Drive train JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1 of 2199

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Service Manual Comment Forms (Rear of Manual)

Page 17 of 2199

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oils

that meet Chrysler material standard MS-6395, be

used. European Grade 10W-40 oils are also accept-

able.

Oils of the SAE 5W-40 or 8W-80 grade number are

preferred when minimum temperatures consistently

fall below -12ÉC.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

FLUID FILL/CHECK

LOCATIONS

INSPECTION - FLUID FILL/CHECK LOCATIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

MAINTENANCE SCHEDULES

DESCRIPTION

9Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.9

LIFT POINTS

STANDARD PROCEDURE - HOISTING AND

JACKING RECOMMENDATIONS

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a WJ vehicle (Fig. 7). Support the vehicle in

the raised position with jack stands at the front and

rear ends of the frame rails.

CAUTION: Do not attempt to lift a vehicle with a

floor jack positioned under:

²An axle tube.

²Aluminum differential.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7).

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

0 - 6 LUBRICATION & MAINTENANCEWJ

FLUID TYPES (Continued)

Page 51 of 2199

PROPELLER SHAFT - FRONT

REMOVAL

NOTE: Different length propeller shafts are used for

different drivetrain applications. Ensure that the

correct propeller shaft is used.

(1) Place vehicle on floor or drive-on hoist with full

weight of vehicle on suspension.

(2) Shift the transmission and transfer case, if nec-

essary, into the Neutral position.

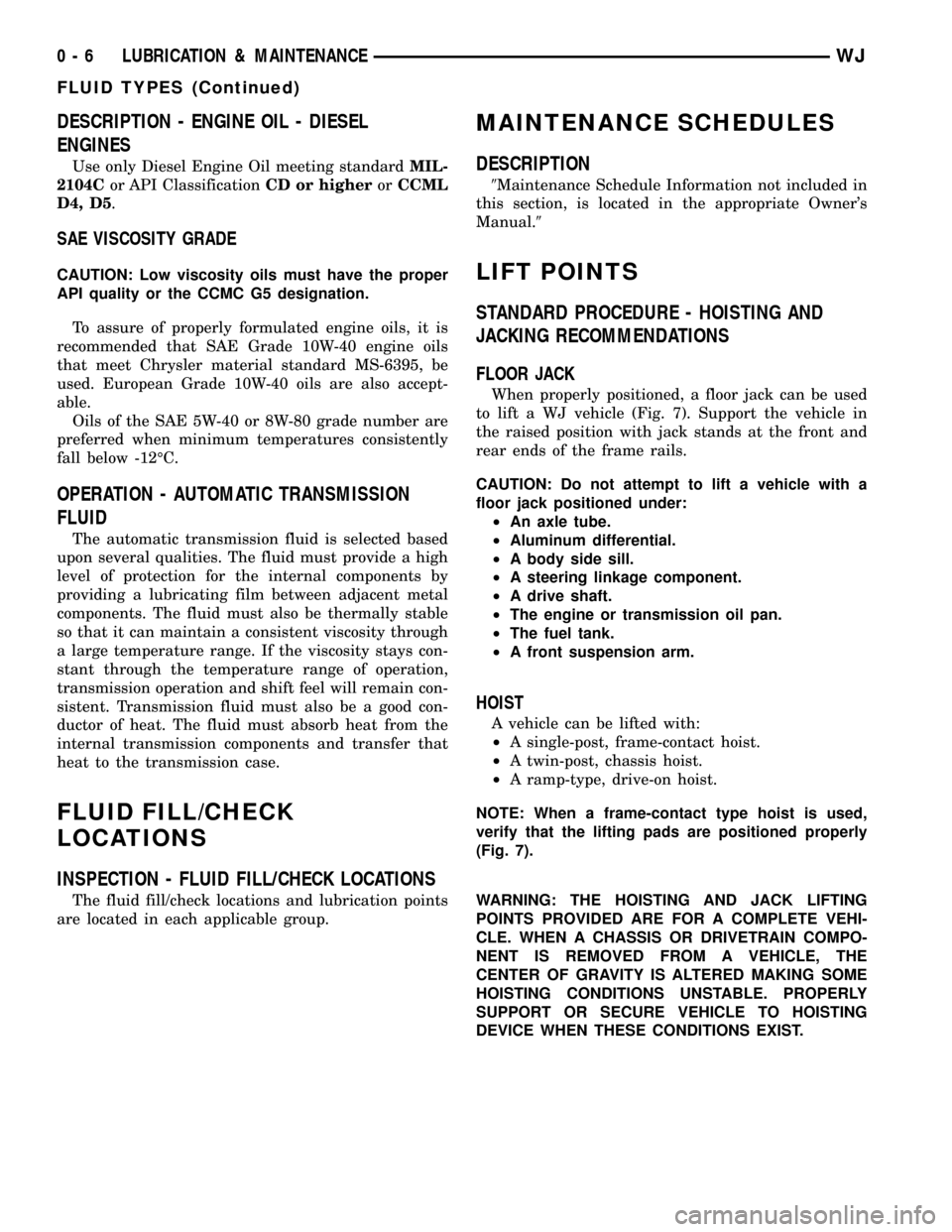

(3) Measure the distance from the face of the C/V

joint cup to the end of the C/V joint boot (Fig. 8).

(4) The correct length is 142.7 mm (5.61 in.).

NOTE: If the measurement is not correct, the wrong

shaft may have been installed or a mating compo-

nent (front axle or transfer case) may be installed

incorrectly. Investigate and correct as necessary.

