Lug nut JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1925 of 2199

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) If the vehicle is not equipped with the optional

automatic headlamps light sensor/vehicle theft secu-

rity system indicator, be certain that the hole plug is

installed in the clearance hole located to the out-

board side of the driver side defroster outlet in the

instrument panel top cover (Fig. 22).

(2) Before installing the top cover onto the top of

the instrument panel, be certain that the rubber top

cover seal is properly positioned on the forward edge

of the top cover panel.

(3) Position the top cover onto the top of the

instrument panel.

(4) Align the four snap clips on the top cover with

the snap clip receptacles in the instrument panel top

pad.

(5) Press firmly downward on the top cover over

each of the four snap clip locations until each of the

snap clips is fully seated in their receptacles in the

instrument panel top pad.

(6) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP PAD

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right and left A-pil-

lars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - REMOVAL).

(3) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(4) Remove the four nuts that secure the instru-

ment panel top pad to the studs on the dash panel

near the windshield fence line (Fig. 23).

(5) Remove the speakers from the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - REMOVAL - INSTRUMENT PANEL

SPEAKER).

(6) Disengage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad. Tuck the loose ends of these speaker take outs

down the defroster ducts to keep them out of the way

during the remainder of this procedure.

(7) If the vehicle is so equipped, remove the two

screws that secure the automatic headlamp light sen-

sor/vehicle theft security system indicator unit to the

instrument panel top pad just outboard of the driver

side defroster outlet. Move the sensor/indicator unit

towards the windshield to keep it out of the way dur-

ing the remainder of this procedure.

(8) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(9) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(10) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(11) Roll the glove box down from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(12) Remove the end cap from the passenger side

lower outboard end of the instrument panel. (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - REMOVAL).

(13) Remove the lower right center bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- REMOVAL).

(14) Remove the glove box lamp and switch from

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - REMOVAL).

23 - 52 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL TOP COVER (Continued)

Page 2080 of 2199

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

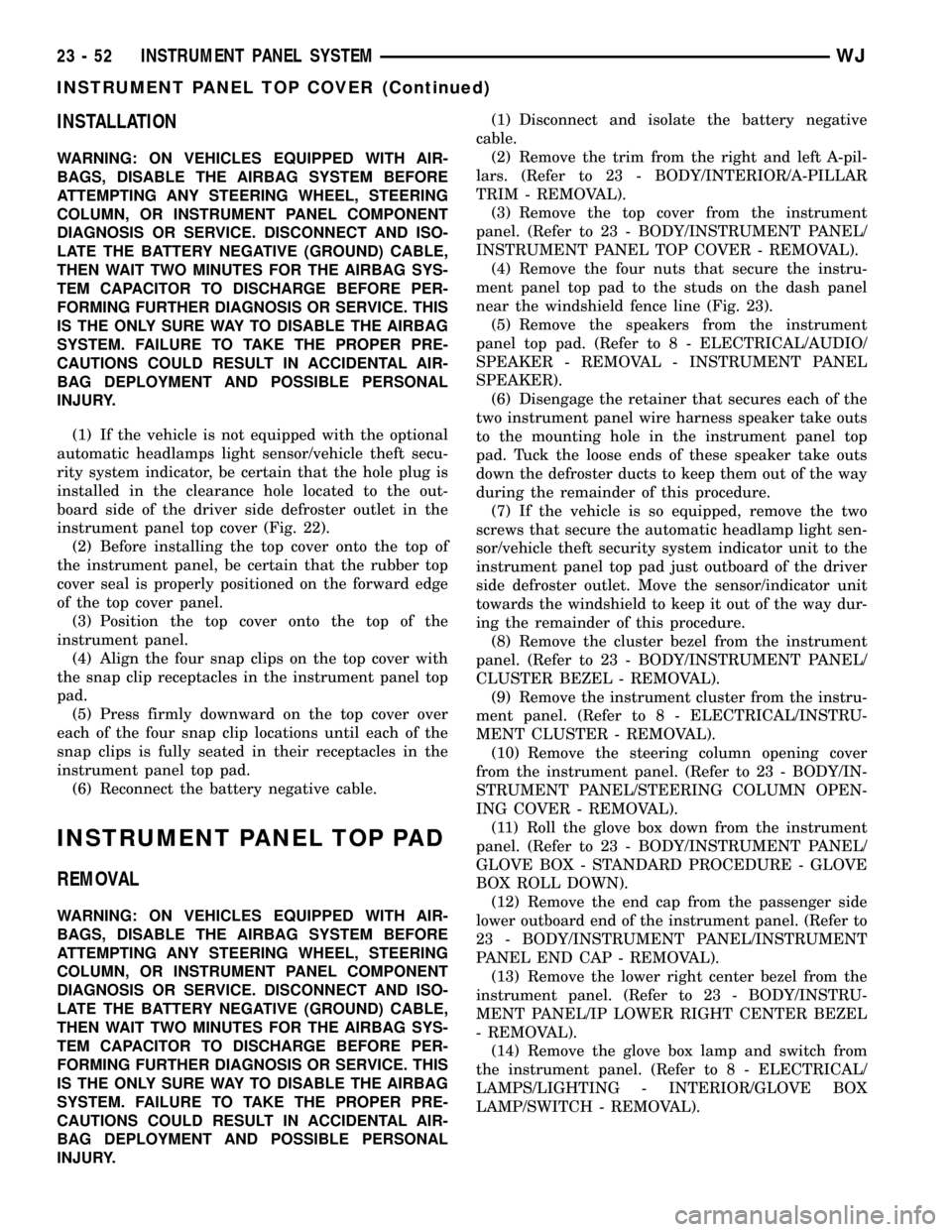

If the vehicle has the optional Automatic Zone Control

(AZC) system, and has intermittent operational prob-

lems or fault codes, be certain that the wire harness

connectors on the HVAC housing are properly seated

(Fig. 2). To check this condition, unplug the two wire

harness connector halves, then plug them in again.

Before performing the following procedure, (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - CAUTION) (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING). The air

temperature in the test room and in the vehicle must

be a minimum of 21É C (70É F) for this test.

(1)

Connect a tachometer and a manifold gauge set.

(2) If the vehicle has the standard manual temper-

ature control, set the A/C Heater mode control switch

knob in the Panel position, the temperature control

knob in the full cool (Fresh Air Mode) position, the

A/C button in the On position, and the blower motor

switch knob in the highest speed position. If the vehi-

cle has the optional AZC, set the A/C Heater mode

control switch knob in the Panel position, the tem-

perature control knob in the full cool position, the

A/C button in the On position, and the blower motor

switch knob in the highest (manual) speed position.

