Power distribution center JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1000 of 2199

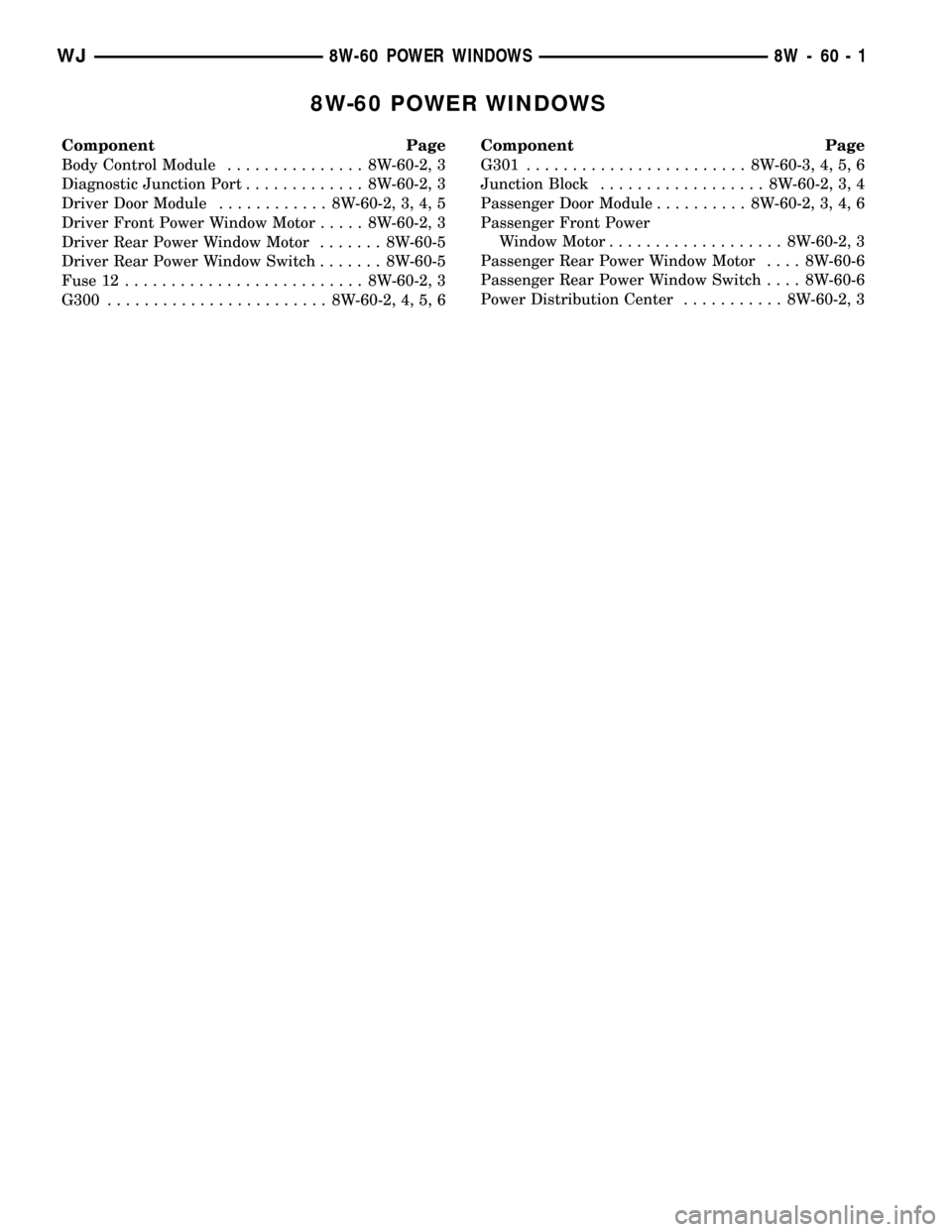

8W-60 POWER WINDOWS

Component Page

Body Control Module............... 8W-60-2, 3

Diagnostic Junction Port............. 8W-60-2, 3

Driver Door Module............ 8W-60-2, 3, 4, 5

Driver Front Power Window Motor..... 8W-60-2, 3

Driver Rear Power Window Motor....... 8W-60-5

Driver Rear Power Window Switch....... 8W-60-5

Fuse 12.......................... 8W-60-2, 3

G300........................ 8W-60-2, 4, 5, 6Component Page

G301........................ 8W-60-3, 4, 5, 6

Junction Block.................. 8W-60-2, 3, 4

Passenger Door Module.......... 8W-60-2, 3, 4, 6

Passenger Front Power

Window Motor................... 8W-60-2, 3

Passenger Rear Power Window Motor.... 8W-60-6

Passenger Rear Power Window Switch.... 8W-60-6

Power Distribution Center........... 8W-60-2, 3

WJ8W-60 POWER WINDOWS 8W - 60 - 1

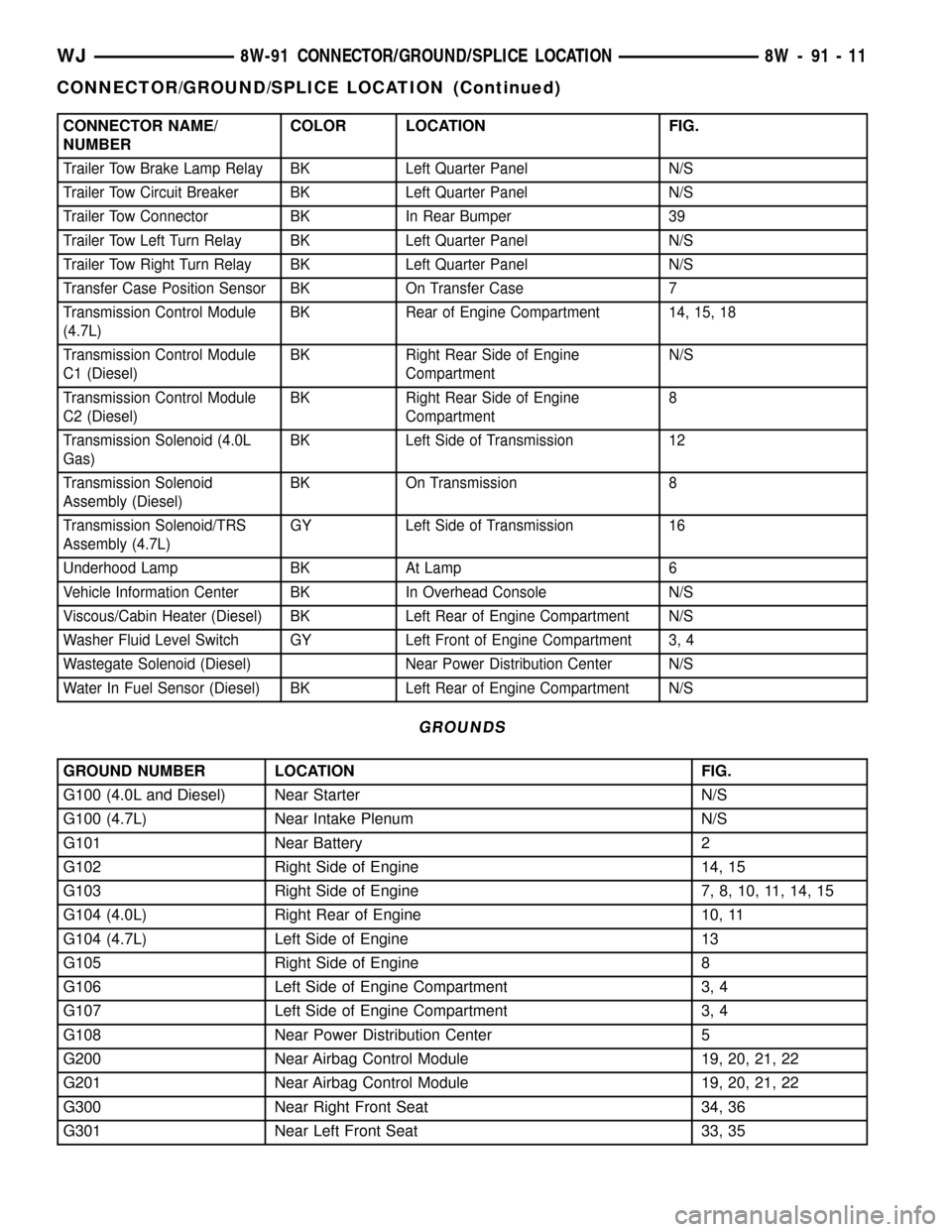

Page 1186 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Trailer Tow Brake Lamp Relay BK Left Quarter Panel N/S

Trailer Tow Circuit Breaker BK Left Quarter Panel N/S

Trailer Tow Connector BK In Rear Bumper 39

Trailer Tow Left Turn Relay BK Left Quarter Panel N/S

Trailer Tow Right Turn Relay BK Left Quarter Panel N/S

Transfer Case Position Sensor BK On Transfer Case 7

Transmission Control Module

(4.7L)BK Rear of Engine Compartment 14, 15, 18

Transmission Control Module