(5) Mark a line across the companion flange at the

transfer case and C/V joint at the rear of the front

propeller shaft for installation reference.

(6) Mark a line across the C/V joints and the pin-

ion companion flanges for installation reference.

(7) Remove bolts from the front C/V joint to the

pinion companion flange.

(8) Remove bolts from the rear C/V joint to the

transfer case companion flange.

(9) Push the propeller shaft forward to clear trans-

fer case companion flange and remove the shaft.

INSTALLATION

NOTE: Different length propeller shafts are used for

different drivetrain applications. Ensure that the

correct propeller shaft is used.

(1) Install the shaft between companion flanges.

(2) The shaft should rotate freely in the pinion

flange.

(3) Align marks on the companion flanges with the

marks on the C/V joints.

(4) Install bolts to the front C/V joint and tighten

bolts to 32 N´m (24 ft. lbs.).

(5) Install the bolts to the rear C/V joint and

tighten bolts to 32 N´m (24 ft. lbs.).

(6) Verify propeller shaft length.

(7) Lower vehicle.

PROPELLER SHAFT - FRONT

4.7L

REMOVAL

(1) Raise and support vehicle.

(2) Remove crossmember/skid plate as necessary to

gain access to the propeller shaft.

(3) Shift transmission and transfer case, if neces-

sary into Neutral.

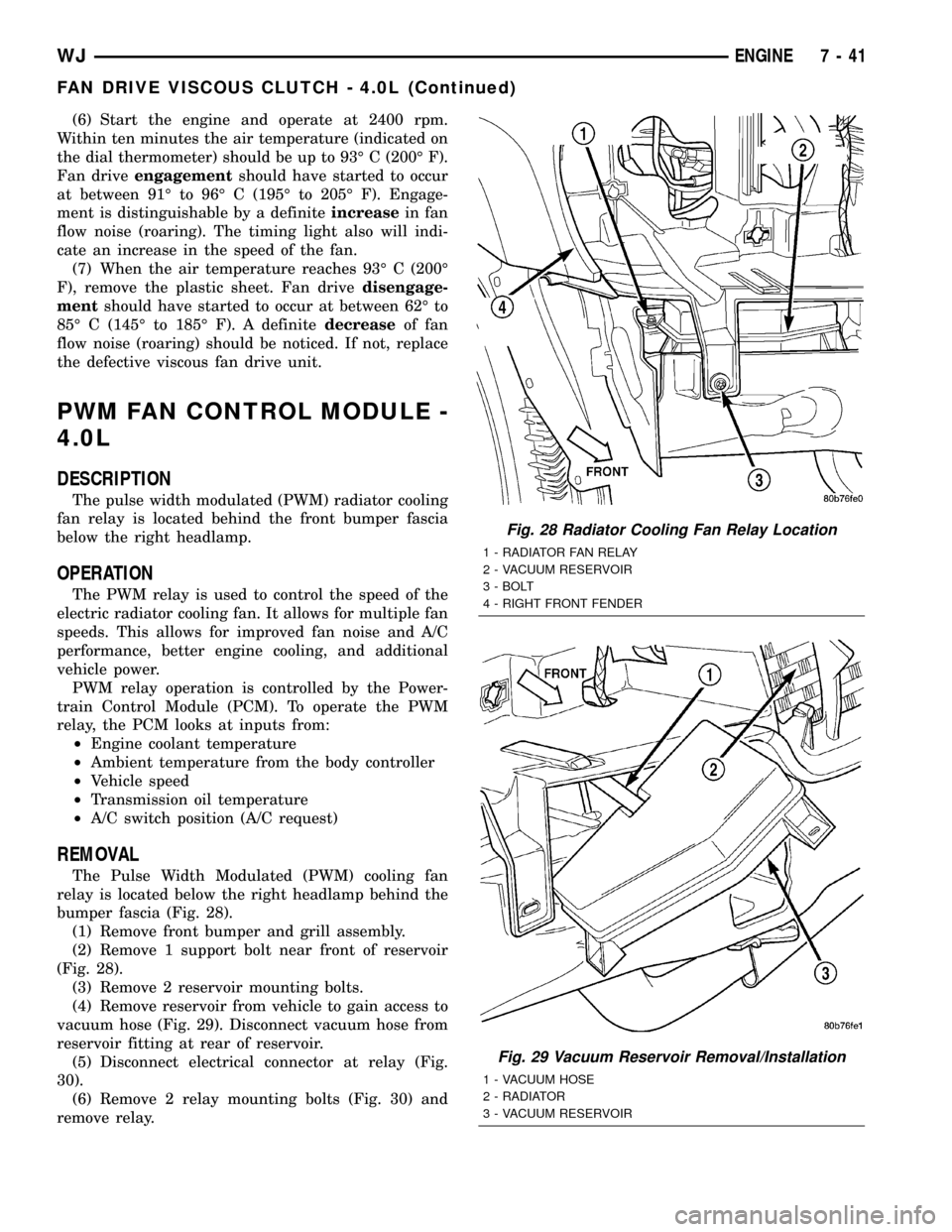

(4) Mark a line across the yoke at the transfer

case, link yoke and propeller shaft yoke at the rear of

the front propeller shaft for installation reference

(Fig. 9).

(5) Mark a line across the propeller shaft yoke and

pinion shaft yoke for installation reference.

Fig. 8 MEASUREMENT

1 - C/V JOINT CUP

2 - C/V BOOT END

3 - MEASUREMENT

Fig. 9 REFERENCE MARKS ON YOKES

1 - REFERENCE MARKS

3 - 6 PROPELLER SHAFTWJ

Page 264 of 2199

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 93É C (200É F).

