length JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 329 of 2199

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM

are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBtScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

²Diagnostic capabilities (with DRBtscan tool)

NOTE: If the TCM has been replaced, the ªQuick

Learn Procedureº must be performed. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

BATTERY FEED

A fused, direct battery feed to the TCM is used for

continuous power. This battery voltage is necessary

to retain adaptive learn values in the TCM's RAM

(Random Access Memory). When the battery (B+) is

disconnected, this memory is lost. When the battery

(B+) is restored, this memory loss is detected by the

TCM and a Diagnostic Trouble Code (DTC) is set.

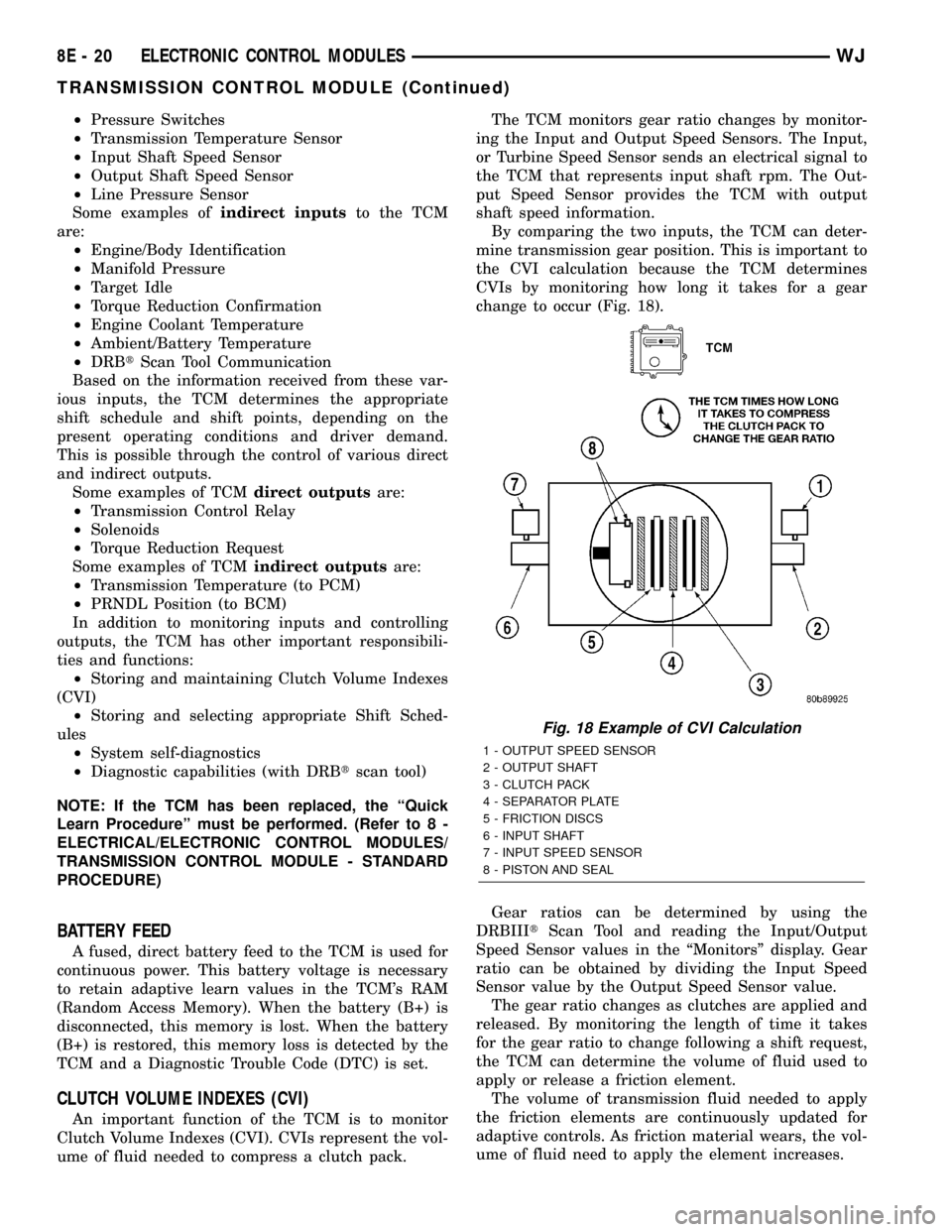

CLUTCH VOLUME INDEXES (CVI)

An important function of the TCM is to monitor

Clutch Volume Indexes (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-

put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transmission gear position. This is important to

the CVI calculation because the TCM determines

CVIs by monitoring how long it takes for a gear

change to occur (Fig. 18).

Gear ratios can be determined by using the

DRBIIItScan Tool and reading the Input/Output

Speed Sensor values in the ªMonitorsº display. Gear

ratio can be obtained by dividing the Input Speed

Sensor value by the Output Speed Sensor value.

The gear ratio changes as clutches are applied and

released. By monitoring the length of time it takes

for the gear ratio to change following a shift request,

the TCM can determine the volume of fluid used to

apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Fig. 18 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

8E - 20 ELECTRONIC CONTROL MODULESWJ

TRANSMISSION CONTROL MODULE (Continued)

