spec JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 343 of 2199

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. In order to

obtain correct indications from the built-in indicator,

it is important that the battery be level and have a

clean sight glass. Additional light may be required to

view the indicator.Do not use open flame as a

source of additional light.

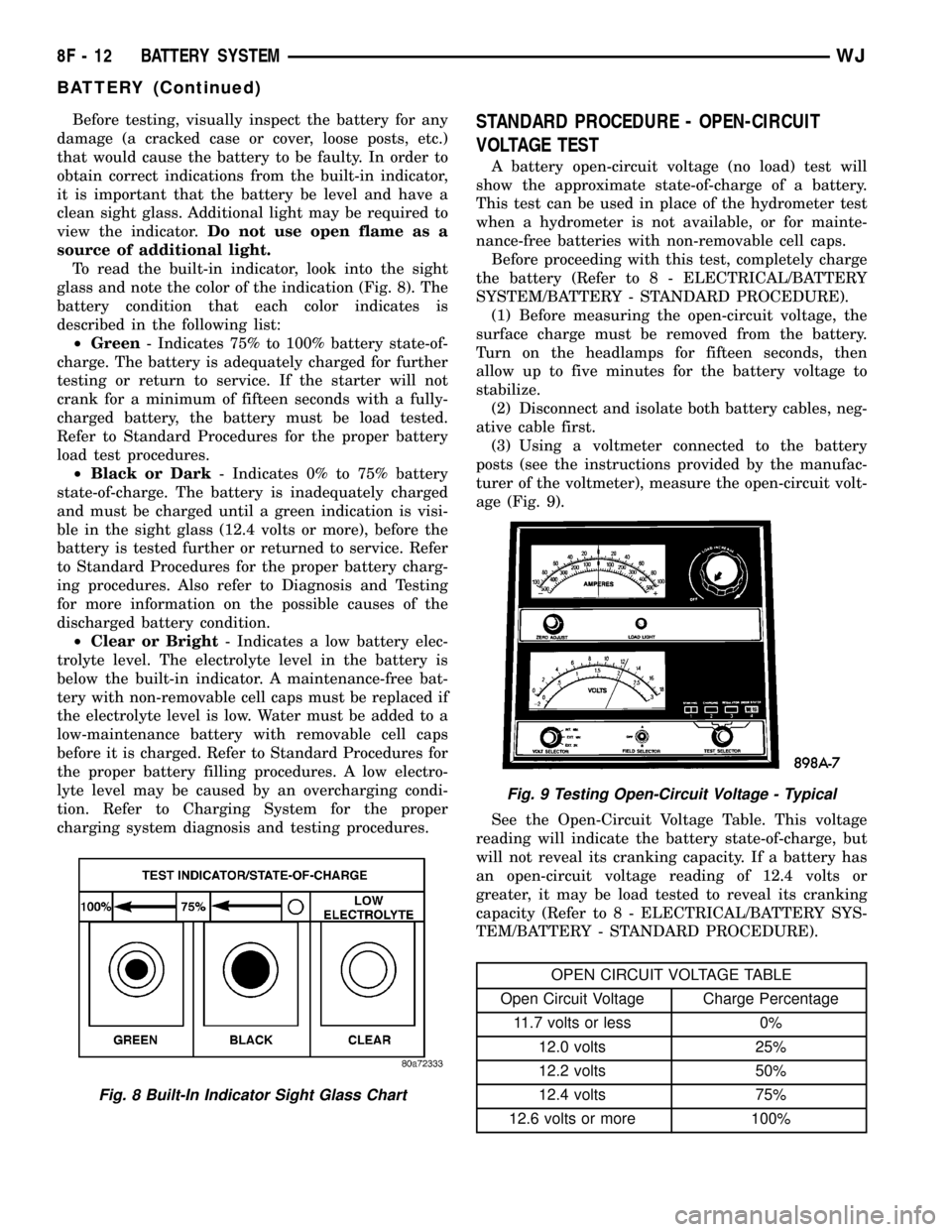

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 8). The

battery condition that each color indicates is

described in the following list:

²Green- Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fully-

charged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

²Black or Dark- Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visi-

ble in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charg-

ing procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

²Clear or Bright- Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free bat-

tery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electro-

lyte level may be caused by an overcharging condi-

tion. Refer to Charging System for the proper

charging system diagnosis and testing procedures.STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for mainte-

nance-free batteries with non-removable cell caps.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

Fig. 8 Built-In Indicator Sight Glass Chart

Fig. 9 Testing Open-Circuit Voltage - Typical

8F - 12 BATTERY SYSTEMWJ

BATTERY (Continued)

