TCM JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 447 of 2199

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The tachome-

ter is an air core magnetic unit that receives battery

current on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM it

will calculate the correct engine speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new

engine speed message and reposition the gauge

pointer accordingly about every 86 milliseconds. The

gauge needle will continue to be positioned at the

actual engine speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about six sec-

onds, or until the ignition switch is turned to the Off

position, whichever occurs first. If a new engine

speed message is not received after about six sec-

onds, the gauge needle will return to the far left

(low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the tachometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TRANS TEMP INDICATOR

DESCRIPTION

A transmission over-temperature indicator is stan-

dard equipment on all gasoline engine instrument

clusters. The transmission over-temperature indica-

tor is located near the lower right corner of theinstrument cluster, to the right of the speedometer.

The transmission over-temperature indicator consists

of the words ªTRANS OVER TEMPº imprinted on an

amber lens. The lens is located behind a cutout in

the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. The words ªTRANS OVER TEMPº appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. The

transmission over-temperature indicator lens is ser-

viced as a unit with the instrument cluster lens, hood

and mask unit.

OPERATION

The transmission over-temperature indicator gives

an indication to the vehicle operator when the trans-

mission fluid temperature is excessive, which may

lead to accelerated transmission component wear or

failure. This indicator is controlled by a transistor on

the instrument cluster electronic circuit board based

upon cluster programming and electronic messages

received by the cluster over the Programmable Com-

munications Interface (PCI) data bus. These mes-

sages are sent by the Powertrain Control Module

(PCM) or by the Transmission Control Module

(TCM), depending on the model of the automatic

transmission. The transmission over-temperature

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the indicator will always be off when the ignition

switch is in any position except On or Start. The bulb

only illuminates when it is provided a path to ground

by the instrument cluster transistor. The instrument

cluster will turn on the transmission over-tempera-

ture indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the transmission over-tem-

perature indicator is illuminated for about three sec-

onds as a bulb test.

²Trans Over-Temp Indicator Lamp-On Mes-

sage- Each time the cluster receives a trans over-

temp indicator lamp-on message from the PCM or

TCM indicating that the transmission fluid tempera-

ture is 135É C (275É F) or higher, the transmission

over-temperature indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a trans over-temp indicator lamp-off mes-

sage from the PCM or TCM, or until the ignition

8J - 32 INSTRUMENT CLUSTERWJ

TACHOMETER (Continued)

Page 448 of 2199

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the transmission over-tem-

perature indicator will be turned on for the duration

of the test to confirm the functionality of the bulb

and the cluster control circuitry.

The PCM or TCM continually monitors the trans-

mission temperature sensor to determine the trans-

mission operating condition. The PCM or TCM then

sends the proper trans over-temp indicator lamp-on

or lamp-off messages to the instrument cluster. If the

transmission over-temperature indicator fails to light

during the bulb test, replace the bulb with a known

good unit. If the instrument cluster turns on the

transmission over-temperature indicator due to a

high transmission oil temperature condition, it may

indicate that the transmission or the transmission

cooling system are being overloaded or that they

require service. For further diagnosis of the trans-

mission over-temperature indicator or the instrument

cluster circuitry that controls the indicator, (Refer to

8 - ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). For proper diagnosis of the

transmission temperature sensor, the PCM, the

TCM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

transmission over-temperature indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

TURN SIGNAL INDICATOR

DESCRIPTION

Two turn signal indicators, one right and one left,

are standard equipment on all instrument clusters.

The turn signal indicators are located near the upper

edge of the instrument cluster, the left one is left of

the tachometer, and the right one is right of the

speedometer. Each turn signal indicator consists of

an International Control and Display Symbol icon for

ªTurn Warningº imprinted on a green lens. Each lens

is located behind a dedicated cutout in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents these icons from

being clearly visible when they are not illuminated.

The icons appear silhouetted against a green field

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

replaceable incandescent bulb and bulb holder unit

located on the instrument cluster electronic circuit

board. The turn signal indicator lenses are serviced

as a unit with the instrument cluster lens, hood and

mask unit.

OPERATION

The turn signal indicators give an indication to the

vehicle operator that the turn signal (left or right

indicator flashing) or hazard warning (both left and

right indicators flashing) have been selected and are

operating. These indicators are controlled by two

individual hard wired inputs from the combination

flasher circuitry to the instrument cluster electronic

circuit board. Each turn signal indicator bulb is

grounded on the instrument cluster electronic circuit

board at all times; therefore, these indicators remain

functional regardless of the ignition switch position.

Each indicator bulb will only illuminate when it is

provided with battery current by the combination

flasher in the Junction Block (JB).

The turn signal indicators are connected in parallel

with the other turn signal circuits. This arrangement

allows the turn signal indicators to remain func-

tional, regardless of the condition of the other cir-

cuits in the turn signal and hazard warning systems.

The combination flasher outputs to the instrument

cluster turn signal indicator inputs can be diagnosed

using conventional diagnostic tools and methods. For

more information on the turn signal and hazard

warning system, (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR - OPERATION - TURN

SIGNAL & HAZARD WARNING SYSTEM).