Page 414 of 2199

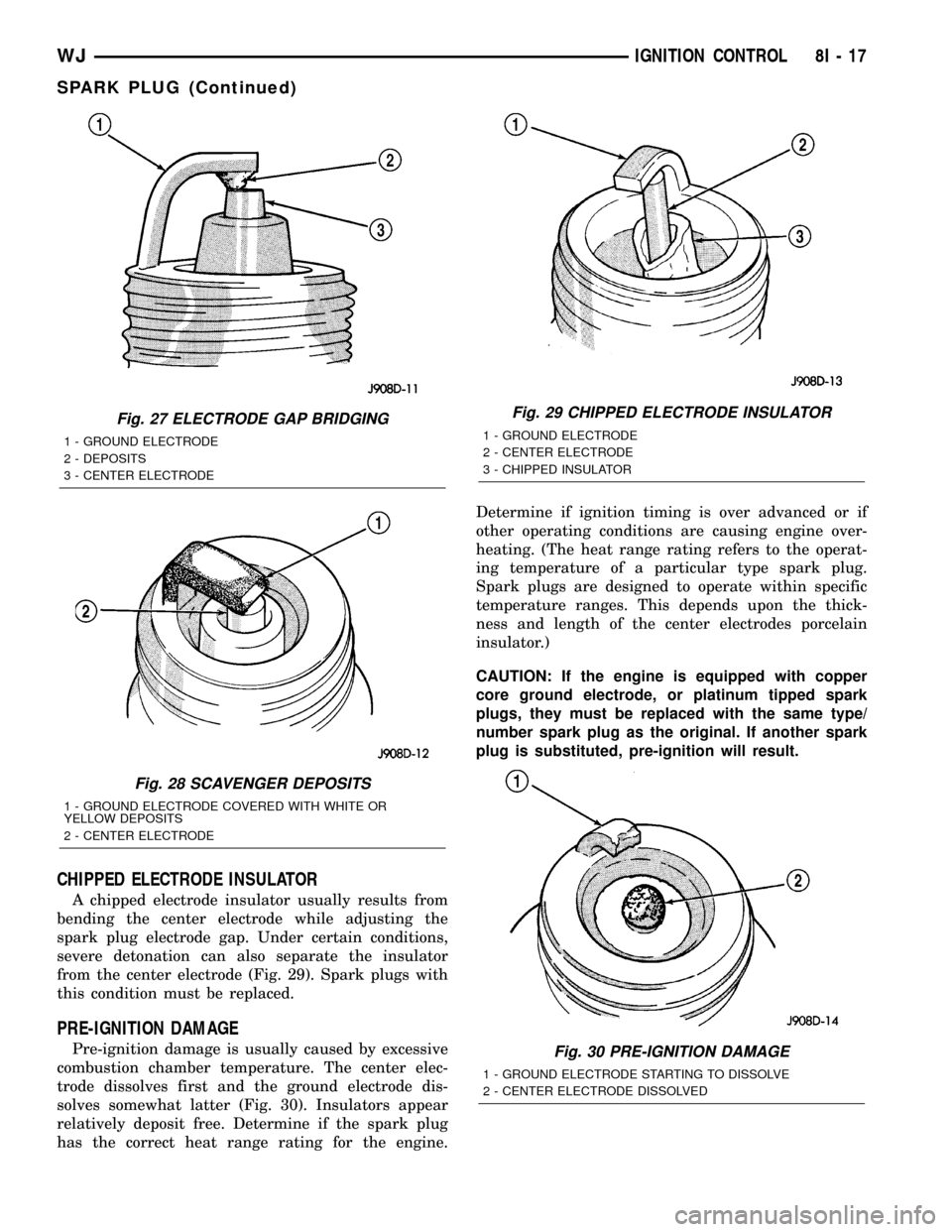

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation can also separate the insulator

from the center electrode (Fig. 29). Spark plugs with

this condition must be replaced.

PRE-IGNITION DAMAGE

Pre-ignition damage is usually caused by excessive

combustion chamber temperature. The center elec-

trode dissolves first and the ground electrode dis-

solves somewhat latter (Fig. 30). Insulators appear

relatively deposit free. Determine if the spark plug

has the correct heat range rating for the engine.Determine if ignition timing is over advanced or if

other operating conditions are causing engine over-

heating. (The heat range rating refers to the operat-

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specific

temperature ranges. This depends upon the thick-

ness and length of the center electrodes porcelain

insulator.)

CAUTION: If the engine is equipped with copper

core ground electrode, or platinum tipped spark

plugs, they must be replaced with the same type/

number spark plug as the original. If another spark

plug is substituted, pre-ignition will result.

Fig. 27 ELECTRODE GAP BRIDGING

1 - GROUND ELECTRODE

2 - DEPOSITS

3 - CENTER ELECTRODE

Fig. 28 SCAVENGER DEPOSITS

1 - GROUND ELECTRODE COVERED WITH WHITE OR

YELLOW DEPOSITS

2 - CENTER ELECTRODE

Fig. 29 CHIPPED ELECTRODE INSULATOR

1 - GROUND ELECTRODE

2 - CENTER ELECTRODE

3 - CHIPPED INSULATOR

Fig. 30 PRE-IGNITION DAMAGE

1 - GROUND ELECTRODE STARTING TO DISSOLVE

2 - CENTER ELECTRODE DISSOLVED

WJIGNITION CONTROL 8I - 17

SPARK PLUG (Continued)

Page 486 of 2199

PROGRAMMABLE FEATURES

²LANGUAGE?-The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default is

English. All EVIC display nomenclature, including the

trip computer functions, warning messages and the pro-

grammable features appear in the selected language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure. It also changes the odome-

ter display in the instrument cluster.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if the

vehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors

and the liftgate. When All Doors is selected, all doors

and the liftgate unlock when the Unlock button of

the RKE transmitter is depressed once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory system. The options

include Yes and No. The default is No. When Yes is

selected, the memory system will recall the Driver 1

or Driver 2 memory settings assigned to the RKE

transmitter being used to unlock the vehicle. When

No is selected, the memory system will only recall

memory settings when the Driver 1 or Driver 2 push

buttons of the memory switch on the driver side front

door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps will

only turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²SERVICE INTV. =- The options include from

1000 to 12000 kilometers in 1000 kilometer incre-

ments (2000 to 7500 miles in 500 mile increments).

