spec JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 140 of 2199

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-

tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle.

WJREAR AXLE - 226RBA 3 - 95

REAR AXLE - 226RBA (Continued)

Page 144 of 2199

NOTE: Arbor Discs 6927A has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in axle housing so dial probe and scooter block are

flush against the rearward surface of the pinion

height block (Fig. 8). Hold scooter block in place and

zero the dial indicator face to the pointer. Tighten

dial indicator face lock screw.

(7) With scooter block still in position against the

pinion height block, slowly slide the dial indicator

probe over the edge of the pinion height block.

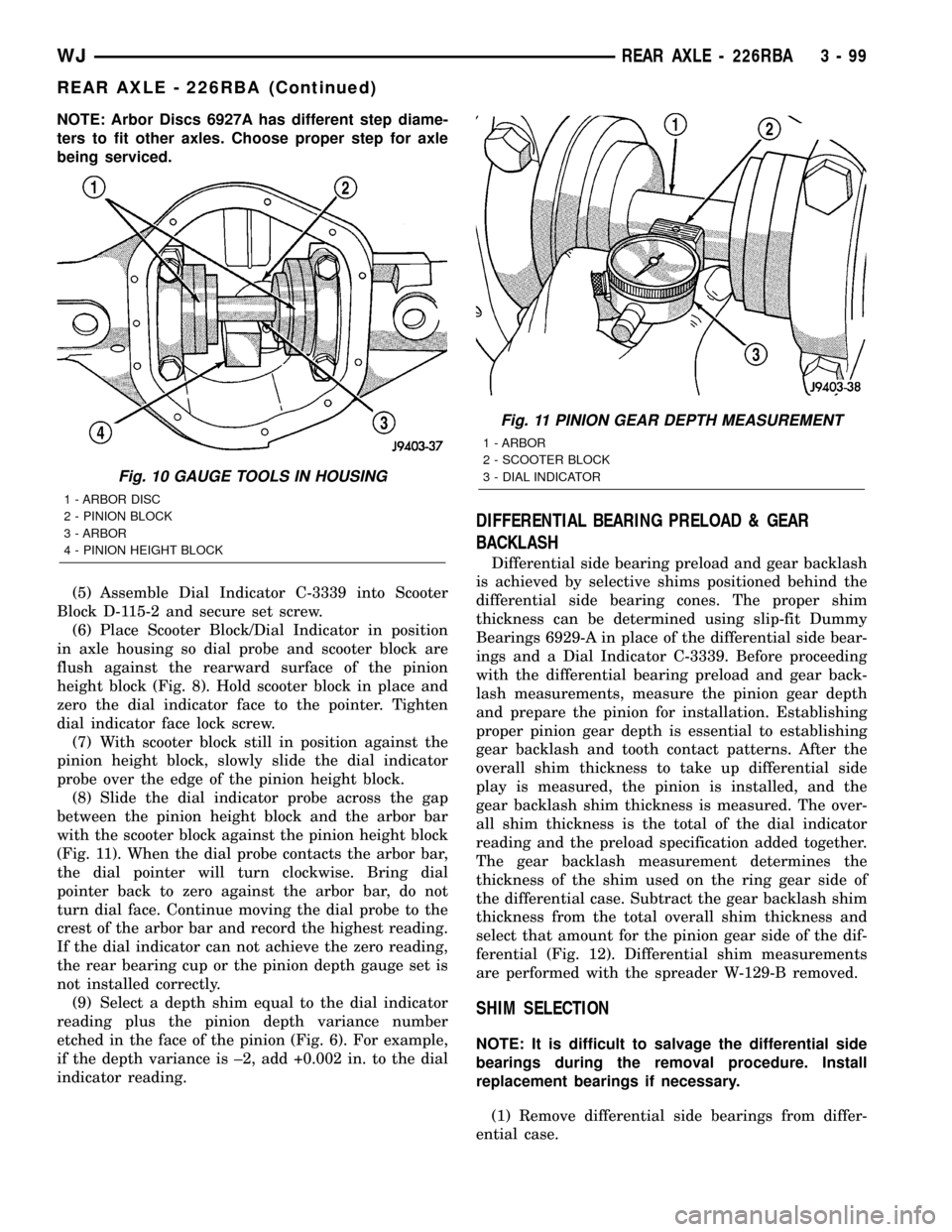

(8) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 11). When the dial probe contacts the arbor bar,

the dial pointer will turn clockwise. Bring dial

pointer back to zero against the arbor bar, do not

turn dial face. Continue moving the dial probe to the

crest of the arbor bar and record the highest reading.

If the dial indicator can not achieve the zero reading,

the rear bearing cup or the pinion depth gauge set is

not installed correctly.

