Battery JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1238 of 2199

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the instrument panel center lower

bezel. Check for continuity between the ground cir-

cuit cavity of the power outlet wire harness connector

and a good ground. There should be continuity. If

OK, go to Step 6. If not OK, repair the open ground

circuit to ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the junction block fuse

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center lower bezel from the instru-

ment panel. Refer toInstrument Panel Center

Lower Bezelin Body for the procedure.

(3) Pull the cigar lighter knob and element or the

protective cap out of the cigar lighter receptacle base,

or open the power outlet door in the instrument

panel center lower bezel.

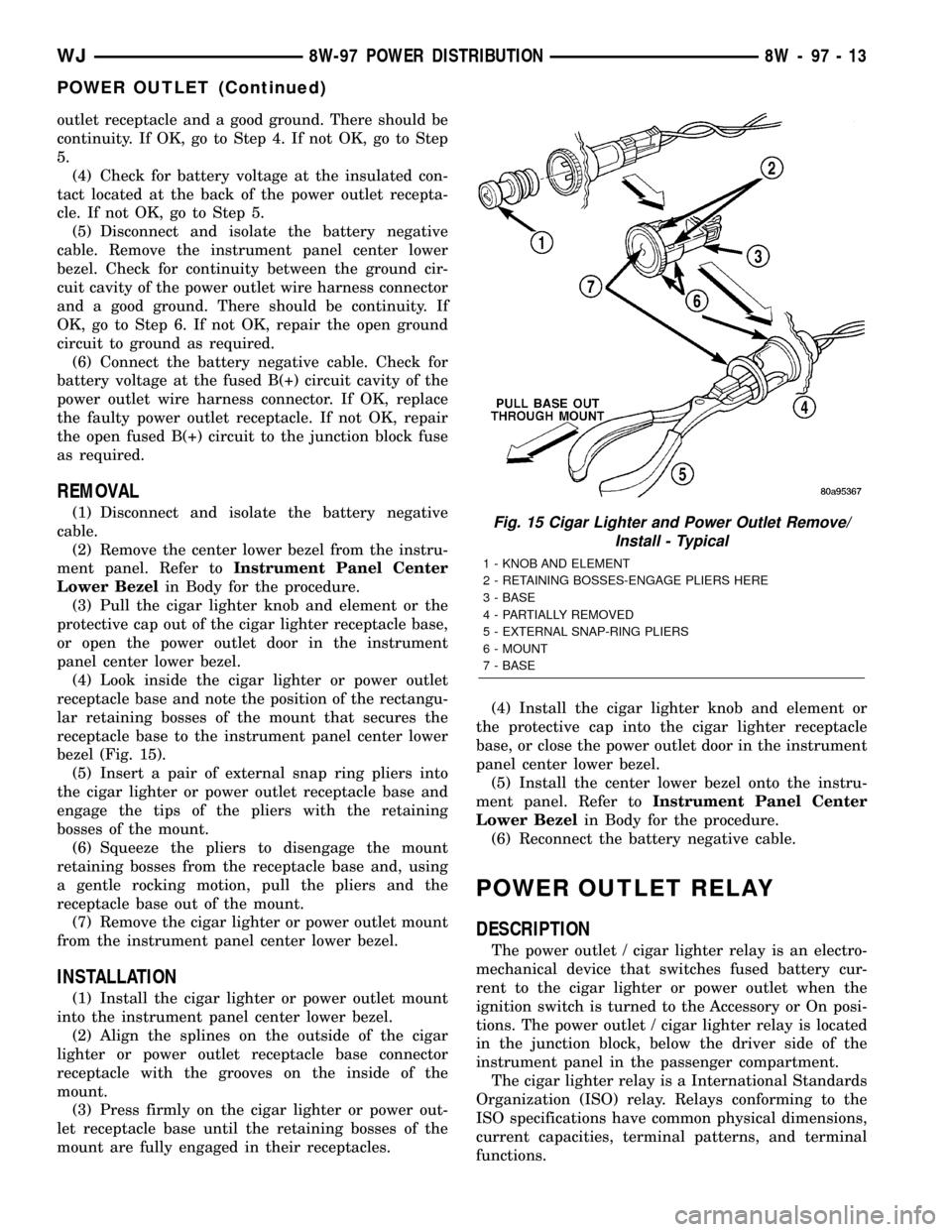

(4) Look inside the cigar lighter or power outlet

receptacle base and note the position of the rectangu-

lar retaining bosses of the mount that secures the

receptacle base to the instrument panel center lower

bezel (Fig. 15).

(5) Insert a pair of external snap ring pliers into

the cigar lighter or power outlet receptacle base and

engage the tips of the pliers with the retaining

bosses of the mount.

(6) Squeeze the pliers to disengage the mount

retaining bosses from the receptacle base and, using

a gentle rocking motion, pull the pliers and the

receptacle base out of the mount.

(7) Remove the cigar lighter or power outlet mount

from the instrument panel center lower bezel.

INSTALLATION

(1) Install the cigar lighter or power outlet mount

into the instrument panel center lower bezel.

(2) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

(3) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.(4) Install the cigar lighter knob and element or

the protective cap into the cigar lighter receptacle

base, or close the power outlet door in the instrument

panel center lower bezel.

(5) Install the center lower bezel onto the instru-

ment panel. Refer toInstrument Panel Center

Lower Bezelin Body for the procedure.

(6) Reconnect the battery negative cable.

POWER OUTLET RELAY

DESCRIPTION

The power outlet / cigar lighter relay is an electro-

mechanical device that switches fused battery cur-

rent to the cigar lighter or power outlet when the

ignition switch is turned to the Accessory or On posi-

tions. The power outlet / cigar lighter relay is located

in the junction block, below the driver side of the

instrument panel in the passenger compartment.

