pack JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1620 of 2199

(5) Install new seal in gear case. On 4x4 gear case,

use Tool Handle C-4171 and Installer C-3860-A to

seat seal in case. On4x2gear case, use same Han-

dle C-4171 and Installer C-3995-A to seat seal in

case.

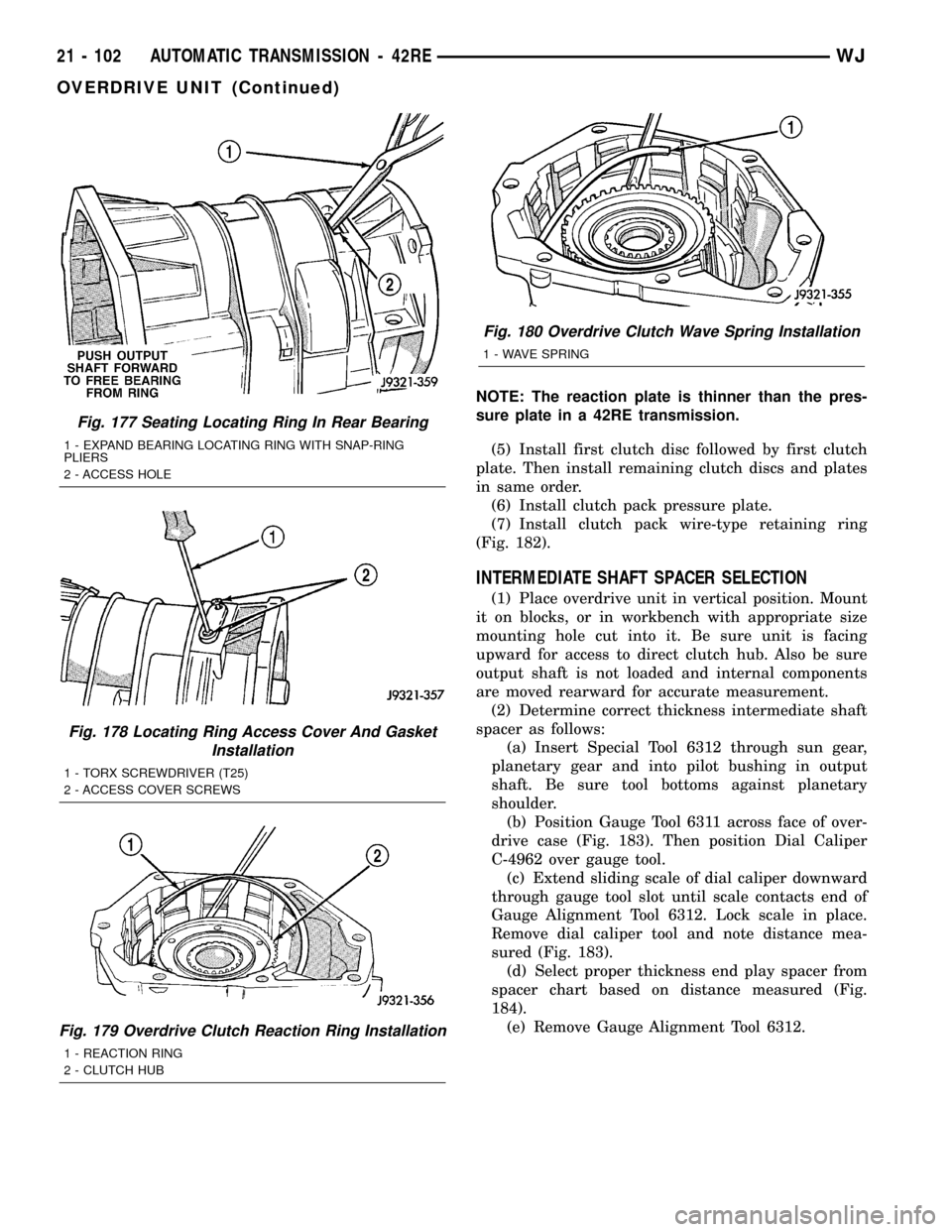

(6) Verify that tab ends of rear bearing locating

ring extend into access hole in gear case (Fig. 175).

(7) Support geartrain on Tool 6227-1 (Fig. 176). Be

sure tool is securely seated in clutch hub.

(8) Install overdrive gear case on geartrain (Fig.

176).

(9) Expand front bearing locating ring with snap-

ring pliers (Fig. 177). Then slide case downward until

locating ring locks in bearing groove and release

snap-ring.

(10) Install locating ring access cover and gasket

in overdrive unit case (Fig. 178).

OVERDRIVE CLUTCH

(1) Install overdrive clutch reaction ring first.

Reaction ring is flat with notched ends (Fig. 179).

(2) Install wave spring on top of reaction ring (Fig.

180). Reaction ring and wave ring both fit in same

ring groove. Use screwdriver to seat each ring

securely in groove. Also ensure that the ends of the

two rings are offset from each other.