(3) Start the engine and hold the idle at 1,300 rpm

with the compressor clutch engaged.

(4) The engine should be at operating temperature.

The doors and windows must be open.

(5)

Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five minutes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

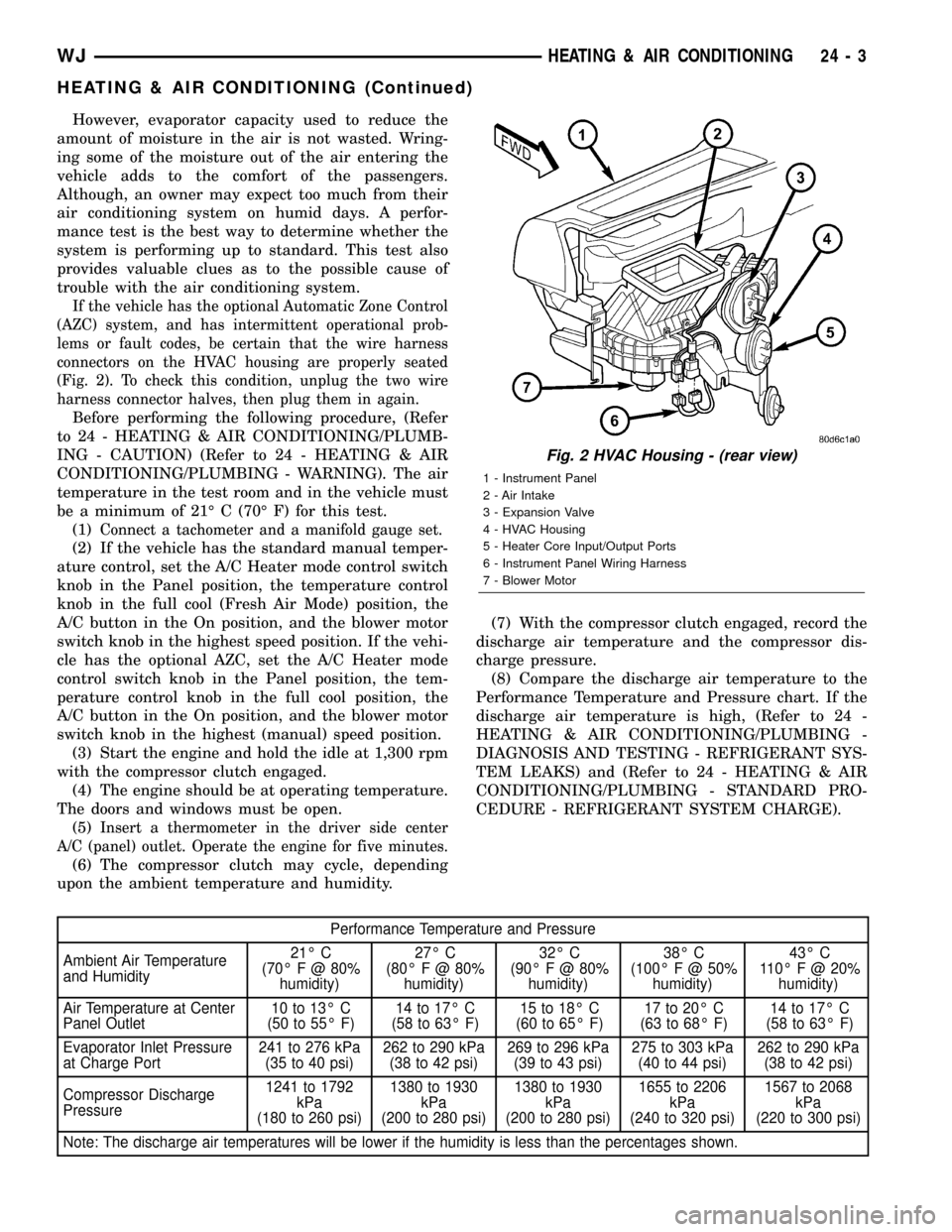

(8) Compare the discharge air temperature to the

Performance Temperature and Pressure chart. If the

discharge air temperature is high, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Performance Temperature and Pressure

Ambient Air Temperature

and Humidity21É C

(70É F @ 80%

humidity)27É C

(80É F @ 80%

humidity)32É C

(90É F @ 80%

humidity)38É C

(100ÉF@50%

humidity)43É C

110É F @ 20%

humidity)

Air Temperature at Center

Panel Outlet10 to 13É C

(50 to 55É F)14 to 17É C

(58 to 63É F)15 to 18É C

(60 to 65É F)17 to 20É C

(63 to 68É F)14 to 17É C

(58 to 63É F)

Evaporator Inlet Pressure

at Charge Port241 to 276 kPa

(35 to 40 psi)262 to 290 kPa

(38 to 42 psi)269 to 296 kPa

(39 to 43 psi)275 to 303 kPa

(40 to 44 psi)262 to 290 kPa

(38 to 42 psi)

Compressor Discharge

Pressure1241 to 1792

kPa

(180 to 260 psi)1380 to 1930

kPa

(200 to 280 psi)1380 to 1930

kPa

(200 to 280 psi)1655 to 2206

kPa

(240 to 320 psi)1567 to 2068

kPa

(220 to 300 psi)

Note: The discharge air temperatures will be lower if the humidity is less than the percentages shown.

Fig. 2 HVAC Housing - (rear view)