Fan driveengagementshould have started to occur

at between 91É to 96É C (195É to 205É F). Engage-

ment is distinguishable by a definiteincreasein fan

flow noise (roaring). The timing light also will indi-

cate an increase in the speed of the fan.

(7) When the air temperature reaches 93É C (200É

F), remove the plastic sheet. Fan drivedisengage-

mentshould have started to occur at between 62É to

85É C (145É to 185É F). A definitedecreaseof fan

flow noise (roaring) should be noticed. If not, replace

the defective viscous fan drive unit.

PWM FAN CONTROL MODULE -

4.0L

DESCRIPTION

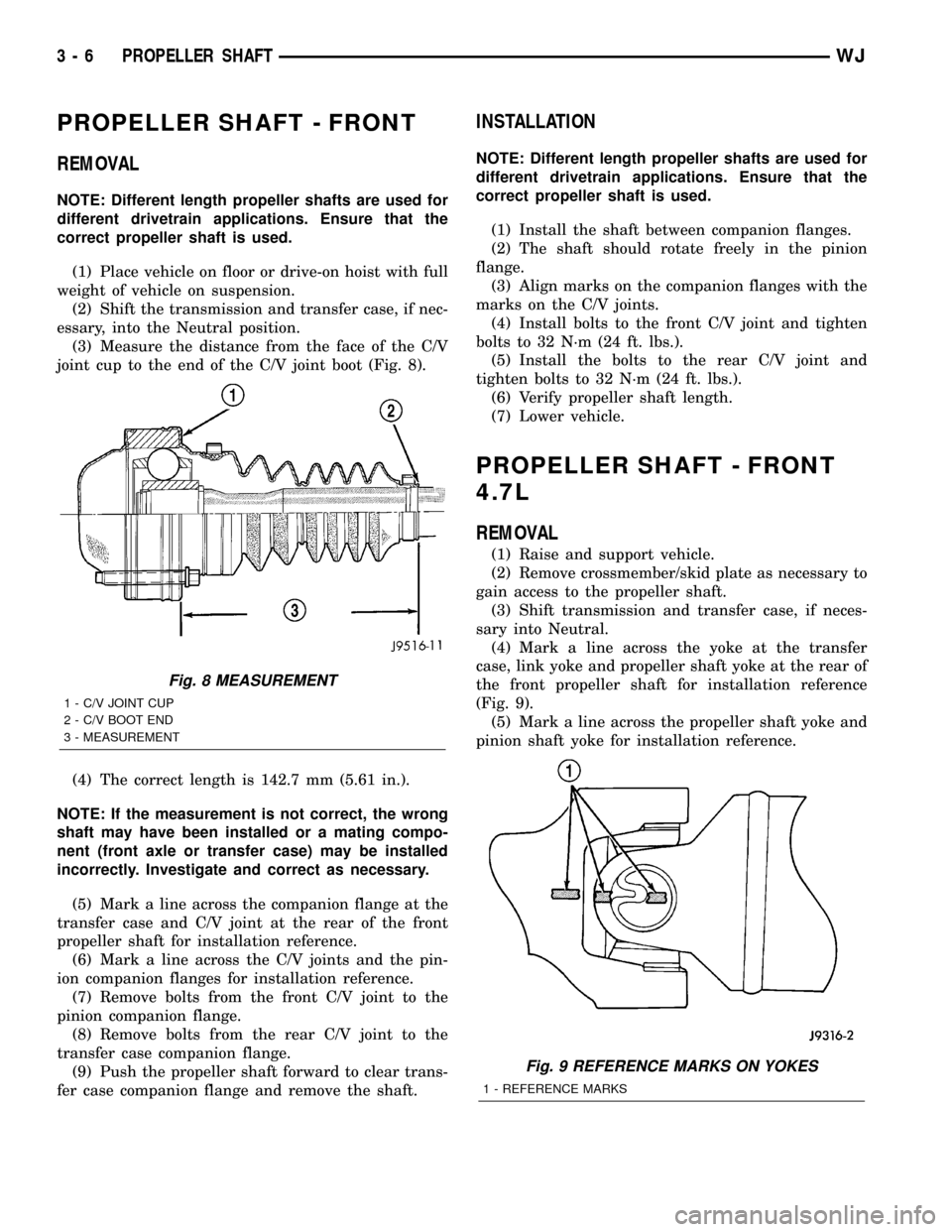

The pulse width modulated (PWM) radiator cooling

fan relay is located behind the front bumper fascia

below the right headlamp.

OPERATION

The PWM relay is used to control the speed of the

electric radiator cooling fan. It allows for multiple fan

speeds. This allows for improved fan noise and A/C

performance, better engine cooling, and additional

vehicle power.

PWM relay operation is controlled by the Power-

train Control Module (PCM). To operate the PWM

relay, the PCM looks at inputs from:

²Engine coolant temperature

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

²A/C switch position (A/C request)

REMOVAL

The Pulse Width Modulated (PWM) cooling fan

relay is located below the right headlamp behind the

bumper fascia (Fig. 28).

(1) Remove front bumper and grill assembly.

(2) Remove 1 support bolt near front of reservoir

(Fig. 28).

(3) Remove 2 reservoir mounting bolts.

(4) Remove reservoir from vehicle to gain access to

vacuum hose (Fig. 29). Disconnect vacuum hose from

reservoir fitting at rear of reservoir.

(5) Disconnect electrical connector at relay (Fig.

30).

(6) Remove 2 relay mounting bolts (Fig. 30) and

remove relay.

