Fan JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 358 of 2199

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Gen-

erator Ratings in the Specifications section at the

back of this group for amperage ratings and part

numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley; incorrect, worn, damaged or misad-

justed fan drive belt; loose mounting bolts; a

misaligned drive pulley or a defective stator or diode.

REMOVAL

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE (B+ WIRE) FROM GENERATOR. FAILURE TO

DO SO CAN RESULT IN INJURY OR DAMAGE TO

ELECTRICAL SYSTEM.

(1) Disconnect negative battery cable at battery.

(2) Remove generator drive belt. Refer to Cooling

System for procedure.

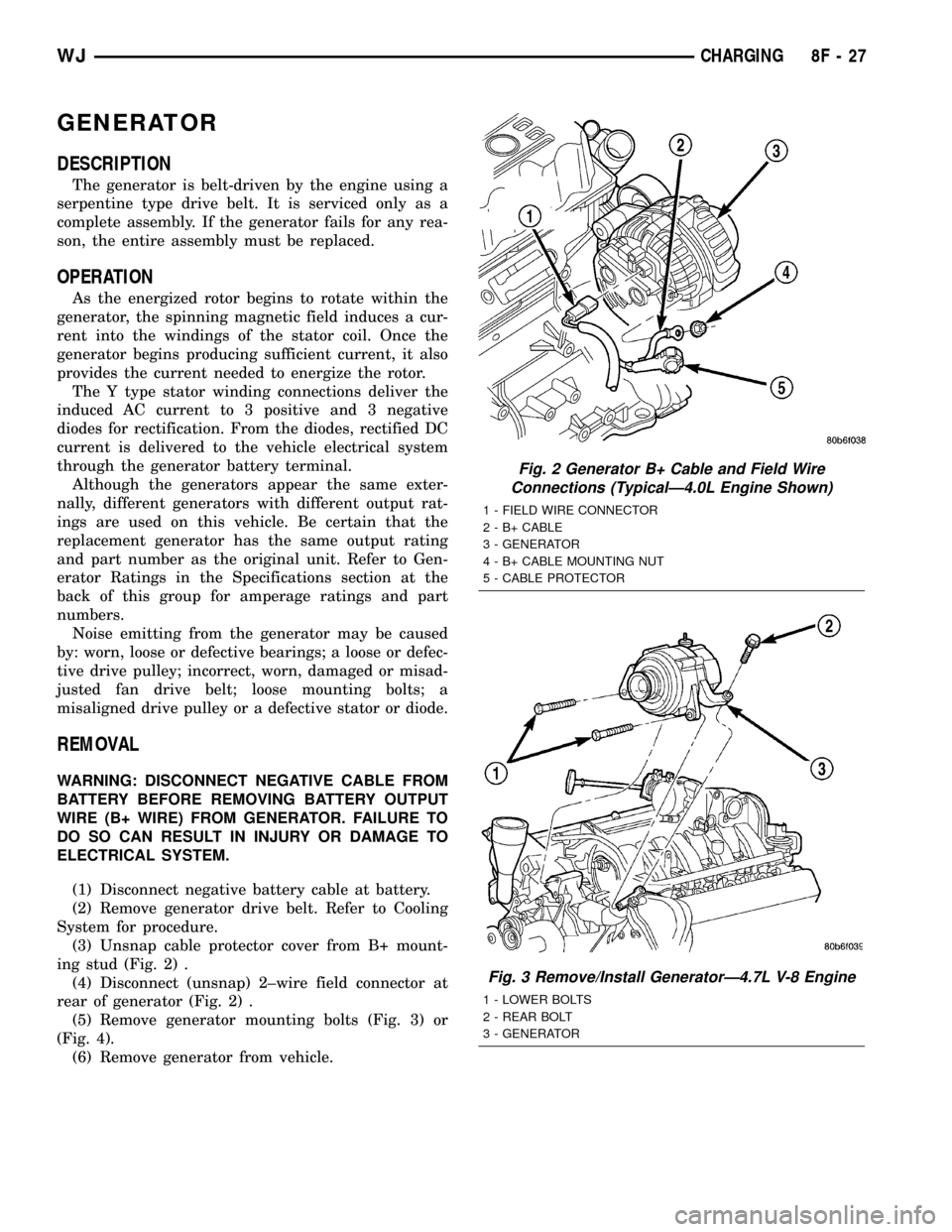

(3) Unsnap cable protector cover from B+ mount-

ing stud (Fig. 2) .

(4) Disconnect (unsnap) 2±wire field connector at

rear of generator (Fig. 2) .