The cigar lighter relay is a International Standards

Organization (ISO) relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions.

Fig. 15 Cigar Lighter and Power Outlet Remove/

Install - Typical

1 - KNOB AND ELEMENT

2 - RETAINING BOSSES-ENGAGE PLIERS HERE

3 - BASE

4 - PARTIALLY REMOVED

5 - EXTERNAL SNAP-RING PLIERS

6 - MOUNT

7 - BASE

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 13

POWER OUTLET (Continued)

Page 1239 of 2199

The cigar lighter relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - POWER OUTLET

RELAY

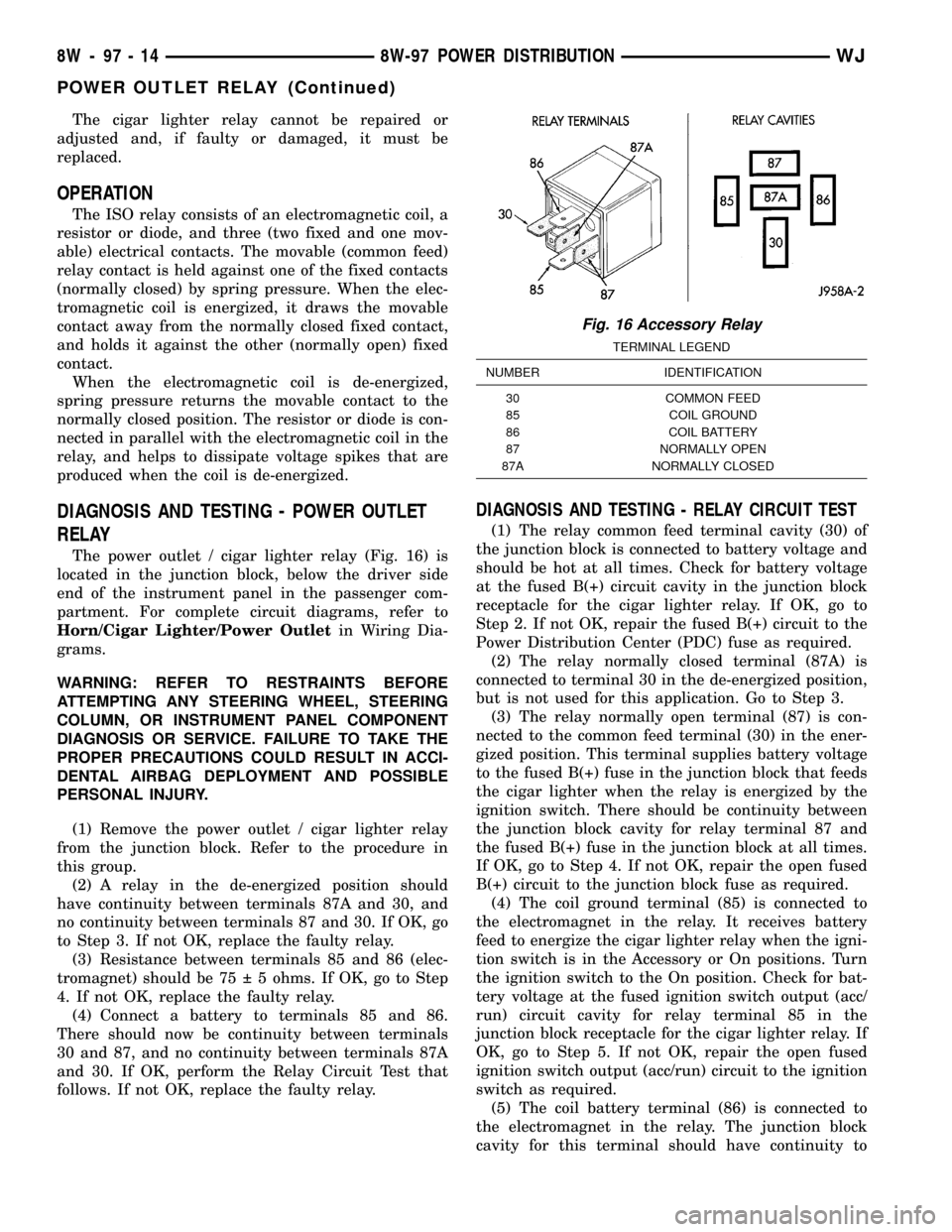

The power outlet / cigar lighter relay (Fig. 16) is

located in the junction block, below the driver side

end of the instrument panel in the passenger com-

partment. For complete circuit diagrams, refer to

Horn/Cigar Lighter/Power Outletin Wiring Dia-

grams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the power outlet / cigar lighter relay

from the junction block. Refer to the procedure in

this group.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS AND TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the junction block is connected to battery voltage and

should be hot at all times. Check for battery voltage

at the fused B(+) circuit cavity in the junction block

receptacle for the cigar lighter relay. If OK, go to

Step 2. If not OK, repair the fused B(+) circuit to the

Power Distribution Center (PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the junction block that feeds

the cigar lighter when the relay is energized by the

ignition switch. There should be continuity between

the junction block cavity for relay terminal 87 and

the fused B(+) fuse in the junction block at all times.

If OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the cigar lighter relay when the igni-

tion switch is in the Accessory or On positions. Turn

the ignition switch to the On position. Check for bat-

tery voltage at the fused ignition switch output (acc/

run) circuit cavity for relay terminal 85 in the

junction block receptacle for the cigar lighter relay. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (acc/run) circuit to the ignition

switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The junction block

cavity for this terminal should have continuity to

Fig. 16 Accessory Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8W - 97 - 14 8W-97 POWER DISTRIBUTIONWJ

POWER OUTLET RELAY (Continued)

Page 1240 of 2199

ground at all times. If not OK, repair the open

ground circuit to ground as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. Refer toSteering Col-

umn Opening Coverin Body for the procedure.

