Not charging JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 361 of 2199

OPERATION

The starting system components form two separate

circuits. A high-amperage feed circuit that feeds the

starter motor between 150 and 350 amperes, and a

low-amperage control circuit that operates on less

than 20 amperes. The high-amperage feed circuit

components include the battery, the battery cables,

the contact disc portion of the starter solenoid, and

the starter motor. The low-amperage control circuit

components include the ignition switch, the park/

neutral position switch, the starter relay, the electro-

magnetic windings of the starter solenoid, and the

connecting wire harness components.

Battery voltage is supplied through the low-amper-

age control circuit to the coil battery terminal of the

starter relay when the ignition switch is turned to

the momentary Start position. The park/neutral posi-

tion switch is installed in series between the starter

relay coil ground terminal and ground. This normally

open switch prevents the starter relay from being

energized and the starter motor from operating

unless the automatic transmission gear selector is in

the Neutral or Park positions.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear on the automatic transmission torque con-

verter drive plate.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

starter pinion gear to spin faster than the pinion

shaft. When the driver releases the ignition switch to

the On position, the starter relay coil is de-energized.

This causes the relay contacts to open. When the

relay contacts open, the starter solenoid plunger

hold-in coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate with one another, and must be tested as a com-

plete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

Group 8A covers the Battery, Group 8B covers the

Starting Systems, and Group 8C covers the Charging

System. We have separated these systems to make it

easier to locate the information you are seeking

within this Service Manual. However, when attempt-

ing to diagnose any of these systems, it is important

that you keep their interdependency in mind.

The diagnostic procedures used in these groups

include the most basic conventional diagnostic meth-

ods, to the more sophisticated On-Board Diagnostics

(OBD) built into the Powertrain Control Module

(PCM). Use of an induction-type milliampere amme-

ter, volt/ohmmeter, battery charger, carbon pile rheo-

stat (load tester), and 12-volt test lamp may be

required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. Refer to

On-Board Diagnostic Test For Charging System

in the Diagnosis and Testing section of Group 8C -

Charging System for more information.

8F - 30 STARTINGWJ

STARTING (Continued)

Page 449 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the instrument cluster from the

instrument panel and disconnect the instrument

panel wire harness for the instrument cluster from

the cluster connector receptacle.

(2) Reconnect the battery negative cable. Activate

the hazard warning system by moving the hazard

warning switch button to the On position. Check for

battery voltage at the inoperative (right or left) turn

signal circuit cavity of the instrument panel wire

harness connector for the instrument cluster. There

should be a switching (on and off) battery voltage sig-

nal present. If OK, replace the faulty (right or left)

turn signal indicator bulb. If not OK, repair the open

(right or left) turn signal circuit between the instru-

ment cluster and the combination flasher in the

Junction Block (JB) as required.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left corner of the instrument cluster, to the

left of the tachometer. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the gauge dial face that reads left-to-right

from 9 volts to 19 volts. An International Control and

Display Symbol icon for ªBattery Charging Condi-

tionº is located on the gauge dial face.

The voltage gauge graphics are either white, gray

and orange against a black gauge dial face (base

cluster) or black, gray and red against a taupe gauge

dial face (premium cluster), making them clearly vis-

ible within the instrument cluster in daylight. When

illuminated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-rior lamps turned On, the base cluster white gauge

graphics appear blue-green and the orange graphics

still appear orange, while the premium cluster taupe

gauge dial face appears blue-green with the black

graphics silhouetted against the illuminated back-

ground and the red graphics still appear red. The

gray gauge graphics for both versions of the cluster

are not illuminated. The orange gauge needle in the

base cluster gauge is internally illuminated, while

the black gauge needle in the premium cluster gauge

is not.

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

voltage gauge is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²System Voltage Message- Each time the clus-

ter receives a message from the PCM indicating the

system voltage, the cluster moves the gauge needle to

the relative voltage level position on the gauge scale.