Fig. 28 Radiator Cooling Fan Relay Location

1 - RADIATOR FAN RELAY

2 - VACUUM RESERVOIR

3 - BOLT

4 - RIGHT FRONT FENDER

Fig. 29 Vacuum Reservoir Removal/Installation

1 - VACUUM HOSE

2 - RADIATOR

3 - VACUUM RESERVOIR

WJENGINE 7 - 41

FAN DRIVE VISCOUS CLUTCH - 4.0L (Continued)

Page 270 of 2199

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator into the vehicle. Guide the two radiator

alignment dowels through the holes in the rubber air

seals first and then through the A/C support brackets

(Fig. 40). Continue to guide the alignment dowels

into the rubber grommets located in lower radiator

crossmember. The holes in the L-shaped brackets

(located on bottom of A/C condenser) must be posi-

tioned between bottom of rubber air seals and top of

rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator (Fig. 41).

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator (Fig. 41).

(4) Connect both transmission cooler lines at the

radiator (Fig. 41).

(5) Install both radiator mounting bolts (Fig. 41).

(6) Install air inlet duct at grill.

(7) Attach electric fan harness to shroud, then con-

nect harness to connector (Fig. 41).

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Install the fan/viscous fan drive assembly to

the water pump.

(10) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(11) Be sure of at least 25 mm (1.0 inch) between

tips of fan blades and fan shroud.

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery cable at battery.

(14) Start and warm engine. Check for leaks.

RADIATOR FAN MOTOR

DIAGNOSIS AND TESTINGÐELECTRIC

COOLING FAN

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) in memory if it detects

a problem in the auxiliary cooling fan relay or circuit.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

If the electric cooling fan is inoperative, check the

15A fuse in the junction block and the 40A fuse in

the Power Distribution Center (PDC) with a 12 volt

test lamp or DVOM. Refer to the inside of the PDC

cover for the exact location of the fuse. If fuses are

okay, refer to ELECTRICAL for cooling fan and relay

circuit schematic.

WATER PUMP - 4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

42).

DESCRIPTIONÐWATER PUMP BYPASS

The 4.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

through the radiator. The thermostat uses a stub

shaft located at the rear of the thermostat (Fig. 43)

to control flow through the bypass gallery.

OPERATION

OPERATIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

WJENGINE 7 - 47

RADIATOR - 4.0L (Continued)

Page 300 of 2199

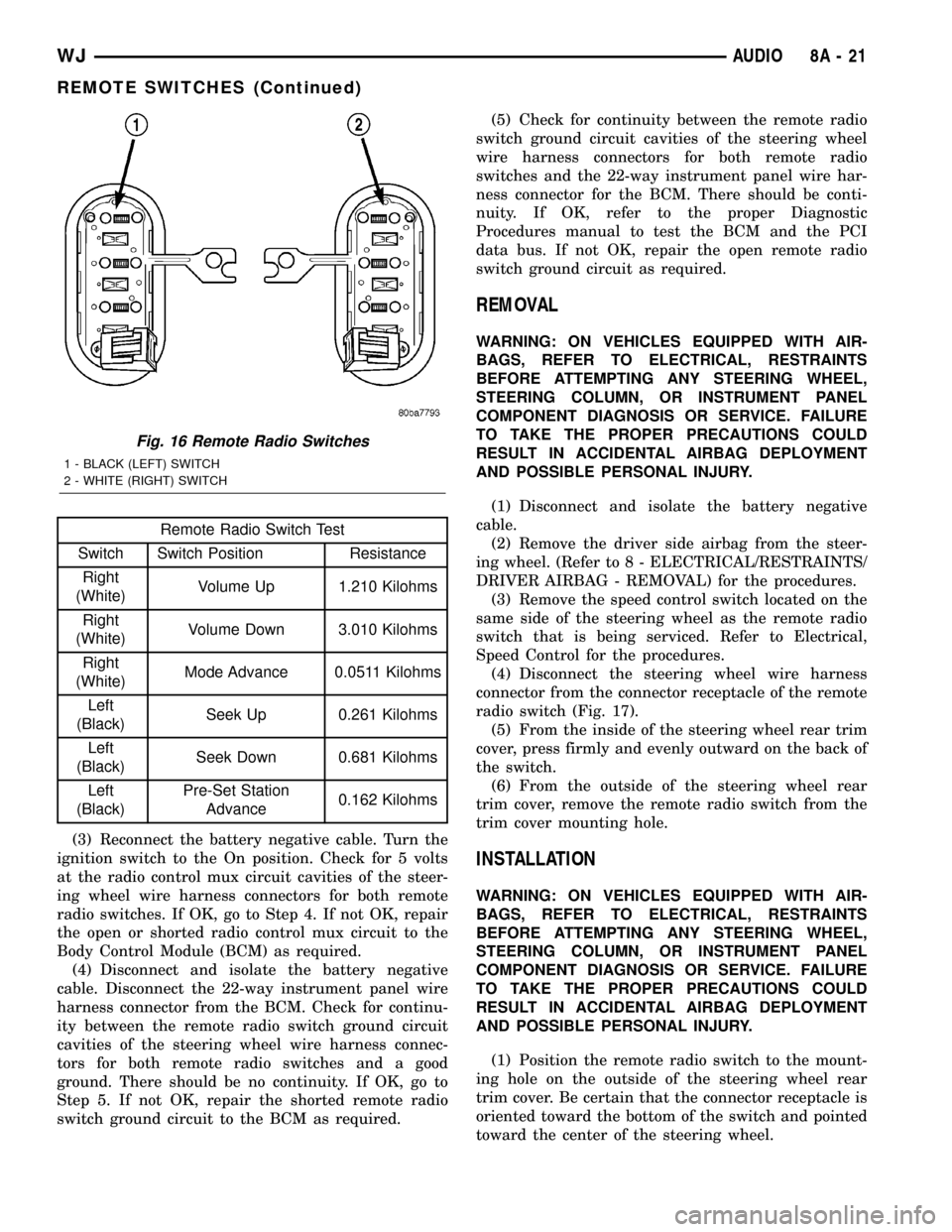

Remote Radio Switch Test

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Body Control Module (BCM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the BCM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the BCM as required.(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the BCM. There should be conti-