DIAGNOSIS AND TESTING - TURN SIGNAL

INDICATOR

The diagnosis found here addresses an inoperative

turn signal indicator condition. If the problem being

diagnosed is related to inoperative turn signal or

hazard warning lamps, be certain to repair the turn

signal and hazard warning system before attempting

to diagnose or repair the turn signal indicators.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR - DIAGNOSIS AND TESTING - TURN

SIGNAL & HAZARD WARNING SYSTEM). If no

turn signal and hazard warning system problem is

found, the following procedure will help locate an

open in the turn signal indicator circuit. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WJINSTRUMENT CLUSTER 8J - 33

TRANS TEMP INDICATOR (Continued)

Page 1113 of 2199

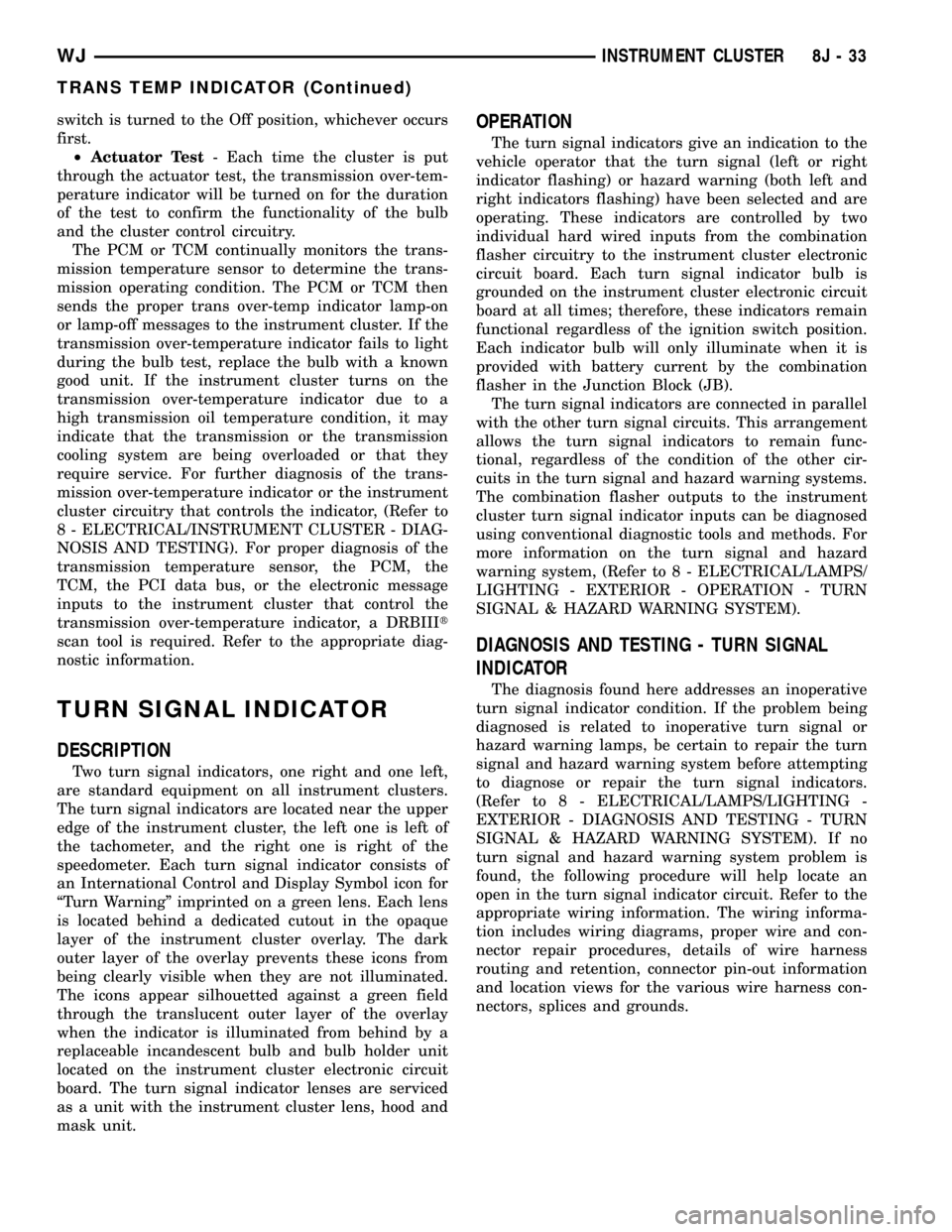

DIAGNOSTIC JUNCTION PORT - BLACK 16 WAY

CAV CIRCUIT FUNCTION

1 D25 20YL/VT/BR PCI BUS (PCM/ECM TCM PDM CD SKIM)

2 D25 20YL/VT/DG (AZC) PCI BUS (AZC)

3 D25 20YL/VT/DB PCI BUS (RADIO)

4 D25 20YL/VT/OR PCI BUS (ACM)

5 D25 20YL/VT/RD PCI BUS (MIC)

6 D25 20YL/VT/WT PCI BUS (BCM)

7 D25 20YL/VT PCI BUS (DLC)

8 D25 20YL/VT/GY PCI BUS (DDM ABS MEM EVIC APM ITM RAIN

SENSOR)

9- -

10 - -

11 D25 20YL/VT (DIESEL) PCI BUS (SHIFTER ASSEMBLY)

12 - -

13 - -

14 - -

15 - -

16 - -

DRIVER AIRBAG SQUIB 1 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 R43 20BK DRIVER SQUIB 1 LINE 1

