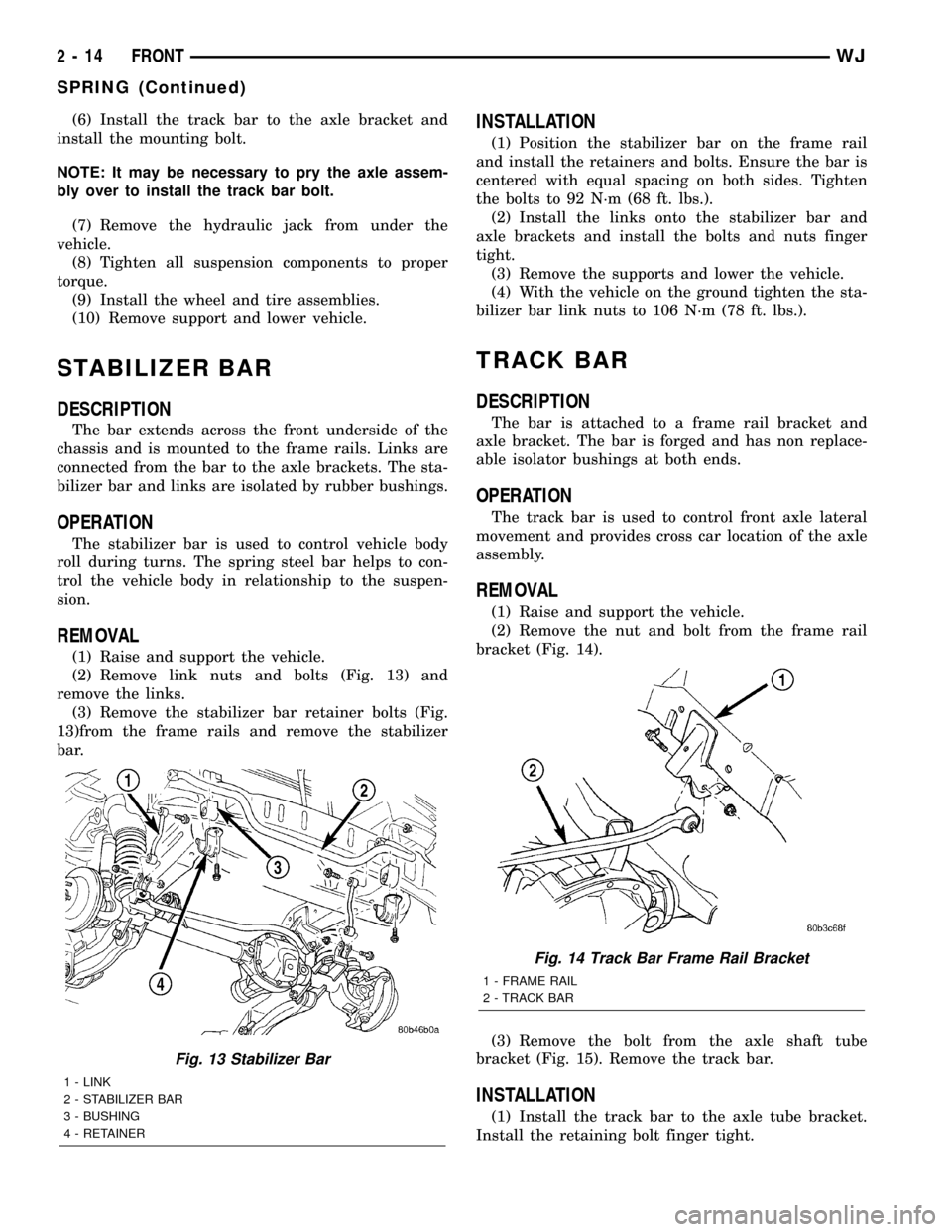

STABILIZER BAR

DESCRIPTION

The bar extends across the front underside of the

chassis and is mounted to the frame rails. Links are

connected from the bar to the axle brackets. The sta-

bilizer bar and links are isolated by rubber bushings.

