Heated seat JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1116 of 2199

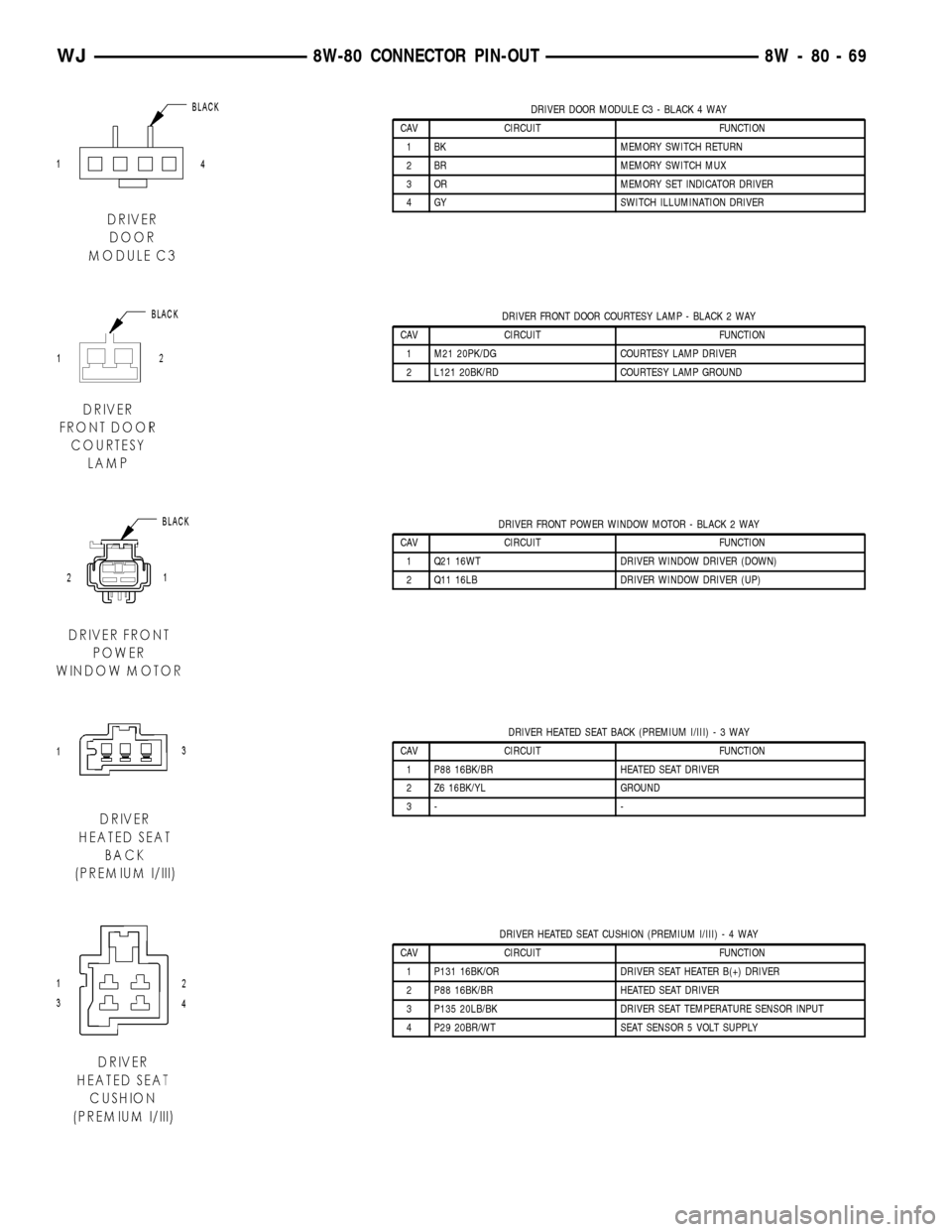

DRIVER DOOR MODULE C3 - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 BK MEMORY SWITCH RETURN

2 BR MEMORY SWITCH MUX

3 OR MEMORY SET INDICATOR DRIVER

4 GY SWITCH ILLUMINATION DRIVER

DRIVER FRONT DOOR COURTESY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 M21 20PK/DG COURTESY LAMP DRIVER

2 L121 20BK/RD COURTESY LAMP GROUND

DRIVER FRONT POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q21 16WT DRIVER WINDOW DRIVER (DOWN)

