spec JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 23 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE PULLS TO ONE

SIDE DURING BRAKING1. Uneven tire pressure. 1. Adjust tire pressure.

2. Worn brake components. 2. Repair brakes as necessary.

3. Air in brake line. 3. Repair as necessary.

VEHICLE LEADS OR

DRIFTS FROM STRAIGHT

AHEAD DIRECTION ON

UNCROWNED ROAD1. Radial tire lead. 1. Cross front tires.

2. Brakes dragging. 2. Repair brake as necessary.

3. Weak or broken spring. 3. Replace spring.

4. Uneven tire pressure. 4. Adjust tire pressure.

5. Wheel Alignment. 5. Align vehicle.

6. Loose or worn steering or

suspension components.6. Repair as necessary.

7. Cross caster out of spec. 7. Align vehicle.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

3. Shock valve. 3. Replace shock.

IMPROPER TRACKING 1. Loose, worn or bent track bar. 1. Inspect, tighten or replace component as

necessary.

2. Loose, worn or bent steering/

suspension components.2. Inspect, tighten or replace components

as necessary.

2 - 2 SUSPENSIONWJ

SUSPENSION (Continued)

Page 24 of 2199

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE

STANDARD PROCEDURE - CAMBER.......3STANDARD PROCEDURE - CASTER.......4

STANDARD PROCEDURE - TOE POSITION . . 4

SPECIFICATIONS

ALIGNMENT..........................5

WHEEL ALIGNMENT

DESCRIPTION

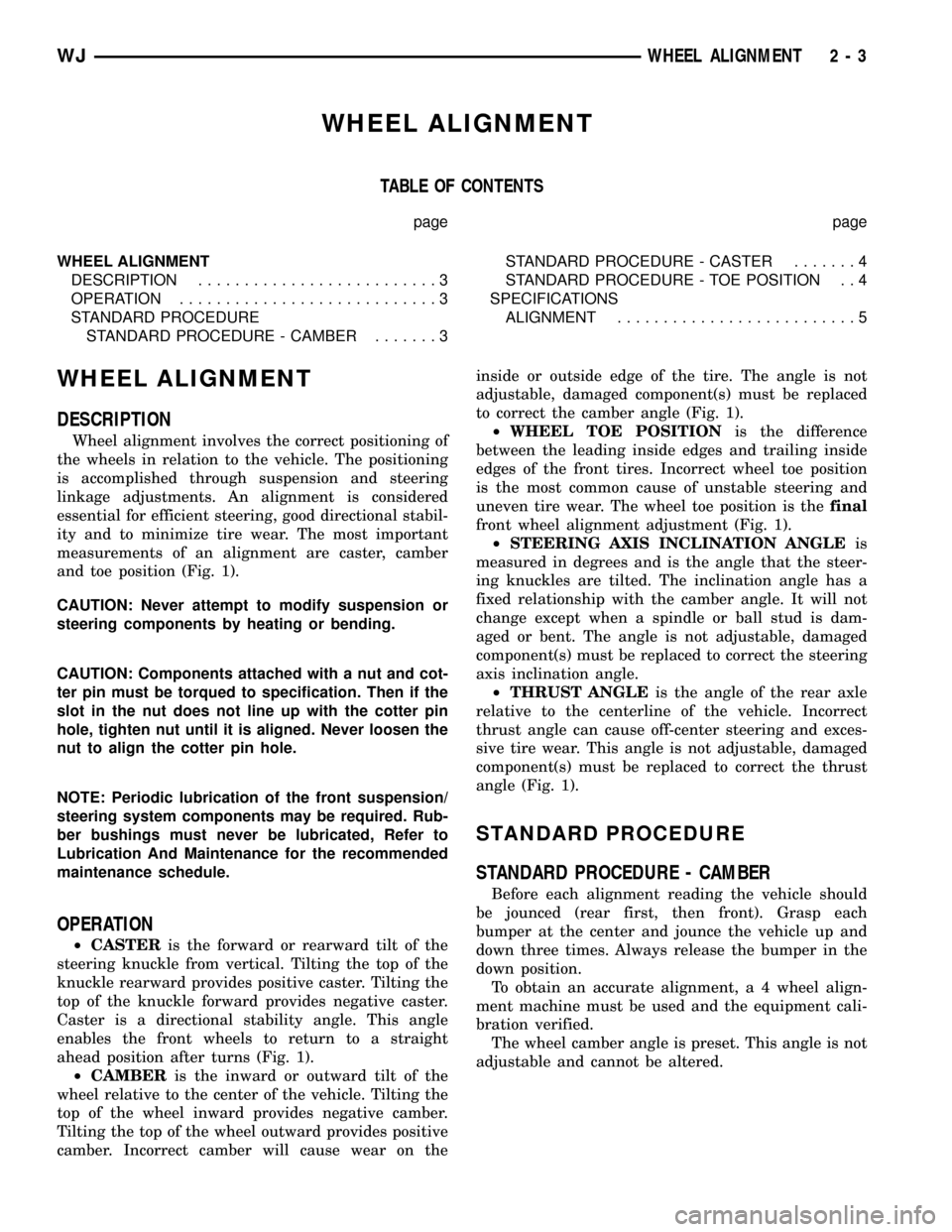

Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stabil-

ity and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe position (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.

NOTE: Periodic lubrication of the front suspension/

steering system components may be required. Rub-

ber bushings must never be lubricated, Refer to

Lubrication And Maintenance for the recommended

maintenance schedule.

OPERATION

²CASTERis the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting the

top of the knuckle forward provides negative caster.

Caster is a directional stability angle. This angle

enables the front wheels to return to a straight

ahead position after turns (Fig. 1).

²CAMBERis the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on theinside or outside edge of the tire. The angle is not

adjustable, damaged component(s) must be replaced

to correct the camber angle (Fig. 1).