nuity. If OK, refer to the proper Diagnostic

Procedures manual to test the BCM and the PCI

data bus. If not OK, repair the open remote radio

switch ground circuit as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

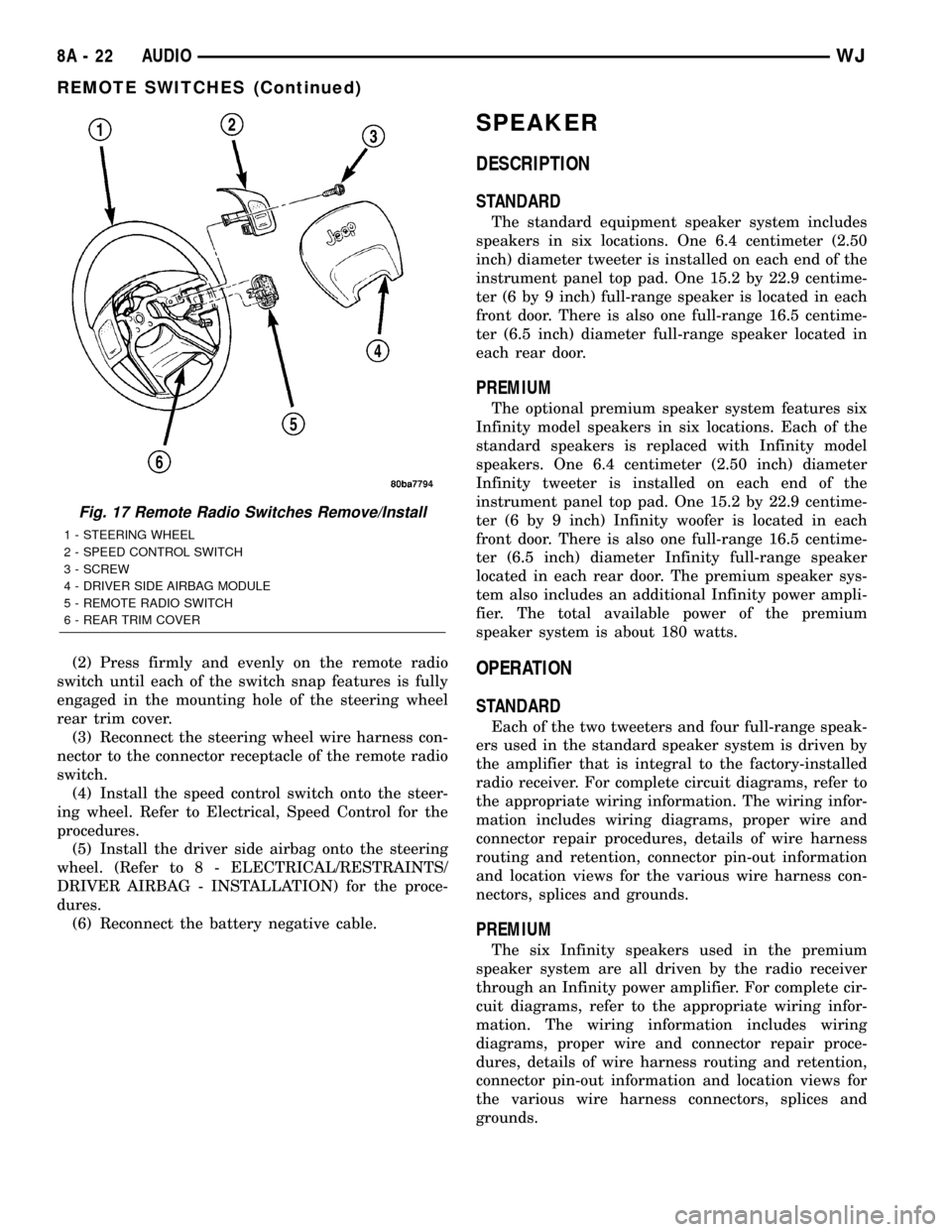

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag from the steer-

ing wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL) for the procedures.

(3) Remove the speed control switch located on the

same side of the steering wheel as the remote radio

switch that is being serviced. Refer to Electrical,

Speed Control for the procedures.

(4) Disconnect the steering wheel wire harness

connector from the connector receptacle of the remote

radio switch (Fig. 17).

(5) From the inside of the steering wheel rear trim

cover, press firmly and evenly outward on the back of

the switch.

(6) From the outside of the steering wheel rear

trim cover, remove the remote radio switch from the

trim cover mounting hole.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the remote radio switch to the mount-

ing hole on the outside of the steering wheel rear

trim cover. Be certain that the connector receptacle is

oriented toward the bottom of the switch and pointed

toward the center of the steering wheel.

Fig. 16 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

WJAUDIO 8A - 21

REMOTE SWITCHES (Continued)

Page 301 of 2199

(2) Press firmly and evenly on the remote radio

switch until each of the switch snap features is fully

engaged in the mounting hole of the steering wheel

rear trim cover.