OPERATION

The stabilizer bar is used to control vehicle body

roll during turns. The spring steel bar helps to con-

trol the vehicle body in relationship to the suspen-

sion.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove link nuts and bolts (Fig. 13) and

remove the links.

(3) Remove the stabilizer bar retainer bolts (Fig.

13)from the frame rails and remove the stabilizer

bar.

INSTALLATION

(1) Position the stabilizer bar on the frame rail

and install the retainers and bolts. Ensure the bar is

centered with equal spacing on both sides. Tighten

the bolts to 92 N´m (68 ft. lbs.).

(2) Install the links onto the stabilizer bar and

axle brackets and install the bolts and nuts finger

tight.

(3) Remove the supports and lower the vehicle.

(4) With the vehicle on the ground tighten the sta-

bilizer bar link nuts to 106 N´m (78 ft. lbs.).

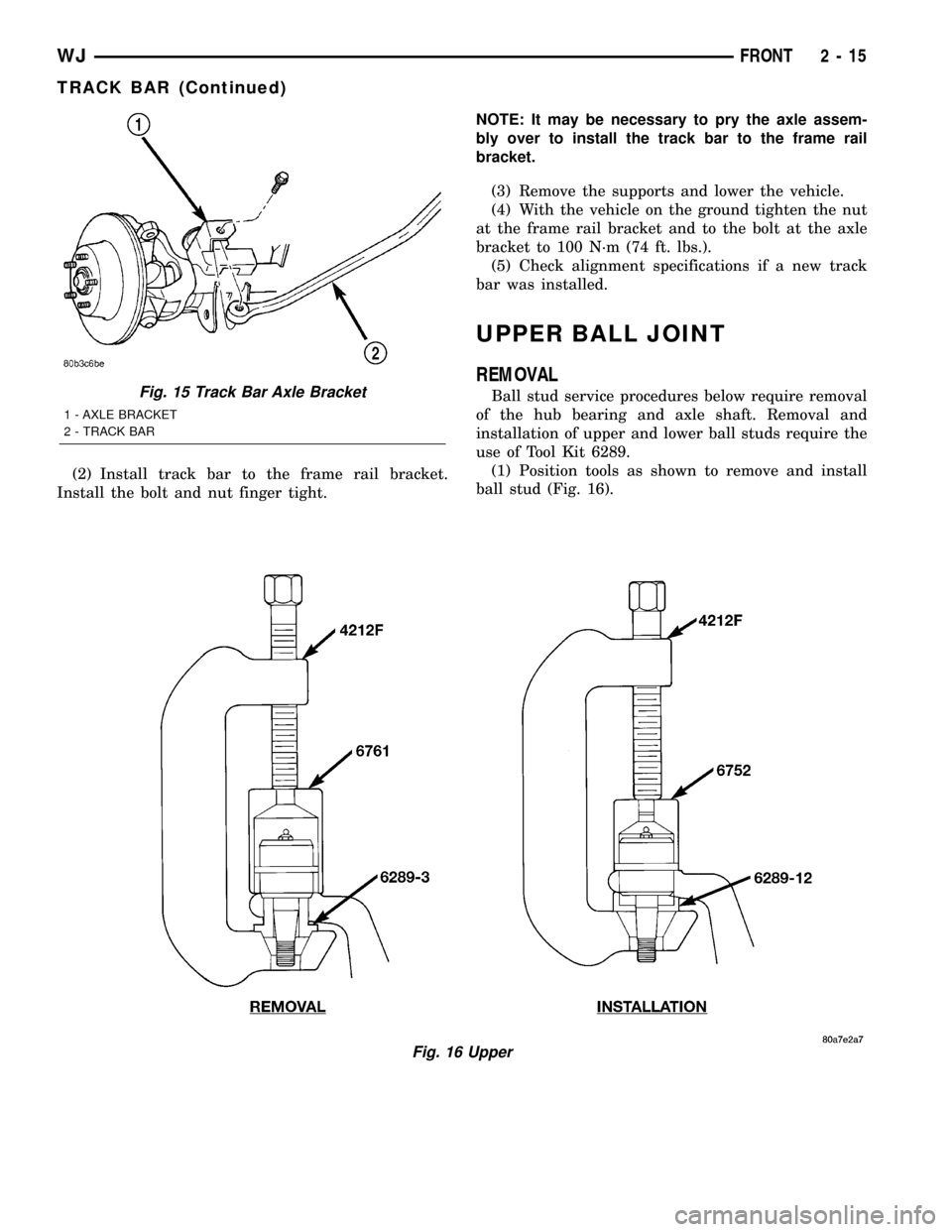

TRACK BAR

DESCRIPTION

The bar is attached to a frame rail bracket and

axle bracket. The bar is forged and has non replace-

able isolator bushings at both ends.

