Dip stick JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1510 of 2199

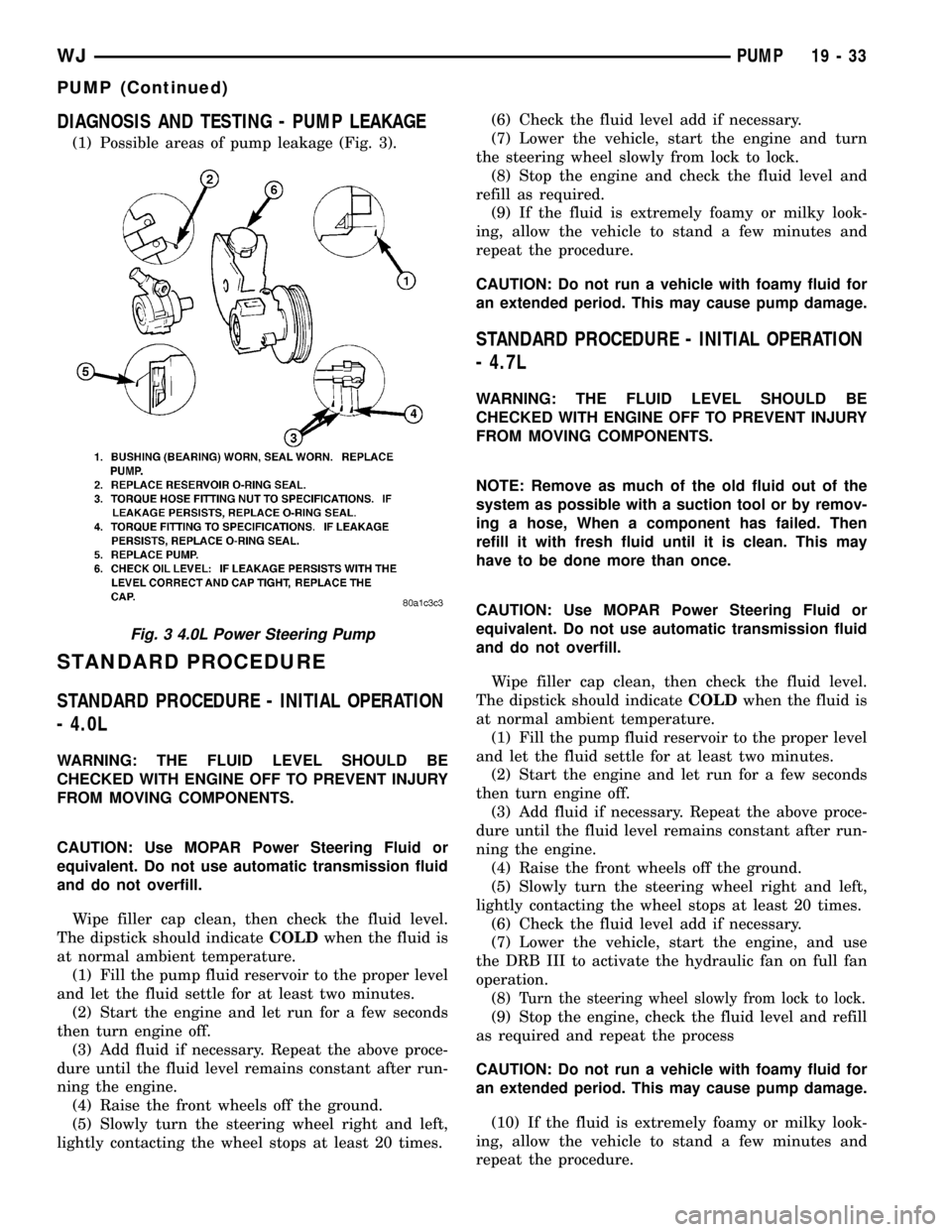

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible areas of pump leakage (Fig. 3).

STANDARD PROCEDURE

STANDARD PROCEDURE - INITIAL OPERATION

- 4.0L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - INITIAL OPERATION

- 4.7L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

NOTE: Remove as much of the old fluid out of the

system as possible with a suction tool or by remov-

ing a hose, When a component has failed. Then

refill it with fresh fluid until it is clean. This may

have to be done more than once.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine, and use

the DRB III to activate the hydraulic fan on full fan

operation.

(8)

Turn the steering wheel slowly from lock to lock.

(9) Stop the engine, check the fluid level and refill

as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

(10) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

Fig. 3 4.0L Power Steering Pump

WJPUMP 19 - 33

PUMP (Continued)

