Coolant Temperature sensor JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 225 of 2199

replacement is necessary, replace with the original

Mopartequipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

OPERATION

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It alsomaintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

OPERATIONÐHOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connec-

tion.

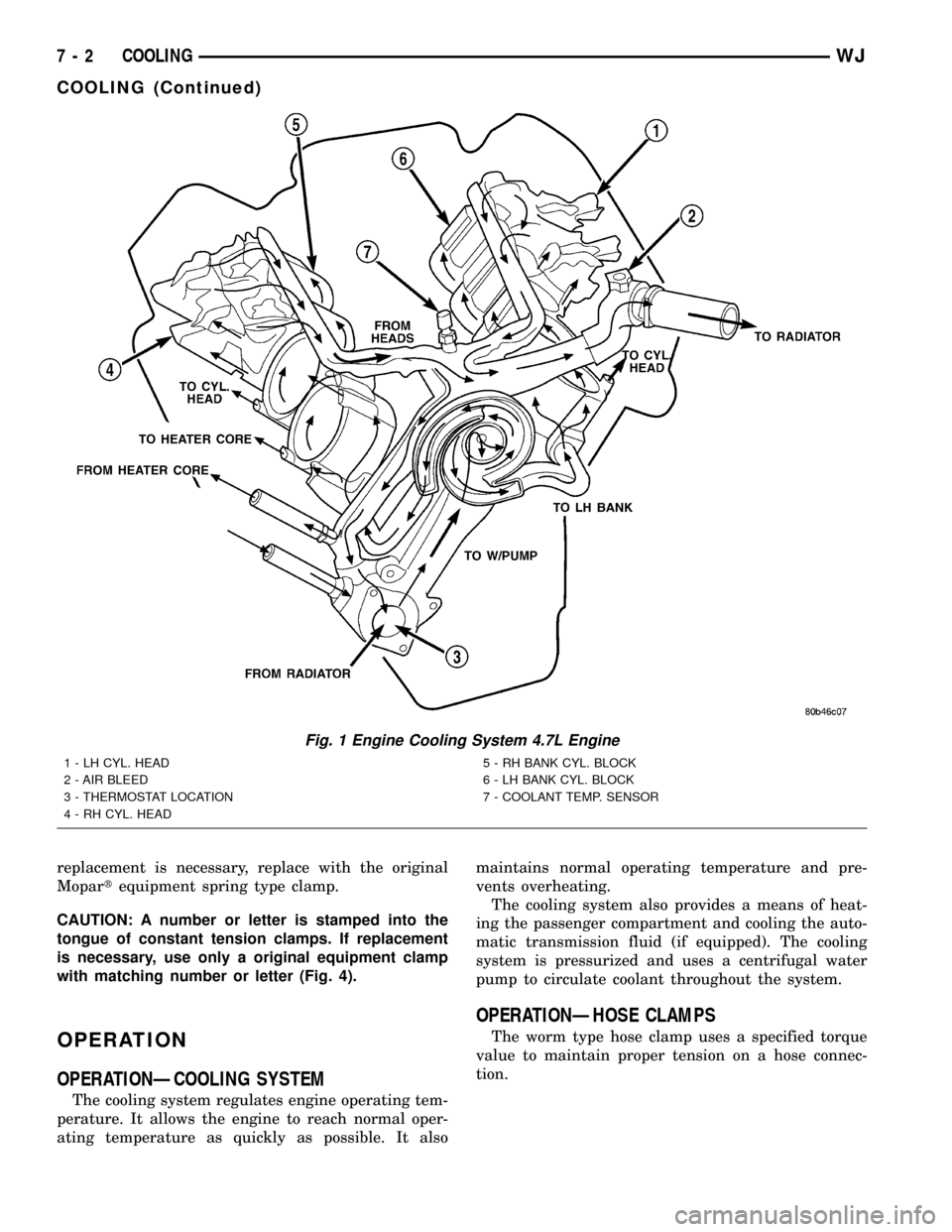

Fig. 1 Engine Cooling System 4.7L Engine

1 - LH CYL. HEAD

2 - AIR BLEED

3 - THERMOSTAT LOCATION

4 - RH CYL. HEAD5 - RH BANK CYL. BLOCK

6 - LH BANK CYL. BLOCK

7 - COOLANT TEMP. SENSOR

7 - 2 COOLINGWJ

COOLING (Continued)

Page 228 of 2199

DIAGNOSIS AND TESTING - COOLING SYSTEM DIAGNOSIS CHART

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open thermostat?1. Refer to (Refer to 25 - EMISSIONS

CONTROL - DESCRIPTION) for On-Board

Diagnostics and DTC information. Replace

thermostat if necessary.

2. Is the temperature sending unit

connected?2. Check the temperature sensor connector.

(Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT TEMP SENSOR -

DESCRIPTION). Repair connector if

necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. Repair as

necessary.

4. Coolant level low in cold ambient

temperatures accompanied with

poor heater performance.4. Check coolant level in the coolant

reserve/overflow tank and the radiator.

Inspect system for leaks. Repair leaks as

necessary.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as necessary.

