Motor JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1471 of 2199

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

REMOVAL - 4.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner duct and air resonator box

at throttle body.

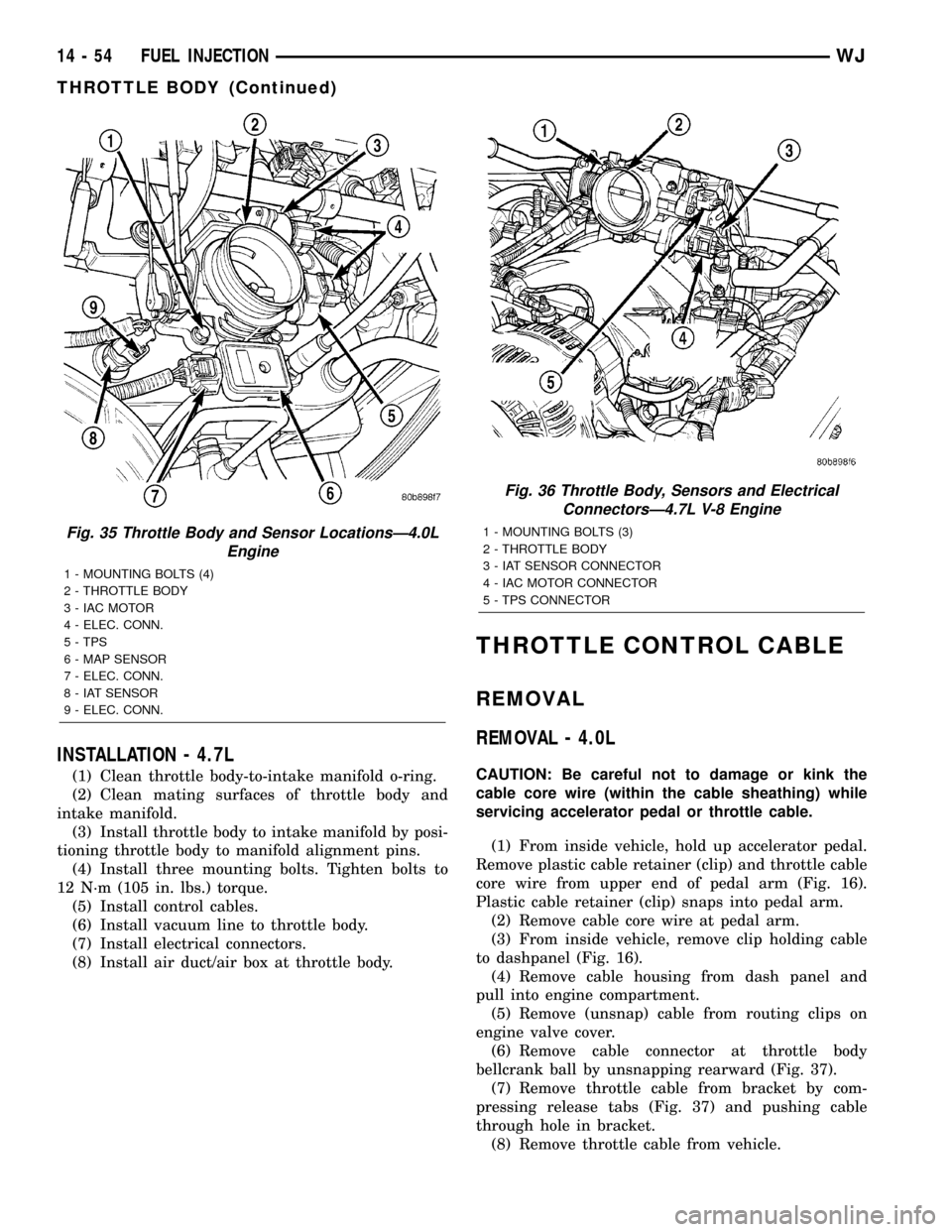

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 35).

