automatic transmission fluid JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 12 of 2199

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS - FLUID CAPACITIES.......1

INTERNATIONAL SYMBOLS

DESCRIPTION..........................2

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE - PARTS &

LUBRICANT RECOMMENDATIONS.........2

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE COOLANT........2

DESCRIPTION - ENGINE COOLANT........3

ENGINE OIL..........................4

DESCRIPTION - ENGINE OIL.............4

DESCRIPTION........................5

DESCRIPTION - TRANSFER CASE - NV242 . . 5

DESCRIPTION - TRANSFER CASE - NV247 . . 5

DESCRIPTION - AUTOMATIC

TRANSMISSION FLUID..................5

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................6OPERATION - AUTOMATIC TRANSMISSION

FLUID...............................6

FLUID FILL/CHECK LOCATIONS

INSPECTION - FLUID FILL/CHECK

LOCATIONS..........................6

MAINTENANCE SCHEDULES

DESCRIPTION..........................6

LIFT POINTS

STANDARD PROCEDURE - HOISTING AND

JACKING RECOMMENDATIONS...........6

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 7

EMERGENCY TOW HOOKS

DESCRIPTION..........................8

TOWING

STANDARD PROCEDURE - TOWING

RECOMMENDATIONS...................8

LUBRICATION &

MAINTENANCE

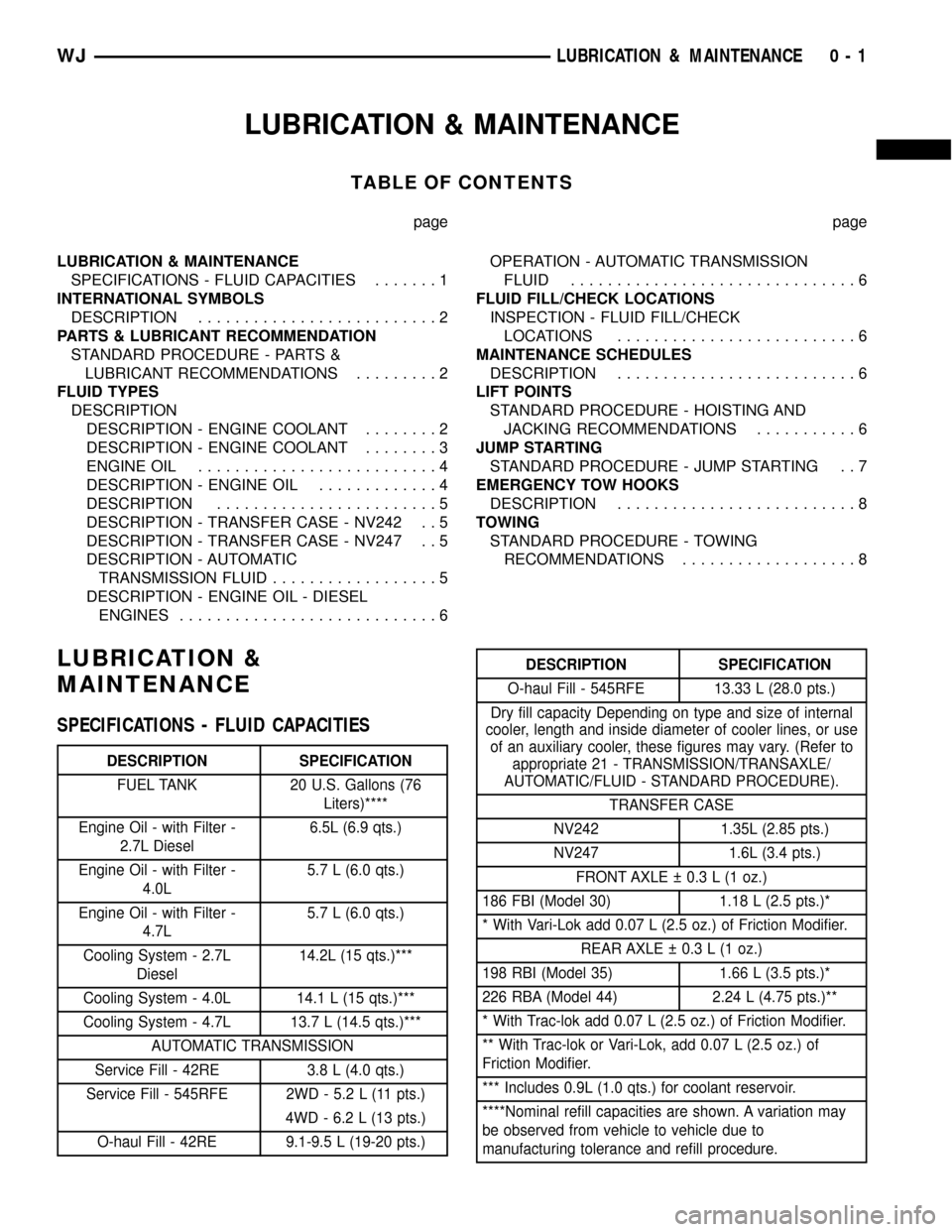

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK 20 U.S. Gallons (76

Liters)****

Engine Oil - with Filter -

2.7L Diesel6.5L (6.9 qts.)