2 R45 20BK DRIVER SQUIB 1 LINE 2

DRIVER AIRBAG SQUIB 2 - GREEN 2 WAY

CAV CIRCUIT FUNCTION

1 R63 20TN/LB DRIVER SQUIB 2 LINE 2

2 R61 20OR/LB DRIVER SQUIB 2 LINE 1

8W - 80 - 66 8W-80 CONNECTOR PIN-OUTWJ

Page 1697 of 2199

INSTALLATION........................253

OUTPUT SPEED SENSOR

DESCRIPTION........................254

OPERATION..........................254

REMOVAL............................254

INSTALLATION........................254

OVERDRIVE SWITCH

DESCRIPTION........................254

OPERATION..........................254

PARK LOCK CABLE

REMOVAL............................255

INSTALLATION........................255

PISTONS

DESCRIPTION........................256

OPERATION..........................256

PLANETARY GEARTRAIN

DESCRIPTION........................258

OPERATION..........................260

DISASSEMBLY........................260

CLEANING...........................260

INSPECTION.........................260

ASSEMBLY...........................261

SHIFT MECHANISM

DESCRIPTION........................261

OPERATION..........................261

REMOVAL............................261

INSTALLATION........................263

SOLENOID SWITCH VALVE

DESCRIPTION........................263

OPERATION..........................263

SOLENOIDS

DESCRIPTION........................263OPERATION..........................264

TORQUE CONVERTER

DESCRIPTION........................264

OPERATION..........................268

REMOVAL............................269

INSTALLATION........................269

TRANSMISSION CONTROL RELAY

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION RANGE SENSOR

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................271

OPERATION..........................271

REMOVAL............................272

INSTALLATION........................272

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................272

OPERATION..........................272

VALVE BODY

DESCRIPTION........................273

OPERATION..........................273

REMOVAL............................274

DISASSEMBLY........................275

CLEANING...........................277

INSPECTION.........................277

ASSEMBLY...........................278

INSTALLATION........................279

AUTOMATIC TRANSMISSION -

545RFE

DESCRIPTION

The 545RFE automatic transmission is a sophisti-

cated, multi-range, electronically controlled transmis-

sion which combines optimized gear ratios for

responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range. An additional overdrive ratio (0.67:1)

is also provided for greater fuel economy and less

NVH at highway speeds.The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.

The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 178 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1698 of 2199

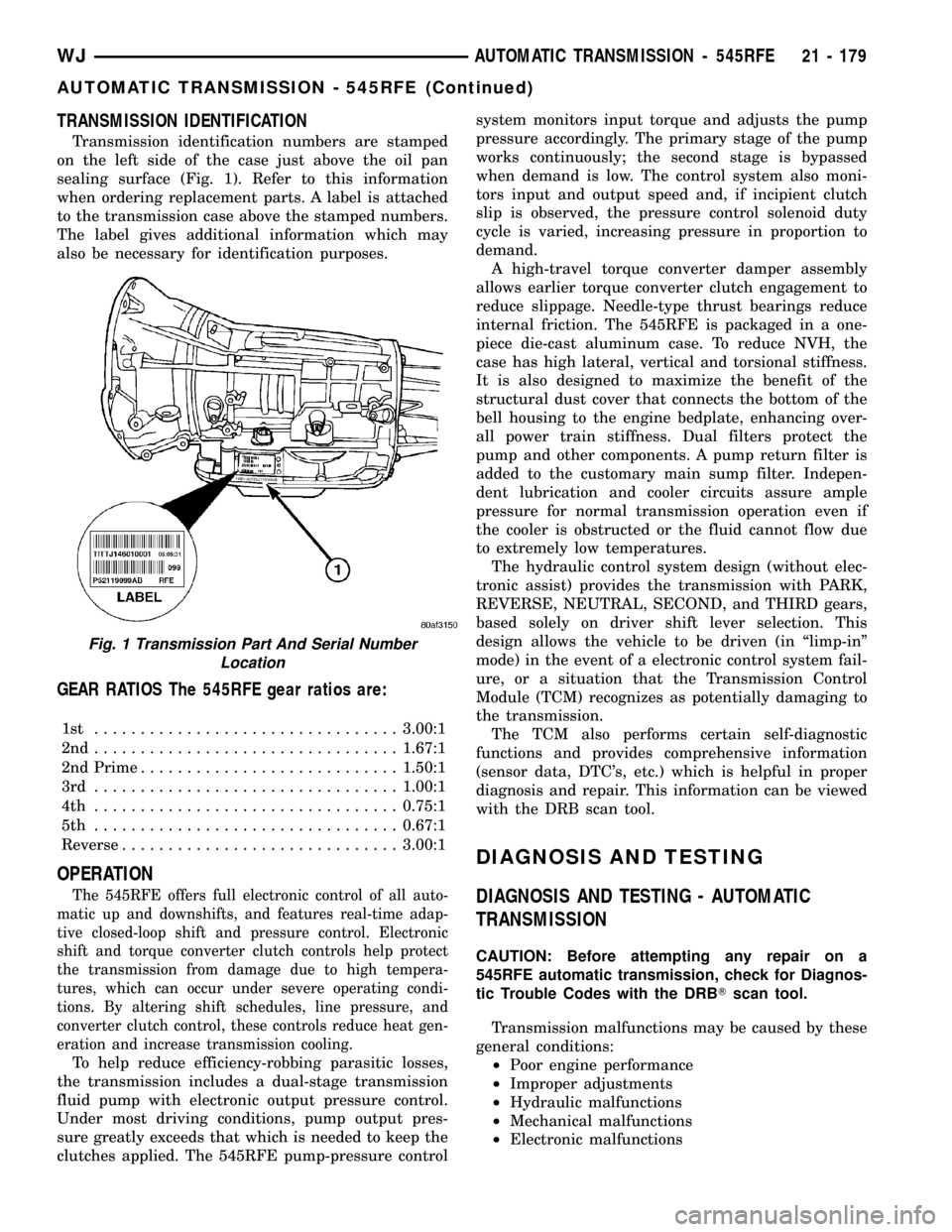

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime............................1.50:1

3rd .................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse..............................3.00:1

OPERATION

The 545RFE offers full electronic control of all auto-

matic up and downshifts, and features real-time adap-

tive closed-loop shift and pressure control. Electronic

shift and torque converter clutch controls help protect

the transmission from damage due to high tempera-

tures, which can occur under severe operating condi-

tions. By altering shift schedules, line pressure, and

converter clutch control, these controls reduce heat gen-

eration and increase transmission cooling.