OPERATION

The track bar is used to control front axle lateral

movement and provides cross car location of the axle

assembly.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the nut and bolt from the frame rail

bracket (Fig. 14).

(3) Remove the bolt from the axle shaft tube

bracket (Fig. 15). Remove the track bar.

INSTALLATION

(1) Install the track bar to the axle tube bracket.

Install the retaining bolt finger tight.

Fig. 13 Stabilizer Bar

1 - LINK

2 - STABILIZER BAR

3 - BUSHING

4 - RETAINER

Fig. 14 Track Bar Frame Rail Bracket

1 - FRAME RAIL

2 - TRACK BAR

2 - 14 FRONTWJ

SPRING (Continued)

Page 36 of 2199

(2) Install track bar to the frame rail bracket.

Install the bolt and nut finger tight.NOTE: It may be necessary to pry the axle assem-

bly over to install the track bar to the frame rail

bracket.

(3) Remove the supports and lower the vehicle.

(4) With the vehicle on the ground tighten the nut

at the frame rail bracket and to the bolt at the axle

bracket to 100 N´m (74 ft. lbs.).

(5) Check alignment specifications if a new track

bar was installed.

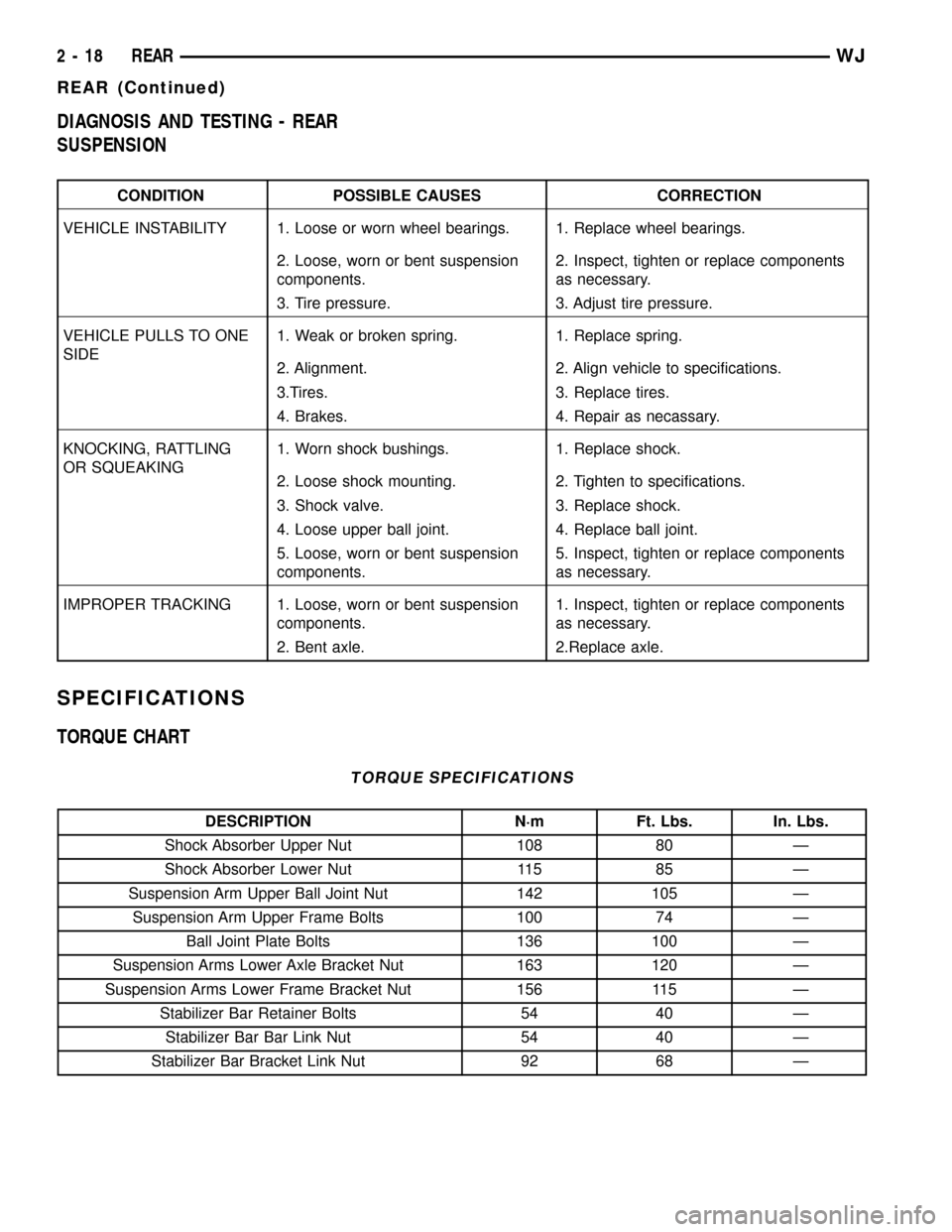

UPPER BALL JOINT

REMOVAL

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal and

installation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Position tools as shown to remove and install

ball stud (Fig. 16).