2 Q11 16LB DRIVER WINDOW DRIVER (UP)

DRIVER HEATED SEAT BACK (PREMIUM I/III)-3WAY

CAV CIRCUIT FUNCTION

1 P88 16BK/BR HEATED SEAT DRIVER

2 Z6 16BK/YL GROUND

3- -

DRIVER HEATED SEAT CUSHION (PREMIUM I/III)-4WAY

CAV CIRCUIT FUNCTION

1 P131 16BK/OR DRIVER SEAT HEATER B(+) DRIVER

2 P88 16BK/BR HEATED SEAT DRIVER

3 P135 20LB/BK DRIVER SEAT TEMPERATURE SENSOR INPUT

4 P29 20BR/WT SEAT SENSOR 5 VOLT SUPPLY

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 69

Page 1117 of 2199

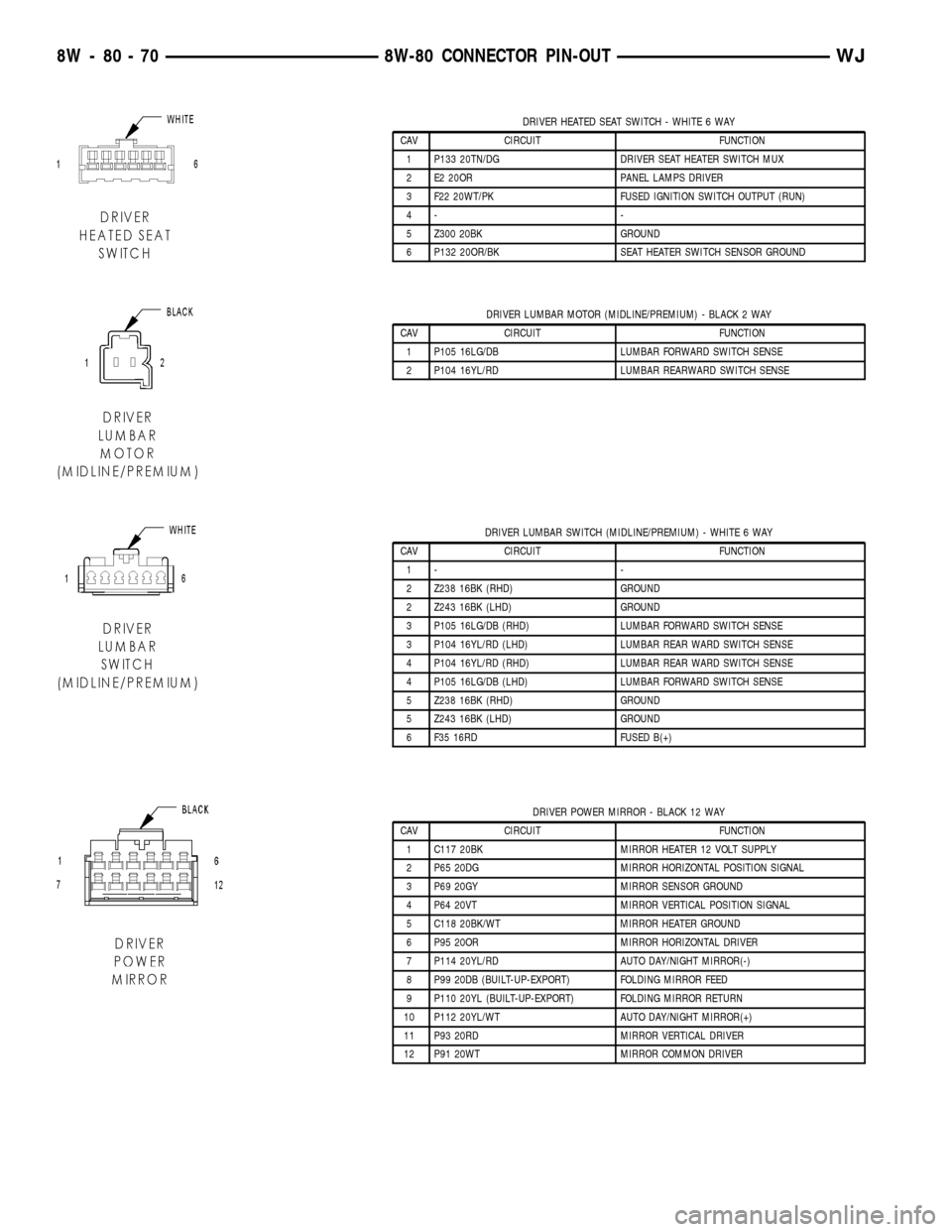

DRIVER HEATED SEAT SWITCH - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1 P133 20TN/DG DRIVER SEAT HEATER SWITCH MUX

2 E2 20OR PANEL LAMPS DRIVER

3 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

4- -

5 Z300 20BK GROUND

6 P132 20OR/BK SEAT HEATER SWITCH SENSOR GROUND

DRIVER LUMBAR MOTOR (MIDLINE/PREMIUM) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 P105 16LG/DB LUMBAR FORWARD SWITCH SENSE