(3) The power outlet / cigar lighter relay is located

on the left side of the combination flasher in the

junction block.

(4) Remove the power outlet / cigar lighter relay

from the junction block.

INSTALLATION

(1) Position the power outlet / cigar lighter relay in

the proper receptacle in the junction block.

(2) Align the power outlet / cigar lighter relay ter-

minals with the terminal cavities in the junction

block receptacle.

(3) Push in firmly on the power outlet / cigar

lighter relay until the terminals are fully seated in

the terminal cavities in the junction block receptacle.

(4) Install the steering column opening cover onto

the instrument panel. Refer toSteering Column

Opening Coverin Body for the procedure.

(5) Reconnect the battery negative cable.

IOD WIRE HARNESS

CONNECTOR

DESCRIPTION

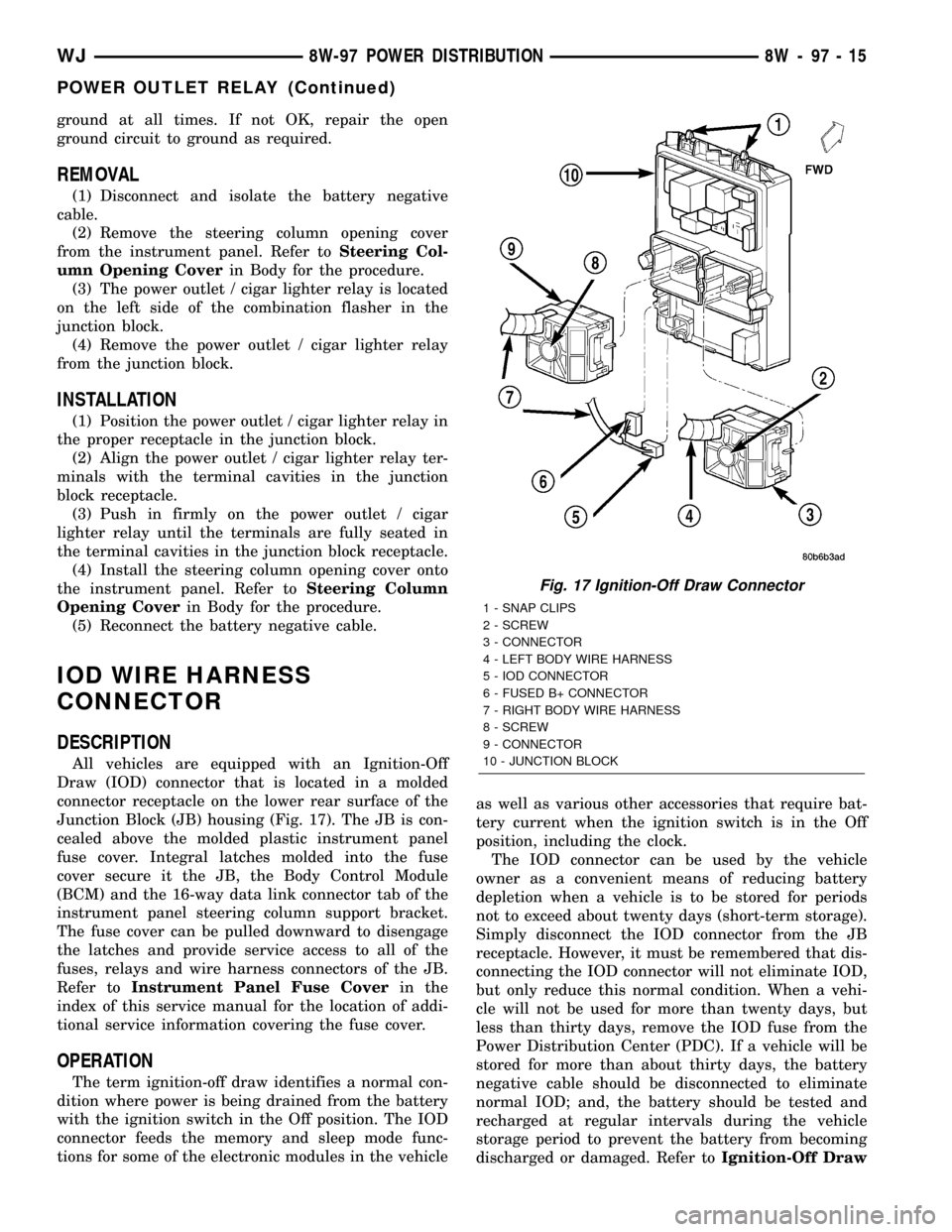

All vehicles are equipped with an Ignition-Off

Draw (IOD) connector that is located in a molded

connector receptacle on the lower rear surface of the

Junction Block (JB) housing (Fig. 17). The JB is con-

cealed above the molded plastic instrument panel

fuse cover. Integral latches molded into the fuse

cover secure it the JB, the Body Control Module

(BCM) and the 16-way data link connector tab of the

instrument panel steering column support bracket.

The fuse cover can be pulled downward to disengage

the latches and provide service access to all of the

fuses, relays and wire harness connectors of the JB.

Refer toInstrument Panel Fuse Coverin the

index of this service manual for the location of addi-

tional service information covering the fuse cover.

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

connector feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicleas well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock.

The IOD connector can be used by the vehicle

owner as a convenient means of reducing battery

depletion when a vehicle is to be stored for periods

not to exceed about twenty days (short-term storage).