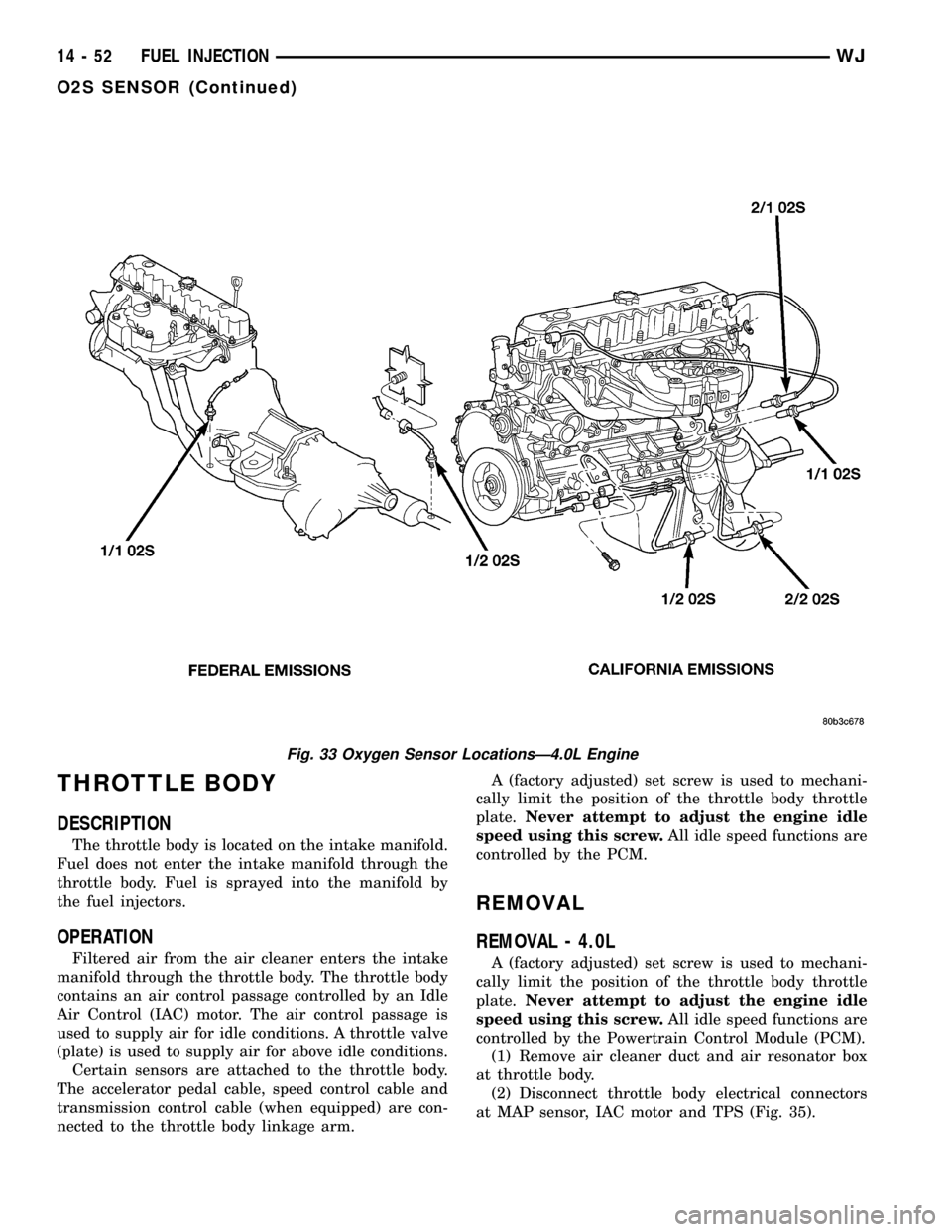

Fig. 33 Oxygen Sensor LocationsÐ4.0L Engine

14 - 52 FUEL INJECTIONWJ

O2S SENSOR (Continued)

Page 1472 of 2199

(3) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(4) Remove four throttle body mounting bolts.

(5) Remove throttle body from intake manifold.

(6) Discard old throttle body-to-intake manifold

gasket.

REMOVAL - 4.7L

(1) Remove the air duct and air resonator box at

throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 36).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 36).

(6) Remove throttle body from intake manifold.

INSTALLATION

INSTALLATION - 4.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 11

N´m (100 in. lbs.) torque.

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air duct and air box at throttle body.

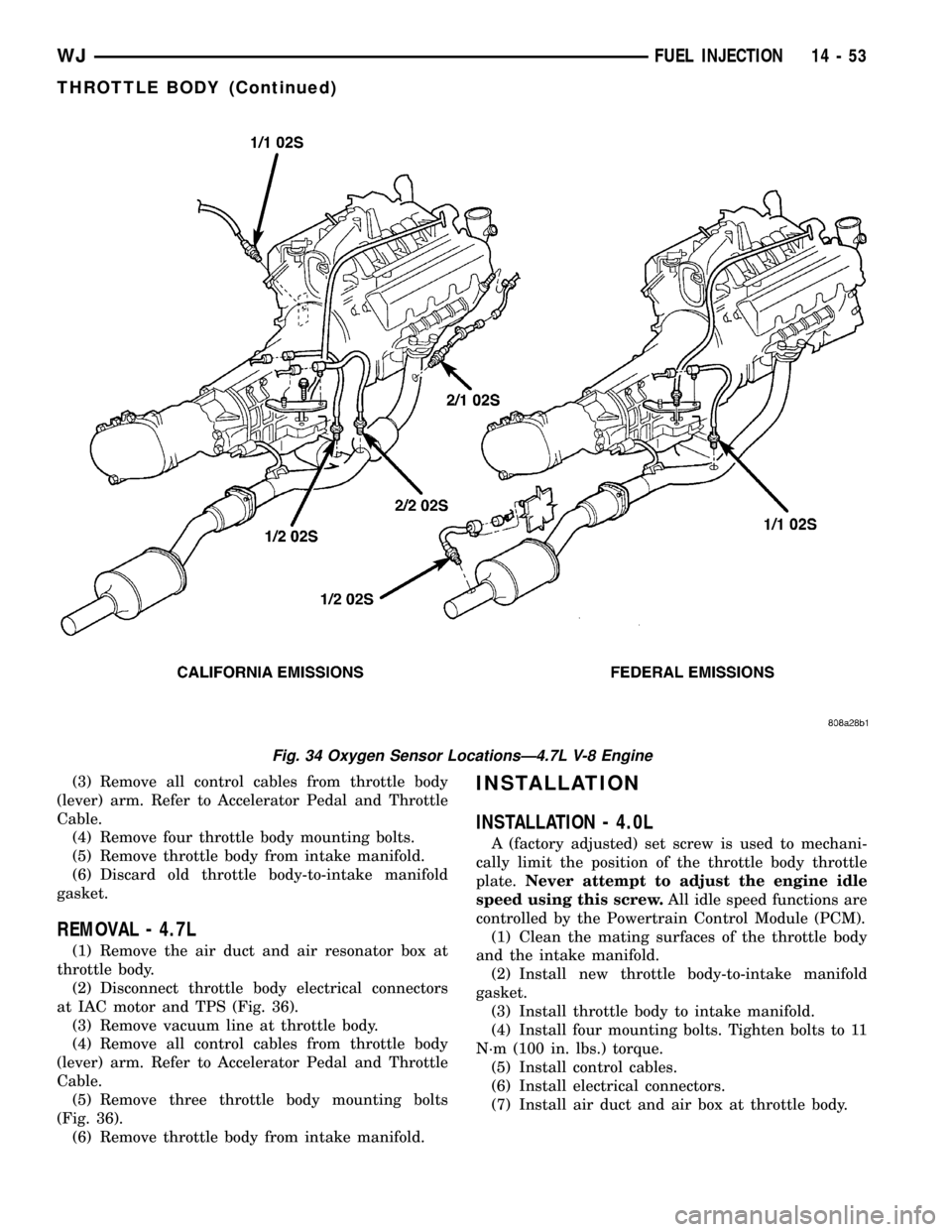

Fig. 34 Oxygen Sensor LocationsÐ4.7L V-8 Engine

WJFUEL INJECTION 14 - 53

THROTTLE BODY (Continued)

Page 1473 of 2199

INSTALLATION - 4.7L

(1) Clean throttle body-to-intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install three mounting bolts. Tighten bolts to

12 N´m (105 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air duct/air box at throttle body.

THROTTLE CONTROL CABLE

REMOVAL

REMOVAL - 4.0L

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 16).

Plastic cable retainer (clip) snaps into pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove clip holding cable

to dashpanel (Fig. 16).

(4) Remove cable housing from dash panel and

pull into engine compartment.

(5) Remove (unsnap) cable from routing clips on

engine valve cover.

(6) Remove cable connector at throttle body

bellcrank ball by unsnapping rearward (Fig. 37).

(7) Remove throttle cable from bracket by com-

pressing release tabs (Fig. 37) and pushing cable

through hole in bracket.

(8) Remove throttle cable from vehicle.