²System Voltage Low Message- Each time the

cluster receives a message from the PCM indicating

the system voltage is low (system voltage is about

eleven volts or lower), the gauge needle is moved to

the relative voltage position in the red zone of the

gauge scale and the check gauges indicator is illumi-

nated. The gauge needle remains in the red zone and

the check gauges indicator remains illuminated until

the cluster receives a message from the PCM indicat-

ing there is no low system voltage condition (system

voltage is above about eleven volts, but lower than

about sixteen volts).

²System Voltage High Message- Each time

the cluster receives a message from the PCM indicat-

8J - 34 INSTRUMENT CLUSTERWJ

TURN SIGNAL INDICATOR (Continued)

Page 450 of 2199

ing the system voltage is high (system voltage is

about sixteen volts or higher), the gauge needle is

moved to the relative voltage position in the red zone

of the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains in the red

zone and the check gauges indicator remains illumi-

nated until the cluster receives a message from the

PCM indicating there is no high system voltage con-

dition (system voltage is below about sixteen volts,

but higher than about eleven volts).

²Communication Error- If the cluster fails to

receive a system voltage message, it will hold the

gauge needle at the last indication for about twelve

seconds, until a new message is received, or until the

ignition switch is turned to the Off position, which-

ever occurs first. After twelve seconds, the cluster

will return the gauge needle to the low end of the

gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back to con-

firm the functionality of the gauge and the cluster

control circuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a system voltage low or high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the volt-

age gauge, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The wait-to-start indicator is

located near the lower edge of the tachometer gauge

dial face, to the right of center. The wait-to-start

indicator consists of an International Control and

Display Symbol icon for ªDiesel Preheatº imprinted

on an amber lens. The lens is located behind a cutout

in the opaque layer of the tachometer gauge dial face

overlay. The dark outer layer of the gauge dial face

overlay prevents the icon from being clearly visible

when the indicator is not illuminated. The icon

appears silhouetted against an amber field throughthe translucent outer layer of the gauge dial face

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The wait-to-start indicator lens

is serviced as a unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine glow

plugs are energized in their preheat operating mode.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The wait-to-start indicator

bulb is completely controlled by the instrument clus-

ter logic circuit, and that logic will only allow this

indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is switched to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the wait-to-start indicator for the following

reasons:

²Wait-To-Start Indicator Lamp-On Message-

Each time the cluster receives a wait-to-start indica-

tor lamp-on message from the PCM indicating the

glow plugs are heating and the driver must wait to

start the engine, the wait-to-start indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a wait-to-start indicator lamp-off

message, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The PCM continually monitors the ambient tem-

perature and the glow plug pre-heater circuits to

determine how long the glow plugs must be heated in

the pre-heat operating mode. The PCM then sends

the proper wait-to-start indicator lamp-on and lamp-

off messages to the instrument cluster. If the wait-to-

start indicator fails to light during the actuator test,

replace the bulb with a known good unit. For further

diagnosis of the wait-to-start indicator or the instru-

ment cluster circuitry that controls the indicator,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the glow plug pre-heater control circuits,

the PCM, the PCI data bus, or the electronic message

WJINSTRUMENT CLUSTER 8J - 35

VOLTAGE GAUGE (Continued)

Page 454 of 2199

ergize the combination flasher in response to mes-

sage inputs received over the Programmable

Communications Interface (PCI) data bus network.

The BCM can energize the combination flasher when

the VTSS is requested.

Vehicles equipped with the optional Electronic

Vehicle Information Center (EVIC) use turn signal

status messages received from the Electro-Mechani-

cal Instrument Cluster (EMIC) and distance mes-

sages received from the Powertrain Control Module

(PCM) over the PCI data bus to determine when the

Turn Signal On warning should be activated. The

EMIC receives hard wired inputs from the combina-

tion flasher to operate the turn signal indicators,

then sends the proper turn signal status message to

the EVIC. If a turn signal is left on for more than

about 1.6 kilometers (1 mile) of driving distance, the

EVIC will display a visual ªTurn Signal Onº message

and will send a request to the BCM over the PCI

data bus to notify the vehicle operator.

During both the turn signal and the hazard warn-

ing operation, if the exterior lamps are turned Off,

the front park/turn signal lamps and the front side

marker lamps will flash in unison. If the exterior

lamps are turned On, the front park/turn signal

lamps and the front side marker lamps will flash

alternately. Refer to the owner's manual.