Simply disconnect the IOD connector from the JB

receptacle. However, it must be remembered that dis-

connecting the IOD connector will not eliminate IOD,

but only reduce this normal condition. When a vehi-

cle will not be used for more than twenty days, but

less than thirty days, remove the IOD fuse from the

Power Distribution Center (PDC). If a vehicle will be

stored for more than about thirty days, the battery

negative cable should be disconnected to eliminate

normal IOD; and, the battery should be tested and

recharged at regular intervals during the vehicle

storage period to prevent the battery from becoming

discharged or damaged. Refer toIgnition-Off Draw

Fig. 17 Ignition-Off Draw Connector

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 15

POWER OUTLET RELAY (Continued)

Page 1241 of 2199

FuseandBatteryin the index in this service man-

ual for the location of additional service information

covering the ignition-off draw fuse and the battery.

FUSE COVER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

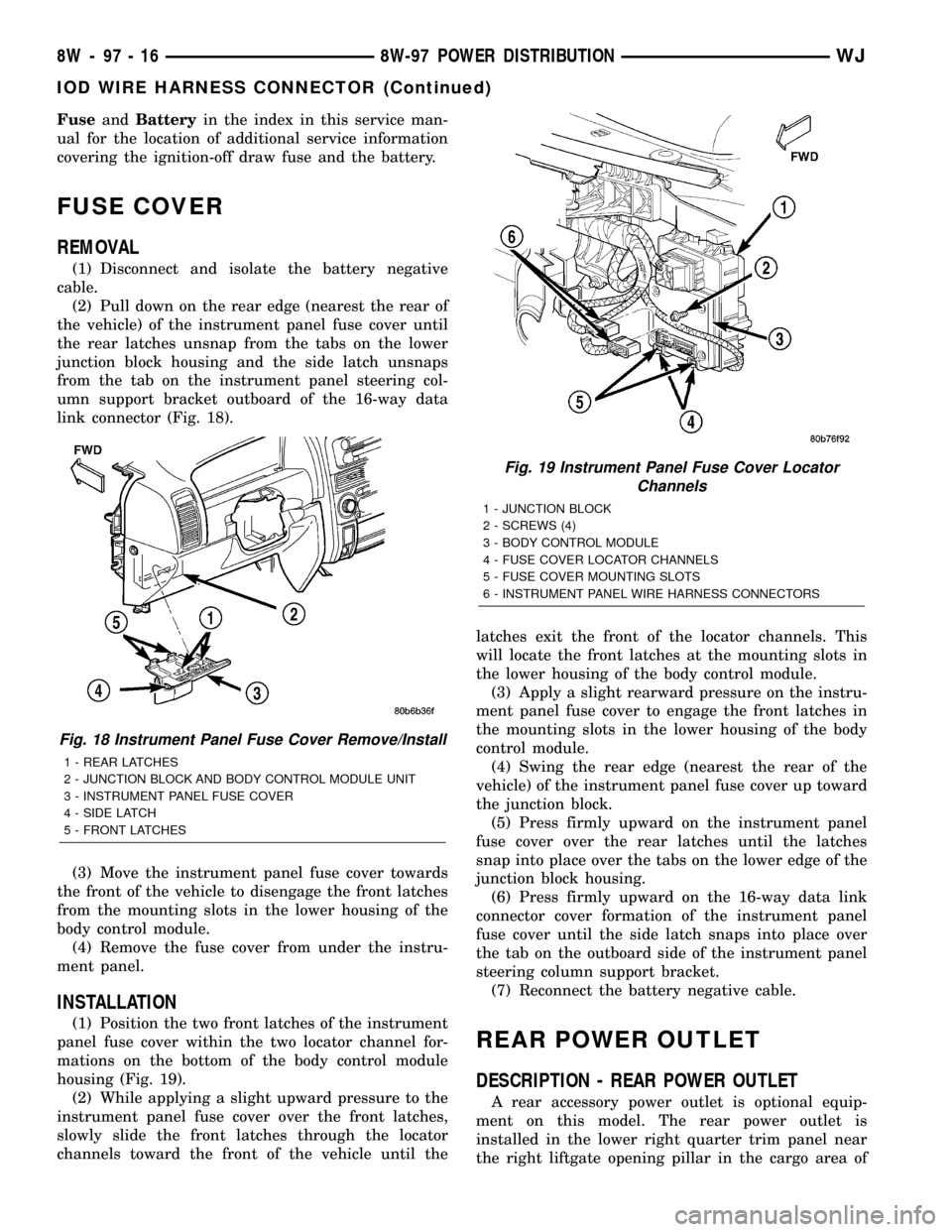

(2) Pull down on the rear edge (nearest the rear of

the vehicle) of the instrument panel fuse cover until

the rear latches unsnap from the tabs on the lower

junction block housing and the side latch unsnaps

from the tab on the instrument panel steering col-

umn support bracket outboard of the 16-way data

link connector (Fig. 18).

(3) Move the instrument panel fuse cover towards

the front of the vehicle to disengage the front latches

from the mounting slots in the lower housing of the

body control module.

(4) Remove the fuse cover from under the instru-

ment panel.

INSTALLATION

(1) Position the two front latches of the instrument

panel fuse cover within the two locator channel for-

mations on the bottom of the body control module

housing (Fig. 19).

(2) While applying a slight upward pressure to the

instrument panel fuse cover over the front latches,

slowly slide the front latches through the locator

channels toward the front of the vehicle until thelatches exit the front of the locator channels. This

will locate the front latches at the mounting slots in

the lower housing of the body control module.

(3) Apply a slight rearward pressure on the instru-

ment panel fuse cover to engage the front latches in

the mounting slots in the lower housing of the body

control module.