2 P104 16YL/RD LUMBAR REARWARD SWITCH SENSE

DRIVER LUMBAR SWITCH (MIDLINE/PREMIUM) - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z238 16BK (RHD) GROUND

2 Z243 16BK (LHD) GROUND

3 P105 16LG/DB (RHD) LUMBAR FORWARD SWITCH SENSE

3 P104 16YL/RD (LHD) LUMBAR REAR WARD SWITCH SENSE

4 P104 16YL/RD (RHD) LUMBAR REAR WARD SWITCH SENSE

4 P105 16LG/DB (LHD) LUMBAR FORWARD SWITCH SENSE

5 Z238 16BK (RHD) GROUND

5 Z243 16BK (LHD) GROUND

6 F35 16RD FUSED B(+)

DRIVER POWER MIRROR - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 C117 20BK MIRROR HEATER 12 VOLT SUPPLY

2 P65 20DG MIRROR HORIZONTAL POSITION SIGNAL

3 P69 20GY MIRROR SENSOR GROUND

4 P64 20VT MIRROR VERTICAL POSITION SIGNAL

5 C118 20BK/WT MIRROR HEATER GROUND

6 P95 20OR MIRROR HORIZONTAL DRIVER

7 P114 20YL/RD AUTO DAY/NIGHT MIRROR(-)

8 P99 20DB (BUILT-UP-EXPORT) FOLDING MIRROR FEED

9 P110 20YL (BUILT-UP-EXPORT) FOLDING MIRROR RETURN

10 P112 20YL/WT AUTO DAY/NIGHT MIRROR(+)

11 P93 20RD MIRROR VERTICAL DRIVER

12 P91 20WT MIRROR COMMON DRIVER

8W - 80 - 70 8W-80 CONNECTOR PIN-OUTWJ

Page 1150 of 2199

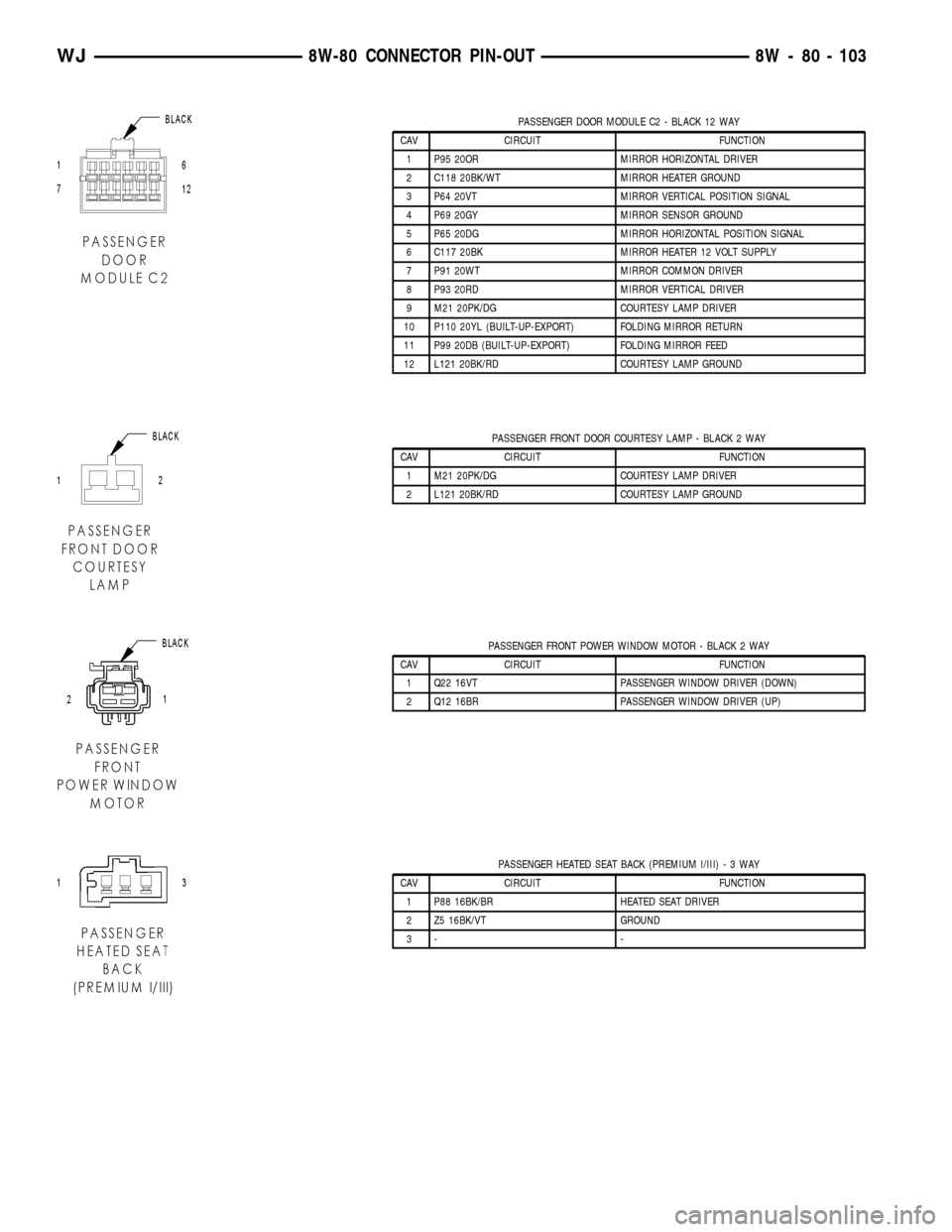

PASSENGER DOOR MODULE C2 - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 P95 20OR MIRROR HORIZONTAL DRIVER

2 C118 20BK/WT MIRROR HEATER GROUND

3 P64 20VT MIRROR VERTICAL POSITION SIGNAL

4 P69 20GY MIRROR SENSOR GROUND

5 P65 20DG MIRROR HORIZONTAL POSITION SIGNAL

6 C117 20BK MIRROR HEATER 12 VOLT SUPPLY

7 P91 20WT MIRROR COMMON DRIVER

8 P93 20RD MIRROR VERTICAL DRIVER

9 M21 20PK/DG COURTESY LAMP DRIVER

10 P110 20YL (BUILT-UP-EXPORT) FOLDING MIRROR RETURN

11 P99 20DB (BUILT-UP-EXPORT) FOLDING MIRROR FEED

12 L121 20BK/RD COURTESY LAMP GROUND

PASSENGER FRONT DOOR COURTESY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 M21 20PK/DG COURTESY LAMP DRIVER

2 L121 20BK/RD COURTESY LAMP GROUND

PASSENGER FRONT POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q22 16VT PASSENGER WINDOW DRIVER (DOWN)