Page 1538 of 2199

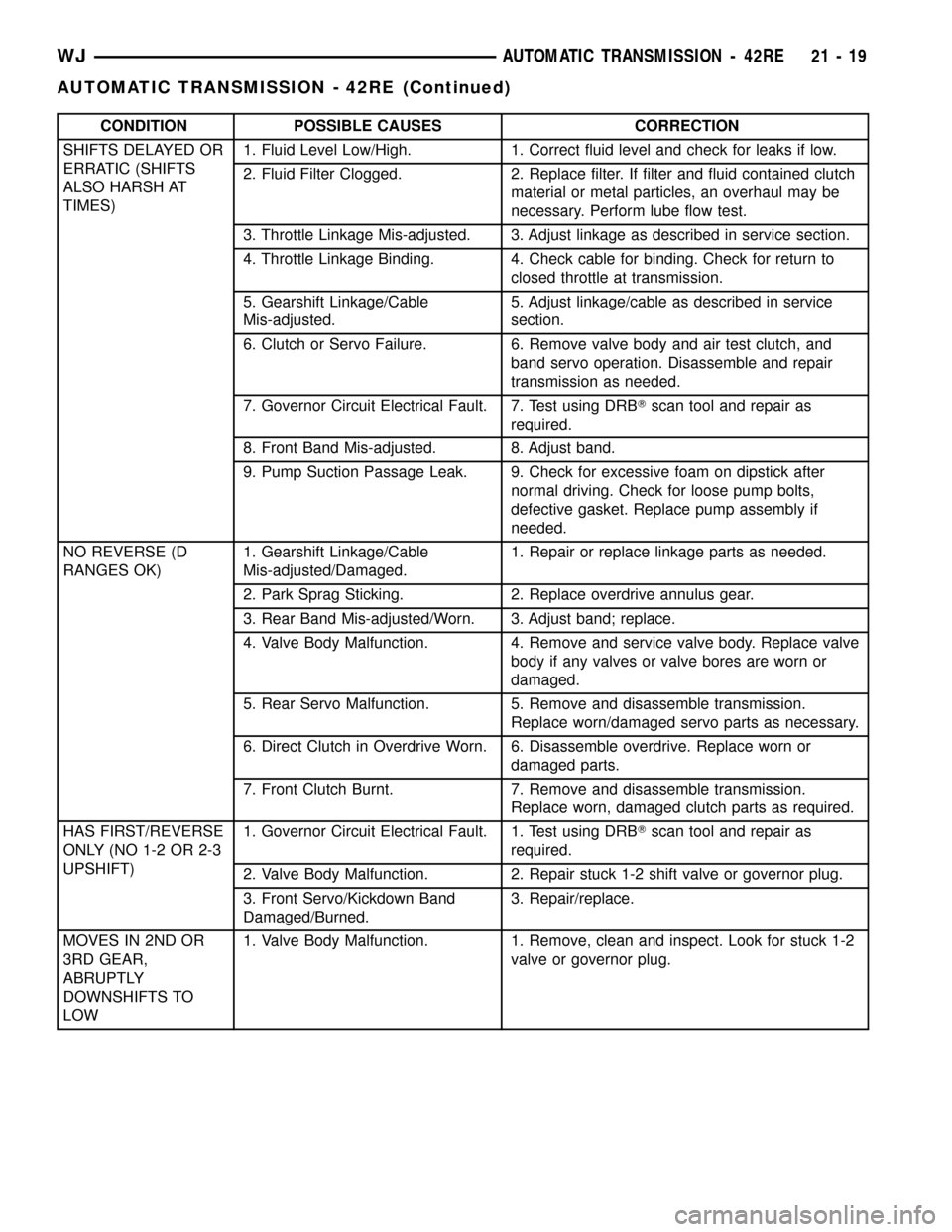

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (SHIFTS

ALSO HARSH AT

TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained clutch

material or metal particles, an overhaul may be

necessary. Perform lube flow test.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage as described in service section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return to

closed throttle at transmission.

5. Gearshift Linkage/Cable

Mis-adjusted.5. Adjust linkage/cable as described in service

section.

6. Clutch or Servo Failure. 6. Remove valve body and air test clutch, and

band servo operation. Disassemble and repair

transmission as needed.

7. Governor Circuit Electrical Fault. 7. Test using DRBTscan tool and repair as

required.

8. Front Band Mis-adjusted. 8. Adjust band.

9. Pump Suction Passage Leak. 9. Check for excessive foam on dipstick after

normal driving. Check for loose pump bolts,

defective gasket. Replace pump assembly if

needed.

NO REVERSE (D

RANGES OK)1. Gearshift Linkage/Cable

Mis-adjusted/Damaged.1. Repair or replace linkage parts as needed.

2. Park Sprag Sticking. 2. Replace overdrive annulus gear.

3. Rear Band Mis-adjusted/Worn. 3. Adjust band; replace.

4. Valve Body Malfunction. 4. Remove and service valve body. Replace valve

body if any valves or valve bores are worn or

damaged.

5. Rear Servo Malfunction. 5. Remove and disassemble transmission.

Replace worn/damaged servo parts as necessary.

6. Direct Clutch in Overdrive Worn. 6. Disassemble overdrive. Replace worn or

damaged parts.

7. Front Clutch Burnt. 7. Remove and disassemble transmission.

Replace worn, damaged clutch parts as required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Circuit Electrical Fault. 1. Test using DRBTscan tool and repair as

required.

2. Valve Body Malfunction. 2. Repair stuck 1-2 shift valve or governor plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR

3RD GEAR,

ABRUPTLY

DOWNSHIFTS TO

LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for stuck 1-2

valve or governor plug.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 19

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1589 of 2199

(1) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to reverse flush cooler and lines after

repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This

is necessary because normal converter flushing proce-

dures will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and

the transmission fluid at normal operating tempera-

ture.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.

The transmission fluid level can be checked two

ways.

PROCEDURE ONE

(1) Transmission fluid must be at normal operat-

ing temperature for accurate fluid level check. Drive

vehicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to NEUTRAL.

(6) Clean top of filler tube and dipstick to keep

dirt from entering tube.