(9) Select a depth shim equal to the dial indicator

reading plus the pinion depth variance number

etched in the face of the pinion (Fig. 6). For example,

if the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

DIFFERENTIAL BEARING PRELOAD & GEAR

BACKLASH

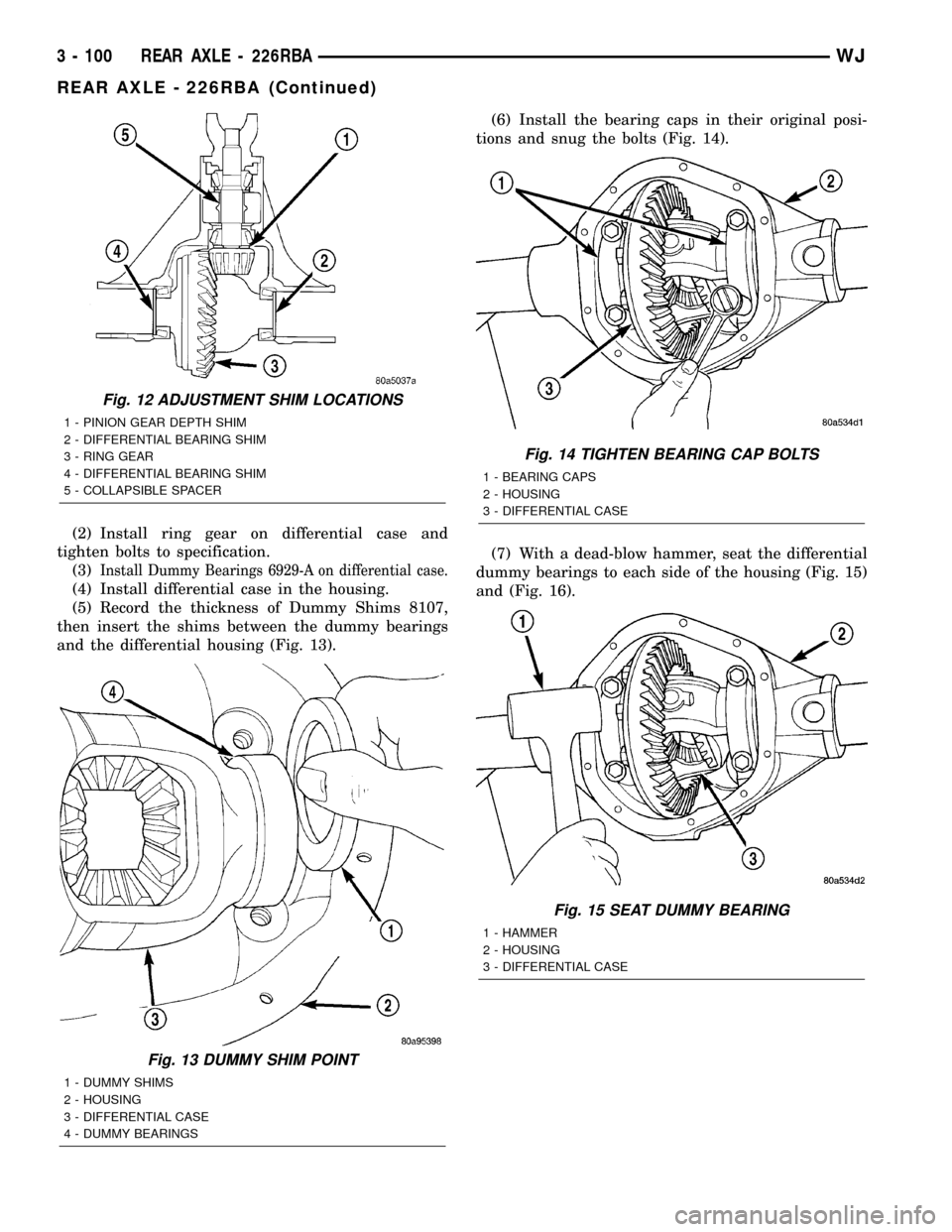

Differential side bearing preload and gear backlash

is achieved by selective shims positioned behind the

differential side bearing cones. The proper shim

thickness can be determined using slip-fit Dummy

Bearings 6929-A in place of the differential side bear-

ings and a Dial Indicator C-3339. Before proceeding

with the differential bearing preload and gear back-

lash measurements, measure the pinion gear depth

and prepare the pinion for installation. Establishing

proper pinion gear depth is essential to establishing

gear backlash and tooth contact patterns. After the

overall shim thickness to take up differential side

play is measured, the pinion is installed, and the

gear backlash shim thickness is measured. The over-

all shim thickness is the total of the dial indicator

reading and the preload specification added together.

The gear backlash measurement determines the

thickness of the shim used on the ring gear side of

the differential case. Subtract the gear backlash shim

thickness from the total overall shim thickness and

select that amount for the pinion gear side of the dif-

ferential (Fig. 12). Differential shim measurements

are performed with the spreader W-129-B removed.

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove differential side bearings from differ-

ential case.