DIAGNOSIS AND TESTING - TURN SIGNAL &

HAZARD WARNING SYSTEMS

When diagnosing the turn signal and hazard warn-

ing circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

concern on the vehicle being diagnosed, test the

charging system as required.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is verydimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indi-

cator(s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the ignition run fuse and the flasher fuse in

the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(3) Check for battery voltage at the flasher fuse in

the JB. If OK, go to Step 4. If not OK, repair the

open fused B(+) circuit between the JB and the

Power Distribution Center (PDC).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the ignition run fuse in

the JB. If OK, go to Step 5. If not OK, repair the

open fused ignition switch output (run) circuit

between the JB and the ignition switch.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from the JB and

replace it with a known good unit. Reconnect the bat-

tery negative cable. Test the operation of the turn

signal and hazard warning systems. If OK, discard

the faulty combination flasher. If not OK, remove the

test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity in the JB for the combina-

tion flasher. If OK, go to Step 7. If not OK, repair the

open fused ignition switch output (run) circuit

between the combination flasher and the ignition run

fuse in the JB.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the B(+) circuit of the JB

for the combination flasher. If OK, go to Step 8. If

not OK, repair the open B(+) circuit between the

combination flasher and the flasher fuse in the JB.

(8) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the turn signal and hazard warning

switches from the multi-function switch connector.

Check for continuity between the ground circuit of

the instrument panel wire harness connector for the

left multi-function switch and a good ground. There

should be continuity. If OK, go to Step 9. If not OK,

repair the open ground circuit.

(9) Check for continuity between the hazard switch

sense circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 10. If not OK, repair the shorted hazard switch

sense circuit between the multi-function switch and

the combination flasher.