2 Q12 16BR PASSENGER WINDOW DRIVER (UP)

PASSENGER HEATED SEAT BACK (PREMIUM I/III)-3WAY

CAV CIRCUIT FUNCTION

1 P88 16BK/BR HEATED SEAT DRIVER

2 Z5 16BK/VT GROUND

3- -

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 103

Page 1151 of 2199

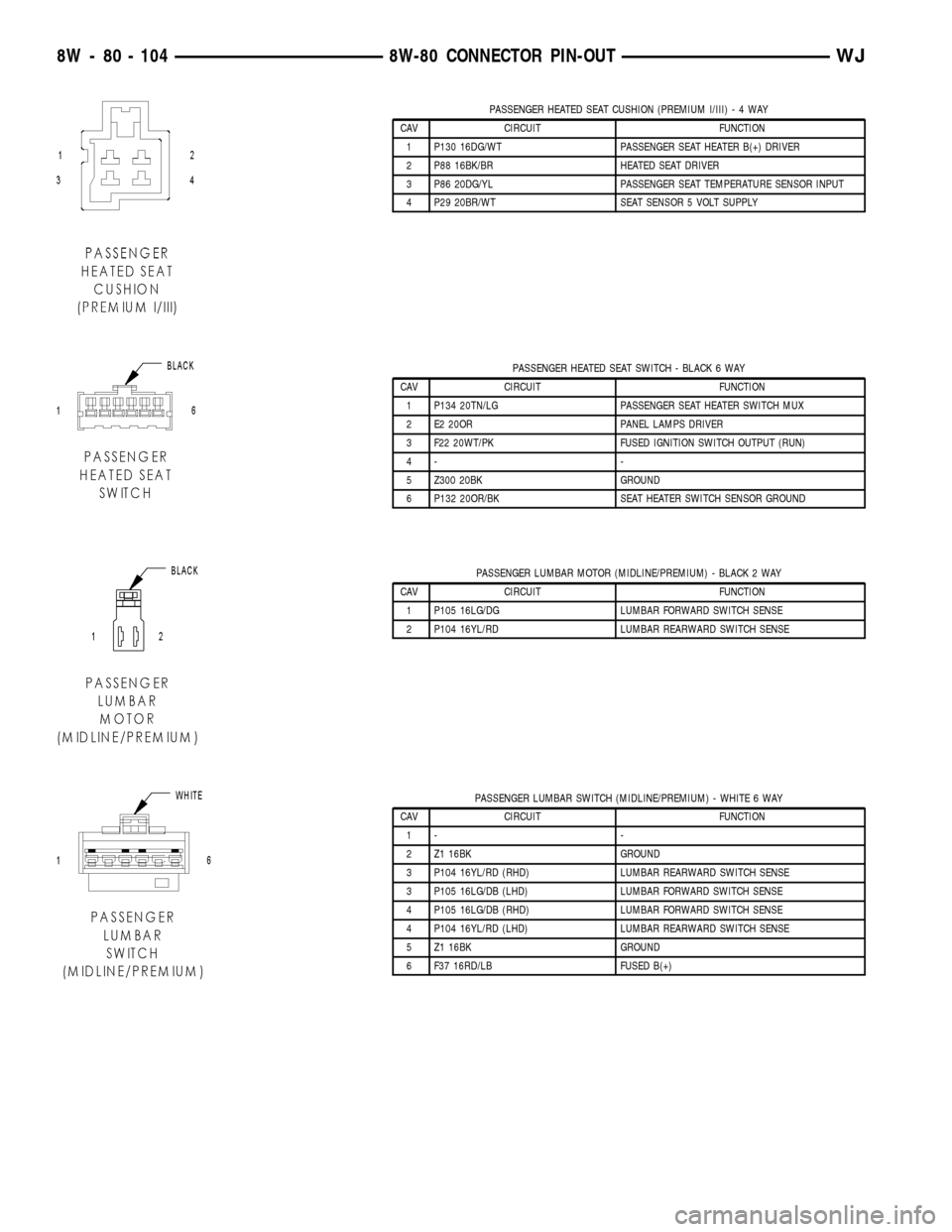

PASSENGER HEATED SEAT CUSHION (PREMIUM I/III)-4WAY

CAV CIRCUIT FUNCTION

1 P130 16DG/WT PASSENGER SEAT HEATER B(+) DRIVER

2 P88 16BK/BR HEATED SEAT DRIVER

3 P86 20DG/YL PASSENGER SEAT TEMPERATURE SENSOR INPUT

4 P29 20BR/WT SEAT SENSOR 5 VOLT SUPPLY

PASSENGER HEATED SEAT SWITCH - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 P134 20TN/LG PASSENGER SEAT HEATER SWITCH MUX

2 E2 20OR PANEL LAMPS DRIVER

3 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

4- -

5 Z300 20BK GROUND

6 P132 20OR/BK SEAT HEATER SWITCH SENSOR GROUND

PASSENGER LUMBAR MOTOR (MIDLINE/PREMIUM) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 P105 16LG/DG LUMBAR FORWARD SWITCH SENSE