²WHEEL TOE POSITIONis the difference

between the leading inside edges and trailing inside

edges of the front tires. Incorrect wheel toe position

is the most common cause of unstable steering and

uneven tire wear. The wheel toe position is thefinal

front wheel alignment adjustment (Fig. 1).

²STEERING AXIS INCLINATION ANGLEis

measured in degrees and is the angle that the steer-

ing knuckles are tilted. The inclination angle has a

fixed relationship with the camber angle. It will not

change except when a spindle or ball stud is dam-

aged or bent. The angle is not adjustable, damaged

component(s) must be replaced to correct the steering

axis inclination angle.

²THRUST ANGLEis the angle of the rear axle

relative to the centerline of the vehicle. Incorrect

thrust angle can cause off-center steering and exces-

sive tire wear. This angle is not adjustable, damaged

component(s) must be replaced to correct the thrust

angle (Fig. 1).

STANDARD PROCEDURE

STANDARD PROCEDURE - CAMBER

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.

To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

The wheel camber angle is preset. This angle is not

adjustable and cannot be altered.

WJWHEEL ALIGNMENT 2 - 3

Page 25 of 2199

STANDARD PROCEDURE - CASTER

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.

To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

The wheel caster angle is preset. This angle is not

adjustable and cannot be altered.

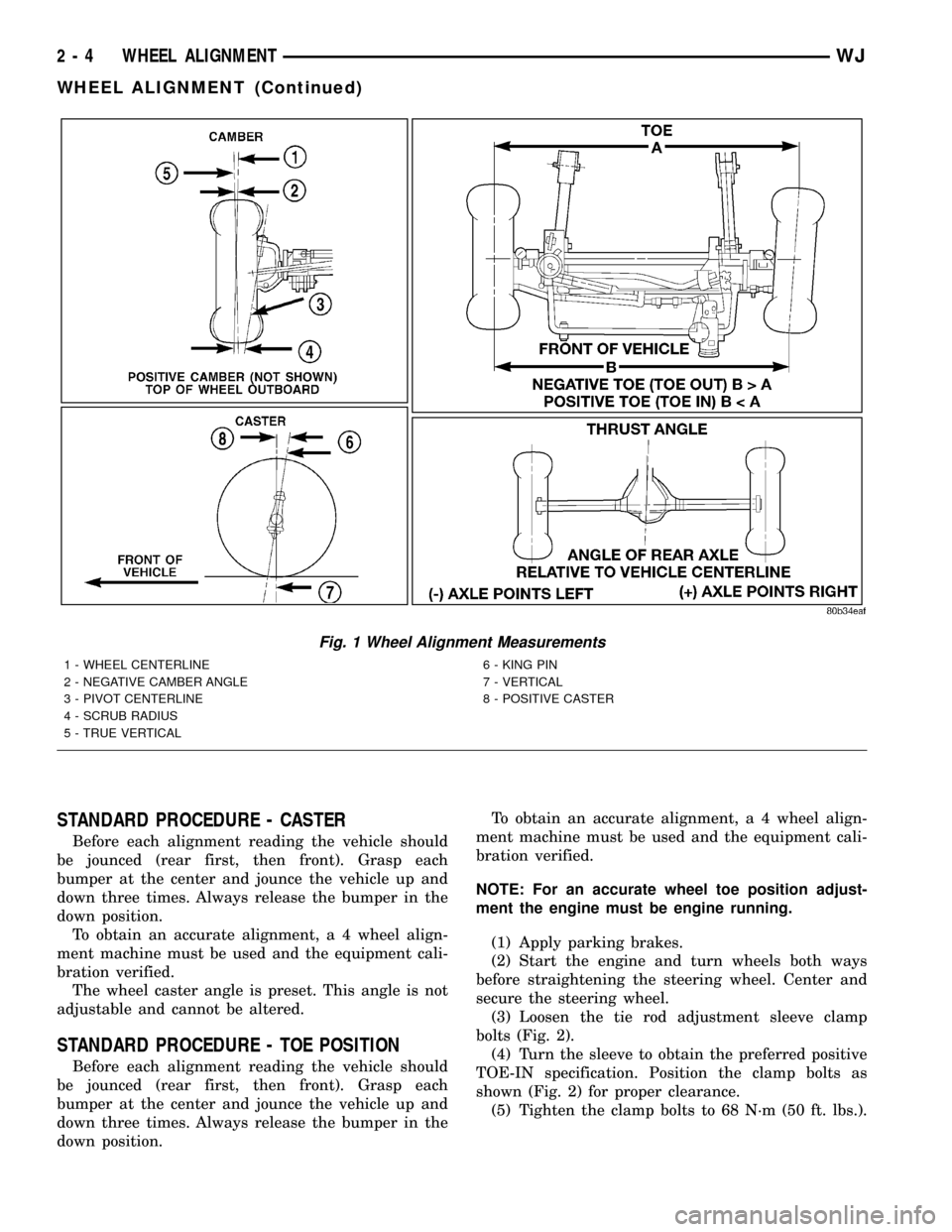

STANDARD PROCEDURE - TOE POSITION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

NOTE: For an accurate wheel toe position adjust-

ment the engine must be engine running.

(1) Apply parking brakes.

(2) Start the engine and turn wheels both ways

before straightening the steering wheel. Center and

secure the steering wheel.

(3) Loosen the tie rod adjustment sleeve clamp

bolts (Fig. 2).

(4) Turn the sleeve to obtain the preferred positive

TOE-IN specification. Position the clamp bolts as

shown (Fig. 2) for proper clearance.

(5) Tighten the clamp bolts to 68 N´m (50 ft. lbs.).

Fig. 1 Wheel Alignment Measurements

1 - WHEEL CENTERLINE

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS

5 - TRUE VERTICAL6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTER

2 - 4 WHEEL ALIGNMENTWJ

WHEEL ALIGNMENT (Continued)

Page 26 of 2199

NOTE: Make sure the toe setting does not change

during clamp tightening.