1 - Instrument Panel

2 - Air Intake

3 - Expansion Valve

4 - HVAC Housing

5 - Heater Core Input/Output Ports

6 - Instrument Panel Wiring Harness

7 - Blower Motor

WJHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2088 of 2199

LOCATING VACUUM LEAKS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

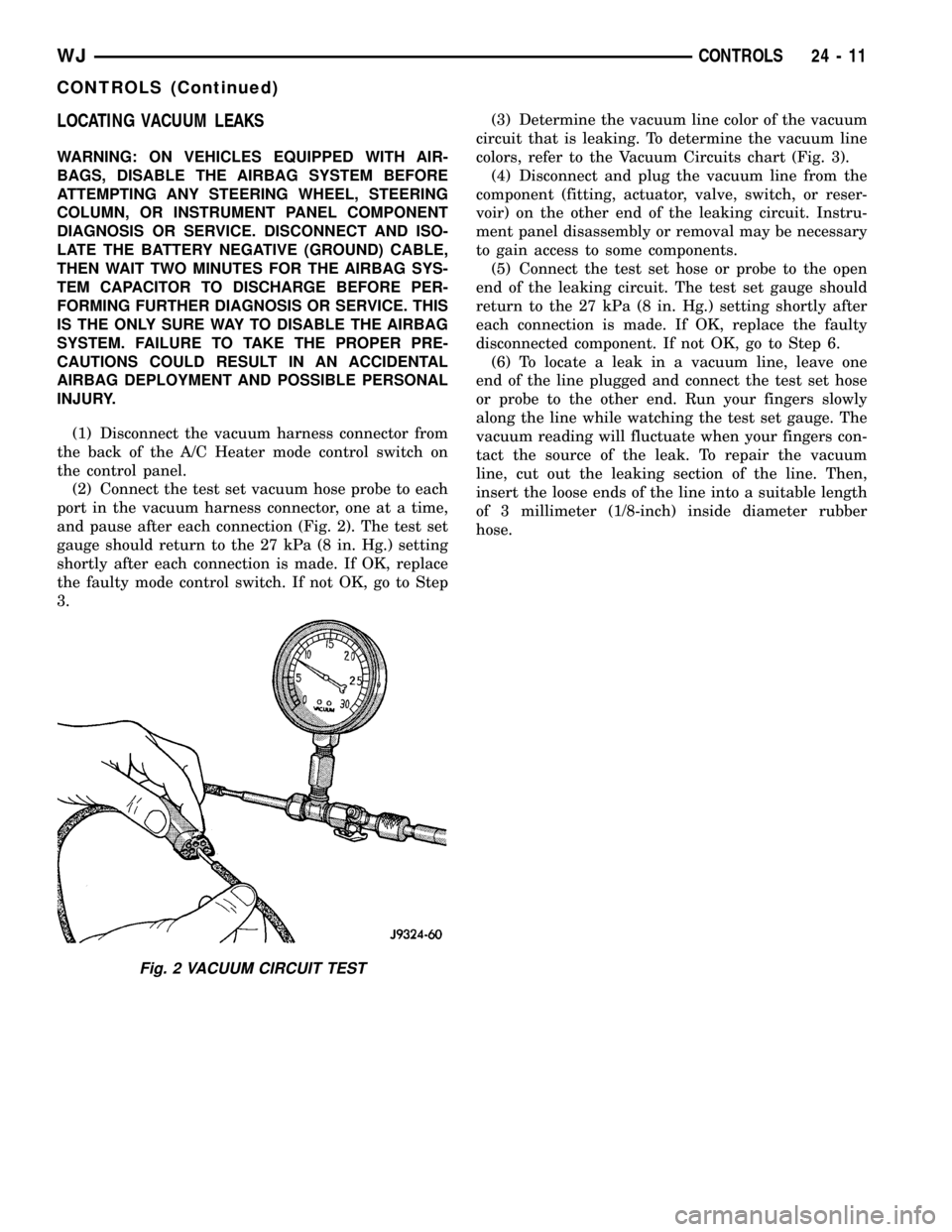

(1) Disconnect the vacuum harness connector from

the back of the A/C Heater mode control switch on

the control panel.

(2) Connect the test set vacuum hose probe to each

port in the vacuum harness connector, one at a time,

and pause after each connection (Fig. 2). The test set

gauge should return to the 27 kPa (8 in. Hg.) setting

shortly after each connection is made. If OK, replace

the faulty mode control switch. If not OK, go to Step

3.(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, refer to the Vacuum Circuits chart (Fig. 3).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reser-

voir) on the other end of the leaking circuit. Instru-

ment panel disassembly or removal may be necessary

to gain access to some components.

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6) To locate a leak in a vacuum line, leave one

end of the line plugged and connect the test set hose

or probe to the other end. Run your fingers slowly

along the line while watching the test set gauge. The

vacuum reading will fluctuate when your fingers con-

tact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then,

insert the loose ends of the line into a suitable length

of 3 millimeter (1/8-inch) inside diameter rubber

hose.

Fig. 2 VACUUM CIRCUIT TEST

WJCONTROLS 24 - 11

CONTROLS (Continued)

