Differential JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1818 of 2199

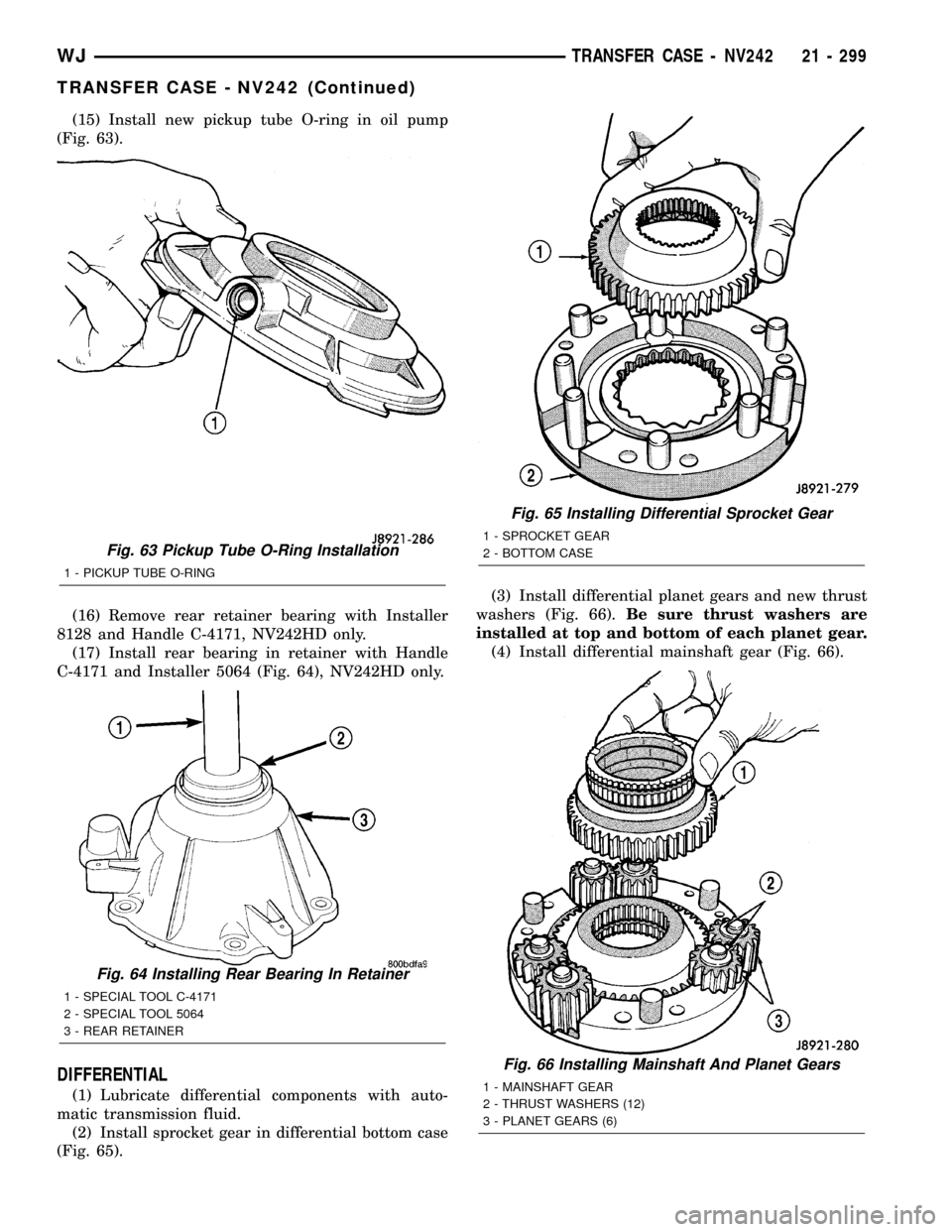

(15) Install new pickup tube O-ring in oil pump

(Fig. 63).

(16) Remove rear retainer bearing with Installer

8128 and Handle C-4171, NV242HD only.

(17) Install rear bearing in retainer with Handle

C-4171 and Installer 5064 (Fig. 64), NV242HD only.

DIFFERENTIAL

(1) Lubricate differential components with auto-

matic transmission fluid.