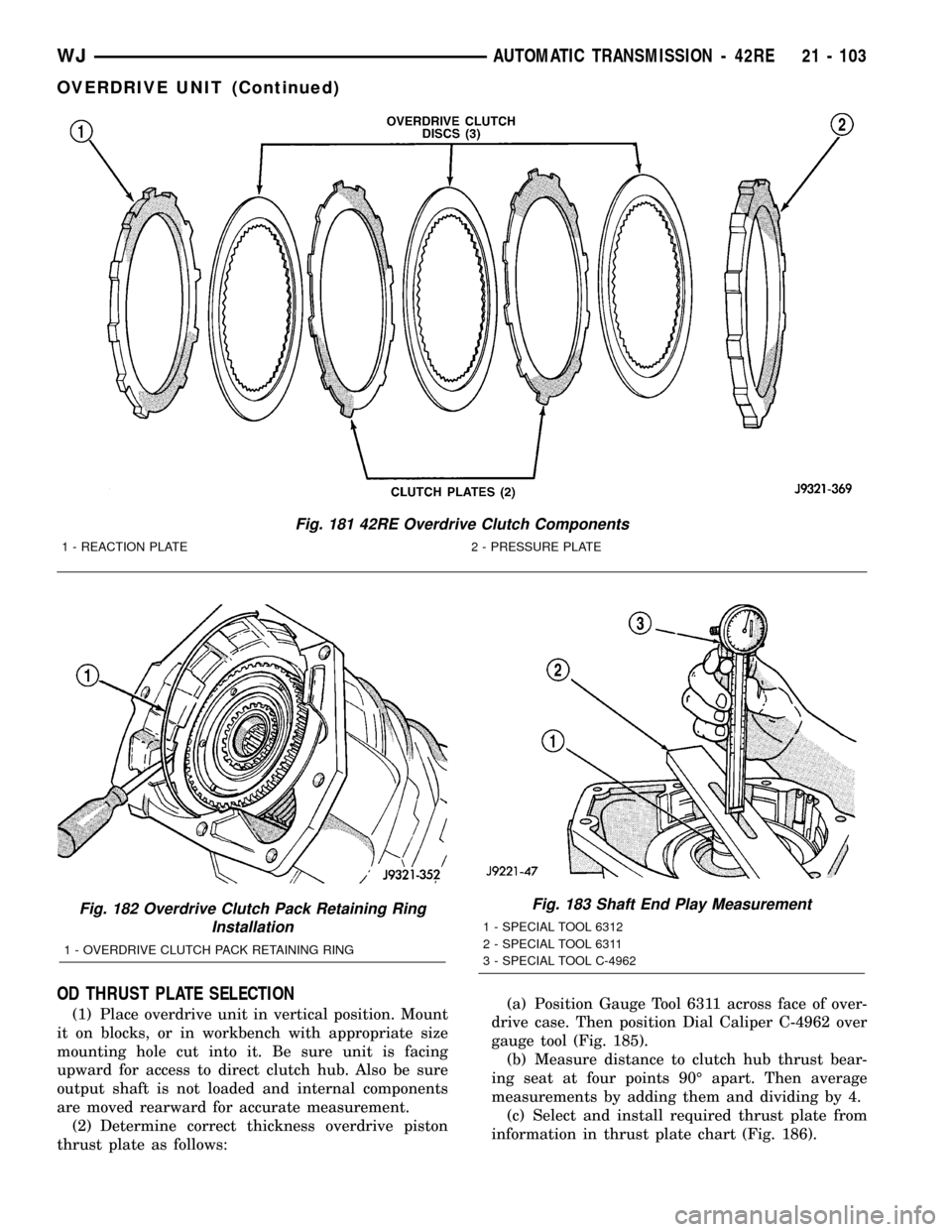

NOTE: The 42RE transmission has 3 overdrive

clutch discs and 2 plates.

(3) Assemble overdrive clutch pack (Fig. 181).

(4) Install overdrive clutch reaction plate first.

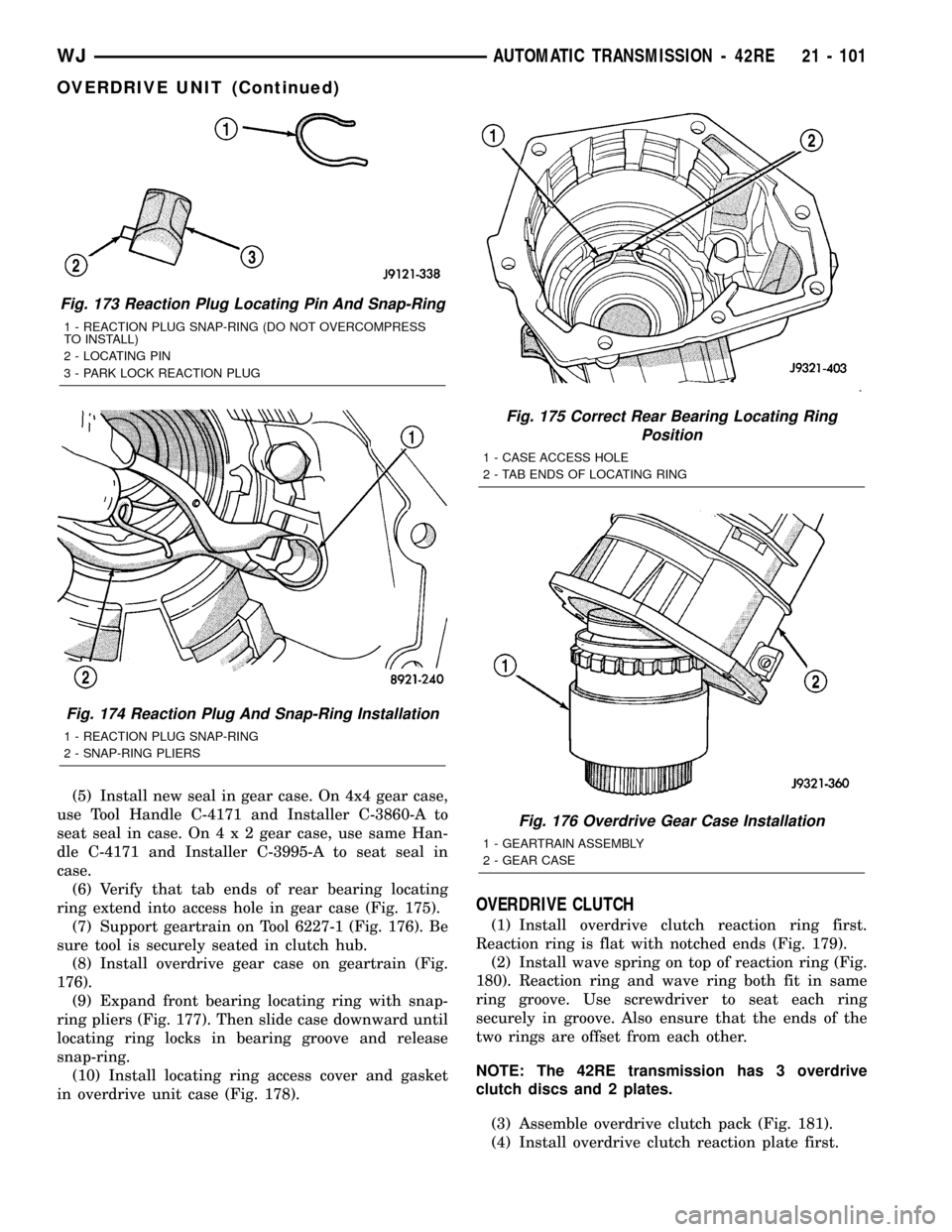

Fig. 173 Reaction Plug Locating Pin And Snap-Ring

1 - REACTION PLUG SNAP-RING (DO NOT OVERCOMPRESS

TO INSTALL)