Page 2101 of 2199

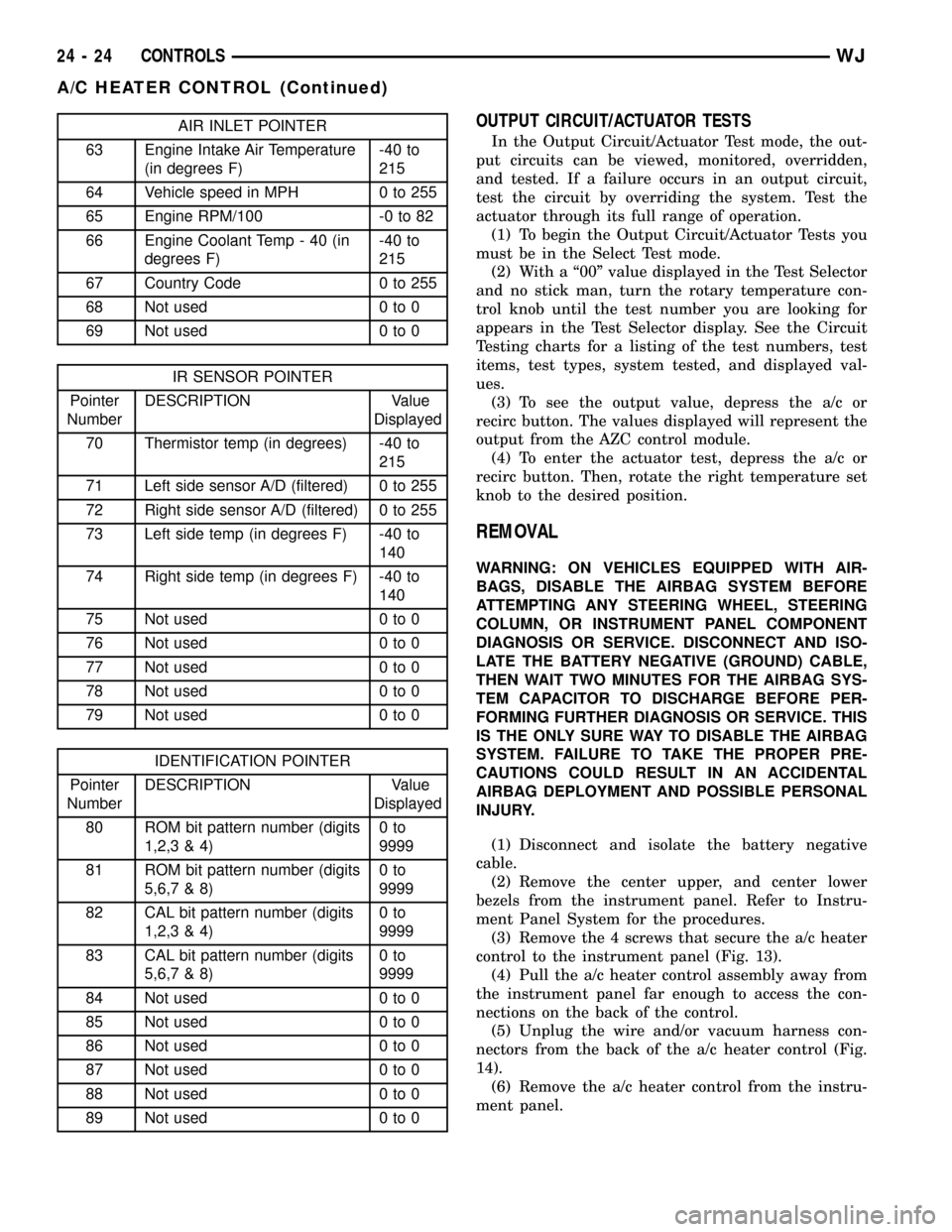

AIR INLET POINTER

63 Engine Intake Air Temperature

(in degrees F)-40 to

215

64 Vehicle speed in MPH 0 to 255

65 Engine RPM/100 -0 to 82

66 Engine Coolant Temp - 40 (in

degrees F)-40 to

215

67 Country Code 0 to 255

68 Not used 0 to 0

69 Not used 0 to 0

IR SENSOR POINTER

Pointer

NumberDESCRIPTION Value

Displayed

70 Thermistor temp (in degrees) -40 to

215

71 Left side sensor A/D (filtered) 0 to 255

72 Right side sensor A/D (filtered) 0 to 255

73 Left side temp (in degrees F) -40 to

140

74 Right side temp (in degrees F) -40 to

140

75 Not used 0 to 0

76 Not used 0 to 0

77 Not used 0 to 0

78 Not used 0 to 0

79 Not used 0 to 0

IDENTIFICATION POINTER

Pointer

NumberDESCRIPTION Value

Displayed

80 ROM bit pattern number (digits

1,2,3 & 4)0to

9999

81 ROM bit pattern number (digits

5,6,7 & 8)0to

9999

82 CAL bit pattern number (digits

1,2,3 & 4)0to

9999

83 CAL bit pattern number (digits

5,6,7 & 8)0to

9999

84 Not used 0 to 0

85 Not used 0 to 0

86 Not used 0 to 0

87 Not used 0 to 0

88 Not used 0 to 0

89 Not used 0 to 0

OUTPUT CIRCUIT/ACTUATOR TESTS

In the Output Circuit/Actuator Test mode, the out-

put circuits can be viewed, monitored, overridden,

and tested. If a failure occurs in an output circuit,

test the circuit by overriding the system. Test the

actuator through its full range of operation.

(1) To begin the Output Circuit/Actuator Tests you

must be in the Select Test mode.

(2) With a ª00º value displayed in the Test Selector

and no stick man, turn the rotary temperature con-

trol knob until the test number you are looking for

appears in the Test Selector display. See the Circuit

Testing charts for a listing of the test numbers, test

items, test types, system tested, and displayed val-

ues.

(3) To see the output value, depress the a/c or

recirc button. The values displayed will represent the

output from the AZC control module.

(4) To enter the actuator test, depress the a/c or

recirc button. Then, rotate the right temperature set

knob to the desired position.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center upper, and center lower

bezels from the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(3) Remove the 4 screws that secure the a/c heater

control to the instrument panel (Fig. 13).

(4) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(5) Unplug the wire and/or vacuum harness con-

nectors from the back of the a/c heater control (Fig.

14).

(6) Remove the a/c heater control from the instru-

ment panel.