(4) Swing the rear edge (nearest the rear of the

vehicle) of the instrument panel fuse cover up toward

the junction block.

(5) Press firmly upward on the instrument panel

fuse cover over the rear latches until the latches

snap into place over the tabs on the lower edge of the

junction block housing.

(6) Press firmly upward on the 16-way data link

connector cover formation of the instrument panel

fuse cover until the side latch snaps into place over

the tab on the outboard side of the instrument panel

steering column support bracket.

(7) Reconnect the battery negative cable.

REAR POWER OUTLET

DESCRIPTION - REAR POWER OUTLET

A rear accessory power outlet is optional equip-

ment on this model. The rear power outlet is

installed in the lower right quarter trim panel near

the right liftgate opening pillar in the cargo area of

Fig. 18 Instrument Panel Fuse Cover Remove/Install

1 - REAR LATCHES

2 - JUNCTION BLOCK AND BODY CONTROL MODULE UNIT

3 - INSTRUMENT PANEL FUSE COVER

4 - SIDE LATCH

5 - FRONT LATCHES

Fig. 19 Instrument Panel Fuse Cover Locator

Channels

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

8W - 97 - 16 8W-97 POWER DISTRIBUTIONWJ

IOD WIRE HARNESS CONNECTOR (Continued)

Page 1242 of 2199

the vehicle. The power outlet base and mount are

secured by a snap fit within the quarter trim panel.

A plastic protective cap snaps into the power outlet

base when the power outlet is not being used, and

hangs from the power outlet base mount by an inte-

gral bail strap while the power outlet is in use. While

the power outlet is very similar to a cigar lighter

base unit, it does not include the two small spring-

clip retainers inside the bottom of the receptacle

shell that are used to secure the cigar lighter heating

element to the insulated contact.

The power outlet receptacle unit and the accessory

power outlet protective cap are available for service.

The power outlet receptacle cannot be repaired and,

if faulty or damaged, it must be replaced.

OPERATION - REAR POWER OUTLET

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the Power Distribution Center (PDC) through a

fuse in the Junction Block (JB) at all times. Refer to

Horn/Cigar Lighter/Power Outletin Wiring Dia-

grams for the location of complete rear power outlet

circuit diagrams.

DIAGNOSIS AND TESTING - REAR POWER

OUTLET

Refer toHorn/Cigar Lighter/Power Outletin

Wiring Diagrams for the location of complete rear

power outlet circuit diagrams.

(1) Check the fused B(+) fuse in the Junction

Block (JB). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the JB. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the Power Distribution

Center (PDC) as required.

(3) Remove the plastic protective cap from the rear

power outlet receptacle. Check for continuity between

the inside circumference of the rear power outlet

receptacle and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, go to Step 5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the rear power outlet

receptacle. If not OK, go to Step 5.(5) Disconnect and isolate the battery negative

cable. Remove the rear power outlet from the right

quarter trim panel. Check for continuity between the

ground circuit cavity of the rear power outlet wire

harness connector and a good ground. There should

be continuity. If OK, go to Step 6. If not OK, repair

the open ground circuit to ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

rear power outlet wire harness connector. If OK,

replace the faulty rear power outlet receptacle base.

If not OK, repair the open fused B(+) circuit to the

JB fuse as required.