Fig. 16 Upper

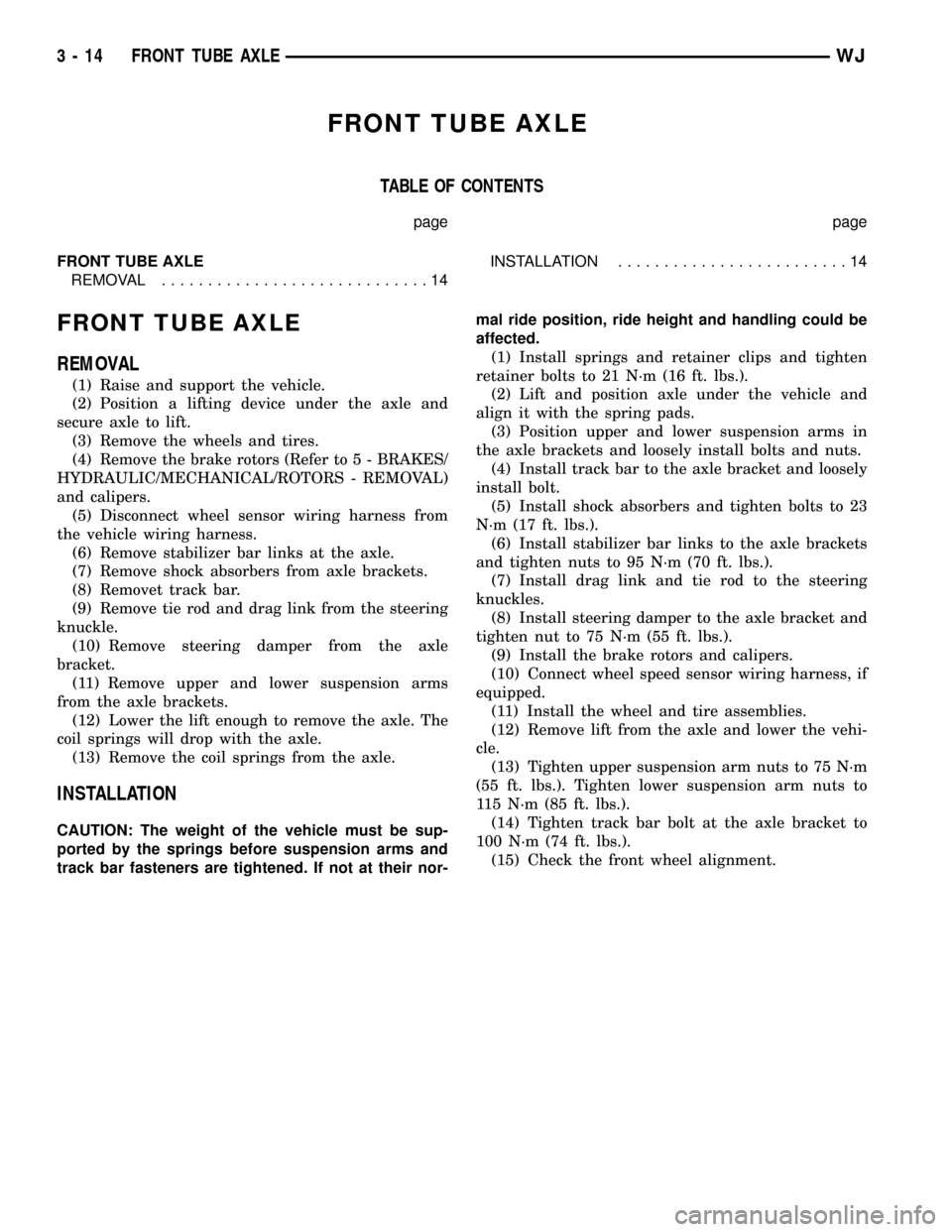

Fig. 15 Track Bar Axle Bracket

1 - AXLE BRACKET

2 - TRACK BAR

WJFRONT 2 - 15

TRACK BAR (Continued)

Page 39 of 2199

DIAGNOSIS AND TESTING - REAR

SUSPENSION

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose, worn or bent suspension

components.2. Inspect, tighten or replace components

as necessary.

3. Tire pressure. 3. Adjust tire pressure.

VEHICLE PULLS TO ONE

SIDE1. Weak or broken spring. 1. Replace spring.

2. Alignment. 2. Align vehicle to specifications.

3.Tires. 3. Replace tires.

4. Brakes. 4. Repair as necassary.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose shock mounting. 2. Tighten to specifications.

3. Shock valve. 3. Replace shock.

4. Loose upper ball joint. 4. Replace ball joint.

5. Loose, worn or bent suspension

components.5. Inspect, tighten or replace components

as necessary.

IMPROPER TRACKING 1. Loose, worn or bent suspension

components.1. Inspect, tighten or replace components

as necessary.

2. Bent axle. 2.Replace axle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 108 80 Ð

Shock Absorber Lower Nut 115 85 Ð

Suspension Arm Upper Ball Joint Nut 142 105 Ð

Suspension Arm Upper Frame Bolts 100 74 Ð

Ball Joint Plate Bolts 136 100 Ð

Suspension Arms Lower Axle Bracket Nut 163 120 Ð

Suspension Arms Lower Frame Bracket Nut 156 115 Ð

Stabilizer Bar Retainer Bolts 54 40 Ð