(6) Verify alignment specifications, then turn the

engine off.

STEERING WHEEL CENTERING

NOTE: The steering wheel can be centered without

affecting the toe position.

(1) Loosen the drag link adjustment sleeve clamp

bolts.

(2) Turn the adjustment sleeve to center the

wheel.

(3) Position the clamp bolts as shown (Fig. 2)for

proper clearance.

(4) Tighten the clamp bolts to 68 N´m (50 ft. lbs.).

(5) Road test the vehicle to verify the wheel is cen-

tered.

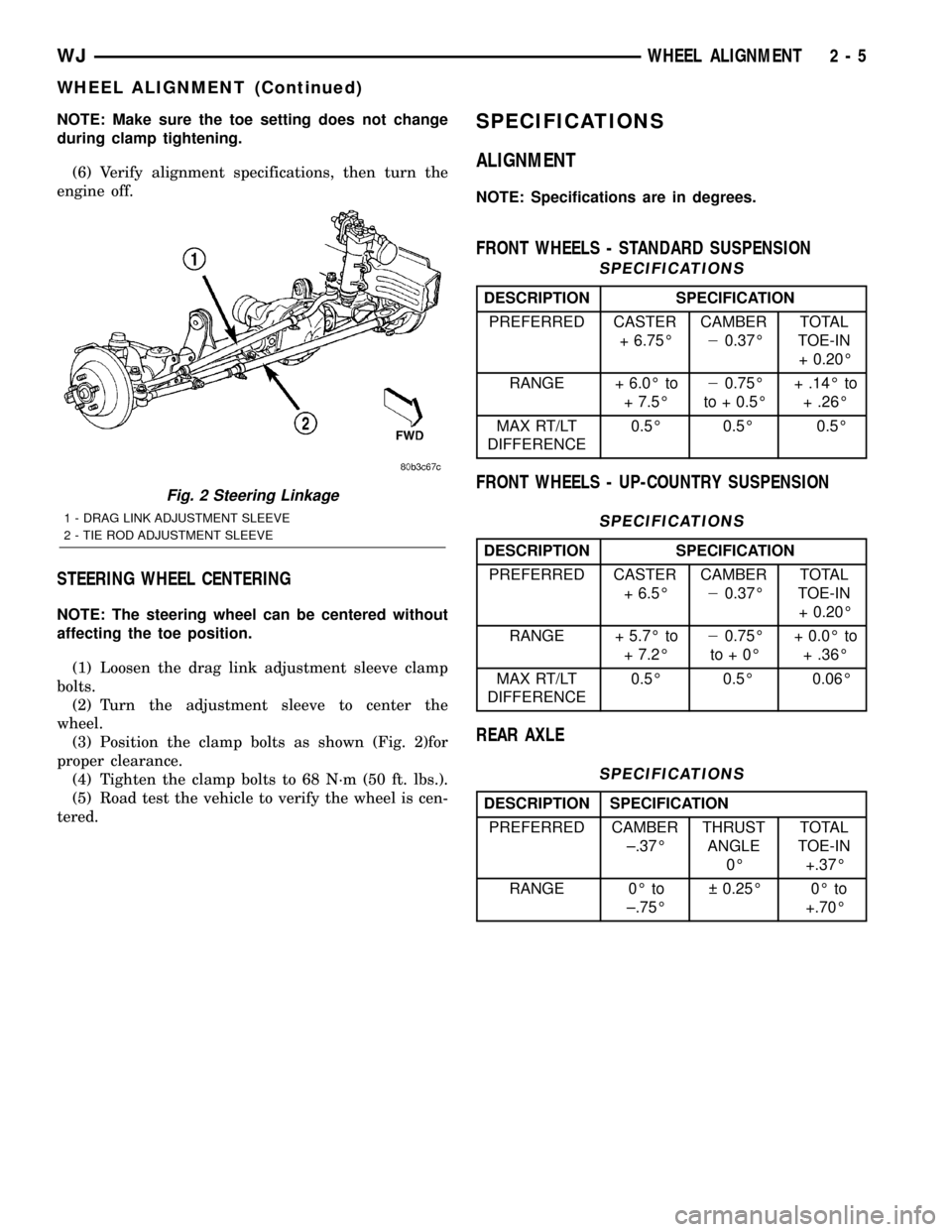

SPECIFICATIONS

ALIGNMENT

NOTE: Specifications are in degrees.

FRONT WHEELS - STANDARD SUSPENSION

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CASTER

+ 6.75ÉCAMBER

20.37ÉTOTAL

TOE-IN

+ 0.20É

RANGE + 6.0É to

+ 7.5É20.75É

to + 0.5É+ .14É to

+ .26É

MAX RT/LT

DIFFERENCE0.5É 0.5É 0.5É

FRONT WHEELS - UP-COUNTRY SUSPENSION

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CASTER

+ 6.5ÉCAMBER

20.37ÉTOTAL

TOE-IN

+ 0.20É

RANGE + 5.7É to

+ 7.2É20.75É

to+0É+ 0.0É to

+ .36É

MAX RT/LT

DIFFERENCE0.5É 0.5É 0.06É

REAR AXLE

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CAMBER

±.37ÉTHRUST

ANGLE

0ÉTOTAL

TOE-IN

+.37É

RANGE 0É to

±.75É 0.25É 0É to

+.70É

Fig. 2 Steering Linkage

1 - DRAG LINK ADJUSTMENT SLEEVE

2 - TIE ROD ADJUSTMENT SLEEVE

WJWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 27 of 2199

FRONT

TABLE OF CONTENTS

page page

FRONT

DESCRIPTION..........................6

STANDARD PROCEDURE - SERVICE

WARNINGS AND CAUTIONS..............6

SPECIFICATIONS

TORQUE CHART......................7

SPECIAL TOOLS

FRONT SUSPENSION...................8

BUSHINGS

REMOVAL.............................9

INSTALLATION..........................9

HUB / BEARING

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION.........................10