2 - LOCATING PIN

3 - PARK LOCK REACTION PLUG

Fig. 174 Reaction Plug And Snap-Ring Installation

1 - REACTION PLUG SNAP-RING

2 - SNAP-RING PLIERS

Fig. 175 Correct Rear Bearing Locating Ring

Position

1 - CASE ACCESS HOLE

2 - TAB ENDS OF LOCATING RING

Fig. 176 Overdrive Gear Case Installation

1 - GEARTRAIN ASSEMBLY

2 - GEAR CASE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 101

OVERDRIVE UNIT (Continued)

Page 1621 of 2199

NOTE: The reaction plate is thinner than the pres-

sure plate in a 42RE transmission.

(5) Install first clutch disc followed by first clutch

plate. Then install remaining clutch discs and plates

in same order.

(6) Install clutch pack pressure plate.

(7) Install clutch pack wire-type retaining ring

(Fig. 182).

INTERMEDIATE SHAFT SPACER SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness intermediate shaft

spacer as follows:

(a) Insert Special Tool 6312 through sun gear,

planetary gear and into pilot bushing in output

shaft. Be sure tool bottoms against planetary

shoulder.

(b) Position Gauge Tool 6311 across face of over-

drive case (Fig. 183). Then position Dial Caliper

C-4962 over gauge tool.

(c) Extend sliding scale of dial caliper downward

through gauge tool slot until scale contacts end of

Gauge Alignment Tool 6312. Lock scale in place.

Remove dial caliper tool and note distance mea-

sured (Fig. 183).

(d) Select proper thickness end play spacer from

spacer chart based on distance measured (Fig.

184).

(e) Remove Gauge Alignment Tool 6312.

Fig. 177 Seating Locating Ring In Rear Bearing

1 - EXPAND BEARING LOCATING RING WITH SNAP-RING

PLIERS

2 - ACCESS HOLE

Fig. 178 Locating Ring Access Cover And Gasket

Installation

1 - TORX SCREWDRIVER (T25)

2 - ACCESS COVER SCREWS

Fig. 179 Overdrive Clutch Reaction Ring Installation

1 - REACTION RING

2 - CLUTCH HUB

Fig. 180 Overdrive Clutch Wave Spring Installation

1 - WAVE SPRING

21 - 102 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1622 of 2199

OD THRUST PLATE SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness overdrive piston

thrust plate as follows:(a) Position Gauge Tool 6311 across face of over-

drive case. Then position Dial Caliper C-4962 over

gauge tool (Fig. 185).

(b) Measure distance to clutch hub thrust bear-

ing seat at four points 90É apart. Then average

measurements by adding them and dividing by 4.

(c) Select and install required thrust plate from

information in thrust plate chart (Fig. 186).

Fig. 181 42RE Overdrive Clutch Components

1 - REACTION PLATE 2 - PRESSURE PLATE

Fig. 182 Overdrive Clutch Pack Retaining Ring

Installation

1 - OVERDRIVE CLUTCH PACK RETAINING RING

Fig. 183 Shaft End Play Measurement

1 - SPECIAL TOOL 6312

2 - SPECIAL TOOL 6311

3 - SPECIAL TOOL C-4962

WJAUTOMATIC TRANSMISSION - 42RE 21 - 103

OVERDRIVE UNIT (Continued)