Stabilizer Bar Bar Link Nut 54 40 Ð

Stabilizer Bar Bracket Link Nut 92 68 Ð

2 - 18 REARWJ

REAR (Continued)

Page 59 of 2199

FRONT TUBE AXLE

TABLE OF CONTENTS

page page

FRONT TUBE AXLE

REMOVAL.............................14INSTALLATION.........................14

FRONT TUBE AXLE

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle to lift.

(3) Remove the wheels and tires.

(4) Remove the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - REMOVAL)

and calipers.

(5) Disconnect wheel sensor wiring harness from

the vehicle wiring harness.

(6) Remove stabilizer bar links at the axle.

(7) Remove shock absorbers from axle brackets.

(8) Removet track bar.

(9) Remove tie rod and drag link from the steering

knuckle.

(10) Remove steering damper from the axle

bracket.

(11) Remove upper and lower suspension arms

from the axle brackets.

(12) Lower the lift enough to remove the axle. The

coil springs will drop with the axle.

(13) Remove the coil springs from the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If not at their nor-mal ride position, ride height and handling could be

affected.

(1) Install springs and retainer clips and tighten

retainer bolts to 21 N´m (16 ft. lbs.).

(2) Lift and position axle under the vehicle and

align it with the spring pads.

(3) Position upper and lower suspension arms in

the axle brackets and loosely install bolts and nuts.