Page 346 of 2199

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

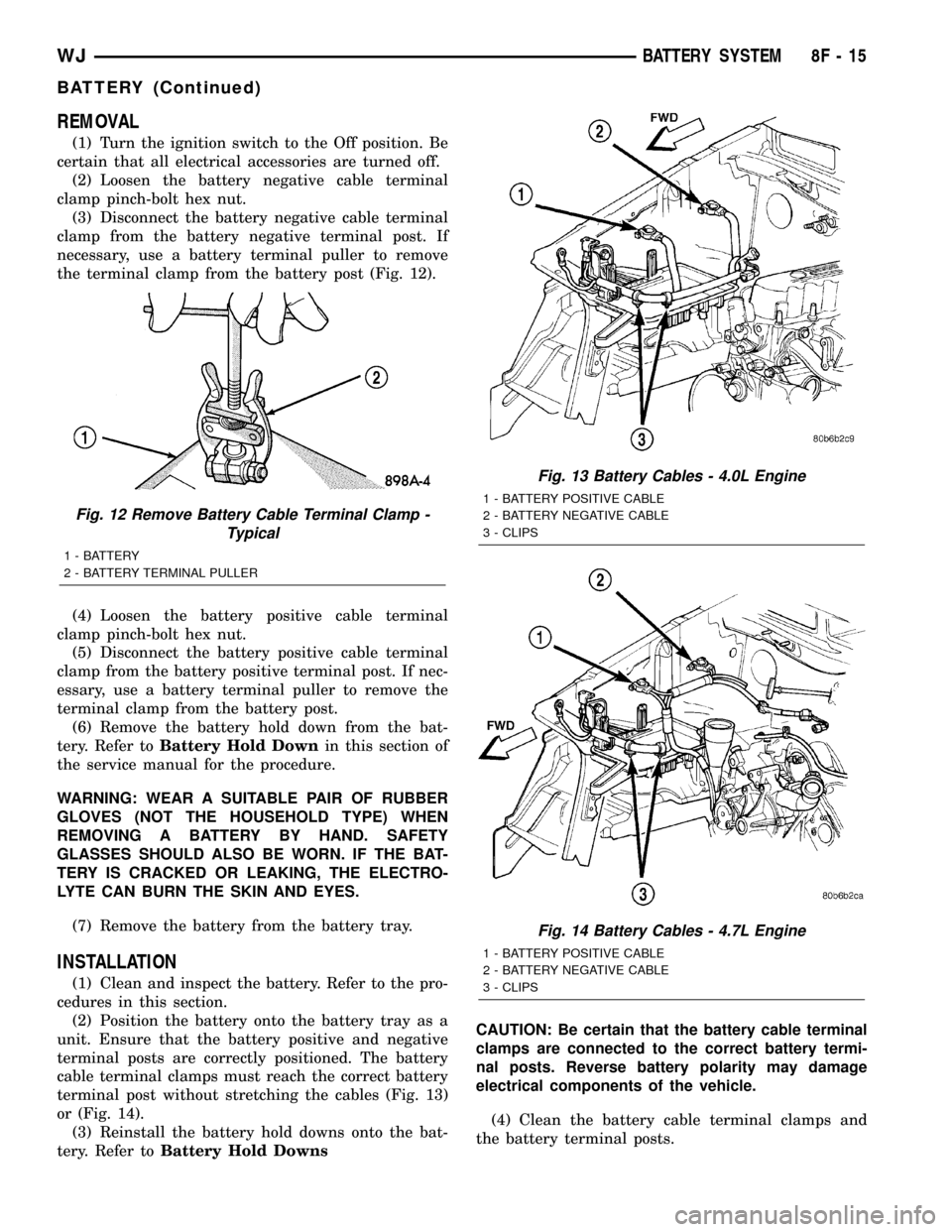

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 12).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Remove the battery hold down from the bat-

tery. Refer toBattery Hold Downin this section of

the service manual for the procedure.

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(7) Remove the battery from the battery tray.

INSTALLATION

(1) Clean and inspect the battery. Refer to the pro-

cedures in this section.

(2) Position the battery onto the battery tray as a

unit. Ensure that the battery positive and negative

terminal posts are correctly positioned. The battery

cable terminal clamps must reach the correct battery

terminal post without stretching the cables (Fig. 13)

or (Fig. 14).

(3) Reinstall the battery hold downs onto the bat-

tery. Refer toBattery Hold DownsCAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reverse battery polarity may damage

electrical components of the vehicle.

(4) Clean the battery cable terminal clamps and

the battery terminal posts.

Fig. 12 Remove Battery Cable Terminal Clamp -

Typical

1 - BATTERY

2 - BATTERY TERMINAL PULLER

Fig. 13 Battery Cables - 4.0L Engine

1 - BATTERY POSITIVE CABLE

2 - BATTERY NEGATIVE CABLE

3 - CLIPS

Fig. 14 Battery Cables - 4.7L Engine

1 - BATTERY POSITIVE CABLE

2 - BATTERY NEGATIVE CABLE

3 - CLIPS

WJBATTERY SYSTEM 8F - 15

BATTERY (Continued)

Page 347 of 2199

(5) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 6.8 N´m (60

in. lbs.).

(6) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 6.8 N´m (

60 in. lbs.).