C1 (Diesel)BK Right Rear Side of Engine

CompartmentN/S

Transmission Control Module

C2 (Diesel)BK Right Rear Side of Engine

Compartment8

Transmission Solenoid (4.0L

Gas)BK Left Side of Transmission 12

Transmission Solenoid

Assembly (Diesel)BK On Transmission 8

Transmission Solenoid/TRS

Assembly (4.7L)GY Left Side of Transmission 16

Underhood Lamp BK At Lamp 6

Vehicle Information Center BK In Overhead Console N/S

Viscous/Cabin Heater (Diesel) BK Left Rear of Engine Compartment N/S

Washer Fluid Level Switch GY Left Front of Engine Compartment 3, 4

Wastegate Solenoid (Diesel) Near Power Distribution Center N/S

Water In Fuel Sensor (Diesel) BK Left Rear of Engine Compartment N/S

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 (4.0L and Diesel) Near Starter N/S

G100 (4.7L) Near Intake Plenum N/S

G101 Near Battery 2

G102 Right Side of Engine 14, 15

G103 Right Side of Engine 7, 8, 10, 11, 14, 15

G104 (4.0L) Right Rear of Engine 10, 11

G104 (4.7L) Left Side of Engine 13

G105 Right Side of Engine 8

G106 Left Side of Engine Compartment 3, 4

G107 Left Side of Engine Compartment 3, 4

G108 Near Power Distribution Center 5

G200 Near Airbag Control Module 19, 20, 21, 22

G201 Near Airbag Control Module 19, 20, 21, 22

G300 Near Right Front Seat 34, 36

G301 Near Left Front Seat 33, 35

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

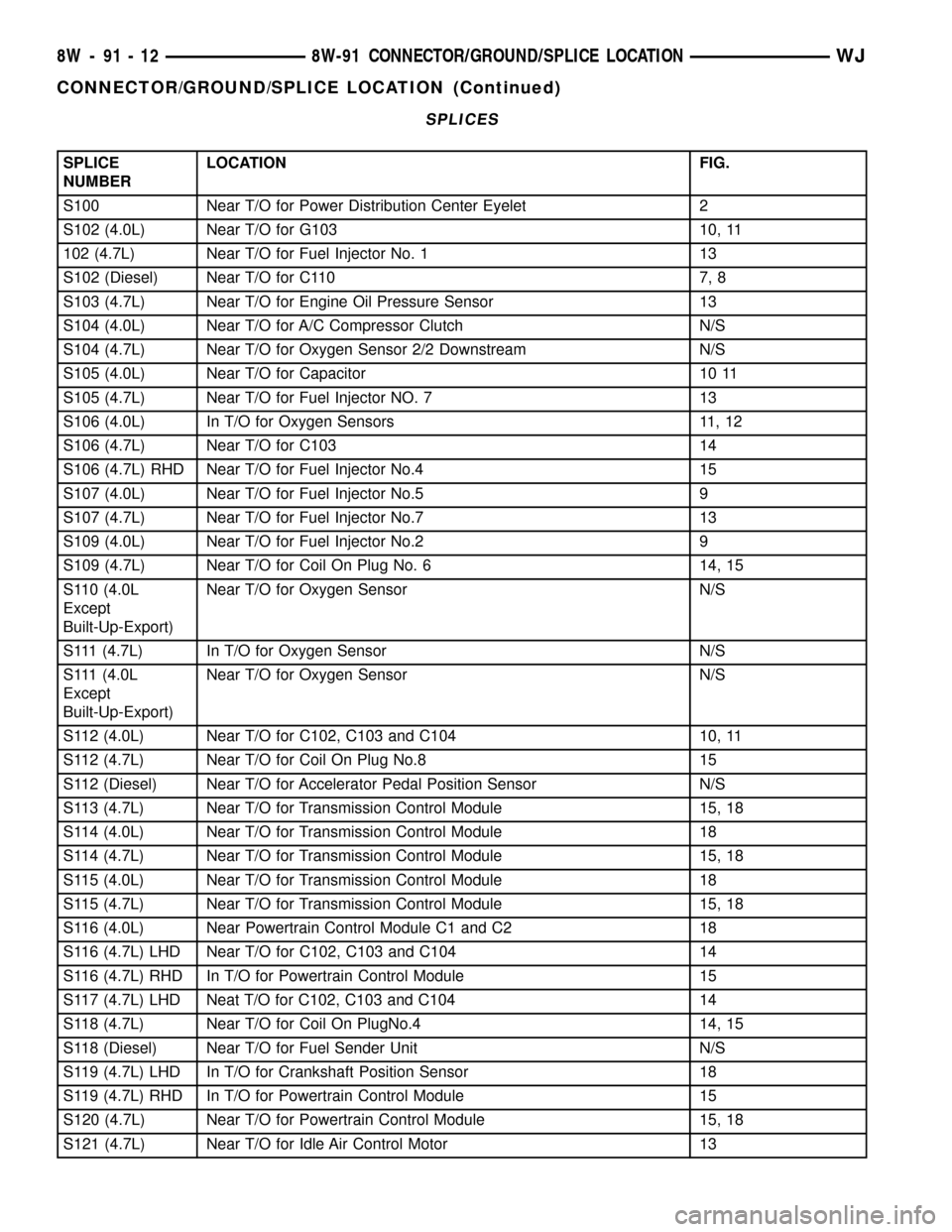

Page 1187 of 2199

SPLICES

SPLICE

NUMBERLOCATION FIG.