Engine Oil - with Filter -

4.0L5.7 L (6.0 qts.)

Engine Oil - with Filter -

4.7L5.7 L (6.0 qts.)

Cooling System - 2.7L

Diesel14.2L (15 qts.)***

Cooling System - 4.0L 14.1 L (15 qts.)***

Cooling System - 4.7L 13.7 L (14.5 qts.)***

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

Service Fill - 545RFE 2WD - 5.2 L (11 pts.)

4WD - 6.2 L (13 pts.)

O-haul Fill - 42RE 9.1-9.5 L (19-20 pts.)

DESCRIPTION SPECIFICATION

O-haul Fill - 545RFE 13.33 L (28.0 pts.)

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or use

of an auxiliary cooler, these figures may vary. (Refer to

appropriate 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE).

TRANSFER CASE

NV242 1.35L (2.85 pts.)

NV247 1.6L (3.4 pts.)

FRONT AXLE 0.3 L (1 oz.)

186 FBI (Model 30) 1.18 L (2.5 pts.)*

* With Vari-Lok add 0.07 L (2.5 oz.) of Friction Modifier.

REAR AXLE 0.3 L (1 oz.)

198 RBI (Model 35) 1.66 L (3.5 pts.)*

226 RBA (Model 44) 2.24 L (4.75 pts.)**

* With Trac-lok add 0.07 L (2.5 oz.) of Friction Modifier.

** With Trac-lok or Vari-Lok, add 0.07 L (2.5 oz.) of

Friction Modifier.