(7) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

BATTERY HOLDDOWN

DESCRIPTION

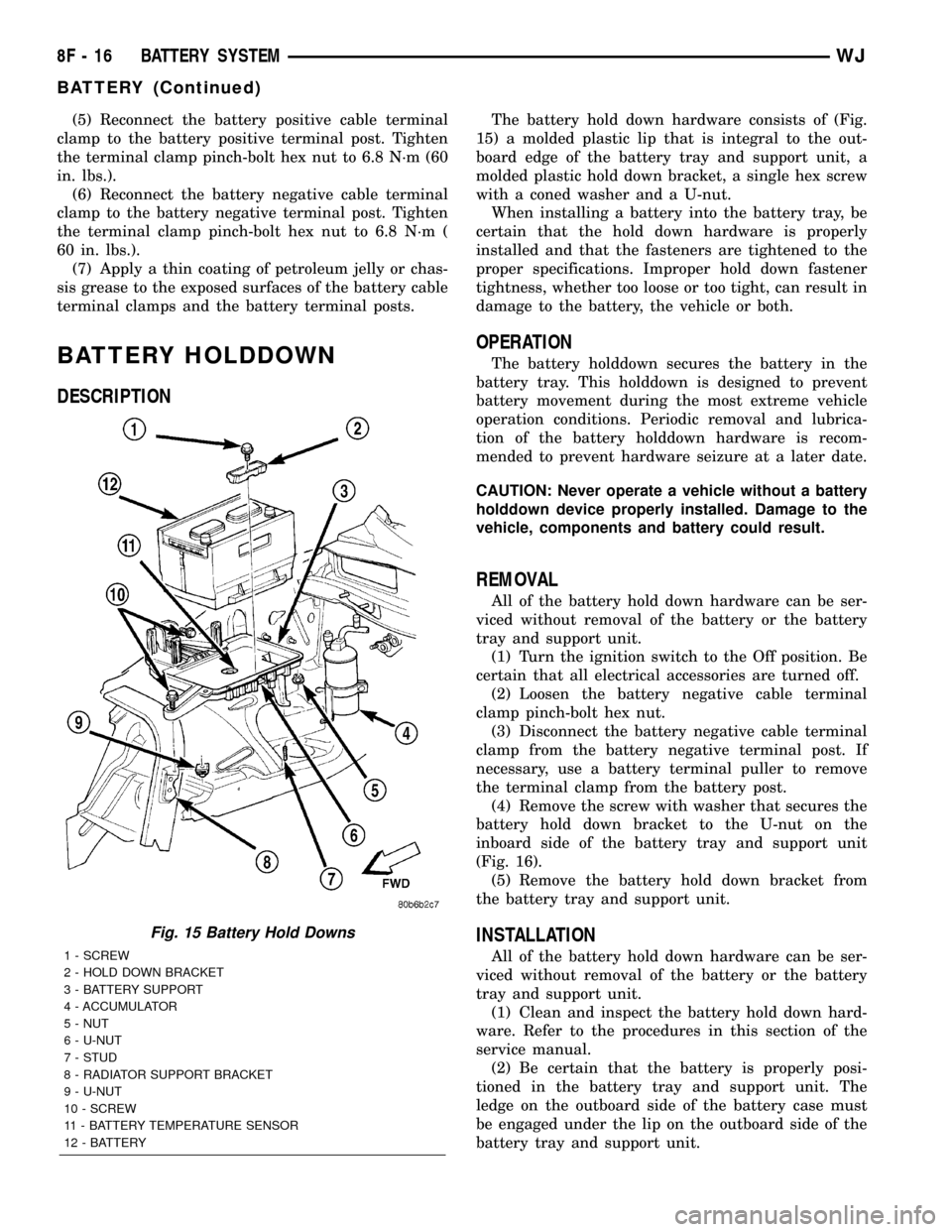

The battery hold down hardware consists of (Fig.

15) a molded plastic lip that is integral to the out-

board edge of the battery tray and support unit, a

molded plastic hold down bracket, a single hex screw

with a coned washer and a U-nut.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

CAUTION: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(4) Remove the screw with washer that secures the

battery hold down bracket to the U-nut on the

inboard side of the battery tray and support unit

(Fig. 16).

(5) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Clean and inspect the battery hold down hard-

ware. Refer to the procedures in this section of the

service manual.

(2) Be certain that the battery is properly posi-

tioned in the battery tray and support unit. The

ledge on the outboard side of the battery case must

be engaged under the lip on the outboard side of the

battery tray and support unit.

Fig. 15 Battery Hold Downs

1 - SCREW

2 - HOLD DOWN BRACKET

3 - BATTERY SUPPORT

4 - ACCUMULATOR

5 - NUT

6 - U-NUT

7 - STUD

8 - RADIATOR SUPPORT BRACKET

9 - U-NUT

10 - SCREW

11 - BATTERY TEMPERATURE SENSOR

12 - BATTERY

8F - 16 BATTERY SYSTEMWJ

BATTERY (Continued)

Page 351 of 2199

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Unlatch and open the cover on the Power Dis-

tribution Center (PDC).

(7) Remove the two nuts that secure the battery

positive cable and generator output cable eyelet ter-

minal to the B(+) terminal studs in the PDC.

(8) Remove the battery positive cable and genera-

tor output cable eyelet terminal from the B(+) termi-

nal studs in the PDC.

(9) Disconnect the battery wire harness connector

from the right headlamp and dash wire harness con-

nector located near the front of the battery.

(10) Remove the screw that secures the battery

negative cable eyelet terminal to the inner fender

shield near the front of the battery.

(11) On models with the 4.7L engine, remove the

nut that secures the battery harness clip to the stud

on the right side of the intake manifold and remove

the clip from the stud.

(12) Unlatch and remove the cover from the gener-

ator output terminal stud housing on the back of the

generator.

(13) Remove the nut that secures the generator

output cable eyelet terminal to the generator output

terminal stud.

(14) Remove the generator output cable eyelet ter-

minal from the generator output terminal stud.

(15) Disconnect the battery wire harness connector

from the generator field terminal connector recepta-

cle on the back of the generator.(16) Remove the screw that secures the battery

negative cable ground eyelet terminal to the right

side of the engine block.

(17) Remove the nut that secures the battery pos-

itive cable eyelet terminal to the B(+) terminal stud

on the starter solenoid.

(18) Remove the battery positive cable eyelet ter-

minal from the B(+) terminal stud on the starter

solenoid.

(19) Disconnect the battery wire harness connector

from the connector receptacle on the starter solenoid.

(20) Remove the battery wire harness from the

engine compartment.