Fig. 35 Throttle Body and Sensor LocationsÐ4.0L

Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

Fig. 36 Throttle Body, Sensors and Electrical

ConnectorsÐ4.7L V-8 Engine

1 - MOUNTING BOLTS (3)

2 - THROTTLE BODY

3 - IAT SENSOR CONNECTOR

4 - IAC MOTOR CONNECTOR

5 - TPS CONNECTOR

14 - 54 FUEL INJECTIONWJ

THROTTLE BODY (Continued)

Page 1476 of 2199

REMOVAL

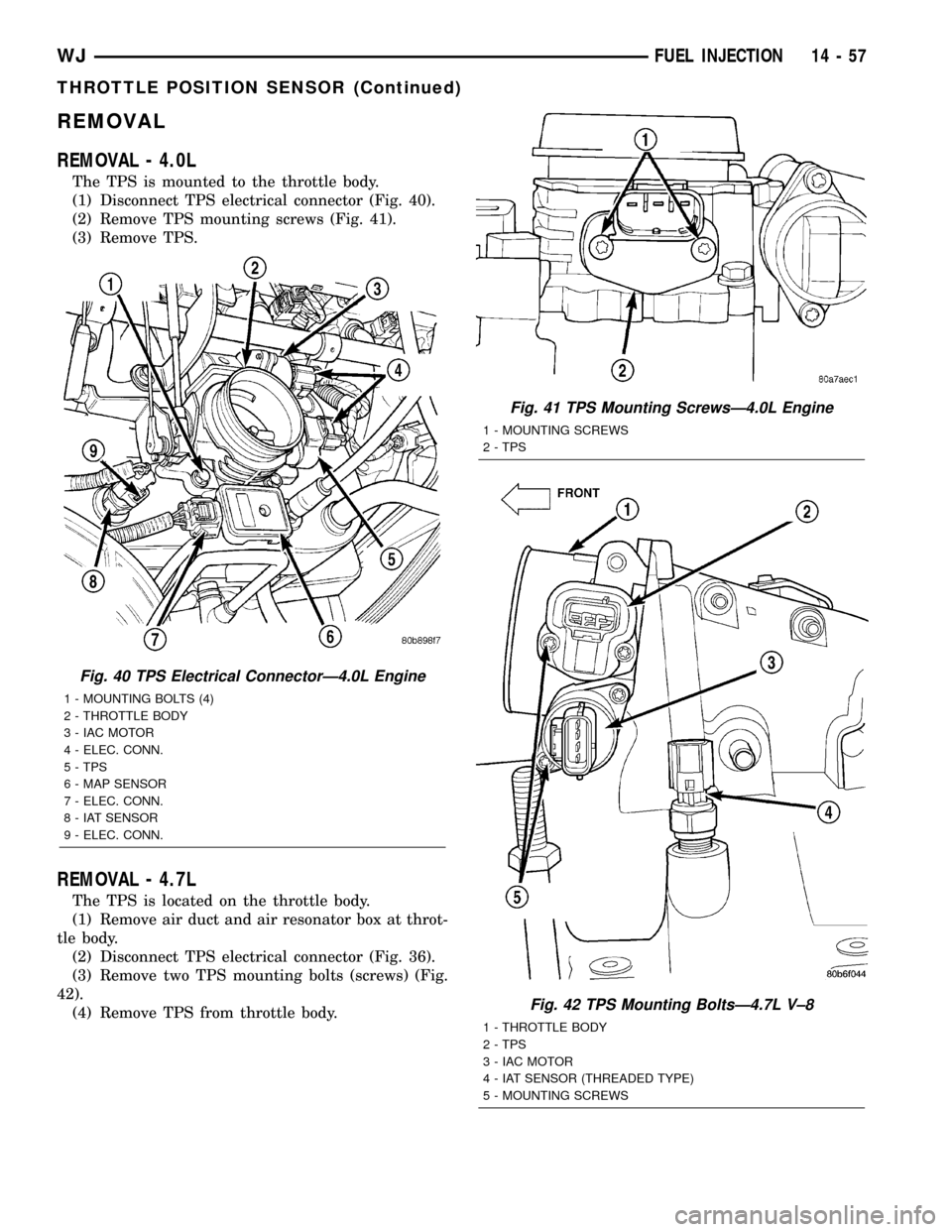

REMOVAL - 4.0L

The TPS is mounted to the throttle body.

(1) Disconnect TPS electrical connector (Fig. 40).

(2) Remove TPS mounting screws (Fig. 41).

(3) Remove TPS.

REMOVAL - 4.7L

The TPS is located on the throttle body.

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect TPS electrical connector (Fig. 36).

(3) Remove two TPS mounting bolts (screws) (Fig.

42).

(4) Remove TPS from throttle body.

Fig. 40 TPS Electrical ConnectorÐ4.0L Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

Fig. 41 TPS Mounting ScrewsÐ4.0L Engine

1 - MOUNTING SCREWS

2 - TPS

Fig. 42 TPS Mounting BoltsÐ4.7L V±8

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR (THREADED TYPE)

5 - MOUNTING SCREWS

WJFUEL INJECTION 14 - 57

THROTTLE POSITION SENSOR (Continued)

