CD changer JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 764 of 2199

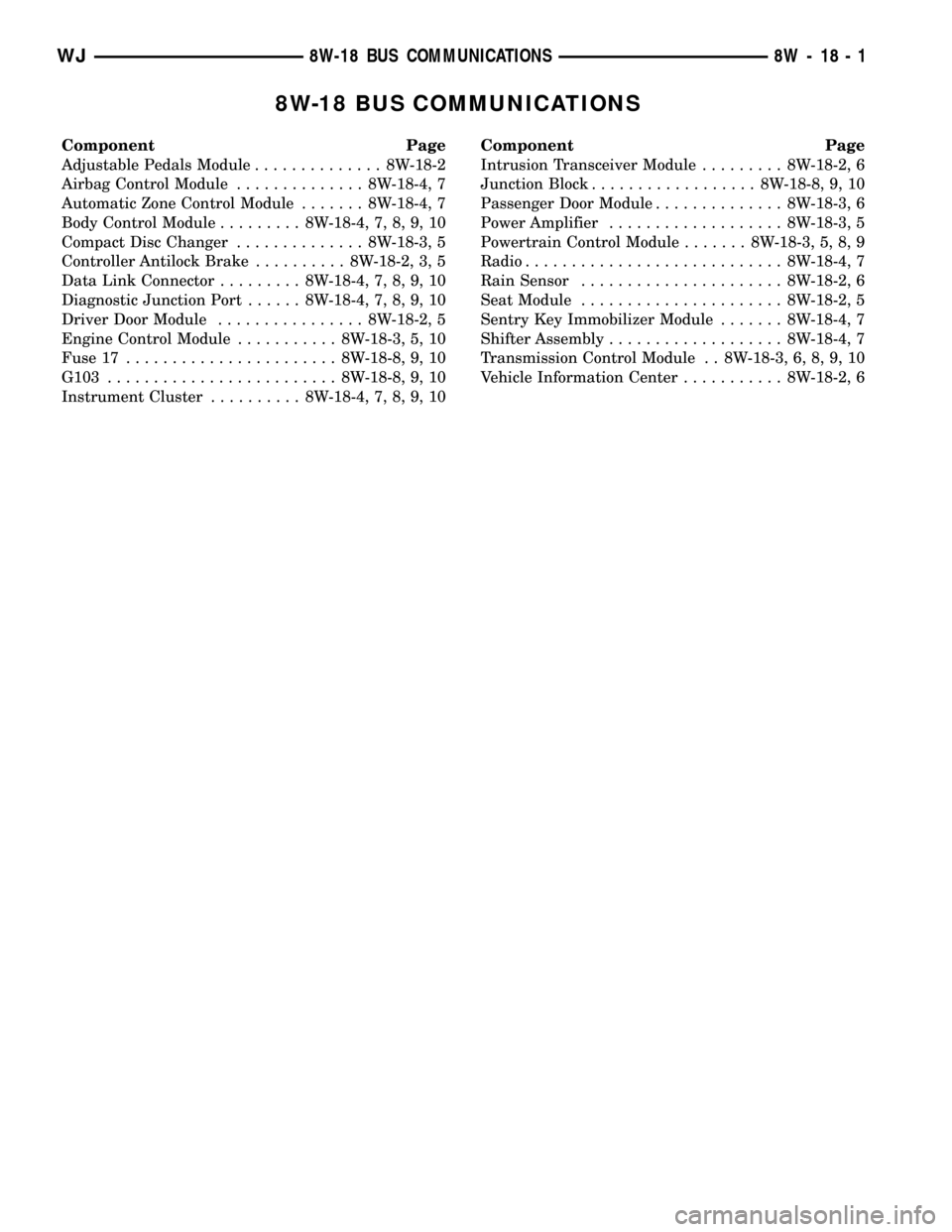

8W-18 BUS COMMUNICATIONS

Component Page

Adjustable Pedals Module.............. 8W-18-2

Airbag Control Module.............. 8W-18-4, 7

Automatic Zone Control Module....... 8W-18-4, 7

Body Control Module......... 8W-18-4, 7, 8, 9, 10

Compact Disc Changer.............. 8W-18-3, 5

Controller Antilock Brake.......... 8W-18-2, 3, 5

Data Link Connector......... 8W-18-4, 7, 8, 9, 10

Diagnostic Junction Port...... 8W-18-4, 7, 8, 9, 10

Driver Door Module................ 8W-18-2, 5

Engine Control Module........... 8W-18-3, 5, 10

Fuse 17....................... 8W-18-8, 9, 10

G103......................... 8W-18-8, 9, 10

Instrument Cluster.......... 8W-18-4, 7, 8, 9, 10Component Page

Intrusion Transceiver Module......... 8W-18-2, 6

Junction Block.................. 8W-18-8, 9, 10

Passenger Door Module.............. 8W-18-3, 6

Power Amplifier................... 8W-18-3, 5

Powertrain Control Module....... 8W-18-3, 5, 8, 9

Radio............................ 8W-18-4, 7

Rain Sensor...................... 8W-18-2, 6

Seat Module...................... 8W-18-2, 5

Sentry Key Immobilizer Module....... 8W-18-4, 7

Shifter Assembly................... 8W-18-4, 7

Transmission Control Module . . 8W-18-3, 6, 8, 9, 10

Vehicle Information Center........... 8W-18-2, 6

WJ8W-18 BUS COMMUNICATIONS 8W - 18 - 1

Page 932 of 2199

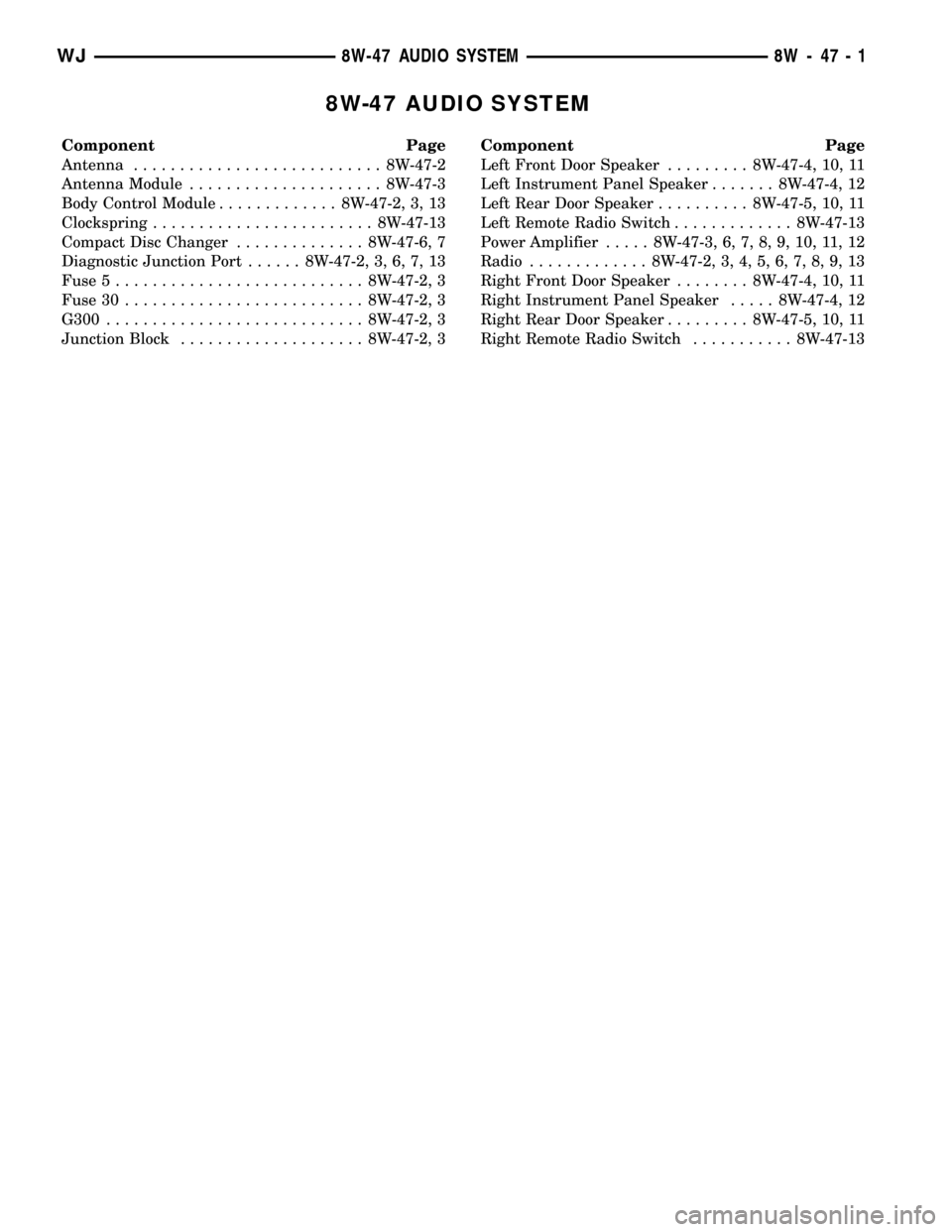

8W-47 AUDIO SYSTEM

Component Page

Antenna........................... 8W-47-2

Antenna Module..................... 8W-47-3

Body Control Module............. 8W-47-2, 3, 13

Clockspring........................ 8W-47-13

Compact Disc Changer.............. 8W-47-6, 7

Diagnostic Junction Port...... 8W-47-2, 3, 6, 7, 13

Fuse 5........................... 8W-47-2, 3

Fuse 30.......................... 8W-47-2, 3

G300............................ 8W-47-2, 3

Junction Block.................... 8W-47-2, 3Component Page

Left Front Door Speaker......... 8W-47-4, 10, 11

Left Instrument Panel Speaker....... 8W-47-4, 12

Left Rear Door Speaker.......... 8W-47-5, 10, 11

Left Remote Radio Switch............. 8W-47-13