KNUCKLE

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL - STEERING KNUCKLE..........10

INSTALLATION.........................10

LOWER BALL JOINT

REMOVAL.............................11

LOWER CONTROL ARM

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11SHOCK

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................12

SPRING

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

STABILIZER BAR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

TRACK BAR

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

UPPER BALL JOINT

REMOVAL.............................15

UPPER CONTROL ARM

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

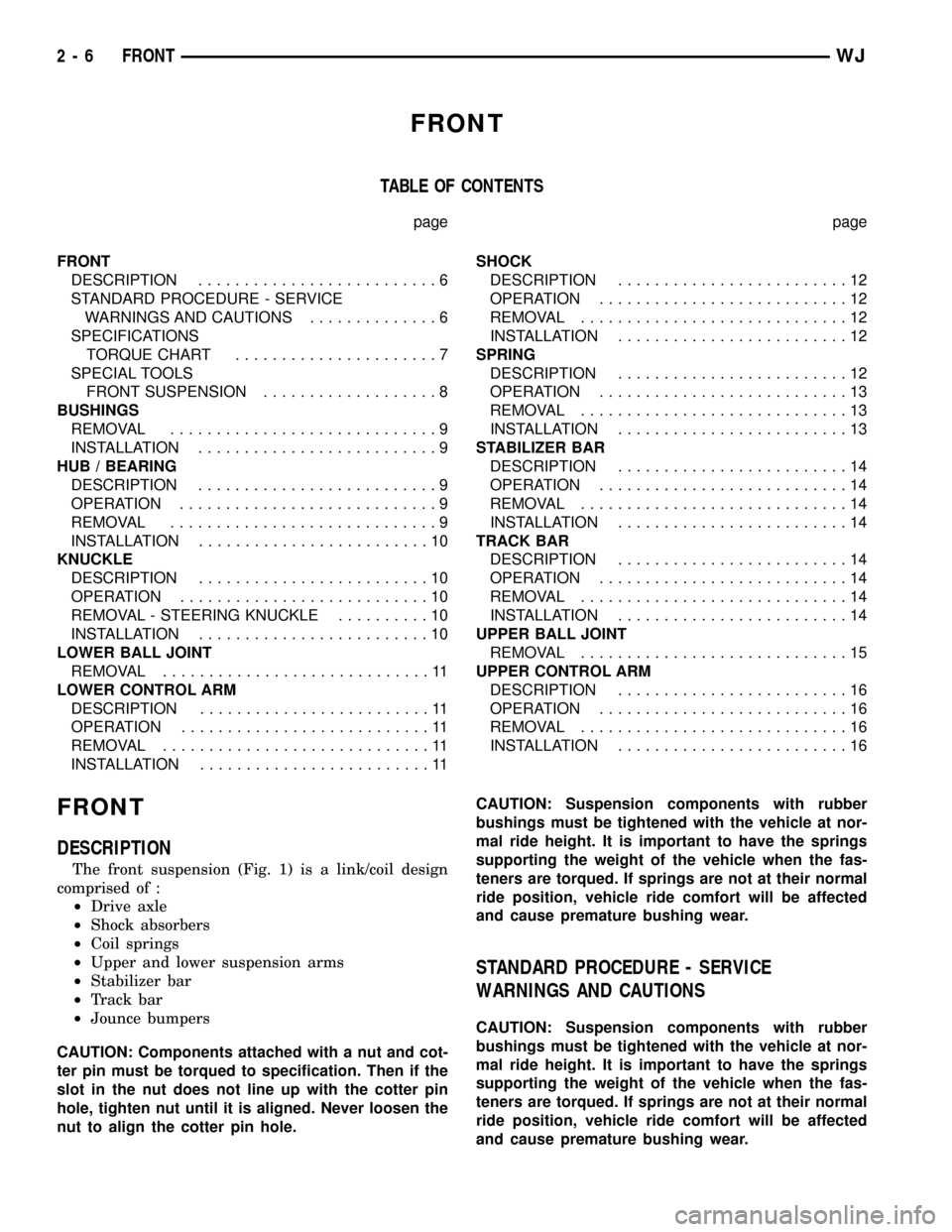

FRONT

DESCRIPTION

The front suspension (Fig. 1) is a link/coil design

comprised of :

²Drive axle

²Shock absorbers

²Coil springs

²Upper and lower suspension arms

²Stabilizer bar

²Track bar

²Jounce bumpers

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.CAUTION: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