INSTALLATION

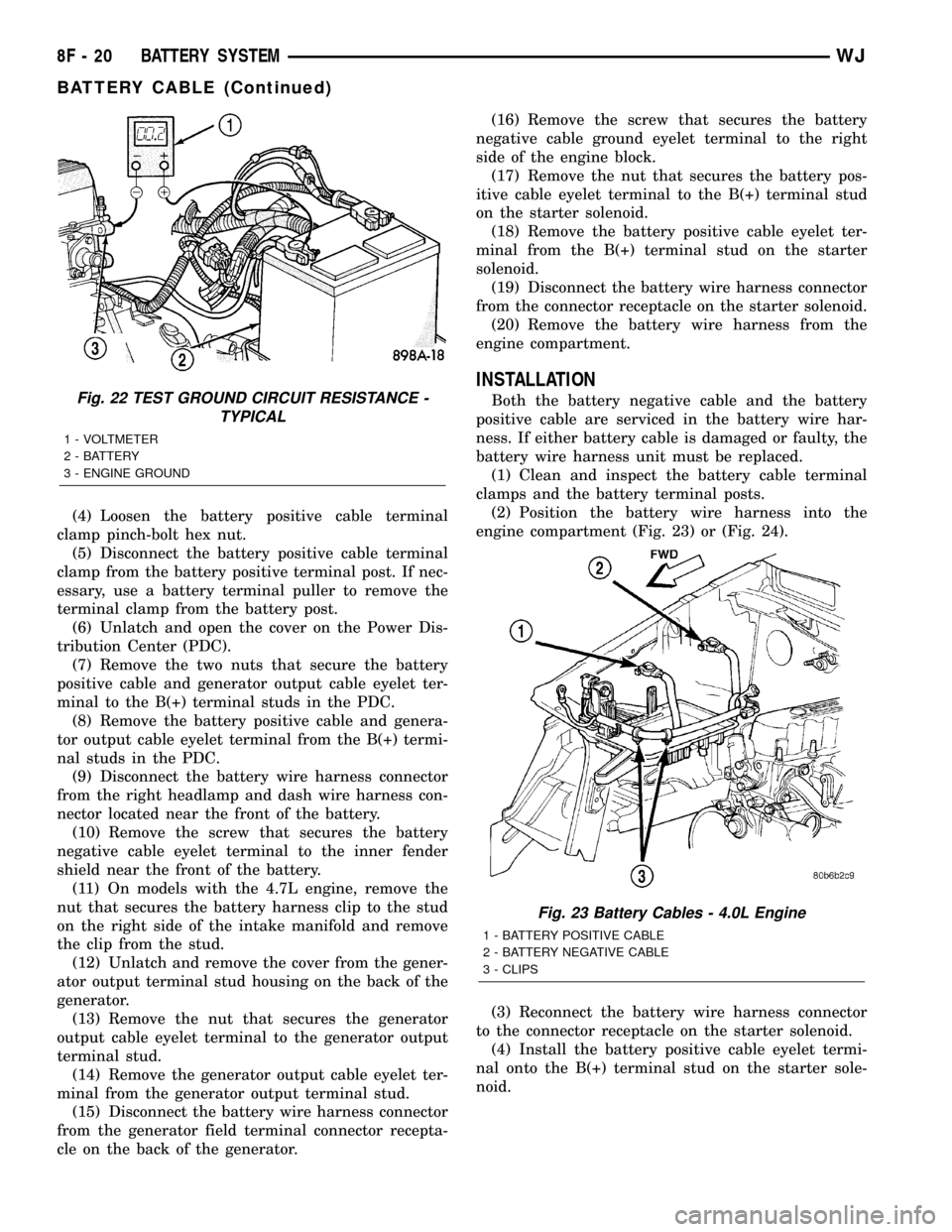

Both the battery negative cable and the battery

positive cable are serviced in the battery wire har-

ness. If either battery cable is damaged or faulty, the

battery wire harness unit must be replaced.

(1) Clean and inspect the battery cable terminal

clamps and the battery terminal posts.

(2) Position the battery wire harness into the

engine compartment (Fig. 23) or (Fig. 24).

(3) Reconnect the battery wire harness connector

to the connector receptacle on the starter solenoid.

(4) Install the battery positive cable eyelet termi-

nal onto the B(+) terminal stud on the starter sole-

noid.Fig. 22 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 23 Battery Cables - 4.0L Engine

1 - BATTERY POSITIVE CABLE

2 - BATTERY NEGATIVE CABLE

3 - CLIPS

8F - 20 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 354 of 2199

INSTALLATION

(1) Clean and inspect the battery tray and support

unit. Refer to the procedures in this section of the

service manual.

(2) Install the battery temperature sensor onto the

battery tray. Refer toBattery Temperature Sensor

in the Charging section of this service manual for

battery temperature sensor installation procedure.

(3) Position the battery tray and support unit into

the right front corner of the engine compartment. Be

certain that no hoses or wire harnesses are trapped

or pinched by the installation of the tray.

(4) Install and tighten the one nut that secures the

rear of the battery tray and support unit to the stud

on the right fender front wheelhouse inner panel.

Tighten the nut to 7.3 N´m (65 in. lbs.).(5) Install and tighten the one screw that secures

the outboard side of the battery tray and support

unit to the right fender side cowl reinforcement.

Tighten the screw to 8.1 N´m (72 in. lbs.).

(6) Install and tighten the one screw that secures

the front of the battery tray and support unit to the

bracket on the right side of the radiator support.

Tighten the screw to 8.1 N´m (72 in. lbs.).

(7) Install the Power Distribution Center (PDC)

onto the stanchions on the outboard side of the bat-

tery tray and support unit. Refer toPower Distri-

bution Centerin the Power Distribution section of

this service manual for PDC installation procedure.

(8) Install the battery onto the battery tray (Refer

to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY -

INSTALLATION).

WJBATTERY SYSTEM 8F - 23

BATTERY TRAY (Continued)

Page 355 of 2199

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING - CHARGING

SYSTEM............................24

SPECIFICATIONS

GENERATOR RATINGS - GAS POWERED . . 25

TORQUE - GAS POWERED.............25

SPECIAL TOOLS.......................26

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................26OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................26

GENERATOR

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................28

VOLTAGE REGULATOR

DESCRIPTION.........................28

OPERATION...........................28

CHARGING

DESCRIPTION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch

²Battery (refer to 8, Battery for information)

²Battery temperature sensor

²Generator Lamp (if equipped)

²Check Gauges Lamp (if equipped)

²Voltmeter (refer to 8, Instrument Cluster for

information)

²Wiring harness and connections (refer to 8, Wir-

ing for information)

OPERATION

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. When the

ASD relay is on, voltage is supplied to the ASD relay

sense circuit at the PCM. This voltage is connected

through the PCM and supplied to one of the genera-

tor field terminals (Gen. Source +) at the back of the

generator.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

A battery temperature sensor, located in the bat-

tery tray housing, is used to sense battery tempera-

ture. This temperature data, along with data from

monitored line voltage, is used by the PCM to vary

the battery charging rate. This is done by cycling theground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects. Refer to

Diagnostic Trouble Codes in; Powertrain Control

Module; Electronic Control Modules for more DTC

information.