Power Amplifier..... 8W-47-3, 6, 7, 8, 9, 10, 11, 12

Radio............. 8W-47-2, 3, 4, 5, 6, 7, 8, 9, 13

Right Front Door Speaker........ 8W-47-4, 10, 11

Right Instrument Panel Speaker..... 8W-47-4, 12

Right Rear Door Speaker......... 8W-47-5, 10, 11

Right Remote Radio Switch........... 8W-47-13

WJ8W-47 AUDIO SYSTEM 8W - 47 - 1

Page 1049 of 2199

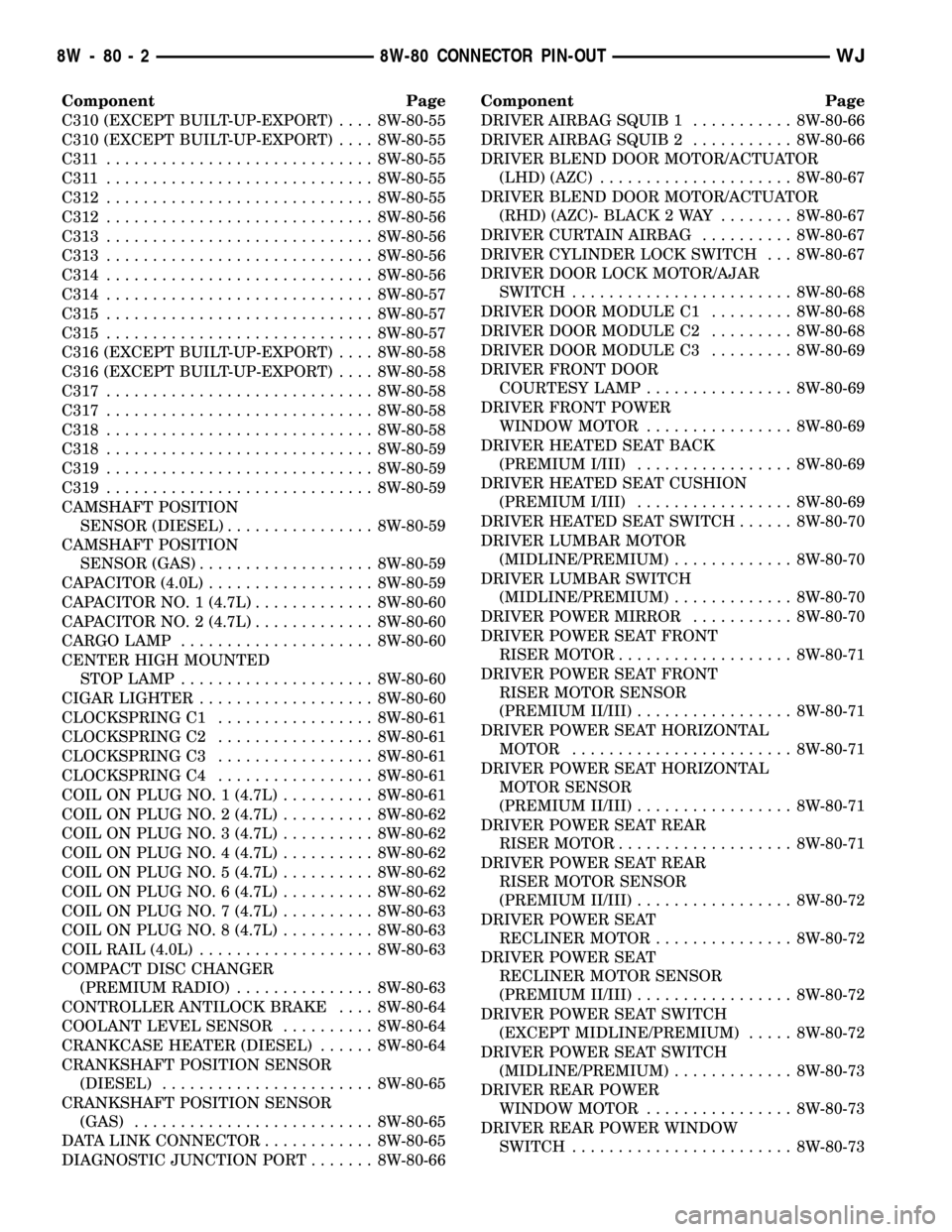

Component Page

C310 (EXCEPT BUILT-UP-EXPORT).... 8W-80-55

C310 (EXCEPT BUILT-UP-EXPORT).... 8W-80-55

C311 ............................. 8W-80-55

C311 ............................. 8W-80-55

C312............................. 8W-80-55

C312............................. 8W-80-56

C313............................. 8W-80-56

C313............................. 8W-80-56

C314............................. 8W-80-56

C314............................. 8W-80-57

C315............................. 8W-80-57

C315............................. 8W-80-57

C316 (EXCEPT BUILT-UP-EXPORT).... 8W-80-58

C316 (EXCEPT BUILT-UP-EXPORT).... 8W-80-58

C317............................. 8W-80-58

C317............................. 8W-80-58

C318............................. 8W-80-58

C318............................. 8W-80-59

C319............................. 8W-80-59

C319............................. 8W-80-59

CAMSHAFT POSITION

SENSOR (DIESEL)................ 8W-80-59

CAMSHAFT POSITION

SENSOR (GAS)................... 8W-80-59

CAPACITOR (4.0L).................. 8W-80-59

CAPACITOR NO. 1 (4.7L)............. 8W-80-60

CAPACITOR NO. 2 (4.7L)............. 8W-80-60

CARGO LAMP..................... 8W-80-60

CENTER HIGH MOUNTED

STOP LAMP..................... 8W-80-60

CIGAR LIGHTER................... 8W-80-60

CLOCKSPRING C1................. 8W-80-61

CLOCKSPRING C2................. 8W-80-61

CLOCKSPRING C3................. 8W-80-61

CLOCKSPRING C4................. 8W-80-61

COIL ON PLUG NO. 1 (4.7L).......... 8W-80-61

COIL ON PLUG NO. 2 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 3 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 4 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 5 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 6 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 7 (4.7L).......... 8W-80-63