STANDARD PROCEDURE - SERVICE

WARNINGS AND CAUTIONS

CAUTION: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

2 - 6 FRONTWJ

Page 28 of 2199

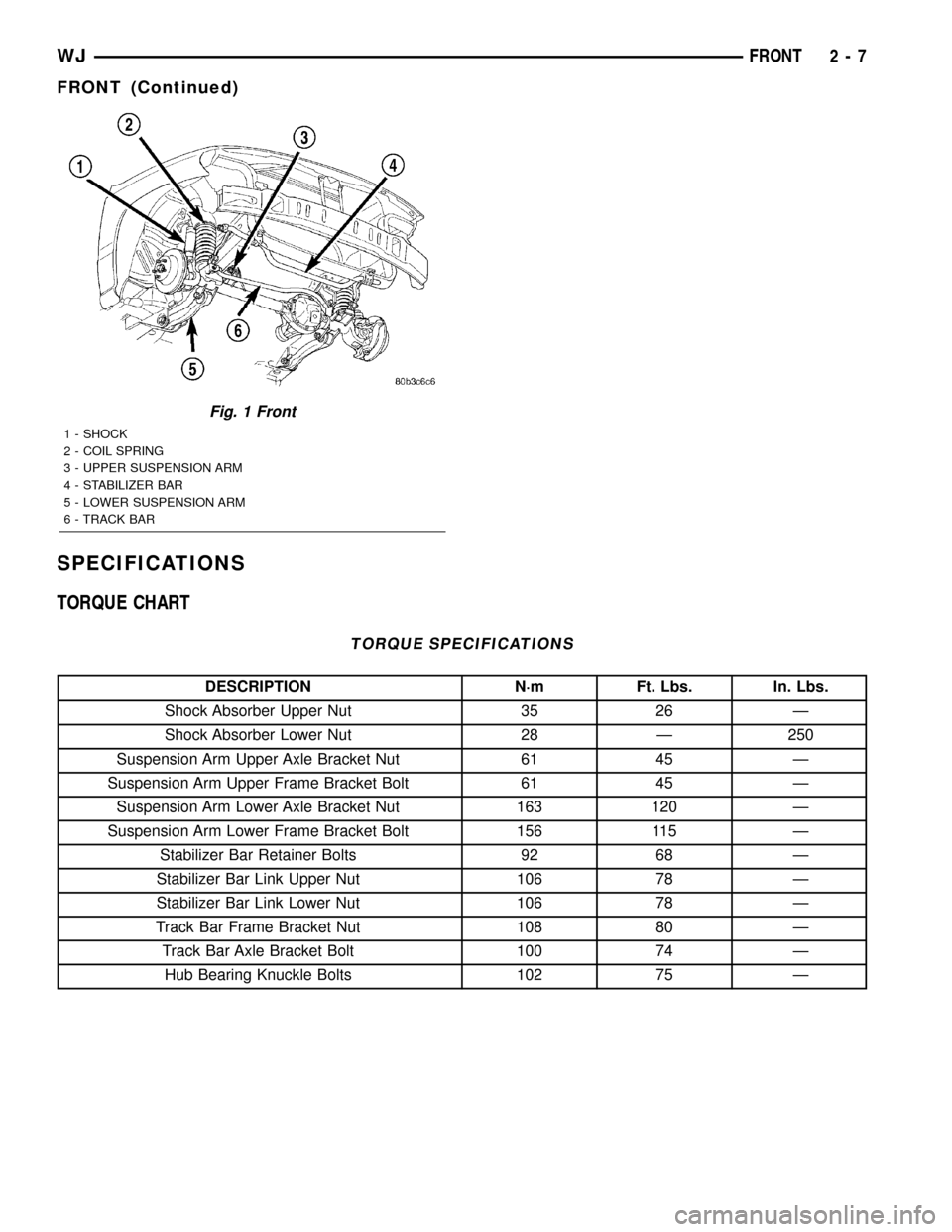

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 35 26 Ð

Shock Absorber Lower Nut 28 Ð 250

Suspension Arm Upper Axle Bracket Nut 61 45 Ð

Suspension Arm Upper Frame Bracket Bolt 61 45 Ð

Suspension Arm Lower Axle Bracket Nut 163 120 Ð

Suspension Arm Lower Frame Bracket Bolt 156 115 Ð

Stabilizer Bar Retainer Bolts 92 68 Ð

Stabilizer Bar Link Upper Nut 106 78 Ð

Stabilizer Bar Link Lower Nut 106 78 Ð

Track Bar Frame Bracket Nut 108 80 Ð

Track Bar Axle Bracket Bolt 100 74 Ð

Hub Bearing Knuckle Bolts 102 75 Ð

Fig. 1 Front

1 - SHOCK

2 - COIL SPRING

3 - UPPER SUSPENSION ARM

4 - STABILIZER BAR

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

WJFRONT 2 - 7

FRONT (Continued)