Page 1480 of 2199

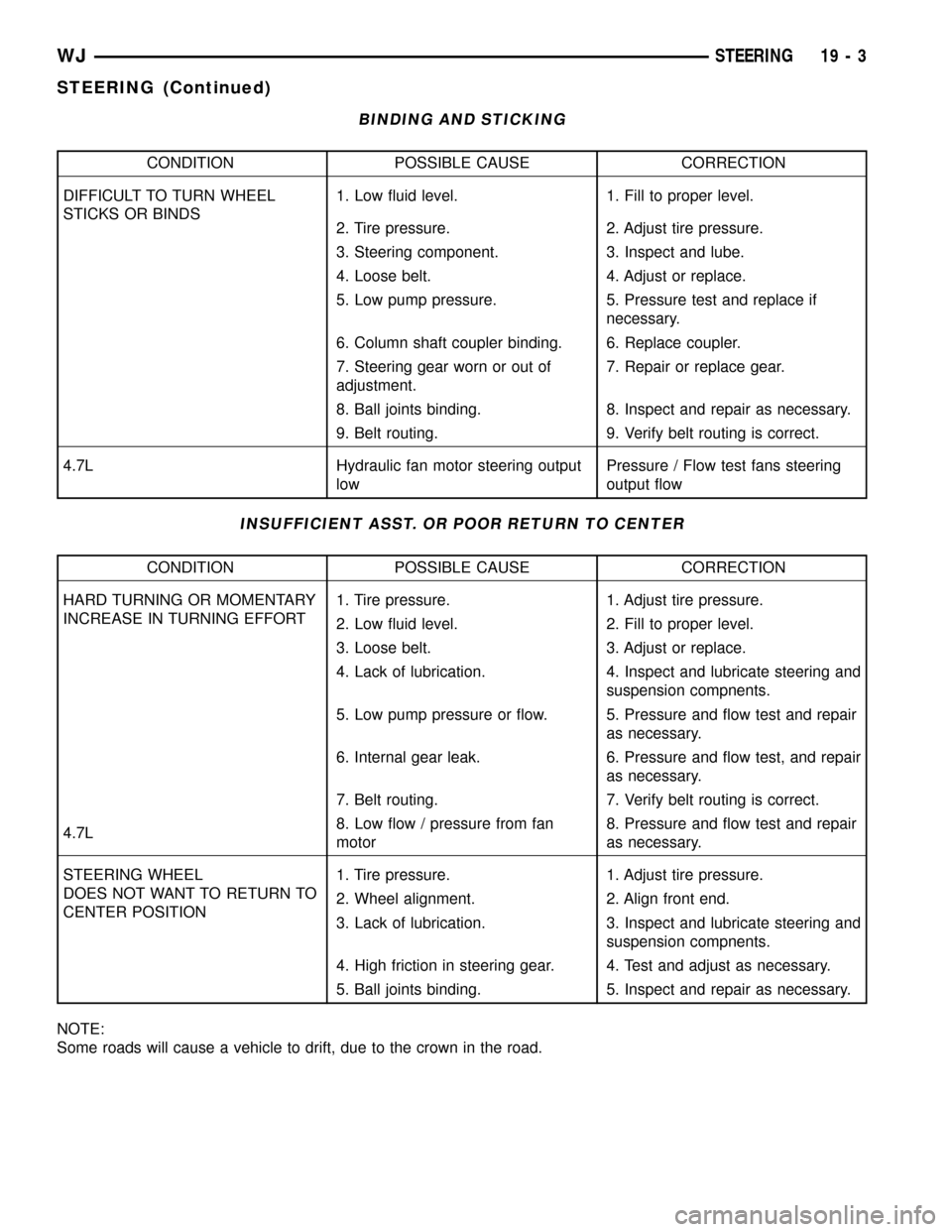

BINDING AND STICKING

CONDITION POSSIBLE CAUSE CORRECTION

DIFFICULT TO TURN WHEEL

STICKS OR BINDS1. Low fluid level. 1. Fill to proper level.

2. Tire pressure. 2. Adjust tire pressure.

3. Steering component. 3. Inspect and lube.

4. Loose belt. 4. Adjust or replace.

5. Low pump pressure. 5. Pressure test and replace if

necessary.

6. Column shaft coupler binding. 6. Replace coupler.

7. Steering gear worn or out of

adjustment.7. Repair or replace gear.

8. Ball joints binding. 8. Inspect and repair as necessary.

9. Belt routing. 9. Verify belt routing is correct.

4.7L Hydraulic fan motor steering output

lowPressure / Flow test fans steering

output flow

INSUFFICIENT ASST. OR POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSE CORRECTION

HARD TURNING OR MOMENTARY

INCREASE IN TURNING EFFORT1. Tire pressure. 1. Adjust tire pressure.

2. Low fluid level. 2. Fill to proper level.

3. Loose belt. 3. Adjust or replace.

4. Lack of lubrication. 4. Inspect and lubricate steering and

suspension compnents.

5. Low pump pressure or flow. 5. Pressure and flow test and repair

as necessary.

6. Internal gear leak. 6. Pressure and flow test, and repair

as necessary.

7. Belt routing. 7. Verify belt routing is correct.

4.7L8. Low flow / pressure from fan

motor8. Pressure and flow test and repair

as necessary.

STEERING WHEEL

DOES NOT WANT TO RETURN TO

CENTER POSITION1. Tire pressure. 1. Adjust tire pressure.

2. Wheel alignment. 2. Align front end.

3. Lack of lubrication. 3. Inspect and lubricate steering and

suspension compnents.

4. High friction in steering gear. 4. Test and adjust as necessary.

5. Ball joints binding. 5. Inspect and repair as necessary.

NOTE:

Some roads will cause a vehicle to drift, due to the crown in the road.

WJSTEERING 19 - 3

STEERING (Continued)

Page 1482 of 2199

(8) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge.

(9) Shut off the engine and check the fluid level,

add fluid as necessary. Start engine again and let

idle.

(10) The initial pressure reading should be

345-552 kPa (50-80 psi). If pressure is higher inspect

the hoses for restrictions and repair as necessary.

(11) Increase the engine speed to 1500 RPM and

read the flow meter. The reading should be 2.4 - 2.8

GPM, if the reading is below this specification the

pump should be replaced.

CAUTION: This next step involves testing maximum

pump pressure output and flow control valve oper-

ation. Do not leave valve closed for more than three

seconds as the pump could be damaged.

(12) Close valve fully three times for three seconds

and record highest pressure indicated each time.All

three readings must be at pump relief pressure

specifications and within 345 kPa (50 psi) of

each other.

²Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 4 seconds at a time

because, pump damage will result.

(13) Open the test valve and turn the steering

wheel to the extreme left and right positions against

the stops. Record the highest pressure reading at

each position. Compare readings to the pump specifi-

cations chart. If pressures readings are not within 50

psi. of each other, the gear is leaking internally and

must be repaired.

GEAR INLET SPECIFICATIONS 4.0L & 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.0L 9653 kPa (1400 psi)

1500 RPM 2.4 - 2.8

GPM

4.7L 9653 kPa (1450 psi)

PUMP MOTOR SPECIFICATIONS 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.7L 9653 kPa (1900 psi)1100 RPM 2.4-2.8