To help reduce efficiency-robbing parasitic losses,

the transmission includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 545RFE pump-pressure controlsystem monitors input torque and adjusts the pump

pressure accordingly. The primary stage of the pump

works continuously; the second stage is bypassed

when demand is low. The control system also moni-

tors input and output speed and, if incipient clutch

slip is observed, the pressure control solenoid duty

cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 545RFE is packaged in a one-

piece die-cast aluminum case. To reduce NVH, the

case has high lateral, vertical and torsional stiffness.

It is also designed to maximize the benefit of the

structural dust cover that connects the bottom of the

bell housing to the engine bedplate, enhancing over-

all power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a

545RFE automatic transmission, check for Diagnos-

tic Trouble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Fig. 1 Transmission Part And Serial Number

Location

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 179

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1763 of 2199

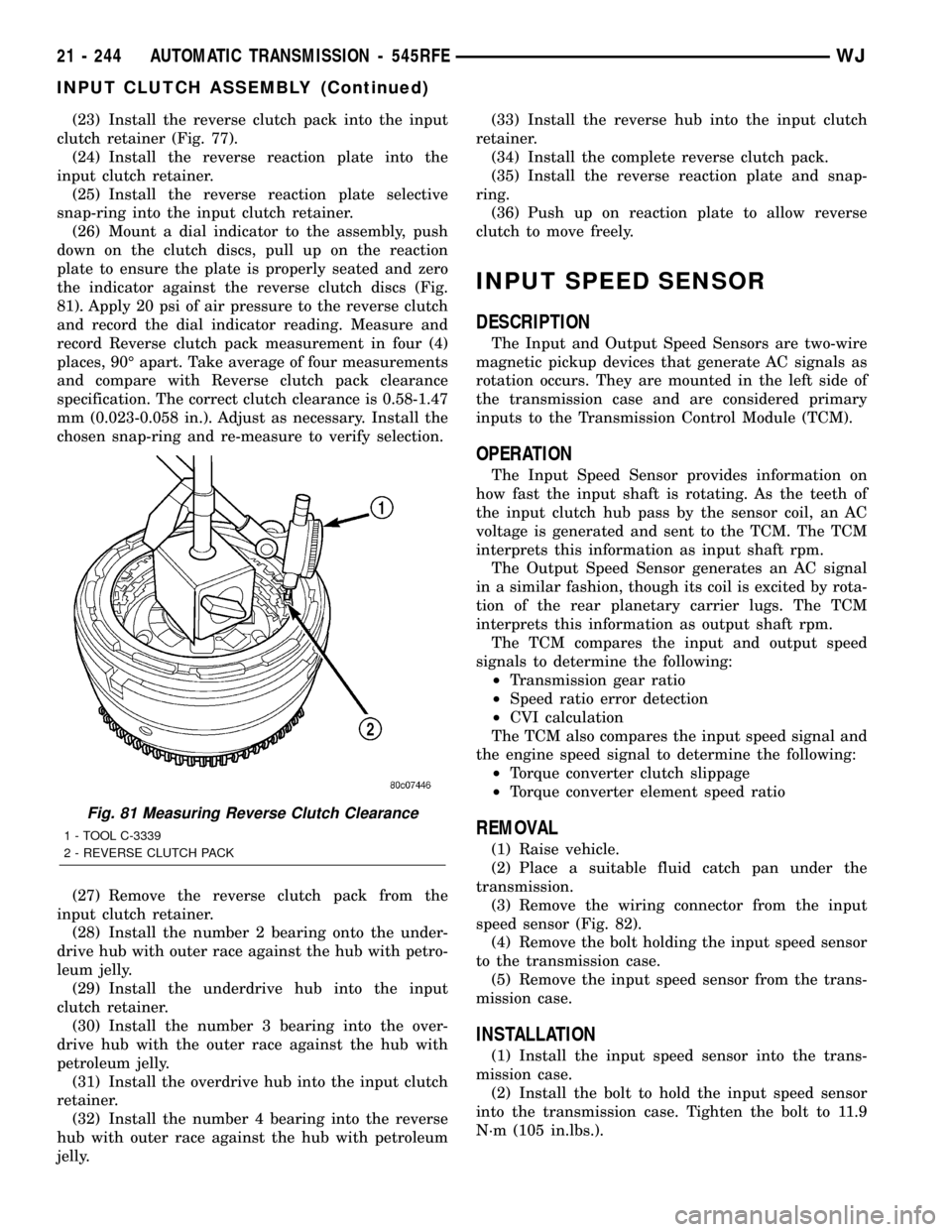

(23) Install the reverse clutch pack into the input

clutch retainer (Fig. 77).

(24) Install the reverse reaction plate into the

input clutch retainer.

(25) Install the reverse reaction plate selective

snap-ring into the input clutch retainer.

(26) Mount a dial indicator to the assembly, push

down on the clutch discs, pull up on the reaction

plate to ensure the plate is properly seated and zero

the indicator against the reverse clutch discs (Fig.

81). Apply 20 psi of air pressure to the reverse clutch

and record the dial indicator reading. Measure and

record Reverse clutch pack measurement in four (4)

places, 90É apart. Take average of four measurements

and compare with Reverse clutch pack clearance

specification. The correct clutch clearance is 0.58-1.47

mm (0.023-0.058 in.). Adjust as necessary. Install the

chosen snap-ring and re-measure to verify selection.

(27) Remove the reverse clutch pack from the

input clutch retainer.

(28) Install the number 2 bearing onto the under-

drive hub with outer race against the hub with petro-

leum jelly.

(29) Install the underdrive hub into the input

clutch retainer.

(30) Install the number 3 bearing into the over-

drive hub with the outer race against the hub with

petroleum jelly.

(31) Install the overdrive hub into the input clutch

retainer.