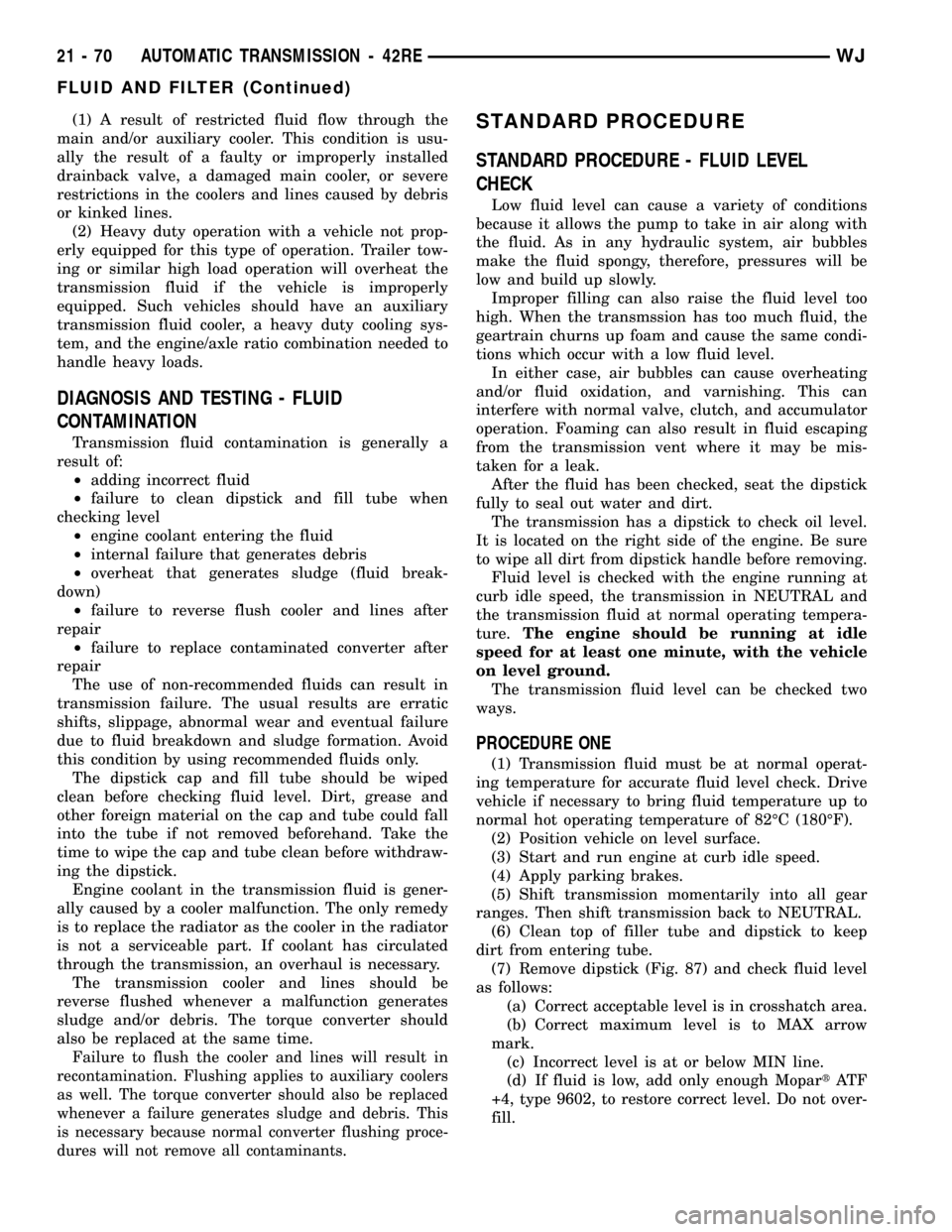

(7) Remove dipstick (Fig. 87) and check fluid level

as follows:

(a) Correct acceptable level is in crosshatch area.

(b) Correct maximum level is to MAX arrow

mark.

(c) Incorrect level is at or below MIN line.

(d) If fluid is low, add only enough MopartAT F

+4, type 9602, to restore correct level. Do not over-

fill.

21 - 70 AUTOMATIC TRANSMISSION - 42REWJ

FLUID AND FILTER (Continued)

Page 1590 of 2199

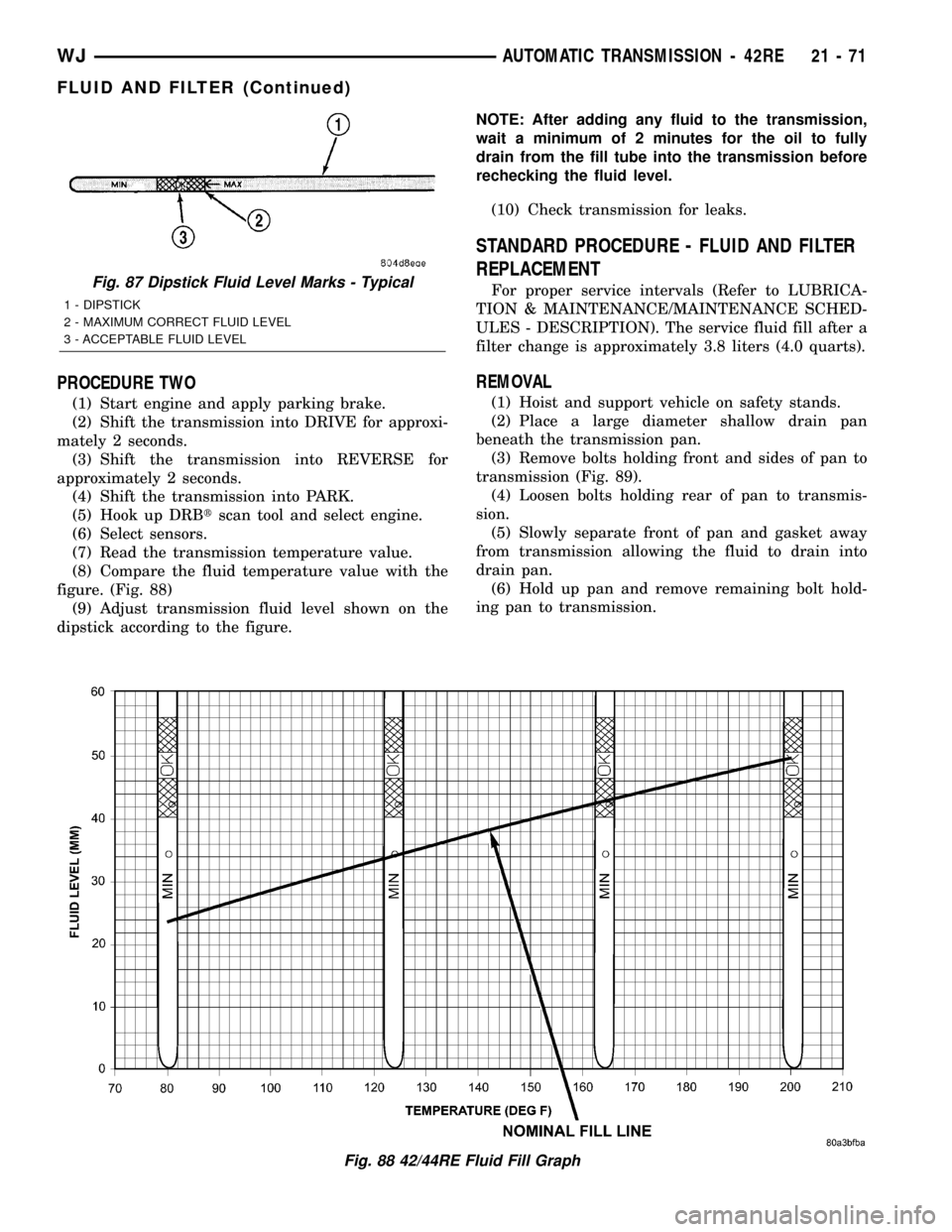

PROCEDURE TWO

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select engine.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

figure. (Fig. 88)