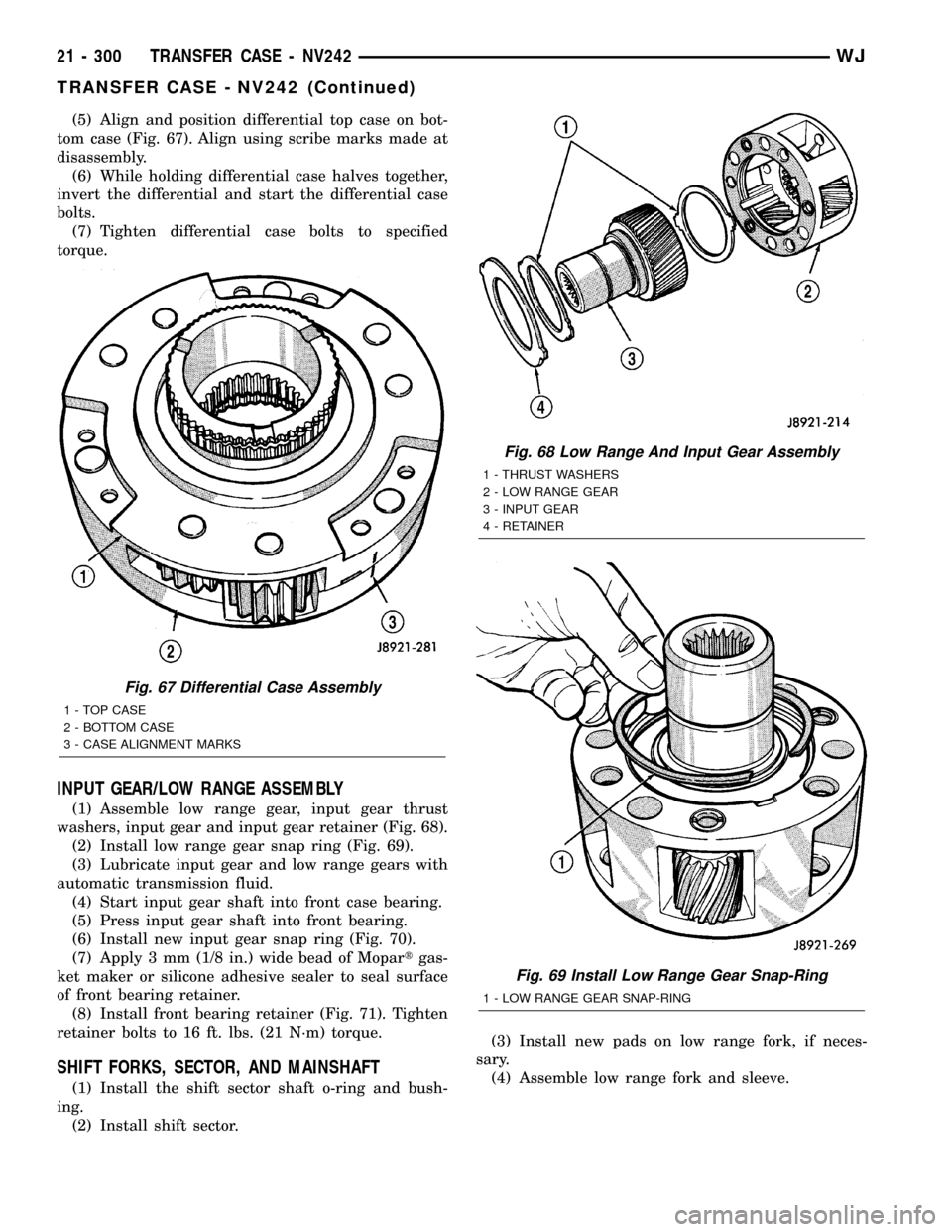

(2) Install sprocket gear in differential bottom case

(Fig. 65).(3) Install differential planet gears and new thrust

washers (Fig. 66).Be sure thrust washers are

installed at top and bottom of each planet gear.

(4) Install differential mainshaft gear (Fig. 66).

Fig. 63 Pickup Tube O-Ring Installation

1 - PICKUP TUBE O-RING

Fig. 64 Installing Rear Bearing In Retainer

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 5064

3 - REAR RETAINER

Fig. 65 Installing Differential Sprocket Gear

1 - SPROCKET GEAR

2 - BOTTOM CASE

Fig. 66 Installing Mainshaft And Planet Gears

1 - MAINSHAFT GEAR

2 - THRUST WASHERS (12)

3 - PLANET GEARS (6)

WJTRANSFER CASE - NV242 21 - 299

TRANSFER CASE - NV242 (Continued)

Page 1819 of 2199

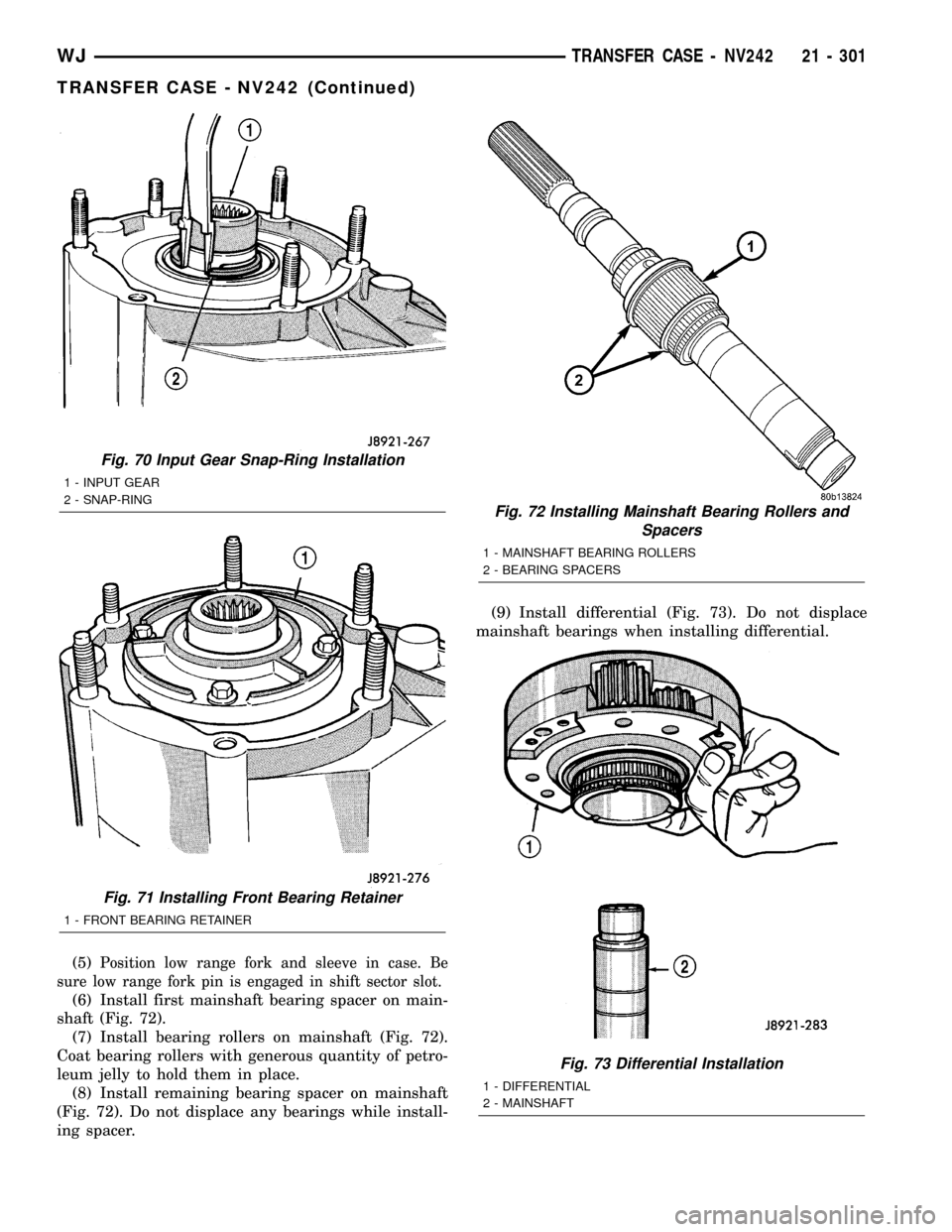

(5) Align and position differential top case on bot-

tom case (Fig. 67). Align using scribe marks made at

disassembly.

(6) While holding differential case halves together,

invert the differential and start the differential case

bolts.

(7) Tighten differential case bolts to specified

torque.