(10) Check for continuity between the hazard

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

WJLAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 463 of 2199

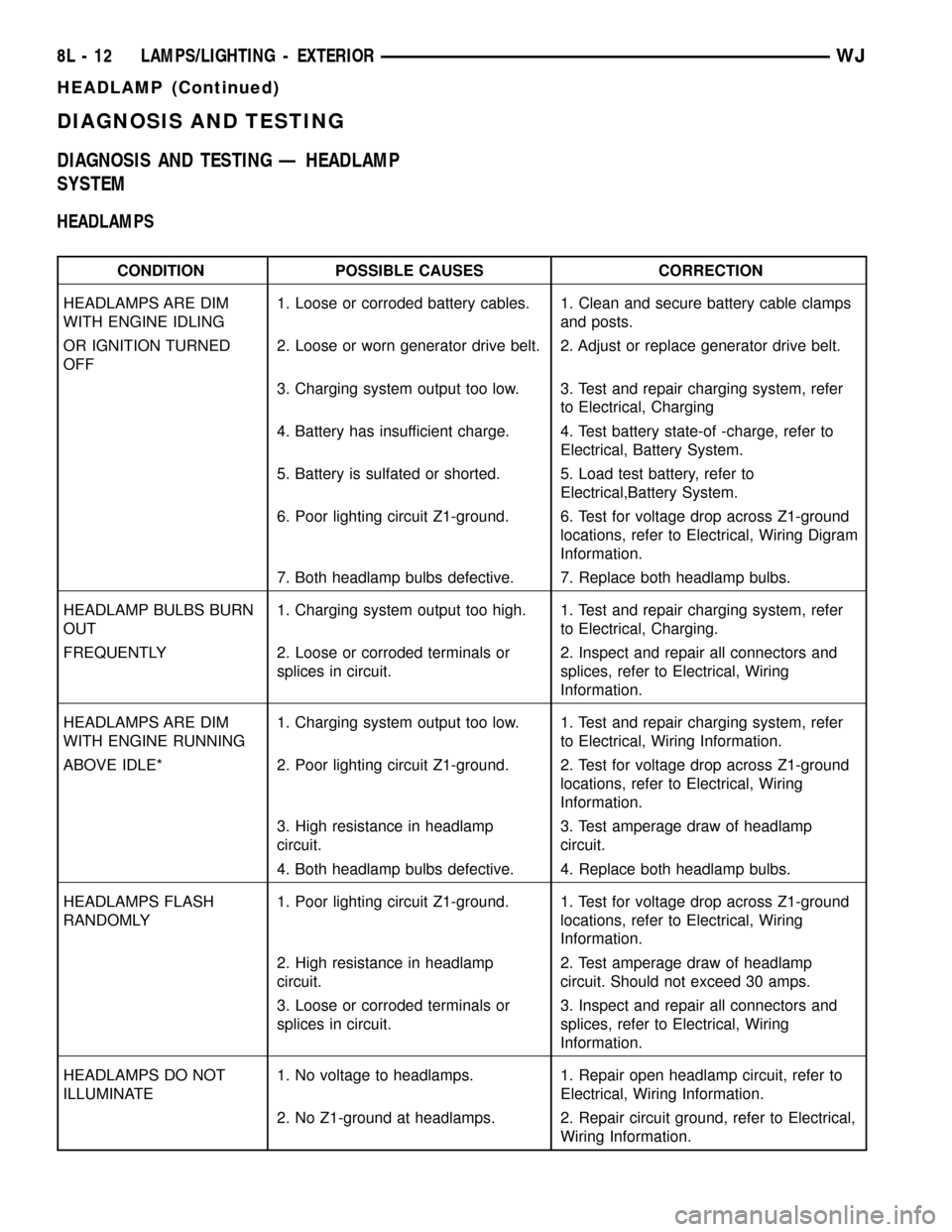

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING Ð HEADLAMP

SYSTEM

HEADLAMPS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer

to Electrical, Charging

4. Battery has insufficient charge. 4. Test battery state-of -charge, refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery, refer to

Electrical,Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring Digram

Information.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT1. Charging system output too high. 1. Test and repair charging system, refer

to Electrical, Charging.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer

to Electrical, Wiring Information.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp

circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp

circuit. Should not exceed 30 amps.

3. Loose or corroded terminals or

splices in circuit.3. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Electrical, Wiring Information.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Electrical,

Wiring Information.

8L - 12 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)