*** Includes 0.9L (1.0 qts.) for coolant reservoir.

****Nominal refill capacities are shown. A variation may

be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

WJLUBRICATION & MAINTENANCE 0 - 1

Page 16 of 2199

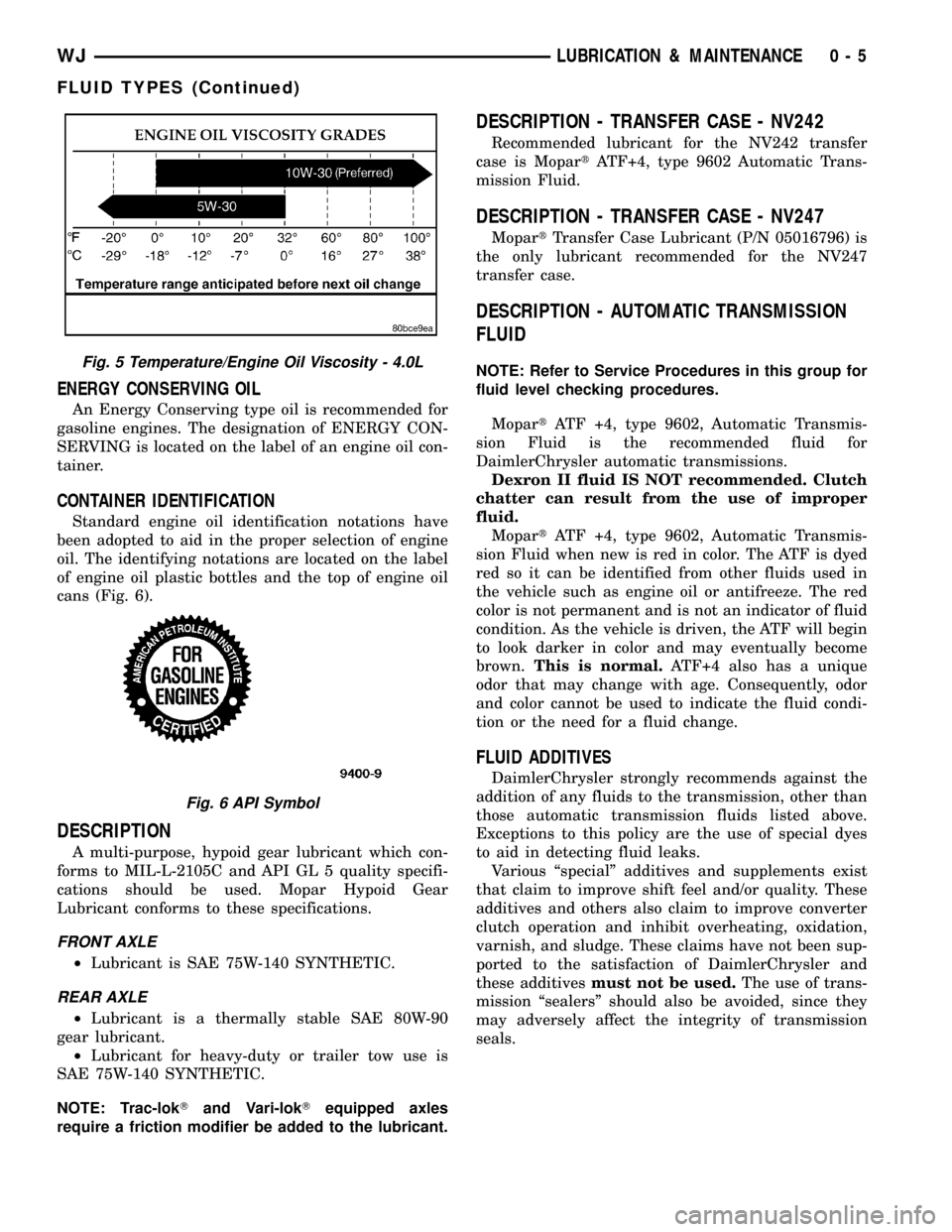

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 6).

DESCRIPTION

A multi-purpose, hypoid gear lubricant which con-

forms to MIL-L-2105C and API GL 5 quality specifi-

cations should be used. Mopar Hypoid Gear

Lubricant conforms to these specifications.

FRONT AXLE

²Lubricant is SAE 75W-140 SYNTHETIC.

REAR AXLE

²Lubricant is a thermally stable SAE 80W-90

gear lubricant.

²Lubricant for heavy-duty or trailer tow use is

SAE 75W-140 SYNTHETIC.

NOTE: Trac-lokTand Vari-lokTequipped axles

require a friction modifier be added to the lubricant.

DESCRIPTION - TRANSFER CASE - NV242

Recommended lubricant for the NV242 transfer

case is MopartATF+4, type 9602 Automatic Trans-

mission Fluid.

DESCRIPTION - TRANSFER CASE - NV247

MopartTransfer Case Lubricant (P/N 05016796) is

the only lubricant recommended for the NV247

transfer case.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

MopartATF +4, type 9602, Automatic Transmis-

sion Fluid is the recommended fluid for

DaimlerChrysler automatic transmissions.

Dexron II fluid IS NOT recommended. Clutch

chatter can result from the use of improper

fluid.

MopartATF +4, type 9602, Automatic Transmis-

sion Fluid when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.ATF+4 also has a unique

odor that may change with age. Consequently, odor

and color cannot be used to indicate the fluid condi-

tion or the need for a fluid change.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

Fig. 5 Temperature/Engine Oil Viscosity - 4.0L

Fig. 6 API Symbol

WJLUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

Page 17 of 2199

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oils

that meet Chrysler material standard MS-6395, be

used. European Grade 10W-40 oils are also accept-

able.

Oils of the SAE 5W-40 or 8W-80 grade number are

preferred when minimum temperatures consistently

fall below -12ÉC.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

FLUID FILL/CHECK

LOCATIONS

INSPECTION - FLUID FILL/CHECK LOCATIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