(3) Reconnect the steering wheel wire harness con-

nector to the connector receptacle of the remote radio

switch.

(4) Install the speed control switch onto the steer-

ing wheel. Refer to Electrical, Speed Control for the

procedures.

(5) Install the driver side airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION) for the proce-

dures.

(6) Reconnect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in six locations. One 6.4 centimeter (2.50

inch) diameter tweeter is installed on each end of the

instrument panel top pad. One 15.2 by 22.9 centime-

ter (6 by 9 inch) full-range speaker is located in each

front door. There is also one full-range 16.5 centime-

ter (6.5 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features six

Infinity model speakers in six locations. Each of the

standard speakers is replaced with Infinity model

speakers. One 6.4 centimeter (2.50 inch) diameter

Infinity tweeter is installed on each end of the

instrument panel top pad. One 15.2 by 22.9 centime-

ter (6 by 9 inch) Infinity woofer is located in each

front door. There is also one full-range 16.5 centime-

ter (6.5 inch) diameter Infinity full-range speaker

located in each rear door. The premium speaker sys-

tem also includes an additional Infinity power ampli-

fier. The total available power of the premium

speaker system is about 180 watts.

OPERATION

STANDARD

Each of the two tweeters and four full-range speak-

ers used in the standard speaker system is driven by

the amplifier that is integral to the factory-installed

radio receiver. For complete circuit diagrams, refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

PREMIUM

The six Infinity speakers used in the premium

speaker system are all driven by the radio receiver

through an Infinity power amplifier. For complete cir-

cuit diagrams, refer to the appropriate wiring infor-

mation. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

Fig. 17 Remote Radio Switches Remove/Install

1 - STEERING WHEEL

2 - SPEED CONTROL SWITCH

3 - SCREW

4 - DRIVER SIDE AIRBAG MODULE

5 - REMOTE RADIO SWITCH

6 - REAR TRIM COVER

8A - 22 AUDIOWJ

REMOTE SWITCHES (Continued)

Page 307 of 2199

The chime warning system provides an audible

indication to the vehicle operator under the following

conditions:

²Fasten Seat Belt Warning- The Body Control

Module (BCM) chime tone generator will generate

repetitive chimes to announce that an input from the

seat belt switch indicates the driver side front seat

belt is not fastened. Unless the driver side front seat

belt is fastened, the chimes will continue to sound for

a duration of about six seconds each time the ignition

switch is turned to the On position or until the driver

side front seat belt is fastened.

²Head/Park Lights-On Warning- The BCM

chime tone generator will generate repetitive chimes

at a fast rate to announce that a Programmable

Communications Interface (PCI) data bus driver door

ajar message, along with hard wired inputs from the

headlamp switch indicate that the exterior lamps are

turned On with the driver side front door opened.

The chime will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position.

²Key-In-Ignition Warning- The BCM chime

tone generator will generate repetitive chimes at a

fast rate to announce that a PCI data bus driver door

ajar message received from the Driver Door Module

(DDM), along with hard wired inputs from the key-

in-ignition warning switch indicate that the key is in

the ignition cylinder with the driver side front door

opened and the ignition switch in the Off position.

The chime will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position.

²Overspeed Warning- The BCM chime tone

generator will generate repetitive chimes at a slowrate to announce that a PCI data bus vehicle speed

message received from the Powertrain Control Mod-

ule (PCM) indicates that the vehicle speed is above

120 kilometers-per-hour (75 miles-per-hour). The

chimes will continue to sound until the vehicle speed

is below 120 kilometers-per-hour (75 miles-per-hour).

This feature is only enabled on a BCM that has been

programmed with a Middle East Gulf Coast Country

(GCC) country code.

²Tactile Beep Support- The BCM chime tone

generator will generate a single beep each time a

PCI data bus tactile beep request message is received

from the Electronic Vehicle Information Center

(EVIC) or the Sentry Key Immobilizer Module

(SKIM). This beep provides an audible confirmation

that an EVIC button was completely depressed, or

that the optional Sentry Key Immobilizer System

(SKIS) is in the ªCustomer Learnº mode.

²Warning Beep Support- The BCM chime tone

generator will generate a short series of beeps each

time a PCI data bus warning beep request message

is received from the EVIC or the Electro-Mechanical

Instrument Cluster (EMIC). These beeps provide an

audible alert to the vehicle operator, of certain visual

warning indications displayed by the EVIC and/or

the EMIC.

The BCM provides chime service for all available

features in the chime warning system. The BCM

relies upon message inputs received from other mod-

ules over the PCI data bus network to provide chime

service for all of the remaining chime warning sys-

tem features.

The internal programming of the BCM determines

the priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

8B - 2 CHIME/BUZZERWJ

CHIME WARNING SYSTEM (Continued)

Page 310 of 2199

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................1

ADJUSTABLE PEDALS MODULE

REMOVAL.............................2

INSTALLATION..........................3

BODY CONTROL MODULE

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE.............................4

REMOVAL.............................5

INSTALLATION..........................5

COMMUNICATION

DESCRIPTION..........................6

OPERATION............................6

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................7

INSTALLATION..........................7

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR.....7

OPERATION - DATA LINK CONNECTOR......7

DOOR MODULE

DESCRIPTION..........................7

OPERATION............................9

DIAGNOSIS AND TESTING - DOOR MODULE . 10

REMOVAL.............................10

INSTALLATION.........................10

MEMORY HEATED SEAT/MIRROR MODULE

DESCRIPTION.........................10OPERATION...........................11

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE............................11