Page 604 of 2199

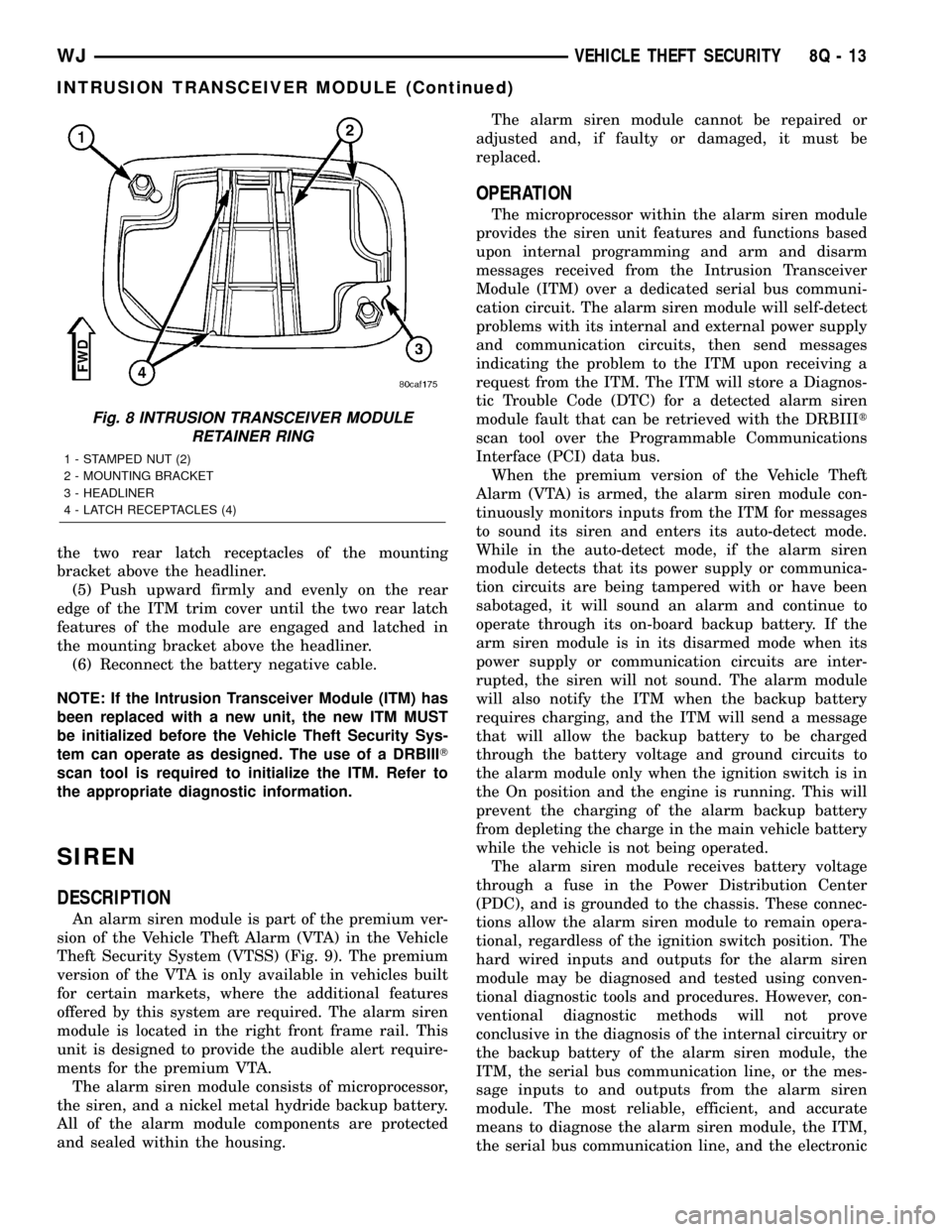

the two rear latch receptacles of the mounting

bracket above the headliner.

(5) Push upward firmly and evenly on the rear

edge of the ITM trim cover until the two rear latch

features of the module are engaged and latched in

the mounting bracket above the headliner.

(6) Reconnect the battery negative cable.

NOTE: If the Intrusion Transceiver Module (ITM) has

been replaced with a new unit, the new ITM MUST

be initialized before the Vehicle Theft Security Sys-

tem can operate as designed. The use of a DRBIIIT

scan tool is required to initialize the ITM. Refer to

the appropriate diagnostic information.

SIREN

DESCRIPTION

An alarm siren module is part of the premium ver-

sion of the Vehicle Theft Alarm (VTA) in the Vehicle

Theft Security System (VTSS) (Fig. 9). The premium

version of the VTA is only available in vehicles built

for certain markets, where the additional features

offered by this system are required. The alarm siren

module is located in the right front frame rail. This

unit is designed to provide the audible alert require-

ments for the premium VTA.

The alarm siren module consists of microprocessor,

the siren, and a nickel metal hydride backup battery.

All of the alarm module components are protected

and sealed within the housing.The alarm siren module cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The microprocessor within the alarm siren module

provides the siren unit features and functions based

upon internal programming and arm and disarm

messages received from the Intrusion Transceiver

Module (ITM) over a dedicated serial bus communi-

cation circuit. The alarm siren module will self-detect

problems with its internal and external power supply

and communication circuits, then send messages

indicating the problem to the ITM upon receiving a

request from the ITM. The ITM will store a Diagnos-

tic Trouble Code (DTC) for a detected alarm siren

module fault that can be retrieved with the DRBIIIt

scan tool over the Programmable Communications

Interface (PCI) data bus.

When the premium version of the Vehicle Theft

Alarm (VTA) is armed, the alarm siren module con-

tinuously monitors inputs from the ITM for messages

to sound its siren and enters its auto-detect mode.