The Check Gauges Lamp (if equipped) monitors:

charging system voltage,engine coolant tempera-

ture and engine oil pressure. If an extreme condition

is indicated, the lamp will be illuminated. This is

done as reminder to check the three gauges. The sig-

nal to activate the lamp is sent via the CCD bus cir-

cuits. The lamp is located on the instrument panel.

Refer to 8, Instrument Cluster for additional infor-

mation.

DIAGNOSIS AND TESTING - CHARGING

SYSTEM

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp (if equipped) is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

8F - 24 CHARGINGWJ

Page 356 of 2199

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test in 8, Battery for more information.

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBtscan tool. Per-

form the following inspections before attaching the

scan tool.(1) Inspect the battery condition. Refer to 8, Bat-

tery for procedures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in 7, Cooling System.

(6) Inspect automatic belt tensioner (if equipped).

Refer to 7, Cooling System for information.

(7) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

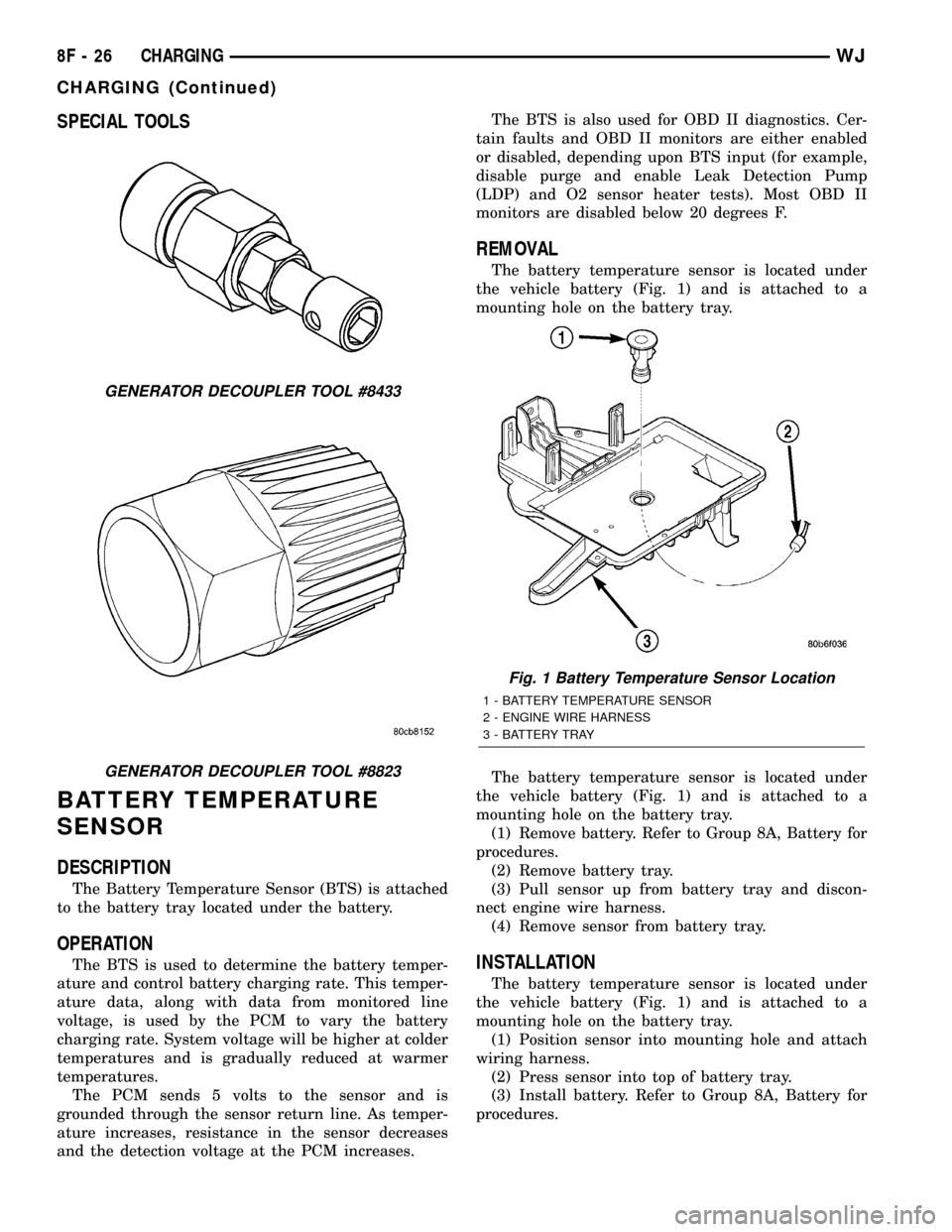

SPECIFICATIONS

GENERATOR RATINGS - GAS POWERED

TYPE PART NUMBER RATED SAE AMPS ENGINES MINIMUM TEST AMPS

BOSCH 56041322 136 4.0L 6-Cylinder 100

DENSO 56041324 136 4.7L V-8 100

TORQUE - GAS POWERED

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Generator Mounting Bolts-4.0L 55 41

Generator Vertical Mounting Bolt-4.7L 40 29

Generator (long) Horizontal Mounting

Bolt-4.7L55 41

Generator (short) Horizontal Mounting

Bolt-4.7L55 41

Generator B+ Terminal Nut 11 95

WJCHARGING 8F - 25

CHARGING (Continued)

Page 357 of 2199

SPECIAL TOOLS

BATTERY TEMPERATURE

SENSOR

DESCRIPTION

The Battery Temperature Sensor (BTS) is attached

to the battery tray located under the battery.