Page 29 of 2199

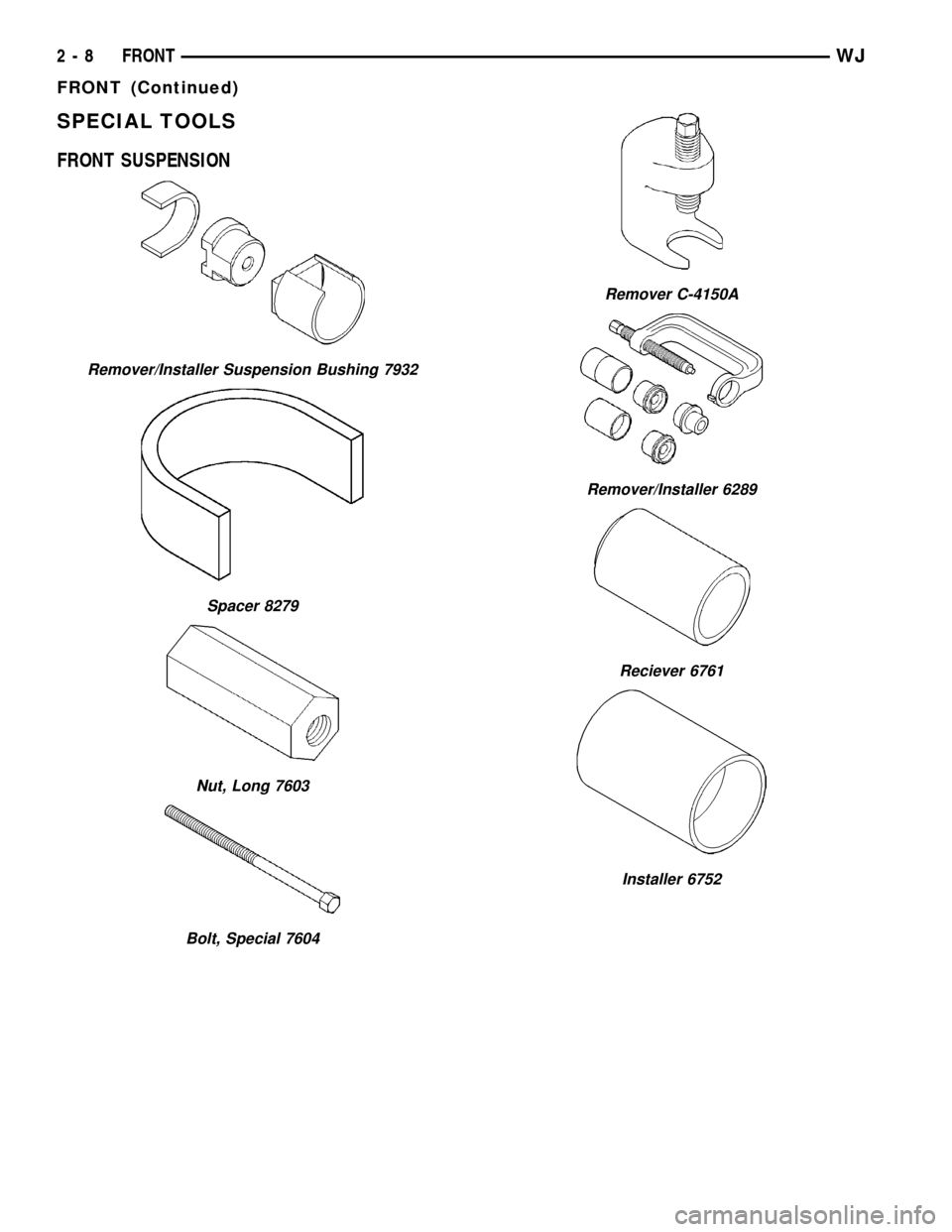

SPECIAL TOOLS

FRONT SUSPENSION

Remover/Installer Suspension Bushing 7932

Spacer 8279

Nut, Long 7603

Bolt, Special 7604

Remover C-4150A

Remover/Installer 6289

Reciever 6761

Installer 6752

2 - 8 FRONTWJ

FRONT (Continued)

Page 32 of 2199

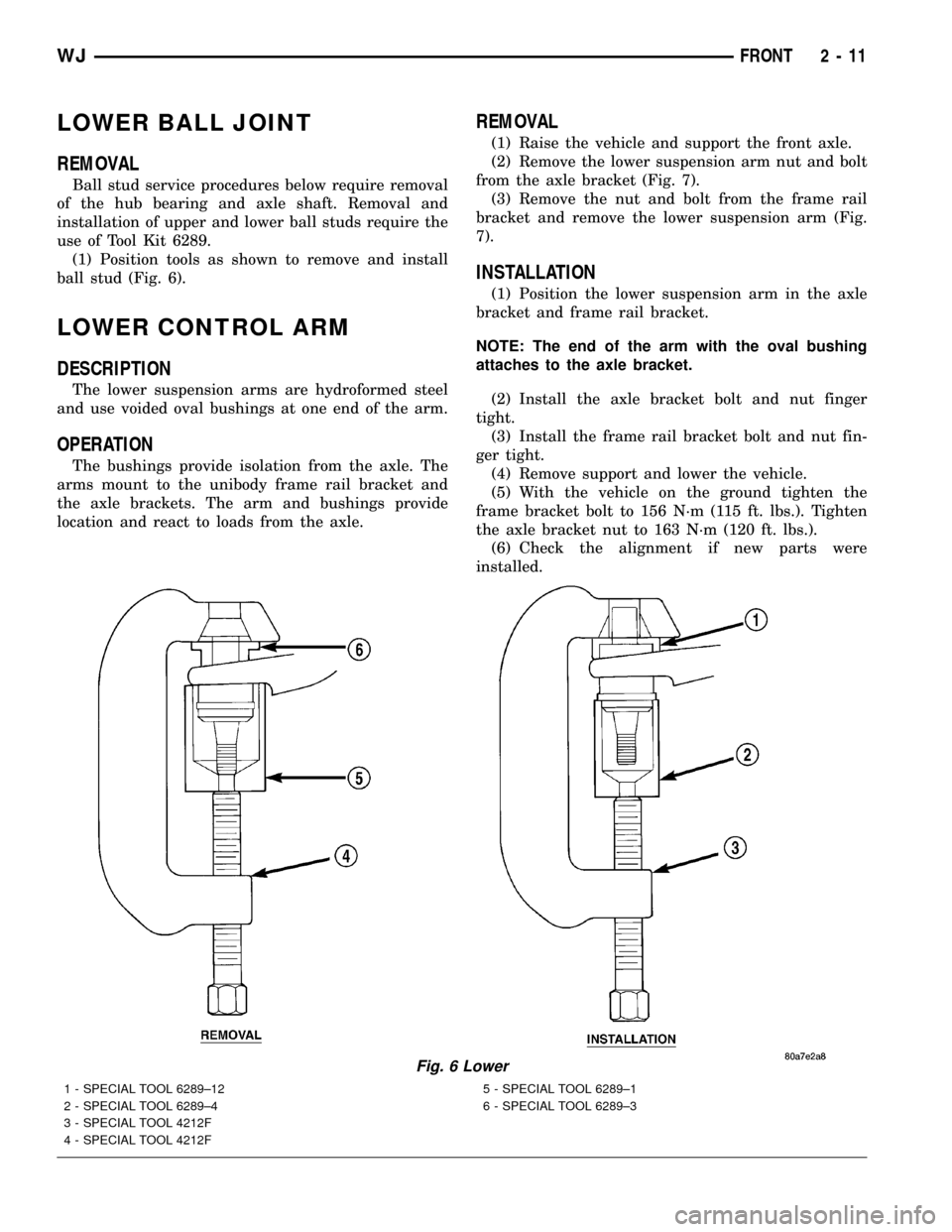

LOWER BALL JOINT

REMOVAL

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal and

installation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Position tools as shown to remove and install

ball stud (Fig. 6).