24 - 24 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2104 of 2199

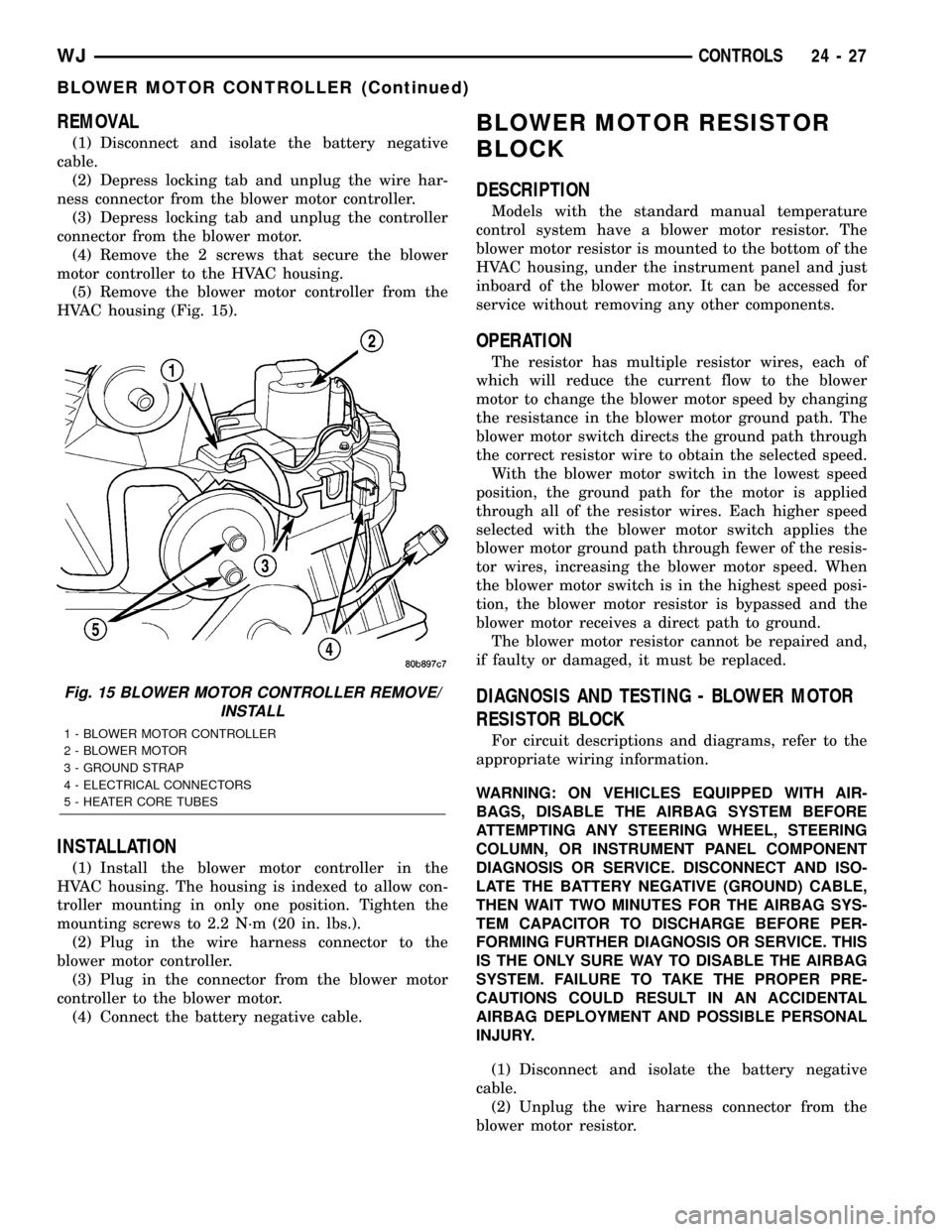

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Depress locking tab and unplug the wire har-

ness connector from the blower motor controller.

(3) Depress locking tab and unplug the controller

connector from the blower motor.

(4) Remove the 2 screws that secure the blower

motor controller to the HVAC housing.

(5) Remove the blower motor controller from the

HVAC housing (Fig. 15).

INSTALLATION

(1) Install the blower motor controller in the

HVAC housing. The housing is indexed to allow con-

troller mounting in only one position. Tighten the

mounting screws to 2.2 N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the

blower motor controller.

(3) Plug in the connector from the blower motor

controller to the blower motor.

(4) Connect the battery negative cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

Models with the standard manual temperature

control system have a blower motor resistor. The

blower motor resistor is mounted to the bottom of the

HVAC housing, under the instrument panel and just

inboard of the blower motor. It can be accessed for

service without removing any other components.

OPERATION

The resistor has multiple resistor wires, each of

which will reduce the current flow to the blower

motor to change the blower motor speed by changing

the resistance in the blower motor ground path. The

blower motor switch directs the ground path through

the correct resistor wire to obtain the selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed. When

the blower motor switch is in the highest speed posi-

tion, the blower motor resistor is bypassed and the

blower motor receives a direct path to ground.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the

blower motor resistor.

Fig. 15 BLOWER MOTOR CONTROLLER REMOVE/

INSTALL

1 - BLOWER MOTOR CONTROLLER

2 - BLOWER MOTOR

3 - GROUND STRAP

4 - ELECTRICAL CONNECTORS

5 - HEATER CORE TUBES

WJCONTROLS 24 - 27

BLOWER MOTOR CONTROLLER (Continued)

Page 2106 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the a/c heater control from the instrument

panel. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS/A/C HEATER CONTROL -

REMOVAL) Check for continuity between the ground

circuit cavity of the a/c heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the a/c heater control wire harness con-

nector unplugged, place the a/c heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the a/c heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the a/c heater control connec-

tor and the blower motor resistor as required. If not

OK, replace the faulty a/c heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTALAIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be adjusted or

repaired, and if faulty or damaged, the a/c heater

control must be replaced. (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

IN-CAR TEMPERATURE

SENSOR

DESCRIPTION

Models equipped with the optional Automatic Zone

Control (AZC) system use automatic dual zone tem-

perature control with infrared sensing technology.

The temperature sensor is located in the center

instrument panel, between the dual temperature

knobs of the AZC.

OPERATION

The Automatic Zone Control uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced.

NOTE: The infrared sensor window may be perma-

nently damaged if any type of cosmetic vinyl dress-

ings are allowed to contact the lens. Avoid spraying

or wiping this area with any cleaner or conditioner.

This may result in impaired temperature sensing

and control.

REMOVAL

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

WJCONTROLS 24 - 29

BLOWER MOTOR SWITCH (Continued)