OPERATION

The BTS is used to determine the battery temper-

ature and control battery charging rate. This temper-

ature data, along with data from monitored line

voltage, is used by the PCM to vary the battery

charging rate. System voltage will be higher at colder

temperatures and is gradually reduced at warmer

temperatures.

The PCM sends 5 volts to the sensor and is

grounded through the sensor return line. As temper-

ature increases, resistance in the sensor decreases

and the detection voltage at the PCM increases.The BTS is also used for OBD II diagnostics. Cer-

tain faults and OBD II monitors are either enabled

or disabled, depending upon BTS input (for example,

disable purge and enable Leak Detection Pump

(LDP) and O2 sensor heater tests). Most OBD II

monitors are disabled below 20 degrees F.

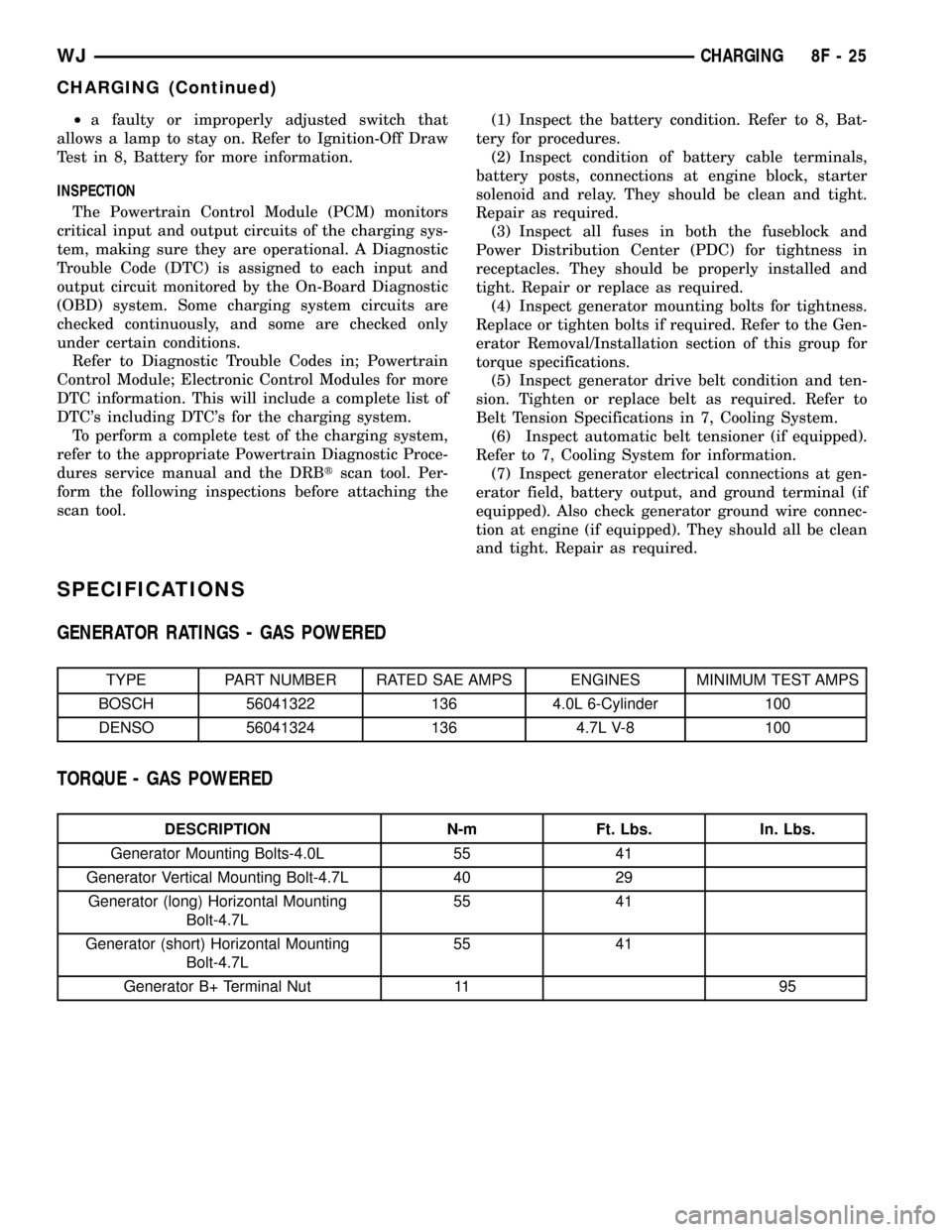

REMOVAL

The battery temperature sensor is located under

the vehicle battery (Fig. 1) and is attached to a

mounting hole on the battery tray.

The battery temperature sensor is located under

the vehicle battery (Fig. 1) and is attached to a

mounting hole on the battery tray.

(1) Remove battery. Refer to Group 8A, Battery for

procedures.

(2) Remove battery tray.

(3) Pull sensor up from battery tray and discon-

nect engine wire harness.

(4) Remove sensor from battery tray.

INSTALLATION

The battery temperature sensor is located under

the vehicle battery (Fig. 1) and is attached to a

mounting hole on the battery tray.

(1) Position sensor into mounting hole and attach

wiring harness.

(2) Press sensor into top of battery tray.

(3) Install battery. Refer to Group 8A, Battery for

procedures.