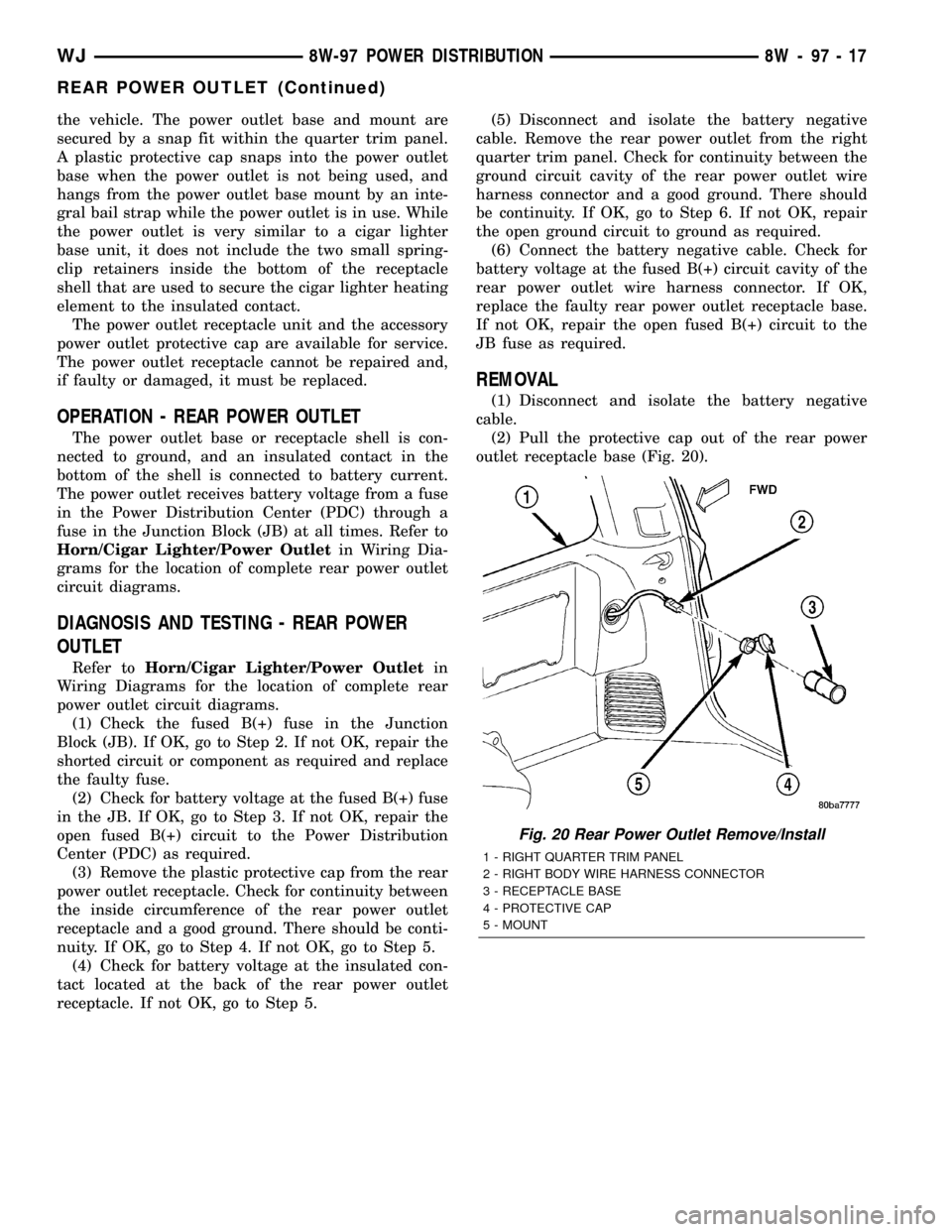

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the protective cap out of the rear power

outlet receptacle base (Fig. 20).

Fig. 20 Rear Power Outlet Remove/Install

1 - RIGHT QUARTER TRIM PANEL

2 - RIGHT BODY WIRE HARNESS CONNECTOR

3 - RECEPTACLE BASE

4 - PROTECTIVE CAP

5 - MOUNT

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 17

REAR POWER OUTLET (Continued)

Page 1243 of 2199

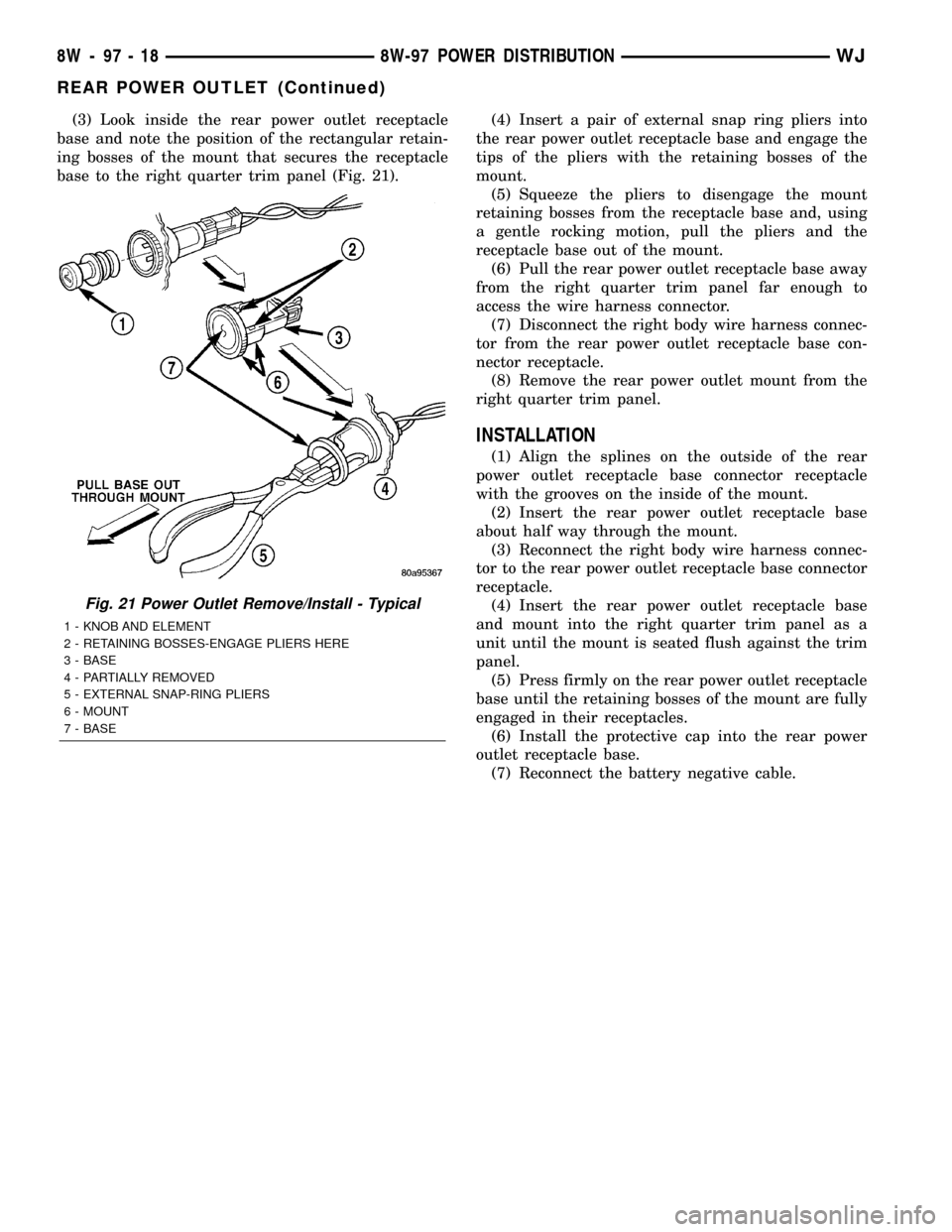

(3) Look inside the rear power outlet receptacle

base and note the position of the rectangular retain-

ing bosses of the mount that secures the receptacle

base to the right quarter trim panel (Fig. 21).(4) Insert a pair of external snap ring pliers into

the rear power outlet receptacle base and engage the

tips of the pliers with the retaining bosses of the

mount.