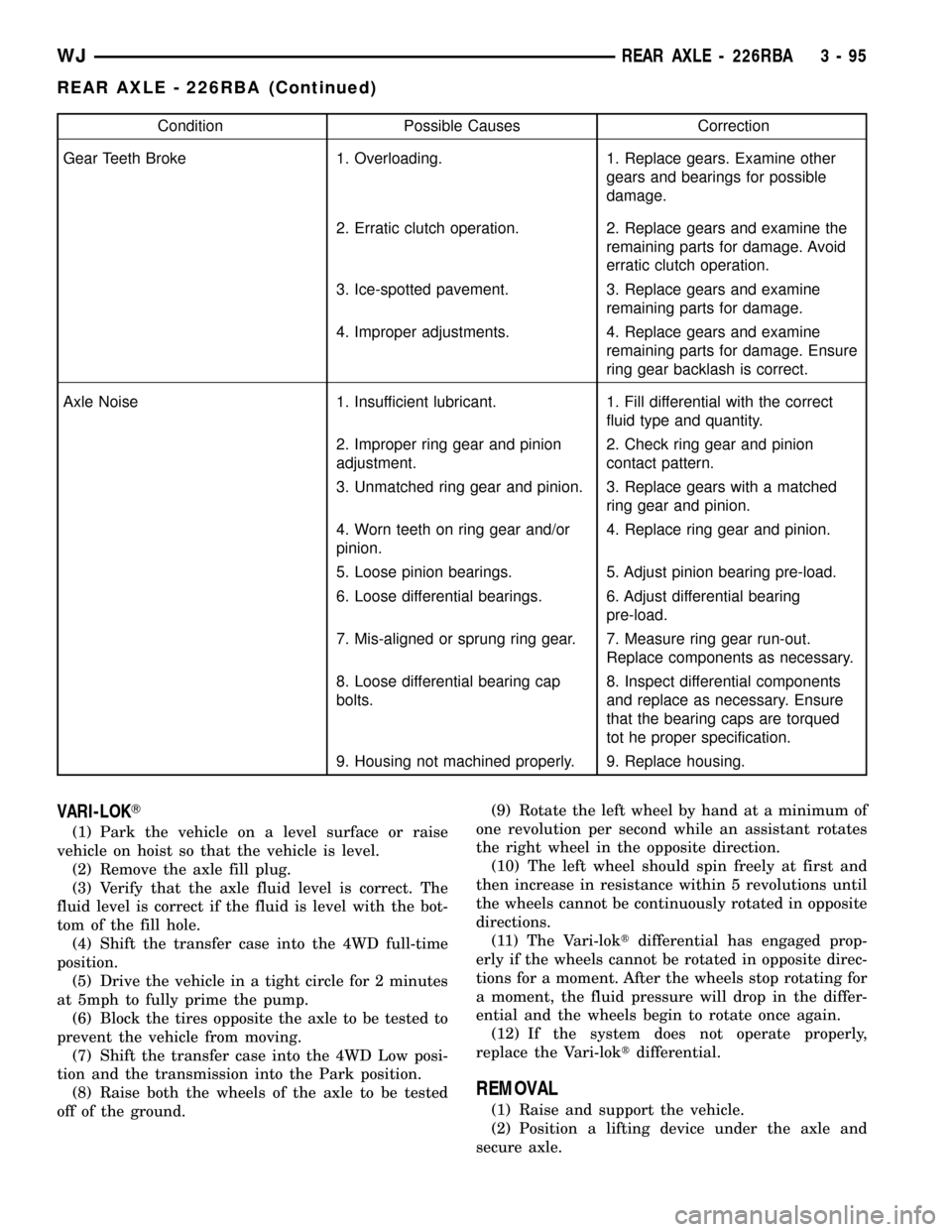

Fig. 10 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 11 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

WJREAR AXLE - 226RBA 3 - 99

REAR AXLE - 226RBA (Continued)

Page 145 of 2199

(2) Install ring gear on differential case and

tighten bolts to specification.

(3)

Install Dummy Bearings 6929-A on differential case.

(4) Install differential case in the housing.

(5) Record the thickness of Dummy Shims 8107,

then insert the shims between the dummy bearings

and the differential housing (Fig. 13).(6) Install the bearing caps in their original posi-

tions and snug the bolts (Fig. 14).

(7) With a dead-blow hammer, seat the differential

dummy bearings to each side of the housing (Fig. 15)

and (Fig. 16).

Fig. 12 ADJUSTMENT SHIM LOCATIONS

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

Fig. 13 DUMMY SHIM POINT

1 - DUMMY SHIMS

2 - HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

Fig. 14 TIGHTEN BEARING CAP BOLTS

1 - BEARING CAPS

2 - HOUSING

3 - DIFFERENTIAL CASE

Fig. 15 SEAT DUMMY BEARING

1 - HAMMER

2 - HOUSING

3 - DIFFERENTIAL CASE

3 - 100 REAR AXLE - 226RBAWJ

REAR AXLE - 226RBA (Continued)

Page 148 of 2199

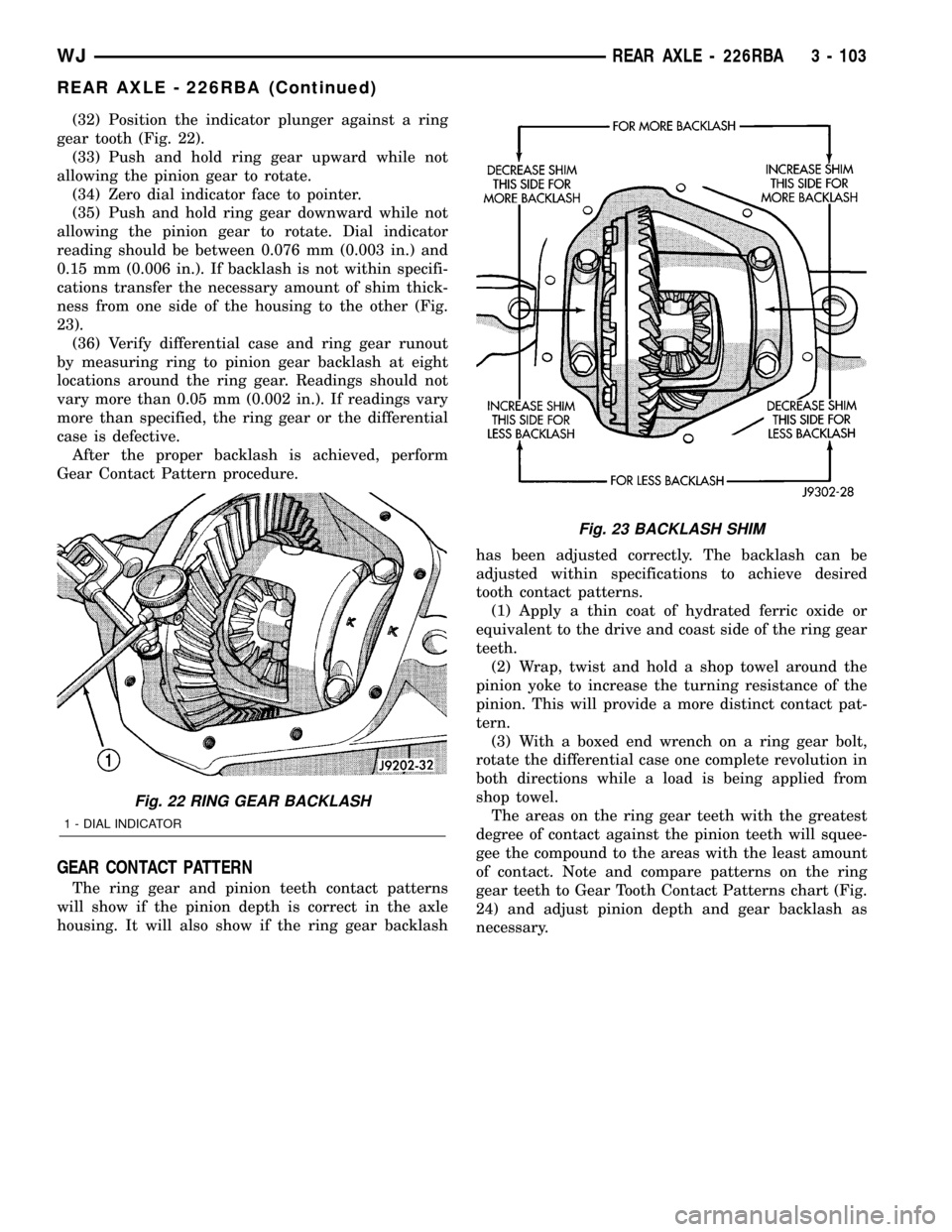

(32) Position the indicator plunger against a ring

gear tooth (Fig. 22).