(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND

TESTING)

TEMPERATURE GAUGE

READS HIGH OR THE

COOLANT LAMP

ILLUMINATES.

COOLANT MAY OR MAY

NOT BE LOST OR

LEAKING FROM THE

COOLING SYSTEM1. Trailer is being towed, a steep hill

is being climbed, vehicle is operated

in slow moving traffic, or engine is

being idled with very high ambient

(outside) temperatures and the air

conditioning is on. Higher altitudes

could aggravate these conditions.1. This may be a temporary condition and

repair is not necessary. Turn off the air

conditioning and attempt to drive the vehicle

without any of the previous conditions.

Observe the temperature gauge. The gauge

should return to the normal range. If the

gauge does not return to the normal range,

determine the cause for overheating and

repair.

2. Is the temperature gauge reading

correctly?2. Check gauge. (Refer to Group 8J -

INSTRUMENT CLUSTER). Repair as

necessary.

3. Is the temperature warning

illuminating unnecessarily?3. Check warning lamp operation. (Refer to

Group 8J - INSTRUMENT CLUSTER).Repair

as necessary.

4. Coolant low in coolant reserve/

overflow tank and radiator?4. Check for coolant leaks and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer to

the following Step 6.5. Tighten cap

WJCOOLING 7 - 5

COOLING (Continued)

Page 230 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

17. Viscous fan drive not operating

properly.17. Check fan drive operation and replace as

necessary. (Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH -

DIAGNOSIS AND TESTING).

18. Cylinder head gasket leaking. 18. Check for cylinder head gasket leaks.

(Refer to 7 - COOLING - DIAGNOSIS AND

TESTING). For repair, (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

19. Heater core leaking. 19. Check heater core for leaks. (Refer to 24

- HEATING & AIR CONDITIONING/

PLUMBING/HEATER CORE - REMOVAL).

Repair as necessary.

20. Hydraulic fan speed too low or

inopertive.20. Check for

DTC code.

Check fan operation speeds.

Refer to fan speed operation table.

Low power steering pump output. Refer to

power steering pump diagnosis - 4.7L engine.

TEMPERATURE GAUGE

READING IS

INCONSISTENT

(FLUCTUATES, CYCLES

OR IS ERRATIC)1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly.1. A normal condition. No correction is

necessary.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.2. Check operation of gauge and repair if

necessary. Refer to Group 8J, Instrument

cluster.

3. Gauge reading rises when vehicle

is brought to a stop after heavy use

(engine still running)3. A normal condition. No correction is

necessary. Gauge should return to normal

range after vehicle is driven.

4. Gauge reading high after

re-starting a warmed up (hot)

engine.4. A normal condition. No correction is

necessary. The gauge should return to

normal range after a few minutes of engine

operation.

5. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open late).5. Check and correct coolant leaks. (Refer to

7 - COOLING - DIAGNOSIS AND TESTING).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a thermostat

to open late.6. (a) Check for cylinder head gasket leaks.

(Refer to 7 - COOLING - DIAGNOSIS AND

TESTING).

(b) Check for coolant in the engine oil.

Inspect for white steam emitting from the

exhaust system. Repair as necessary.

WJCOOLING 7 - 7

COOLING (Continued)

Page 233 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT LEVEL

CHANGES IN COOLANT

RESERVE/OVERFLOW

TANK. TEMPERATURE

GAUGE IS IN NORMAL

RANGE1. Level changes are to be expected

as coolant volume fluctuates with

engine temperature. If the level in

the tank was between the FULL and

ADD marks at normal operating

temperature, the level should return

to within that range after operation

at elevated temperatures.1. A normal condition. No repair is necessary.

FAN RUNS ALL THE

TIME1. Fan control sensors inoperative. 1. Check for DTC's. Verify sensor readings.

2. Fan control solenoid stuck9on9. 2. Check fan operation speeds. Refer to fan

speed operation table.

3. Fan control solenoid harness

damaged.3. Check for DTC 1499. Repair as required.

4. Transmission temperature too

high.4. Check for transmission over temp. DTC.

5. Engine coolant temperature too

high.5. (a) Check coolant level. Correct level as

required.

(b) Thermostat stuck. Replace thermostat.

(c) Water pump failed. Replace water pump.

(d) Coolant flow restricted. Clean radiator.