(9) Adjust transmission fluid level shown on the

dipstick according to the figure.NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION). The service fluid fill after a

filter change is approximately 3.8 liters (4.0 quarts).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

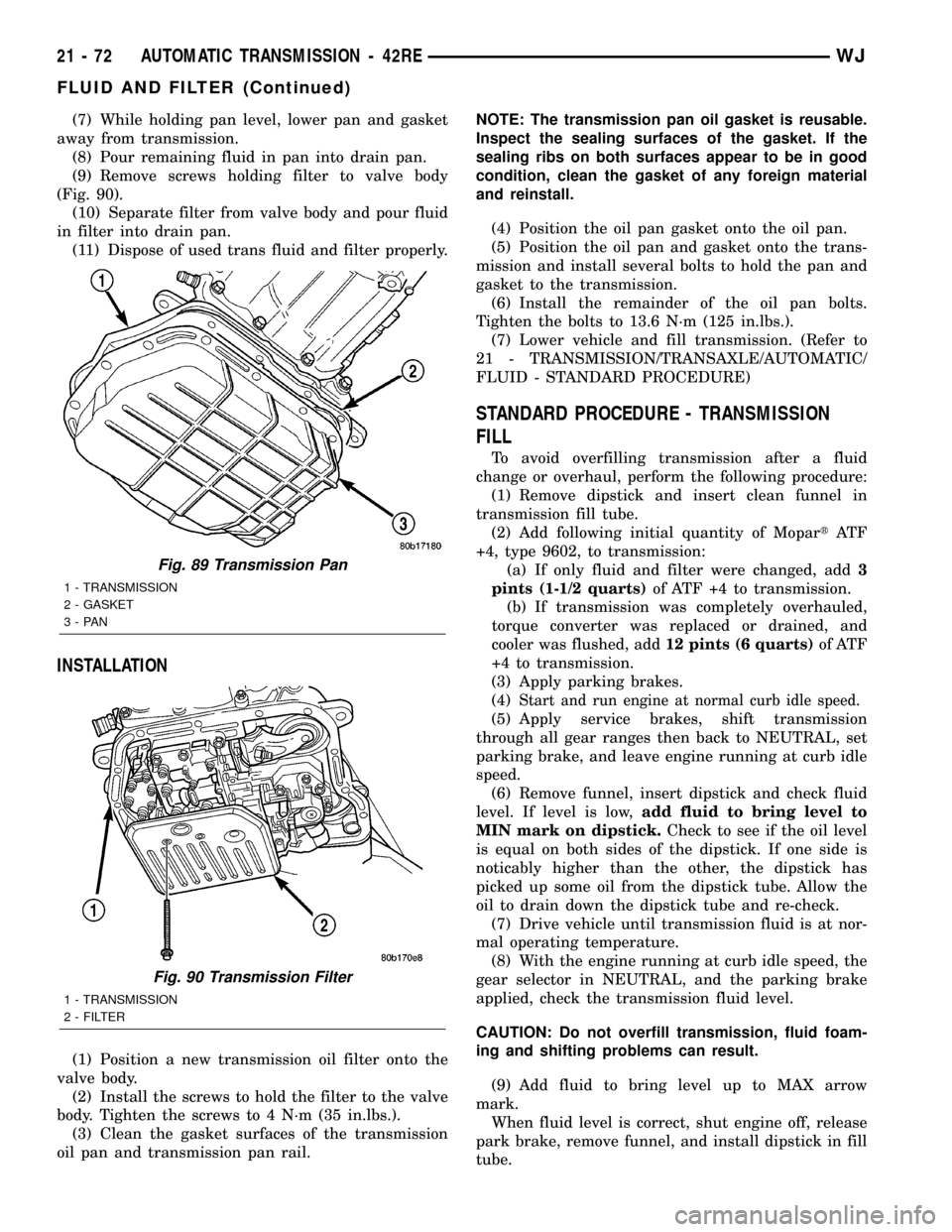

(3) Remove bolts holding front and sides of pan to

transmission (Fig. 89).

(4) Loosen bolts holding rear of pan to transmis-

sion.

(5) Slowly separate front of pan and gasket away

from transmission allowing the fluid to drain into

drain pan.

(6) Hold up pan and remove remaining bolt hold-

ing pan to transmission.

Fig. 88 42/44RE Fluid Fill Graph

Fig. 87 Dipstick Fluid Level Marks - Typical

1 - DIPSTICK

2 - MAXIMUM CORRECT FLUID LEVEL

3 - ACCEPTABLE FLUID LEVEL

WJAUTOMATIC TRANSMISSION - 42RE 21 - 71

FLUID AND FILTER (Continued)

Page 1591 of 2199

(7) While holding pan level, lower pan and gasket

away from transmission.

(8) Pour remaining fluid in pan into drain pan.