GPM Minium

@ 200 psi

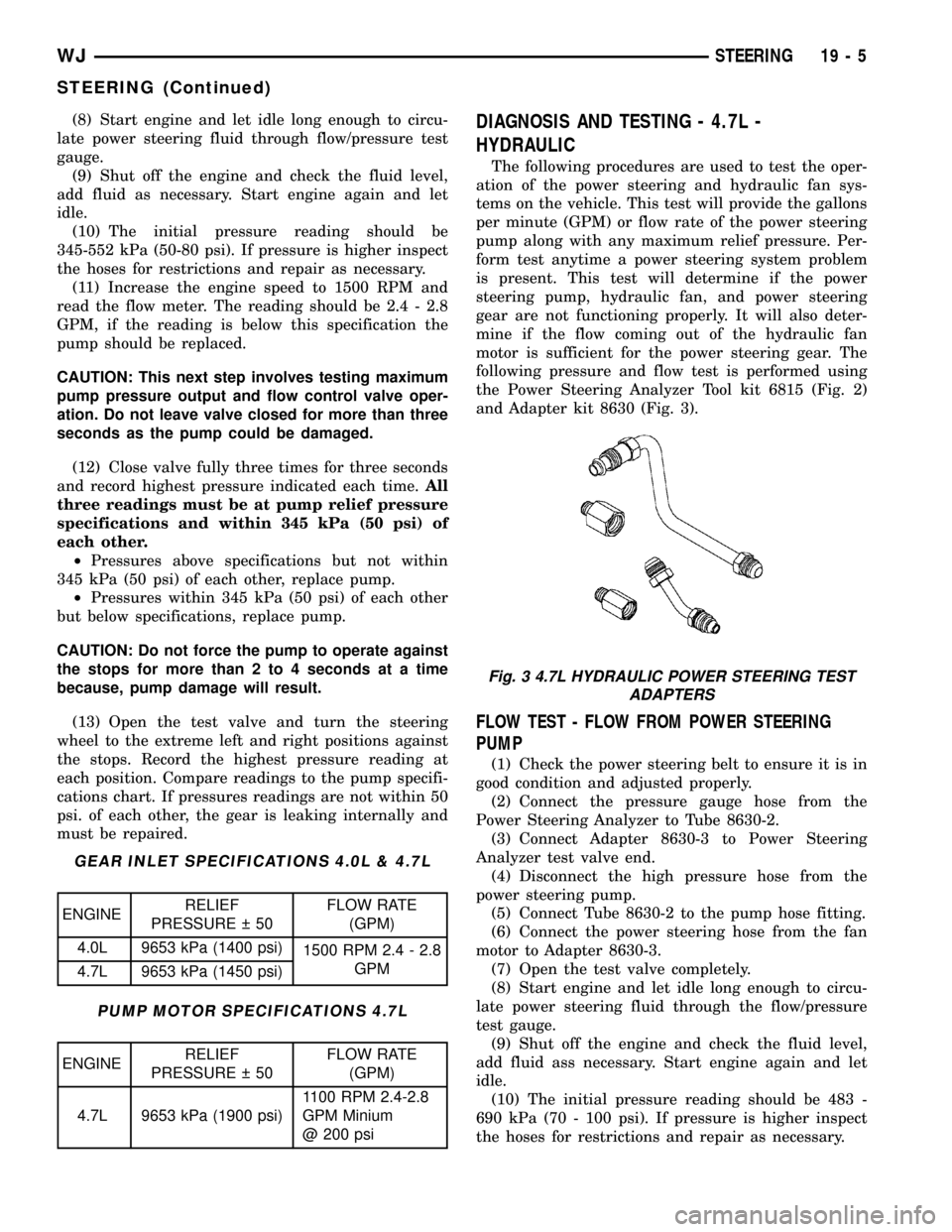

DIAGNOSIS AND TESTING - 4.7L -

HYDRAULIC

The following procedures are used to test the oper-

ation of the power steering and hydraulic fan sys-

tems on the vehicle. This test will provide the gallons

per minute (GPM) or flow rate of the power steering

pump along with any maximum relief pressure. Per-

form test anytime a power steering system problem

is present. This test will determine if the power

steering pump, hydraulic fan, and power steering

gear are not functioning properly. It will also deter-

mine if the flow coming out of the hydraulic fan

motor is sufficient for the power steering gear. The

following pressure and flow test is performed using

the Power Steering Analyzer Tool kit 6815 (Fig. 2)

and Adapter kit 8630 (Fig. 3).

FLOW TEST - FLOW FROM POWER STEERING

PUMP

(1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect the pressure gauge hose from the

Power Steering Analyzer to Tube 8630-2.

(3) Connect Adapter 8630-3 to Power Steering

Analyzer test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect Tube 8630-2 to the pump hose fitting.

(6) Connect the power steering hose from the fan

motor to Adapter 8630-3.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circu-

late power steering fluid through the flow/pressure

test gauge.

(9) Shut off the engine and check the fluid level,

add fluid ass necessary. Start engine again and let

idle.

(10) The initial pressure reading should be 483 -

690 kPa (70 - 100 psi). If pressure is higher inspect

the hoses for restrictions and repair as necessary.

Fig. 3 4.7L HYDRAULIC POWER STEERING TEST

ADAPTERS

WJSTEERING 19 - 5

STEERING (Continued)

Page 1483 of 2199

(11) Increase the engine speed to 1100 rpm and

read the flow meter. The reading should be 2.6 GPM

minimum, if the reading is below this specification,

the pump should be replaced.

FLOW AND PRESSURE TEST - FLOW FROM

HYDRAULIC FAN MOTOR TO STEERING GEAR

(should be done if necessary after the Pump flow

test)

(1) Connect the pressure gauge hose from the

Power Steering Analyzer to Fitting 8630-1.

(2) Connect Adapter 8630-4 to Power Steering

Analyzer test valve end.

(3) Disconnect the high pressure hose from the

power steering gear.

(4) Connect Fitting 8630-1 to the high pressure

hose.

(5) Connect Adapter 8630-4 to the power steering

gear.

(6) Open the test valve completely.

(7) Start engine and let idle long enough to circu-

late power steering fluid through the flow/pressure

test gauge.

(8) Shut off the engine and check the fluid level,

add fluid ass necessary. Start engine again and let

idle.

(9) The initial pressure reading should be 345-552

kPa (50-80 psi). If pressure is higher inspect the

hoses for restrictions and repair as necessary.(10) Increase the engine speed to 1500 RPM and

read the flow meter. The reading should be 2.4 - 2.8

GPM if the reading is below this specification the fan

should be replaced.

CAUTION: This next step involves testing maximum

fan motor steering relief pressure. Do not leave the

valve closed for more than three seconds.

(11) Close the valve fully three times for three sec-

onds and record highest pressures indicated each

time. All three readings must be at fan motor steer-

ing relief pressures.

(12) Open the test valve and turn the steering

wheel to the extreme left and right positions against

the stops. Record the highest pressure readings at

each position. If pressure readings are not within 50

psi from each other, the gear is leaking internally

and must be repaired.