2 P104 16YL/RD LUMBAR REARWARD SWITCH SENSE

PASSENGER LUMBAR SWITCH (MIDLINE/PREMIUM) - WHITE 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z1 16BK GROUND

3 P104 16YL/RD (RHD) LUMBAR REARWARD SWITCH SENSE

3 P105 16LG/DB (LHD) LUMBAR FORWARD SWITCH SENSE

4 P105 16LG/DB (RHD) LUMBAR FORWARD SWITCH SENSE

4 P104 16YL/RD (LHD) LUMBAR REARWARD SWITCH SENSE

5 Z1 16BK GROUND

6 F37 16RD/LB FUSED B(+)

8W - 80 - 104 8W-80 CONNECTOR PIN-OUTWJ

Page 1179 of 2199

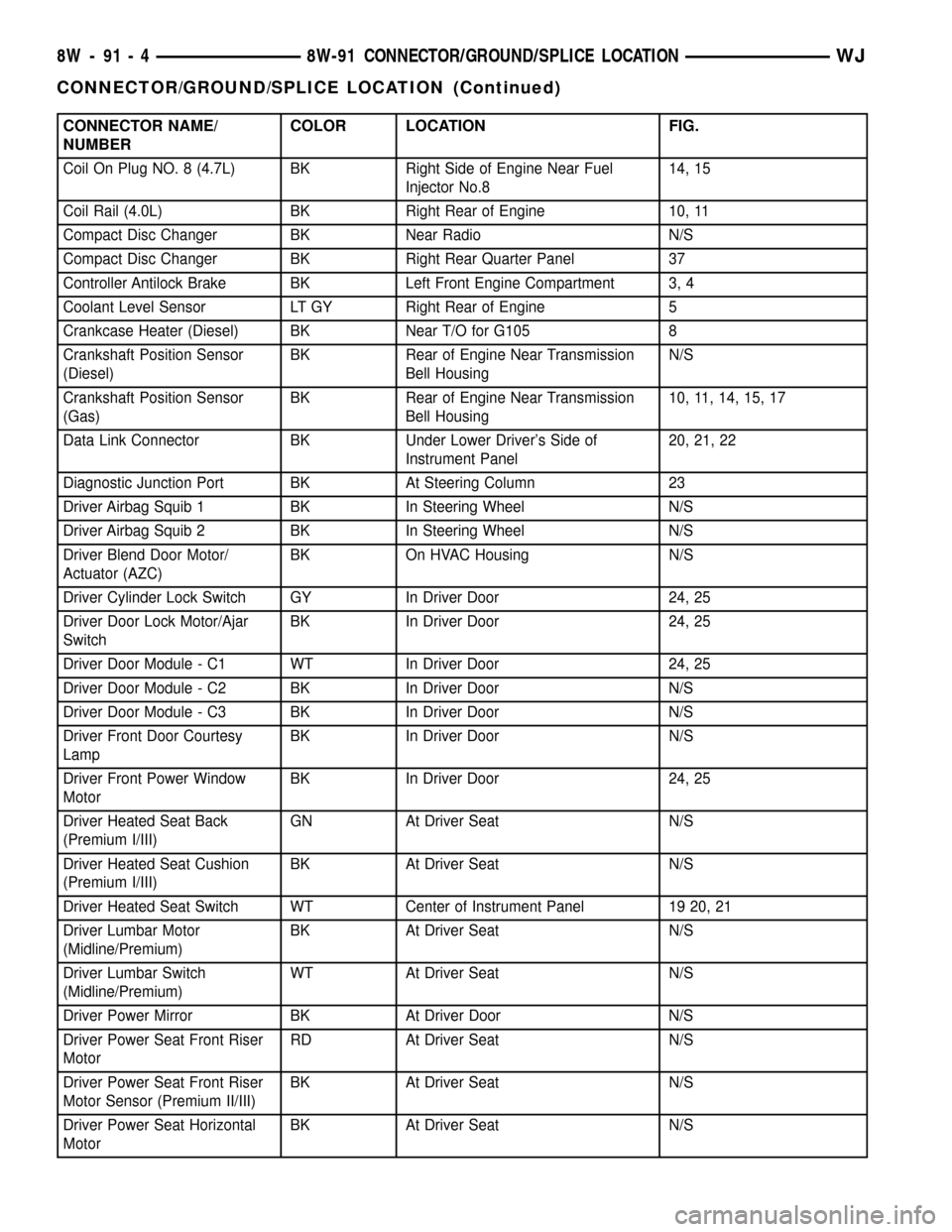

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1183 of 2199

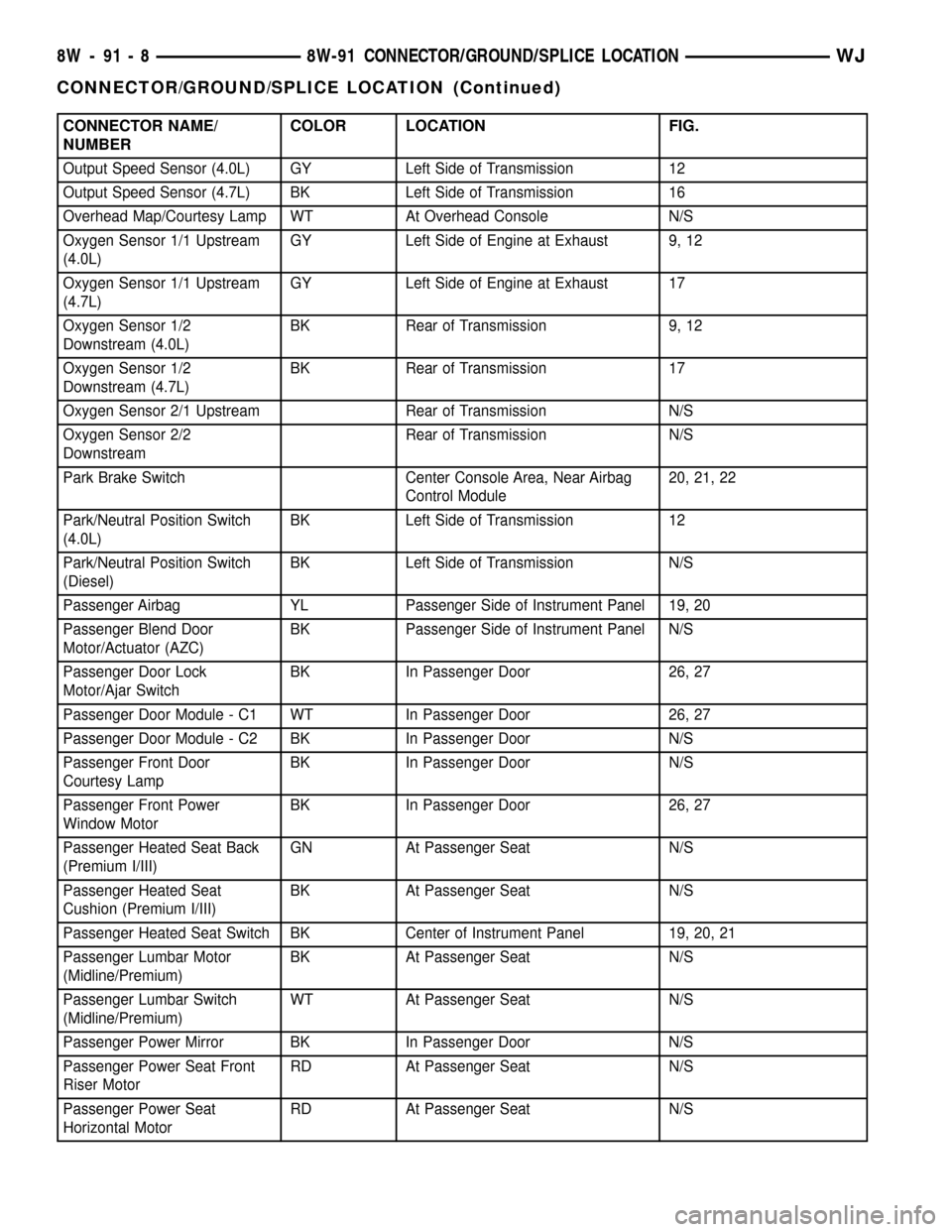

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Output Speed Sensor (4.0L) GY Left Side of Transmission 12

Output Speed Sensor (4.7L) BK Left Side of Transmission 16

Overhead Map/Courtesy Lamp WT At Overhead Console N/S

Oxygen Sensor 1/1 Upstream

(4.0L)GY Left Side of Engine at Exhaust 9, 12

Oxygen Sensor 1/1 Upstream

(4.7L)GY Left Side of Engine at Exhaust 17

Oxygen Sensor 1/2

Downstream (4.0L)BK Rear of Transmission 9, 12

Oxygen Sensor 1/2

Downstream (4.7L)BK Rear of Transmission 17

Oxygen Sensor 2/1 Upstream Rear of Transmission N/S

Oxygen Sensor 2/2

DownstreamRear of Transmission N/S

Park Brake Switch Center Console Area, Near Airbag

Control Module20, 21, 22

Park/Neutral Position Switch

(4.0L)BK Left Side of Transmission 12

Park/Neutral Position Switch

(Diesel)BK Left Side of Transmission N/S

Passenger Airbag YL Passenger Side of Instrument Panel 19, 20

Passenger Blend Door

Motor/Actuator (AZC)BK Passenger Side of Instrument Panel N/S

Passenger Door Lock

Motor/Ajar SwitchBK In Passenger Door 26, 27

Passenger Door Module - C1 WT In Passenger Door 26, 27

Passenger Door Module - C2 BK In Passenger Door N/S

Passenger Front Door

Courtesy LampBK In Passenger Door N/S

Passenger Front Power

Window MotorBK In Passenger Door 26, 27

Passenger Heated Seat Back

(Premium I/III)GN At Passenger Seat N/S

Passenger Heated Seat

Cushion (Premium I/III)BK At Passenger Seat N/S

Passenger Heated Seat Switch BK Center of Instrument Panel 19, 20, 21

Passenger Lumbar Motor

(Midline/Premium)BK At Passenger Seat N/S

Passenger Lumbar Switch

(Midline/Premium)WT At Passenger Seat N/S

Passenger Power Mirror BK In Passenger Door N/S

Passenger Power Seat Front

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Horizontal MotorRD At Passenger Seat N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1189 of 2199