(5) Squeeze the pliers to disengage the mount

retaining bosses from the receptacle base and, using

a gentle rocking motion, pull the pliers and the

receptacle base out of the mount.

(6) Pull the rear power outlet receptacle base away

from the right quarter trim panel far enough to

access the wire harness connector.

(7) Disconnect the right body wire harness connec-

tor from the rear power outlet receptacle base con-

nector receptacle.

(8) Remove the rear power outlet mount from the

right quarter trim panel.

INSTALLATION

(1) Align the splines on the outside of the rear

power outlet receptacle base connector receptacle

with the grooves on the inside of the mount.

(2) Insert the rear power outlet receptacle base

about half way through the mount.

(3) Reconnect the right body wire harness connec-

tor to the rear power outlet receptacle base connector

receptacle.

(4) Insert the rear power outlet receptacle base

and mount into the right quarter trim panel as a

unit until the mount is seated flush against the trim

panel.

(5) Press firmly on the rear power outlet receptacle

base until the retaining bosses of the mount are fully

engaged in their receptacles.

(6) Install the protective cap into the rear power

outlet receptacle base.

(7) Reconnect the battery negative cable.

Fig. 21 Power Outlet Remove/Install - Typical

1 - KNOB AND ELEMENT

2 - RETAINING BOSSES-ENGAGE PLIERS HERE

3 - BASE

4 - PARTIALLY REMOVED

5 - EXTERNAL SNAP-RING PLIERS

6 - MOUNT

7 - BASE

8W - 97 - 18 8W-97 POWER DISTRIBUTIONWJ

REAR POWER OUTLET (Continued)

Page 1247 of 2199

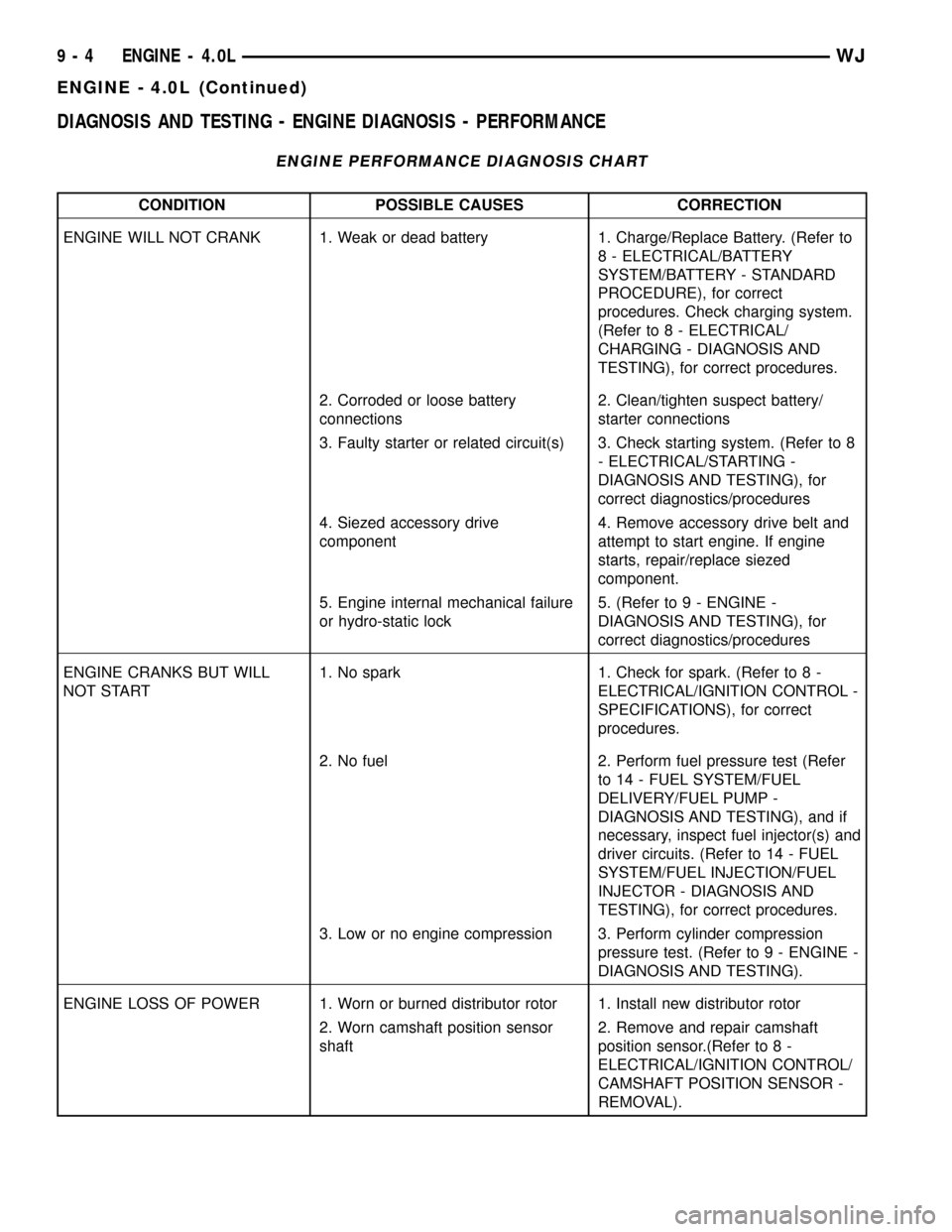

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

ENGINE PERFORMANCE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to

8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD

PROCEDURE), for correct

procedures. Check charging system.

(Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING), for correct procedures.