GENERATOR DECOUPLER TOOL #8433

GENERATOR DECOUPLER TOOL #8823

Fig. 1 Battery Temperature Sensor Location

1 - BATTERY TEMPERATURE SENSOR

2 - ENGINE WIRE HARNESS

3 - BATTERY TRAY

8F - 26 CHARGINGWJ

CHARGING (Continued)

Page 358 of 2199

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Gen-

erator Ratings in the Specifications section at the

back of this group for amperage ratings and part

numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley; incorrect, worn, damaged or misad-

justed fan drive belt; loose mounting bolts; a

misaligned drive pulley or a defective stator or diode.

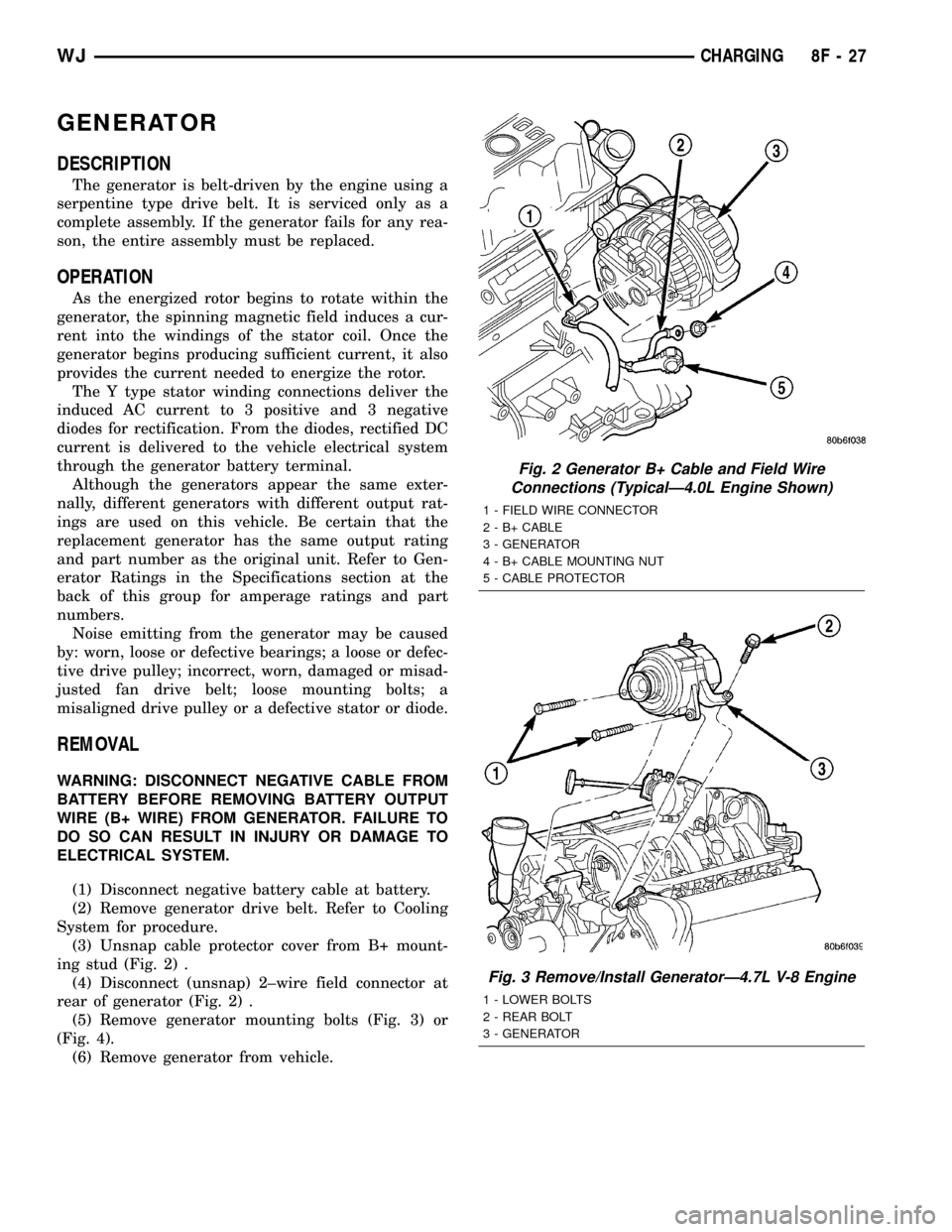

REMOVAL

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE (B+ WIRE) FROM GENERATOR. FAILURE TO

DO SO CAN RESULT IN INJURY OR DAMAGE TO

ELECTRICAL SYSTEM.

(1) Disconnect negative battery cable at battery.

(2) Remove generator drive belt. Refer to Cooling

System for procedure.

(3) Unsnap cable protector cover from B+ mount-

ing stud (Fig. 2) .

(4) Disconnect (unsnap) 2±wire field connector at

rear of generator (Fig. 2) .