(4) Install track bar to the axle bracket and loosely

install bolt.

(5) Install shock absorbers and tighten bolts to 23

N´m (17 ft. lbs.).

(6) Install stabilizer bar links to the axle brackets

and tighten nuts to 95 N´m (70 ft. lbs.).

(7) Install drag link and tie rod to the steering

knuckles.

(8) Install steering damper to the axle bracket and

tighten nut to 75 N´m (55 ft. lbs.).

(9) Install the brake rotors and calipers.

(10) Connect wheel speed sensor wiring harness, if

equipped.

(11) Install the wheel and tire assemblies.

(12) Remove lift from the axle and lower the vehi-

cle.

(13) Tighten upper suspension arm nuts to 75 N´m

(55 ft. lbs.). Tighten lower suspension arm nuts to

115 N´m (85 ft. lbs.).

(14) Tighten track bar bolt at the axle bracket to

100 N´m (74 ft. lbs.).

(15) Check the front wheel alignment.

3 - 14 FRONT TUBE AXLEWJ

Page 65 of 2199

Condition Possible Causes Correction

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.

(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-

tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the

axle.

(3) Secure axle to lift.

(4) Remove the wheels and tires.

(5) Remove the brake calipers and rotors (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/ROTORS

- REMOVAL) from the axle.

(6) Disconnect the wheel sensor wiring harness

from the vehicle wiring harness.

(7) Disconnect the vent hose from the axle shaft

tube.

(8) Mark propeller shaft and yoke/pinion flange for

installation alignment reference.

(9) Remove propeller shaft.

(10) Disconnect stabilizer bar links at the axle.

(11) Disconnect shock absorbers from axle brack-

ets.

(12) Disconnect track bar.

(13) Disconnect the tie rod and drag link from the

steering knuckle.

(14) Disconnect the steering damper from the axle

bracket.

(15) Disconnect the upper and lower suspension

arms from the axle brackets.

(16) Lower the lifting device enough to remove the

axle. The coil springs will drop with the axle.

(17) Remove the coil springs from the axle.

3 - 20 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 66 of 2199

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners can be tightened. If springs are

not at their normal ride position, ride height and

handling could be affected.

(1) Install the springs and retainer clips. Tighten

the retainer bolts to 21 N´m (16 ft. lbs.).

(2) Support the axle on a lifting device and posi-

tion axle under the vehicle.

(3) Raise the axle and align it with the spring

pads.

(4) Position the upper and lower suspension arms

in the axle brackets. Loosely install bolts and nuts to

hold suspension arms to the axle brackets.

(5) Install vent hose to the axle shaft tube.

(6) Install track bar in the axle bracket and install

the bolt loosely.

(7) Install shock absorbers and tighten the bolts to

23 N´m (17 ft. lbs.).

(8) Install stabilizer bar links to the axle brackets

and tighten the nuts to 95 N´m (70 ft. lbs.).

(9) Install drag link and tie rod to the steering

knuckles.

(10) Install steering damper to the axle bracket

and tighten the nut to 75 N´m (55 ft. lbs.).

(11) Install the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and calipers.

(12) Connect the wheel speed sensor wiring har-

ness to the vehicle wiring harness.

(13) Align the previously made marks on the pro-

peller shaft and the yoke/pinion flange.

(14) Install propeller shaft to pinion flange bolts ,

if equipped.

(15) Install propeller shaft to yoke straps and

bolts, if equipped.

(16) Check and fill axle lubricant.

(17) Install the wheel and tire assemblies.

(18) Remove the lifting device from the axle and

lower the vehicle.

(19) Tighten the upper suspension arm nuts to 75

N´m (55 ft. lbs.). Tighten the lower suspension arm

nuts to 115 N´m (85 ft. lbs.).

(20) Tighten the track bar bolt at the axle bracket

to 100 N´m (74 ft. lbs.).

(21) Check the front wheel alignment.