COIL ON PLUG NO. 8 (4.7L).......... 8W-80-63

COIL RAIL (4.0L)................... 8W-80-63

COMPACT DISC CHANGER

(PREMIUM RADIO)............... 8W-80-63

CONTROLLER ANTILOCK BRAKE.... 8W-80-64

COOLANT LEVEL SENSOR.......... 8W-80-64

CRANKCASE HEATER (DIESEL)...... 8W-80-64

CRANKSHAFT POSITION SENSOR

(DIESEL)....................... 8W-80-65

CRANKSHAFT POSITION SENSOR

(GAS).......................... 8W-80-65

DATA LINK CONNECTOR............ 8W-80-65

DIAGNOSTIC JUNCTION PORT....... 8W-80-66Component Page

DRIVER AIRBAG SQUIB 1........... 8W-80-66

DRIVER AIRBAG SQUIB 2........... 8W-80-66

DRIVER BLEND DOOR MOTOR/ACTUATOR

(LHD) (AZC)..................... 8W-80-67

DRIVER BLEND DOOR MOTOR/ACTUATOR

(RHD) (AZC)- BLACK 2 WAY........ 8W-80-67

DRIVER CURTAIN AIRBAG.......... 8W-80-67

DRIVER CYLINDER LOCK SWITCH . . . 8W-80-67

DRIVER DOOR LOCK MOTOR/AJAR

SWITCH........................ 8W-80-68

DRIVER DOOR MODULE C1......... 8W-80-68

DRIVER DOOR MODULE C2......... 8W-80-68

DRIVER DOOR MODULE C3......... 8W-80-69

DRIVER FRONT DOOR

COURTESY LAMP................ 8W-80-69

DRIVER FRONT POWER

WINDOW MOTOR................ 8W-80-69

DRIVER HEATED SEAT BACK

(PREMIUM I/III)................. 8W-80-69

DRIVER HEATED SEAT CUSHION

(PREMIUM I/III)................. 8W-80-69

DRIVER HEATED SEAT SWITCH...... 8W-80-70

DRIVER LUMBAR MOTOR

(MIDLINE/PREMIUM)............. 8W-80-70

DRIVER LUMBAR SWITCH

(MIDLINE/PREMIUM)............. 8W-80-70

DRIVER POWER MIRROR........... 8W-80-70

DRIVER POWER SEAT FRONT

RISER MOTOR................... 8W-80-71

DRIVER POWER SEAT FRONT

RISER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-71

DRIVER POWER SEAT HORIZONTAL

MOTOR........................ 8W-80-71

DRIVER POWER SEAT HORIZONTAL

MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-71