The default is 12000 kilometers (7500 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

²LOW FUEL CHIME?- The options include Yes

and No. The default is Yes. When Yes is selected, a

single chime will sound as an audible alert whenever

the instrument cluster low fuel warning lamp lights.

The chime will sound only once per ignition cycle.

When No is selected, only the low fuel warning lamp

in the instrument cluster will light and no chime will

sound.

WJMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 487 of 2199

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional tire pressure monitoring system. The

options include Yes and No. The default is No. When

Yes is selected and the menu button is depressed, the

EVIC will enter the training mode starting with the

left front tire.

²EASY EXIT SEAT?- This programmable fea-

ture only applies to vehicles equipped with the

optional memory system. The options include Yes and

No. The default is No. When Yes is selected, the

driver seat moves rearward about 55 millimeters

(two inches) or to the farthest rearward position,

whichever comes first, when the key is removed from

the ignition switch lock cylinder. This provides addi-

tional ease for exiting from the vehicle. The seat will

automatically return to the memory system setting

position when the Driver 1 or Driver 2 button of the

memory switch on the door panel is depressed or, if

theREMOTE LINKED TO MEMORYprogramma-

ble feature is enabled, when the RKE Unlock button

is depressed. While not automatic, an easy entry fea-

ture can be obtained by enabling theEASY EXIT

SEATfeature and disabling theREMOTE LINKED

TO MEMORYfeature. Then theEASY EXIT SEAT

feature will move the seat back, but the RKE unlock

event will not reposition the seat. Thus, the seat

remains positioned for easy entry, and the memory

switch on the door panel can be depressed after

entering the vehicle to return the seat to the desired

memory position.

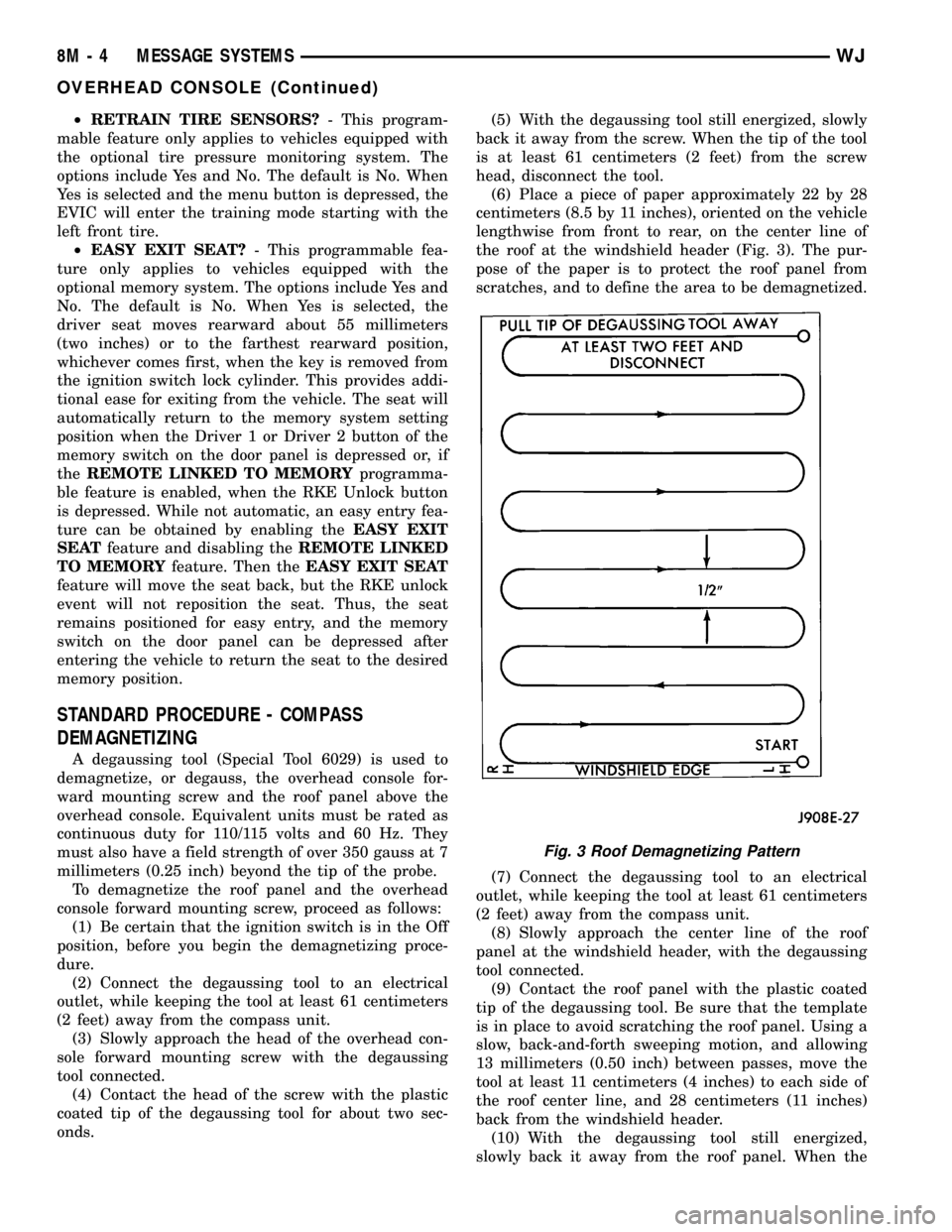

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing proce-

dure.

(2) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(3) Slowly approach the head of the overhead con-

sole forward mounting screw with the degaussing

tool connected.

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two sec-

onds.(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 3). The pur-

pose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

(7) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(8) Slowly approach the center line of the roof

panel at the windshield header, with the degaussing

tool connected.