(32) Install the number 4 bearing into the reverse

hub with outer race against the hub with petroleum

jelly.(33) Install the reverse hub into the input clutch

retainer.

(34) Install the complete reverse clutch pack.

(35) Install the reverse reaction plate and snap-

ring.

(36) Push up on reaction plate to allow reverse

clutch to move freely.

INPUT SPEED SENSOR

DESCRIPTION

The Input and Output Speed Sensors are two-wire

magnetic pickup devices that generate AC signals as

rotation occurs. They are mounted in the left side of

the transmission case and are considered primary

inputs to the Transmission Control Module (TCM).

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil, an AC

voltage is generated and sent to the TCM. The TCM

interprets this information as input shaft rpm.

The Output Speed Sensor generates an AC signal

in a similar fashion, though its coil is excited by rota-

tion of the rear planetary carrier lugs. The TCM

interprets this information as output shaft rpm.

The TCM compares the input and output speed

signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The TCM also compares the input speed signal and

the engine speed signal to determine the following:

²Torque converter clutch slippage

²Torque converter element speed ratio

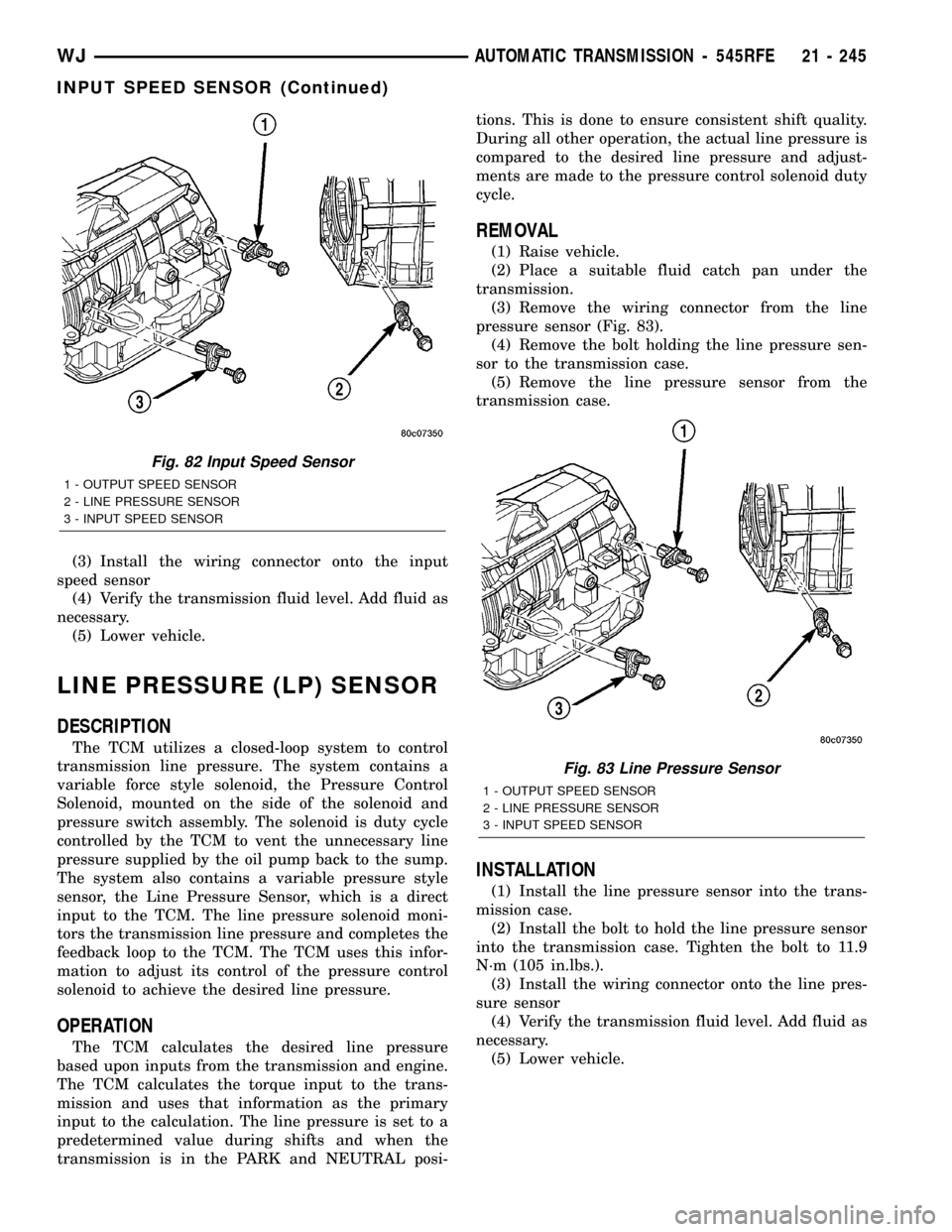

REMOVAL

(1) Raise vehicle.

(2) Place a suitable fluid catch pan under the

transmission.

(3) Remove the wiring connector from the input

speed sensor (Fig. 82).

(4) Remove the bolt holding the input speed sensor

to the transmission case.

(5) Remove the input speed sensor from the trans-

mission case.

INSTALLATION

(1) Install the input speed sensor into the trans-

mission case.

(2) Install the bolt to hold the input speed sensor

into the transmission case. Tighten the bolt to 11.9

N´m (105 in.lbs.).

Fig. 81 Measuring Reverse Clutch Clearance

1 - TOOL C-3339

2 - REVERSE CLUTCH PACK

21 - 244 AUTOMATIC TRANSMISSION - 545RFEWJ

INPUT CLUTCH ASSEMBLY (Continued)

Page 1764 of 2199

(3) Install the wiring connector onto the input

speed sensor

(4) Verify the transmission fluid level. Add fluid as

necessary.