(e) Air flow over radiator obstructed.Remove

obstruction.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

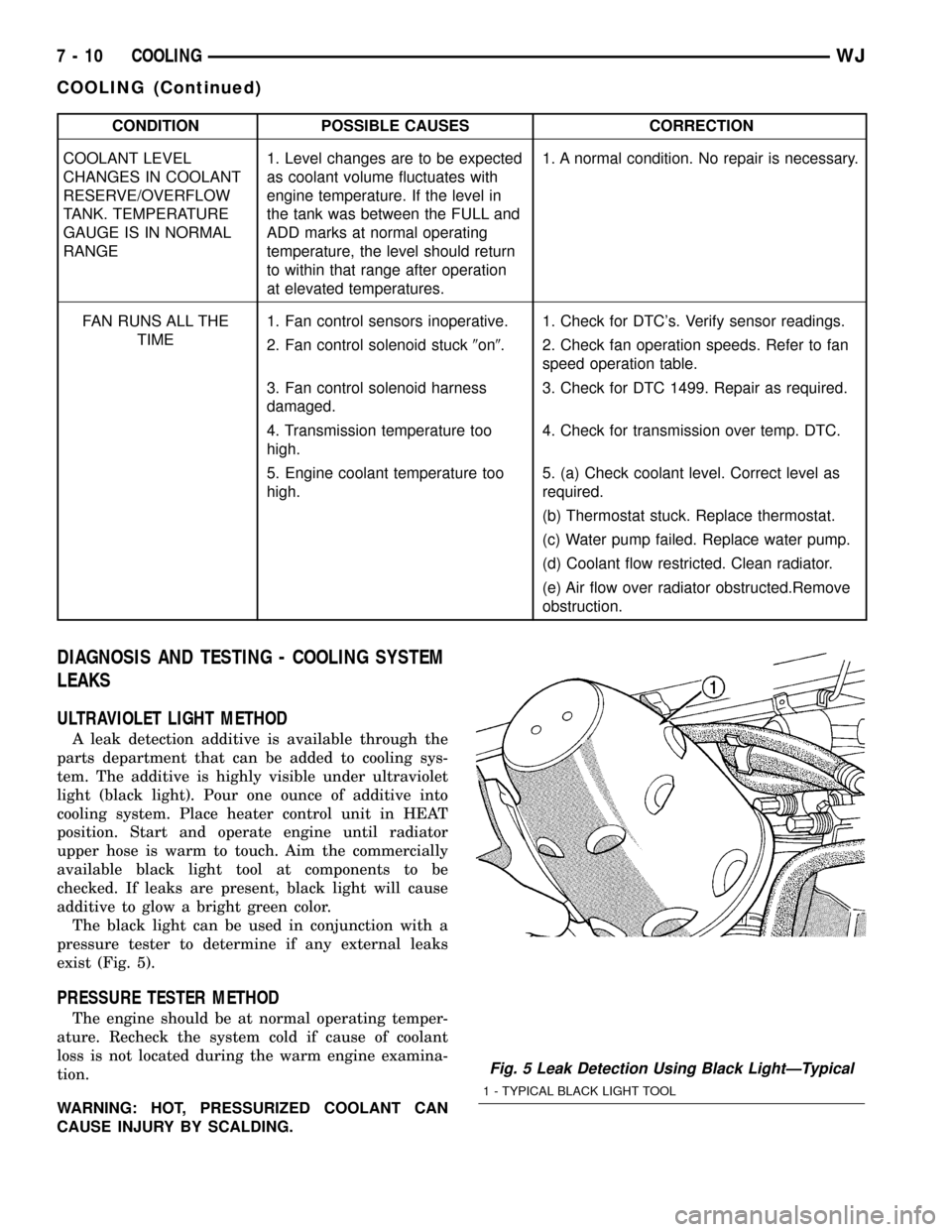

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Fig. 5 Leak Detection Using Black LightÐTypical

1 - TYPICAL BLACK LIGHT TOOL

7 - 10 COOLINGWJ

COOLING (Continued)

Page 236 of 2199

STANDARD PROCEDURE - DRAINING COOLING

SYSTEM - 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the right/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