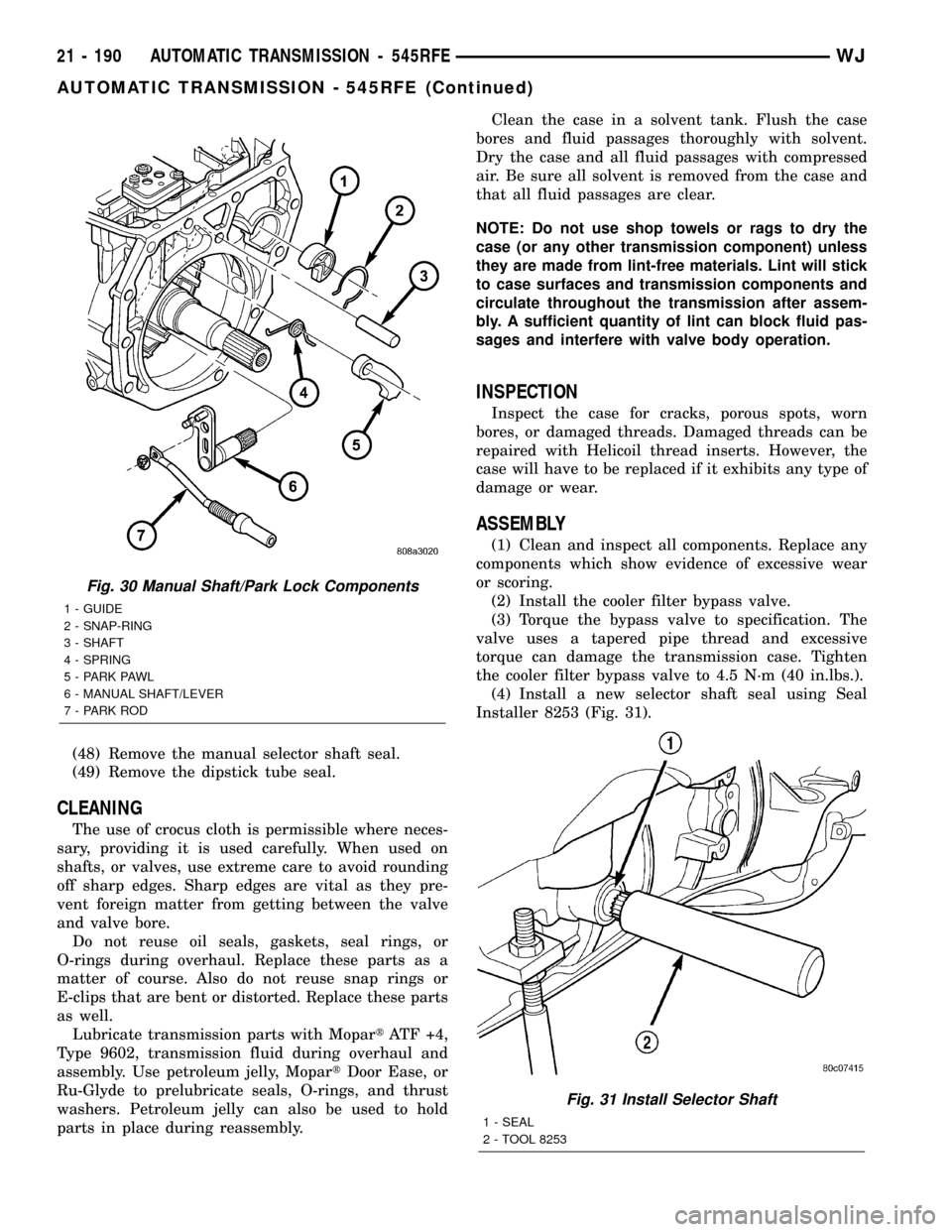

(9) Remove screws holding filter to valve body

(Fig. 90).

(10) Separate filter from valve body and pour fluid

in filter into drain pan.

(11) Dispose of used trans fluid and filter properly.

INSTALLATION

(1) Position a new transmission oil filter onto the

valve body.

(2) Install the screws to hold the filter to the valve

body. Tighten the screws to 4 N´m (35 in.lbs.).

(3) Clean the gasket surfaces of the transmission

oil pan and transmission pan rail.NOTE: The transmission pan oil gasket is reusable.

Inspect the sealing surfaces of the gasket. If the

sealing ribs on both surfaces appear to be in good

condition, clean the gasket of any foreign material

and reinstall.

(4) Position the oil pan gasket onto the oil pan.

(5) Position the oil pan and gasket onto the trans-

mission and install several bolts to hold the pan and

gasket to the transmission.

(6) Install the remainder of the oil pan bolts.

Tighten the bolts to 13.6 N´m (125 in.lbs.).

(7) Lower vehicle and fill transmission. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC/

FLUID - STANDARD PROCEDURE)

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4, type 9602, to transmission:

(a) If only fluid and filter were changed, add3

pints (1-1/2 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add12 pints (6 quarts)of ATF

+4 to transmission.

(3) Apply parking brakes.

(4)

Start and run engine at normal curb idle speed.

(5) Apply service brakes, shift transmission

through all gear ranges then back to NEUTRAL, set

parking brake, and leave engine running at curb idle

speed.

(6) Remove funnel, insert dipstick and check fluid

level. If level is low,add fluid to bring level to

MIN mark on dipstick.Check to see if the oil level

is equal on both sides of the dipstick. If one side is

noticably higher than the other, the dipstick has

picked up some oil from the dipstick tube. Allow the

oil to drain down the dipstick tube and re-check.

(7) Drive vehicle until transmission fluid is at nor-

mal operating temperature.

(8) With the engine running at curb idle speed, the

gear selector in NEUTRAL, and the parking brake

applied, check the transmission fluid level.

CAUTION: Do not overfill transmission, fluid foam-

ing and shifting problems can result.

(9) Add fluid to bring level up to MAX arrow

mark.

When fluid level is correct, shut engine off, release

park brake, remove funnel, and install dipstick in fill

tube.

Fig. 89 Transmission Pan

1 - TRANSMISSION

2 - GASKET

3-PAN

Fig. 90 Transmission Filter

1 - TRANSMISSION

2 - FILTER

21 - 72 AUTOMATIC TRANSMISSION - 42REWJ

FLUID AND FILTER (Continued)

Page 1709 of 2199

(48) Remove the manual selector shaft seal.

(49) Remove the dipstick tube seal.

CLEANING

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

Lubricate transmission parts with MopartATF +4,

Type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-Glyde to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install the cooler filter bypass valve.

(3) Torque the bypass valve to specification. The

valve uses a tapered pipe thread and excessive

torque can damage the transmission case. Tighten

the cooler filter bypass valve to 4.5 N´m (40 in.lbs.).

(4) Install a new selector shaft seal using Seal

Installer 8253 (Fig. 31).