DRIVER POWER SEAT REAR

RISER MOTOR................... 8W-80-71

DRIVER POWER SEAT REAR

RISER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-72

DRIVER POWER SEAT

RECLINER MOTOR............... 8W-80-72

DRIVER POWER SEAT

RECLINER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-72

DRIVER POWER SEAT SWITCH

(EXCEPT MIDLINE/PREMIUM)..... 8W-80-72

DRIVER POWER SEAT SWITCH

(MIDLINE/PREMIUM)............. 8W-80-73

DRIVER REAR POWER

WINDOW MOTOR................ 8W-80-73

DRIVER REAR POWER WINDOW

SWITCH........................ 8W-80-73

8W - 80 - 2 8W-80 CONNECTOR PIN-OUTWJ

Page 1110 of 2199

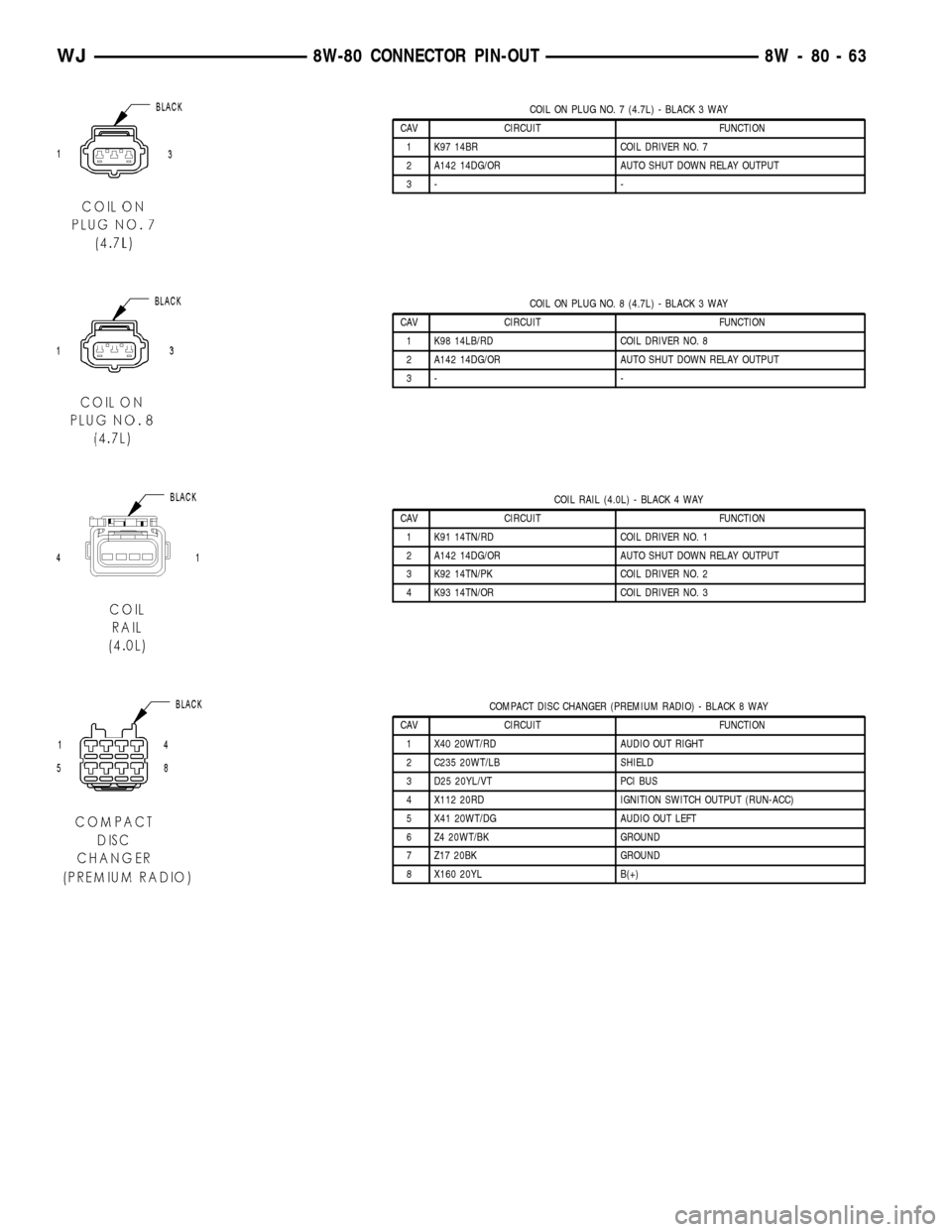

COIL ON PLUG NO. 7 (4.7L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K97 14BR COIL DRIVER NO. 7

2 A142 14DG/OR AUTO SHUT DOWN RELAY OUTPUT

3- -

COIL ON PLUG NO. 8 (4.7L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K98 14LB/RD COIL DRIVER NO. 8

2 A142 14DG/OR AUTO SHUT DOWN RELAY OUTPUT

3- -

COIL RAIL (4.0L) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 K91 14TN/RD COIL DRIVER NO. 1

2 A142 14DG/OR AUTO SHUT DOWN RELAY OUTPUT

3 K92 14TN/PK COIL DRIVER NO. 2

4 K93 14TN/OR COIL DRIVER NO. 3

COMPACT DISC CHANGER (PREMIUM RADIO) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 X40 20WT/RD AUDIO OUT RIGHT

2 C235 20WT/LB SHIELD

3 D25 20YL/VT PCI BUS

4 X112 20RD IGNITION SWITCH OUTPUT (RUN-ACC)

5 X41 20WT/DG AUDIO OUT LEFT

6 Z4 20WT/BK GROUND

7 Z17 20BK GROUND

8 X160 20YL B(+)

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 63

Page 1179 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1872 of 2199

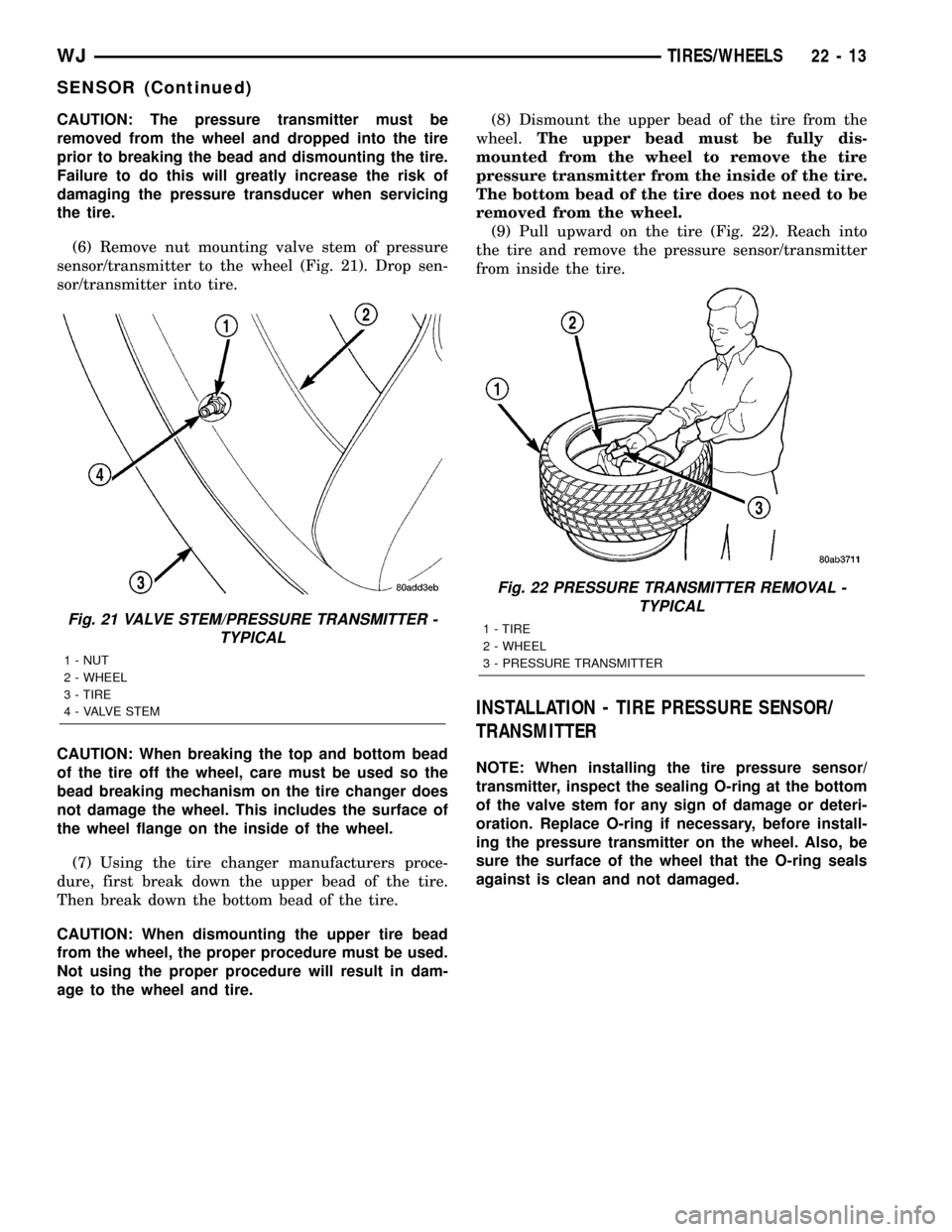

CAUTION: The pressure transmitter must be

removed from the wheel and dropped into the tire

prior to breaking the bead and dismounting the tire.