While in the auto-detect mode, if the alarm siren

module detects that its power supply or communica-

tion circuits are being tampered with or have been

sabotaged, it will sound an alarm and continue to

operate through its on-board backup battery. If the

arm siren module is in its disarmed mode when its

power supply or communication circuits are inter-

rupted, the siren will not sound. The alarm module

will also notify the ITM when the backup battery

requires charging, and the ITM will send a message

that will allow the backup battery to be charged

through the battery voltage and ground circuits to

the alarm module only when the ignition switch is in

the On position and the engine is running. This will

prevent the charging of the alarm backup battery

from depleting the charge in the main vehicle battery

while the vehicle is not being operated.

The alarm siren module receives battery voltage

through a fuse in the Power Distribution Center

(PDC), and is grounded to the chassis. These connec-

tions allow the alarm siren module to remain opera-

tional, regardless of the ignition switch position. The

hard wired inputs and outputs for the alarm siren

module may be diagnosed and tested using conven-

tional diagnostic tools and procedures. However, con-

ventional diagnostic methods will not prove

conclusive in the diagnosis of the internal circuitry or

the backup battery of the alarm siren module, the

ITM, the serial bus communication line, or the mes-

sage inputs to and outputs from the alarm siren

module. The most reliable, efficient, and accurate

means to diagnose the alarm siren module, the ITM,

the serial bus communication line, and the electronic

Fig. 8 INTRUSION TRANSCEIVER MODULE

RETAINER RING

1 - STAMPED NUT (2)

2 - MOUNTING BRACKET

3 - HEADLINER

4 - LATCH RECEPTACLES (4)

WJVEHICLE THEFT SECURITY 8Q - 13

INTRUSION TRANSCEIVER MODULE (Continued)