Page 1637 of 2199

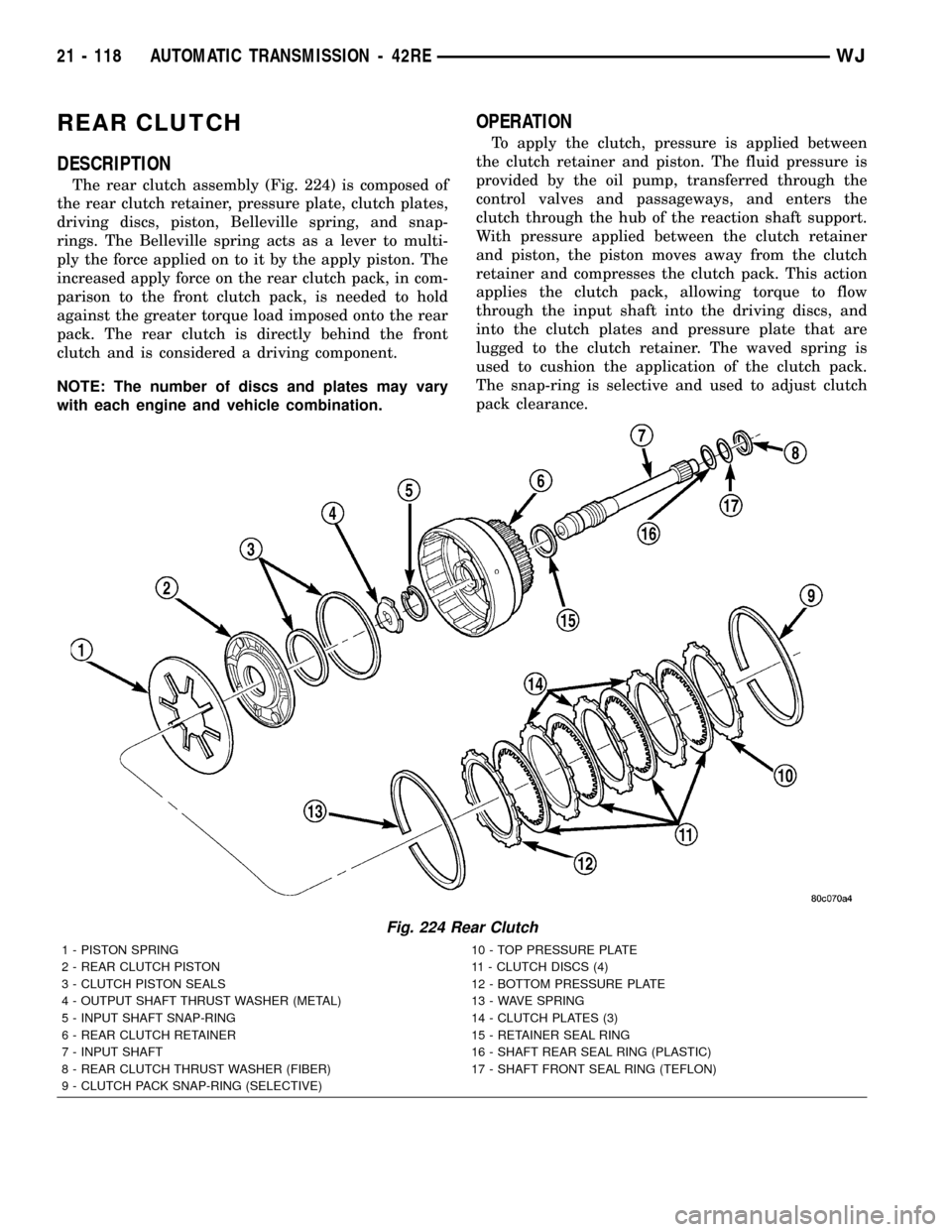

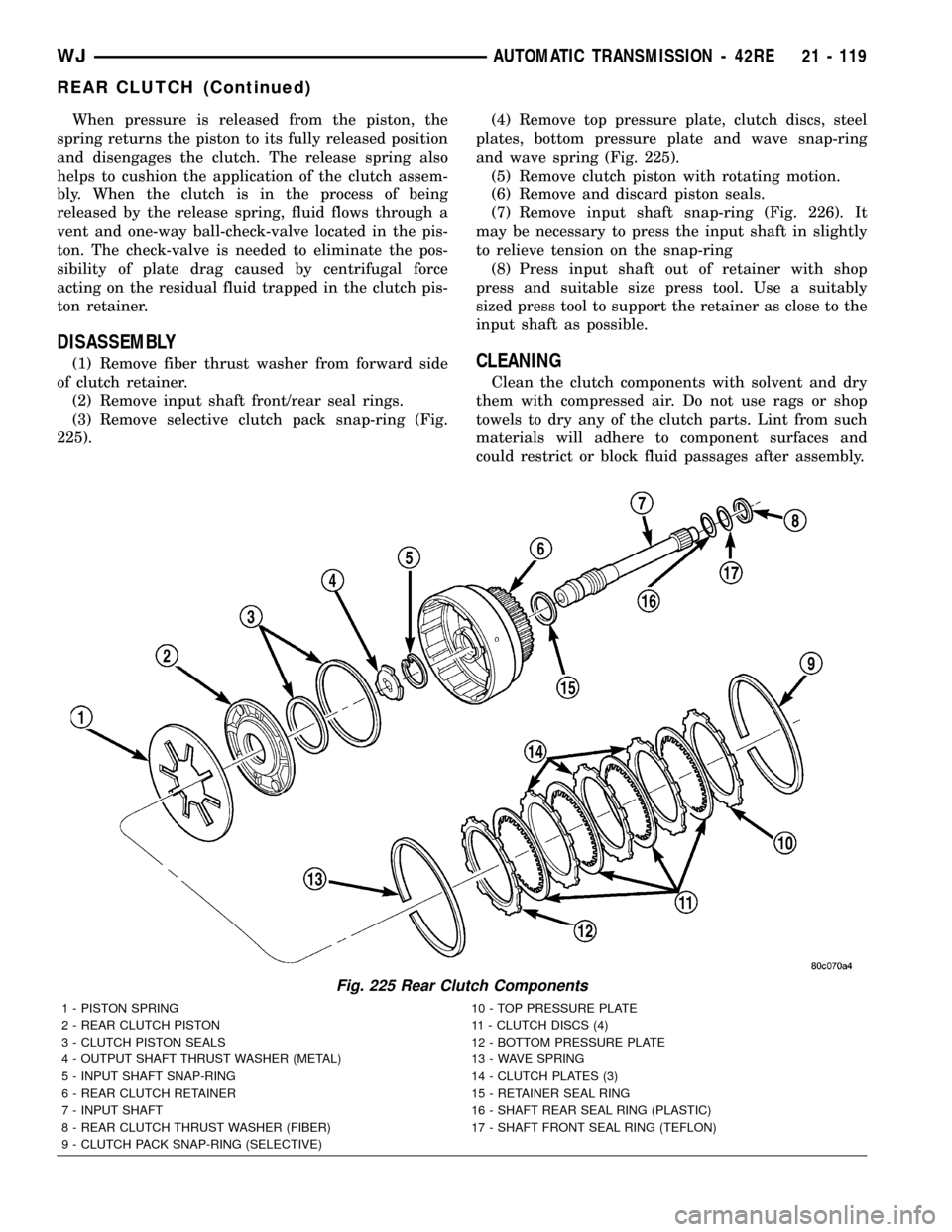

REAR CLUTCH

DESCRIPTION

The rear clutch assembly (Fig. 224) is composed of

the rear clutch retainer, pressure plate, clutch plates,

driving discs, piston, Belleville spring, and snap-

rings. The Belleville spring acts as a lever to multi-

ply the force applied on to it by the apply piston. The

increased apply force on the rear clutch pack, in com-

parison to the front clutch pack, is needed to hold

against the greater torque load imposed onto the rear

pack. The rear clutch is directly behind the front

clutch and is considered a driving component.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved spring is

used to cushion the application of the clutch pack.

The snap-ring is selective and used to adjust clutch

pack clearance.

Fig. 224 Rear Clutch

1 - PISTON SPRING 10 - TOP PRESSURE PLATE

2 - REAR CLUTCH PISTON 11 - CLUTCH DISCS (4)

3 - CLUTCH PISTON SEALS 12 - BOTTOM PRESSURE PLATE

4 - OUTPUT SHAFT THRUST WASHER (METAL) 13 - WAVE SPRING

5 - INPUT SHAFT SNAP-RING 14 - CLUTCH PLATES (3)

6 - REAR CLUTCH RETAINER 15 - RETAINER SEAL RING

7 - INPUT SHAFT 16 - SHAFT REAR SEAL RING (PLASTIC)

8 - REAR CLUTCH THRUST WASHER (FIBER) 17 - SHAFT FRONT SEAL RING (TEFLON)

9 - CLUTCH PACK SNAP-RING (SELECTIVE)

21 - 118 AUTOMATIC TRANSMISSION - 42REWJ

Page 1638 of 2199

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the pis-

ton. The check-valve is needed to eliminate the pos-

sibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch pis-

ton retainer.

DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove input shaft front/rear seal rings.

(3) Remove selective clutch pack snap-ring (Fig.

225).(4) Remove top pressure plate, clutch discs, steel

plates, bottom pressure plate and wave snap-ring

and wave spring (Fig. 225).

(5) Remove clutch piston with rotating motion.

(6) Remove and discard piston seals.

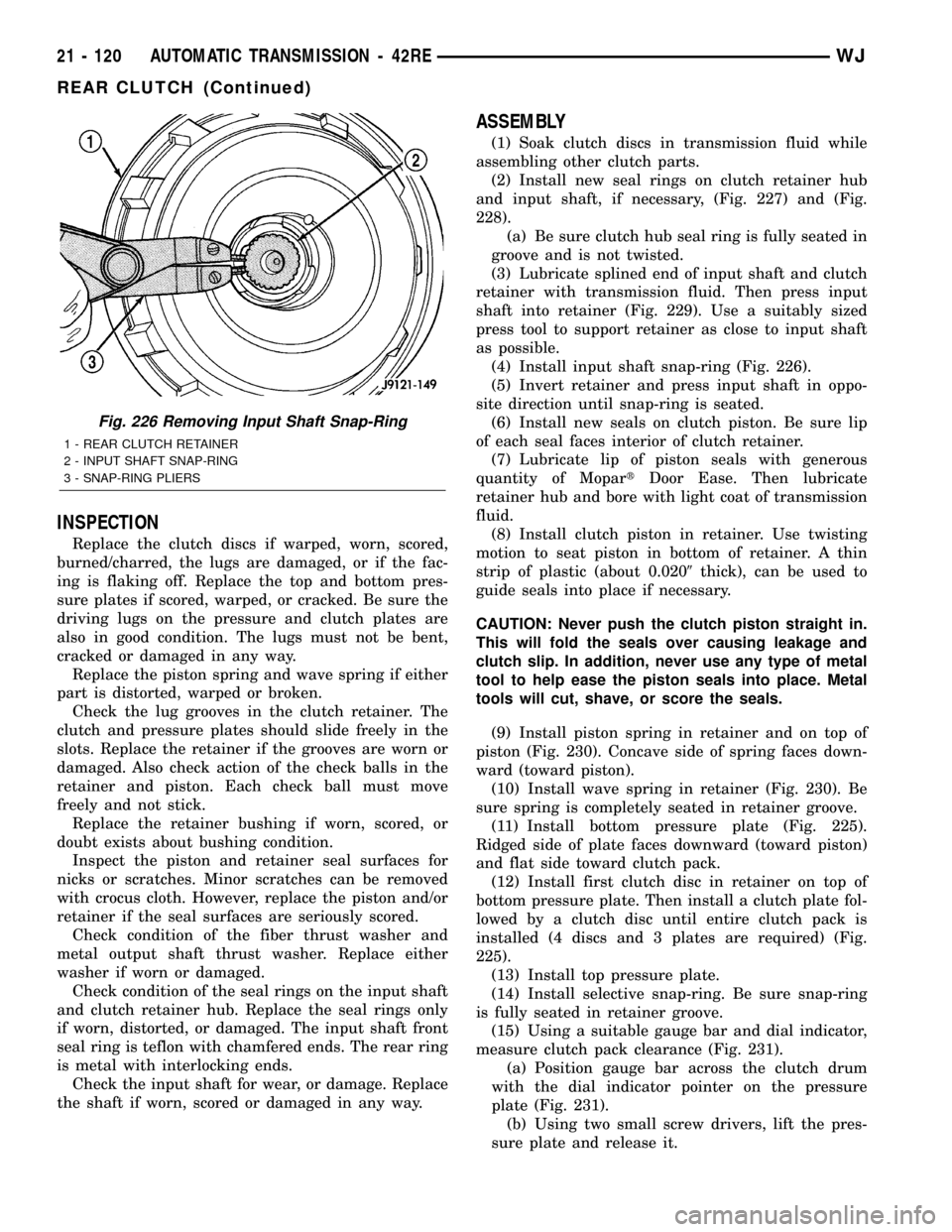

(7) Remove input shaft snap-ring (Fig. 226). It

may be necessary to press the input shaft in slightly

to relieve tension on the snap-ring

(8) Press input shaft out of retainer with shop

press and suitable size press tool. Use a suitably

sized press tool to support the retainer as close to the

input shaft as possible.CLEANING

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

Fig. 225 Rear Clutch Components

1 - PISTON SPRING 10 - TOP PRESSURE PLATE

2 - REAR CLUTCH PISTON 11 - CLUTCH DISCS (4)

3 - CLUTCH PISTON SEALS 12 - BOTTOM PRESSURE PLATE

4 - OUTPUT SHAFT THRUST WASHER (METAL) 13 - WAVE SPRING

5 - INPUT SHAFT SNAP-RING 14 - CLUTCH PLATES (3)

6 - REAR CLUTCH RETAINER 15 - RETAINER SEAL RING

7 - INPUT SHAFT 16 - SHAFT REAR SEAL RING (PLASTIC)

8 - REAR CLUTCH THRUST WASHER (FIBER) 17 - SHAFT FRONT SEAL RING (TEFLON)

9 - CLUTCH PACK SNAP-RING (SELECTIVE)

WJAUTOMATIC TRANSMISSION - 42RE 21 - 119

REAR CLUTCH (Continued)

Page 1639 of 2199

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft, if necessary, (Fig. 227) and (Fig.

228).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 229). Use a suitably sized

press tool to support retainer as close to input shaft

as possible.

(4) Install input shaft snap-ring (Fig. 226).