MAINTENANCE SCHEDULES

DESCRIPTION

9Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.9

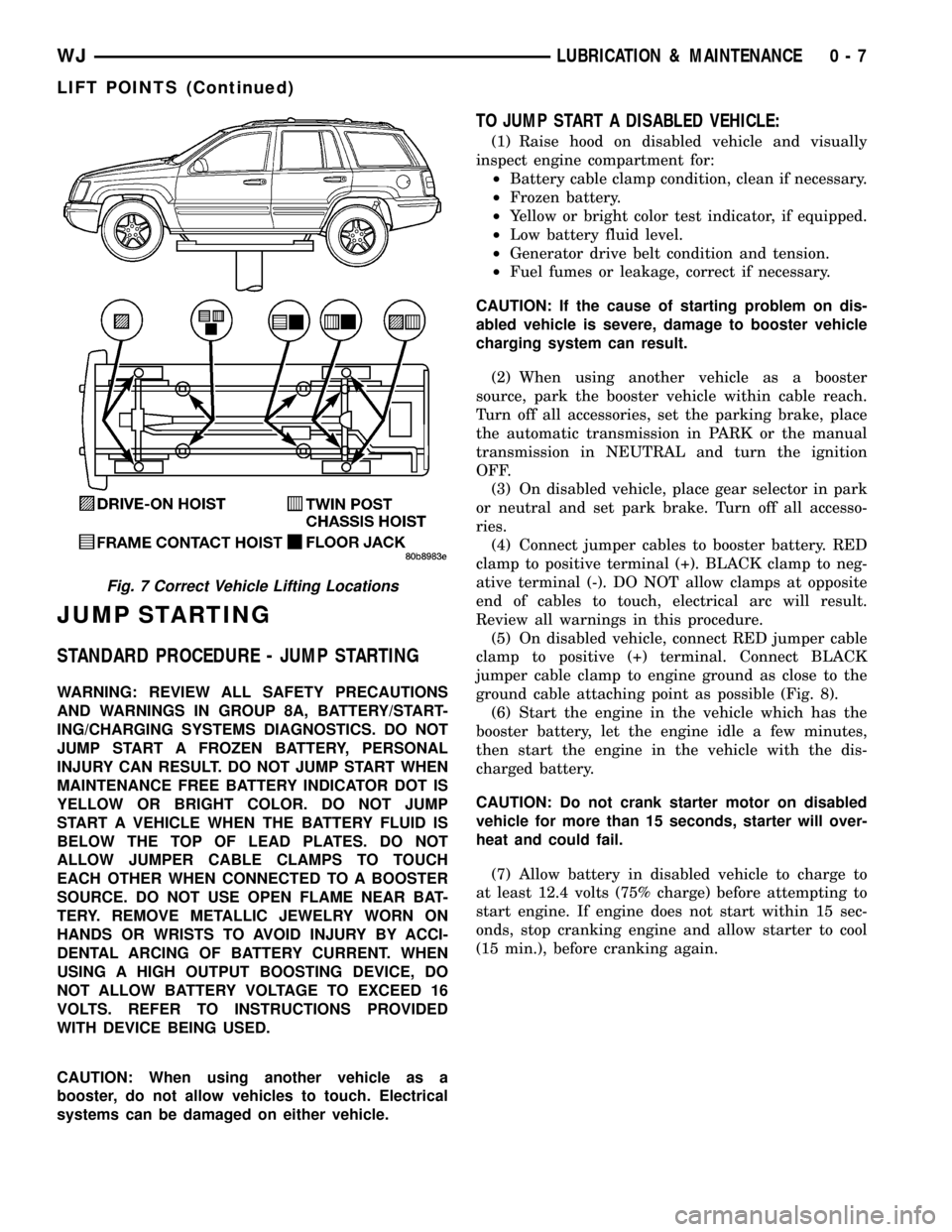

LIFT POINTS

STANDARD PROCEDURE - HOISTING AND

JACKING RECOMMENDATIONS

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a WJ vehicle (Fig. 7). Support the vehicle in

the raised position with jack stands at the front and

rear ends of the frame rails.

CAUTION: Do not attempt to lift a vehicle with a

floor jack positioned under:

²An axle tube.

²Aluminum differential.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7).

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

0 - 6 LUBRICATION & MAINTENANCEWJ

FLUID TYPES (Continued)

Page 18 of 2199

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

Fig. 7 Correct Vehicle Lifting Locations

WJLUBRICATION & MAINTENANCE 0 - 7

LIFT POINTS (Continued)

Page 278 of 2199

TRANSMISSION

TABLE OF CONTENTS

page page

TRANS COOLER

DESCRIPTION.........................55STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES.................55

TRANS COOLER

DESCRIPTION

An internal high capacity/high efficiency cooler is

used on all vehicles these coolers are an oil-to-coolant

type which consists of plates mounted in the radiator

outlet tank (Fig. 36). Because the internal oil cooler

is so efficient, no auxiliary oil cooler is offered The

cooler is not servicable seperatly from the radiator.

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES

When a transmission failure has contaminated the

fluid, the oil cooler(s) must be flushed. The torque

converter must also be replaced. This will insure that

metal particles or sludged oil are not later trans-

ferred back into the reconditioned (or replaced) trans-

mission.

The only recommended procedure for flushing cool-

ers and lines is to use Tool 6906-B Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906-B.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.(2) Reinstall filler plug on Tool 6906-B.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

NOTE: The converter drainback valve must be

removed and an appropriate replacement hose

installed to bridge the space between the transmis-

sion cooler line and the cooler fitting. Failure to

remove the drainback valve will prevent reverse

flushing the system. A suitable replacement hose

can be found in the adapter kit supplied with the

flushing tool.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF +4, type 9602, Automatic

Transmission Fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

WJTRANSMISSION 7 - 55

Page 421 of 2199

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the data bus message inputs to the EMIC that con-

trol the VFD functions requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for the odometer

and trip odometer functions of the VFD may be found

elsewhere in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC circuit

board. The turn signal indicators are hard wired. The

brake indicator is controlled by PCI data bus mes-

sages from the Controller Antilock Brake (CAB) as

well as by hard wired park brake switch and brake

fluid level switch inputs to the EMIC. The Malfunc-

tion Indicator Lamp (MIL) is normally controlled by

PCI data bus messages from the Powertrain Control

Module (PCM); however, if the EMIC loses PCI data

bus communication, the EMIC circuitry will automat-

ically turn the MIL on until PCI data bus communi-

cation is restored. The EMIC uses PCI data bus

messages from the Airbag Control Module (ACM), the

BCM, the PCM, the CAB, the Sentry Key Immobi-

lizer Module (SKIM), and the Transmission Control

Module (TCM) to control all of the remaining indica-

tors.

The various indicators are controlled by different

strategies; some receive fused ignition switch output

from the EMIC circuitry and have a switched ground,

others are grounded through the EMIC circuitry and

have a switched battery feed, while still others are

completely controlled by the EMIC microprocessor

based upon various hard wired and electronic mes-

sage inputs. Some indicators are illuminated at a

fixed intensity, while the illumination intensity of

others is synchronized with that of the EMIC general

illumination lamps.