(5) Lower vehicle.

LINE PRESSURE (LP) SENSOR

DESCRIPTION

The TCM utilizes a closed-loop system to control

transmission line pressure. The system contains a

variable force style solenoid, the Pressure Control

Solenoid, mounted on the side of the solenoid and

pressure switch assembly. The solenoid is duty cycle

controlled by the TCM to vent the unnecessary line

pressure supplied by the oil pump back to the sump.

The system also contains a variable pressure style

sensor, the Line Pressure Sensor, which is a direct

input to the TCM. The line pressure solenoid moni-

tors the transmission line pressure and completes the

feedback loop to the TCM. The TCM uses this infor-

mation to adjust its control of the pressure control

solenoid to achieve the desired line pressure.

OPERATION

The TCM calculates the desired line pressure

based upon inputs from the transmission and engine.

The TCM calculates the torque input to the trans-

mission and uses that information as the primary

input to the calculation. The line pressure is set to a

predetermined value during shifts and when the

transmission is in the PARK and NEUTRAL posi-tions. This is done to ensure consistent shift quality.

During all other operation, the actual line pressure is

compared to the desired line pressure and adjust-

ments are made to the pressure control solenoid duty

cycle.

REMOVAL

(1) Raise vehicle.

(2) Place a suitable fluid catch pan under the

transmission.

(3) Remove the wiring connector from the line

pressure sensor (Fig. 83).

(4) Remove the bolt holding the line pressure sen-

sor to the transmission case.

(5) Remove the line pressure sensor from the

transmission case.

INSTALLATION

(1) Install the line pressure sensor into the trans-

mission case.

(2) Install the bolt to hold the line pressure sensor

into the transmission case. Tighten the bolt to 11.9

N´m (105 in.lbs.).

(3) Install the wiring connector onto the line pres-

sure sensor

(4) Verify the transmission fluid level. Add fluid as

necessary.

(5) Lower vehicle.

Fig. 82 Input Speed Sensor

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

Fig. 83 Line Pressure Sensor

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 245

INPUT SPEED SENSOR (Continued)

Page 1773 of 2199

OUTPUT SPEED SENSOR

DESCRIPTION

The Input and Output Speed Sensors are two-wire

magnetic pickup devices that generate AC signals as

rotation occurs. They are mounted in the left side of

the transmission case and are considered primary

inputs to the Transmission Control Module (TCM).

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil, an AC

voltage is generated and sent to the TCM. The TCM

interprets this information as input shaft rpm.

The Output Speed Sensor generates an AC signal

in a similar fashion, though its coil is excited by rota-

tion of the rear planetary carrier lugs. The TCM

interprets this information as output shaft rpm.

The TCM compares the input and output speed

signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The TCM also compares the input speed signal and

the engine speed signal to determine the following:

²Torque converter clutch slippage

²Torque converter element speed ratio

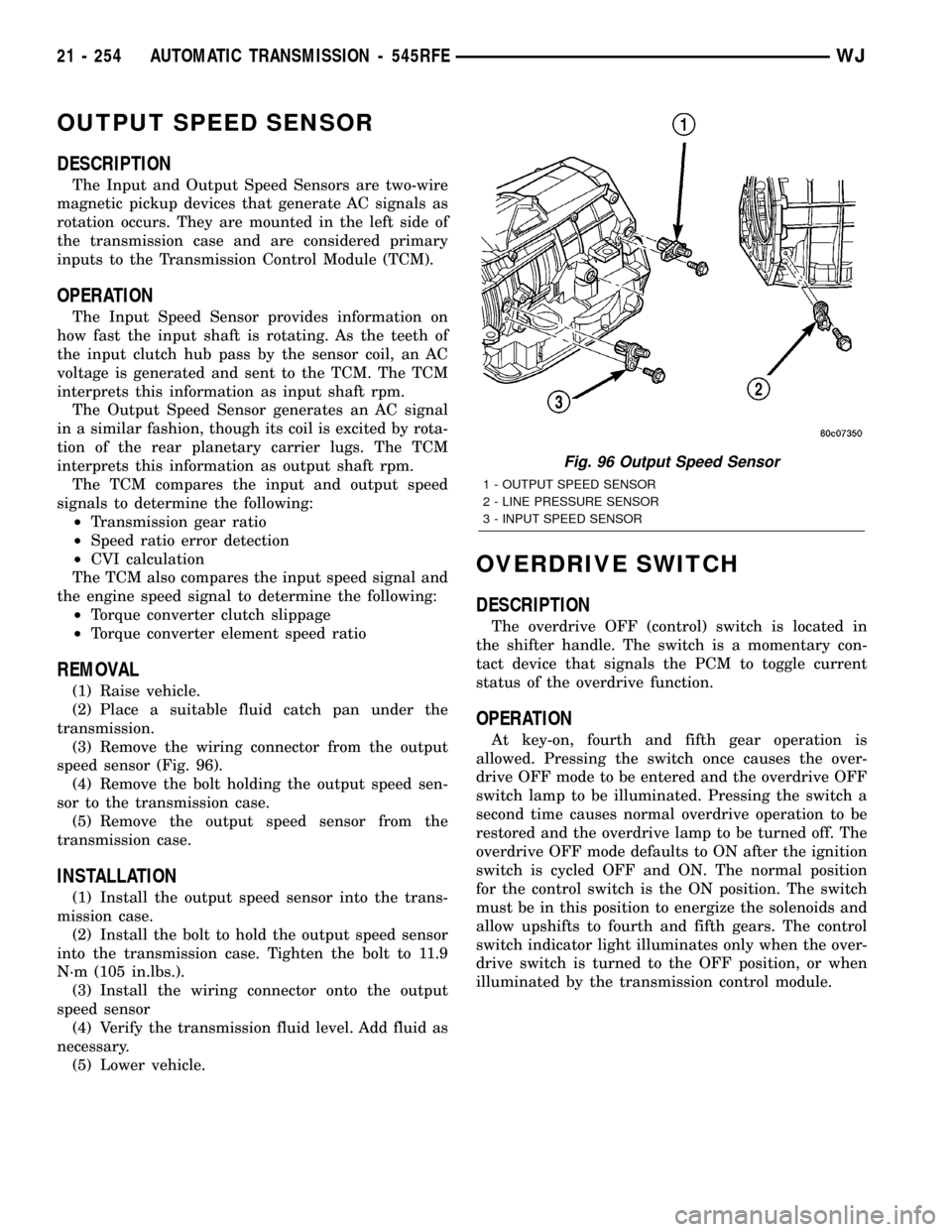

REMOVAL

(1) Raise vehicle.

(2) Place a suitable fluid catch pan under the

transmission.

(3) Remove the wiring connector from the output

speed sensor (Fig. 96).

(4) Remove the bolt holding the output speed sen-

sor to the transmission case.

(5) Remove the output speed sensor from the

transmission case.

INSTALLATION

(1) Install the output speed sensor into the trans-

mission case.

(2) Install the bolt to hold the output speed sensor

into the transmission case. Tighten the bolt to 11.9

N´m (105 in.lbs.).

(3) Install the wiring connector onto the output

speed sensor

(4) Verify the transmission fluid level. Add fluid as

necessary.

(5) Lower vehicle.

OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth and fifth gear operation is

allowed. Pressing the switch once causes the over-

drive OFF mode to be entered and the overdrive OFF

switch lamp to be illuminated. Pressing the switch a

second time causes normal overdrive operation to be

restored and the overdrive lamp to be turned off. The

overdrive OFF mode defaults to ON after the ignition

switch is cycled OFF and ON. The normal position

for the control switch is the ON position. The switch

must be in this position to energize the solenoids and

allow upshifts to fourth and fifth gears. The control

switch indicator light illuminates only when the over-

drive switch is turned to the OFF position, or when

illuminated by the transmission control module.

Fig. 96 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

21 - 254 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1786 of 2199

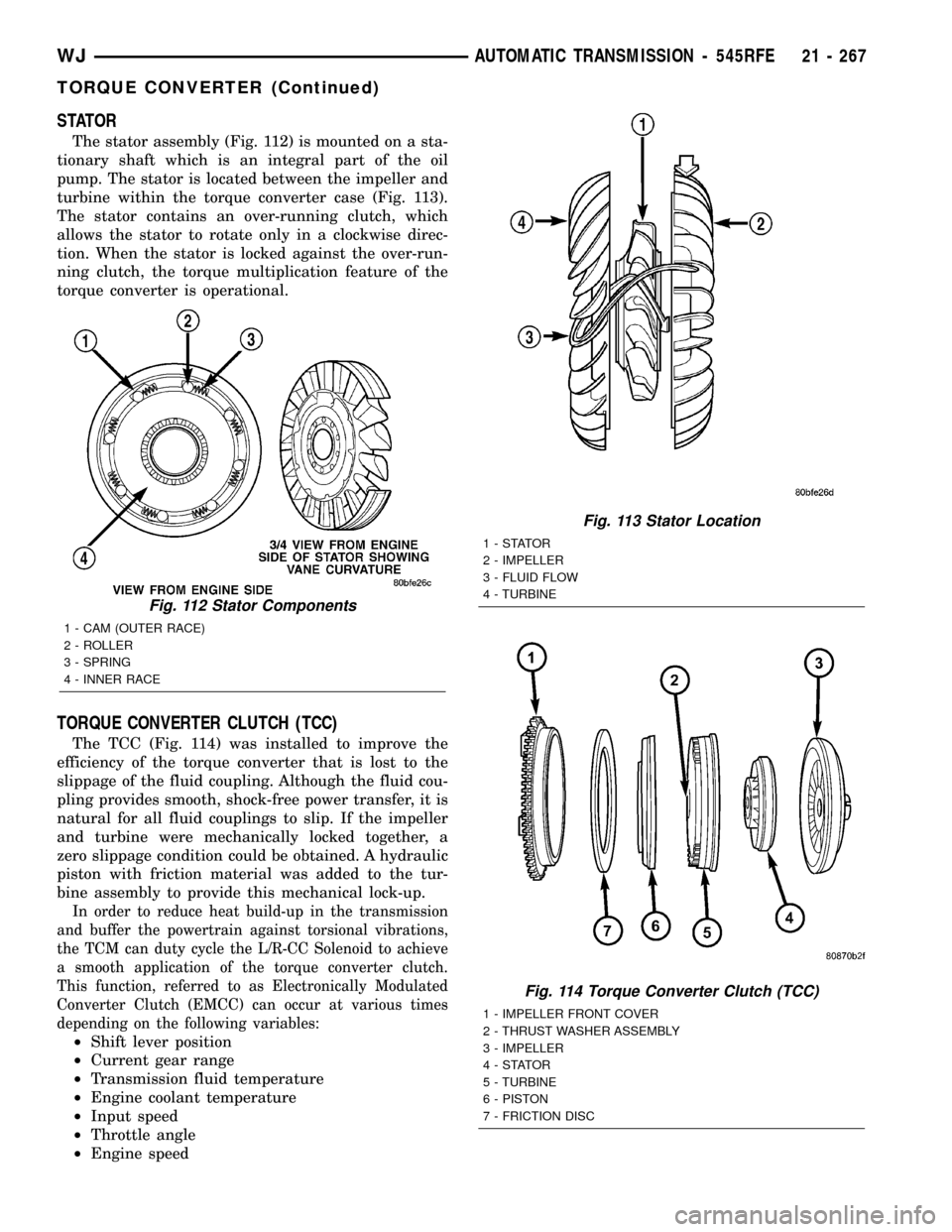

STATOR

The stator assembly (Fig. 112) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 113).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 114) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston with friction material was added to the tur-

bine assembly to provide this mechanical lock-up.