Failure to do this will greatly increase the risk of

damaging the pressure transducer when servicing

the tire.

(6) Remove nut mounting valve stem of pressure

sensor/transmitter to the wheel (Fig. 21). Drop sen-

sor/transmitter into tire.

CAUTION: When breaking the top and bottom bead

of the tire off the wheel, care must be used so the

bead breaking mechanism on the tire changer does

not damage the wheel. This includes the surface of

the wheel flange on the inside of the wheel.

(7) Using the tire changer manufacturers proce-

dure, first break down the upper bead of the tire.

Then break down the bottom bead of the tire.

CAUTION: When dismounting the upper tire bead

from the wheel, the proper procedure must be used.

Not using the proper procedure will result in dam-

age to the wheel and tire.(8) Dismount the upper bead of the tire from the

wheel.The upper bead must be fully dis-

mounted from the wheel to remove the tire

pressure transmitter from the inside of the tire.

The bottom bead of the tire does not need to be

removed from the wheel.

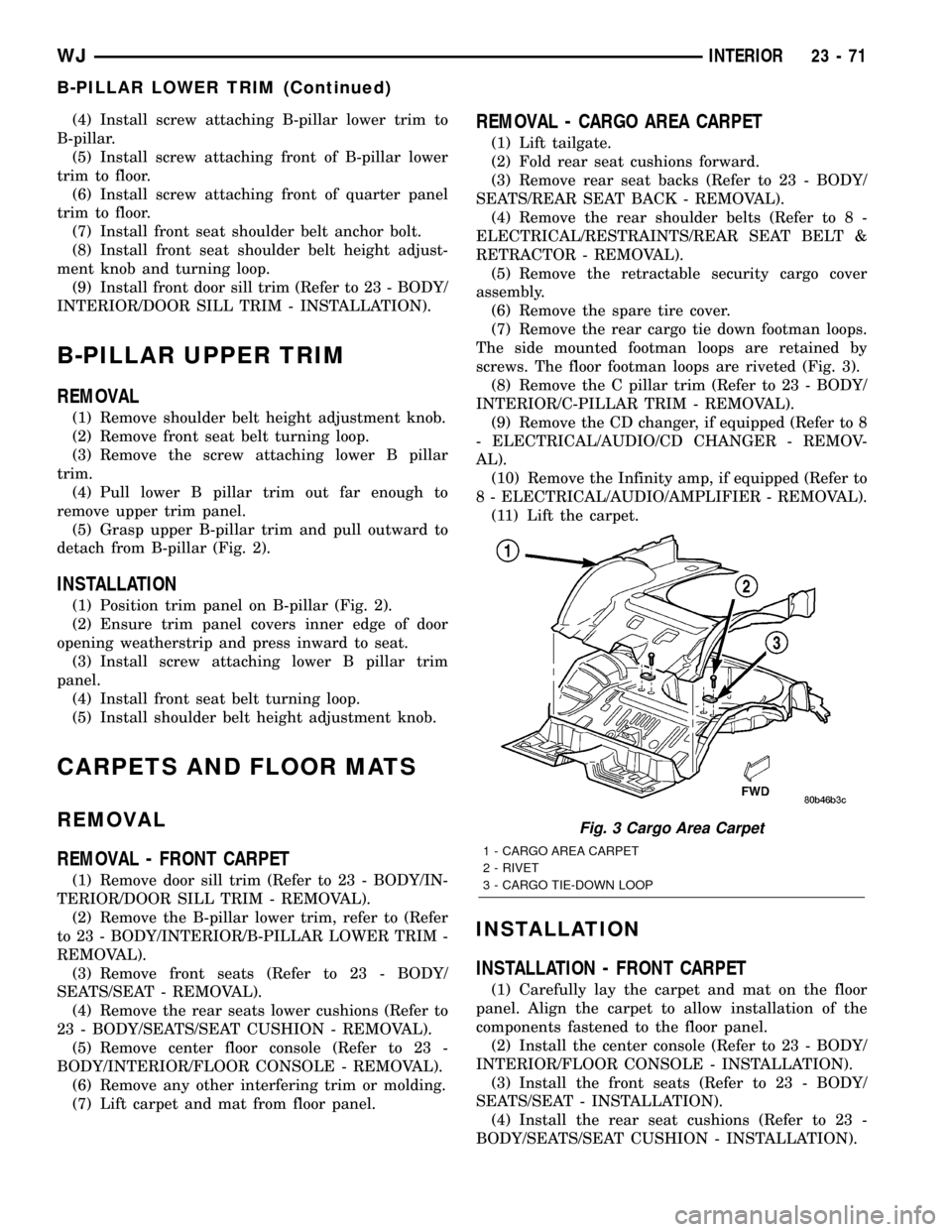

(9) Pull upward on the tire (Fig. 22). Reach into

the tire and remove the pressure sensor/transmitter

from inside the tire.

INSTALLATION - TIRE PRESSURE SENSOR/

TRANSMITTER

NOTE: When installing the tire pressure sensor/

transmitter, inspect the sealing O-ring at the bottom

of the valve stem for any sign of damage or deteri-

oration. Replace O-ring if necessary, before install-

ing the pressure transmitter on the wheel. Also, be

sure the surface of the wheel that the O-ring seals

against is clean and not damaged.

Fig. 21 VALVE STEM/PRESSURE TRANSMITTER -

TYPICAL

1 - NUT

2 - WHEEL

3 - TIRE

4 - VALVE STEM

Fig. 22 PRESSURE TRANSMITTER REMOVAL -

TYPICAL

1 - TIRE

2 - WHEEL

3 - PRESSURE TRANSMITTER

WJTIRES/WHEELS 22 - 13

SENSOR (Continued)

Page 1944 of 2199

(4) Install screw attaching B-pillar lower trim to

B-pillar.

(5) Install screw attaching front of B-pillar lower

trim to floor.

(6) Install screw attaching front of quarter panel

trim to floor.

(7) Install front seat shoulder belt anchor bolt.