(9) Contact the roof panel with the plastic coated

tip of the degaussing tool. Be sure that the template

is in place to avoid scratching the roof panel. Using a

slow, back-and-forth sweeping motion, and allowing

13 millimeters (0.50 inch) between passes, move the

tool at least 11 centimeters (4 inches) to each side of

the roof center line, and 28 centimeters (11 inches)

back from the windshield header.

(10) With the degaussing tool still energized,

slowly back it away from the roof panel. When the

Fig. 3 Roof Demagnetizing Pattern

8M - 4 MESSAGE SYSTEMSWJ

OVERHEAD CONSOLE (Continued)

Page 535 of 2199

INSTALLATION

(1) Position the power window switch to the rear

door trim panel switch receptacle.

(2) Press firmly and evenly on the back of the

power window switch until it snaps into rear door

trim panel switch receptacle.

(3) Install the trim panel onto the rear door. (Refer

to 23 - BODY/DOORS - REAR/TRIM PANEL -

INSTALLATION) for the procedures.

(4) Reconnect the battery negative cable.

WINDOW MOTOR

DESCRIPTION

Power operated front and rear door windows are

standard equipment on this model. Each door has a

permanent magnet reversible electric motor with an

integral right angle gearbox mechanism that oper-

ates the window regulator. In addition, each power

window motor is equipped with an integral self-reset-

ting circuit breaker to protect the motor from over-

loads.

The power window motor gearbox housing is

secured to the window regulator drum housing with

screws. The window regulators used in all four doors

are single vertical post cable-and-drum type. A

molded plastic slider guided by the post is driven by

the regulator cables. The slider raises and lowers the

window glass through a steel lift plate attachment.

Front and rear glass channels within each door guide

and stabilize each end of the glass.

The power window motor and gearbox assembly

cannot be repaired and, if faulty or damaged, the

entire power window motor and gearbox unit must be

replaced. The window regulators are available for

service. (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL) for the regulator service procedures.

OPERATION

A positive and negative battery connection to the

two motor terminals will cause the power window

motor to rotate in one direction. Reversing the cur-

rent through these same two connections will cause

the motor to rotate in the opposite direction.

When the power window motor operates, it rotates

the regulator cable drum through its gearbox. The

window regulator cable drum is connected through

two cables to the plastic slider on the vertical post.

As the cable drum rotates, it lets cable out on one

side of the drum, and takes cable in on the other side

of the drum. The changes in cable length move the

slider up or down the vertical post, raising or lower-

ing the window glass.If the window regulator or window glass bind,

encounter obstructions, or reach their travel limits it

overloads the power window motor. The overloading

condition causes the power window motor self-reset-

ting circuit breaker to open, which stops the motor

from running.

DIAGNOSIS AND TESTING - WINDOW MOTOR

Before you proceed with this diagnosis, confirm

proper switch operation. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DRIVER

DOOR MODULE - OPERATION) or (Refer to 8 -

ELECTRICAL/POWER WINDOWS/POWER WIN-

DOW SWITCH - OPERATION). For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove the trim panel from the door with the

inoperative power window. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL) or

(Refer to 23 - BODY/DOORS - REAR/TRIM PANEL -

REMOVAL) for the procedures.

(2) Disconnect the door wire harness connector

from the power window motor wire harness connec-

tor. Apply battery current to one cavity of the power

window motor wire harness connector, and apply

ground to the other cavity of the connector. The

power window motor should operate in one direction.

Remember, if the window is in the full up or full

down position, the motor will not operate in that

direction by design. If OK, go to Step 3. If not OK,

replace the faulty power window motor.

(3) Reverse the battery and ground connections to

the two cavities of the power window motor wire har-

ness connector. The power window motor should now

operate in the other direction. Remember, if the win-

dow is in the full up or full down position, the motor

will not operate in that direction by design. If OK, go

to Step 4. If not OK, replace the faulty power window

motor.

(4) If the power window motor operates in both

directions, check the operation of the window glass

and regulator mechanism through its complete up

and down travel. There should be no binding or stick-

ing of the window glass or regulator mechanism

through the entire travel range. If not OK, (Refer to

23 - BODY/DOOR - FRONT/WINDOW REGULATOR

- REMOVAL) or (Refer to 23 - BODY/DOORS -

REAR/WINDOW REGULATOR - REMOVAL) to

check for proper installation or damage of the win-

dow glass mounting and operating hardware.

8N - 38 POWER WINDOWSWJ

POWER WINDOW SWITCH (Continued)

Page 583 of 2199

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the PCM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

PCM when the RES/ACCEL is released. The PCM

also has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the RES/ACCEL

switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

8P - 2 SPEED CONTROLWJ

SPEED CONTROL (Continued)

Page 602 of 2199

INSTALLATION - HOOD AJAR SWITCH

STRIKER

(1) Align the three integral retainers of the hood

ajar switch striker with their mounting holes in the

inner hood panel reinforcement (Fig. 4).

(2) Using hand pressure, firmly press the hood

ajar switch striker against the inner hood panel rein-

forcement until all of the striker retainers are fully

engaged in their mounting holes.

(3) Close and latch the hood.