LOWER CONTROL ARM

DESCRIPTION

The lower suspension arms are hydroformed steel

and use voided oval bushings at one end of the arm.

OPERATION

The bushings provide isolation from the axle. The

arms mount to the unibody frame rail bracket and

the axle brackets. The arm and bushings provide

location and react to loads from the axle.

REMOVAL

(1) Raise the vehicle and support the front axle.

(2) Remove the lower suspension arm nut and bolt

from the axle bracket (Fig. 7).

(3) Remove the nut and bolt from the frame rail

bracket and remove the lower suspension arm (Fig.

7).

INSTALLATION

(1) Position the lower suspension arm in the axle

bracket and frame rail bracket.

NOTE: The end of the arm with the oval bushing

attaches to the axle bracket.

(2) Install the axle bracket bolt and nut finger

tight.

(3) Install the frame rail bracket bolt and nut fin-

ger tight.

(4) Remove support and lower the vehicle.

(5) With the vehicle on the ground tighten the

frame bracket bolt to 156 N´m (115 ft. lbs.). Tighten

the axle bracket nut to 163 N´m (120 ft. lbs.).

(6) Check the alignment if new parts were

installed.

Fig. 6 Lower

1 - SPECIAL TOOL 6289±12

2 - SPECIAL TOOL 6289±4

3 - SPECIAL TOOL 4212F

4 - SPECIAL TOOL 4212F5 - SPECIAL TOOL 6289±1

6 - SPECIAL TOOL 6289±3

WJFRONT 2 - 11

Page 34 of 2199

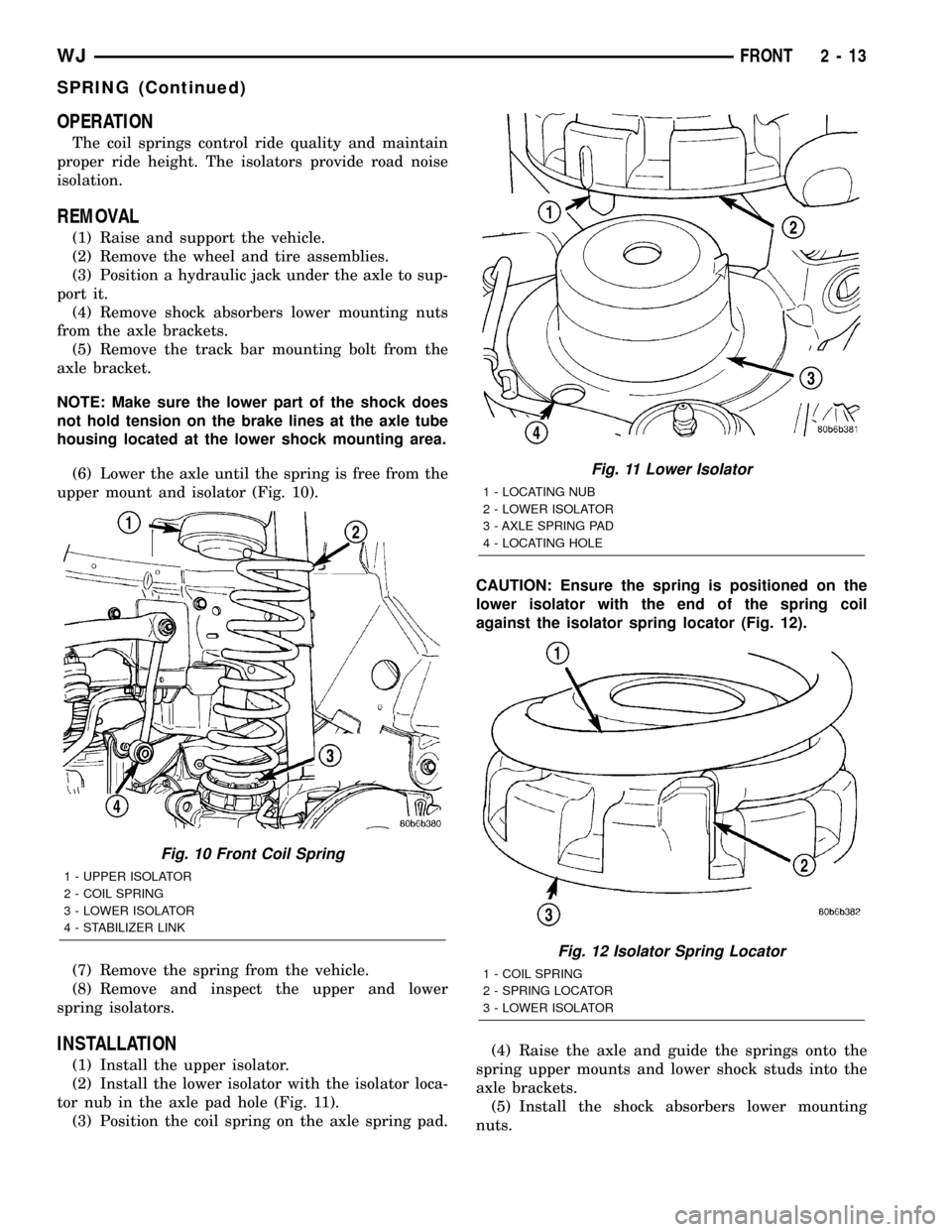

OPERATION

The coil springs control ride quality and maintain

proper ride height. The isolators provide road noise

isolation.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assemblies.

(3) Position a hydraulic jack under the axle to sup-

port it.

(4) Remove shock absorbers lower mounting nuts

from the axle brackets.

(5) Remove the track bar mounting bolt from the

axle bracket.

NOTE: Make sure the lower part of the shock does

not hold tension on the brake lines at the axle tube

housing located at the lower shock mounting area.