ADJUSTMENTS

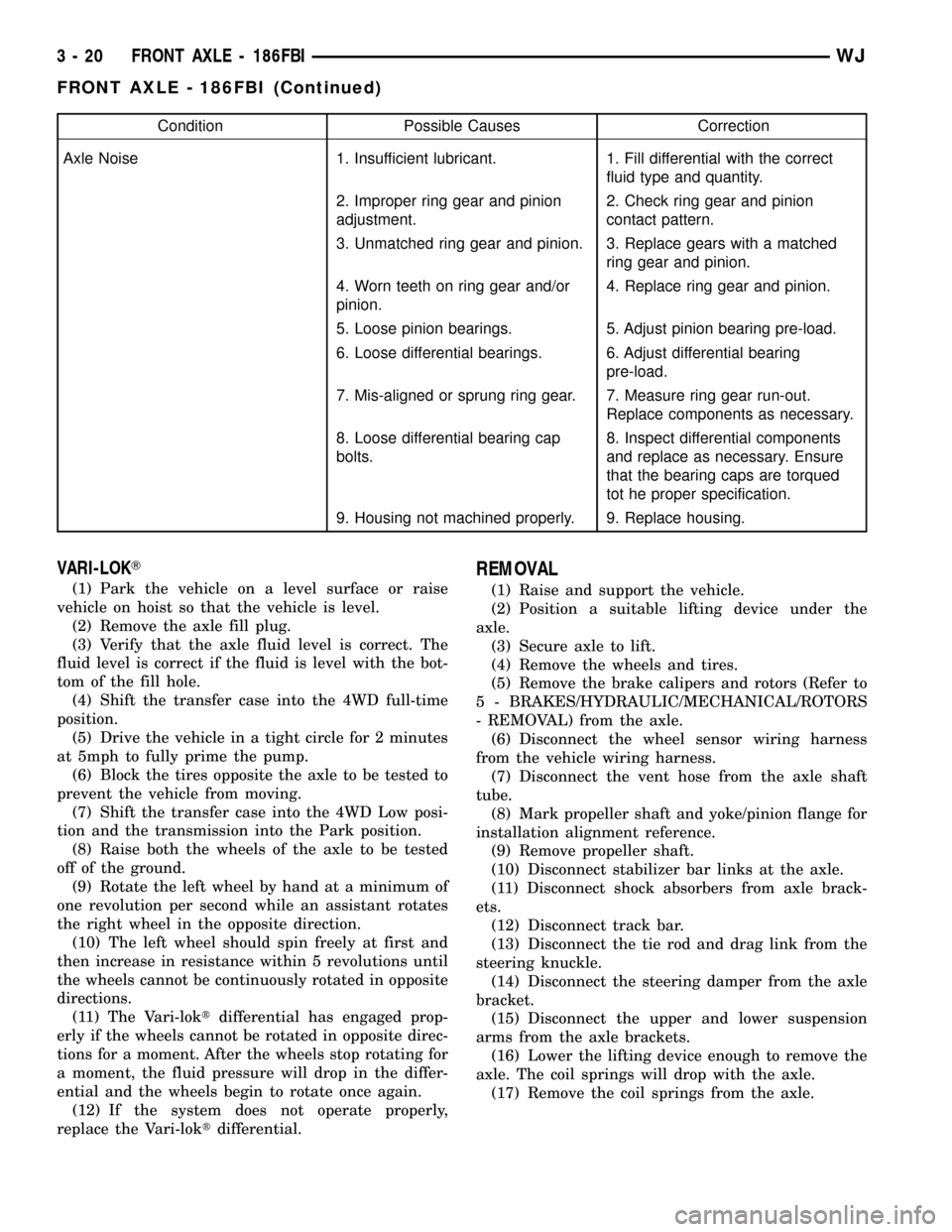

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched onto each gear (Fig. 3). A plus

(+) number, minus (±) number or zero (0) is etched

into the face of the pinion gear. This number is theamount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched

with a (0). The standard setting from the center line

of the ring gear to the back face of the pinion is 92.1

mm (3.625 in.). The standard depth provides the best

gear tooth contact pattern. Refer to Backlash and

Contact Pattern Analysis paragraph in this section

for additional information.