INTRUSION TRANSCEIVER

MODULE

DESCRIPTION

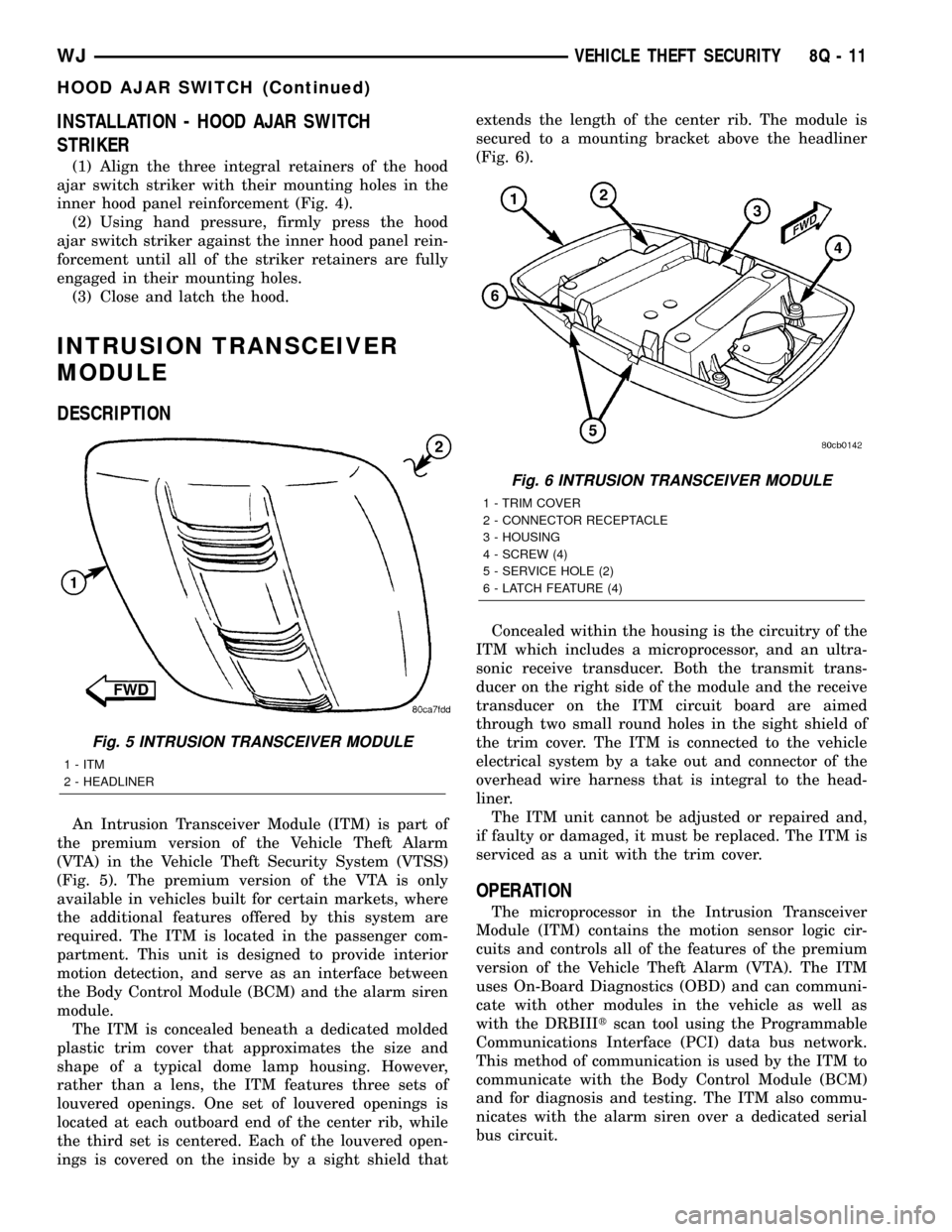

An Intrusion Transceiver Module (ITM) is part of

the premium version of the Vehicle Theft Alarm

(VTA) in the Vehicle Theft Security System (VTSS)

(Fig. 5). The premium version of the VTA is only

available in vehicles built for certain markets, where

the additional features offered by this system are

required. The ITM is located in the passenger com-

partment. This unit is designed to provide interior

motion detection, and serve as an interface between

the Body Control Module (BCM) and the alarm siren

module.

The ITM is concealed beneath a dedicated molded

plastic trim cover that approximates the size and

shape of a typical dome lamp housing. However,

rather than a lens, the ITM features three sets of

louvered openings. One set of louvered openings is

located at each outboard end of the center rib, while

the third set is centered. Each of the louvered open-

ings is covered on the inside by a sight shield thatextends the length of the center rib. The module is

secured to a mounting bracket above the headliner

(Fig. 6).

Concealed within the housing is the circuitry of the

ITM which includes a microprocessor, and an ultra-

sonic receive transducer. Both the transmit trans-

ducer on the right side of the module and the receive

transducer on the ITM circuit board are aimed

through two small round holes in the sight shield of

the trim cover. The ITM is connected to the vehicle

electrical system by a take out and connector of the

overhead wire harness that is integral to the head-

liner.

The ITM unit cannot be adjusted or repaired and,

if faulty or damaged, it must be replaced. The ITM is

serviced as a unit with the trim cover.

OPERATION

The microprocessor in the Intrusion Transceiver

Module (ITM) contains the motion sensor logic cir-

cuits and controls all of the features of the premium

version of the Vehicle Theft Alarm (VTA). The ITM

uses On-Board Diagnostics (OBD) and can communi-

cate with other modules in the vehicle as well as

with the DRBIIItscan tool using the Programmable

Communications Interface (PCI) data bus network.

This method of communication is used by the ITM to

communicate with the Body Control Module (BCM)

and for diagnosis and testing. The ITM also commu-

nicates with the alarm siren over a dedicated serial

bus circuit.

Fig. 5 INTRUSION TRANSCEIVER MODULE

1 - ITM

2 - HEADLINER

Fig. 6 INTRUSION TRANSCEIVER MODULE

1 - TRIM COVER

2 - CONNECTOR RECEPTACLE

3 - HOUSING

4 - SCREW (4)

5 - SERVICE HOLE (2)

6 - LATCH FEATURE (4)

WJVEHICLE THEFT SECURITY 8Q - 11

HOOD AJAR SWITCH (Continued)

Page 612 of 2199

tem functions, as well as separate hard wired sense

inputs to the BCM for the high speed continuous

wipe and front washer system functions.