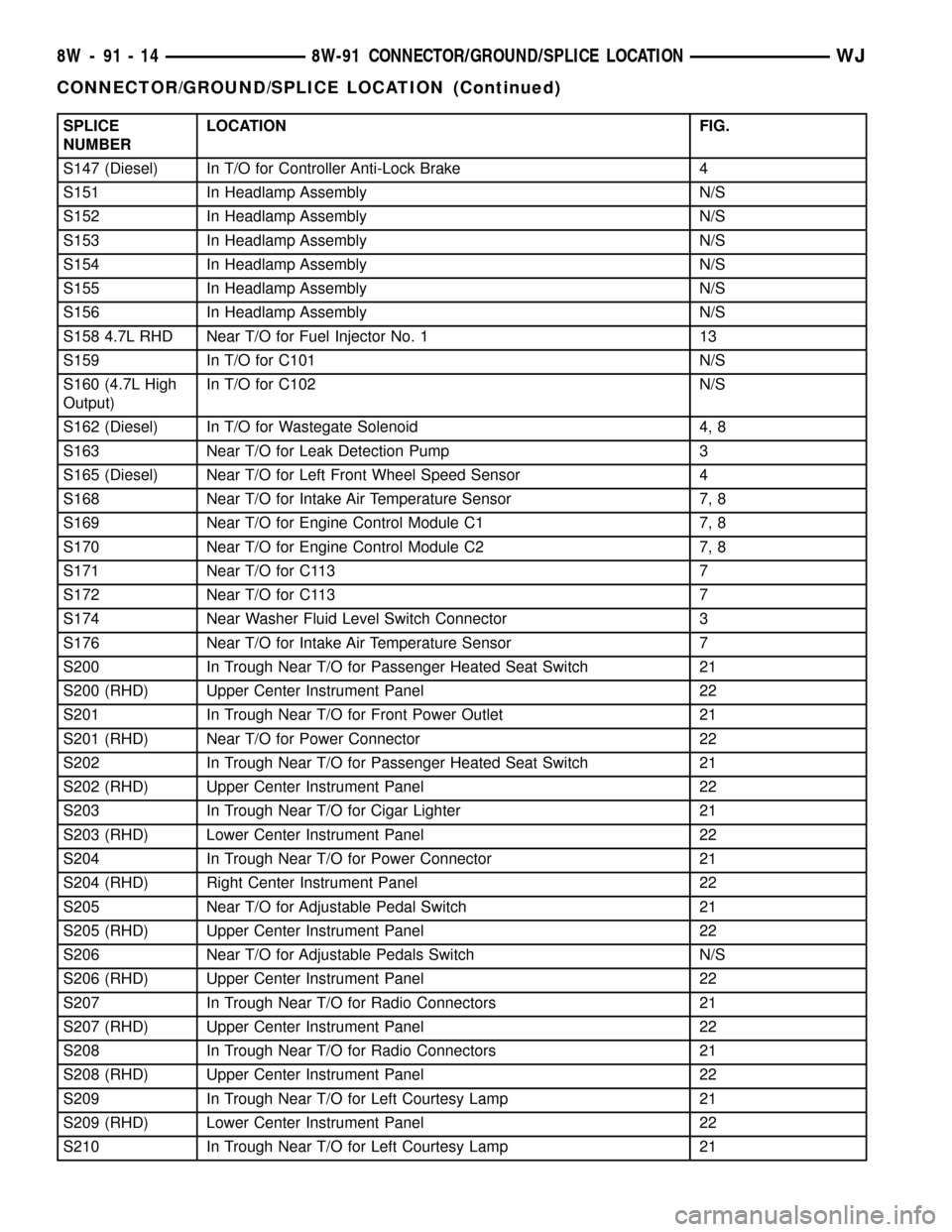

SPLICE

NUMBERLOCATION FIG.