The hard wired indicators are diagnosed using con-

ventional diagnostic methods. The EMIC and PCI

bus message controlled indicators are diagnosed

using the EMIC self-diagnostic actuator test. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). Proper testing of the

PCI data bus and the electronic data bus message

inputs to the EMIC that control each indicator

require the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.CLUSTER ILLUMINATION

Two types of general cluster illumination are avail-

able in this model. Base versions of the EMIC have

several incandescent illumination lamps, while pre-

mium versions of the EMIC have a single electro-lu-

minescent lamp. Both types of lamps provide cluster

back lighting whenever the exterior lighting is

turned On with the control knob on the left (lighting)

multi-function switch control stalk. The illumination

intensity of these lamps is adjusted by the EMIC

microprocessor based upon electronic dimming level

messages received from the Body Control Module

(BCM) over the PCI data bus. The BCM provides

electronic dimming level messages to the EMIC

based upon internal programming and inputs it

receives when the control ring on the left (lighting)

multi-function switch control stalk is rotated (down

to dim, up to brighten) to one of six available minor

detent positions.

The incandescent illumination lamps receive bat-

tery current at all times, while the ground for these

lamps is controlled by a 12-volt Pulse Width Modu-

lated (PWM) output of the EMIC electronic circuitry.

The illumination intensity of these bulbs and of the

vacuum-fluorescent electronic display are controlled

by the instrument cluster microprocessor based upon

dimming level messages received from the Body Con-

trol Module (BCM) over the PCI data bus. The BCM

uses inputs from the headlamp and panel dimmer

switches within the left (lighting) multi-function

switch control stalk and internal programming to

decide what dimming level message is required. The

BCM then sends the proper dimming level messages

to the EMIC over the PCI data bus.

The electro-luminescent lamp unit consists of lay-

ers of phosphor, carbon, idium tin oxide, and dielec-

tric applied by a silk-screen process between two

polyester membranes and includes a short pigtail

wire and connector. The lamp pigtail wire is con-

nected to a small connector receptacle on the EMIC

circuit board through a small clearance hole in the

cluster housing rear cover. The EMIC electronic cir-

cuitry also uses a PWM strategy to control the illu-

mination intensity of this lamp; however, the EMIC

powers this lamp with an Alternating Current (AC)

rated at 80 volts rms (root mean squared) and 415

Hertz, which excites the phosphor particles causing

them to luminesce.

The BCM also has several hard wired panel lamp

driver outputs and sends the proper panel lamps

dimming level messages over the PCI data bus to

coordinate the illumination intensity of all of the

instrument panel lighting and the VFDs of other

electronic modules on the PCI data bus. Vehicles

equipped with the Auto Headlamps option have an

automatic parade mode. In this mode, the BCM uses

8J - 6 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 447 of 2199

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The tachome-

ter is an air core magnetic unit that receives battery

current on the instrument cluster electronic circuit

board through the fused ignition switch output (run-

start) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Engine Speed Message- Each time the cluster

receives an engine speed message from the PCM it

will calculate the correct engine speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new

engine speed message and reposition the gauge

pointer accordingly about every 86 milliseconds. The

gauge needle will continue to be positioned at the

actual engine speed position on the gauge scale until

the ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about six sec-

onds, or until the ignition switch is turned to the Off

position, whichever occurs first. If a new engine

speed message is not received after about six sec-

onds, the gauge needle will return to the far left

(low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the crankshaft posi-

tion sensor to determine the engine speed, then

sends the proper engine speed messages to the

instrument cluster. For further diagnosis of the

tachometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the crankshaft position

sensor, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the tachometer, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

TRANS TEMP INDICATOR

DESCRIPTION

A transmission over-temperature indicator is stan-

dard equipment on all gasoline engine instrument

clusters. The transmission over-temperature indica-

tor is located near the lower right corner of theinstrument cluster, to the right of the speedometer.

The transmission over-temperature indicator consists

of the words ªTRANS OVER TEMPº imprinted on an

amber lens. The lens is located behind a cutout in

the opaque layer of the instrument cluster overlay.

The dark outer layer of the overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. The words ªTRANS OVER TEMPº appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. The

transmission over-temperature indicator lens is ser-

viced as a unit with the instrument cluster lens, hood

and mask unit.

OPERATION

The transmission over-temperature indicator gives

an indication to the vehicle operator when the trans-

mission fluid temperature is excessive, which may

lead to accelerated transmission component wear or

failure. This indicator is controlled by a transistor on

the instrument cluster electronic circuit board based

upon cluster programming and electronic messages

received by the cluster over the Programmable Com-

munications Interface (PCI) data bus. These mes-

sages are sent by the Powertrain Control Module

(PCM) or by the Transmission Control Module

(TCM), depending on the model of the automatic

transmission. The transmission over-temperature

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the indicator will always be off when the ignition

switch is in any position except On or Start. The bulb

only illuminates when it is provided a path to ground

by the instrument cluster transistor. The instrument

cluster will turn on the transmission over-tempera-

ture indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the transmission over-tem-

perature indicator is illuminated for about three sec-

onds as a bulb test.