In order to reduce heat build-up in the transmission

and buffer the powertrain against torsional vibrations,

the TCM can duty cycle the L/R-CC Solenoid to achieve

a smooth application of the torque converter clutch.

This function, referred to as Electronically Modulated

Converter Clutch (EMCC) can occur at various times

depending on the following variables:

²Shift lever position

²Current gear range

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle

²Engine speed

Fig. 112 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 113 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 114 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 267

TORQUE CONVERTER (Continued)

Page 1788 of 2199

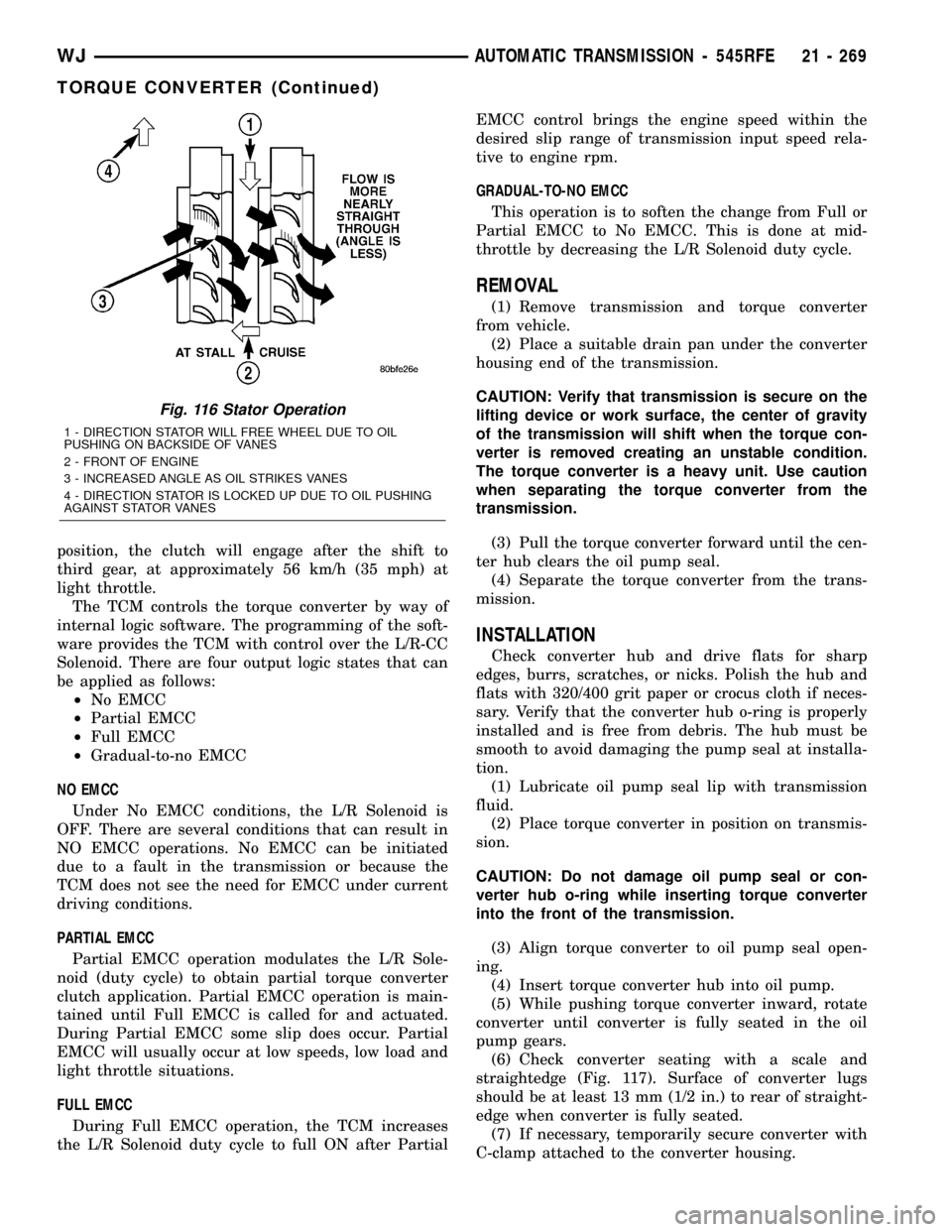

position, the clutch will engage after the shift to

third gear, at approximately 56 km/h (35 mph) at

light throttle.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

²No EMCC

²Partial EMCC

²Full EMCC

²Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is

OFF. There are several conditions that can result in

NO EMCC operations. No EMCC can be initiated

due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Sole-

noid (duty cycle) to obtain partial torque converter

clutch application. Partial EMCC operation is main-

tained until Full EMCC is called for and actuated.

During Partial EMCC some slip does occur. Partial

EMCC will usually occur at low speeds, low load and

light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases

the L/R Solenoid duty cycle to full ON after PartialEMCC control brings the engine speed within the

desired slip range of transmission input speed rela-

tive to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or

Partial EMCC to No EMCC. This is done at mid-

throttle by decreasing the L/R Solenoid duty cycle.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive flats for sharp

edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if neces-

sary. Verify that the converter hub o-ring is properly

installed and is free from debris. The hub must be

smooth to avoid damaging the pump seal at installa-

tion.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 117). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

Fig. 116 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 269

TORQUE CONVERTER (Continued)