REMOVAL.............................11

INSTALLATION.........................12

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM..................12

MODES OF OPERATION................12

DESCRIPTION - 5 VOLT SUPPLIES.......14

DESCRIPTION - IGNITION CIRCUIT SENSE . 14

DESCRIPTION - POWER GROUNDS......15

DESCRIPTION - SENSOR RETURN.......15

OPERATION

OPERATION - PCM....................15

OPERATION - 5 VOLT SUPPLIES.........16

OPERATION - IGNITION CIRCUIT SENSE . . . 16

REMOVAL.............................16

INSTALLATION.........................17

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................18

INSTALLATION.........................19

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................19

OPERATION...........................19

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK

LEARN..............................22

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM, be sure to check

the related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM failures are caused by internal compo-

nent failures (i.e. relays and solenoids) and shorted

circuits (i.e. pull-ups, drivers, and switched cir-

cuits). These failures are difficult to detect when a

double fault has occurred and only one DTC has

been set.When a PCM (JTEC) and the SKIM are replaced

at the same time, perform the following steps in

order:

(1) Program the new PCM (JTEC).

(2) Program the new SKIM.

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (JTEC)

The SKIS Secret Key is an ID code that is unique

to each SKIM. This code is programmed and stored

in the SKIM, the PCM, and the ignition key tran-

sponder chip(s). When replacing the PCM, it is nec-

essary to program the secret key into the new PCM

using the DRBIIItscan tool. Perform the following

steps to program the secret key into the PCM.

WJELECTRONIC CONTROL MODULES 8E - 1

Page 316 of 2199

faults arenoterased if the battery is disconnected.

(Fig. 4)

REMOVAL

(1) Remove negative battery cable from the bat-

tery.

(2) Remove air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL) OR (Refer to 9 - ENGINE/

AIR INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

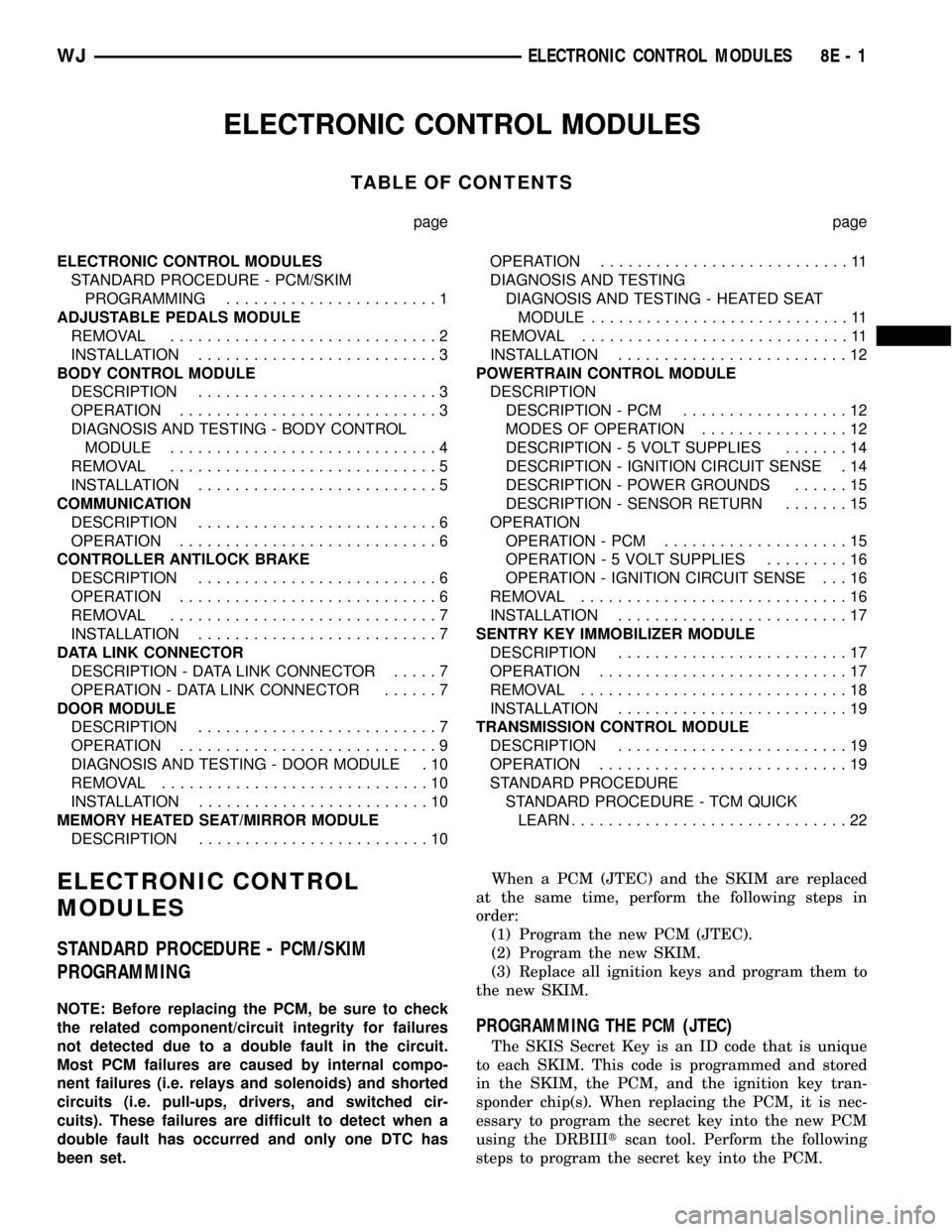

(3) Release CAB harness connector and remove

connector (Fig. 5).