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.076 mm (0.003 in.) and

0.15 mm (0.006 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the housing to the other (Fig.

23).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the axle

housing. It will also show if the ring gear backlashhas been adjusted correctly. The backlash can be

adjusted within specifications to achieve desired

tooth contact patterns.

(1) Apply a thin coat of hydrated ferric oxide or

equivalent to the drive and coast side of the ring gear

teeth.

(2) Wrap, twist and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) With a boxed end wrench on a ring gear bolt,

rotate the differential case one complete revolution in

both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squee-

gee the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

24) and adjust pinion depth and gear backlash as

necessary.

Fig. 22 RING GEAR BACKLASH

1 - DIAL INDICATOR

Fig. 23 BACKLASH SHIM

WJREAR AXLE - 226RBA 3 - 103

REAR AXLE - 226RBA (Continued)

Page 150 of 2199

DIFFERENTIAL BEARING PRELOAD CHECK

The final check on the differential assembly before

installing the axles is torque to rotate pinion and dif-

ferential combined. This will verify the correct differ-

ential bearing preload.Torque to rotate the differential and pinion should

be the torque to rotate the pinion plus 0.79-1.24 N´m

(7-11 in. lbs.).

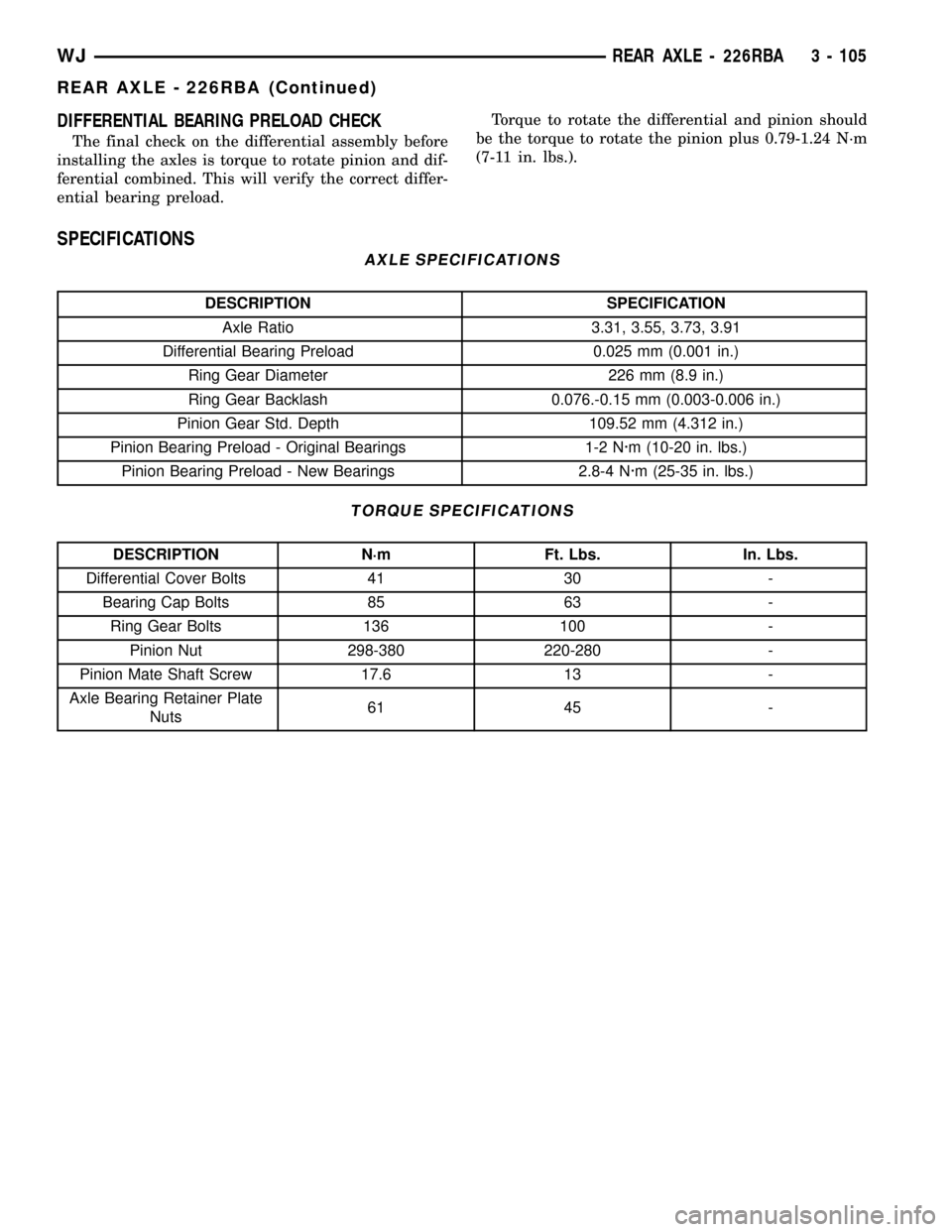

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.31, 3.55, 3.73, 3.91

Differential Bearing Preload 0.025 mm (0.001 in.)

Ring Gear Diameter 226 mm (8.9 in.)

Ring Gear Backlash 0.076.-0.15 mm (0.003-0.006 in.)

Pinion Gear Std. Depth 109.52 mm (4.312 in.)

Pinion Bearing Preload - Original Bearings 1-2 N´m (10-20 in. lbs.)