S147 (Diesel) In T/O for Controller Anti-Lock Brake 4

S151 In Headlamp Assembly N/S

S152 In Headlamp Assembly N/S

S153 In Headlamp Assembly N/S

S154 In Headlamp Assembly N/S

S155 In Headlamp Assembly N/S

S156 In Headlamp Assembly N/S

S158 4.7L RHD Near T/O for Fuel Injector No. 1 13

S159 In T/O for C101 N/S

S160 (4.7L High

Output)In T/O for C102 N/S

S162 (Diesel) In T/O for Wastegate Solenoid 4, 8

S163 Near T/O for Leak Detection Pump 3

S165 (Diesel) Near T/O for Left Front Wheel Speed Sensor 4

S168 Near T/O for Intake Air Temperature Sensor 7, 8

S169 Near T/O for Engine Control Module C1 7, 8

S170 Near T/O for Engine Control Module C2 7, 8

S171 Near T/O for C113 7

S172 Near T/O for C113 7

S174 Near Washer Fluid Level Switch Connector 3

S176 Near T/O for Intake Air Temperature Sensor 7

S200 In Trough Near T/O for Passenger Heated Seat Switch 21

S200 (RHD) Upper Center Instrument Panel 22

S201 In Trough Near T/O for Front Power Outlet 21

S201 (RHD) Near T/O for Power Connector 22

S202 In Trough Near T/O for Passenger Heated Seat Switch 21

S202 (RHD) Upper Center Instrument Panel 22

S203 In Trough Near T/O for Cigar Lighter 21

S203 (RHD) Lower Center Instrument Panel 22

S204 In Trough Near T/O for Power Connector 21

S204 (RHD) Right Center Instrument Panel 22

S205 Near T/O for Adjustable Pedal Switch 21

S205 (RHD) Upper Center Instrument Panel 22

S206 Near T/O for Adjustable Pedals Switch N/S

S206 (RHD) Upper Center Instrument Panel 22

S207 In Trough Near T/O for Radio Connectors 21

S207 (RHD) Upper Center Instrument Panel 22

S208 In Trough Near T/O for Radio Connectors 21

S208 (RHD) Upper Center Instrument Panel 22

S209 In Trough Near T/O for Left Courtesy Lamp 21

S209 (RHD) Lower Center Instrument Panel 22

S210 In Trough Near T/O for Left Courtesy Lamp 21

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1930 of 2199

INSTRUMENT PANEL CENTER

BEZEL - LOWER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

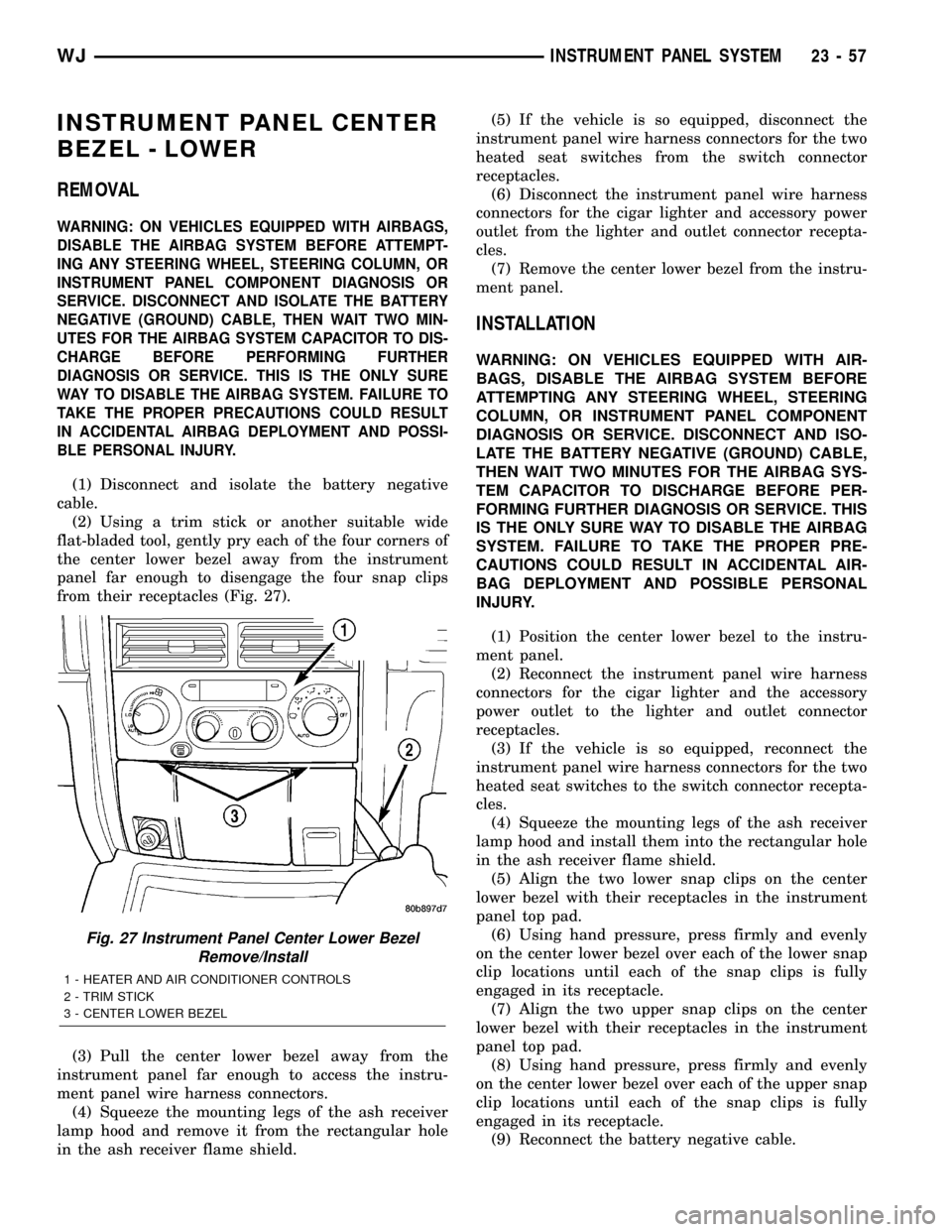

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each of the four corners of

the center lower bezel away from the instrument

panel far enough to disengage the four snap clips

from their receptacles (Fig. 27).

(3) Pull the center lower bezel away from the

instrument panel far enough to access the instru-

ment panel wire harness connectors.

(4) Squeeze the mounting legs of the ash receiver

lamp hood and remove it from the rectangular hole

in the ash receiver flame shield.(5) If the vehicle is so equipped, disconnect the

instrument panel wire harness connectors for the two

heated seat switches from the switch connector

receptacles.

(6) Disconnect the instrument panel wire harness

connectors for the cigar lighter and accessory power

outlet from the lighter and outlet connector recepta-

cles.

(7) Remove the center lower bezel from the instru-

ment panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the center lower bezel to the instru-

ment panel.

(2) Reconnect the instrument panel wire harness

connectors for the cigar lighter and the accessory

power outlet to the lighter and outlet connector

receptacles.

(3) If the vehicle is so equipped, reconnect the

instrument panel wire harness connectors for the two

heated seat switches to the switch connector recepta-

cles.

(4) Squeeze the mounting legs of the ash receiver

lamp hood and install them into the rectangular hole

in the ash receiver flame shield.

(5) Align the two lower snap clips on the center

lower bezel with their receptacles in the instrument

panel top pad.

(6) Using hand pressure, press firmly and evenly

on the center lower bezel over each of the lower snap

clip locations until each of the snap clips is fully

engaged in its receptacle.

(7) Align the two upper snap clips on the center

lower bezel with their receptacles in the instrument

panel top pad.

(8) Using hand pressure, press firmly and evenly

on the center lower bezel over each of the upper snap

clip locations until each of the snap clips is fully

engaged in its receptacle.

(9) Reconnect the battery negative cable.

Fig. 27 Instrument Panel Center Lower Bezel

Remove/Install

1 - HEATER AND AIR CONDITIONER CONTROLS

2 - TRIM STICK

3 - CENTER LOWER BEZEL

WJINSTRUMENT PANEL SYSTEM 23 - 57

Page 1958 of 2199

INSTALLATION

(1) Position seat on floor pan.

(2) If equipped, connect power seat wire harness

connector.

(3) Install rear bolts attaching seat to floor pan.

Tighten bolts to 40 N´m (30 ft. lbs.) torque.

(4) If equipped, install cover on seat track.

(5) Move seat to full rearward position.

(6) Install front bolts attaching seat to floor pan.

Tighten bolts to 40 N´m (30 ft. lbs.) torque.