(4) Remove pump motor connector.

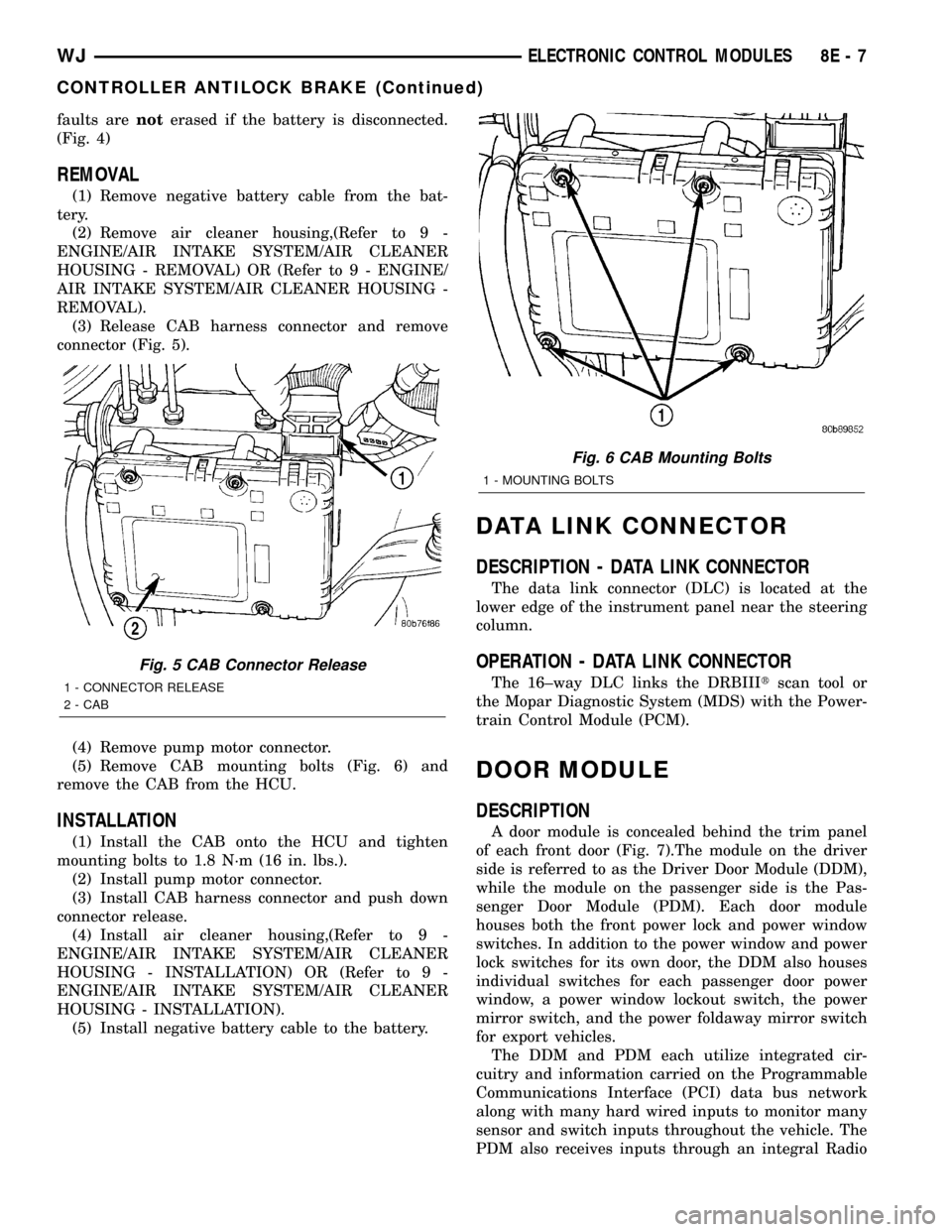

(5) Remove CAB mounting bolts (Fig. 6) and

remove the CAB from the HCU.

INSTALLATION

(1) Install the CAB onto the HCU and tighten

mounting bolts to 1.8 N´m (16 in. lbs.).

(2) Install pump motor connector.

(3) Install CAB harness connector and push down

connector release.

(4) Install air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION) OR (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(5) Install negative battery cable to the battery.

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR

The data link connector (DLC) is located at the

lower edge of the instrument panel near the steering

column.

OPERATION - DATA LINK CONNECTOR

The 16±way DLC links the DRBIIItscan tool or

the Mopar Diagnostic System (MDS) with the Power-

train Control Module (PCM).

DOOR MODULE

DESCRIPTION

A door module is concealed behind the trim panel

of each front door (Fig. 7).The module on the driver

side is referred to as the Driver Door Module (DDM),

while the module on the passenger side is the Pas-

senger Door Module (PDM). Each door module

houses both the front power lock and power window

switches. In addition to the power window and power

lock switches for its own door, the DDM also houses

individual switches for each passenger door power

window, a power window lockout switch, the power

mirror switch, and the power foldaway mirror switch

for export vehicles.

The DDM and PDM each utilize integrated cir-

cuitry and information carried on the Programmable

Communications Interface (PCI) data bus network

along with many hard wired inputs to monitor many

sensor and switch inputs throughout the vehicle. The

PDM also receives inputs through an integral Radio

Fig. 5 CAB Connector Release

1 - CONNECTOR RELEASE

2 - CAB

Fig. 6 CAB Mounting Bolts

1 - MOUNTING BOLTS

WJELECTRONIC CONTROL MODULES 8E - 7

CONTROLLER ANTILOCK BRAKE (Continued)