Page 2107 of 2199

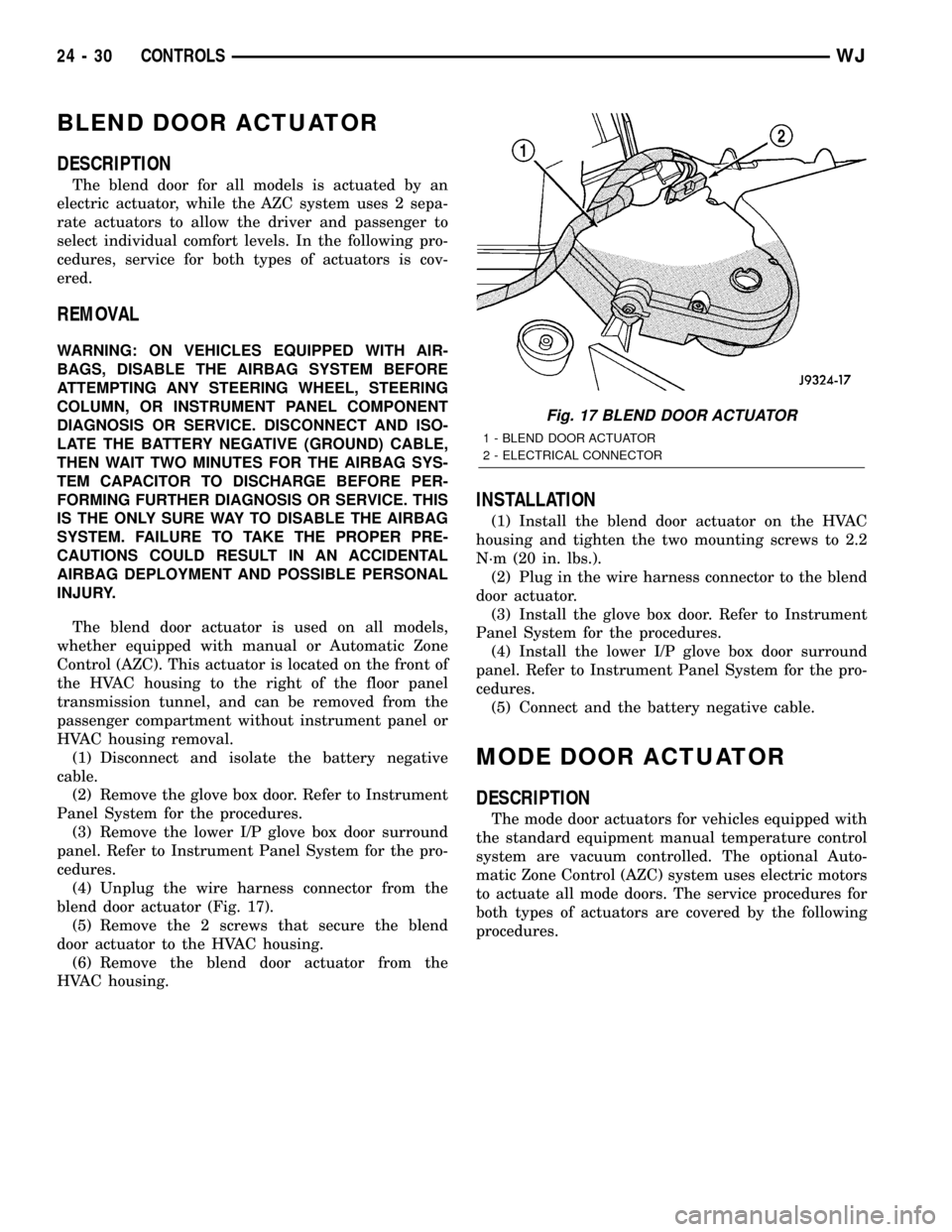

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door for all models is actuated by an

electric actuator, while the AZC system uses 2 sepa-

rate actuators to allow the driver and passenger to

select individual comfort levels. In the following pro-

cedures, service for both types of actuators is cov-

ered.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blend door actuator is used on all models,

whether equipped with manual or Automatic Zone

Control (AZC). This actuator is located on the front of

the HVAC housing to the right of the floor panel

transmission tunnel, and can be removed from the

passenger compartment without instrument panel or

HVAC housing removal.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box door. Refer to Instrument

Panel System for the procedures.

(3) Remove the lower I/P glove box door surround

panel. Refer to Instrument Panel System for the pro-

cedures.

(4) Unplug the wire harness connector from the

blend door actuator (Fig. 17).

(5) Remove the 2 screws that secure the blend

door actuator to the HVAC housing.

(6) Remove the blend door actuator from the

HVAC housing.

INSTALLATION

(1) Install the blend door actuator on the HVAC

housing and tighten the two mounting screws to 2.2

N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the blend

door actuator.

(3) Install the glove box door. Refer to Instrument

Panel System for the procedures.

(4) Install the lower I/P glove box door surround

panel. Refer to Instrument Panel System for the pro-

cedures.

(5) Connect and the battery negative cable.

MODE DOOR ACTUATOR

DESCRIPTION

The mode door actuators for vehicles equipped with

the standard equipment manual temperature control

system are vacuum controlled. The optional Auto-

matic Zone Control (AZC) system uses electric motors

to actuate all mode doors. The service procedures for

both types of actuators are covered by the following

procedures.

Fig. 17 BLEND DOOR ACTUATOR

1 - BLEND DOOR ACTUATOR

2 - ELECTRICAL CONNECTOR

24 - 30 CONTROLSWJ

Page 2108 of 2199

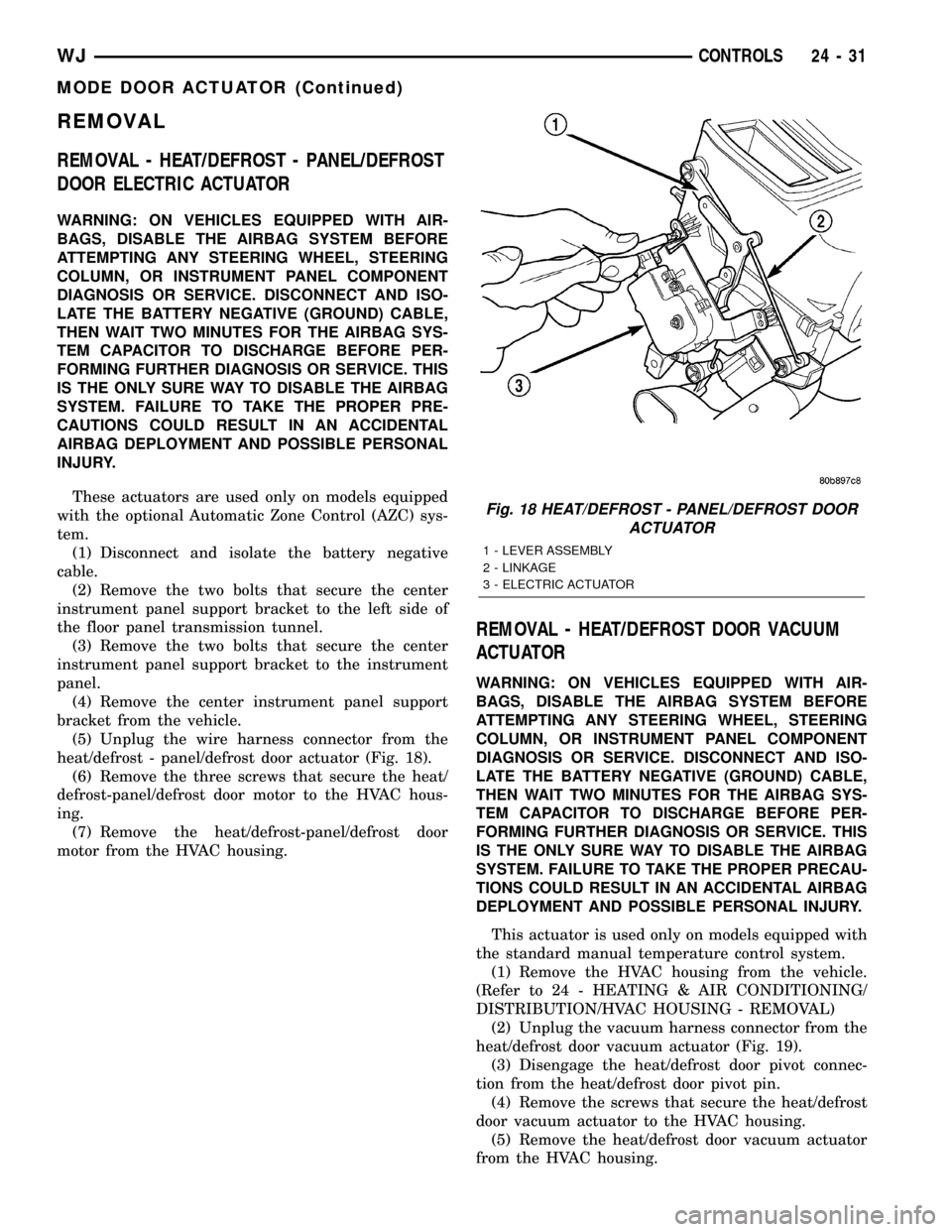

REMOVAL

REMOVAL - HEAT/DEFROST - PANEL/DEFROST

DOOR ELECTRIC ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

These actuators are used only on models equipped

with the optional Automatic Zone Control (AZC) sys-

tem.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two bolts that secure the center

instrument panel support bracket to the left side of

the floor panel transmission tunnel.