S100 Near T/O for Power Distribution Center Eyelet 2

S102 (4.0L) Near T/O for G103 10, 11

102 (4.7L) Near T/O for Fuel Injector No. 1 13

S102 (Diesel) Near T/O for C110 7, 8

S103 (4.7L) Near T/O for Engine Oil Pressure Sensor 13

S104 (4.0L) Near T/O for A/C Compressor Clutch N/S

S104 (4.7L) Near T/O for Oxygen Sensor 2/2 Downstream N/S

S105 (4.0L) Near T/O for Capacitor 10 11

S105 (4.7L) Near T/O for Fuel Injector NO. 7 13

S106 (4.0L) In T/O for Oxygen Sensors 11, 12

S106 (4.7L) Near T/O for C103 14

S106 (4.7L) RHD Near T/O for Fuel Injector No.4 15

S107 (4.0L) Near T/O for Fuel Injector No.5 9

S107 (4.7L) Near T/O for Fuel Injector No.7 13

S109 (4.0L) Near T/O for Fuel Injector No.2 9

S109 (4.7L) Near T/O for Coil On Plug No. 6 14, 15

S110 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S111 (4.7L) In T/O for Oxygen Sensor N/S

S111 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S112 (4.0L) Near T/O for C102, C103 and C104 10, 11

S112 (4.7L) Near T/O for Coil On Plug No.8 15

S112 (Diesel) Near T/O for Accelerator Pedal Position Sensor N/S

S113 (4.7L) Near T/O for Transmission Control Module 15, 18

S114 (4.0L) Near T/O for Transmission Control Module 18

S114 (4.7L) Near T/O for Transmission Control Module 15, 18

S115 (4.0L) Near T/O for Transmission Control Module 18

S115 (4.7L) Near T/O for Transmission Control Module 15, 18

S116 (4.0L) Near Powertrain Control Module C1 and C2 18

S116 (4.7L) LHD Near T/O for C102, C103 and C104 14

S116 (4.7L) RHD In T/O for Powertrain Control Module 15

S117 (4.7L) LHD Neat T/O for C102, C103 and C104 14

S118 (4.7L) Near T/O for Coil On PlugNo.4 14, 15

S118 (Diesel) Near T/O for Fuel Sender Unit N/S

S119 (4.7L) LHD In T/O for Crankshaft Position Sensor 18

S119 (4.7L) RHD In T/O for Powertrain Control Module 15

S120 (4.7L) Near T/O for Powertrain Control Module 15, 18

S121 (4.7L) Near T/O for Idle Air Control Motor 13

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

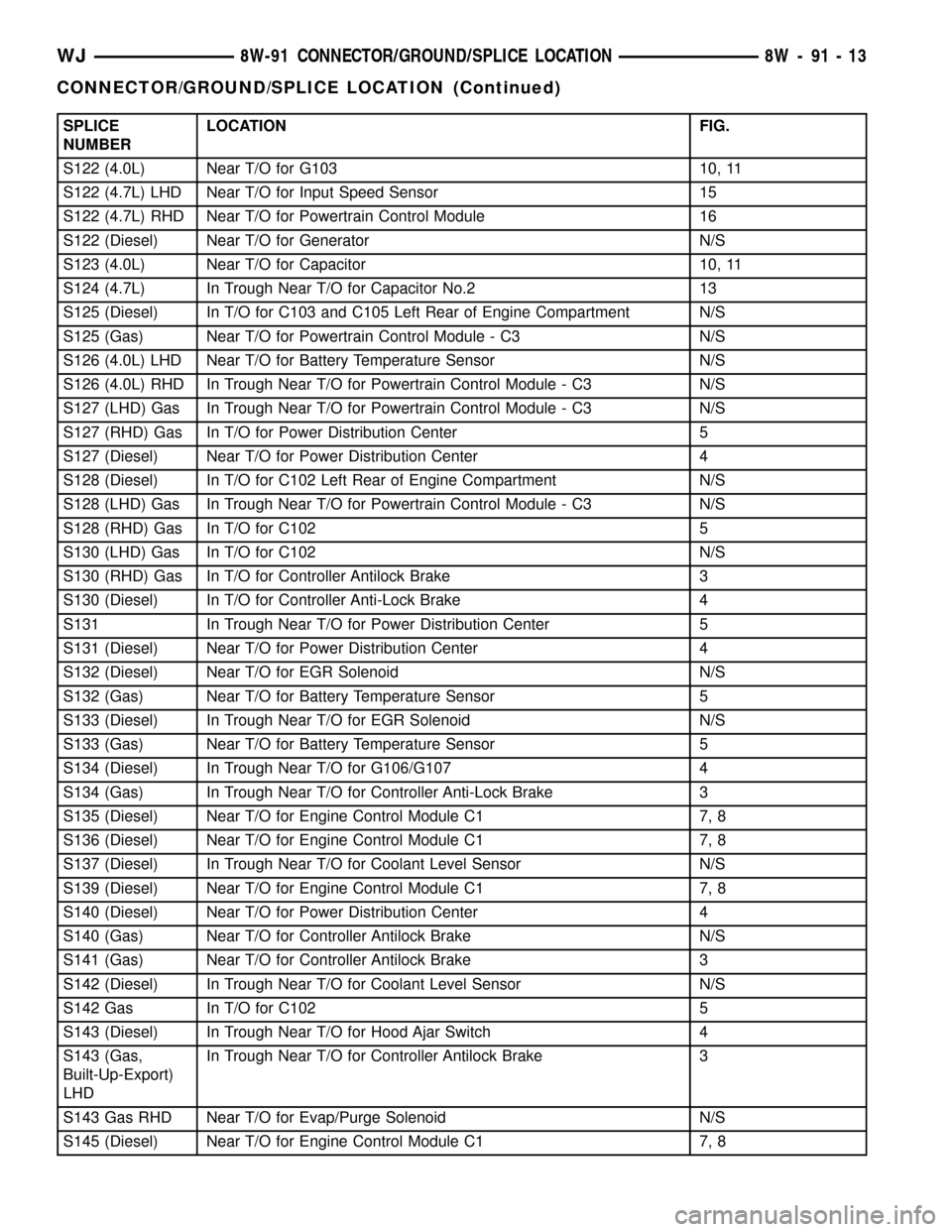

Page 1188 of 2199

SPLICE

NUMBERLOCATION FIG.