Page 661 of 2199

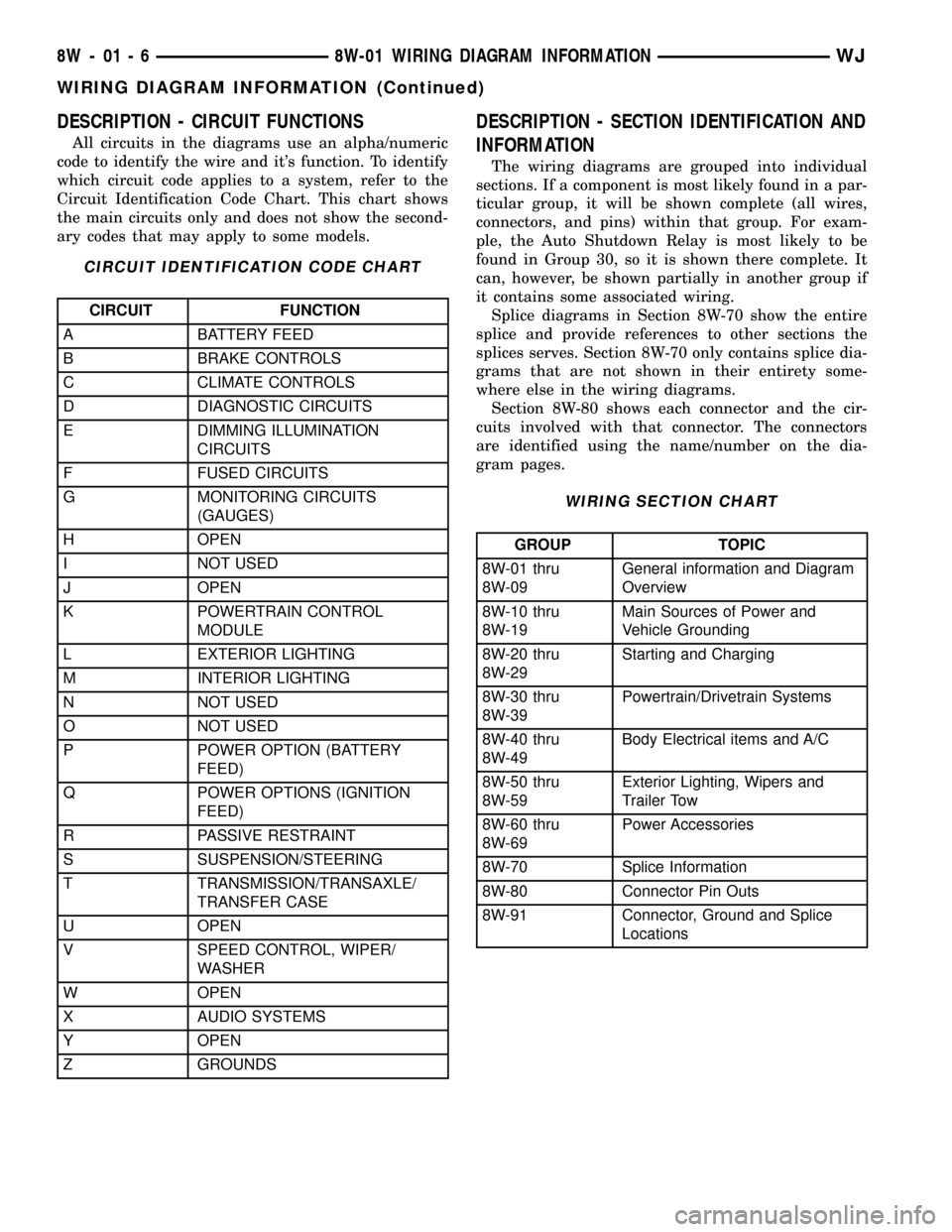

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONWJ

WIRING DIAGRAM INFORMATION (Continued)