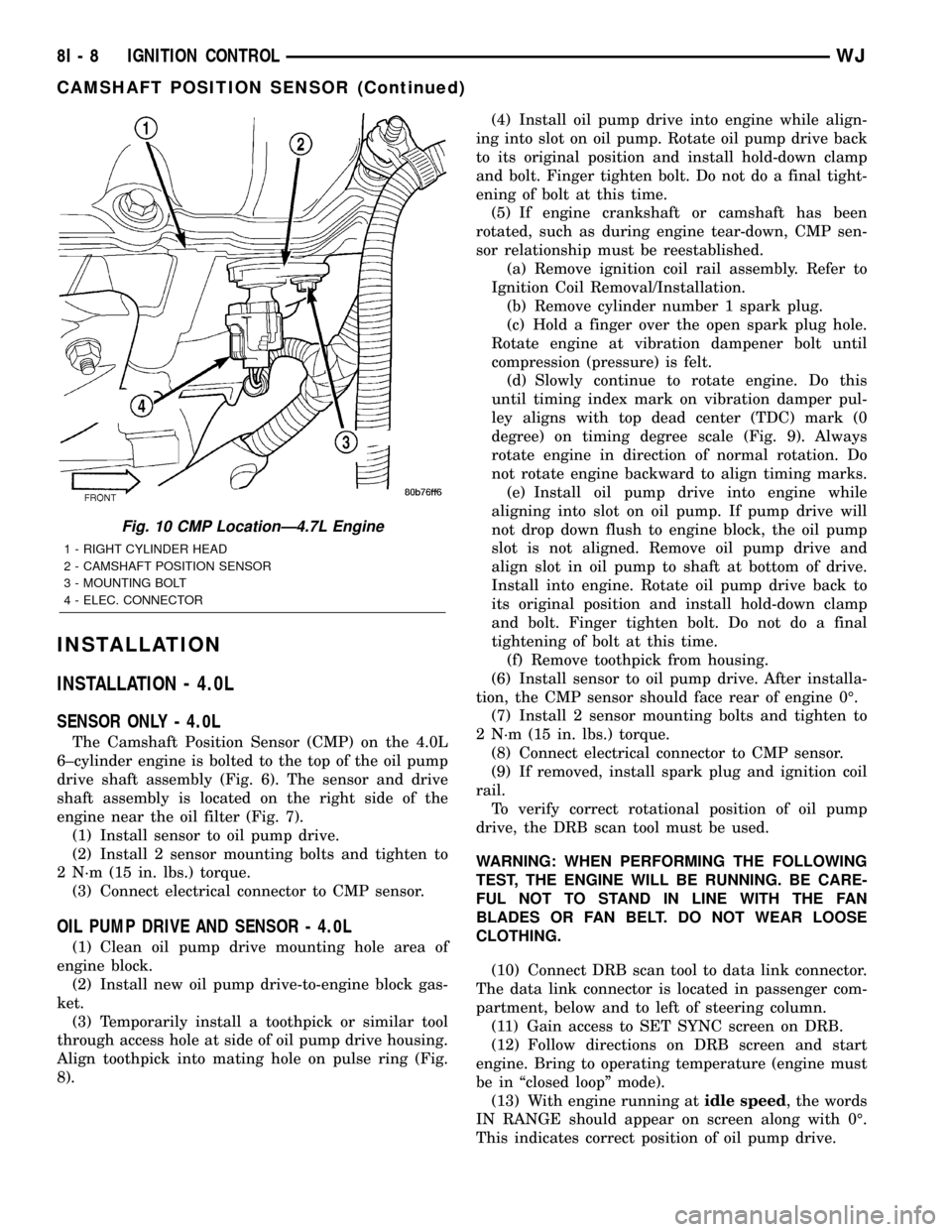

(5) Remove generator mounting bolts (Fig. 3) or

(Fig. 4).

(6) Remove generator from vehicle.

Fig. 2 Generator B+ Cable and Field Wire

Connections (TypicalÐ4.0L Engine Shown)

1 - FIELD WIRE CONNECTOR

2 - B+ CABLE

3 - GENERATOR

4 - B+ CABLE MOUNTING NUT

5 - CABLE PROTECTOR

Fig. 3 Remove/Install GeneratorÐ4.7L V-8 Engine

1 - LOWER BOLTS

2 - REAR BOLT

3 - GENERATOR

WJCHARGING 8F - 27

Page 405 of 2199

INSTALLATION

INSTALLATION - 4.0L

SENSOR ONLY - 4.0L

The Camshaft Position Sensor (CMP) on the 4.0L

6±cylinder engine is bolted to the top of the oil pump

drive shaft assembly (Fig. 6). The sensor and drive

shaft assembly is located on the right side of the

engine near the oil filter (Fig. 7).

(1) Install sensor to oil pump drive.

(2) Install 2 sensor mounting bolts and tighten to

2 N´m (15 in. lbs.) torque.

(3) Connect electrical connector to CMP sensor.

OIL PUMP DRIVE AND SENSOR - 4.0L

(1) Clean oil pump drive mounting hole area of

engine block.

(2) Install new oil pump drive-to-engine block gas-

ket.

(3) Temporarily install a toothpick or similar tool

through access hole at side of oil pump drive housing.

Align toothpick into mating hole on pulse ring (Fig.

8).(4) Install oil pump drive into engine while align-

ing into slot on oil pump. Rotate oil pump drive back

to its original position and install hold-down clamp

and bolt. Finger tighten bolt. Do not do a final tight-

ening of bolt at this time.

(5) If engine crankshaft or camshaft has been

rotated, such as during engine tear-down, CMP sen-

sor relationship must be reestablished.

(a) Remove ignition coil rail assembly. Refer to

Ignition Coil Removal/Installation.

(b) Remove cylinder number 1 spark plug.

(c) Hold a finger over the open spark plug hole.

Rotate engine at vibration dampener bolt until

compression (pressure) is felt.

(d) Slowly continue to rotate engine. Do this

until timing index mark on vibration damper pul-

ley aligns with top dead center (TDC) mark (0

degree) on timing degree scale (Fig. 9). Always

rotate engine in direction of normal rotation. Do

not rotate engine backward to align timing marks.

(e) Install oil pump drive into engine while

aligning into slot on oil pump. If pump drive will

not drop down flush to engine block, the oil pump

slot is not aligned. Remove oil pump drive and

align slot in oil pump to shaft at bottom of drive.

Install into engine. Rotate oil pump drive back to

its original position and install hold-down clamp

and bolt. Finger tighten bolt. Do not do a final

tightening of bolt at this time.

(f) Remove toothpick from housing.

(6) Install sensor to oil pump drive. After installa-

tion, the CMP sensor should face rear of engine 0É.

(7) Install 2 sensor mounting bolts and tighten to

2 N´m (15 in. lbs.) torque.

(8) Connect electrical connector to CMP sensor.

(9) If removed, install spark plug and ignition coil

rail.

To verify correct rotational position of oil pump

drive, the DRB scan tool must be used.

WARNING: WHEN PERFORMING THE FOLLOWING

TEST, THE ENGINE WILL BE RUNNING. BE CARE-

FUL NOT TO STAND IN LINE WITH THE FAN

BLADES OR FAN BELT. DO NOT WEAR LOOSE

CLOTHING.

(10) Connect DRB scan tool to data link connector.

The data link connector is located in passenger com-

partment, below and to left of steering column.

(11) Gain access to SET SYNC screen on DRB.

(12) Follow directions on DRB screen and start

engine. Bring to operating temperature (engine must

be in ªclosed loopº mode).

(13) With engine running atidle speed, the words

IN RANGE should appear on screen along with 0É.

This indicates correct position of oil pump drive.

Fig. 10 CMP LocationÐ4.7L Engine

1 - RIGHT CYLINDER HEAD

2 - CAMSHAFT POSITION SENSOR

3 - MOUNTING BOLT

4 - ELEC. CONNECTOR

8I - 8 IGNITION CONTROLWJ

CAMSHAFT POSITION SENSOR (Continued)