S122 (4.0L) Near T/O for G103 10, 11

S122 (4.7L) LHD Near T/O for Input Speed Sensor 15

S122 (4.7L) RHD Near T/O for Powertrain Control Module 16

S122 (Diesel) Near T/O for Generator N/S

S123 (4.0L) Near T/O for Capacitor 10, 11

S124 (4.7L) In Trough Near T/O for Capacitor No.2 13

S125 (Diesel) In T/O for C103 and C105 Left Rear of Engine Compartment N/S

S125 (Gas) Near T/O for Powertrain Control Module - C3 N/S

S126 (4.0L) LHD Near T/O for Battery Temperature Sensor N/S

S126 (4.0L) RHD In Trough Near T/O for Powertrain Control Module - C3 N/S

S127 (LHD) Gas In Trough Near T/O for Powertrain Control Module - C3 N/S

S127 (RHD) Gas In T/O for Power Distribution Center 5

S127 (Diesel) Near T/O for Power Distribution Center 4

S128 (Diesel) In T/O for C102 Left Rear of Engine Compartment N/S

S128 (LHD) Gas In Trough Near T/O for Powertrain Control Module - C3 N/S

S128 (RHD) Gas In T/O for C102 5

S130 (LHD) Gas In T/O for C102 N/S

S130 (RHD) Gas In T/O for Controller Antilock Brake 3

S130 (Diesel) In T/O for Controller Anti-Lock Brake 4

S131 In Trough Near T/O for Power Distribution Center 5

S131 (Diesel) Near T/O for Power Distribution Center 4

S132 (Diesel) Near T/O for EGR Solenoid N/S

S132 (Gas) Near T/O for Battery Temperature Sensor 5

S133 (Diesel) In Trough Near T/O for EGR Solenoid N/S

S133 (Gas) Near T/O for Battery Temperature Sensor 5

S134 (Diesel) In Trough Near T/O for G106/G107 4

S134 (Gas) In Trough Near T/O for Controller Anti-Lock Brake 3

S135 (Diesel) Near T/O for Engine Control Module C1 7, 8

S136 (Diesel) Near T/O for Engine Control Module C1 7, 8

S137 (Diesel) In Trough Near T/O for Coolant Level Sensor N/S

S139 (Diesel) Near T/O for Engine Control Module C1 7, 8

S140 (Diesel) Near T/O for Power Distribution Center 4

S140 (Gas) Near T/O for Controller Antilock Brake N/S

S141 (Gas) Near T/O for Controller Antilock Brake 3

S142 (Diesel) In Trough Near T/O for Coolant Level Sensor N/S

S142 Gas In T/O for C102 5

S143 (Diesel) In Trough Near T/O for Hood Ajar Switch 4

S143 (Gas,

Built-Up-Export)

LHDIn Trough Near T/O for Controller Antilock Brake 3

S143 Gas RHD Near T/O for Evap/Purge Solenoid N/S

S145 (Diesel) Near T/O for Engine Control Module C1 7, 8

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1226 of 2199

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

CIGAR LIGHTER OUTLET DOOR SPRING

REMOVAL.............................3

INSTALLATION..........................3

IOD FUSE

DESCRIPTION..........................3

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

JUNCTION BLOCK

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

POWER DISTRIBUTION CENTER

DESCRIPTION..........................7

OPERATION............................8

REMOVAL.............................8

DISASSEMBLY

POWER DISTRIBUTION CENTER

DISASSEMBLY........................9ASSEMBLY

POWER DISTRIBUTION CENTER

ASSEMBLY..........................11

INSTALLATION.........................12

POWER OUTLET

DESCRIPTION - FRONT POWER OUTLET....12

OPERATION - FRONT POWER OUTLET......12

DIAGNOSIS AND TESTING - POWER OUTLET . 12

REMOVAL.............................13

INSTALLATION.........................13

POWER OUTLET RELAY

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING - POWER OUTLET

RELAY..............................14

REMOVAL.............................15

INSTALLATION.........................15

IOD WIRE HARNESS CONNECTOR

DESCRIPTION.........................15

OPERATION...........................15

FUSE COVER

REMOVAL.............................16

INSTALLATION.........................16

REAR POWER OUTLET

DESCRIPTION - REAR POWER OUTLET.....16

OPERATION - REAR POWER OUTLET.......17

DIAGNOSIS AND TESTING - REAR POWER

OUTLET............................17

REMOVAL.............................17

INSTALLATION.........................18

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Power Distribution Center (PDC)

²Junction Block (JB)

²Power Outlets

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses²Circuit splice blocks

²Flashers

²Fusible links

²Standard and Micro-Relays

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components. Refer to Wir-

ing Diagrams for complete circuit diagrams.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the standard and optional factory-in-

stalled electrical and electronic powertrain, chassis,

safety, security, comfort and convenience systems. At

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1227 of 2199

the same time, the power distribution system was

designed to provide ready access to these electrical

distribution points for the vehicle technician to use

when conducting diagnosis and repair of faulty cir-

cuits. The power distribution system can also prove

useful for the sourcing of additional electrical circuits

that may be required to provide the electrical current

needed to operate accessories that the vehicle owner

may choose to have installed in the aftermarket.

NOTE: DO NOT ATTEMPT TO SWAP POWER DIS-

TRIBUTION CENTERS FROM ONE VEHICLE TO

ANOTHER. MOST OF THESE ASSEMBLIES ARE

VEHICLE FEATURE SPECIFIC AND THEREFORE

NOT INTERCHANGEABLE. ALWAYS USE THE COR-

RECT PART NUMBERED ASSEMBLY WHEN DIAG-

NOSING OR REPLACING A POWER DISTRIBUTION

CENTER.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

A cigar lighter outlet is standard equipment on

this model. On models equipped with the optional

Smoker's Package, the cigar lighter knob and heating

element are included. On models without the Smok-

er's Package, the cigar lighter outlet is equipped with

a snap fit plastic cap and is treated as an extra

accessory power outlet. The cigar lighter outlet is

installed in the instrument panel center lower bezel,

which is located near the bottom of the instrument

panel center stack area, below the heater and air

conditioner controls. The cigar lighter outlet is

secured by a snap fit within the center lower bezel.The cigar lighter outlet, plastic cap and the knob

and heating element unit are available for service

replacement. These components cannot be repaired

and, if faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or outlet shell. The receptacle shell is

connected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The cigar lighter receives battery voltage from a fuse

in the junction block when the ignition switch is in

the Accessory or On positions.

The cigar lighter knob and heating element are

encased within a spring-loaded housing, which also

features a sliding protective heat shield. When the

knob and heating element are inserted in the outlet

shell, the heating element resistor coil is grounded

through its housing to the outlet shell. If the cigar

lighter knob is pushed inward, the heat shield slides

up toward the knob exposing the heating element,

and the heating element extends from the housing

toward the insulated contact in the bottom of the

outlet shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the outlet shell. These clips engage and hold the

heating element against the insulated contact long

enough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the outlet shell, the protective heat

shield slides downward on the housing so that the

heating element is recessed and shielded around its

circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For complete circuit diagrams, refer toHorn/Ci-

gar Lighter/Power Outletin Wiring Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused B(+) fuse in

Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION (Continued)

Page 1228 of 2199

the junction block. If OK, go to Step 3. If not OK,

repair the open or short as required.