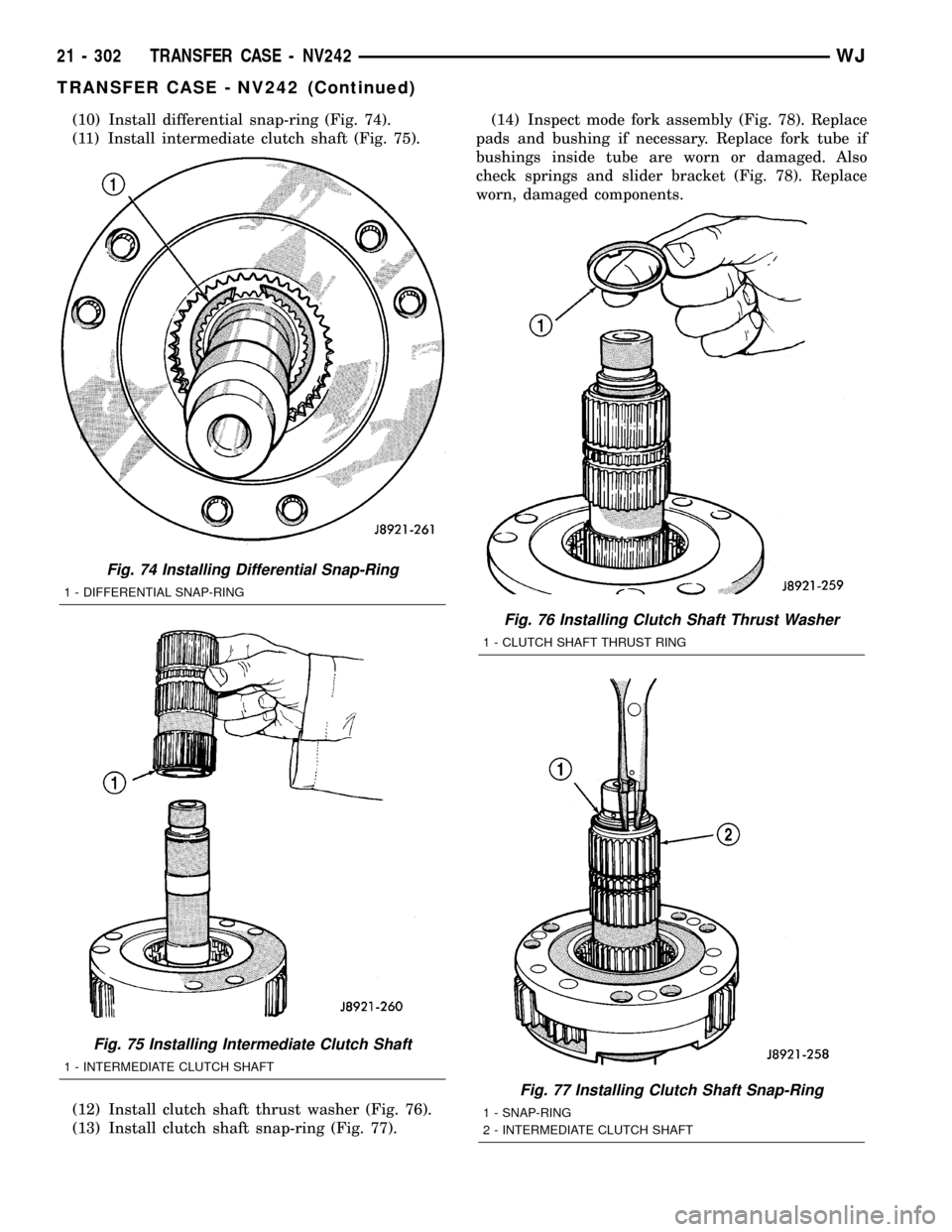

INPUT GEAR/LOW RANGE ASSEMBLY

(1) Assemble low range gear, input gear thrust

washers, input gear and input gear retainer (Fig. 68).

(2) Install low range gear snap ring (Fig. 69).

(3) Lubricate input gear and low range gears with

automatic transmission fluid.

(4) Start input gear shaft into front case bearing.

(5) Press input gear shaft into front bearing.

(6) Install new input gear snap ring (Fig. 70).

(7) Apply 3 mm (1/8 in.) wide bead of Mopartgas-

ket maker or silicone adhesive sealer to seal surface

of front bearing retainer.

(8) Install front bearing retainer (Fig. 71). Tighten

retainer bolts to 16 ft. lbs. (21 N´m) torque.

SHIFT FORKS, SECTOR, AND MAINSHAFT

(1) Install the shift sector shaft o-ring and bush-

ing.

(2) Install shift sector.(3) Install new pads on low range fork, if neces-

sary.

(4) Assemble low range fork and sleeve.

Fig. 67 Differential Case Assembly

1 - TOP CASE

2 - BOTTOM CASE

3 - CASE ALIGNMENT MARKS

Fig. 68 Low Range And Input Gear Assembly

1 - THRUST WASHERS

2 - LOW RANGE GEAR

3 - INPUT GEAR

4 - RETAINER

Fig. 69 Install Low Range Gear Snap-Ring

1 - LOW RANGE GEAR SNAP-RING

21 - 300 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1820 of 2199

(5)Position low range fork and sleeve in case. Be

sure low range fork pin is engaged in shift sector slot.

(6) Install first mainshaft bearing spacer on main-

shaft (Fig. 72).

(7) Install bearing rollers on mainshaft (Fig. 72).

Coat bearing rollers with generous quantity of petro-

leum jelly to hold them in place.

(8) Install remaining bearing spacer on mainshaft

(Fig. 72). Do not displace any bearings while install-

ing spacer.(9) Install differential (Fig. 73). Do not displace

mainshaft bearings when installing differential.

Fig. 70 Input Gear Snap-Ring Installation

1 - INPUT GEAR

2 - SNAP-RING

Fig. 71 Installing Front Bearing Retainer

1 - FRONT BEARING RETAINER

Fig. 72 Installing Mainshaft Bearing Rollers and

Spacers

1 - MAINSHAFT BEARING ROLLERS

2 - BEARING SPACERS

Fig. 73 Differential Installation

1 - DIFFERENTIAL

2 - MAINSHAFT

WJTRANSFER CASE - NV242 21 - 301

TRANSFER CASE - NV242 (Continued)

Page 1821 of 2199

(10) Install differential snap-ring (Fig. 74).

(11) Install intermediate clutch shaft (Fig. 75).

(12) Install clutch shaft thrust washer (Fig. 76).

(13) Install clutch shaft snap-ring (Fig. 77).(14) Inspect mode fork assembly (Fig. 78). Replace

pads and bushing if necessary. Replace fork tube if

bushings inside tube are worn or damaged. Also

check springs and slider bracket (Fig. 78). Replace

worn, damaged components.