PUMP MOTOR SPECIFICATIONS 4.7L

ENGINERELIEF

PRESSURE 50FLOW RATE

(GPM)

4.7L 9653 kPa (1900 psi)1100 RPM 2.4-2.8

GPM Minium

@ 200 psi

19 - 6 STEERINGWJ

STEERING (Continued)

Page 1515 of 2199

HOSES - 4.7L

DESCRIPTION

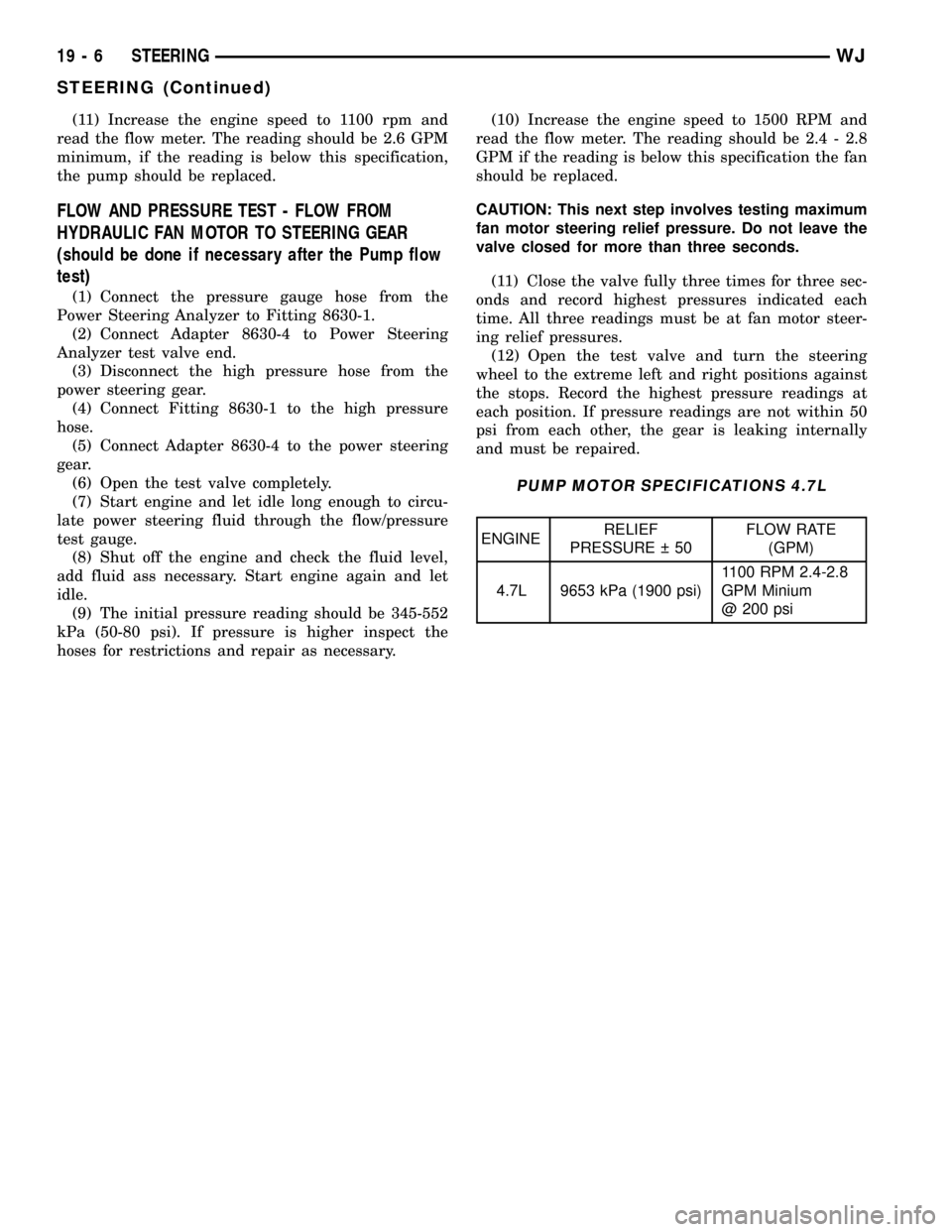

DESCRIPTION - 1/2º PRESSURE HOSE

The hose consists of two metal ends and a rubber

center with quick connect nuts at both ends. The

hose connects the power steering pump to the

hydraulic fan motor and is clipped to the fan shroud

(Fig. 8). Lubrication must be used on the quick con-

nect nuts and o-rings when installing.