(3) Remove the cigar lighter knob and element

from the cigar lighter outlet shell. Check for continu-

ity between the inside circumference of the cigar

lighter outlet shell and a good ground. there should

be continuity. If OK, go to Step 4. If not OK, go to

Step 5.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the insulated contact

located at the back of the cigar lighter outlet shell. If

OK, replace the faulty cigar lighter knob and ele-

ment. If not OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument panel center lower bezel.

Check for continuity between the ground circuit cav-

ity of the cigar lighter wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Turn the

ignition switch to the Accessory or On positions.

Check for battery voltage at the fused B(+) circuit

cavity of the cigar lighter wire harness connector. If

OK, replace the faulty cigar lighter outlet. If not OK,

repair the open fused B(+) circuit to the junction

block fuse as required.

CIGAR LIGHTER OUTLET

DOOR SPRING

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the instrument panel center lower

bezel from the I.P. Refer to Body for the procedure.

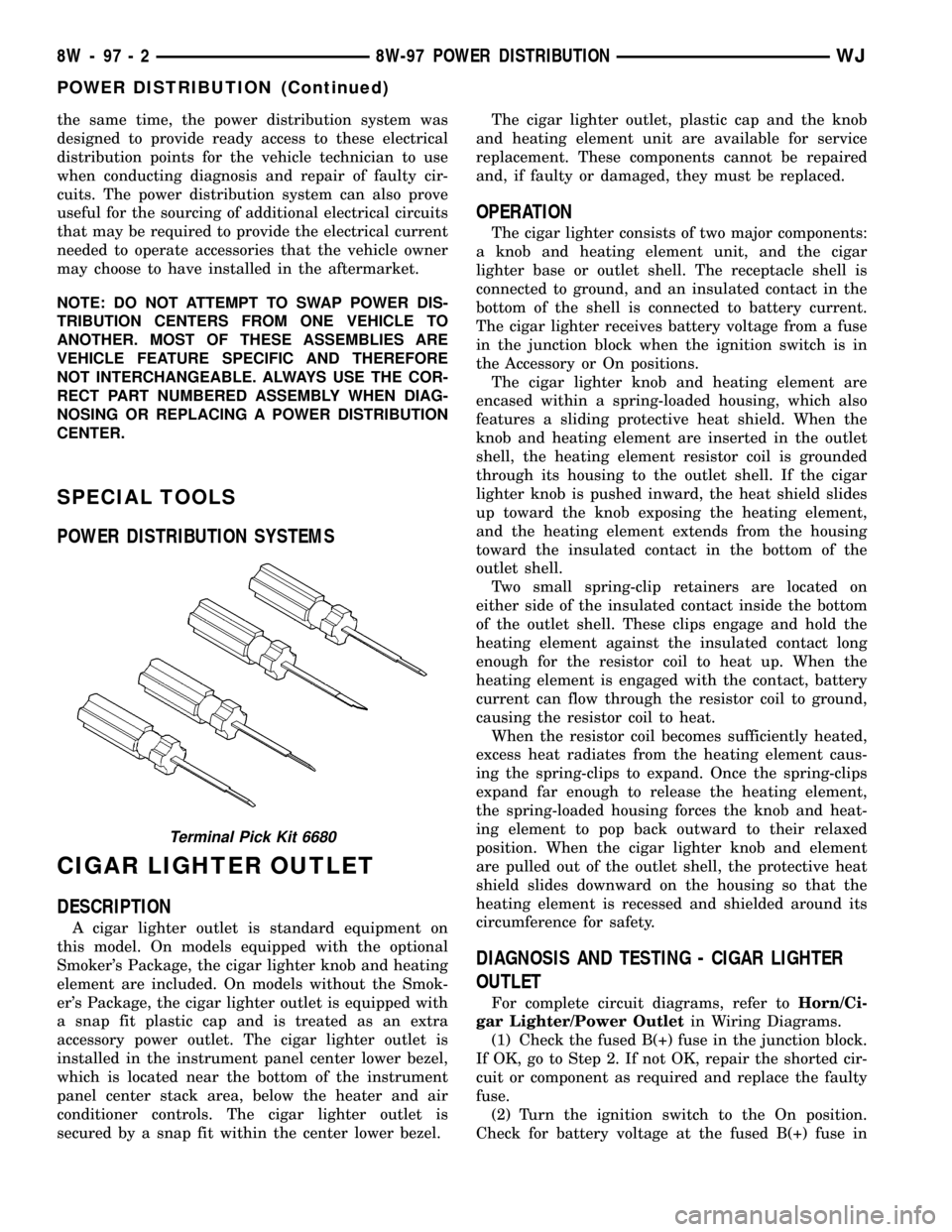

(3) Remove the cigar lighter outlet door spring

from its locating holes (Fig. 1).

INSTALLATION

(1) Install the cigar outlet door spring in its locat-

ing holes.

(2) Install the instrument panel center lower bezel

on the I.P. Refer to Body for the procedure.

(3) Connect the negative battery cable.