Fig. 74 Installing Differential Snap-Ring

1 - DIFFERENTIAL SNAP-RING

Fig. 75 Installing Intermediate Clutch Shaft

1 - INTERMEDIATE CLUTCH SHAFT

Fig. 76 Installing Clutch Shaft Thrust Washer

1 - CLUTCH SHAFT THRUST RING

Fig. 77 Installing Clutch Shaft Snap-Ring

1 - SNAP-RING

2 - INTERMEDIATE CLUTCH SHAFT

21 - 302 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1826 of 2199

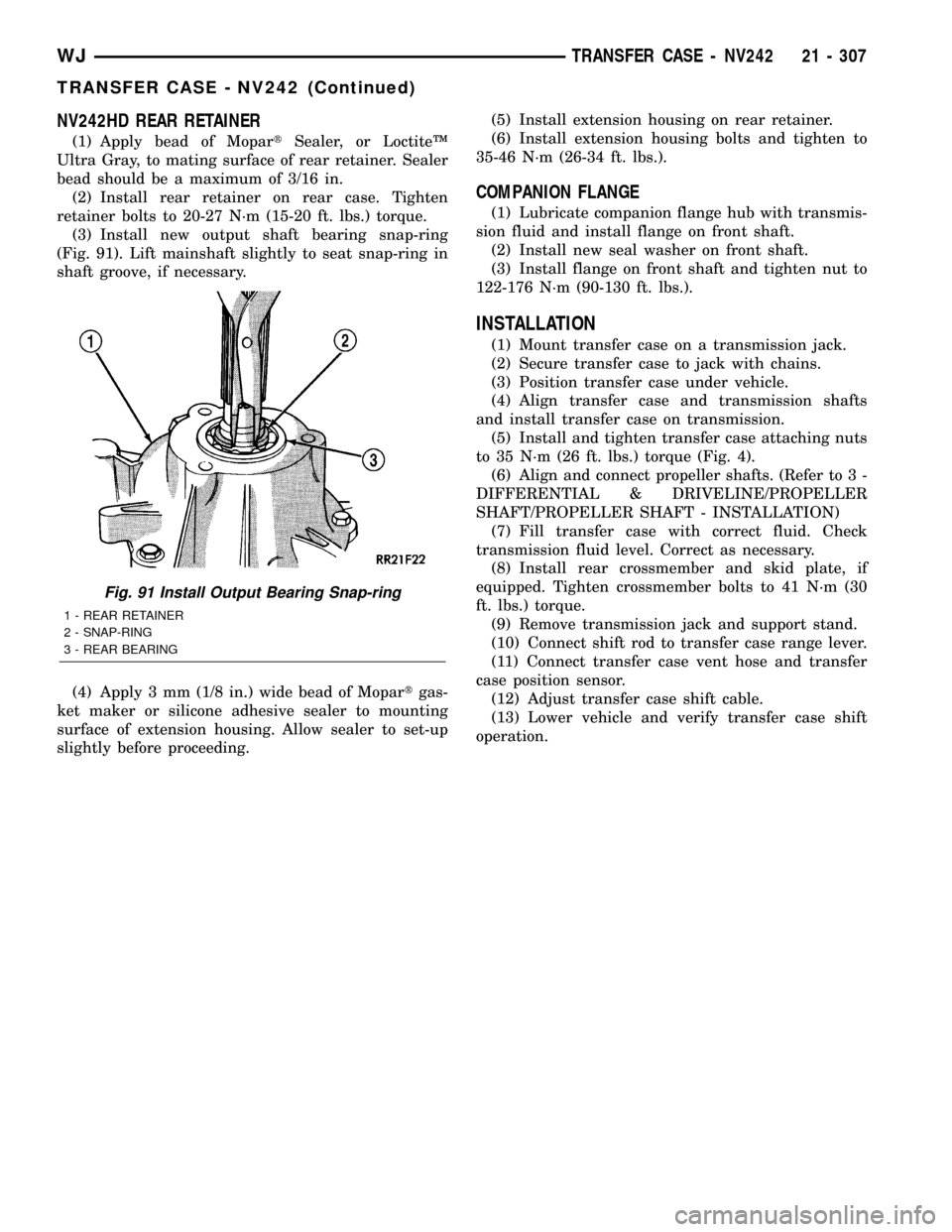

NV242HD REAR RETAINER

(1) Apply bead of MopartSealer, or LoctiteŸ

Ultra Gray, to mating surface of rear retainer. Sealer

bead should be a maximum of 3/16 in.

(2) Install rear retainer on rear case. Tighten

retainer bolts to 20-27 N´m (15-20 ft. lbs.) torque.

(3) Install new output shaft bearing snap-ring

(Fig. 91). Lift mainshaft slightly to seat snap-ring in

shaft groove, if necessary.

(4) Apply 3 mm (1/8 in.) wide bead of Mopartgas-

ket maker or silicone adhesive sealer to mounting

surface of extension housing. Allow sealer to set-up

slightly before proceeding.(5) Install extension housing on rear retainer.

(6) Install extension housing bolts and tighten to

35-46 N´m (26-34 ft. lbs.).

COMPANION FLANGE

(1) Lubricate companion flange hub with transmis-

sion fluid and install flange on front shaft.

(2) Install new seal washer on front shaft.

(3) Install flange on front shaft and tighten nut to

122-176 N´m (90-130 ft. lbs.).

INSTALLATION

(1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case on transmission.

(5) Install and tighten transfer case attaching nuts

to 35 N´m (26 ft. lbs.) torque (Fig. 4).

(6) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(7) Fill transfer case with correct fluid. Check

transmission fluid level. Correct as necessary.

(8) Install rear crossmember and skid plate, if

equipped. Tighten crossmember bolts to 41 N´m (30

ft. lbs.) torque.

(9) Remove transmission jack and support stand.

(10) Connect shift rod to transfer case range lever.

(11) Connect transfer case vent hose and transfer

case position sensor.

(12) Adjust transfer case shift cable.

(13) Lower vehicle and verify transfer case shift

operation.

Fig. 91 Install Output Bearing Snap-ring

1 - REAR RETAINER

2 - SNAP-RING

3 - REAR BEARING

WJTRANSFER CASE - NV242 21 - 307

TRANSFER CASE - NV242 (Continued)

Page 1832 of 2199

(5) Install the rear propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(6) Verify proper fluid level.

(7) Lower vehicle.