²Trans Over-Temp Indicator Lamp-On Mes-

sage- Each time the cluster receives a trans over-

temp indicator lamp-on message from the PCM or

TCM indicating that the transmission fluid tempera-

ture is 135É C (275É F) or higher, the transmission

over-temperature indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a trans over-temp indicator lamp-off mes-

sage from the PCM or TCM, or until the ignition

8J - 32 INSTRUMENT CLUSTERWJ

TACHOMETER (Continued)

Page 490 of 2199

for door and liftgate open indications and to show if a

turn signal has been left on. The EVIC messages and

displays are coordinated with warning indicators in

the instrument cluster to avoid duplication.

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) data bus network. The PCI data bus

network allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities.

The EVIC module includes the following display

options:

²Compass and Temperature- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Average fuel economy- shows the average

fuel economy since the last trip computer reset.

²Distance to empty- shows the estimated dis-

tance that can be travelled with the fuel remaining

in the fuel tank. This estimated distance is computed

using the average miles-per-gallon from the last 30

gallons of fuel used.

²Instant fuel economy- shows the present fuel

economy based upon the current vehicle distance and

fuel used information.

²Trip distance- shows the distance travelled

since the last trip computer reset.

²Elapsed time- shows the accumulated igni-

tion-on time since the last trip computer reset.

²Distance to service- shows the distance

remaining until the next scheduled service interval.

²Tire Pressure- shows the tire pressure in each

tire.

²Blank screen- the EVIC compass/temperature/

trip computer VFD is turned off.

The EVIC is capable of displaying the following

alert messages, which are accompanied by an audible

announcement consisting of a series of beeps:

²TURN SIGNALS ON (with vehicle graphic)-

Indicates that a turn signal has remained on for

about 1.6 kilometers (one mile).

²PERFORM SERVICE- Indicates that a cus-

tomer programmable service interval distance has

been reached.

²DOOR OPEN (one or more, with vehicle

graphic)- Indicates that a door is open or not fully

closed.

²LIFTGATE OPEN (with vehicle graphic)-

Indicates that the liftgate is open or not fully closed.

²LIFTGLASS OPEN (with vehicle graphic)-

Indicates that the liftglass is open or not fully closed.²COOLANT LEVEL LOW (with vehicle

graphic)- Indicates that the coolant level in the

engine coolant reservoir is low.

²XX LOW PRESSURE (with vehicle graphic)

- Indicates that the air pressure in the selected tire

is low.

²WASHER FLUID LOW (with vehicle

graphic)- Indicates that the fluid level in the

washer fluid reservoir is low.

The EVIC ªMenuº push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Refer toELECTRONIC VEHICLE INFORMA-

TION CENTER PROGRAMMINGin the Service

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional mem-

ory system, the EVIC will display the following mem-

ory system messages:

²MEMORY #X POSITION SET (X = Driver 1

or Driver 2)- This message appears in the EVIC

display each time the memory system is successfully

programmed. It is accompanied by an audible

announcement chime tone.

²MEMORY SYSTEM DISABLED- The memory

system is automatically disabled while the driver

side seat belt is fastened and/or while the automatic

transmission gear selector is in any position except

Park or Neutral. This message appears in the EVIC

display as a reminder when a memory switch push

button is depressed while the memory system is dis-

abled. If the REMOTE LINKED TO MEMORY cus-

tomer programmable feature has been selected, this

message will also appear when the Unlock button of

the Remote Keyless Entry (RKE) transmitter is

depressed while the memory system is disabled.

If the vehicle is equipped with the optional Univer-

sal Transmitter transceiver, the EVIC will also dis-

play messages and an icon indicating when the

Universal Transmitter is being trained, which of the

three transmitter buttons is transmitting, and when

the transceiver is cleared.

If the vehicle is equipped with the optionalTire

Pressure Monitoring System, the EVIC will also

display messages and an icon indicating when the

tire air pressure falls below a given set-point, and

which of the five tires is transmitting the low pres-

sure warning, and when the condition is cleared.

Refer to the Tires/Wheels section of this manual for

complete Tire Pressure Monitoring System descrip-

tion. Refer to this section of the service manual for

EVIC modules function description for the Tire Pres-

sure Monitoring.