(5) Invert retainer and press input shaft in oppo-

site direction until snap-ring is seated.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston (Fig. 230). Concave side of spring faces down-

ward (toward piston).

(10) Install wave spring in retainer (Fig. 230). Be

sure spring is completely seated in retainer groove.

(11) Install bottom pressure plate (Fig. 225).

Ridged side of plate faces downward (toward piston)

and flat side toward clutch pack.

(12) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is

installed (4 discs and 3 plates are required) (Fig.

225).

(13) Install top pressure plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

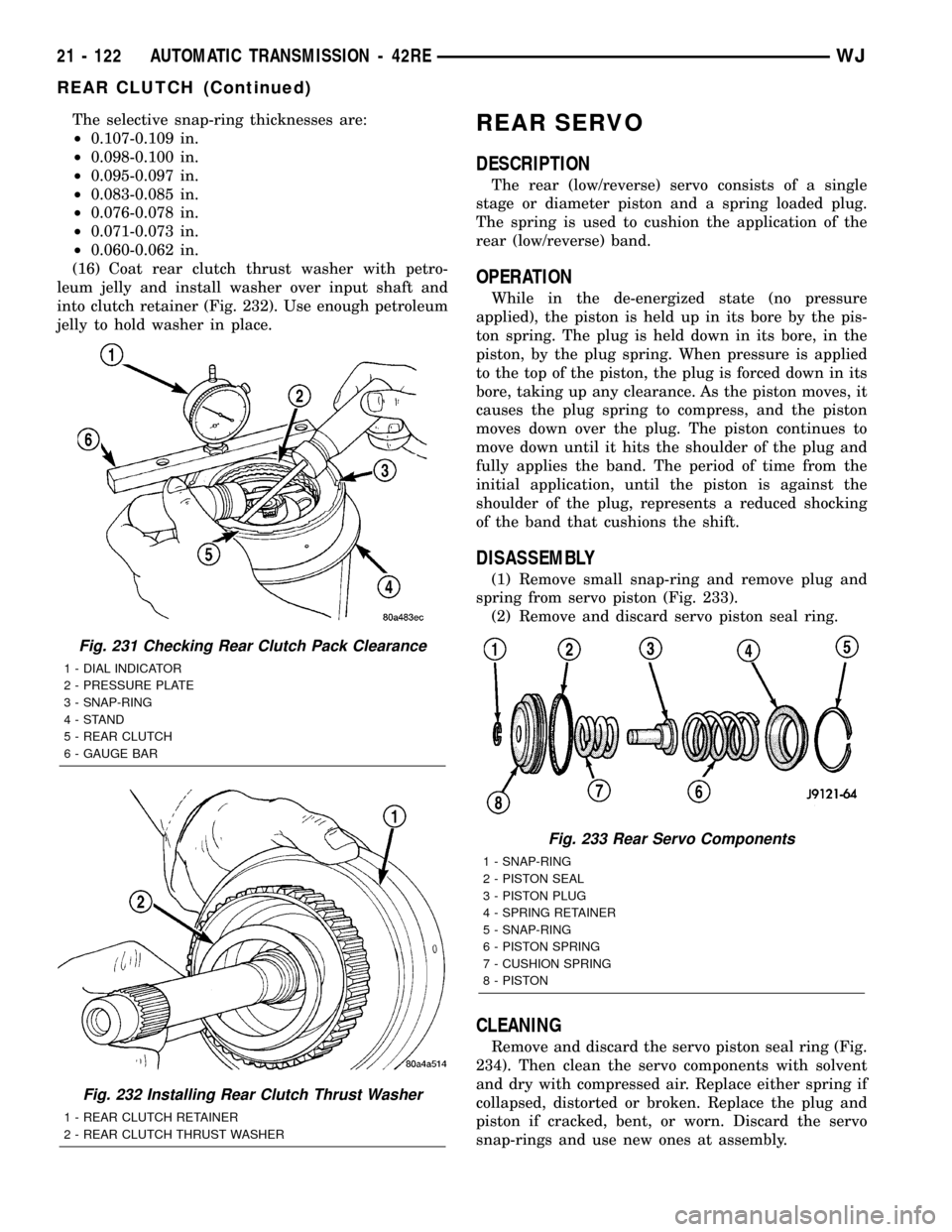

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 231).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 231).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

Fig. 226 Removing Input Shaft Snap-Ring

1 - REAR CLUTCH RETAINER

2 - INPUT SHAFT SNAP-RING

3 - SNAP-RING PLIERS

21 - 120 AUTOMATIC TRANSMISSION - 42REWJ

REAR CLUTCH (Continued)

Page 1641 of 2199

The selective snap-ring thicknesses are:

²0.107-0.109 in.

²0.098-0.100 in.

²0.095-0.097 in.

²0.083-0.085 in.

²0.076-0.078 in.

²0.071-0.073 in.

²0.060-0.062 in.

(16) Coat rear clutch thrust washer with petro-

leum jelly and install washer over input shaft and

into clutch retainer (Fig. 232). Use enough petroleum

jelly to hold washer in place.REAR SERVO

DESCRIPTION

The rear (low/reverse) servo consists of a single

stage or diameter piston and a spring loaded plug.

The spring is used to cushion the application of the

rear (low/reverse) band.

OPERATION

While in the de-energized state (no pressure

applied), the piston is held up in its bore by the pis-

ton spring. The plug is held down in its bore, in the

piston, by the plug spring. When pressure is applied

to the top of the piston, the plug is forced down in its

bore, taking up any clearance. As the piston moves, it

causes the plug spring to compress, and the piston

moves down over the plug. The piston continues to

move down until it hits the shoulder of the plug and

fully applies the band. The period of time from the

initial application, until the piston is against the

shoulder of the plug, represents a reduced shocking

of the band that cushions the shift.

DISASSEMBLY

(1) Remove small snap-ring and remove plug and

spring from servo piston (Fig. 233).

(2) Remove and discard servo piston seal ring.

CLEANING

Remove and discard the servo piston seal ring (Fig.

234). Then clean the servo components with solvent

and dry with compressed air. Replace either spring if

collapsed, distorted or broken. Replace the plug and

piston if cracked, bent, or worn. Discard the servo

snap-rings and use new ones at assembly.