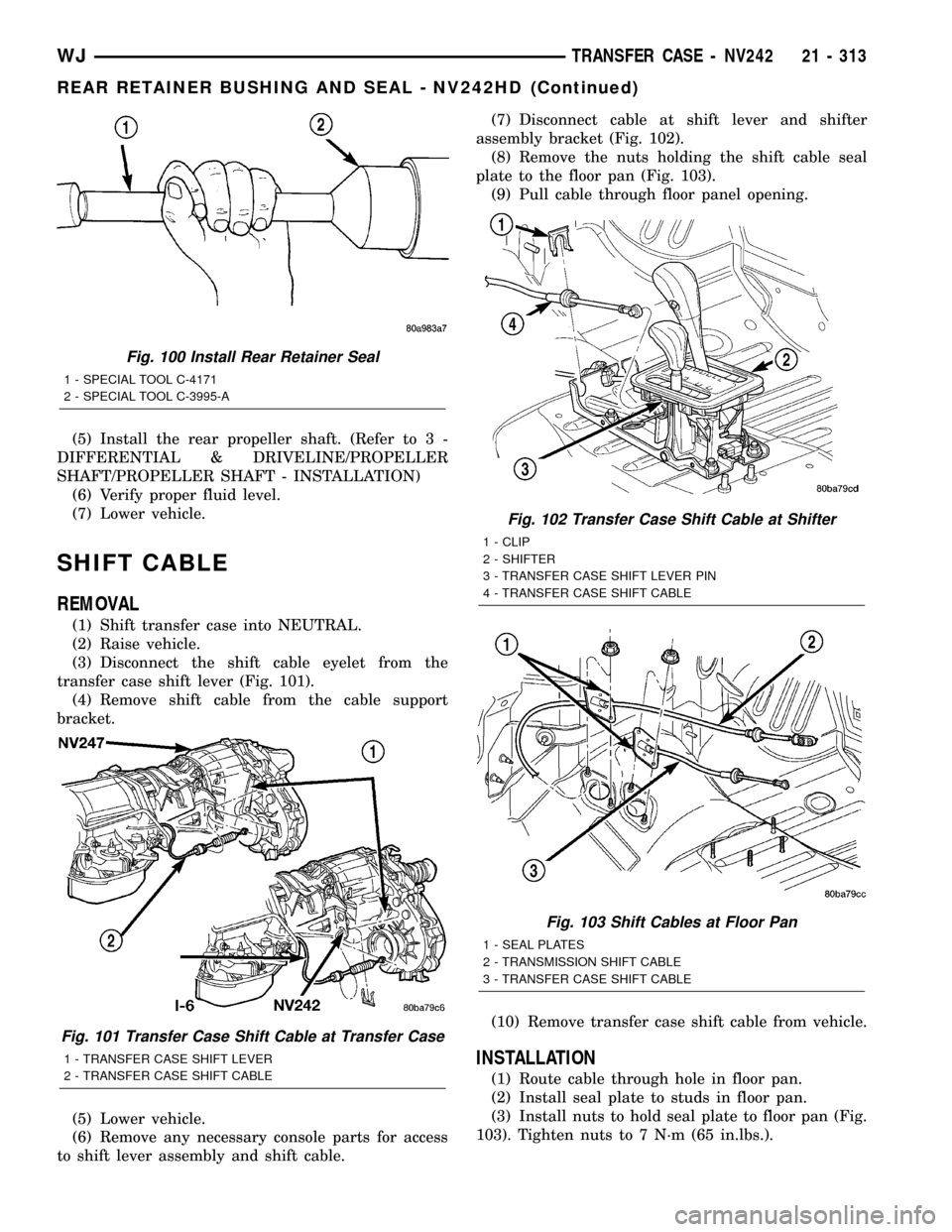

SHIFT CABLE

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Disconnect the shift cable eyelet from the

transfer case shift lever (Fig. 101).

(4) Remove shift cable from the cable support

bracket.

(5) Lower vehicle.

(6) Remove any necessary console parts for access

to shift lever assembly and shift cable.(7) Disconnect cable at shift lever and shifter

assembly bracket (Fig. 102).

(8) Remove the nuts holding the shift cable seal

plate to the floor pan (Fig. 103).

(9) Pull cable through floor panel opening.

(10) Remove transfer case shift cable from vehicle.

INSTALLATION

(1) Route cable through hole in floor pan.

(2) Install seal plate to studs in floor pan.

(3) Install nuts to hold seal plate to floor pan (Fig.

103). Tighten nuts to 7 N´m (65 in.lbs.).

Fig. 100 Install Rear Retainer Seal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL C-3995-A

Fig. 101 Transfer Case Shift Cable at Transfer Case

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 102 Transfer Case Shift Cable at Shifter

1 - CLIP

2 - SHIFTER

3 - TRANSFER CASE SHIFT LEVER PIN

4 - TRANSFER CASE SHIFT CABLE

Fig. 103 Shift Cables at Floor Pan

1 - SEAL PLATES

2 - TRANSMISSION SHIFT CABLE

3 - TRANSFER CASE SHIFT CABLE

WJTRANSFER CASE - NV242 21 - 313

REAR RETAINER BUSHING AND SEAL - NV242HD (Continued)