The front wiper and washer system will only oper-

ate when the ignition switch is in the Accessory or

On positions. Battery current is directed from a B(+)

fuse in the Power Distribution Center (PDC) to the

wiper and washer system circuit breaker in the Junc-

tion Block (JB) through a fused ignition switch out-

put (run-acc) circuit. The automatic resetting circuit

breaker then provides battery current through a

fused ignition switch output (run-acc) circuit to the

wiper on/off relay, and the park switch in the front

wiper motor. A separate fuse in the JB provides bat-

tery current through another fused ignition switch

output (run-acc) circuit to the right multi-function

switch. The right multi-function switch circuitry uses

this battery feed to directly control the operation of

the front washer pump/motor unit. The BCM uses

low side drivers to control front wiper system opera-

tion by energizing or de-energizing the wiper high/

low and wiper on/off relays.

The hard wired circuits and components of the

front wiper and washer system may be diagnosed

and tested using conventional diagnostic tools and

procedures. However, conventional diagnostic meth-

ods may not prove conclusive in the diagnosis of the

Body Control Module (BCM), or the inputs to or out-

puts from the BCM that control the front wiper and

washer system operating modes. The most reliable,

efficient, and accurate means to diagnose the BCM,

or the BCM inputs and outputs related to the various

front wiper and washer system operating modes

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

Following are paragraphs that briefly describe the

operation of each of the front wiper and washer sys-

tem operating modes.

CONTINUOUS WIPE MODE

When the Low position of the control knob on the

control stalk of the right (wiper) multi-function

switch is selected, the Body Control Module (BCM)

energizes the wiper on/off relay. This directs battery

current through the normally open contacts of the

energized wiper on/off relay and the normally closed

contacts of the de-energized wiper high/low relay to

the low speed brush of the front wiper motor, causing

the front wipers to cycle at low speed. When the

High position of the control knob is selected, the

BCM energizes both the wiper on/off relay and the

wiper high/low relay. This directs battery current

through the normally open contacts of the energized

wiper on/off relay and the normally open contacts of

the energized wiper high/low relay to the high speedbrush of the front wiper motor, causing the front wip-

ers to cycle at high speed.

When the Off position of the control knob is

selected, the BCM de-energizes both the wiper on/off

and wiper high/low relays, then one of two events

will occur. The event that will occur depends upon

the position of the wiper blades on the windshield at

the moment that the control knob Off position is

selected. If the wiper blades are in the down position

on the windshield when the Off position is selected,

the park switch that is integral to the front wiper

motor is closed to ground and the wiper motor ceases

to operate. If the wiper blades are not in the down

position on the windshield at the moment the Off

position is selected, the park switch is closed to bat-

tery current from the fused ignition switch output

(run-acc) circuit of the front wiper motor. The park

switch directs this battery current to the low speed

brush of the wiper motor through the wiper park

switch sense circuit and the normally closed contacts

of the wiper on/off and wiper high/low relays. This

causes the wiper motor to continue running at low

speed until the wiper blades are in the down position

on the windshield and the park switch is again

closed to ground.

INTERMITTENT WIPE MODE

On models not equipped with the optional auto-

matic wiper system, when the control knob on the

control stalk of the right (wiper) multi-function

switch is moved to one of the five Delay interval posi-

tions, the BCM electronic intermittent wipe logic cir-

cuit responds by calculating the correct length of

time between wiper sweeps based upon the selected

delay interval input. The BCM monitors the chang-

ing state of the wiper motor park switch through a

hard wired front wiper park switch sense circuit

input. This input allows the BCM to determine the

proper intervals at which to energize and de-energize

the wiper on/off relay to operate the front wiper

motor intermittently for one low speed cycle at a

time. The BCM logic is also programmed to provide

an immediate wipe cycle and begin a new delay

interval timing cycle each time a shorter delay inter-

val is selected, and to add the remaining delay tim-

ing interval to the new delay interval timing before

the next wipe cycle occurs each time a longer delay

interval is selected.

The intermittent wipe mode delay times are speed

sensitive. The BCM monitors vehicle speed messages

received from the Powertrain Control Module (PCM)

over the Programmable Communications Interface

(PCI) data bus network in order to provide the speed

sensitive delay intervals. Above about sixteen kilome-

ters-per-hour (ten miles-per-hour) the delay is driver

adjustable from about one-half second to about eigh-

WJFRONT WIPERS/WASHERS 8R - 5

FRONT WIPERS/WASHERS (Continued)

Page 616 of 2199

WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/

FRONT WIPERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back together

using an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,

sharp bends that might pinch the washer hose must

be avoided.

FRONT CHECK VALVE

DESCRIPTION

A front washer system check valve is standard

equipment on this model. The front check valve is

integral to the front washer nozzle plumbing wye fit-

ting located in the cowl plenum beneath the cowl ple-

num cover/grille panel near the base of the

windshield. The check valve consists of a molded

plastic body with a round center section. Three

barbed hose nipples are formed in a wye configura-

tion on the outside circumference of the center sec-

tion of the valve body. Within the check valve body, a

small check valve operated by a small coiled spring

restricts flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

The front check valve cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The front check valve provides more than one func-

tion in this application. It serves as a wye connector

fitting between the cowl grille panel and washer noz-

zle sections of the front washer supply hose. It also

prevents washer fluid from draining out of the front

washer supply hoses back to the washer reservoir.

This drain-back would result in a lengthy delay from

when the front washer switch is actuated until

washer fluid was dispensed through the front washer

nozzles, because the front washer pump would have

to refill the front washer plumbing from the reservoir

to the nozzles. Finally, the front check valve prevents

washer fluid from siphoning through the front

washer nozzles after the front washer system is

turned Off. When the front washer pump pressurizes

and pumps washer fluid from the reservoir through

the front washer plumbing, the fluid pressure over-

rides the spring pressure applied to the check valve

and unseats the valve, allowing washer fluid to flow

toward the front washer nozzles. When the front

washer pump stops operating, spring pressure seats

the check valve and fluid flow in either direction

within the front washer plumbing is prevented.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/FRONT WIPERS/WASH-

ERS/FRONT WIPER ARMS - REMOVAL).