Fig. 231 Checking Rear Clutch Pack Clearance

1 - DIAL INDICATOR

2 - PRESSURE PLATE

3 - SNAP-RING

4-STAND

5 - REAR CLUTCH

6 - GAUGE BAR

Fig. 232 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER

Fig. 233 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

21 - 122 AUTOMATIC TRANSMISSION - 42REWJ

REAR CLUTCH (Continued)

Page 1697 of 2199

INSTALLATION........................253

OUTPUT SPEED SENSOR

DESCRIPTION........................254

OPERATION..........................254

REMOVAL............................254

INSTALLATION........................254

OVERDRIVE SWITCH

DESCRIPTION........................254

OPERATION..........................254

PARK LOCK CABLE

REMOVAL............................255

INSTALLATION........................255

PISTONS

DESCRIPTION........................256

OPERATION..........................256

PLANETARY GEARTRAIN

DESCRIPTION........................258

OPERATION..........................260

DISASSEMBLY........................260

CLEANING...........................260

INSPECTION.........................260

ASSEMBLY...........................261

SHIFT MECHANISM

DESCRIPTION........................261

OPERATION..........................261

REMOVAL............................261

INSTALLATION........................263

SOLENOID SWITCH VALVE

DESCRIPTION........................263

OPERATION..........................263

SOLENOIDS

DESCRIPTION........................263OPERATION..........................264

TORQUE CONVERTER

DESCRIPTION........................264

OPERATION..........................268

REMOVAL............................269

INSTALLATION........................269

TRANSMISSION CONTROL RELAY

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION RANGE SENSOR

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................271

OPERATION..........................271

REMOVAL............................272

INSTALLATION........................272

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................272

OPERATION..........................272

VALVE BODY

DESCRIPTION........................273

OPERATION..........................273

REMOVAL............................274

DISASSEMBLY........................275

CLEANING...........................277

INSPECTION.........................277

ASSEMBLY...........................278

INSTALLATION........................279

AUTOMATIC TRANSMISSION -

545RFE

DESCRIPTION

The 545RFE automatic transmission is a sophisti-

cated, multi-range, electronically controlled transmis-

sion which combines optimized gear ratios for

responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range. An additional overdrive ratio (0.67:1)

is also provided for greater fuel economy and less

NVH at highway speeds.The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.

The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 178 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1698 of 2199

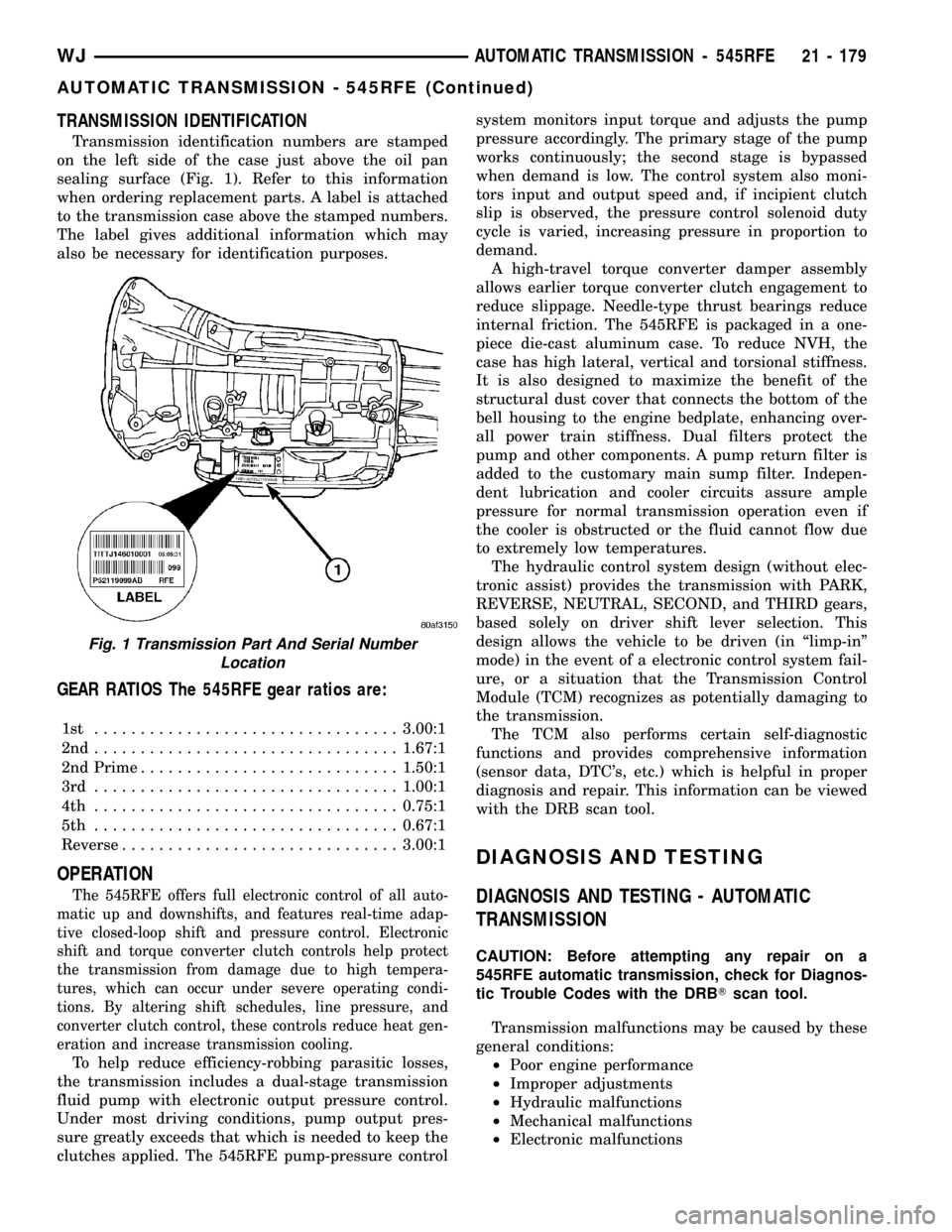

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime............................1.50:1

3rd .................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse..............................3.00:1

OPERATION

The 545RFE offers full electronic control of all auto-

matic up and downshifts, and features real-time adap-

tive closed-loop shift and pressure control. Electronic

shift and torque converter clutch controls help protect

the transmission from damage due to high tempera-

tures, which can occur under severe operating condi-

tions. By altering shift schedules, line pressure, and

converter clutch control, these controls reduce heat gen-

eration and increase transmission cooling.