Page 590 of 2199

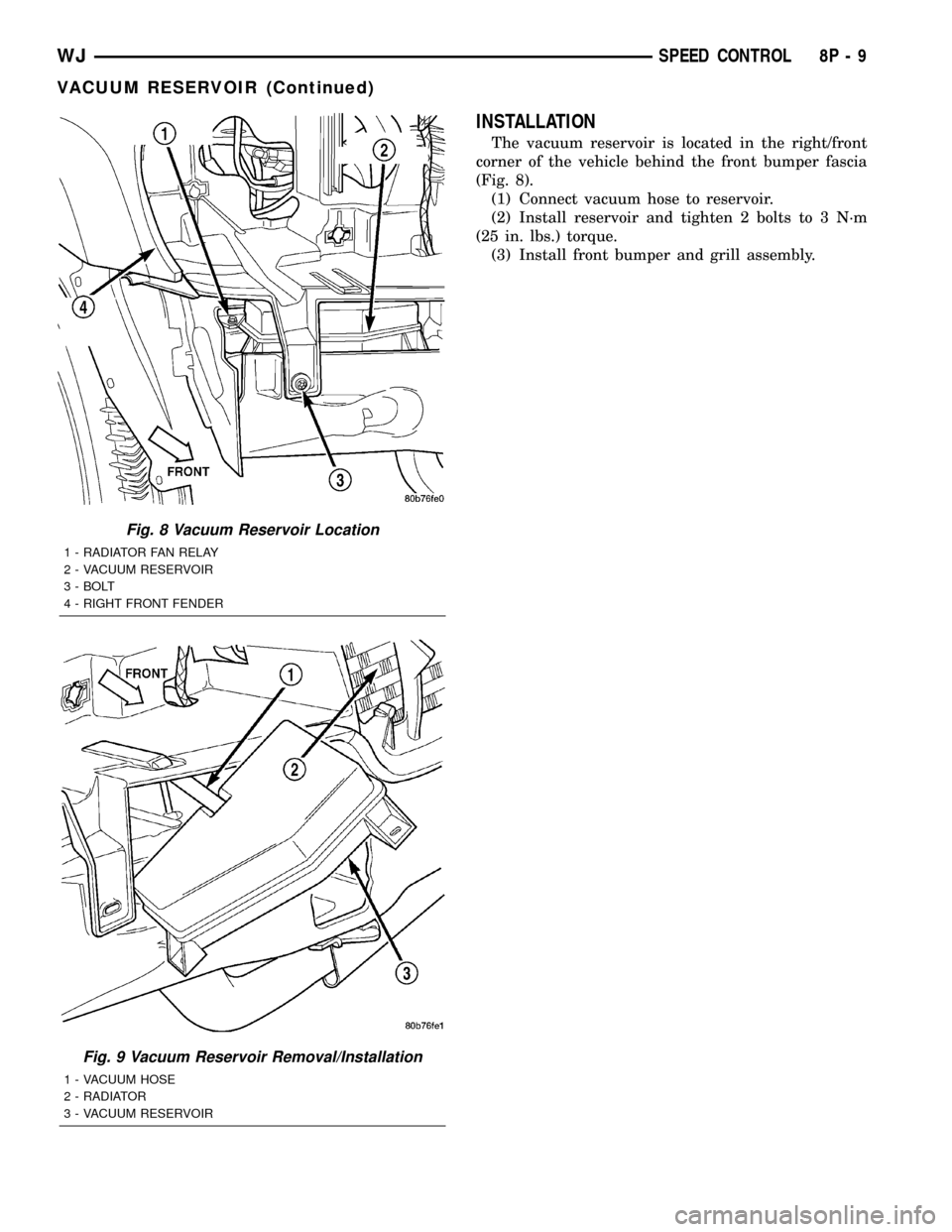

INSTALLATION

The vacuum reservoir is located in the right/front

corner of the vehicle behind the front bumper fascia

(Fig. 8).

(1) Connect vacuum hose to reservoir.

(2) Install reservoir and tighten 2 bolts to 3 N´m

(25 in. lbs.) torque.

(3) Install front bumper and grill assembly.

Fig. 8 Vacuum Reservoir Location

1 - RADIATOR FAN RELAY

2 - VACUUM RESERVOIR

3 - BOLT

4 - RIGHT FRONT FENDER

Fig. 9 Vacuum Reservoir Removal/Installation

1 - VACUUM HOSE

2 - RADIATOR

3 - VACUUM RESERVOIR

WJSPEED CONTROL 8P - 9

VACUUM RESERVOIR (Continued)