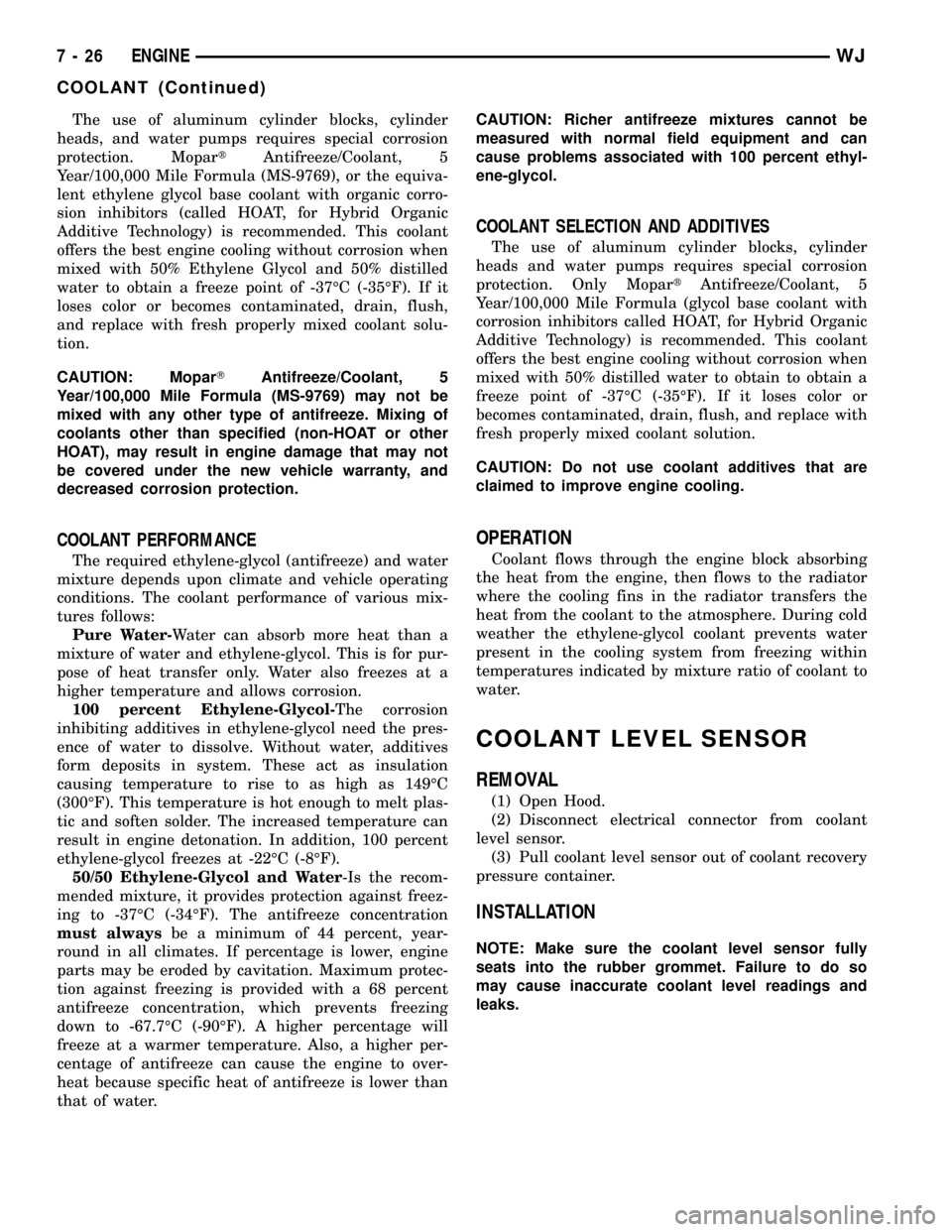

To drain the engine of coolant, remove the cylinder

block drain plug located on the side of cylinder block

(Fig. 9).