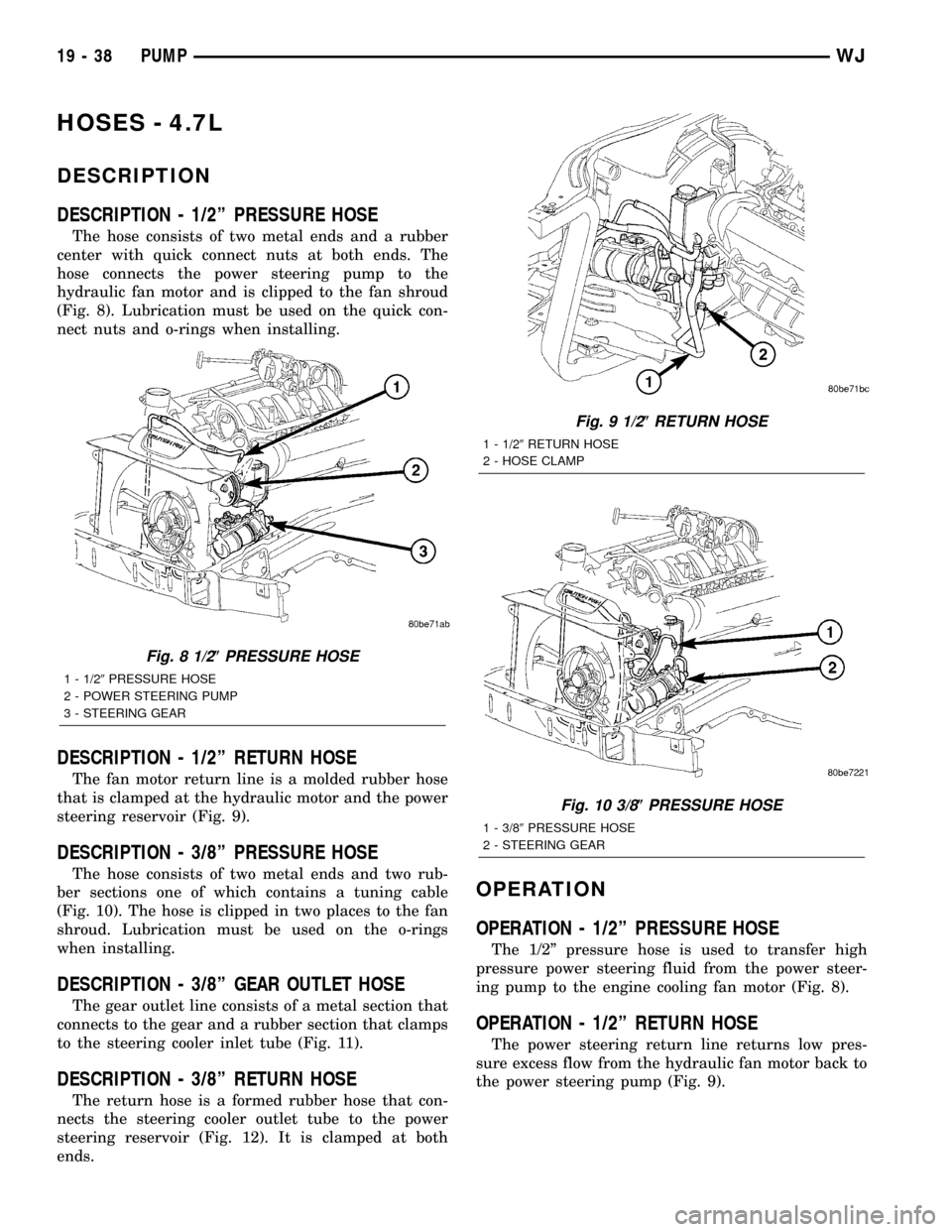

DESCRIPTION - 1/2º RETURN HOSE

The fan motor return line is a molded rubber hose

that is clamped at the hydraulic motor and the power

steering reservoir (Fig. 9).

DESCRIPTION - 3/8º PRESSURE HOSE

The hose consists of two metal ends and two rub-

ber sections one of which contains a tuning cable

(Fig. 10). The hose is clipped in two places to the fan

shroud. Lubrication must be used on the o-rings

when installing.

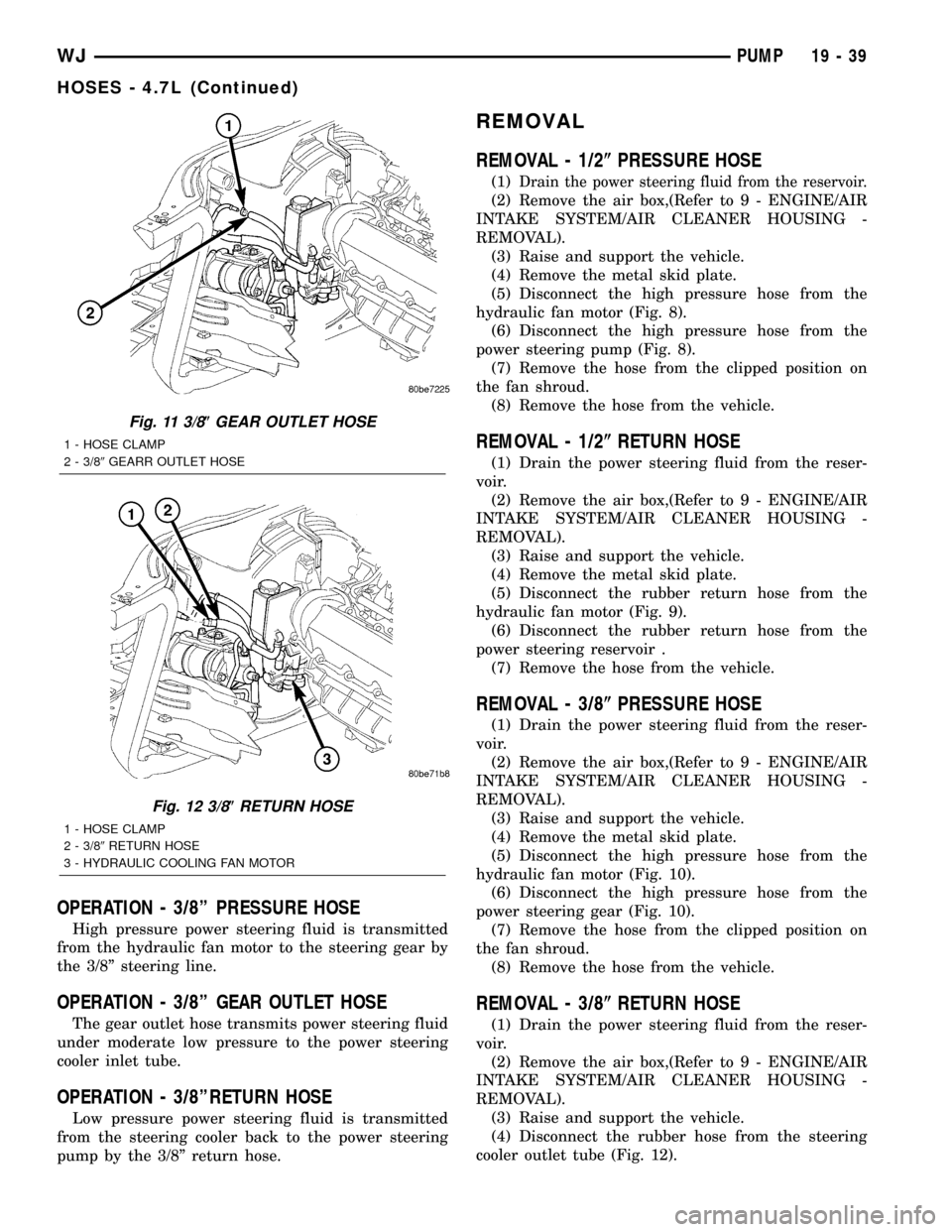

DESCRIPTION - 3/8º GEAR OUTLET HOSE

The gear outlet line consists of a metal section that

connects to the gear and a rubber section that clamps

to the steering cooler inlet tube (Fig. 11).

DESCRIPTION - 3/8º RETURN HOSE

The return hose is a formed rubber hose that con-

nects the steering cooler outlet tube to the power

steering reservoir (Fig. 12). It is clamped at both

ends.

OPERATION

OPERATION - 1/2º PRESSURE HOSE

The 1/2º pressure hose is used to transfer high

pressure power steering fluid from the power steer-

ing pump to the engine cooling fan motor (Fig. 8).

OPERATION - 1/2º RETURN HOSE

The power steering return line returns low pres-

sure excess flow from the hydraulic fan motor back to

the power steering pump (Fig. 9).

Fig. 8 1/2(PRESSURE HOSE

1 - 1/29PRESSURE HOSE

2 - POWER STEERING PUMP

3 - STEERING GEAR

Fig. 9 1/2(RETURN HOSE

1 - 1/29RETURN HOSE

2 - HOSE CLAMP

Fig. 10 3/8(PRESSURE HOSE

1 - 3/89PRESSURE HOSE

2 - STEERING GEAR

19 - 38 PUMPWJ

Page 1516 of 2199

OPERATION - 3/8º PRESSURE HOSE

High pressure power steering fluid is transmitted

from the hydraulic fan motor to the steering gear by

the 3/8º steering line.

OPERATION - 3/8º GEAR OUTLET HOSE

The gear outlet hose transmits power steering fluid

under moderate low pressure to the power steering

cooler inlet tube.