Page 662 of 2199

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 1051 of 2199

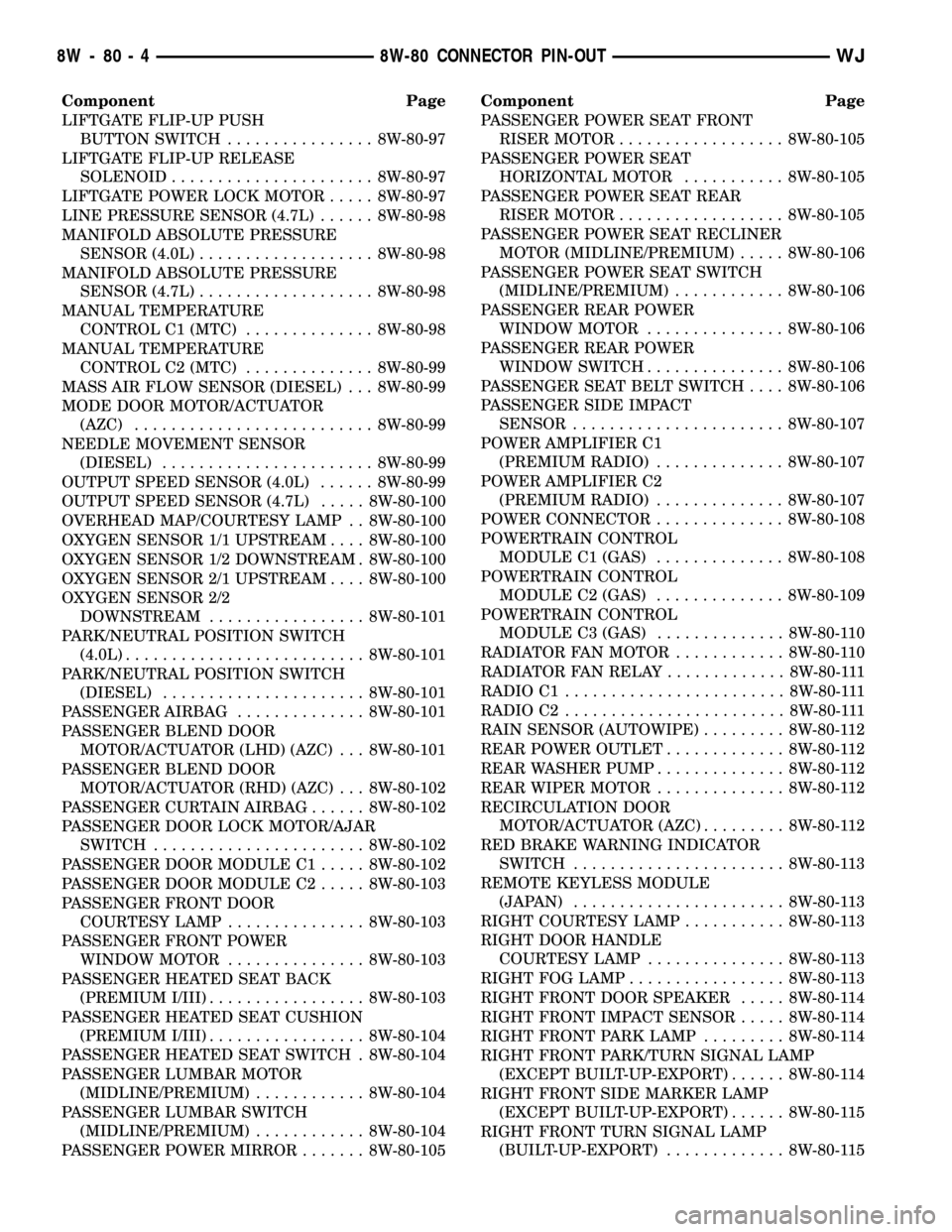

Component Page

LIFTGATE FLIP-UP PUSH

BUTTON SWITCH................ 8W-80-97

LIFTGATE FLIP-UP RELEASE

SOLENOID...................... 8W-80-97

LIFTGATE POWER LOCK MOTOR..... 8W-80-97

LINE PRESSURE SENSOR (4.7L)...... 8W-80-98

MANIFOLD ABSOLUTE PRESSURE

SENSOR (4.0L)................... 8W-80-98

MANIFOLD ABSOLUTE PRESSURE

SENSOR (4.7L)................... 8W-80-98

MANUAL TEMPERATURE

CONTROL C1 (MTC).............. 8W-80-98

MANUAL TEMPERATURE

CONTROL C2 (MTC).............. 8W-80-99

MASS AIR FLOW SENSOR (DIESEL) . . . 8W-80-99

MODE DOOR MOTOR/ACTUATOR

(AZC).......................... 8W-80-99

NEEDLE MOVEMENT SENSOR

(DIESEL)....................... 8W-80-99

OUTPUT SPEED SENSOR (4.0L)...... 8W-80-99

OUTPUT SPEED SENSOR (4.7L)..... 8W-80-100

OVERHEAD MAP/COURTESY LAMP . . 8W-80-100

OXYGEN SENSOR 1/1 UPSTREAM.... 8W-80-100

OXYGEN SENSOR 1/2 DOWNSTREAM . 8W-80-100

OXYGEN SENSOR 2/1 UPSTREAM.... 8W-80-100

OXYGEN SENSOR 2/2

DOWNSTREAM................. 8W-80-101

PARK/NEUTRAL POSITION SWITCH

(4.0L).......................... 8W-80-101

PARK/NEUTRAL POSITION SWITCH

(DIESEL)...................... 8W-80-101

PASSENGER AIRBAG.............. 8W-80-101

PASSENGER BLEND DOOR

MOTOR/ACTUATOR (LHD) (AZC) . . . 8W-80-101

PASSENGER BLEND DOOR

MOTOR/ACTUATOR (RHD) (AZC) . . . 8W-80-102

PASSENGER CURTAIN AIRBAG...... 8W-80-102

PASSENGER DOOR LOCK MOTOR/AJAR

SWITCH....................... 8W-80-102

PASSENGER DOOR MODULE C1..... 8W-80-102

PASSENGER DOOR MODULE C2..... 8W-80-103

PASSENGER FRONT DOOR

COURTESY LAMP............... 8W-80-103

PASSENGER FRONT POWER

WINDOW MOTOR............... 8W-80-103

PASSENGER HEATED SEAT BACK

(PREMIUM I/III)................. 8W-80-103

PASSENGER HEATED SEAT CUSHION

(PREMIUM I/III)................. 8W-80-104

PASSENGER HEATED SEAT SWITCH . 8W-80-104

PASSENGER LUMBAR MOTOR

(MIDLINE/PREMIUM)............ 8W-80-104

PASSENGER LUMBAR SWITCH

(MIDLINE/PREMIUM)............ 8W-80-104

PASSENGER POWER MIRROR....... 8W-80-105Component Page