(8) Install front seat shoulder belt height adjust-

ment knob and turning loop.

(9) Install front door sill trim (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - INSTALLATION).

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove shoulder belt height adjustment knob.

(2) Remove front seat belt turning loop.

(3) Remove the screw attaching lower B pillar

trim.

(4) Pull lower B pillar trim out far enough to

remove upper trim panel.

(5) Grasp upper B-pillar trim and pull outward to

detach from B-pillar (Fig. 2).

INSTALLATION

(1) Position trim panel on B-pillar (Fig. 2).

(2) Ensure trim panel covers inner edge of door

opening weatherstrip and press inward to seat.

(3) Install screw attaching lower B pillar trim

panel.

(4) Install front seat belt turning loop.

(5) Install shoulder belt height adjustment knob.

CARPETS AND FLOOR MATS

REMOVAL

REMOVAL - FRONT CARPET

(1) Remove door sill trim (Refer to 23 - BODY/IN-

TERIOR/DOOR SILL TRIM - REMOVAL).

(2) Remove the B-pillar lower trim, refer to (Refer

to 23 - BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

(3) Remove front seats (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL).

(4) Remove the rear seats lower cushions (Refer to

23 - BODY/SEATS/SEAT CUSHION - REMOVAL).

(5) Remove center floor console (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - REMOVAL).

(6) Remove any other interfering trim or molding.

(7) Lift carpet and mat from floor panel.

REMOVAL - CARGO AREA CARPET

(1) Lift tailgate.

(2) Fold rear seat cushions forward.

(3) Remove rear seat backs (Refer to 23 - BODY/

SEATS/REAR SEAT BACK - REMOVAL).

(4) Remove the rear shoulder belts (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR SEAT BELT &

RETRACTOR - REMOVAL).

(5) Remove the retractable security cargo cover

assembly.

(6) Remove the spare tire cover.

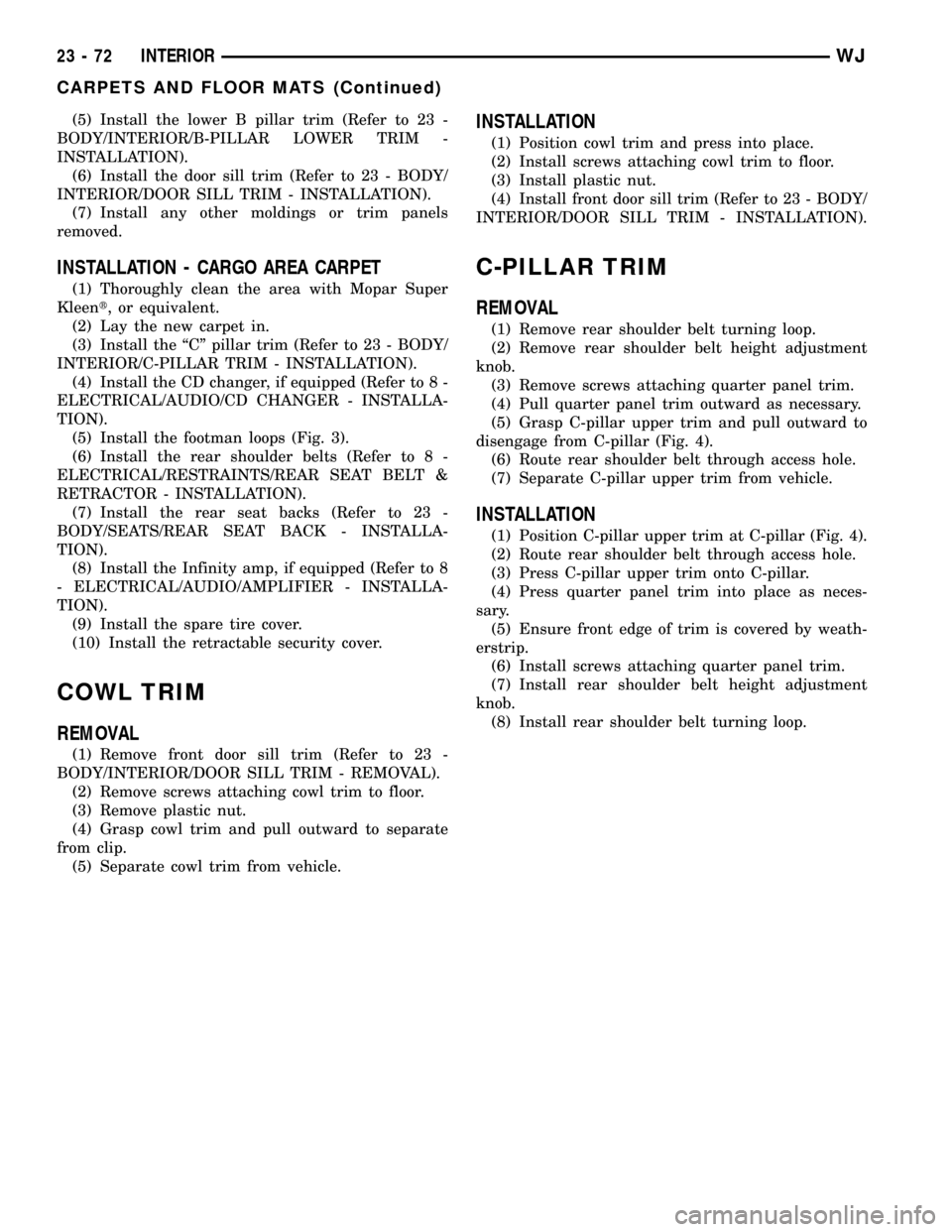

(7) Remove the rear cargo tie down footman loops.

The side mounted footman loops are retained by

screws. The floor footman loops are riveted (Fig. 3).

(8) Remove the C pillar trim (Refer to 23 - BODY/

INTERIOR/C-PILLAR TRIM - REMOVAL).

(9) Remove the CD changer, if equipped (Refer to 8

- ELECTRICAL/AUDIO/CD CHANGER - REMOV-

AL).

(10) Remove the Infinity amp, if equipped (Refer to

8 - ELECTRICAL/AUDIO/AMPLIFIER - REMOVAL).

(11) Lift the carpet.

INSTALLATION

INSTALLATION - FRONT CARPET

(1) Carefully lay the carpet and mat on the floor

panel. Align the carpet to allow installation of the

components fastened to the floor panel.

(2) Install the center console (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION).

(3) Install the front seats (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(4) Install the rear seat cushions (Refer to 23 -

BODY/SEATS/SEAT CUSHION - INSTALLATION).

Fig. 3 Cargo Area Carpet

1 - CARGO AREA CARPET

2 - RIVET

3 - CARGO TIE-DOWN LOOP

WJINTERIOR 23 - 71

B-PILLAR LOWER TRIM (Continued)

Page 1945 of 2199

(5) Install the lower B pillar trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

INSTALLATION).