Page 1835 of 2199

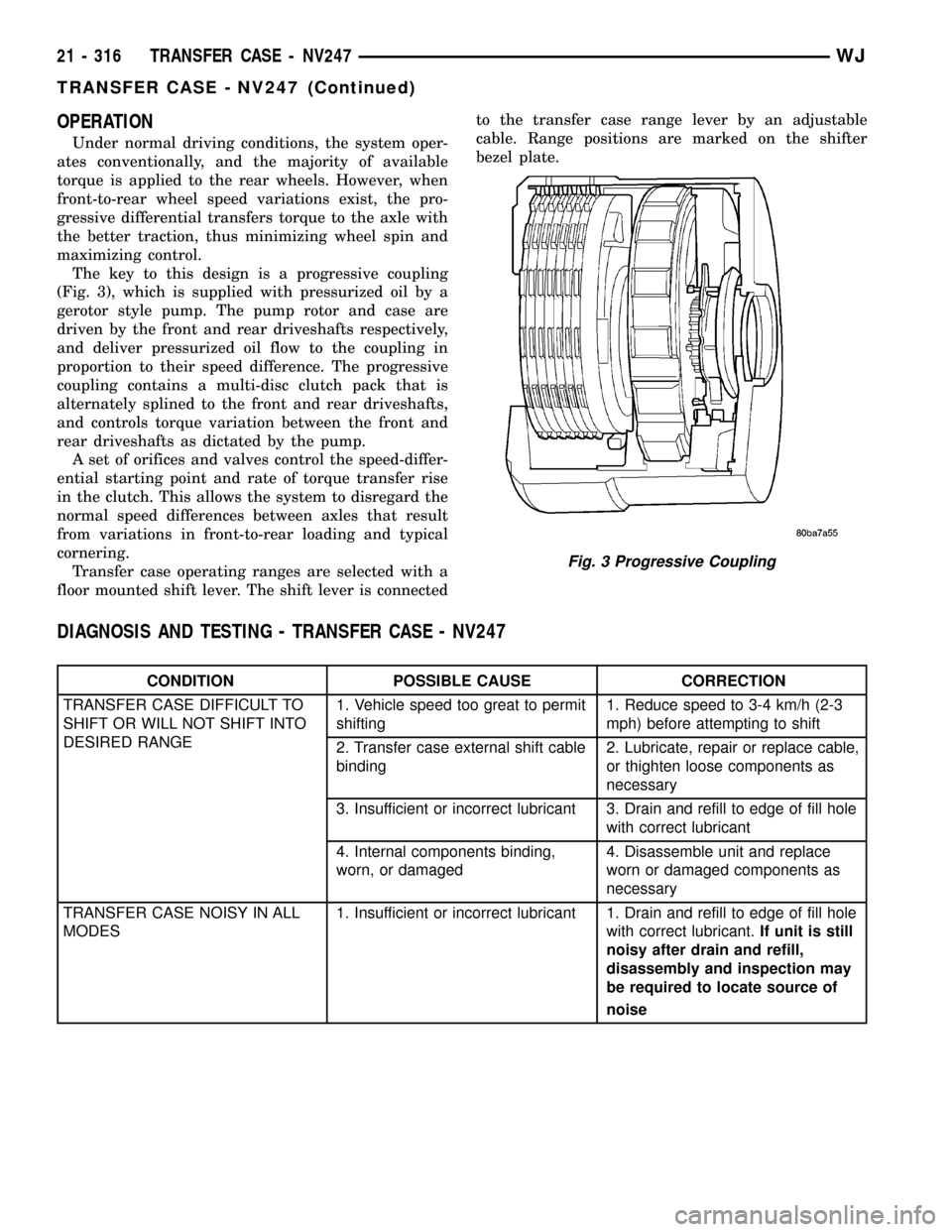

OPERATION

Under normal driving conditions, the system oper-

ates conventionally, and the majority of available

torque is applied to the rear wheels. However, when

front-to-rear wheel speed variations exist, the pro-

gressive differential transfers torque to the axle with

the better traction, thus minimizing wheel spin and

maximizing control.

The key to this design is a progressive coupling

(Fig. 3), which is supplied with pressurized oil by a

gerotor style pump. The pump rotor and case are

driven by the front and rear driveshafts respectively,

and deliver pressurized oil flow to the coupling in

proportion to their speed difference. The progressive

coupling contains a multi-disc clutch pack that is

alternately splined to the front and rear driveshafts,

and controls torque variation between the front and

rear driveshafts as dictated by the pump.

A set of orifices and valves control the speed-differ-

ential starting point and rate of torque transfer rise

in the clutch. This allows the system to disregard the

normal speed differences between axles that result

from variations in front-to-rear loading and typical

cornering.

Transfer case operating ranges are selected with a

floor mounted shift lever. The shift lever is connectedto the transfer case range lever by an adjustable

cable. Range positions are marked on the shifter

bezel plate.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV247

CONDITION POSSIBLE CAUSE CORRECTION

TRANSFER CASE DIFFICULT TO

SHIFT OR WILL NOT SHIFT INTO

DESIRED RANGE1. Vehicle speed too great to permit

shifting1. Reduce speed to 3-4 km/h (2-3

mph) before attempting to shift

2. Transfer case external shift cable

binding2. Lubricate, repair or replace cable,

or thighten loose components as

necessary

3. Insufficient or incorrect lubricant 3. Drain and refill to edge of fill hole

with correct lubricant

4. Internal components binding,

worn, or damaged4. Disassemble unit and replace

worn or damaged components as

necessary

TRANSFER CASE NOISY IN ALL

MODES1. Insufficient or incorrect lubricant 1. Drain and refill to edge of fill hole

with correct lubricant.If unit is still

noisy after drain and refill,

disassembly and inspection may

be required to locate source of

noise

Fig. 3 Progressive Coupling

21 - 316 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1836 of 2199

CONDITION POSSIBLE CAUSE CORRECTION

NOISY INÐOR JUMPS OUT OF

4WD LOW RANGE1. Transfer case not completely

engaged in 4WD LOW (possibly

from shift to 4L while rolling)1. Stop vehicle, shift transfer case

to neutral, then shift back to 4WD

LOW

2. Shift linkage loose, binding, or is

misadjusted2. Tighten, lubricate, or repair

linkage as necessary. Adjust linkage

if necessary

3. Range fork cracked, inserts

worn, or fork is binding on shift rail3. Disassemble unit and repair as

necessary

4. Annulus gear or lockplate worn

or damaged4. Disassemble unit and repair as

necessary

LUBRICANT LEAKING FROM

OUTPUT SHAFT SEALS OR FROM

VENT1. Transfer case over filled 1. Drain to correct level

2. Vent closed or restricted 2. Clear or replace vent if necessary

3. Output shaft seals damaged or

installed correctly3. Replace seals. Be sure seal lip

faces interior of case when installed.

Also be sure yoke seal surfaces are

not scored or nicked. Remove

scores and nicks with fine

sandpaper or replace yoke(s) if

necessary.