PASSENGER POWER SEAT FRONT

RISER MOTOR.................. 8W-80-105

PASSENGER POWER SEAT

HORIZONTAL MOTOR........... 8W-80-105

PASSENGER POWER SEAT REAR

RISER MOTOR.................. 8W-80-105

PASSENGER POWER SEAT RECLINER

MOTOR (MIDLINE/PREMIUM)..... 8W-80-106

PASSENGER POWER SEAT SWITCH

(MIDLINE/PREMIUM)............ 8W-80-106

PASSENGER REAR POWER

WINDOW MOTOR............... 8W-80-106

PASSENGER REAR POWER

WINDOW SWITCH............... 8W-80-106

PASSENGER SEAT BELT SWITCH.... 8W-80-106

PASSENGER SIDE IMPACT

SENSOR....................... 8W-80-107

POWER AMPLIFIER C1

(PREMIUM RADIO).............. 8W-80-107

POWER AMPLIFIER C2

(PREMIUM RADIO).............. 8W-80-107

POWER CONNECTOR.............. 8W-80-108

POWERTRAIN CONTROL

MODULE C1 (GAS).............. 8W-80-108

POWERTRAIN CONTROL

MODULE C2 (GAS).............. 8W-80-109

POWERTRAIN CONTROL

MODULE C3 (GAS).............. 8W-80-110

RADIATOR FAN MOTOR............ 8W-80-110

RADIATOR FAN RELAY............. 8W-80-111

RADIO C1........................ 8W-80-111

RADIO C2........................ 8W-80-111

RAIN SENSOR (AUTOWIPE)......... 8W-80-112

REAR POWER OUTLET............. 8W-80-112

REAR WASHER PUMP.............. 8W-80-112

REAR WIPER MOTOR.............. 8W-80-112

RECIRCULATION DOOR

MOTOR/ACTUATOR (AZC)......... 8W-80-112

RED BRAKE WARNING INDICATOR

SWITCH....................... 8W-80-113

REMOTE KEYLESS MODULE

(JAPAN)....................... 8W-80-113

RIGHT COURTESY LAMP........... 8W-80-113

RIGHT DOOR HANDLE

COURTESY LAMP............... 8W-80-113

RIGHT FOG LAMP................. 8W-80-113

RIGHT FRONT DOOR SPEAKER..... 8W-80-114

RIGHT FRONT IMPACT SENSOR..... 8W-80-114

RIGHT FRONT PARK LAMP......... 8W-80-114

RIGHT FRONT PARK/TURN SIGNAL LAMP

(EXCEPT BUILT-UP-EXPORT)...... 8W-80-114

RIGHT FRONT SIDE MARKER LAMP

(EXCEPT BUILT-UP-EXPORT)...... 8W-80-115

RIGHT FRONT TURN SIGNAL LAMP

(BUILT-UP-EXPORT)............. 8W-80-115

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTWJ

Page 1123 of 2199

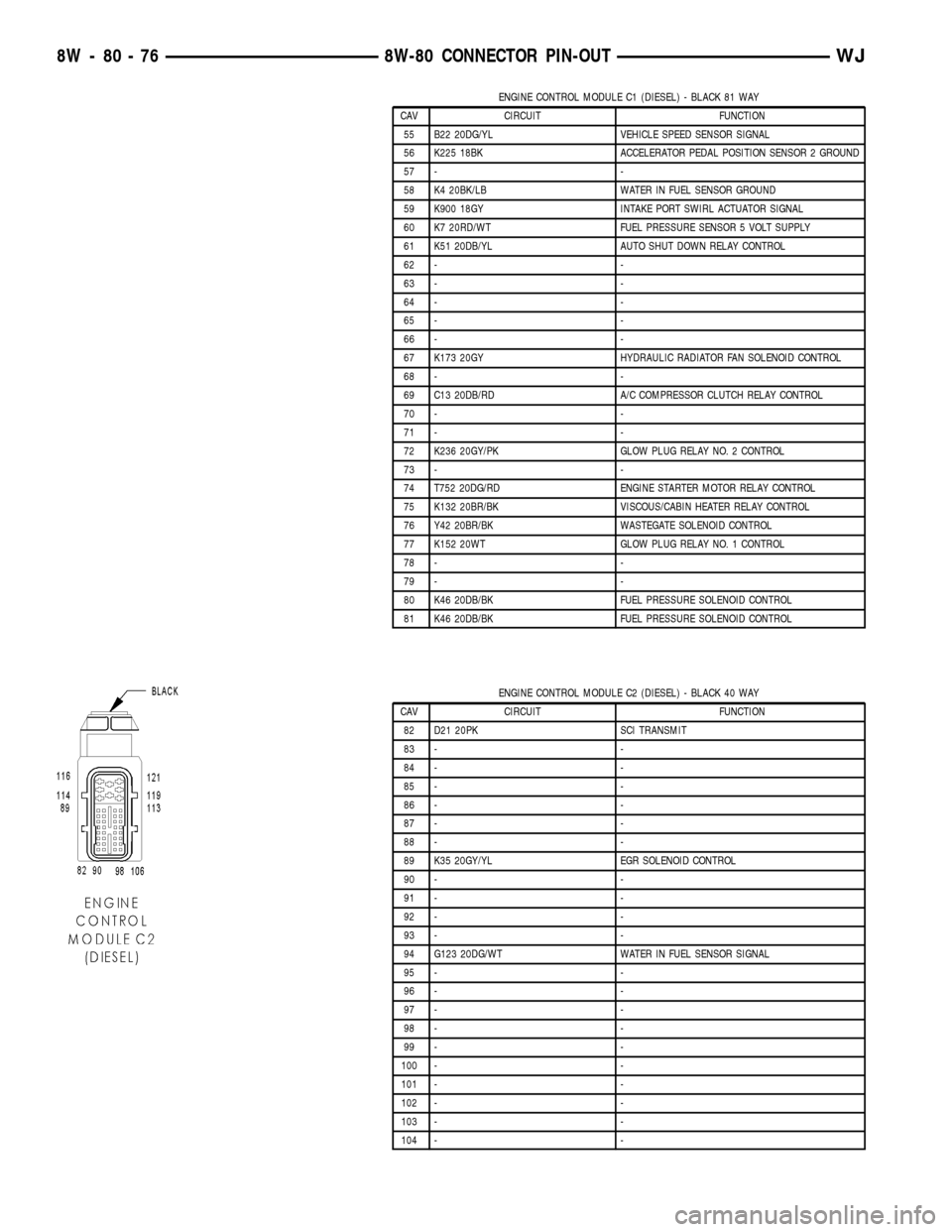

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY

CAV CIRCUIT FUNCTION

55 B22 20DG/YL VEHICLE SPEED SENSOR SIGNAL

56 K225 18BK ACCELERATOR PEDAL POSITION SENSOR 2 GROUND

57 - -

58 K4 20BK/LB WATER IN FUEL SENSOR GROUND

59 K900 18GY INTAKE PORT SWIRL ACTUATOR SIGNAL

60 K7 20RD/WT FUEL PRESSURE SENSOR 5 VOLT SUPPLY

61 K51 20DB/YL AUTO SHUT DOWN RELAY CONTROL

62 - -

63 - -

64 - -

65 - -

66 - -

67 K173 20GY HYDRAULIC RADIATOR FAN SOLENOID CONTROL

68 - -

69 C13 20DB/RD A/C COMPRESSOR CLUTCH RELAY CONTROL

70 - -

71 - -

72 K236 20GY/PK GLOW PLUG RELAY NO. 2 CONTROL

73 - -

74 T752 20DG/RD ENGINE STARTER MOTOR RELAY CONTROL

75 K132 20BR/BK VISCOUS/CABIN HEATER RELAY CONTROL

76 Y42 20BR/BK WASTEGATE SOLENOID CONTROL

77 K152 20WT GLOW PLUG RELAY NO. 1 CONTROL

78 - -

79 - -

80 K46 20DB/BK FUEL PRESSURE SOLENOID CONTROL

81 K46 20DB/BK FUEL PRESSURE SOLENOID CONTROL

ENGINE CONTROL MODULE C2 (DIESEL) - BLACK 40 WAY

CAV CIRCUIT FUNCTION

82 D21 20PK SCI TRANSMIT

83 - -

84 - -

85 - -

86 - -

87 - -

88 - -

89 K35 20GY/YL EGR SOLENOID CONTROL

90 - -

91 - -

92 - -

93 - -

94 G123 20DG/WT WATER IN FUEL SENSOR SIGNAL

95 - -

96 - -

97 - -

98 - -

99 - -

100 - -

101 - -

102 - -

103 - -

104 - -

8W - 80 - 76 8W-80 CONNECTOR PIN-OUTWJ

Page 1131 of 2199

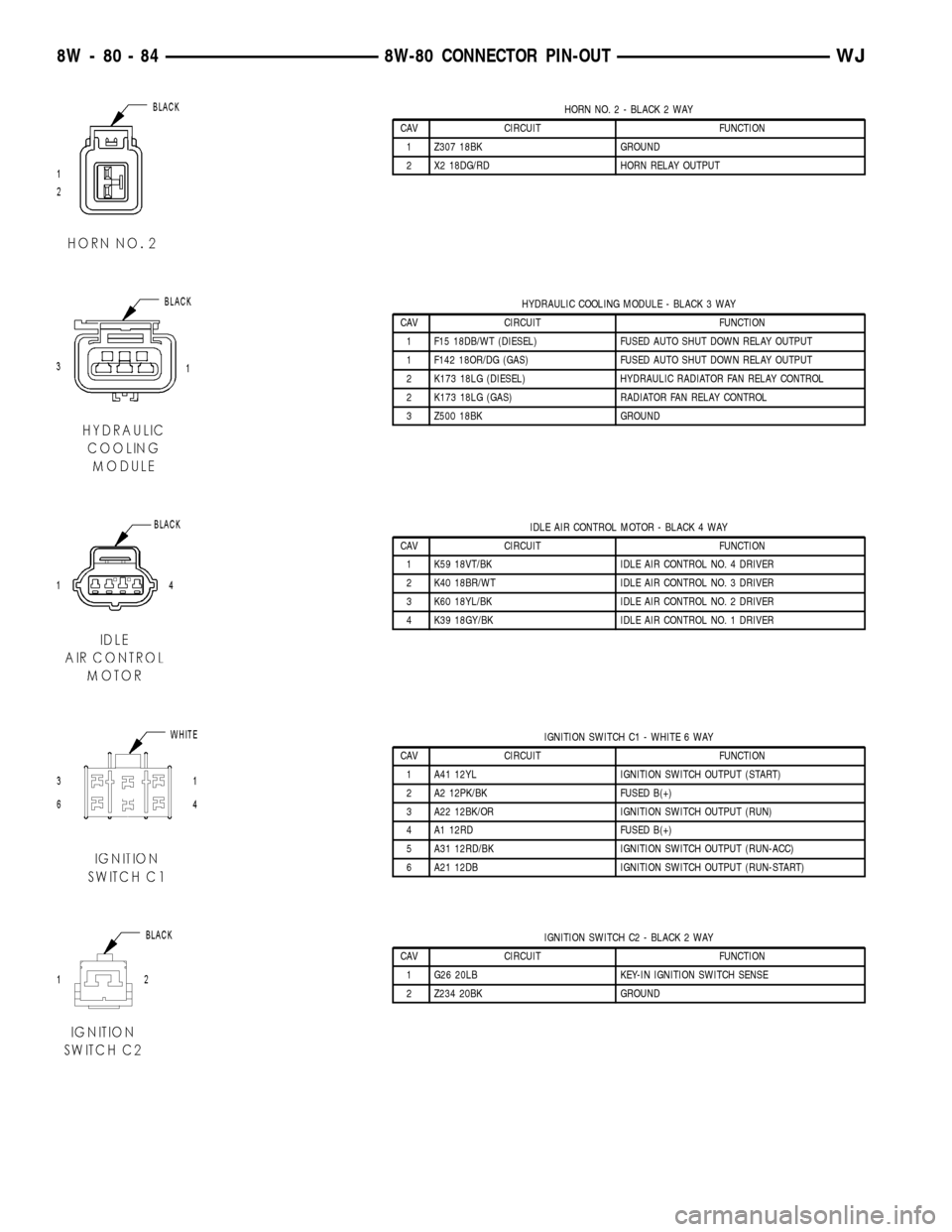

HORN NO. 2 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z307 18BK GROUND

2 X2 18DG/RD HORN RELAY OUTPUT

HYDRAULIC COOLING MODULE - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F15 18DB/WT (DIESEL) FUSED AUTO SHUT DOWN RELAY OUTPUT

1 F142 18OR/DG (GAS) FUSED AUTO SHUT DOWN RELAY OUTPUT

2 K173 18LG (DIESEL) HYDRAULIC RADIATOR FAN RELAY CONTROL

2 K173 18LG (GAS) RADIATOR FAN RELAY CONTROL

3 Z500 18BK GROUND

IDLE AIR CONTROL MOTOR - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 K59 18VT/BK IDLE AIR CONTROL NO. 4 DRIVER

2 K40 18BR/WT IDLE AIR CONTROL NO. 3 DRIVER

3 K60 18YL/BK IDLE AIR CONTROL NO. 2 DRIVER

4 K39 18GY/BK IDLE AIR CONTROL NO. 1 DRIVER

IGNITION SWITCH C1 - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1 A41 12YL IGNITION SWITCH OUTPUT (START)