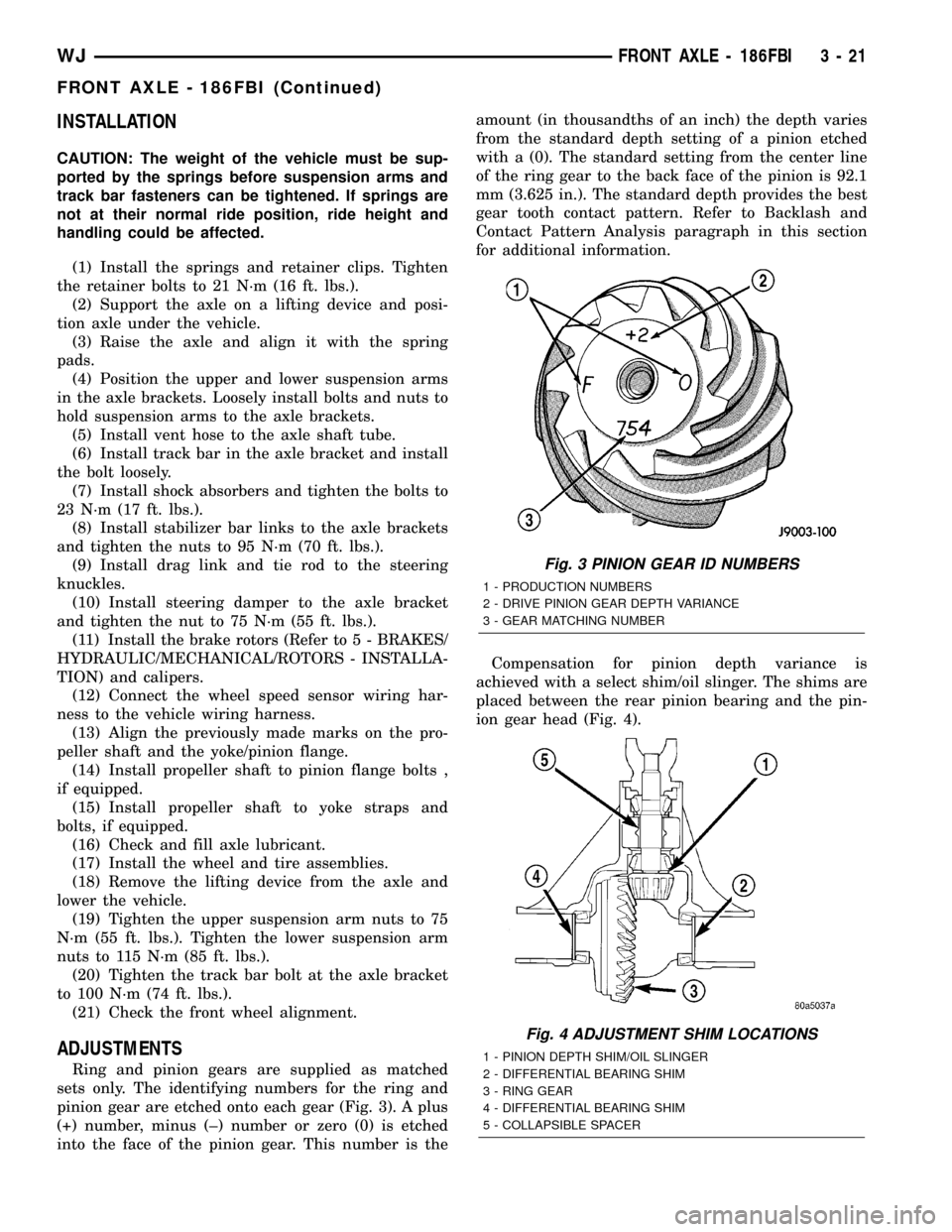

Compensation for pinion depth variance is

achieved with a select shim/oil slinger. The shims are

placed between the rear pinion bearing and the pin-

ion gear head (Fig. 4).

Fig. 3 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - DRIVE PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 4 ADJUSTMENT SHIM LOCATIONS

1 - PINION DEPTH SHIM/OIL SLINGER

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

WJFRONT AXLE - 186FBI 3 - 21

FRONT AXLE - 186FBI (Continued)