Pinion Bearing Preload - New Bearings 2.8-4 N´m (25-35 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Differential Cover Bolts 41 30 -

Bearing Cap Bolts 85 63 -

Ring Gear Bolts 136 100 -

Pinion Nut 298-380 220-280 -

Pinion Mate Shaft Screw 17.6 13 -

Axle Bearing Retainer Plate

Nuts61 45 -

WJREAR AXLE - 226RBA 3 - 105

REAR AXLE - 226RBA (Continued)

Page 151 of 2199

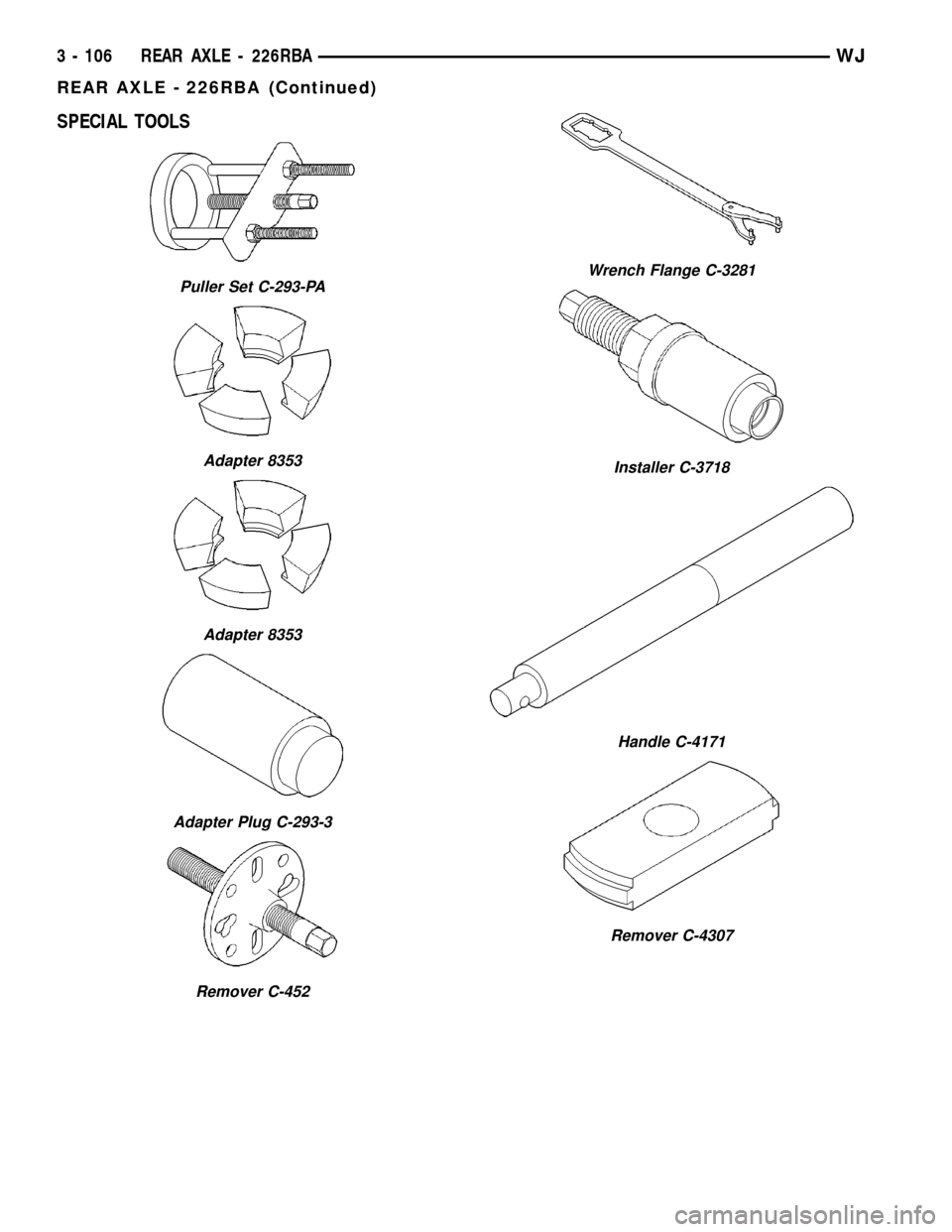

SPECIAL TOOLS

Puller Set C-293-PA

Adapter 8353

Adapter 8353

Adapter Plug C-293-3

Remover C-452

Wrench Flange C-3281

Installer C-3718

Handle C-4171

Remover C-4307

3 - 106 REAR AXLE - 226RBAWJ

REAR AXLE - 226RBA (Continued)