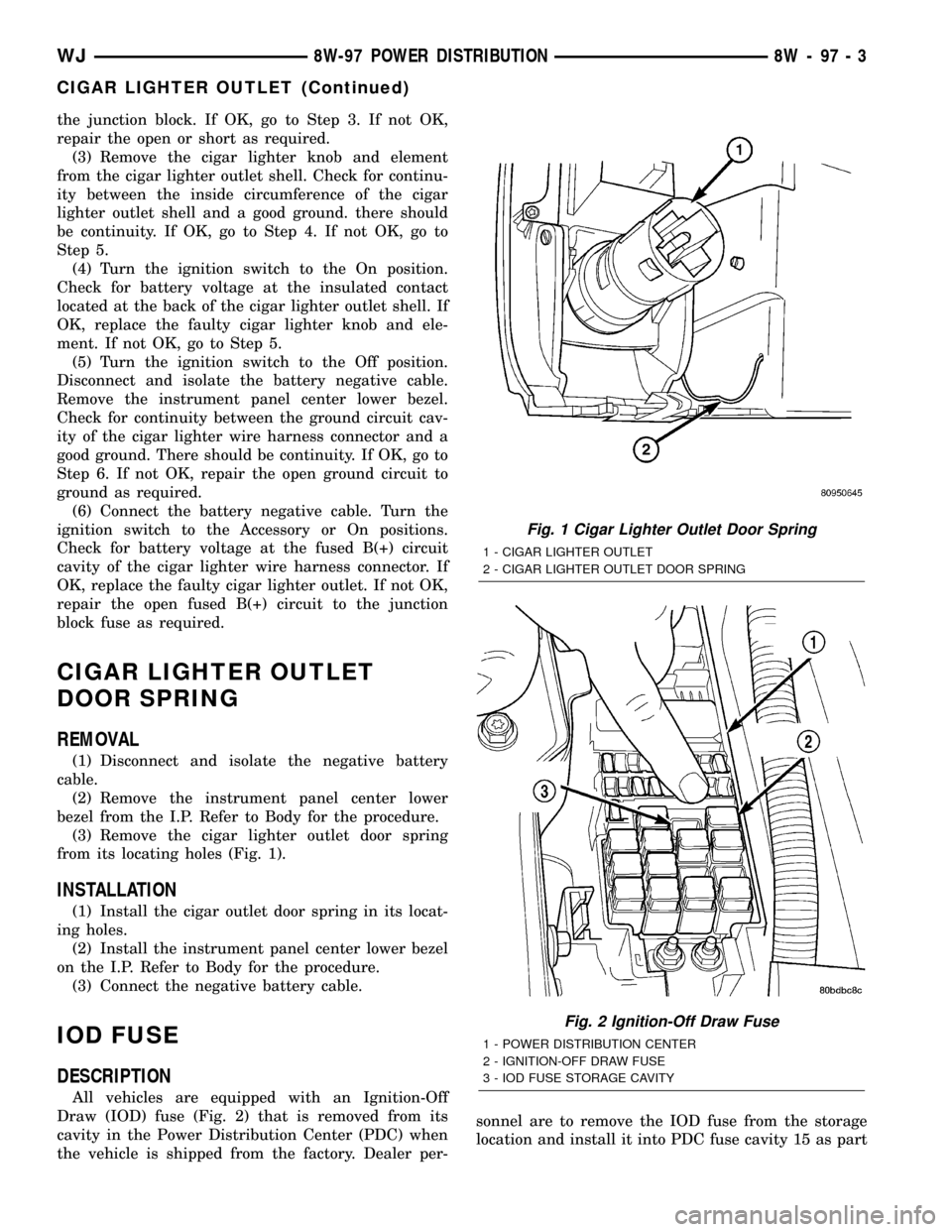

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse (Fig. 2) that is removed from its

cavity in the Power Distribution Center (PDC) when

the vehicle is shipped from the factory. Dealer per-sonnel are to remove the IOD fuse from the storage

location and install it into PDC fuse cavity 15 as part

Fig. 1 Cigar Lighter Outlet Door Spring

1 - CIGAR LIGHTER OUTLET

2 - CIGAR LIGHTER OUTLET DOOR SPRING

Fig. 2 Ignition-Off Draw Fuse

1 - POWER DISTRIBUTION CENTER

2 - IGNITION-OFF DRAW FUSE

3 - IOD FUSE STORAGE CAVITY

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 3

CIGAR LIGHTER OUTLET (Continued)

Page 1229 of 2199

of the preparation procedures performed just prior to

new vehicle delivery.

The PDC has a molded plastic cover that can be

removed to provide service access to all of the fuses

and relays in the PDC. An integral latch and hinges

are molded into the PDC cover for easy removal. A

fuse layout map is integral to the underside of the

PDC cover to ensure proper fuse and relay identifica-

tion. The IOD fuse is a 50 ampere maxi-type car-

tridge fuse and, when removed, it is stored in a spare

fuse cavity within the PDC.

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

removed is to reduce the normal IOD of the vehicle

electrical system during new vehicle transportation

and pre-delivery storage to reduce battery depletion,

while still allowing vehicle operation so that the

vehicle can be loaded, unloaded and moved as needed

by both vehicle transportation company and dealer

personnel.

The IOD fuse is removed from PDC fuse cavity 15

when the vehicle is shipped from the assembly plant.

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation. Once the

vehicle is prepared for delivery, the IOD function of

this fuse becomes transparent and the fuse that has

been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not toexceed about thirty days. However, it must be

remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Battery Systemfor additional service information.

REMOVAL

The Ignition-Off Draw (IOD) fuses normal installa-

tion location is cavity 15 in the power distribution

center. When the vehicle is shipped from the assem-

bly plant the fuse is removed to maintain proper bat-

tery voltage during vehicle storage (in some cases).

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for customer delivery in

order to restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Unlatch and open the cover of the power distri-

bution center.

(3) Remove the IOD fuse from fusecavity 15of

the power distribution center (Fig. 2).

(4) Store the removed IOD fuse by installing it in

the unused fuse storagecavity 11of the PDC (Fig.

2).

(5) Close and latch the power distribution center

cover.

INSTALLATION

(1) Be certain the ignition switch is in the Off posi-

tion.

(2) Unlatch and open the cover of the power distri-

bution center.

(3) Remove the stored IOD fuse from fuse storage

cavity 11of the power distribution center.

(4) Use a thumb to press the IOD fuse firmly down

into power distribution center fusecavity 15.

(5) Close and latch the power distribution center

cover.

8W - 97 - 4 8W-97 POWER DISTRIBUTIONWJ

IOD FUSE (Continued)