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

(2) Fill system using a 50/50 mixture of ethylene-

glycol antifreeze and low mineral content water. Fill

radiator to top and install radiator cap. Add suffi-

cient coolant to the reserve/overflow tank to raise

level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

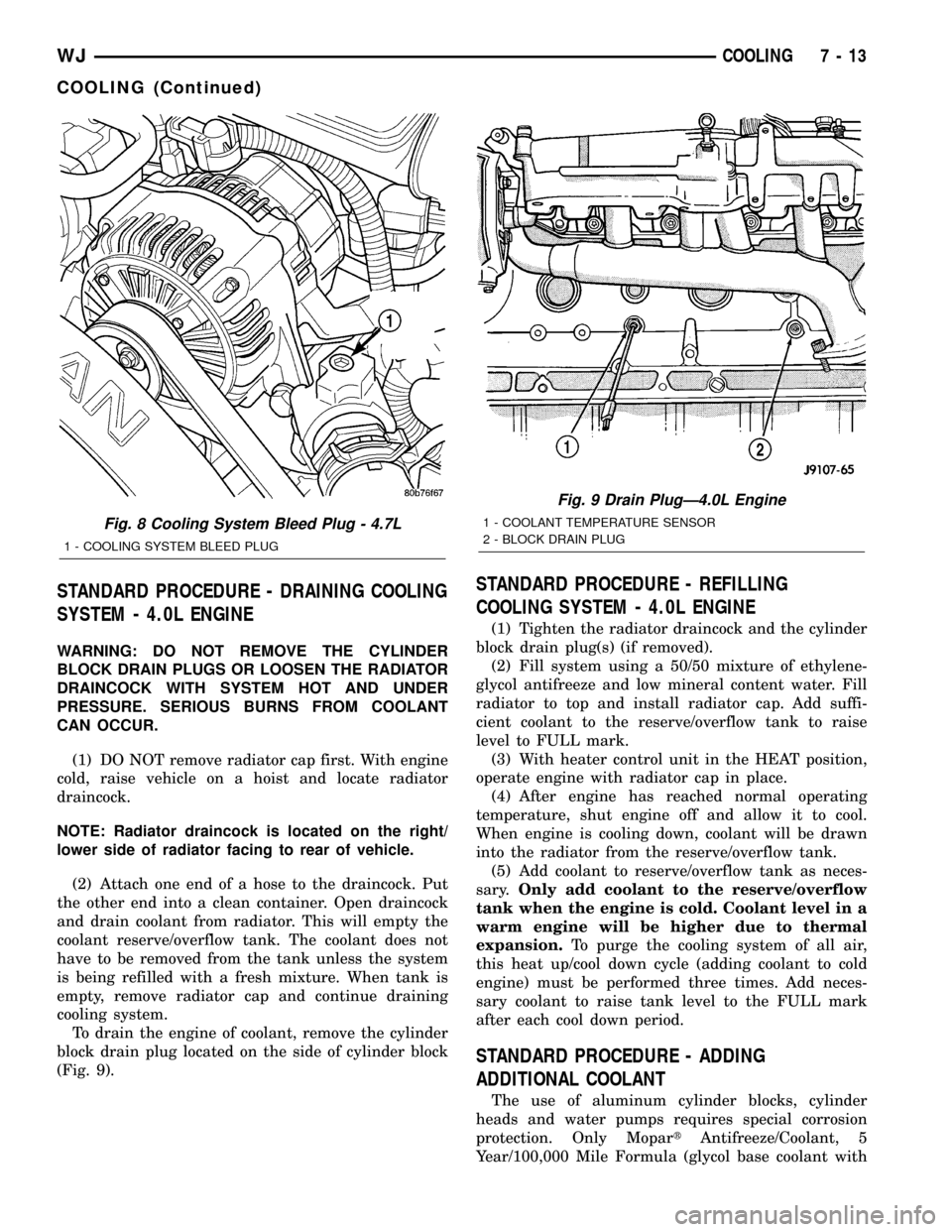

Fig. 8 Cooling System Bleed Plug - 4.7L

1 - COOLING SYSTEM BLEED PLUG

Fig. 9 Drain PlugÐ4.0L Engine

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

WJCOOLING 7 - 13

COOLING (Continued)

Page 249 of 2199

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

tic and soften solder. The increased temperature can

result in engine detonation. In addition, 100 percent

ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION AND ADDITIVES

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

OPERATION

Coolant flows through the engine block absorbing

the heat from the engine, then flows to the radiator

where the cooling fins in the radiator transfers the

heat from the coolant to the atmosphere. During cold

weather the ethylene-glycol coolant prevents water

present in the cooling system from freezing within

temperatures indicated by mixture ratio of coolant to

water.

COOLANT LEVEL SENSOR

REMOVAL

(1) Open Hood.

(2) Disconnect electrical connector from coolant

level sensor.

(3) Pull coolant level sensor out of coolant recovery

pressure container.

INSTALLATION

NOTE: Make sure the coolant level sensor fully

seats into the rubber grommet. Failure to do so

may cause inaccurate coolant level readings and

leaks.

7 - 26 ENGINEWJ

COOLANT (Continued)

Page 258 of 2199

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 19).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