(3) Remove the two bolts that secure the center

instrument panel support bracket to the instrument

panel.

(4) Remove the center instrument panel support

bracket from the vehicle.

(5) Unplug the wire harness connector from the

heat/defrost - panel/defrost door actuator (Fig. 18).

(6) Remove the three screws that secure the heat/

defrost-panel/defrost door motor to the HVAC hous-

ing.

(7) Remove the heat/defrost-panel/defrost door

motor from the HVAC housing.

REMOVAL - HEAT/DEFROST DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRECAU-

TIONS COULD RESULT IN AN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

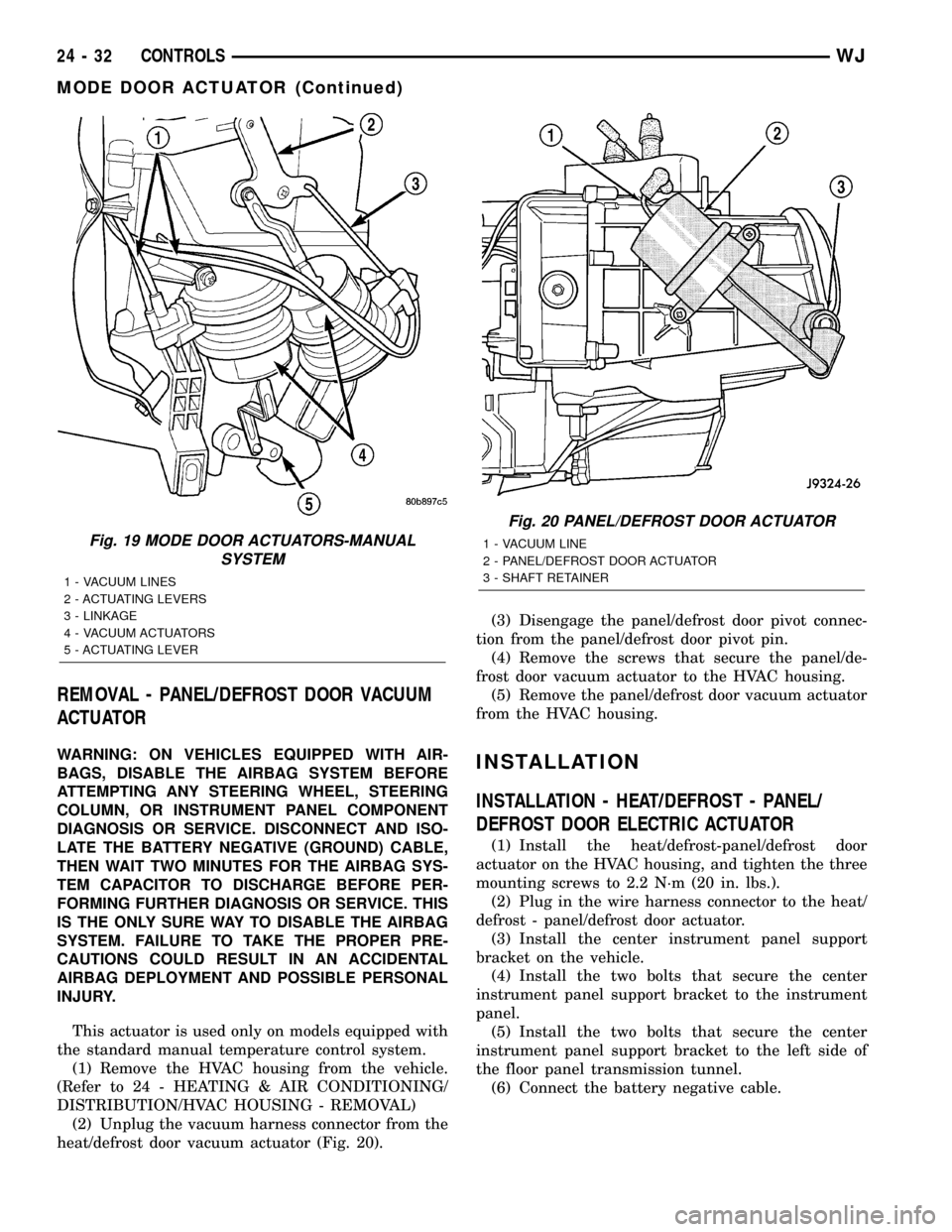

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Unplug the vacuum harness connector from the

heat/defrost door vacuum actuator (Fig. 19).

(3) Disengage the heat/defrost door pivot connec-

tion from the heat/defrost door pivot pin.

(4) Remove the screws that secure the heat/defrost

door vacuum actuator to the HVAC housing.

(5) Remove the heat/defrost door vacuum actuator

from the HVAC housing.

Fig. 18 HEAT/DEFROST - PANEL/DEFROST DOOR

ACTUATOR

1 - LEVER ASSEMBLY

2 - LINKAGE

3 - ELECTRIC ACTUATOR

WJCONTROLS 24 - 31

MODE DOOR ACTUATOR (Continued)