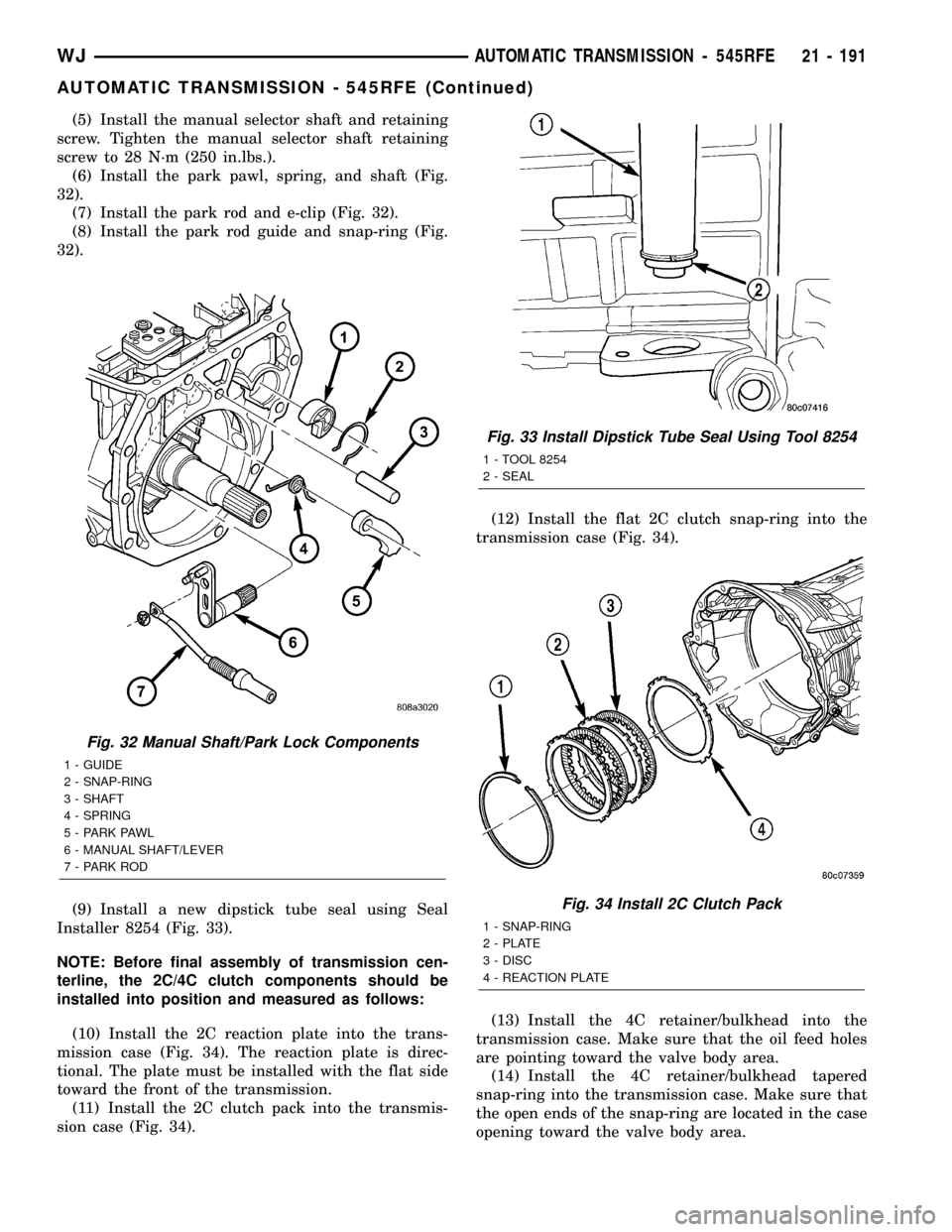

Fig. 30 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 31 Install Selector Shaft

1 - SEAL

2 - TOOL 8253

21 - 190 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1710 of 2199

(5) Install the manual selector shaft and retaining

screw. Tighten the manual selector shaft retaining

screw to 28 N´m (250 in.lbs.).

(6) Install the park pawl, spring, and shaft (Fig.

32).

(7) Install the park rod and e-clip (Fig. 32).

(8) Install the park rod guide and snap-ring (Fig.

32).

(9) Install a new dipstick tube seal using Seal

Installer 8254 (Fig. 33).

NOTE: Before final assembly of transmission cen-

terline, the 2C/4C clutch components should be

installed into position and measured as follows:

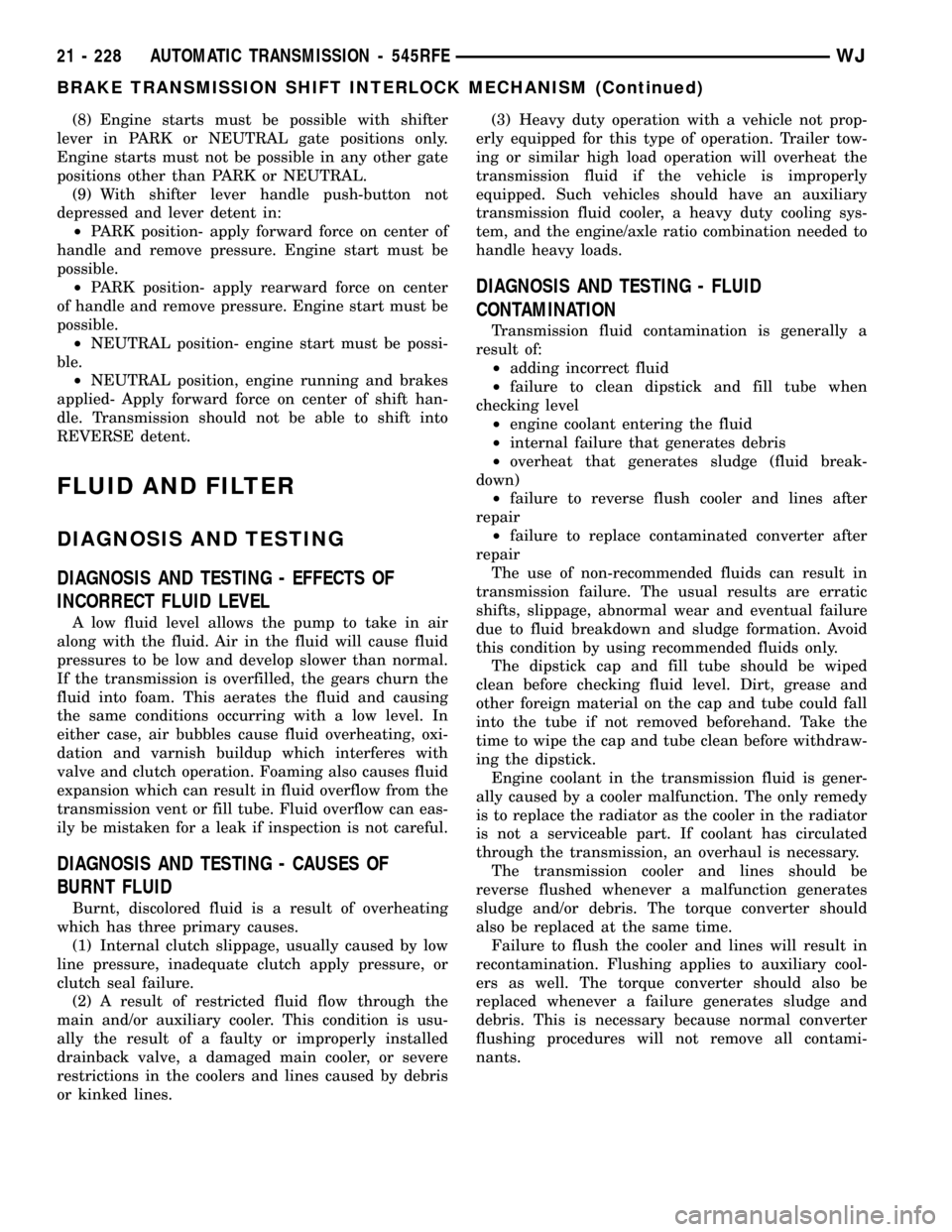

(10) Install the 2C reaction plate into the trans-

mission case (Fig. 34). The reaction plate is direc-

tional. The plate must be installed with the flat side

toward the front of the transmission.

(11) Install the 2C clutch pack into the transmis-

sion case (Fig. 34).(12) Install the flat 2C clutch snap-ring into the

transmission case (Fig. 34).

(13) Install the 4C retainer/bulkhead into the

transmission case. Make sure that the oil feed holes

are pointing toward the valve body area.

(14) Install the 4C retainer/bulkhead tapered

snap-ring into the transmission case. Make sure that

the open ends of the snap-ring are located in the case

opening toward the valve body area.

Fig. 32 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 33 Install Dipstick Tube Seal Using Tool 8254

1 - TOOL 8254

2 - SEAL

Fig. 34 Install 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 191

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1747 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to reverse flush cooler and lines after

repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary cool-

ers as well. The torque converter should also be

replaced whenever a failure generates sludge and

debris. This is necessary because normal converter

flushing procedures will not remove all contami-

nants.

21 - 228 AUTOMATIC TRANSMISSION - 545RFEWJ

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1748 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

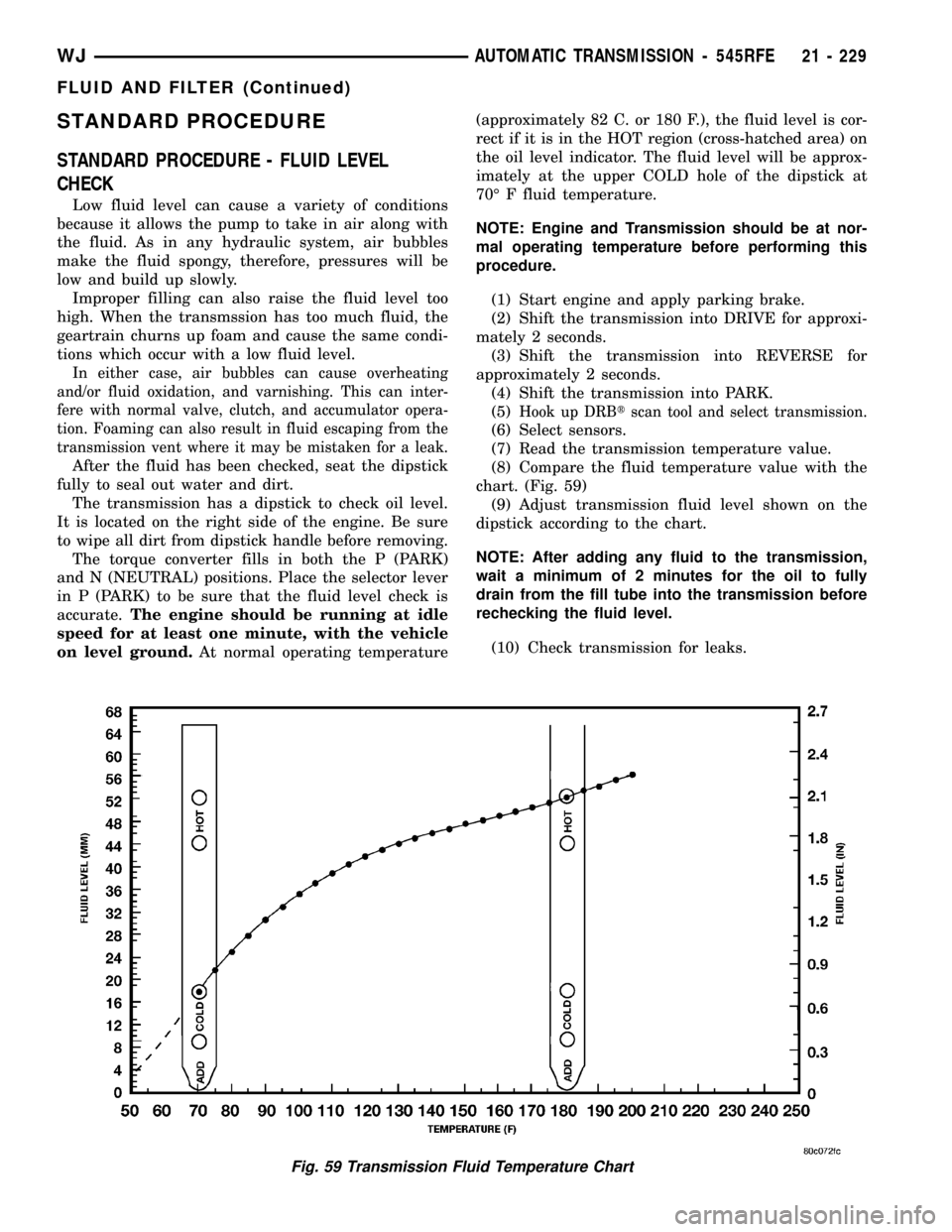

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transmission vent where it may be mistaken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.At normal operating temperature(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5)