(6) Install the door sill trim (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - INSTALLATION).

(7) Install any other moldings or trim panels

removed.

INSTALLATION - CARGO AREA CARPET

(1) Thoroughly clean the area with Mopar Super

Kleent, or equivalent.

(2) Lay the new carpet in.

(3) Install the ªCº pillar trim (Refer to 23 - BODY/

INTERIOR/C-PILLAR TRIM - INSTALLATION).

(4) Install the CD changer, if equipped (Refer to 8 -

ELECTRICAL/AUDIO/CD CHANGER - INSTALLA-

TION).

(5) Install the footman loops (Fig. 3).

(6) Install the rear shoulder belts (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR SEAT BELT &

RETRACTOR - INSTALLATION).

(7) Install the rear seat backs (Refer to 23 -

BODY/SEATS/REAR SEAT BACK - INSTALLA-

TION).

(8) Install the Infinity amp, if equipped (Refer to 8

- ELECTRICAL/AUDIO/AMPLIFIER - INSTALLA-

TION).

(9) Install the spare tire cover.

(10) Install the retractable security cover.

COWL TRIM

REMOVAL

(1) Remove front door sill trim (Refer to 23 -

BODY/INTERIOR/DOOR SILL TRIM - REMOVAL).

(2) Remove screws attaching cowl trim to floor.

(3) Remove plastic nut.

(4) Grasp cowl trim and pull outward to separate

from clip.

(5) Separate cowl trim from vehicle.

INSTALLATION

(1) Position cowl trim and press into place.

(2) Install screws attaching cowl trim to floor.

(3) Install plastic nut.

(4) Install front door sill trim (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - INSTALLATION).

C-PILLAR TRIM

REMOVAL

(1) Remove rear shoulder belt turning loop.

(2) Remove rear shoulder belt height adjustment

knob.

(3) Remove screws attaching quarter panel trim.

(4) Pull quarter panel trim outward as necessary.

(5) Grasp C-pillar upper trim and pull outward to

disengage from C-pillar (Fig. 4).

(6) Route rear shoulder belt through access hole.

(7) Separate C-pillar upper trim from vehicle.

INSTALLATION

(1) Position C-pillar upper trim at C-pillar (Fig. 4).

(2) Route rear shoulder belt through access hole.

(3) Press C-pillar upper trim onto C-pillar.

(4) Press quarter panel trim into place as neces-

sary.

(5) Ensure front edge of trim is covered by weath-

erstrip.

(6) Install screws attaching quarter panel trim.

(7) Install rear shoulder belt height adjustment

knob.

(8) Install rear shoulder belt turning loop.

23 - 72 INTERIORWJ

CARPETS AND FLOOR MATS (Continued)

Page 2139 of 2199

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(9) Connect the negative battery cable.

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow in front of

the engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When the refrigerant gas gives up its heat, it con-

denses. When the refrigerant leaves the condenser, it

has become a high-pressure liquid refrigerant. The

volume of air flowing over the condenser fins is crit-

ical to the proper cooling performance of the air con-

ditioning system. Therefore, it is important that

there are no objects placed in front of the radiator

grille openings in the front of the vehicle or foreign

material on the condenser fins that might obstruct

proper air flow. Also, any factory-installed air seals or

shrouds must be properly reinstalled following radia-

tor or condenser service.

The condenser cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS GROUP BEFORE

PERFORMING THE FOLLOWING OPERATION.

CAUTION: Before removing the condenser, note the

location of each of the radiator and condenser air

seals. These seals are used to direct air through the

condenser and radiator. The air seals must be rein-

stalled in their proper locations in order for the air

conditioning and engine cooling systems to per-

form as designed.(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the screws attaching the grille and

headlamp mounting module to the upper crossmem-

ber of the vehicle. Refer to Body for this and further

steps in the procedure.

(4) Remove the headlamps from their mounts.

(5) Remove the nuts that secure the hood latch

and brace to the upper crossmember.

(6) The radiator upper crossmember can be

adjusted left or right through the use of its slotted

mounting holes. Before removal, mark the original

position of the crossmember.