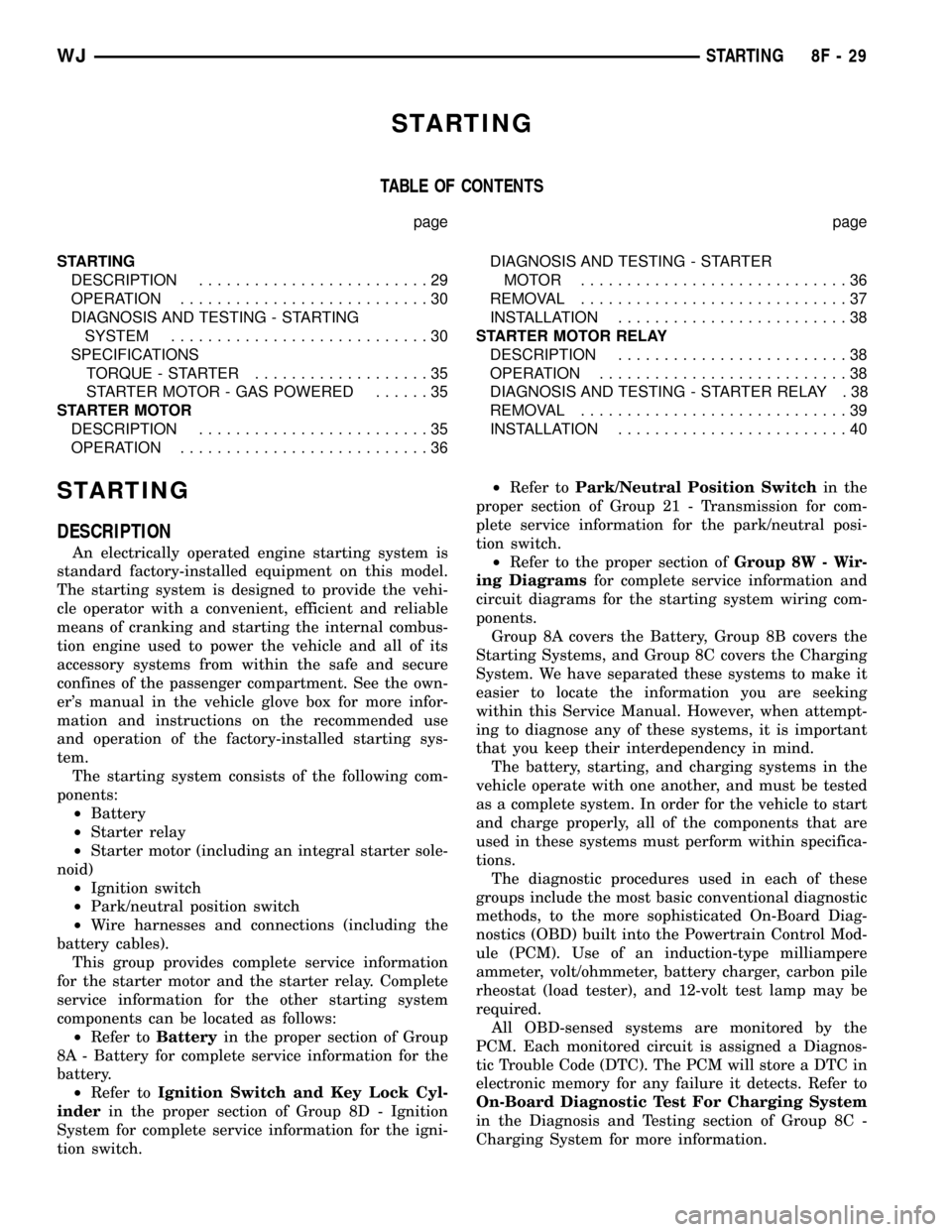

(5) Remove generator mounting bolts (Fig. 3) or

(Fig. 4).

(6) Remove generator from vehicle.

Fig. 2 Generator B+ Cable and Field Wire

Connections (TypicalÐ4.0L Engine Shown)

1 - FIELD WIRE CONNECTOR

2 - B+ CABLE

3 - GENERATOR

4 - B+ CABLE MOUNTING NUT

5 - CABLE PROTECTOR

Fig. 3 Remove/Install GeneratorÐ4.7L V-8 Engine

1 - LOWER BOLTS

2 - REAR BOLT

3 - GENERATOR

WJCHARGING 8F - 27

Page 360 of 2199

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................29

OPERATION...........................30

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................30

SPECIFICATIONS

TORQUE - STARTER...................35

STARTER MOTOR - GAS POWERED......35

STARTER MOTOR

DESCRIPTION.........................35

OPERATION...........................36DIAGNOSIS AND TESTING - STARTER

MOTOR .............................36

REMOVAL.............................37

INSTALLATION.........................38

STARTER MOTOR RELAY

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING - STARTER RELAY . 38

REMOVAL.............................39

INSTALLATION.........................40

STARTING

DESCRIPTION

An electrically operated engine starting system is

standard factory-installed equipment on this model.

The starting system is designed to provide the vehi-

cle operator with a convenient, efficient and reliable

means of cranking and starting the internal combus-

tion engine used to power the vehicle and all of its

accessory systems from within the safe and secure

confines of the passenger compartment. See the own-

er's manual in the vehicle glove box for more infor-

mation and instructions on the recommended use

and operation of the factory-installed starting sys-

tem.

The starting system consists of the following com-

ponents:

²Battery

²Starter relay

²Starter motor (including an integral starter sole-

noid)

²Ignition switch

²Park/neutral position switch

²Wire harnesses and connections (including the

battery cables).

This group provides complete service information

for the starter motor and the starter relay. Complete

service information for the other starting system

components can be located as follows:

²Refer toBatteryin the proper section of Group

8A - Battery for complete service information for the

battery.

²Refer toIgnition Switch and Key Lock Cyl-

inderin the proper section of Group 8D - Ignition

System for complete service information for the igni-

tion switch.²Refer toPark/Neutral Position Switchin the

proper section of Group 21 - Transmission for com-

plete service information for the park/neutral posi-

tion switch.

²Refer to the proper section ofGroup 8W - Wir-

ing Diagramsfor complete service information and

circuit diagrams for the starting system wiring com-

ponents.

Group 8A covers the Battery, Group 8B covers the

Starting Systems, and Group 8C covers the Charging

System. We have separated these systems to make it

easier to locate the information you are seeking

within this Service Manual. However, when attempt-

ing to diagnose any of these systems, it is important

that you keep their interdependency in mind.

The battery, starting, and charging systems in the

vehicle operate with one another, and must be tested

as a complete system. In order for the vehicle to start

and charge properly, all of the components that are

used in these systems must perform within specifica-

tions.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. Refer to

On-Board Diagnostic Test For Charging System

in the Diagnosis and Testing section of Group 8C -

Charging System for more information.

WJSTARTING 8F - 29