Page 1247 of 2199

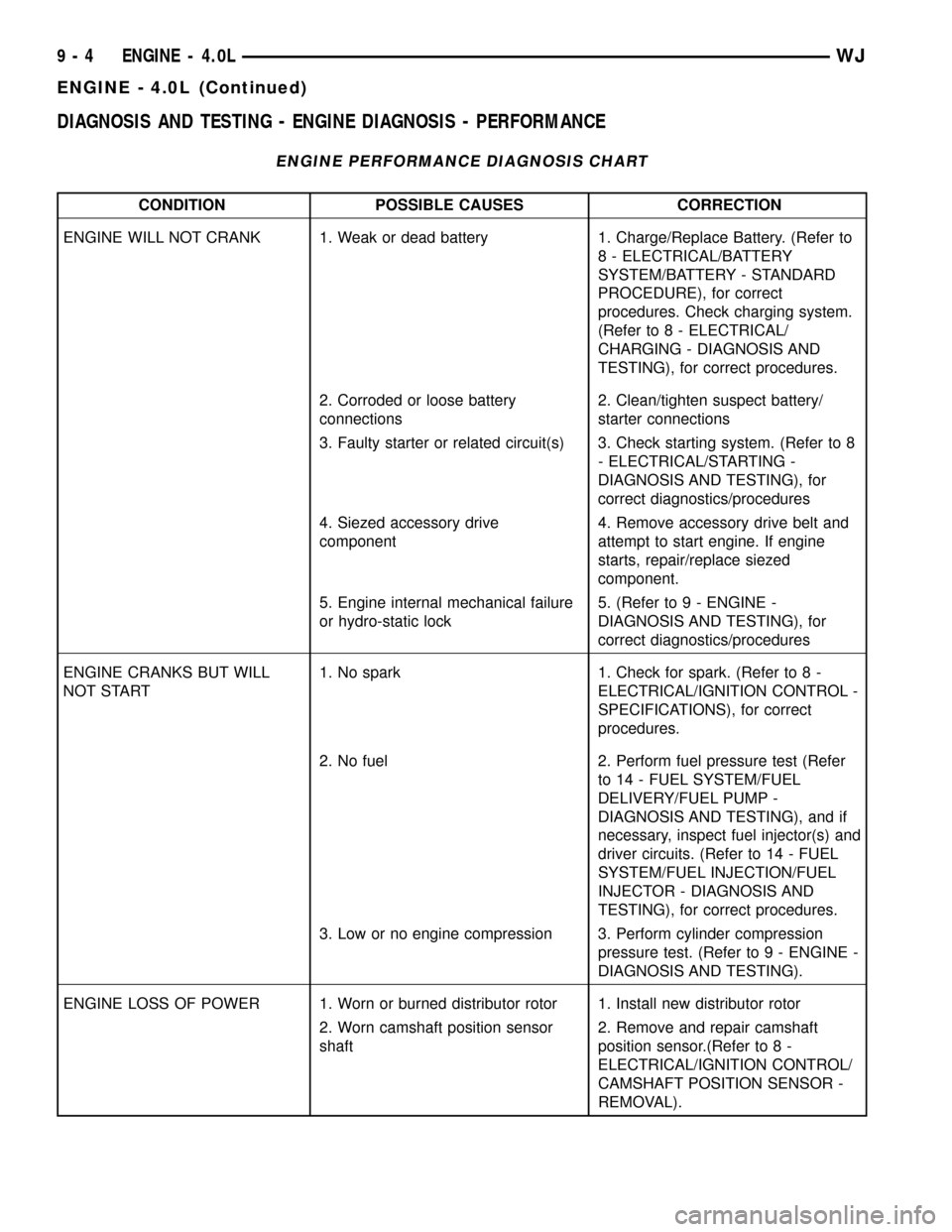

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

ENGINE PERFORMANCE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to

8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD

PROCEDURE), for correct

procedures. Check charging system.

(Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING), for correct procedures.

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/

starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8

- ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING), for

correct diagnostics/procedures

4. Siezed accessory drive

component4. Remove accessory drive belt and

attempt to start engine. If engine

starts, repair/replace siezed

component.

5. Engine internal mechanical failure

or hydro-static lock5. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING), for

correct diagnostics/procedures

ENGINE CRANKS BUT WILL

NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

SPECIFICATIONS), for correct

procedures.

2. No fuel 2. Perform fuel pressure test (Refer

to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING), and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL

INJECTOR - DIAGNOSIS AND

TESTING), for correct procedures.

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn camshaft position sensor

shaft2. Remove and repair camshaft

position sensor.(Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

CAMSHAFT POSITION SENSOR -

REMOVAL).

9 - 4 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 2130 of 2199

CAUTION

CAUTION

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

Never add R-12 to a refrigerant system designed to

use R-134a. Damage to the system will result.

R-12 refrigerant oil must not be mixed with R-134a

refrigerant oil. They are not compatible.

Do not use R-12 equipment or parts on the R-134a

system. Damage to the system will result.

Do not overcharge the refrigerant system. This will

cause excessive compressor head pressure and

can cause noise and system failure.

Recover the refrigerant before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. Never open

or loosen a connection before recovering the refrig-

erant.

The refrigerant system must always be evacuated

before charging.

Do not open the refrigerant system or uncap a

replacement component until you are ready to ser-

vice the system. This will prevent contamination in

the system.

Before disconnecting a component, clean the out-

side of the fittings thoroughly to prevent contami-

nation from entering the refrigerant system.

Immediately after disconnecting a component from

the refrigerant system, seal the open fittings with a

cap or plug.

Before connecting an open refrigerant fitting,

always install a new seal or gasket. Coat the fitting

and seal with clean refrigerant oil before connect-

ing.

Do not remove the sealing caps from a replacement

component until it is to be installed.

When installing a refrigerant line, avoid sharp

bends that may restrict refrigerant flow. Position the

refrigerant lines away from exhaust system compo-

nents or any sharp edges, which may damage the

line.

Tighten refrigerant fittings only to the specified

torque. The aluminum fittings used in the refriger-

ant system will not tolerate overtightening.

When disconnecting a refrigerant fitting, use a

wrench on both halves of the fitting. This will pre-

vent twisting of the refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. Do not open a container of

refrigerant oil until you are ready to use it. Replace

the cap on the oil container immediately after using.

Store refrigerant oil only in a clean, airtight, and

moisture-free container.Keep service tools and the work area clean. Con-

tamination of the refrigerant system through care-

less work habits must be avoided.REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing

will reduce the capacity of the entire system. High

pressures are produced in the system when it is oper-

ating. Extreme care must be exercised to make sure

that all refrigerant system connections are pressure

tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings

that are the correct size and approved for use with

R-134a refrigerant. Failure to do so may result in a

leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

WJPLUMBING 24 - 53

PLUMBING (Continued)