2 A2 12PK/BK FUSED B(+)

3 A22 12BK/OR IGNITION SWITCH OUTPUT (RUN)

4 A1 12RD FUSED B(+)

5 A31 12RD/BK IGNITION SWITCH OUTPUT (RUN-ACC)

6 A21 12DB IGNITION SWITCH OUTPUT (RUN-START)

IGNITION SWITCH C2 - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 G26 20LB KEY-IN IGNITION SWITCH SENSE

2 Z234 20BK GROUND

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTWJ

Page 1156 of 2199

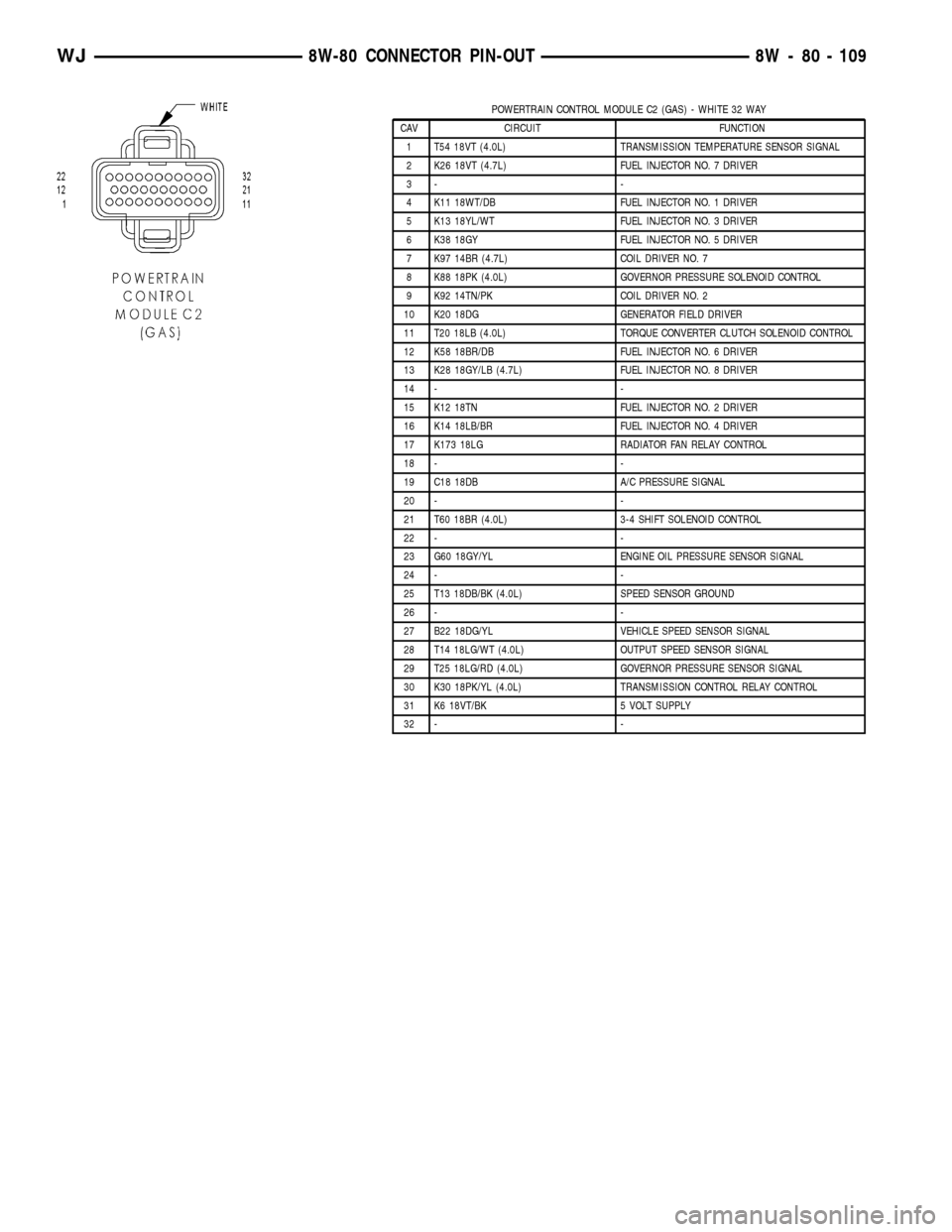

POWERTRAIN CONTROL MODULE C2 (GAS) - WHITE 32 WAY

CAV CIRCUIT FUNCTION

1 T54 18VT (4.0L) TRANSMISSION TEMPERATURE SENSOR SIGNAL

2 K26 18VT (4.7L) FUEL INJECTOR NO. 7 DRIVER

3- -

4 K11 18WT/DB FUEL INJECTOR NO. 1 DRIVER

5 K13 18YL/WT FUEL INJECTOR NO. 3 DRIVER

6 K38 18GY FUEL INJECTOR NO. 5 DRIVER

7 K97 14BR (4.7L) COIL DRIVER NO. 7

8 K88 18PK (4.0L) GOVERNOR PRESSURE SOLENOID CONTROL

9 K92 14TN/PK COIL DRIVER NO. 2

10 K20 18DG GENERATOR FIELD DRIVER

11 T20 18LB (4.0L) TORQUE CONVERTER CLUTCH SOLENOID CONTROL

12 K58 18BR/DB FUEL INJECTOR NO. 6 DRIVER

13 K28 18GY/LB (4.7L) FUEL INJECTOR NO. 8 DRIVER

14 - -

15 K12 18TN FUEL INJECTOR NO. 2 DRIVER

16 K14 18LB/BR FUEL INJECTOR NO. 4 DRIVER

17 K173 18LG RADIATOR FAN RELAY CONTROL

18 - -

19 C18 18DB A/C PRESSURE SIGNAL

20 - -

21 T60 18BR (4.0L) 3-4 SHIFT SOLENOID CONTROL

22 - -

23 G60 18GY/YL ENGINE OIL PRESSURE SENSOR SIGNAL

24 - -

25 T13 18DB/BK (4.0L) SPEED SENSOR GROUND

26 - -

27 B22 18DG/YL VEHICLE SPEED SENSOR SIGNAL

28 T14 18LG/WT (4.0L) OUTPUT SPEED SENSOR SIGNAL

29 T25 18LG/RD (4.0L) GOVERNOR PRESSURE SENSOR SIGNAL

30 K30 18PK/YL (4.0L) TRANSMISSION CONTROL RELAY CONTROL

31 K6 18VT/BK 5 VOLT SUPPLY

32 - -

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 109

Page 1157 of 2199

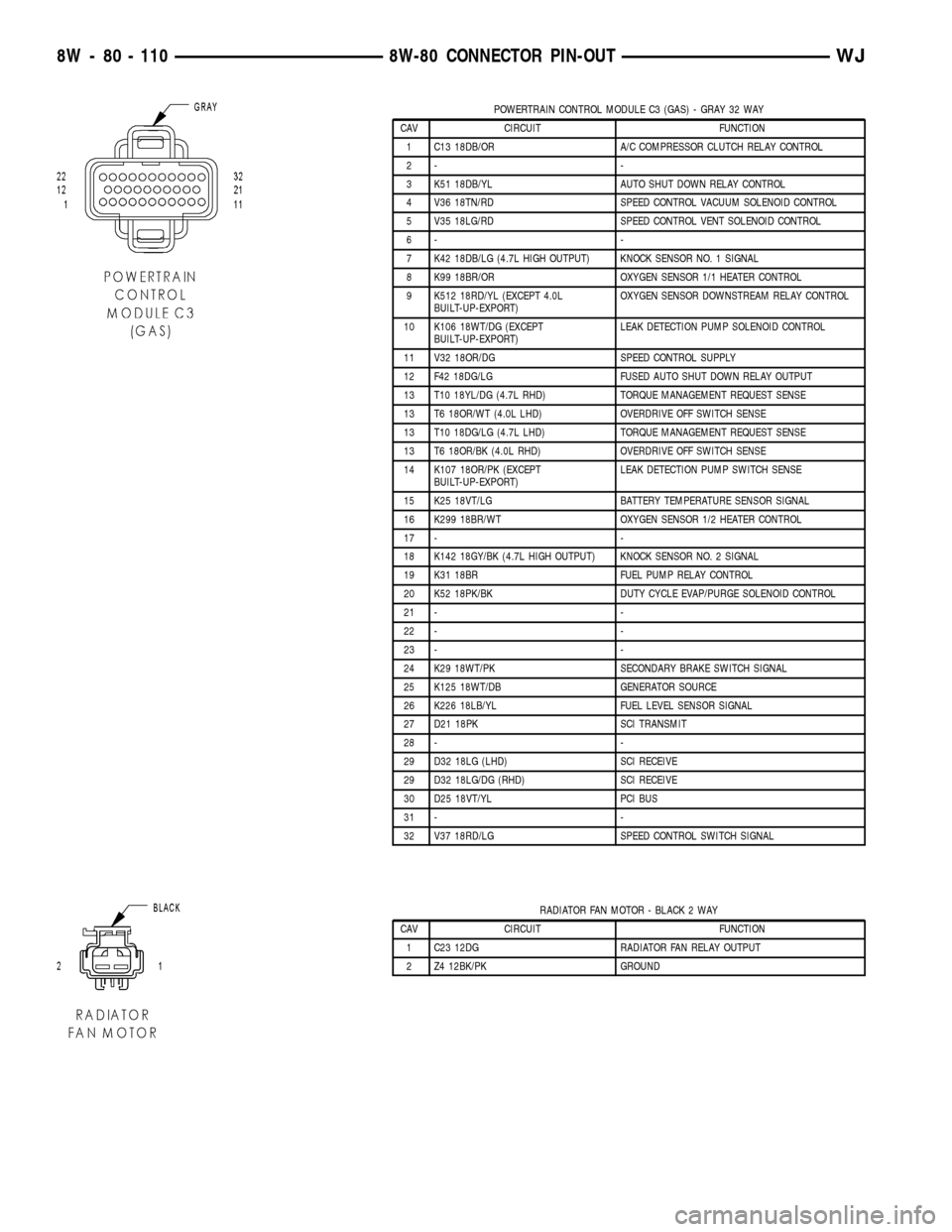

POWERTRAIN CONTROL MODULE C3 (GAS) - GRAY 32 WAY

CAV CIRCUIT FUNCTION

1 C13 18DB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

2- -

3 K51 18DB/YL AUTO SHUT DOWN RELAY CONTROL

4 V36 18TN/RD SPEED CONTROL VACUUM SOLENOID CONTROL

5 V35 18LG/RD SPEED CONTROL VENT SOLENOID CONTROL

6- -

7 K42 18DB/LG (4.7L HIGH OUTPUT) KNOCK SENSOR NO. 1 SIGNAL

8 K99 18BR/OR OXYGEN SENSOR 1/1 HEATER CONTROL

9 K512 18RD/YL (EXCEPT 4.0L

BUILT-UP-EXPORT)OXYGEN SENSOR DOWNSTREAM RELAY CONTROL

10 K106 18WT/DG (EXCEPT

BUILT-UP-EXPORT)LEAK DETECTION PUMP SOLENOID CONTROL