Page 159 of 2199

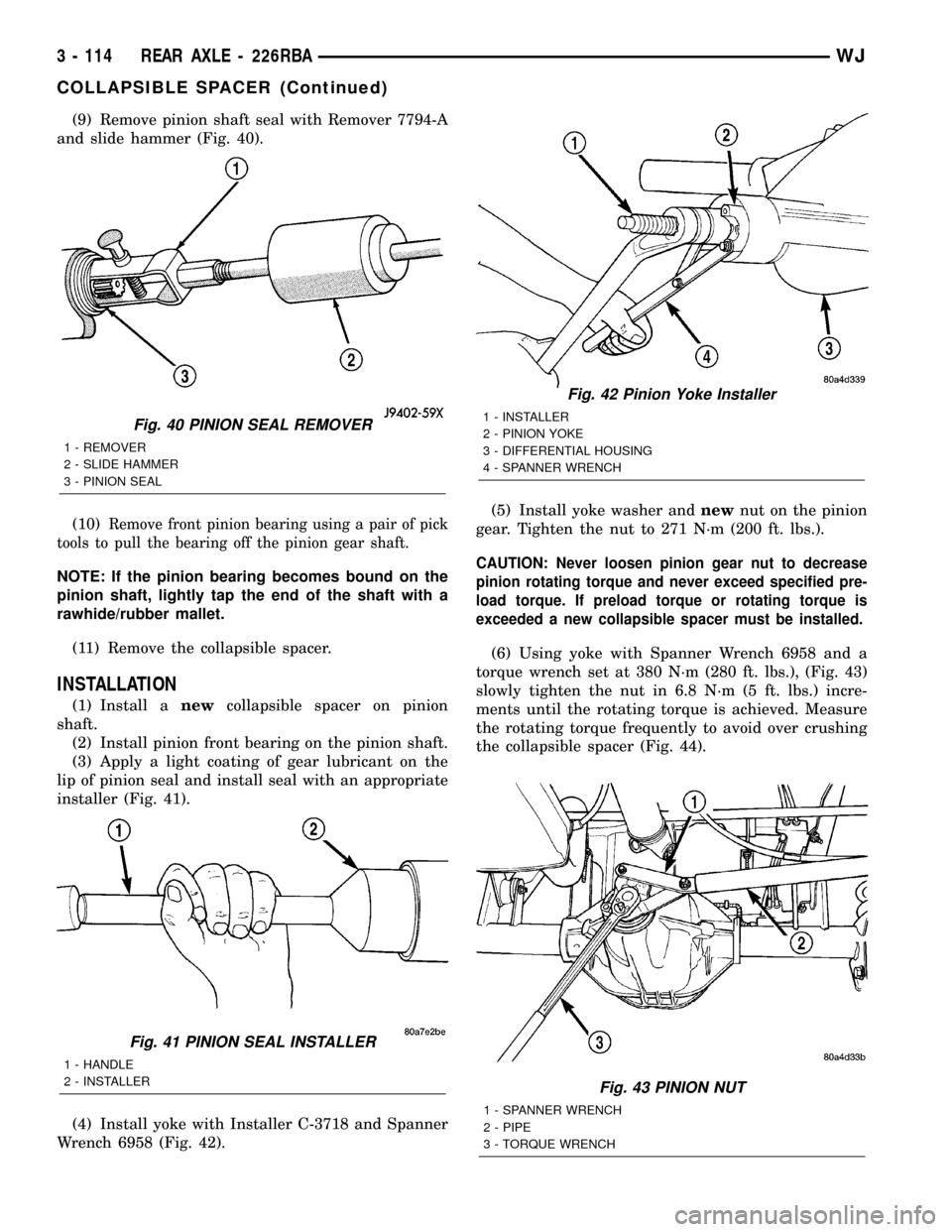

(9) Remove pinion shaft seal with Remover 7794-A

and slide hammer (Fig. 40).

(10)

Remove front pinion bearing using a pair of pick

tools to pull the bearing off the pinion gear shaft.

NOTE: If the pinion bearing becomes bound on the

pinion shaft, lightly tap the end of the shaft with a

rawhide/rubber mallet.

(11) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible spacer on pinion

shaft.

(2) Install pinion front bearing on the pinion shaft.

(3) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with an appropriate

installer (Fig. 41).

(4) Install yoke with Installer C-3718 and Spanner

Wrench 6958 (Fig. 42).(5) Install yoke washer andnewnut on the pinion

gear. Tighten the nut to 271 N´m (200 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified pre-

load torque. If preload torque or rotating torque is

exceeded a new collapsible spacer must be installed.

(6) Using yoke with Spanner Wrench 6958 and a

torque wrench set at 380 N´m (280 ft. lbs.), (Fig. 43)

slowly tighten the nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the rotating torque is achieved. Measure

the rotating torque frequently to avoid over crushing

the collapsible spacer (Fig. 44).

Fig. 43 PINION NUT

1 - SPANNER WRENCH

2 - PIPE

3 - TORQUE WRENCH

Fig. 40 PINION SEAL REMOVER

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

Fig. 41 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 42 Pinion Yoke Installer

1 - INSTALLER

2 - PINION YOKE

3 - DIFFERENTIAL HOUSING

4 - SPANNER WRENCH

3 - 114 REAR AXLE - 226RBAWJ

COLLAPSIBLE SPACER (Continued)

Page 164 of 2199

(12) Install cover and tighten bolts in a criss-cross

pattern to 41 N´m (30 ft. lbs.).

(13) Refill the differential with Mopar Hypoid

Gear Lubricant or equivalent to bottom of the fill

plug hole.

(14) Install fill hole plug.

(15) Remove support and lower the vehicle.