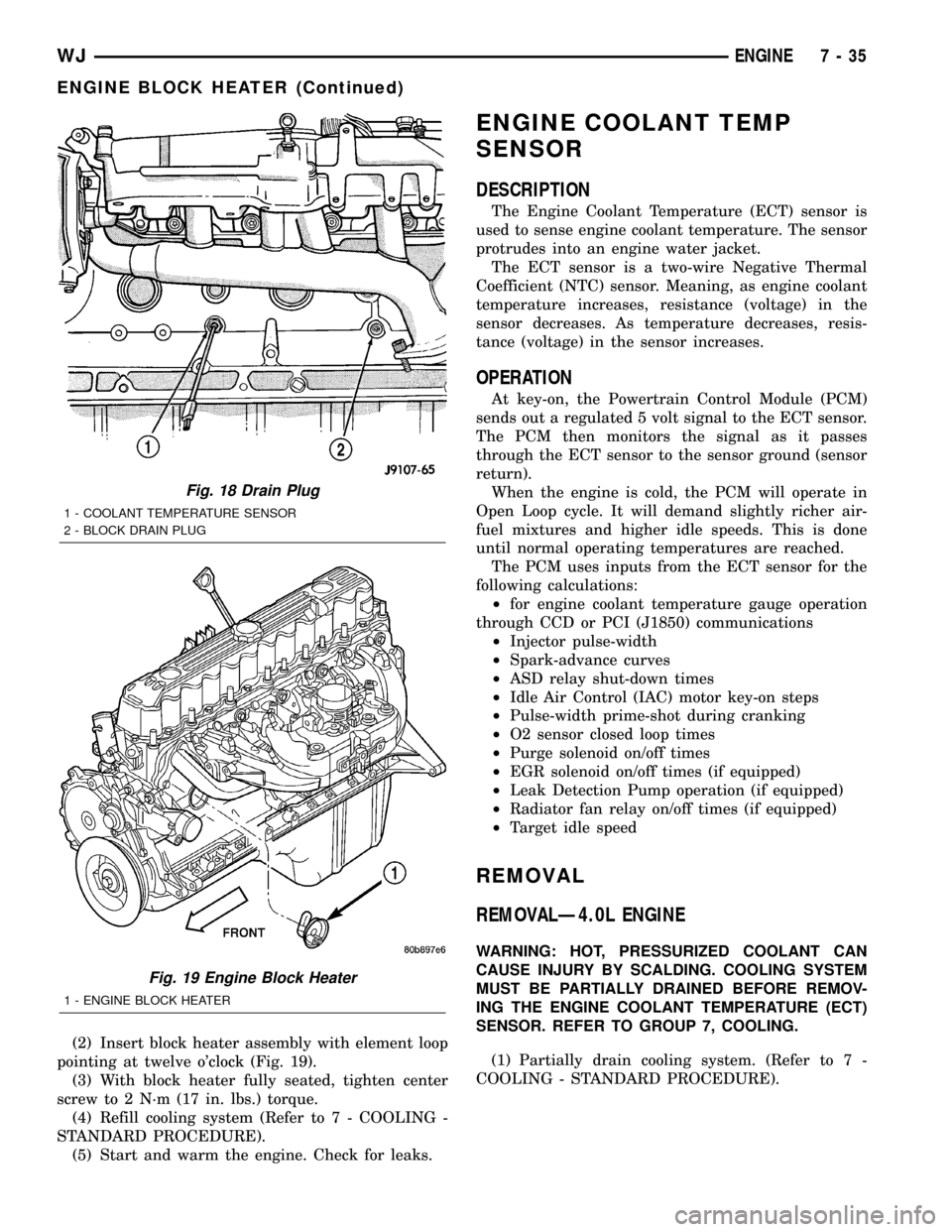

Fig. 18 Drain Plug

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

Fig. 19 Engine Block Heater

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 35

ENGINE BLOCK HEATER (Continued)

Page 259 of 2199

(2) Disconnect electrical connector from ECT sen-

sor (Fig. 20).

(3) Remove sensor from thermostat housing.

REMOVALÐ4.7L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

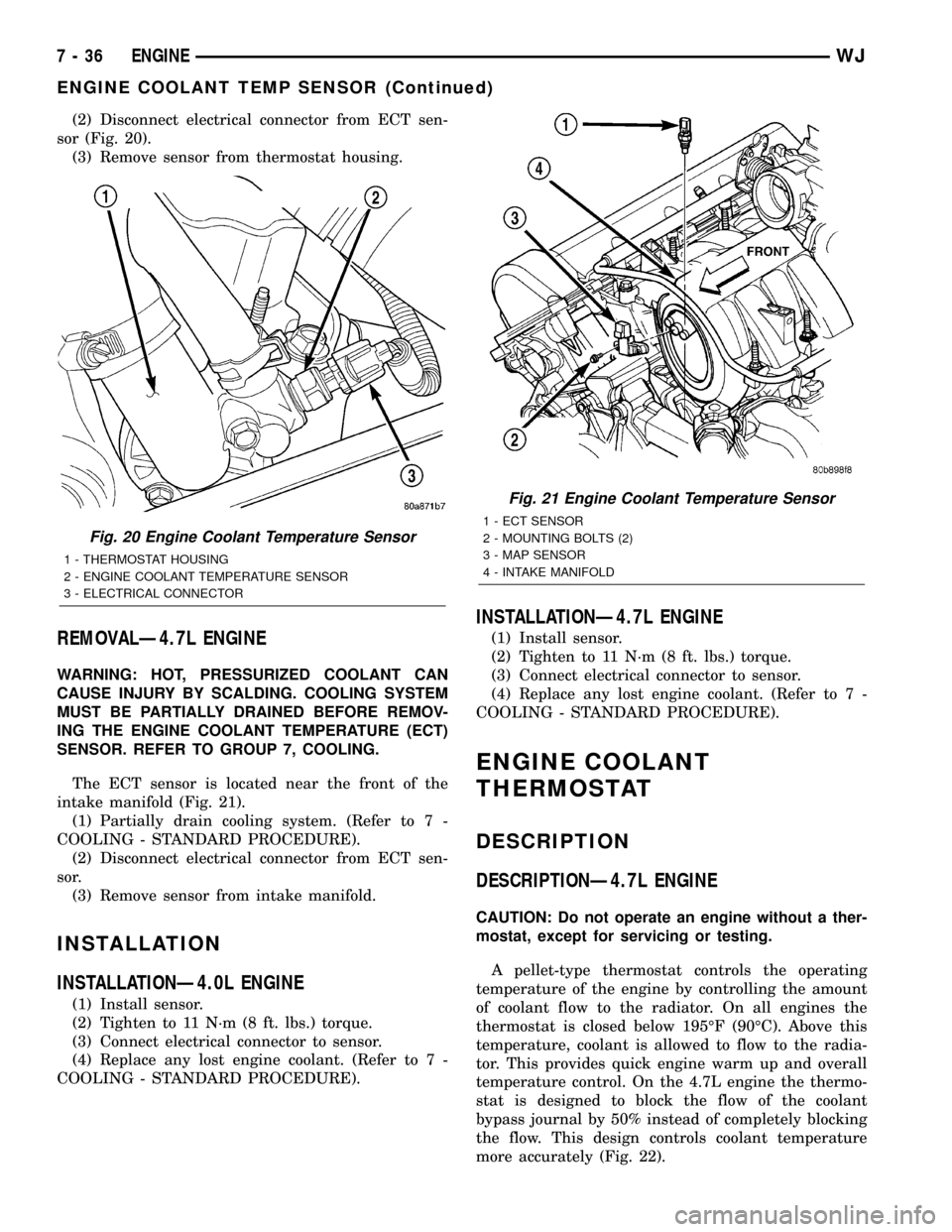

The ECT sensor is located near the front of the

intake manifold (Fig. 21).

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(2) Disconnect electrical connector from ECT sen-

sor.

(3) Remove sensor from intake manifold.

INSTALLATION

INSTALLATIONÐ4.0L ENGINE

(1) Install sensor.

(2) Tighten to 11 N´m (8 ft. lbs.) torque.

(3) Connect electrical connector to sensor.