To help reduce efficiency-robbing parasitic losses,

the transmission includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 545RFE pump-pressure controlsystem monitors input torque and adjusts the pump

pressure accordingly. The primary stage of the pump

works continuously; the second stage is bypassed

when demand is low. The control system also moni-

tors input and output speed and, if incipient clutch

slip is observed, the pressure control solenoid duty

cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 545RFE is packaged in a one-

piece die-cast aluminum case. To reduce NVH, the

case has high lateral, vertical and torsional stiffness.

It is also designed to maximize the benefit of the

structural dust cover that connects the bottom of the

bell housing to the engine bedplate, enhancing over-

all power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a

545RFE automatic transmission, check for Diagnos-

tic Trouble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Fig. 1 Transmission Part And Serial Number

Location

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 179

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1707 of 2199

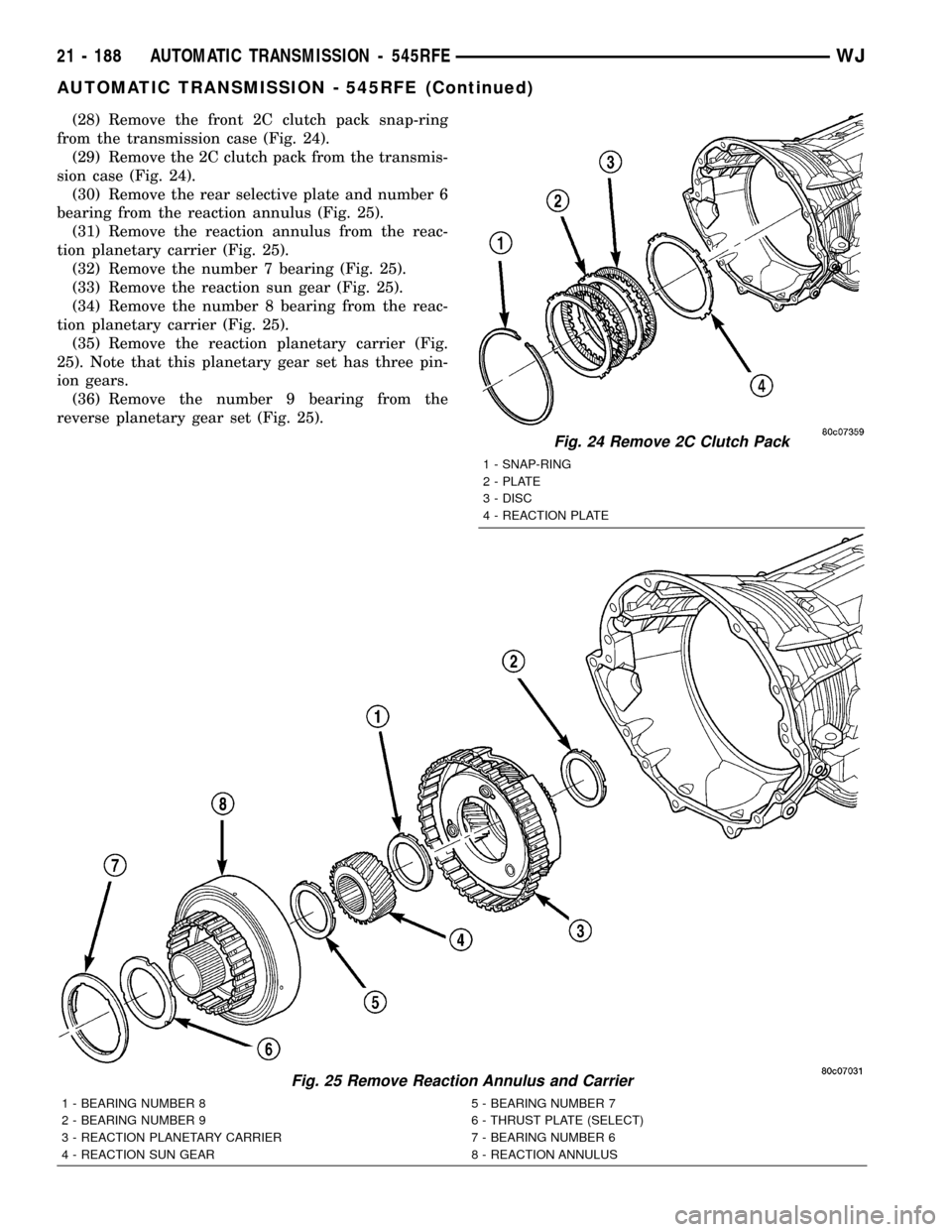

(28) Remove the front 2C clutch pack snap-ring

from the transmission case (Fig. 24).

(29) Remove the 2C clutch pack from the transmis-

sion case (Fig. 24).

(30) Remove the rear selective plate and number 6

bearing from the reaction annulus (Fig. 25).

(31) Remove the reaction annulus from the reac-

tion planetary carrier (Fig. 25).

(32) Remove the number 7 bearing (Fig. 25).

(33) Remove the reaction sun gear (Fig. 25).

(34) Remove the number 8 bearing from the reac-

tion planetary carrier (Fig. 25).

(35) Remove the reaction planetary carrier (Fig.

25). Note that this planetary gear set has three pin-

ion gears.

(36) Remove the number 9 bearing from the

reverse planetary gear set (Fig. 25).

Fig. 24 Remove 2C Clutch Pack

1 - SNAP-RING

2 - PLATE

3 - DISC

4 - REACTION PLATE

Fig. 25 Remove Reaction Annulus and Carrier

1 - BEARING NUMBER 8 5 - BEARING NUMBER 7

2 - BEARING NUMBER 9 6 - THRUST PLATE (SELECT)

3 - REACTION PLANETARY CARRIER 7 - BEARING NUMBER 6

4 - REACTION SUN GEAR 8 - REACTION ANNULUS

21 - 188 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)