Hook up DRBtscan tool and select transmission.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 59)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

Fig. 59 Transmission Fluid Temperature Chart

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 229

FLUID AND FILTER (Continued)

Page 1749 of 2199

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

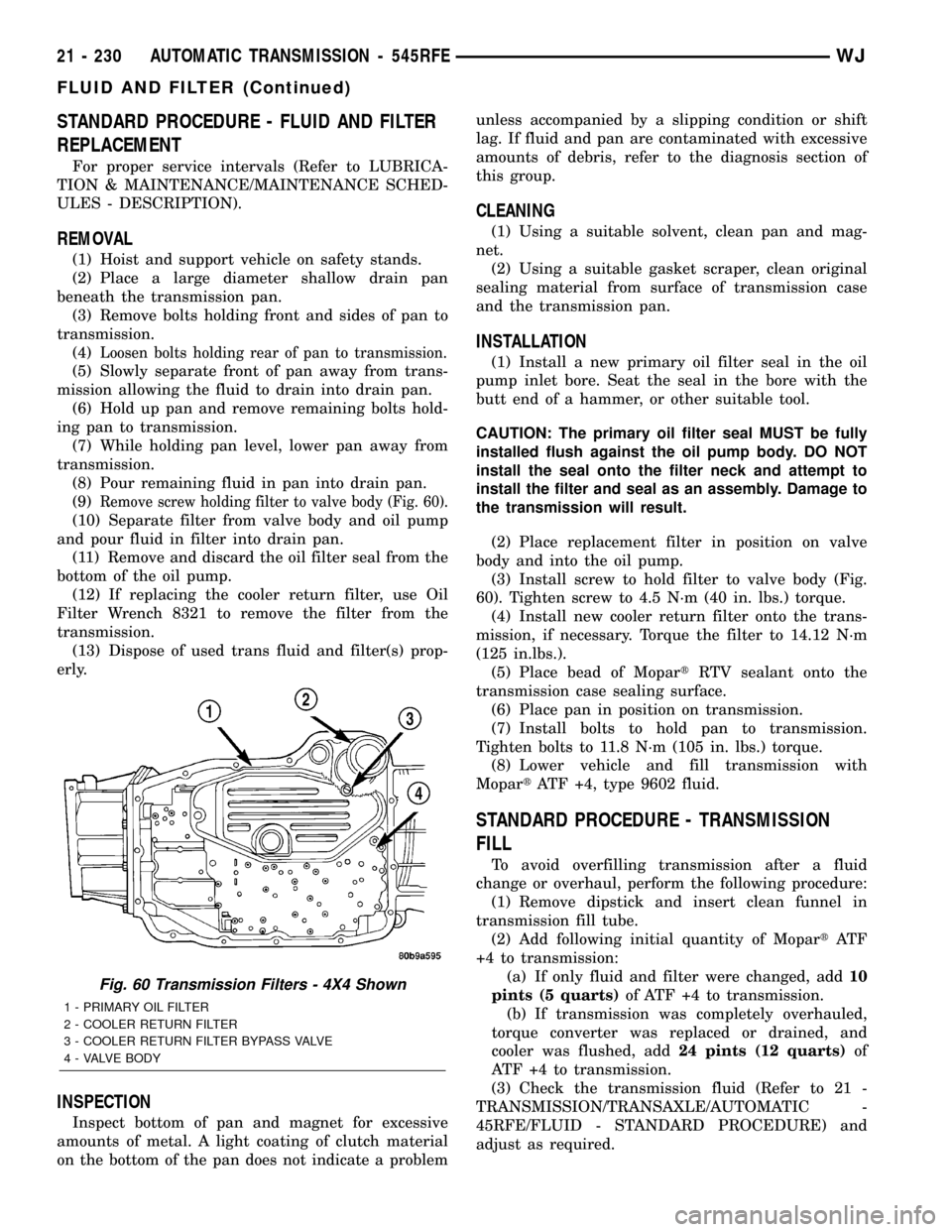

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4)

Loosen bolts holding rear of pan to transmission.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

(9)

Remove screw holding filter to valve body (Fig. 60).

(10) Separate filter from valve body and oil pump

and pour fluid in filter into drain pan.

(11) Remove and discard the oil filter seal from the

bottom of the oil pump.

(12) If replacing the cooler return filter, use Oil

Filter Wrench 8321 to remove the filter from the

transmission.

(13) Dispose of used trans fluid and filter(s) prop-

erly.

INSPECTION

Inspect bottom of pan and magnet for excessive

amounts of metal. A light coating of clutch material

on the bottom of the pan does not indicate a problemunless accompanied by a slipping condition or shift

lag. If fluid and pan are contaminated with excessive

amounts of debris, refer to the diagnosis section of

this group.

CLEANING

(1) Using a suitable solvent, clean pan and mag-

net.

(2) Using a suitable gasket scraper, clean original

sealing material from surface of transmission case

and the transmission pan.

INSTALLATION

(1) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(2) Place replacement filter in position on valve

body and into the oil pump.

(3) Install screw to hold filter to valve body (Fig.

60). Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(4) Install new cooler return filter onto the trans-

mission, if necessary. Torque the filter to 14.12 N´m

(125 in.lbs.).

(5) Place bead of MopartRTV sealant onto the

transmission case sealing surface.

(6) Place pan in position on transmission.

(7) Install bolts to hold pan to transmission.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(8) Lower vehicle and fill transmission with

MopartATF +4, type 9602 fluid.

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4 to transmission:

(a) If only fluid and filter were changed, add10

pints (5 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add24 pints (12 quarts)of

ATF +4 to transmission.

(3) Check the transmission fluid (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

45RFE/FLUID - STANDARD PROCEDURE) and

adjust as required.

Fig. 60 Transmission Filters - 4X4 Shown

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 230 AUTOMATIC TRANSMISSION - 545RFEWJ

FLUID AND FILTER (Continued)