Page 2109 of 2199

REMOVAL - PANEL/DEFROST DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

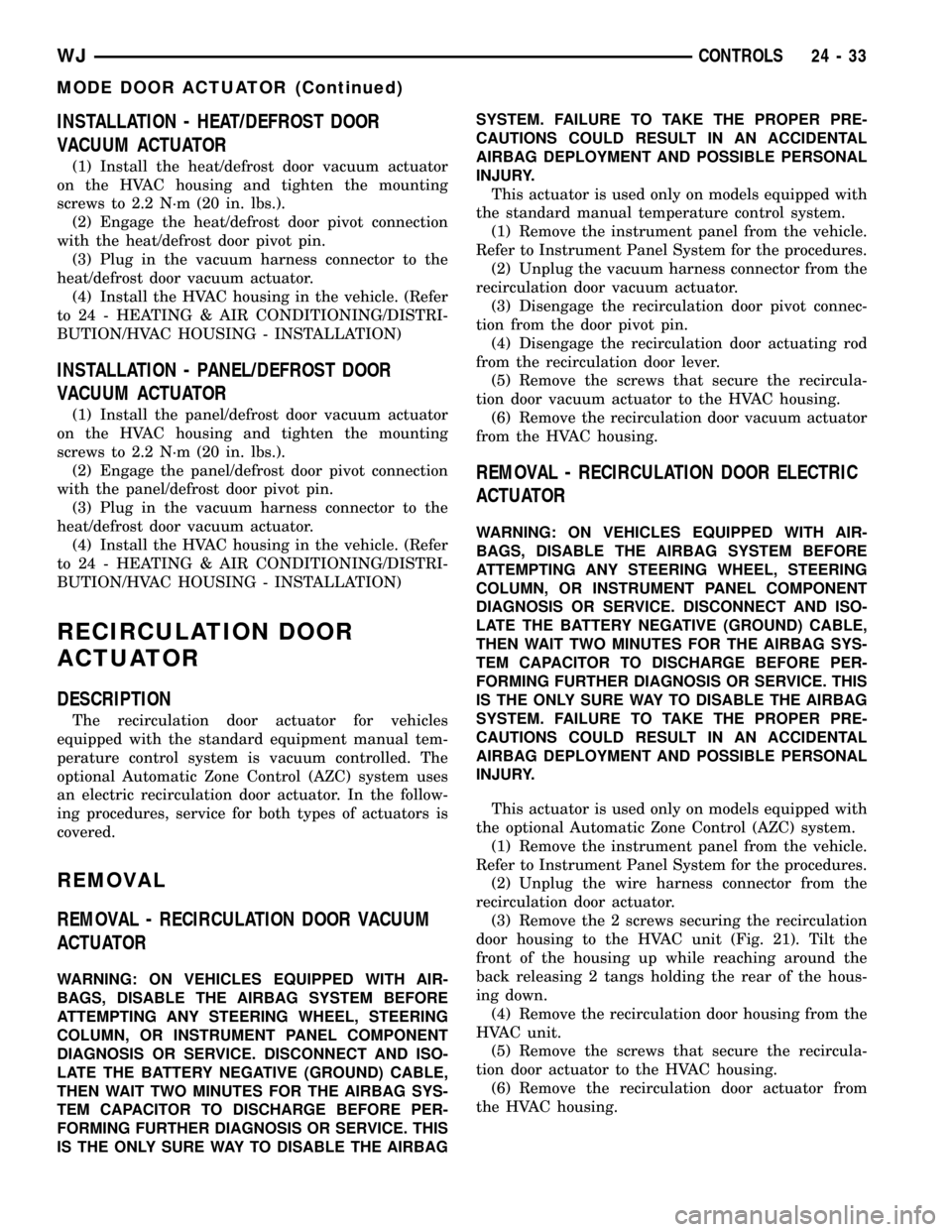

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Unplug the vacuum harness connector from the

heat/defrost door vacuum actuator (Fig. 20).(3) Disengage the panel/defrost door pivot connec-

tion from the panel/defrost door pivot pin.

(4) Remove the screws that secure the panel/de-

frost door vacuum actuator to the HVAC housing.

(5) Remove the panel/defrost door vacuum actuator

from the HVAC housing.INSTALLATION

INSTALLATION - HEAT/DEFROST - PANEL/

DEFROST DOOR ELECTRIC ACTUATOR

(1) Install the heat/defrost-panel/defrost door

actuator on the HVAC housing, and tighten the three

mounting screws to 2.2 N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the heat/

defrost - panel/defrost door actuator.

(3) Install the center instrument panel support

bracket on the vehicle.

(4) Install the two bolts that secure the center

instrument panel support bracket to the instrument

panel.

(5) Install the two bolts that secure the center

instrument panel support bracket to the left side of

the floor panel transmission tunnel.

(6) Connect the battery negative cable.

Fig. 19 MODE DOOR ACTUATORS-MANUAL

SYSTEM

1 - VACUUM LINES

2 - ACTUATING LEVERS

3 - LINKAGE

4 - VACUUM ACTUATORS

5 - ACTUATING LEVER

Fig. 20 PANEL/DEFROST DOOR ACTUATOR

1 - VACUUM LINE

2 - PANEL/DEFROST DOOR ACTUATOR

3 - SHAFT RETAINER

24 - 32 CONTROLSWJ

MODE DOOR ACTUATOR (Continued)

Page 2110 of 2199

INSTALLATION - HEAT/DEFROST DOOR

VACUUM ACTUATOR

(1) Install the heat/defrost door vacuum actuator

on the HVAC housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Engage the heat/defrost door pivot connection

with the heat/defrost door pivot pin.

(3) Plug in the vacuum harness connector to the

heat/defrost door vacuum actuator.

(4) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

INSTALLATION - PANEL/DEFROST DOOR

VACUUM ACTUATOR

(1) Install the panel/defrost door vacuum actuator

on the HVAC housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Engage the panel/defrost door pivot connection

with the panel/defrost door pivot pin.

(3) Plug in the vacuum harness connector to the

heat/defrost door vacuum actuator.

(4) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator for vehicles

equipped with the standard equipment manual tem-

perature control system is vacuum controlled. The

optional Automatic Zone Control (AZC) system uses

an electric recirculation door actuator. In the follow-

ing procedures, service for both types of actuators is

covered.

REMOVAL

REMOVAL - RECIRCULATION DOOR VACUUM

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAGSYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the standard manual temperature control system.

(1) Remove the instrument panel from the vehicle.

Refer to Instrument Panel System for the procedures.

(2) Unplug the vacuum harness connector from the

recirculation door vacuum actuator.

(3) Disengage the recirculation door pivot connec-

tion from the door pivot pin.

(4) Disengage the recirculation door actuating rod

from the recirculation door lever.

(5) Remove the screws that secure the recircula-

tion door vacuum actuator to the HVAC housing.

(6) Remove the recirculation door vacuum actuator

from the HVAC housing.

REMOVAL - RECIRCULATION DOOR ELECTRIC

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

This actuator is used only on models equipped with

the optional Automatic Zone Control (AZC) system.

(1) Remove the instrument panel from the vehicle.

Refer to Instrument Panel System for the procedures.

(2) Unplug the wire harness connector from the

recirculation door actuator.

(3) Remove the 2 screws securing the recirculation

door housing to the HVAC unit (Fig. 21). Tilt the

front of the housing up while reaching around the

back releasing 2 tangs holding the rear of the hous-

ing down.

(4) Remove the recirculation door housing from the

HVAC unit.

(5) Remove the screws that secure the recircula-

tion door actuator to the HVAC housing.

(6) Remove the recirculation door actuator from

the HVAC housing.

WJCONTROLS 24 - 33

MODE DOOR ACTUATOR (Continued)