Page 1230 of 2199

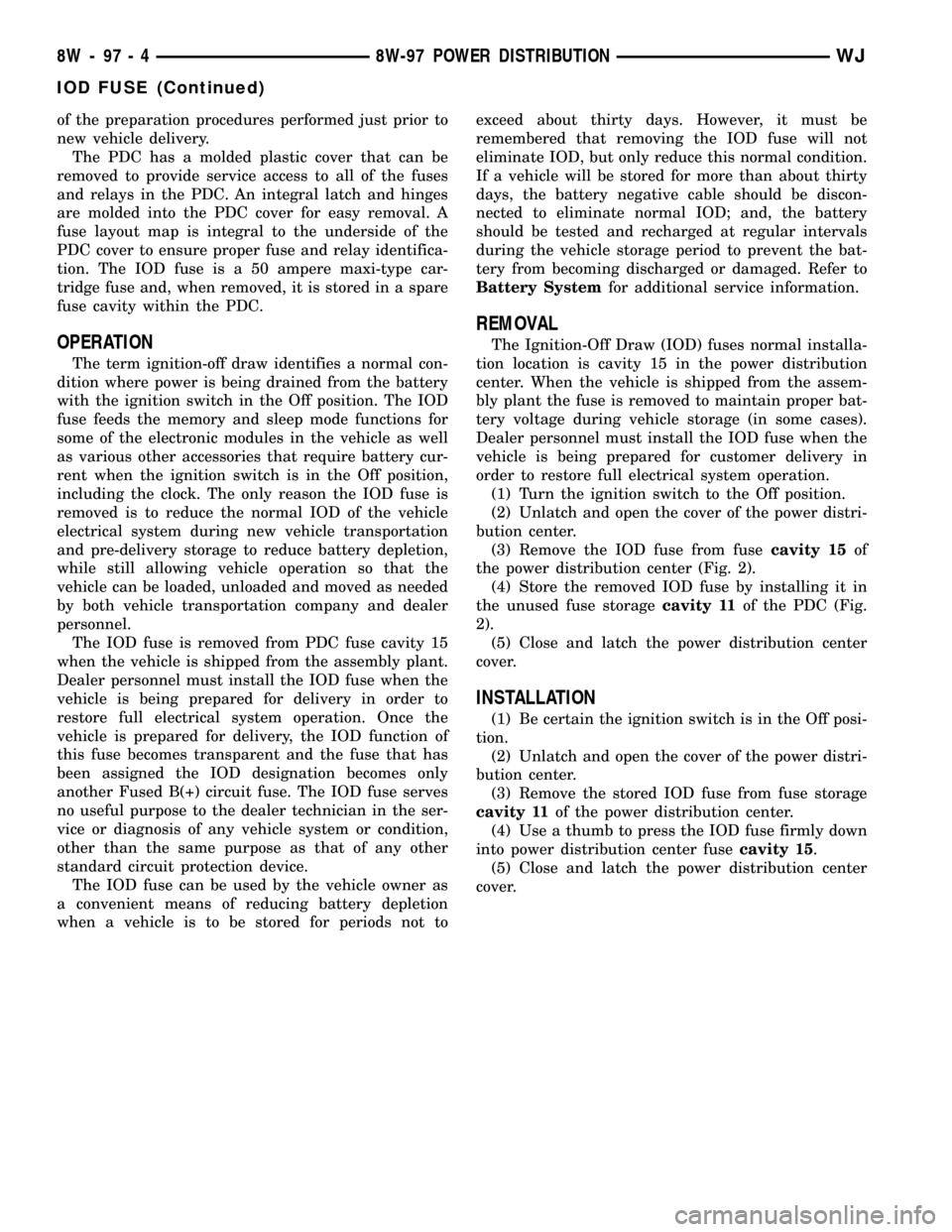

JUNCTION BLOCK

DESCRIPTION

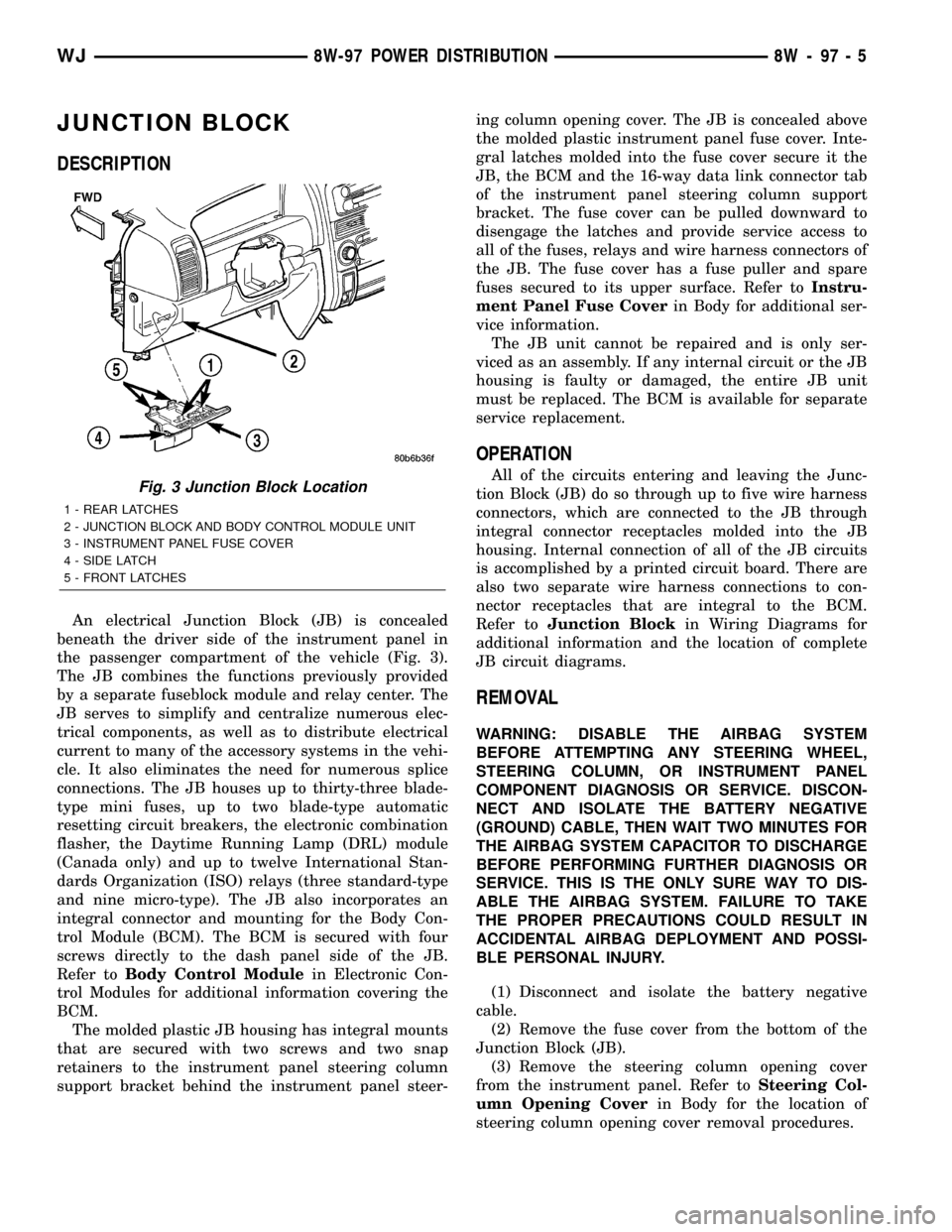

An electrical Junction Block (JB) is concealed

beneath the driver side of the instrument panel in

the passenger compartment of the vehicle (Fig. 3).

The JB combines the functions previously provided

by a separate fuseblock module and relay center. The

JB serves to simplify and centralize numerous elec-

trical components, as well as to distribute electrical

current to many of the accessory systems in the vehi-

cle. It also eliminates the need for numerous splice

connections. The JB houses up to thirty-three blade-

type mini fuses, up to two blade-type automatic

resetting circuit breakers, the electronic combination

flasher, the Daytime Running Lamp (DRL) module

(Canada only) and up to twelve International Stan-

dards Organization (ISO) relays (three standard-type

and nine micro-type). The JB also incorporates an

integral connector and mounting for the Body Con-

trol Module (BCM). The BCM is secured with four

screws directly to the dash panel side of the JB.

Refer toBody Control Modulein Electronic Con-

trol Modules for additional information covering the

BCM.

The molded plastic JB housing has integral mounts

that are secured with two screws and two snap

retainers to the instrument panel steering column

support bracket behind the instrument panel steer-ing column opening cover. The JB is concealed above

the molded plastic instrument panel fuse cover. Inte-

gral latches molded into the fuse cover secure it the

JB, the BCM and the 16-way data link connector tab

of the instrument panel steering column support

bracket. The fuse cover can be pulled downward to

disengage the latches and provide service access to

all of the fuses, relays and wire harness connectors of

the JB. The fuse cover has a fuse puller and spare

fuses secured to its upper surface. Refer toInstru-

ment Panel Fuse Coverin Body for additional ser-

vice information.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced. The BCM is available for separate

service replacement.