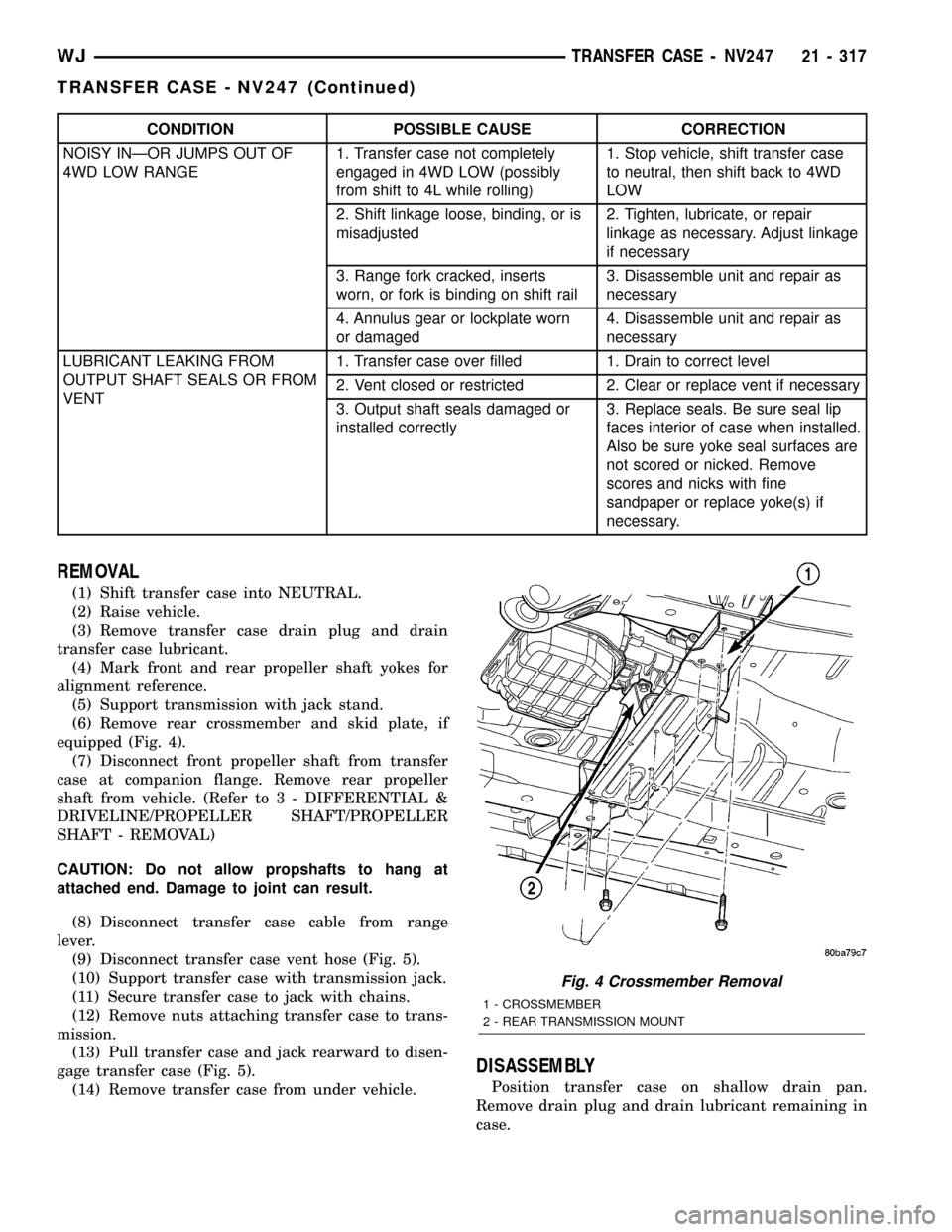

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Remove transfer case drain plug and drain

transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember and skid plate, if

equipped (Fig. 4).

(7) Disconnect front propeller shaft from transfer

case at companion flange. Remove rear propeller

shaft from vehicle. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - REMOVAL)

CAUTION: Do not allow propshafts to hang at

attached end. Damage to joint can result.

(8) Disconnect transfer case cable from range

lever.

(9) Disconnect transfer case vent hose (Fig. 5).

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission.

(13) Pull transfer case and jack rearward to disen-

gage transfer case (Fig. 5).

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case on shallow drain pan.

Remove drain plug and drain lubricant remaining in

case.

Fig. 4 Crossmember Removal

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

WJTRANSFER CASE - NV247 21 - 317

TRANSFER CASE - NV247 (Continued)

Page 1855 of 2199

(6) Connect front propeller shaft and install rear

propeller shaft. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION)

(7) Fill transfer case with correct fluid. Check

transmission fluid level. Correct as necessary.