(6) Lower the axle until the spring is free from the

upper mount and isolator (Fig. 10).

(7) Remove the spring from the vehicle.

(8) Remove and inspect the upper and lower

spring isolators.

INSTALLATION

(1) Install the upper isolator.

(2) Install the lower isolator with the isolator loca-

tor nub in the axle pad hole (Fig. 11).

(3) Position the coil spring on the axle spring pad.CAUTION: Ensure the spring is positioned on the

lower isolator with the end of the spring coil

against the isolator spring locator (Fig. 12).

(4) Raise the axle and guide the springs onto the

spring upper mounts and lower shock studs into the

axle brackets.

(5) Install the shock absorbers lower mounting

nuts.

Fig. 10 Front Coil Spring

1 - UPPER ISOLATOR

2 - COIL SPRING

3 - LOWER ISOLATOR

4 - STABILIZER LINK

Fig. 11 Lower Isolator

1 - LOCATING NUB

2 - LOWER ISOLATOR

3 - AXLE SPRING PAD

4 - LOCATING HOLE

Fig. 12 Isolator Spring Locator

1 - COIL SPRING

2 - SPRING LOCATOR

3 - LOWER ISOLATOR

WJFRONT 2 - 13

SPRING (Continued)

Page 36 of 2199

(2) Install track bar to the frame rail bracket.

Install the bolt and nut finger tight.NOTE: It may be necessary to pry the axle assem-

bly over to install the track bar to the frame rail

bracket.

(3) Remove the supports and lower the vehicle.

(4) With the vehicle on the ground tighten the nut

at the frame rail bracket and to the bolt at the axle

bracket to 100 N´m (74 ft. lbs.).

(5) Check alignment specifications if a new track

bar was installed.

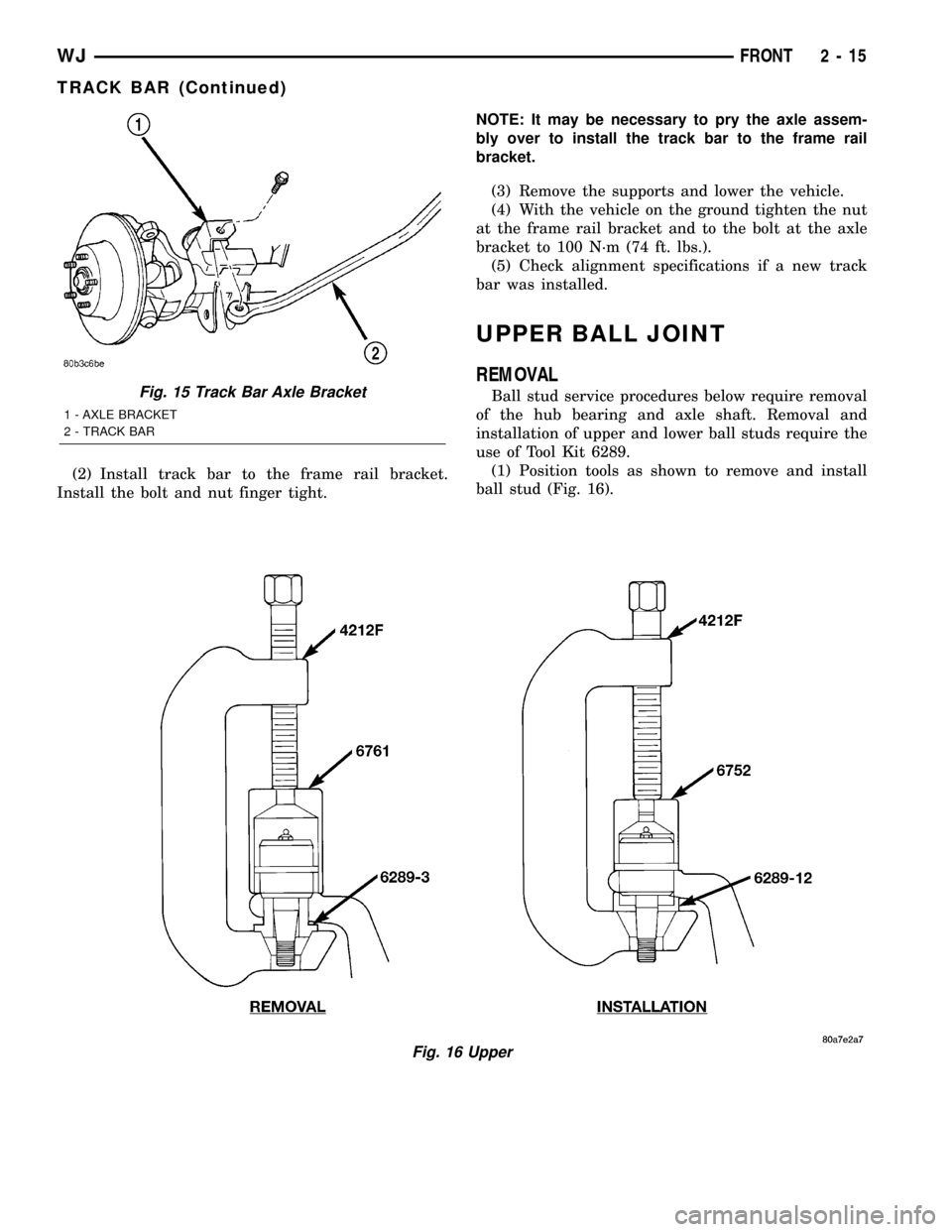

UPPER BALL JOINT

REMOVAL

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal and

installation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Position tools as shown to remove and install

ball stud (Fig. 16).

Fig. 16 Upper

Fig. 15 Track Bar Axle Bracket

1 - AXLE BRACKET

2 - TRACK BAR

WJFRONT 2 - 15

TRACK BAR (Continued)