OPERATION

All of the circuits entering and leaving the Junc-

tion Block (JB) do so through up to five wire harness

connectors, which are connected to the JB through

integral connector receptacles molded into the JB

housing. Internal connection of all of the JB circuits

is accomplished by a printed circuit board. There are

also two separate wire harness connections to con-

nector receptacles that are integral to the BCM.

Refer toJunction Blockin Wiring Diagrams for

additional information and the location of complete

JB circuit diagrams.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse cover from the bottom of the

Junction Block (JB).

(3) Remove the steering column opening cover

from the instrument panel. Refer toSteering Col-

umn Opening Coverin Body for the location of

steering column opening cover removal procedures.

Fig. 3 Junction Block Location

1 - REAR LATCHES

2 - JUNCTION BLOCK AND BODY CONTROL MODULE UNIT

3 - INSTRUMENT PANEL FUSE COVER

4 - SIDE LATCH

5 - FRONT LATCHES

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 5

Page 1231 of 2199

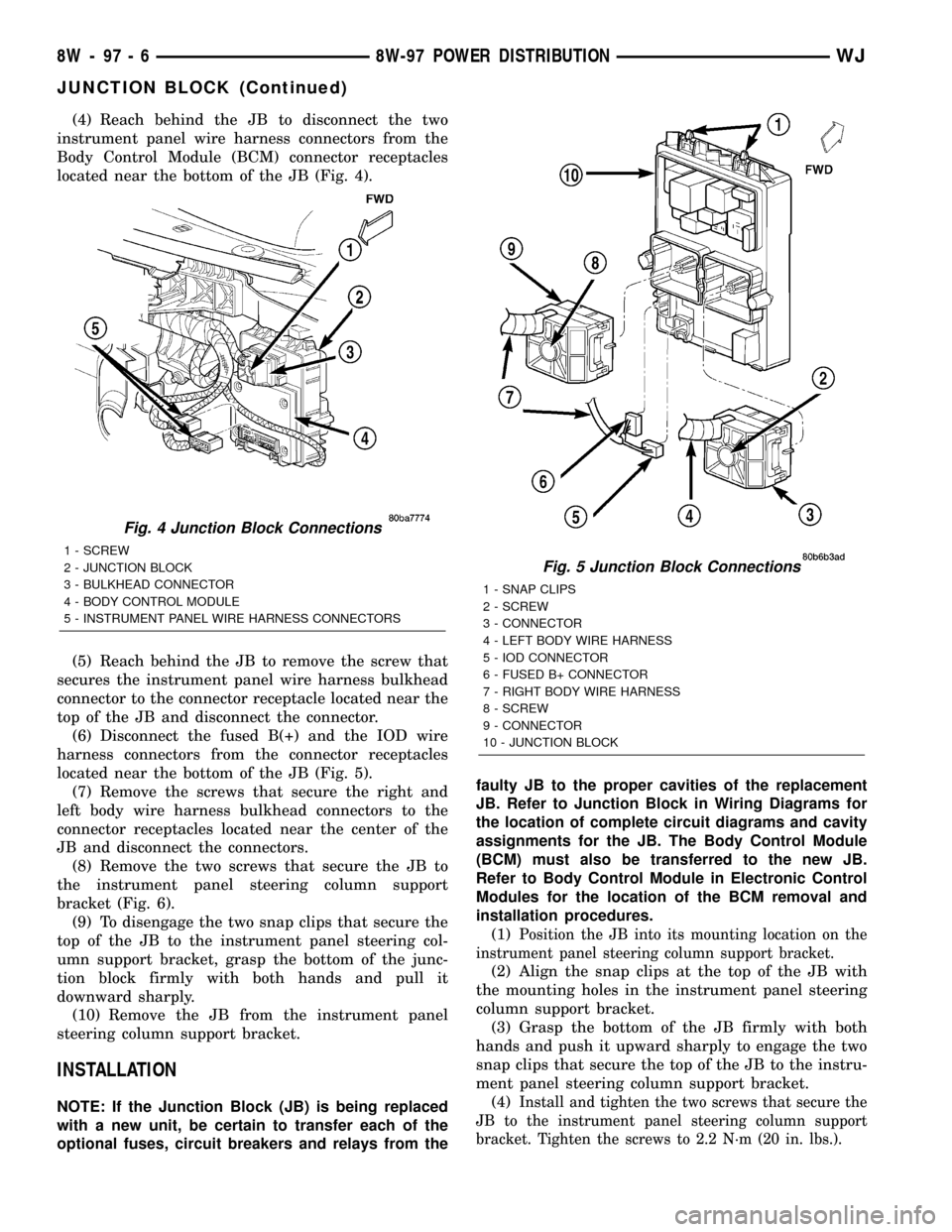

(4) Reach behind the JB to disconnect the two

instrument panel wire harness connectors from the

Body Control Module (BCM) connector receptacles

located near the bottom of the JB (Fig. 4).

(5) Reach behind the JB to remove the screw that

secures the instrument panel wire harness bulkhead

connector to the connector receptacle located near the

top of the JB and disconnect the connector.

(6) Disconnect the fused B(+) and the IOD wire

harness connectors from the connector receptacles

located near the bottom of the JB (Fig. 5).

(7) Remove the screws that secure the right and

left body wire harness bulkhead connectors to the

connector receptacles located near the center of the

JB and disconnect the connectors.

(8) Remove the two screws that secure the JB to

the instrument panel steering column support

bracket (Fig. 6).

(9) To disengage the two snap clips that secure the

top of the JB to the instrument panel steering col-

umn support bracket, grasp the bottom of the junc-

tion block firmly with both hands and pull it

downward sharply.

(10) Remove the JB from the instrument panel

steering column support bracket.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

optional fuses, circuit breakers and relays from thefaulty JB to the proper cavities of the replacement

JB. Refer to Junction Block in Wiring Diagrams for

the location of complete circuit diagrams and cavity

assignments for the JB. The Body Control Module

(BCM) must also be transferred to the new JB.

Refer to Body Control Module in Electronic Control

Modules for the location of the BCM removal and

installation procedures.

(1)

Position the JB into its mounting location on the

instrument panel steering column support bracket.

(2) Align the snap clips at the top of the JB with

the mounting holes in the instrument panel steering

column support bracket.

(3) Grasp the bottom of the JB firmly with both

hands and push it upward sharply to engage the two

snap clips that secure the top of the JB to the instru-

ment panel steering column support bracket.

(4)

Install and tighten the two screws that secure the

JB to the instrument panel steering column support

bracket. Tighten the screws to 2.2 N´m (20 in. lbs.).

Fig. 4 Junction Block Connections

1 - SCREW

2 - JUNCTION BLOCK

3 - BULKHEAD CONNECTOR

4 - BODY CONTROL MODULE

5 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

8W - 97 - 6 8W-97 POWER DISTRIBUTIONWJ

JUNCTION BLOCK (Continued)