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/

starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8

- ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING), for

correct diagnostics/procedures

4. Siezed accessory drive

component4. Remove accessory drive belt and

attempt to start engine. If engine

starts, repair/replace siezed

component.

5. Engine internal mechanical failure

or hydro-static lock5. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING), for

correct diagnostics/procedures

ENGINE CRANKS BUT WILL

NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

SPECIFICATIONS), for correct

procedures.

2. No fuel 2. Perform fuel pressure test (Refer

to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING), and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL

INJECTOR - DIAGNOSIS AND

TESTING), for correct procedures.

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn camshaft position sensor

shaft2. Remove and repair camshaft

position sensor.(Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

CAMSHAFT POSITION SENSOR -

REMOVAL).

9 - 4 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1251 of 2199

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise, the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Secure the throttle in the wide-open position.

(4) Disconnect the ignition coil.

(5) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(6) Record the compression pressure on the third

revolution. Continue the test for the remaining cylin-

ders.

(Refer to 9 - ENGINE - SPECIFICATIONS) for the

correct engine compression pressures.

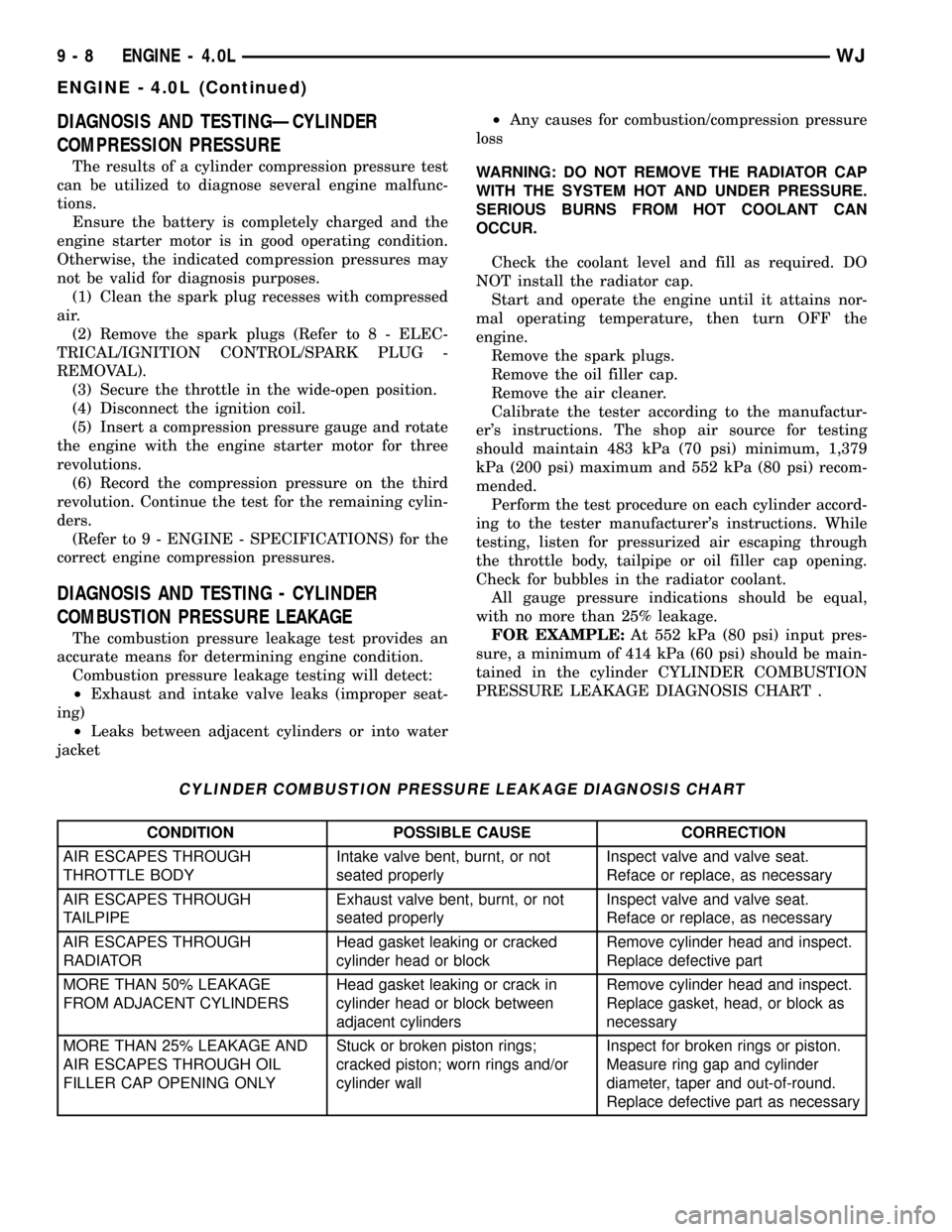

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing)

²Leaks between adjacent cylinders or into water

jacket²Any causes for combustion/compression pressure

loss

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM HOT COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn OFF the

engine.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedure on each cylinder accord-

ing to the tester manufacturer's instructions. While

testing, listen for pressurized air escaping through

the throttle body, tailpipe or oil filler cap opening.

Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder CYLINDER COMBUSTION

PRESSURE LEAKAGE DIAGNOSIS CHART .

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

9 - 8 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1252 of 2199

DIAGNOSIS AND TESTINGÐREAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurized the crank-

case as outlined in (Refer to 9 - ENGINE/LUBRICA-

TION - DIAGNOSIS AND TESTING)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL), for proper replacement

procedures.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

WJENGINE - 4.0L 9 - 9

ENGINE - 4.0L (Continued)

Page 1253 of 2199

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gaskets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1)

Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light scuff-

ing, scoring and scratches. Usually, a few strokes will

clean up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

9 - 10 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)