(7) Remove the bolts that secure the radiator to

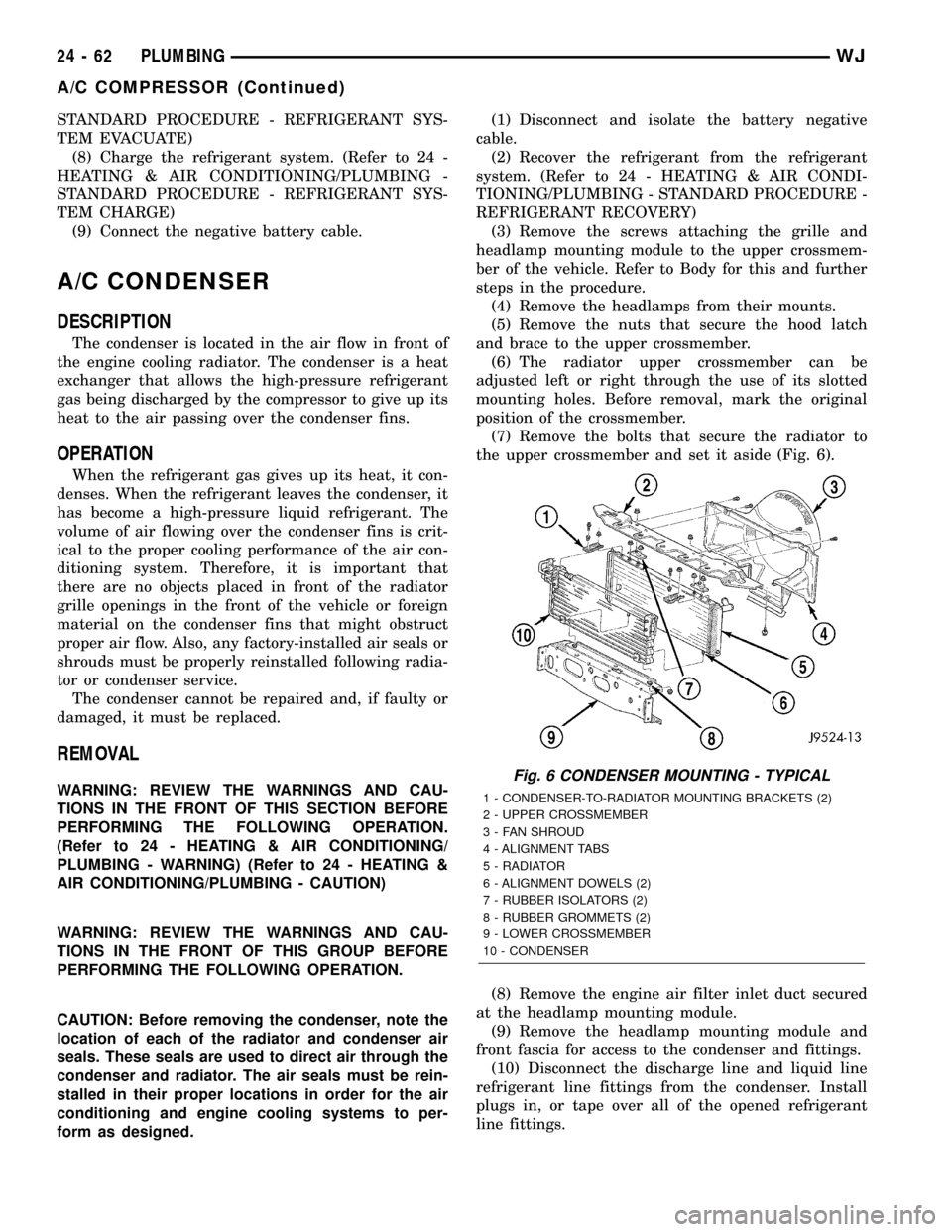

the upper crossmember and set it aside (Fig. 6).

(8) Remove the engine air filter inlet duct secured

at the headlamp mounting module.

(9) Remove the headlamp mounting module and

front fascia for access to the condenser and fittings.

(10) Disconnect the discharge line and liquid line

refrigerant line fittings from the condenser. Install

plugs in, or tape over all of the opened refrigerant

line fittings.Fig. 6 CONDENSER MOUNTING - TYPICAL

1 - CONDENSER-TO-RADIATOR MOUNTING BRACKETS (2)

2 - UPPER CROSSMEMBER

3 - FAN SHROUD

4 - ALIGNMENT TABS

5 - RADIATOR

6 - ALIGNMENT DOWELS (2)

7 - RUBBER ISOLATORS (2)

8 - RUBBER GROMMETS (2)

9 - LOWER CROSSMEMBER

10 - CONDENSER

24 - 62 PLUMBINGWJ

A/C COMPRESSOR (Continued)

Page 2148 of 2199

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The temperature

control door allows control of the heater output air

temperature by controlling how much of the air flow-

ing through the HVAC housing is directed through

the heater core. The blower motor speed controls the

volume of air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced. Refer to Cooling for

more information on the engine cooling system, the

engine coolant and the heater hoses.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Remove the foam gasket surrounding the core

tubes.

NOTE: Notice the orientation of the irregularly

shaped gasket on the tubes. The gasket must be

placed correctly to ensure proper sealing against

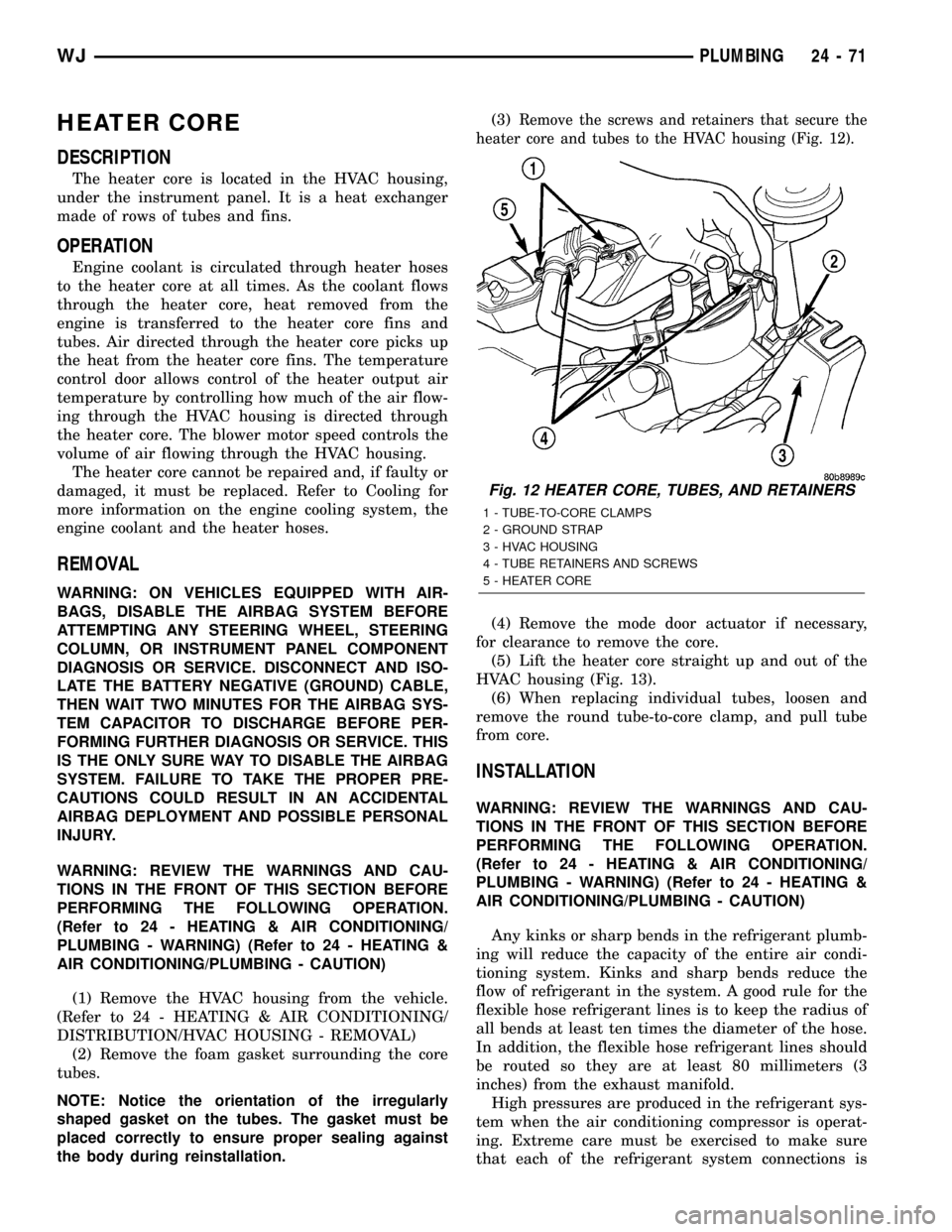

the body during reinstallation.(3)

Remove the screws and retainers that secure the

heater core and tubes to the HVAC housing (Fig. 12).

(4) Remove the mode door actuator if necessary,

for clearance to remove the core.

(5) Lift the heater core straight up and out of the

HVAC housing (Fig. 13).

(6) When replacing individual tubes, loosen and

remove the round tube-to-core clamp, and pull tube

from core.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

Fig. 12 HEATER CORE, TUBES, AND RETAINERS

1 - TUBE-TO-CORE CLAMPS

2 - GROUND STRAP

3 - HVAC HOUSING

4 - TUBE RETAINERS AND SCREWS

5 - HEATER CORE

WJPLUMBING 24 - 71