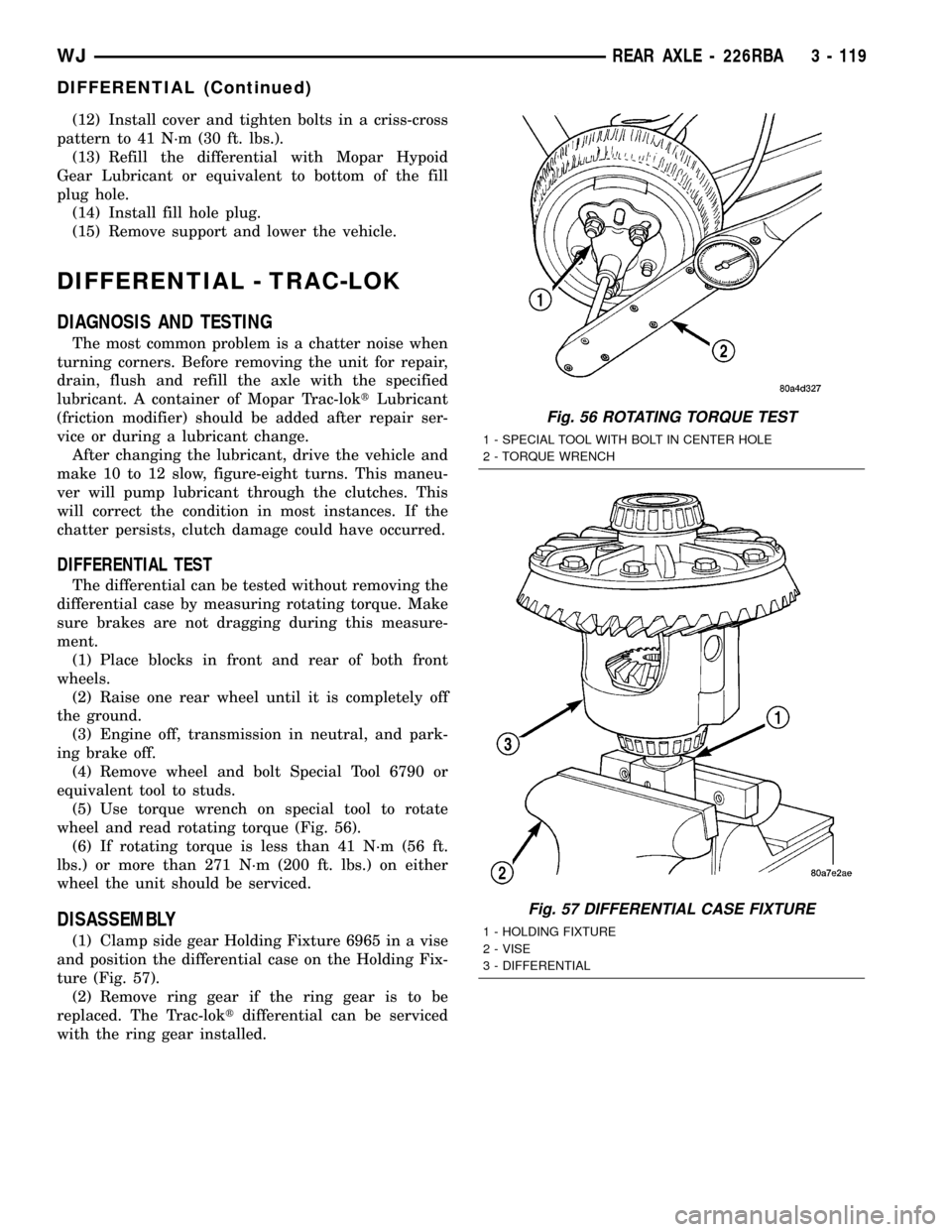

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 56).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

(1) Clamp side gear Holding Fixture 6965 in a vise

and position the differential case on the Holding Fix-

ture (Fig. 57).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-loktdifferential can be serviced

with the ring gear installed.

Fig. 56 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 57 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

WJREAR AXLE - 226RBA 3 - 119

DIFFERENTIAL (Continued)

Page 166 of 2199

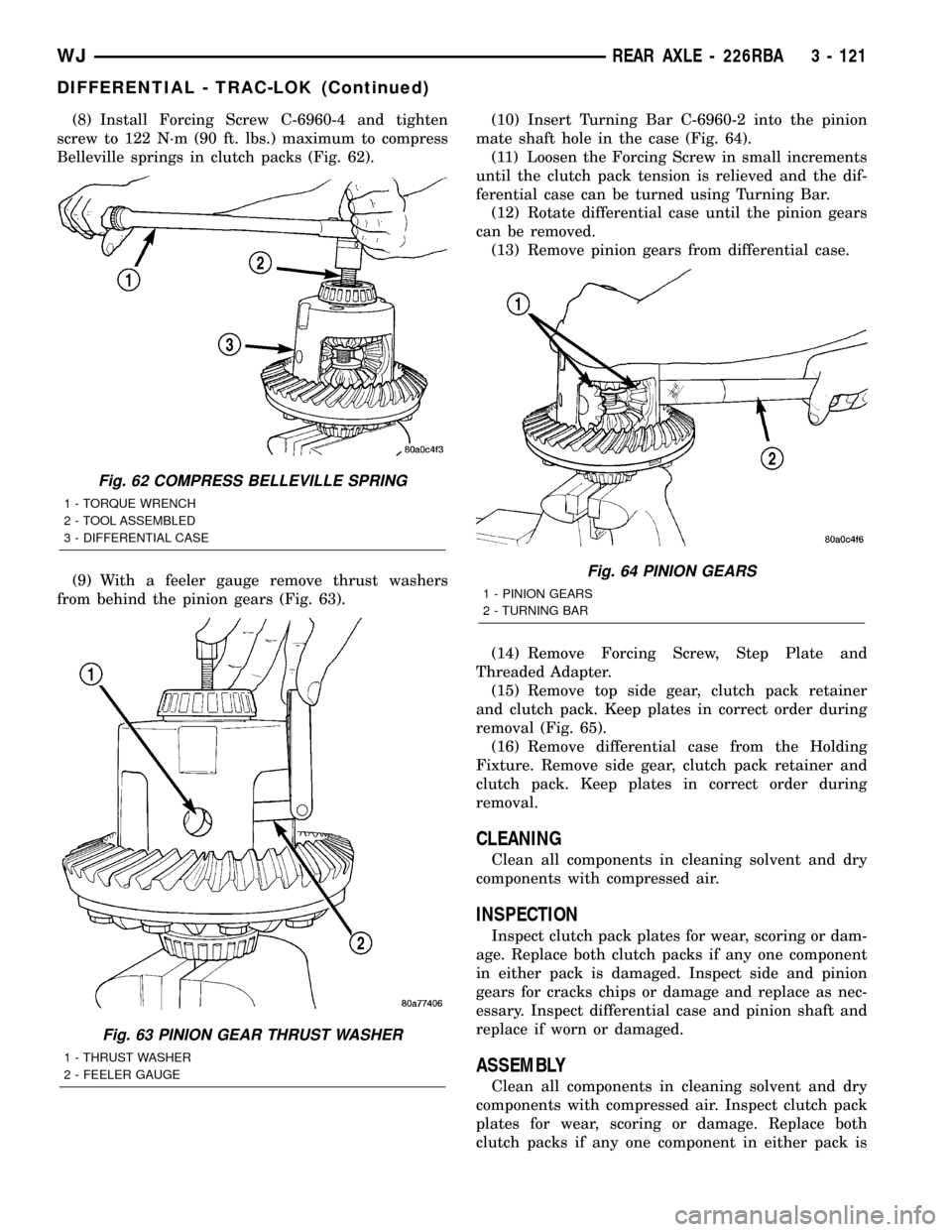

(8) Install Forcing Screw C-6960-4 and tighten

screw to 122 N´m (90 ft. lbs.) maximum to compress

Belleville springs in clutch packs (Fig. 62).