(4) Replace any lost engine coolant. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

INSTALLATIONÐ4.7L ENGINE

(1) Install sensor.

(2) Tighten to 11 N´m (8 ft. lbs.) torque.

(3) Connect electrical connector to sensor.

(4) Replace any lost engine coolant. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

DESCRIPTIONÐ4.7L ENGINE

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 4.7L engine the thermo-

stat is designed to block the flow of the coolant

bypass journal by 50% instead of completely blocking

the flow. This design controls coolant temperature

more accurately (Fig. 22).

Fig. 20 Engine Coolant Temperature Sensor

1 - THERMOSTAT HOUSING

2 - ENGINE COOLANT TEMPERATURE SENSOR

3 - ELECTRICAL CONNECTOR

Fig. 21 Engine Coolant Temperature Sensor

1 - ECT SENSOR

2 - MOUNTING BOLTS (2)

3 - MAP SENSOR

4 - INTAKE MANIFOLD

7 - 36 ENGINEWJ

ENGINE COOLANT TEMP SENSOR (Continued)

Page 261 of 2199

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

(1) Drain the coolant from the radiator until the

level is below the thermostat housing (Refer to 7 -

COOLING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 52). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with matching number or letter.

(2) Remove radiator upper hose and heater hose at

thermostat housing.

(3) Disconnect wiring connector at engine coolant

temperature sensor.

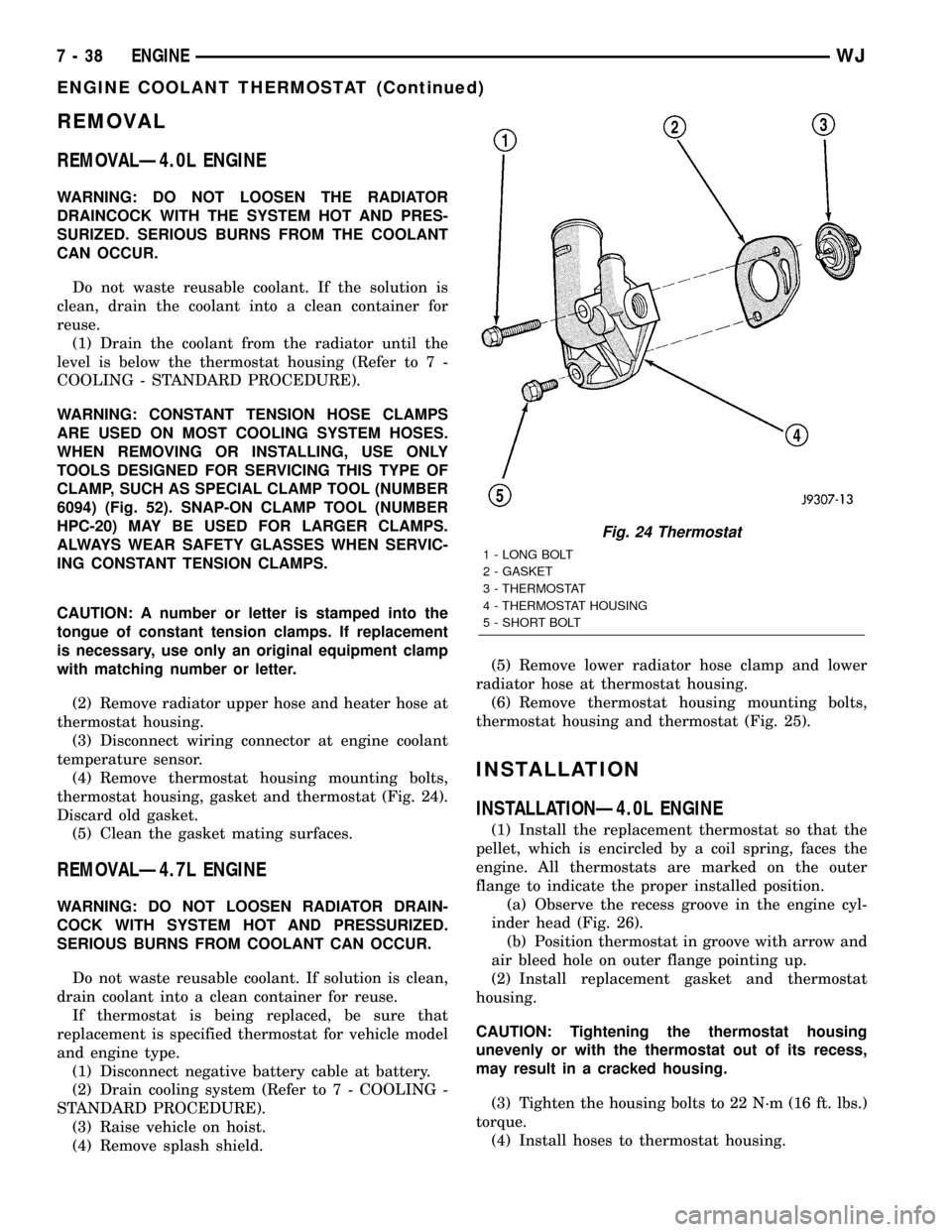

(4) Remove thermostat housing mounting bolts,

thermostat housing, gasket and thermostat (Fig. 24).