(3) Open the hood and pull the hood to plenum

seal off of the forward flanges of the cowl grille cover

and the plenum panel.

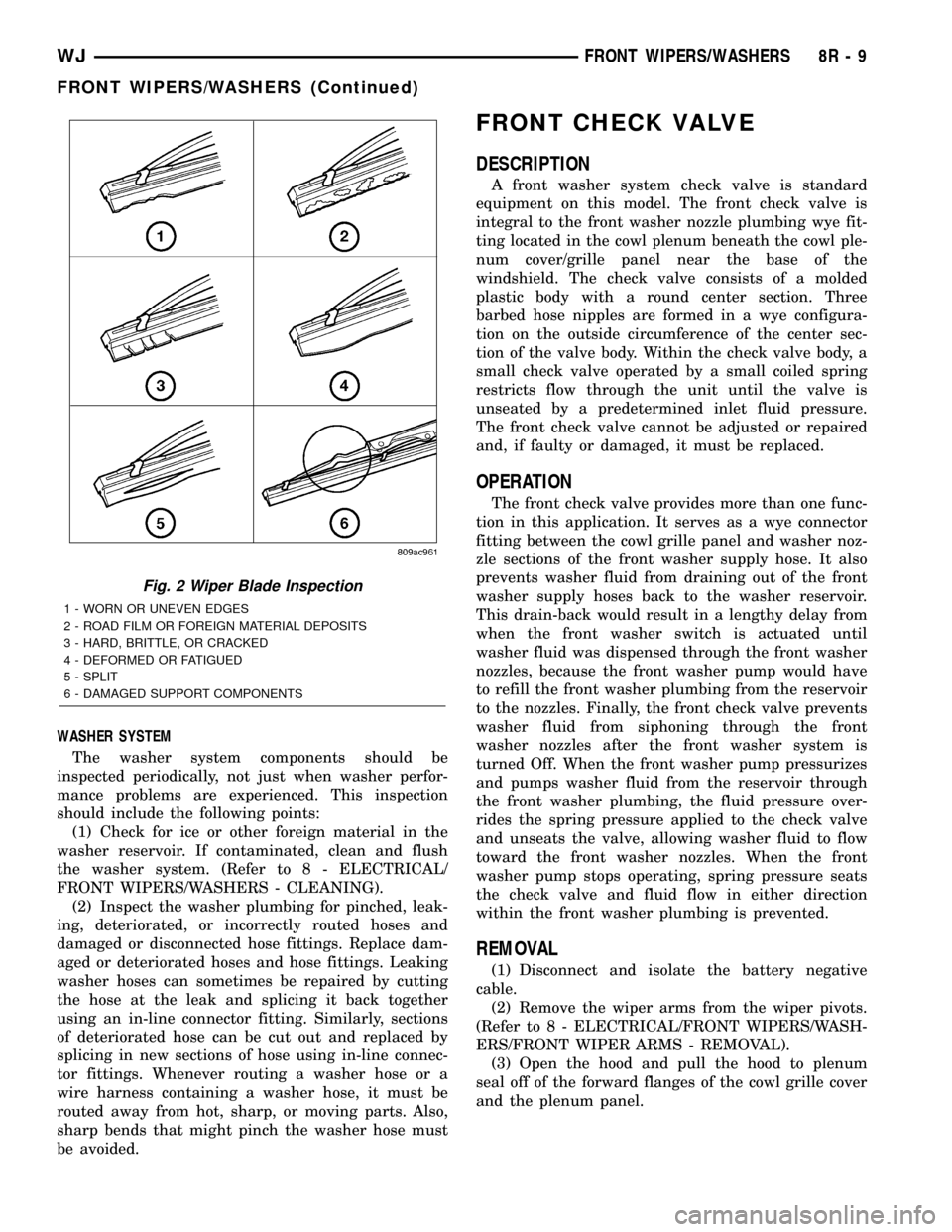

Fig. 2 Wiper Blade Inspection

1 - WORN OR UNEVEN EDGES

2 - ROAD FILM OR FOREIGN MATERIAL DEPOSITS

3 - HARD, BRITTLE, OR CRACKED

4 - DEFORMED OR FATIGUED

5 - SPLIT

6 - DAMAGED SUPPORT COMPONENTS

WJFRONT WIPERS/WASHERS 8R - 9

FRONT WIPERS/WASHERS (Continued)

Page 618 of 2199

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the front washer pump/motor through the

front washer system plumbing and fittings to the two

front washer nozzles. Whenever routing the washer

hose or a wire harness containing a washer hose, it

must be routed away from hot, sharp, or moving

parts; and, sharp bends that might pinch the hose

must be avoided.

FRONT WASHER NOZZLE

DESCRIPTION

The two front washer nozzles have integral snap

features that secure them in dedicated holes in the

cowl plenum cover/grille panel located near the base

of the windshield. The domed upper surface of the

washer nozzle is visible on the top of the plenum cov-

er/grille panel, and the nozzle orifice is oriented

towards the windshield glass. The washer plumbing

fittings for the washer nozzles are concealed beneath

the cowl plenum cover/grille panel. These fluidic

washer nozzles are constructed of molded plastic. The

cowl plenum cover/grille panel must be removed from

the vehicle to access the nozzles for service. The

washer nozzles cannot be adjusted or repaired. If

faulty or damaged, they must be replaced.