11 V32 18OR/DG SPEED CONTROL SUPPLY

12 F42 18DG/LG FUSED AUTO SHUT DOWN RELAY OUTPUT

13 T10 18YL/DG (4.7L RHD) TORQUE MANAGEMENT REQUEST SENSE

13 T6 18OR/WT (4.0L LHD) OVERDRIVE OFF SWITCH SENSE

13 T10 18DG/LG (4.7L LHD) TORQUE MANAGEMENT REQUEST SENSE

13 T6 18OR/BK (4.0L RHD) OVERDRIVE OFF SWITCH SENSE

14 K107 18OR/PK (EXCEPT

BUILT-UP-EXPORT)LEAK DETECTION PUMP SWITCH SENSE

15 K25 18VT/LG BATTERY TEMPERATURE SENSOR SIGNAL

16 K299 18BR/WT OXYGEN SENSOR 1/2 HEATER CONTROL

17 - -

18 K142 18GY/BK (4.7L HIGH OUTPUT) KNOCK SENSOR NO. 2 SIGNAL

19 K31 18BR FUEL PUMP RELAY CONTROL

20 K52 18PK/BK DUTY CYCLE EVAP/PURGE SOLENOID CONTROL

21 - -

22 - -

23 - -

24 K29 18WT/PK SECONDARY BRAKE SWITCH SIGNAL

25 K125 18WT/DB GENERATOR SOURCE

26 K226 18LB/YL FUEL LEVEL SENSOR SIGNAL

27 D21 18PK SCI TRANSMIT

28 - -

29 D32 18LG (LHD) SCI RECEIVE

29 D32 18LG/DG (RHD) SCI RECEIVE

30 D25 18VT/YL PCI BUS

31 - -

32 V37 18RD/LG SPEED CONTROL SWITCH SIGNAL

RADIATOR FAN MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 C23 12DG RADIATOR FAN RELAY OUTPUT

2 Z4 12BK/PK GROUND

8W - 80 - 110 8W-80 CONNECTOR PIN-OUTWJ

Page 1158 of 2199

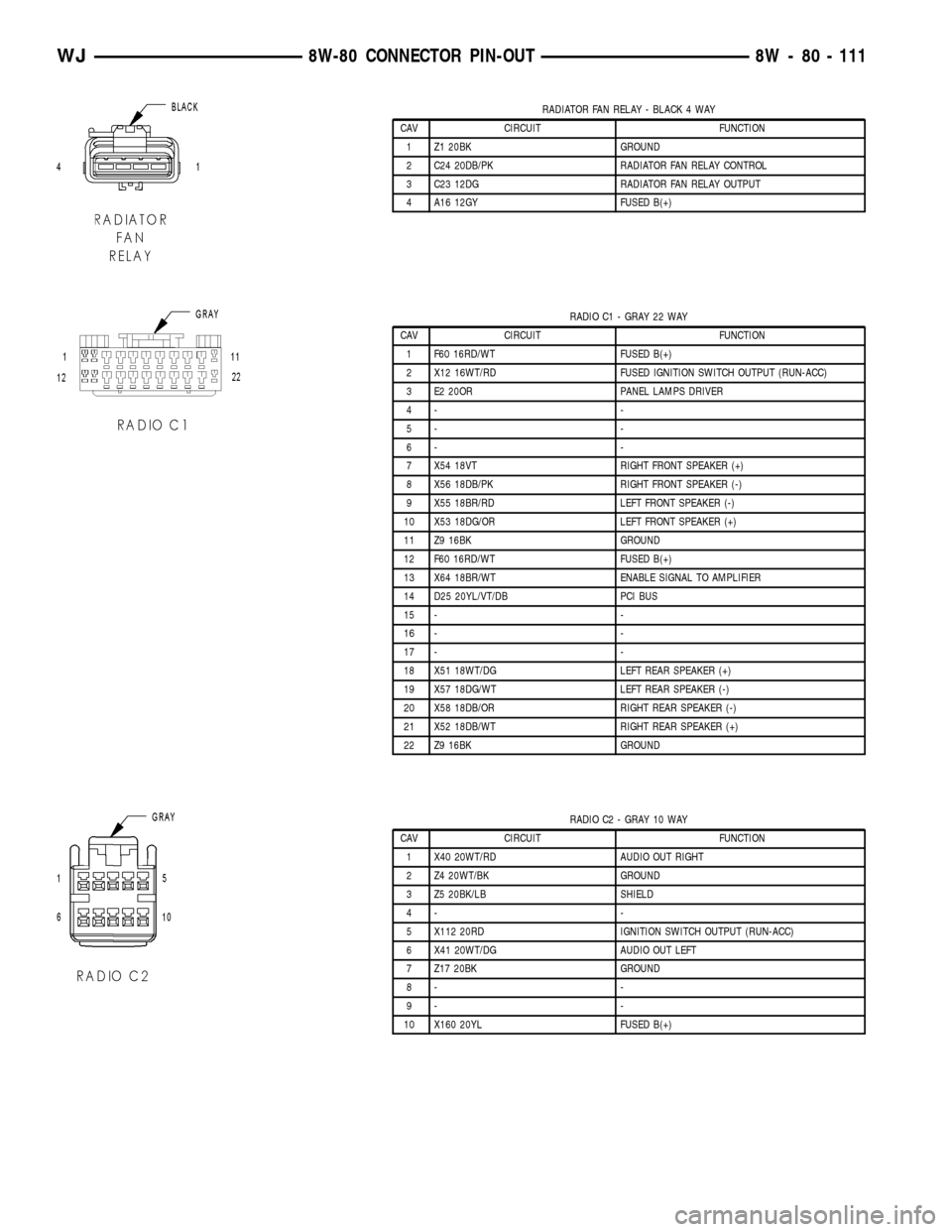

RADIATOR FAN RELAY - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 Z1 20BK GROUND

2 C24 20DB/PK RADIATOR FAN RELAY CONTROL

3 C23 12DG RADIATOR FAN RELAY OUTPUT

4 A16 12GY FUSED B(+)

RADIO C1 - GRAY 22 WAY

CAV CIRCUIT FUNCTION

1 F60 16RD/WT FUSED B(+)

2 X12 16WT/RD FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

3 E2 20OR PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X54 18VT RIGHT FRONT SPEAKER (+)

8 X56 18DB/PK RIGHT FRONT SPEAKER (-)

9 X55 18BR/RD LEFT FRONT SPEAKER (-)

10 X53 18DG/OR LEFT FRONT SPEAKER (+)

11 Z9 16BK GROUND

12 F60 16RD/WT FUSED B(+)

13 X64 18BR/WT ENABLE SIGNAL TO AMPLIFIER

14 D25 20YL/VT/DB PCI BUS

15 - -

16 - -

17 - -

18 X51 18WT/DG LEFT REAR SPEAKER (+)

19 X57 18DG/WT LEFT REAR SPEAKER (-)

20 X58 18DB/OR RIGHT REAR SPEAKER (-)

21 X52 18DB/WT RIGHT REAR SPEAKER (+)

22 Z9 16BK GROUND

RADIO C2 - GRAY 10 WAY

CAV CIRCUIT FUNCTION

1 X40 20WT/RD AUDIO OUT RIGHT

2 Z4 20WT/BK GROUND

3 Z5 20BK/LB SHIELD

4- -

5 X112 20RD IGNITION SWITCH OUTPUT (RUN-ACC)

6 X41 20WT/DG AUDIO OUT LEFT

7 Z17 20BK GROUND

8- -

9- -

10 X160 20YL FUSED B(+)

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 111