Data input for all EVIC functions, including VFD

dimming level, is received through PCI data bus

WJMESSAGE SYSTEMS 8M - 7

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 742 of 2199

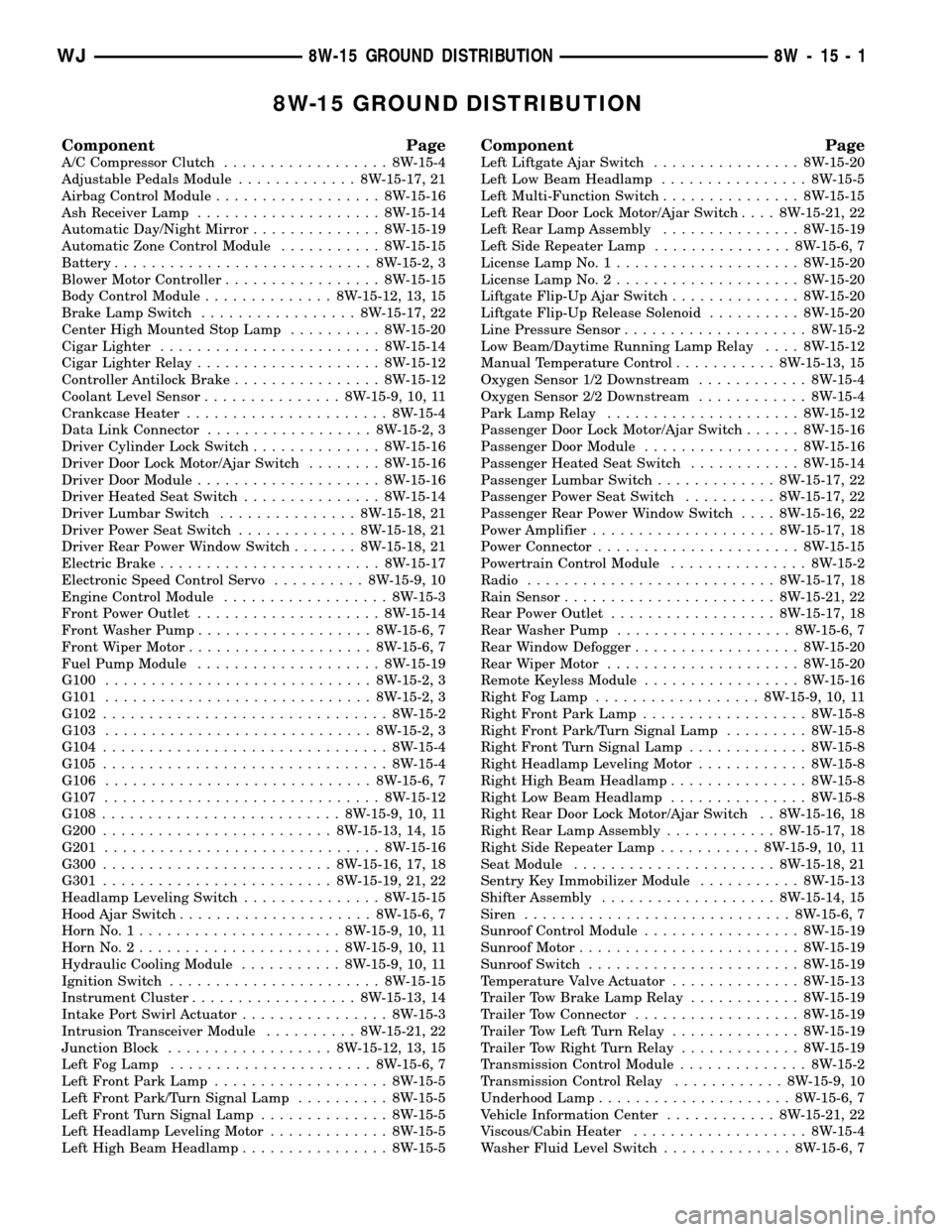

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch.................. 8W-15-4