(9) With a feeler gauge remove thrust washers

from behind the pinion gears (Fig. 63).(10) Insert Turning Bar C-6960-2 into the pinion

mate shaft hole in the case (Fig. 64).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 65).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in correct order during

removal.

CLEANING

Clean all components in cleaning solvent and dry

components with compressed air.

INSPECTION

Inspect clutch pack plates for wear, scoring or dam-

age. Replace both clutch packs if any one component

in either pack is damaged. Inspect side and pinion

gears for cracks chips or damage and replace as nec-

essary. Inspect differential case and pinion shaft and

replace if worn or damaged.

ASSEMBLY

Clean all components in cleaning solvent and dry

components with compressed air. Inspect clutch pack

plates for wear, scoring or damage. Replace both

clutch packs if any one component in either pack is

Fig. 62 COMPRESS BELLEVILLE SPRING

1 - TORQUE WRENCH

2 - TOOL ASSEMBLED

3 - DIFFERENTIAL CASE

Fig. 63 PINION GEAR THRUST WASHER

1 - THRUST WASHER

2 - FEELER GAUGE

Fig. 64 PINION GEARS

1 - PINION GEARS

2 - TURNING BAR

WJREAR AXLE - 226RBA 3 - 121

DIFFERENTIAL - TRAC-LOK (Continued)

Page 167 of 2199

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged.

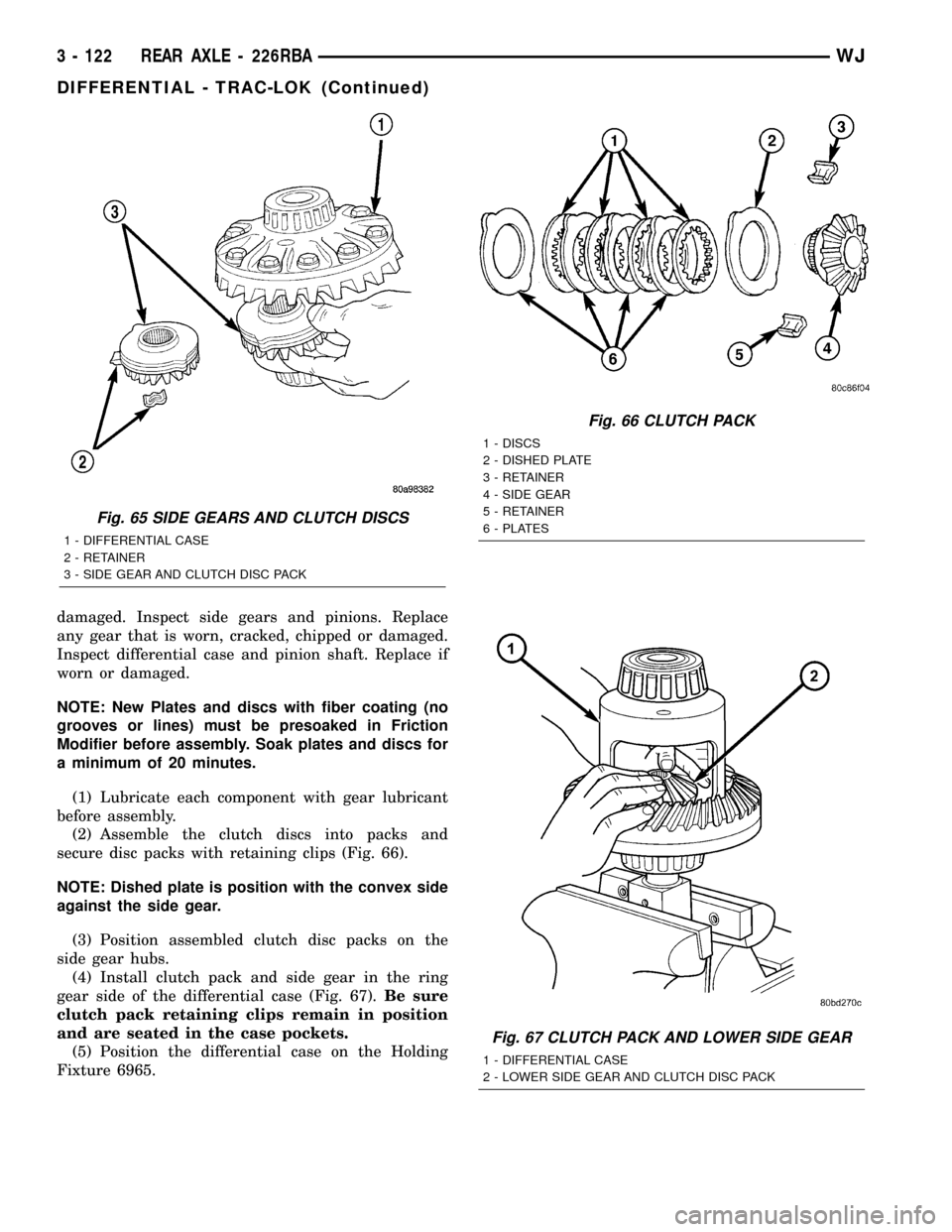

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(1) Lubricate each component with gear lubricant

before assembly.

(2) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 66).

NOTE: Dished plate is position with the convex side

against the side gear.

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 67).Be sure

clutch pack retaining clips remain in position

and are seated in the case pockets.

(5) Position the differential case on the Holding

Fixture 6965.

Fig. 65 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 66 CLUTCH PACK

1 - DISCS

2 - DISHED PLATE

3 - RETAINER

4 - SIDE GEAR

5 - RETAINER

6 - PLATES

Fig. 67 CLUTCH PACK AND LOWER SIDE GEAR

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH DISC PACK

3 - 122 REAR AXLE - 226RBAWJ

DIFFERENTIAL - TRAC-LOK (Continued)