Discard old gasket.

(5) Clean the gasket mating surfaces.

REMOVALÐ4.7L ENGINE

WARNING: DO NOT LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND PRESSURIZED.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

If thermostat is being replaced, be sure that

replacement is specified thermostat for vehicle model

and engine type.

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Remove splash shield.(5) Remove lower radiator hose clamp and lower

radiator hose at thermostat housing.

(6) Remove thermostat housing mounting bolts,

thermostat housing and thermostat (Fig. 25).

INSTALLATION

INSTALLATIONÐ4.0L ENGINE

(1) Install the replacement thermostat so that the

pellet, which is encircled by a coil spring, faces the

engine. All thermostats are marked on the outer

flange to indicate the proper installed position.

(a) Observe the recess groove in the engine cyl-

inder head (Fig. 26).

(b) Position thermostat in groove with arrow and

air bleed hole on outer flange pointing up.

(2) Install replacement gasket and thermostat

housing.

CAUTION: Tightening the thermostat housing

unevenly or with the thermostat out of its recess,

may result in a cracked housing.

(3) Tighten the housing bolts to 22 N´m (16 ft. lbs.)

torque.

(4) Install hoses to thermostat housing.

Fig. 24 Thermostat

1 - LONG BOLT

2 - GASKET

3 - THERMOSTAT

4 - THERMOSTAT HOUSING

5 - SHORT BOLT

7 - 38 ENGINEWJ

ENGINE COOLANT THERMOSTAT (Continued)

Page 313 of 2199

BCM programming then performs those tasks and

provides features through both PCI data bus commu-

nication with other electronic modules and hard

wired outputs to a number of relays. These relays

provide the BCM with the ability to control numer-

ous high current accessory systems in the vehicle.

The BCM circuitry operates on battery current

received through fuses in the Junction Block (JB) on a

non-switched fused B(+) circuit, a fused ignition switch

output (start-run) circuit, and a fused ignition switch

output (run-accessory) circuit. This arrangement allows

the BCM to provide some features regardless of the

ignition switch position. The BCM circuitry is grounded

through the chassis beneath the center console.

The BCM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the BCM include the fol-

lowing:

²A/C switch signal

²Ambient temperature sensor signal

²Body control module flash enable

²Coolant level switch sense

²Door ajar switch sense (two circuits - one left

rear, and one right rear)

²Driver seat heater switch mux

²Fog lamp switch sense

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (st-run)

²Ground (five circuits - two Z1, and three Z2)

²Hazard switch sense

²Headlamp switch mux

²High beam switch sense

²Hood ajar switch sense (export)

²Key-in ignition switch sense

²Liftgate ajar switch sense

²Liftgate courtesy disable

²Liftgate flip-up ajar switch sense

²Panel lamps dimmer signal

²Park lamp relay output

²Passenger seat heater switch mux

²PCI bus

²Radio control mux

²Rear window defogger switch sense

²Seat belt switch sense

²Ultralight sensor signal

²Washer fluid switch sense

²Washer pump switch sense

²Windshield wiper switch mux

²Wiper park switch sense

MESSAGING

The BCM uses the following messages received

from other electronic modules over the PCI data bus:

²Accessory Delay Control (DDM/PDM)

²Battery Temperature (PCM)

²Chime Request (EMIC, EVIC, SKIM)

²Cylinder Lock Switch Status (DDM)

²Door Ajar Status/Front Doors (DDM/PDM)

²Door Lock Status (DDM/PDM)

²Engine Model (PCM)

²Engine RPM (PCM)

²Engine Temperature (PCM)

²English/Metric Default (EMIC)

²Fuel Tank Level (PCM)

²Fuel Used/Injector Pulses (PCM)

²Panic Control (PDM)

²Programmable Features Preferences/Audible &

Optical Chirps/Headlamp Delay (EVIC)

²RKE Status (PDM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Switch Status (PCM)

²Ambient Temperature Data (AZC/EVIC/PCM)

²Average/Instantaneous Fuel Economy (EVIC)

²Country Code (EMIC)

²Courtesy Lamp Status (DDM/PDM)

²Distance To Empty (EVIC)

²Elapsed Ignition On Timer (EVIC)

²English/Metric Status (EMIC)

²Front & Rear Door Ajar Status (EVIC)

²Front & Rear Fog Lamp Status (EMIC)

²Heated Seat Switch Status (HSM/MHSM)

²High Beam Status (EMIC)

²Ignition Off Timer (EVIC)

²Ignition Switch Position (DDM/PDM)

²Key-In Ignition Status (DDM/PDM)

²Low Beam Status (EMIC)

²Panel Lamp Status (AZC/EMIC/Radio)

²Rear Window Defogger Relay Status (DDM/

PDM)

²Remote Radio Switch Status (Radio)

²Seatbelt Status (EMIC/MHSM/MSM)

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM) may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. Refer to the appropriate wiring information.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the BCM. In order to

obtain conclusive testing of the BCM, the Program-

mable Communications Interface (PCI) data bus net-

work and all of the electronic modules that provide

8E - 4 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)