OPERATION

The two front washer nozzles are designed to dis-

pense washer fluid into the wiper pattern area on the

outside of the windshield glass. Pressurized washer

fluid is fed to each nozzle from the washer reservoir

by the front washer pump/motor through a single

hose, which is attached to a barbed nipple on each

front washer nozzle below the cowl plenum cover/

grille panel. The washer nozzles incorporate a fluidic

design, which causes the nozzle to emit the pressur-

ized washer fluid as an oscillating stream to more

effectively cover a larger area of the glass area to be

cleaned.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/FRONT WIPERS/WASH-

ERS/FRONT WIPER ARMS - REMOVAL).

(3) Unlatch and open the hood.(4) Pull the hood to plenum seal off of the forward

flanges of the cowl grille cover and the plenum panel.

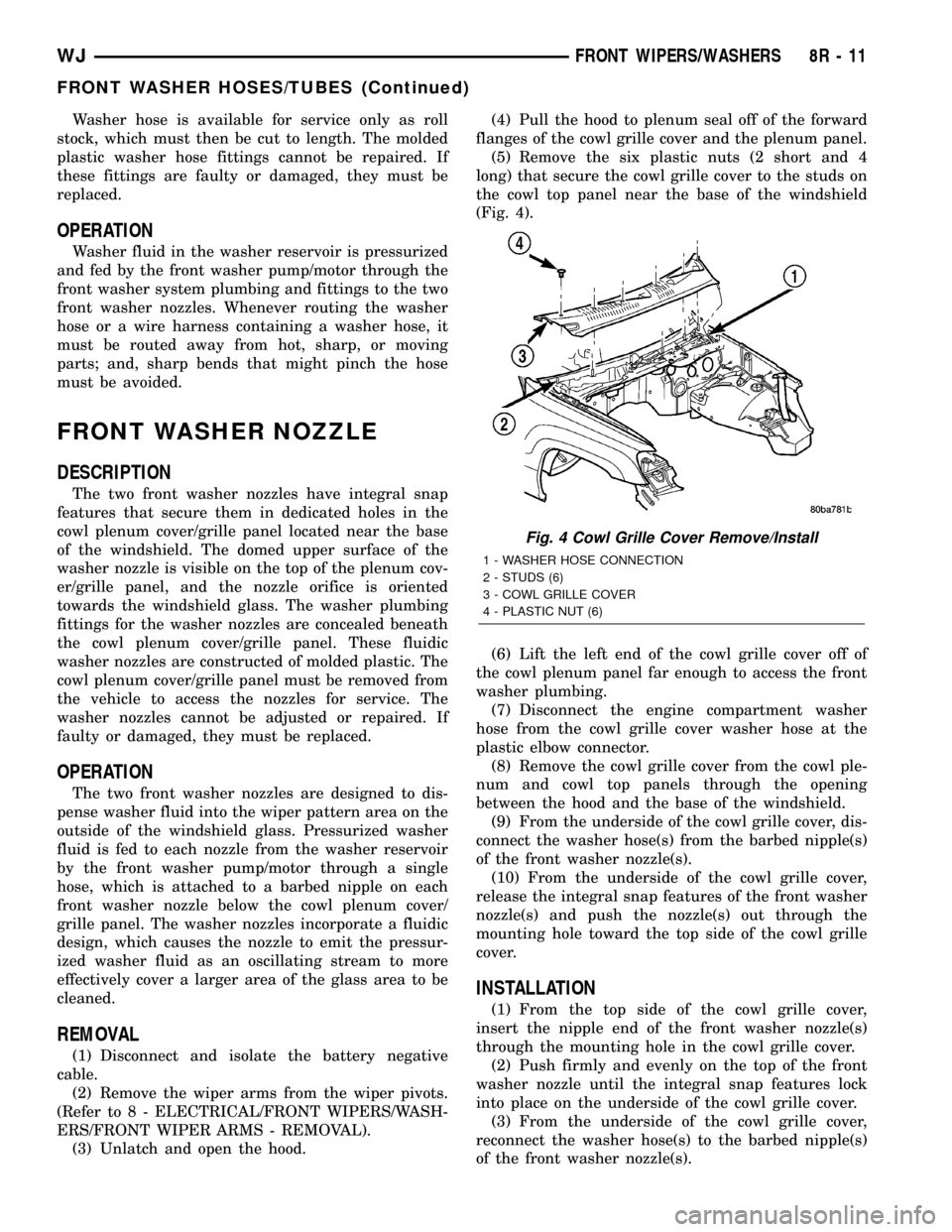

(5) Remove the six plastic nuts (2 short and 4

long) that secure the cowl grille cover to the studs on

the cowl top panel near the base of the windshield

(Fig. 4).

(6) Lift the left end of the cowl grille cover off of

the cowl plenum panel far enough to access the front

washer plumbing.

(7) Disconnect the engine compartment washer

hose from the cowl grille cover washer hose at the

plastic elbow connector.

(8) Remove the cowl grille cover from the cowl ple-

num and cowl top panels through the opening

between the hood and the base of the windshield.

(9) From the underside of the cowl grille cover, dis-

connect the washer hose(s) from the barbed nipple(s)

of the front washer nozzle(s).

(10) From the underside of the cowl grille cover,

release the integral snap features of the front washer

nozzle(s) and push the nozzle(s) out through the

mounting hole toward the top side of the cowl grille

cover.

INSTALLATION

(1) From the top side of the cowl grille cover,

insert the nipple end of the front washer nozzle(s)

through the mounting hole in the cowl grille cover.

(2) Push firmly and evenly on the top of the front

washer nozzle until the integral snap features lock

into place on the underside of the cowl grille cover.

(3) From the underside of the cowl grille cover,

reconnect the washer hose(s) to the barbed nipple(s)

of the front washer nozzle(s).

Fig. 4 Cowl Grille Cover Remove/Install

1 - WASHER HOSE CONNECTION

2 - STUDS (6)

3 - COWL GRILLE COVER

4 - PLASTIC NUT (6)

WJFRONT WIPERS/WASHERS 8R - 11

FRONT WASHER HOSES/TUBES (Continued)