OPERATION - 3/8ºRETURN HOSE

Low pressure power steering fluid is transmitted

from the steering cooler back to the power steering

pump by the 3/8º return hose.

REMOVAL

REMOVAL - 1/2(PRESSURE HOSE

(1)Drain the power steering fluid from the reservoir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 8).

(6) Disconnect the high pressure hose from the

power steering pump (Fig. 8).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 1/2(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the rubber return hose from the

hydraulic fan motor (Fig. 9).

(6) Disconnect the rubber return hose from the

power steering reservoir .

(7) Remove the hose from the vehicle.

REMOVAL - 3/8(PRESSURE HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 10).

(6) Disconnect the high pressure hose from the

power steering gear (Fig. 10).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 3/8(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler outlet tube (Fig. 12).

Fig. 11 3/8(GEAR OUTLET HOSE

1 - HOSE CLAMP

2 - 3/89GEARR OUTLET HOSE

Fig. 12 3/8(RETURN HOSE

1 - HOSE CLAMP

2 - 3/89RETURN HOSE

3 - HYDRAULIC COOLING FAN MOTOR

WJPUMP 19 - 39

HOSES - 4.7L (Continued)

Page 1517 of 2199

(5) Disconnect the rubber hose from the power

steering reservoir (Fig. 12).

(6) Remove the hose from the vehicle.

REMOVAL - 3/8(GEAR OUTLET HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler inlet tube (Fig. 11).

(5) Disconnect the metal tube from the power

steering gear (Fig. 11).

(6) Remove the hose from the vehicle.

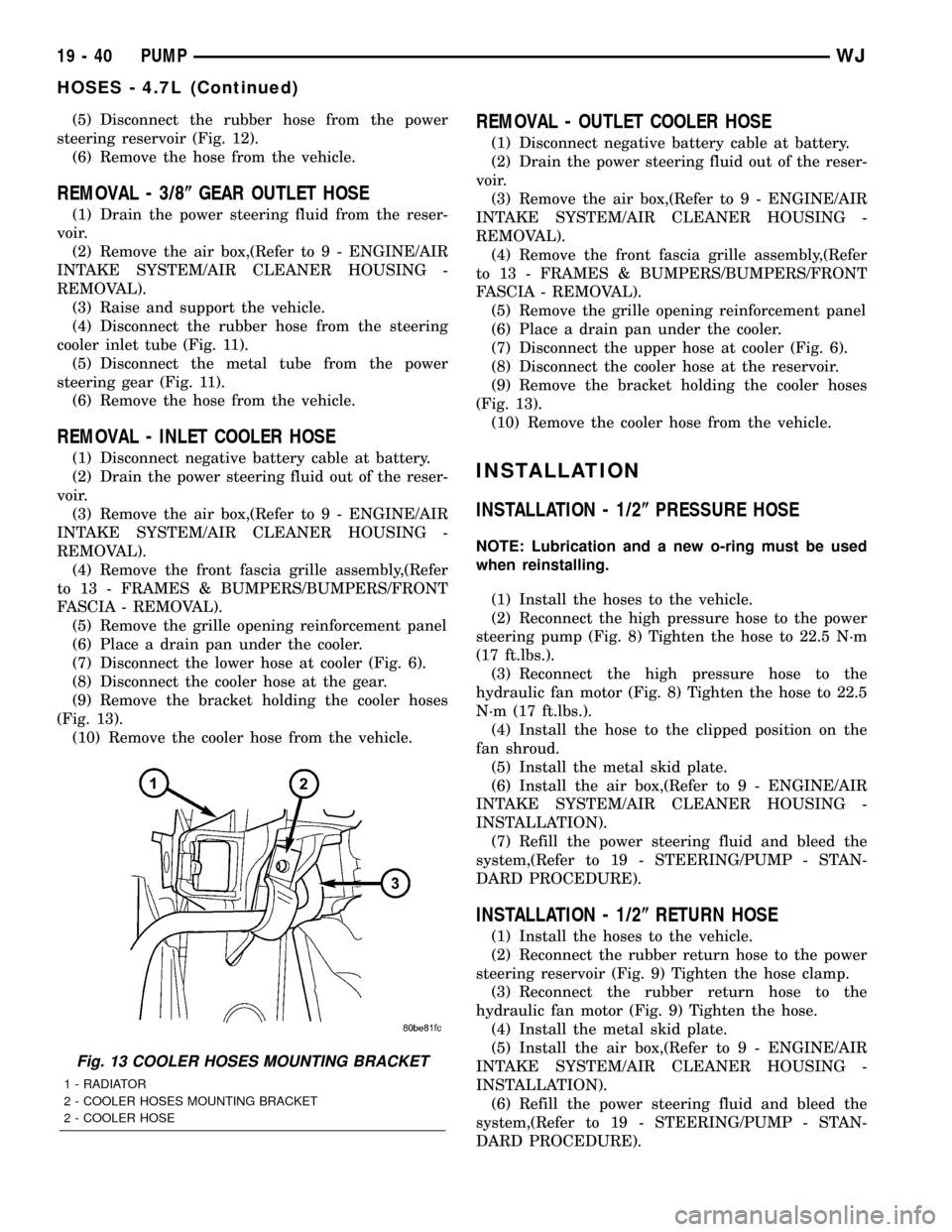

REMOVAL - INLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the lower hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the gear.

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

REMOVAL - OUTLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the upper hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the reservoir.

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

INSTALLATION

INSTALLATION - 1/2(PRESSURE HOSE

NOTE: Lubrication and a new o-ring must be used

when reinstalling.

(1) Install the hoses to the vehicle.

(2) Reconnect the high pressure hose to the power

steering pump (Fig. 8) Tighten the hose to 22.5 N´m

(17 ft.lbs.).

(3) Reconnect the high pressure hose to the

hydraulic fan motor (Fig. 8) Tighten the hose to 22.5

N´m (17 ft.lbs.).

(4) Install the hose to the clipped position on the

fan shroud.

(5) Install the metal skid plate.

(6) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(7) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - 1/2(RETURN HOSE

(1) Install the hoses to the vehicle.

(2) Reconnect the rubber return hose to the power

steering reservoir (Fig. 9) Tighten the hose clamp.

(3) Reconnect the rubber return hose to the

hydraulic fan motor (Fig. 9) Tighten the hose.

(4) Install the metal skid plate.

(5) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

Fig. 13 COOLER HOSES MOUNTING BRACKET

1 - RADIATOR

2 - COOLER HOSES MOUNTING BRACKET

2 - COOLER HOSE

19 - 40 PUMPWJ

HOSES - 4.7L (Continued)