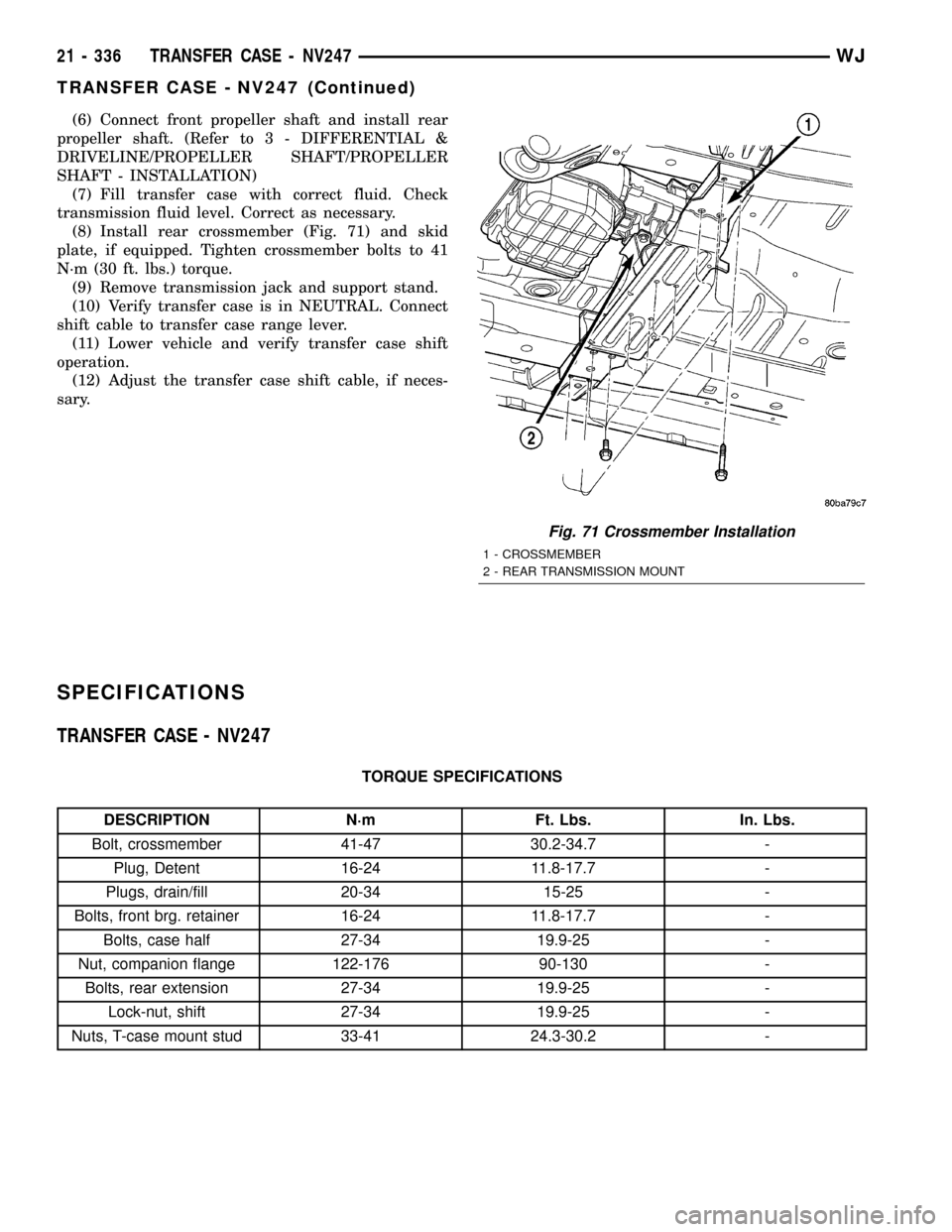

(8) Install rear crossmember (Fig. 71) and skid

plate, if equipped. Tighten crossmember bolts to 41

N´m (30 ft. lbs.) torque.

(9) Remove transmission jack and support stand.

(10) Verify transfer case is in NEUTRAL. Connect

shift cable to transfer case range lever.

(11) Lower vehicle and verify transfer case shift

operation.

(12) Adjust the transfer case shift cable, if neces-

sary.

SPECIFICATIONS

TRANSFER CASE - NV247

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, crossmember 41-47 30.2-34.7 -

Plug, Detent 16-24 11.8-17.7 -

Plugs, drain/fill 20-34 15-25 -

Bolts, front brg. retainer 16-24 11.8-17.7 -

Bolts, case half 27-34 19.9-25 -

Nut, companion flange 122-176 90-130 -

Bolts, rear extension 27-34 19.9-25 -

Lock-nut, shift 27-34 19.9-25 -

Nuts, T-case mount stud 33-41 24.3-30.2 -

Fig. 71 Crossmember Installation

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

21 - 336 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1867 of 2199

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

DIAGNOSIS AND TESTING - TREAD WEAR

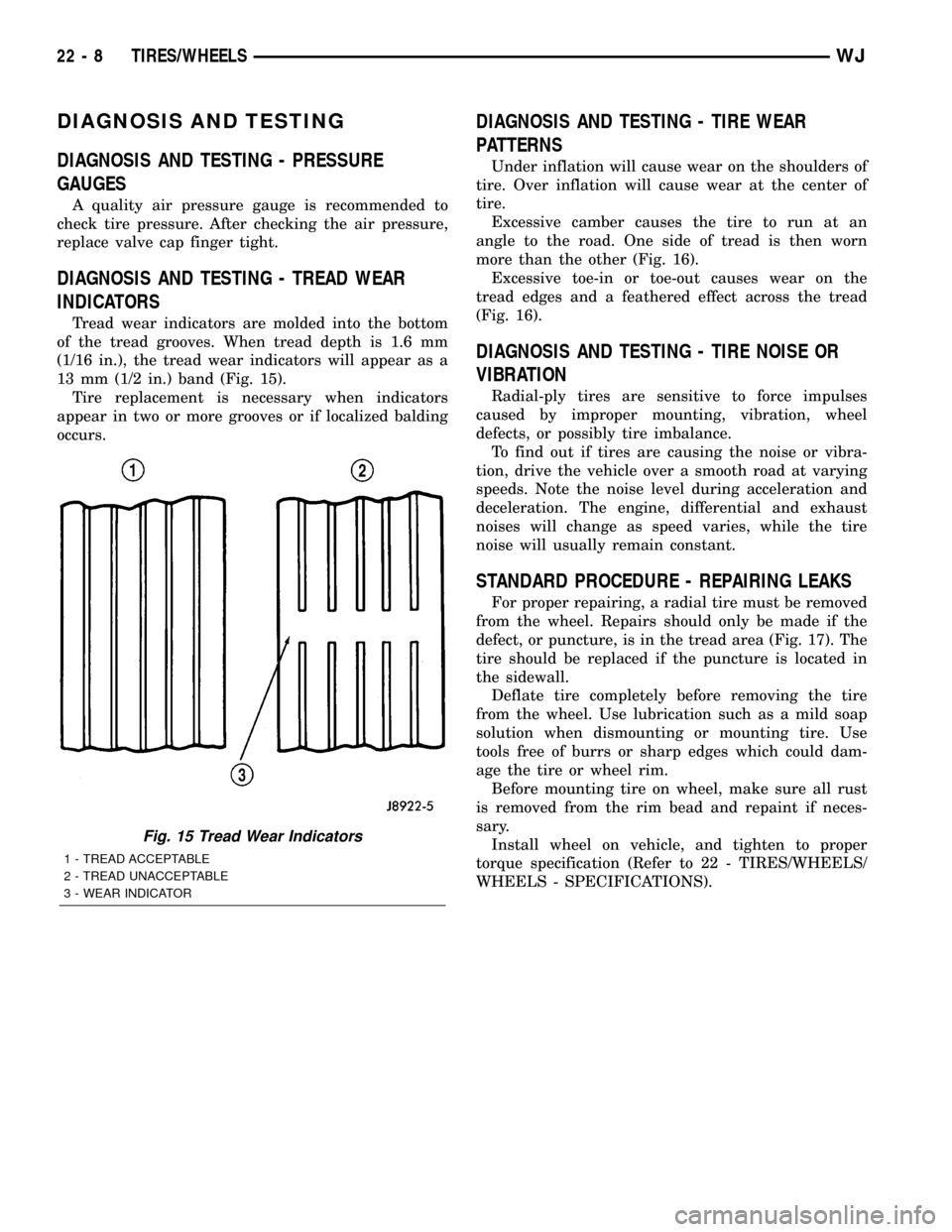

INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 15).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 16).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 16).

DIAGNOSIS AND TESTING - TIRE NOISE OR

VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varying

speeds. Note the noise level during acceleration and

deceleration. The engine, differential and exhaust

noises will change as speed varies, while the tire

noise will usually remain constant.

STANDARD PROCEDURE - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 17). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and tighten to proper

torque specification (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

Fig. 15 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

22 - 8 TIRES/WHEELSWJ