FRONT SEAT BACK

REMOVAL

(1) Move seat to full rearward position.

(2) Remove inboard bolt attaching seat back frame

to seat cushion frame.

(3) Move seat to full forward position.

(4) Move seat back to full recline position.

(5) Remove screws attaching seat side shield to

seat frame.

(6) Disconnect wire harness connector from

recliner motor, if equipped.

(7) From the underside of the seat, disconnect the

wire harness connector for the power lumber and/or

heated seat, if equipped.

(8) Remove outboard bolts attaching recliner to

seat cushion frame.

(9) Route the power lumber and/or heated seat

harness through the seat cushion cover, if equipped.

(10) Separate seat back from seat cushion.

INSTALLATION

(1) Position seat back on seat cushion.

(2) Route the power lumber and heater harness

through the seat cushion cover, if equipped.

(3) Install recliner bolts attaching seat back frame

to seat cushion frame. Tighten bolts to 28 N´m (20 ft.

lbs.) torque.

(4) Install the inboard bolt attaching seat back

frame to seat cushion frame. Tighten bolt to 47N´m

(35 ft.lbs.).

(5) Connect wire harness connector to recliner

motor and/or heated seat, if equipped.

(6) From the underside of the seat, connect the

power lumber and/or heated seat wire harness con-

nector to the seat harness, if equipped.

(7) Install screws attaching seat side shield to seat

frame.

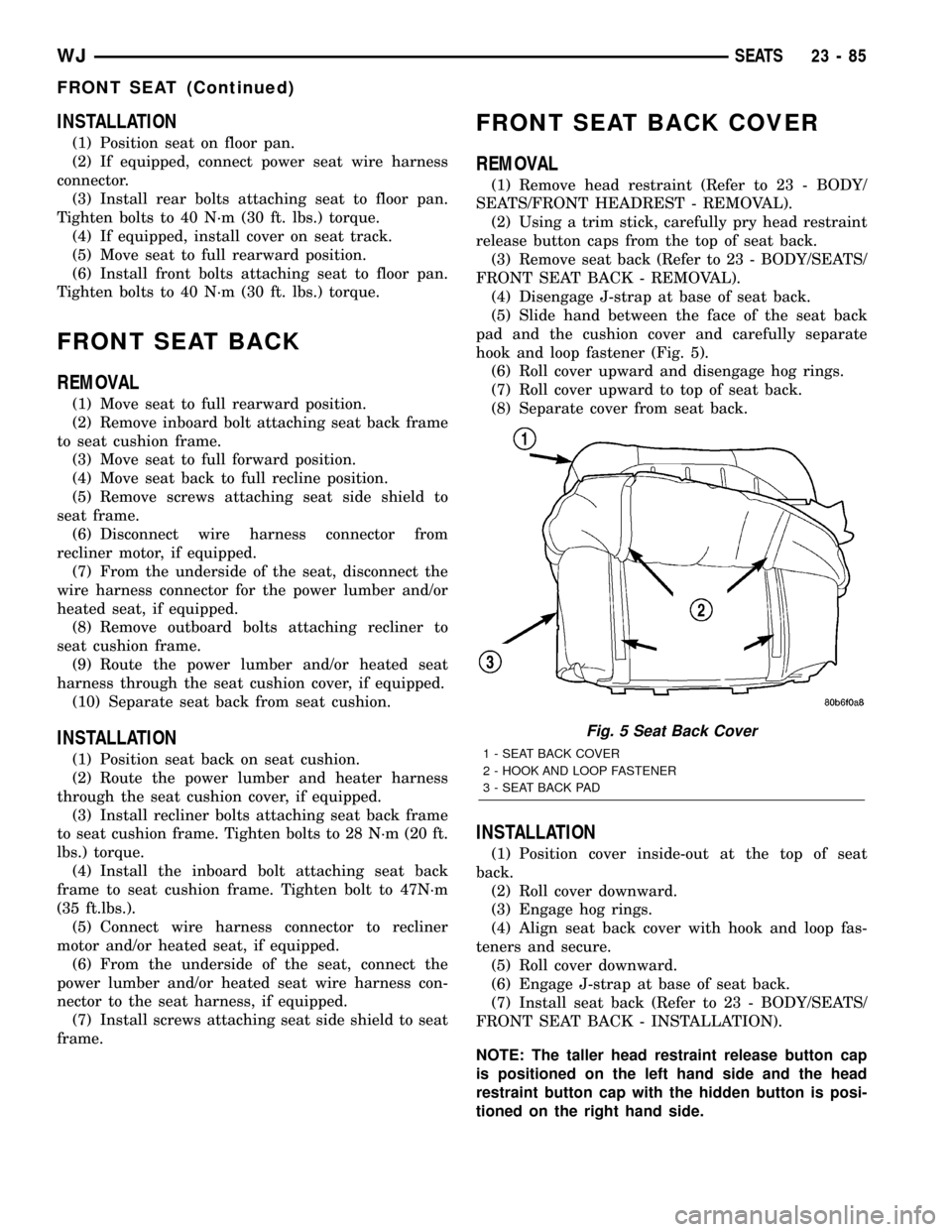

FRONT SEAT BACK COVER

REMOVAL

(1) Remove head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - REMOVAL).

(2) Using a trim stick, carefully pry head restraint

release button caps from the top of seat back.

(3) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

(4) Disengage J-strap at base of seat back.

(5) Slide hand between the face of the seat back

pad and the cushion cover and carefully separate

hook and loop fastener (Fig. 5).

(6) Roll cover upward and disengage hog rings.

(7) Roll cover upward to top of seat back.

(8) Separate cover from seat back.

INSTALLATION

(1) Position cover inside-out at the top of seat

back.

(2) Roll cover downward.

(3) Engage hog rings.

(4) Align seat back cover with hook and loop fas-

teners and secure.

(5) Roll cover downward.

(6) Engage J-strap at base of seat back.

(7) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).

NOTE: The taller head restraint release button cap

is positioned on the left hand side and the head

restraint button cap with the hidden button is posi-

tioned on the right hand side.

Fig. 5 Seat Back Cover

1 - SEAT BACK COVER

2 - HOOK AND LOOP FASTENER

3 - SEAT BACK PAD

WJSEATS 23 - 85

FRONT SEAT (Continued)

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)