Adjustable Pedals Module............. 8W-15-17, 21

Airbag Control Module.................. 8W-15-16

Ash Receiver Lamp.................... 8W-15-14

Automatic Day/Night Mirror.............. 8W-15-19

Automatic Zone Control Module........... 8W-15-15

Battery............................ 8W-15-2, 3

Blower Motor Controller................. 8W-15-15

Body Control Module.............. 8W-15-12, 13, 15

Brake Lamp Switch................. 8W-15-17, 22

Center High Mounted Stop Lamp.......... 8W-15-20

Cigar Lighter........................ 8W-15-14

Cigar Lighter Relay.................... 8W-15-12

Controller Antilock Brake................ 8W-15-12

Coolant Level Sensor............... 8W-15-9, 10, 11

Crankcase Heater...................... 8W-15-4

Data Link Connector.................. 8W-15-2, 3

Driver Cylinder Lock Switch.............. 8W-15-16

Driver Door Lock Motor/Ajar Switch........ 8W-15-16

Driver Door Module.................... 8W-15-16

Driver Heated Seat Switch............... 8W-15-14

Driver Lumbar Switch............... 8W-15-18, 21

Driver Power Seat Switch............. 8W-15-18, 21

Driver Rear Power Window Switch....... 8W-15-18, 21

Electric Brake........................ 8W-15-17

Electronic Speed Control Servo.......... 8W-15-9, 10

Engine Control Module.................. 8W-15-3

Front Power Outlet.................... 8W-15-14

Front Washer Pump................... 8W-15-6, 7

Front Wiper Motor.................... 8W-15-6, 7

Fuel Pump Module.................... 8W-15-19

G100............................. 8W-15-2, 3

G101............................. 8W-15-2, 3

G102............................... 8W-15-2

G103............................. 8W-15-2, 3

G104............................... 8W-15-4

G105............................... 8W-15-4

G106............................. 8W-15-6, 7

G107.............................. 8W-15-12

G108.......................... 8W-15-9, 10, 11

G200......................... 8W-15-13, 14, 15

G201.............................. 8W-15-16

G300......................... 8W-15-16, 17, 18

G301......................... 8W-15-19, 21, 22

Headlamp Leveling Switch............... 8W-15-15

Hood Ajar Switch..................... 8W-15-6, 7

Horn No. 1...................... 8W-15-9, 10, 11

Horn No. 2...................... 8W-15-9, 10, 11

Hydraulic Cooling Module........... 8W-15-9, 10, 11

Ignition Switch....................... 8W-15-15

Instrument Cluster.................. 8W-15-13, 14

Intake Port Swirl Actuator................ 8W-15-3

Intrusion Transceiver Module.......... 8W-15-21, 22

Junction Block.................. 8W-15-12, 13, 15

Left Fog Lamp...................... 8W-15-6, 7

Left Front Park Lamp................... 8W-15-5

Left Front Park/Turn Signal Lamp.......... 8W-15-5

Left Front Turn Signal Lamp.............. 8W-15-5

Left Headlamp Leveling Motor............. 8W-15-5

Left High Beam Headlamp................ 8W-15-5

Component Page

Left Liftgate Ajar Switch................ 8W-15-20

Left Low Beam Headlamp................ 8W-15-5

Left Multi-Function Switch............... 8W-15-15

Left Rear Door Lock Motor/Ajar Switch.... 8W-15-21, 22

Left Rear Lamp Assembly............... 8W-15-19

Left Side Repeater Lamp............... 8W-15-6, 7

License Lamp No. 1.................... 8W-15-20

License Lamp No. 2.................... 8W-15-20

Liftgate Flip-Up Ajar Switch.............. 8W-15-20

Liftgate Flip-Up Release Solenoid.......... 8W-15-20

Line Pressure Sensor.................... 8W-15-2

Low Beam/Daytime Running Lamp Relay.... 8W-15-12

Manual Temperature Control........... 8W-15-13, 15

Oxygen Sensor 1/2 Downstream............ 8W-15-4

Oxygen Sensor 2/2 Downstream............ 8W-15-4

Park Lamp Relay..................... 8W-15-12

Passenger Door Lock Motor/Ajar Switch...... 8W-15-16

Passenger Door Module................. 8W-15-16

Passenger Heated Seat Switch............ 8W-15-14

Passenger Lumbar Switch............. 8W-15-17, 22

Passenger Power Seat Switch.......... 8W-15-17, 22

Passenger Rear Power Window Switch.... 8W-15-16, 22

Power Amplifier.................... 8W-15-17, 18

Power Connector...................... 8W-15-15

Powertrain Control Module............... 8W-15-2

Radio........................... 8W-15-17, 18

Rain Sensor....................... 8W-15-21, 22

Rear Power Outlet.................. 8W-15-17, 18

Rear Washer Pump................... 8W-15-6, 7

Rear Window Defogger.................. 8W-15-20

Rear Wiper Motor..................... 8W-15-20

Remote Keyless Module................. 8W-15-16

Right Fog Lamp.................. 8W-15-9, 10, 11

Right Front Park Lamp.................. 8W-15-8

Right Front Park/Turn Signal Lamp......... 8W-15-8

Right Front Turn Signal Lamp............. 8W-15-8

Right Headlamp Leveling Motor............ 8W-15-8

Right High Beam Headlamp............... 8W-15-8

Right Low Beam Headlamp............... 8W-15-8

Right Rear Door Lock Motor/Ajar Switch . . 8W-15-16, 18

Right Rear Lamp Assembly............ 8W-15-17, 18

Right Side Repeater Lamp........... 8W-15-9, 10, 11

Seat Module...................... 8W-15-18, 21

Sentry Key Immobilizer Module........... 8W-15-13

Shifter Assembly................... 8W-15-14, 15

Siren............................. 8W-15-6, 7

Sunroof Control Module................. 8W-15-19

Sunroof Motor........................ 8W-15-19

Sunroof Switch....................... 8W-15-19

Temperature Valve Actuator.............. 8W-15-13

Trailer Tow Brake Lamp Relay............ 8W-15-19

Trailer Tow Connector.................. 8W-15-19

Trailer Tow Left Turn Relay.............. 8W-15-19

Trailer Tow Right Turn Relay............. 8W-15-19

Transmission Control Module.............. 8W-15-2

Transmission Control Relay............ 8W-15-9, 10

Underhood Lamp..................... 8W-15-6, 7

Vehicle Information Center............ 8W-15-21, 22

Viscous/Cabin Heater................... 8W-15-4

Washer Fluid Level Switch.............. 8W-15-6, 7

WJ8W-15 GROUND DISTRIBUTION 8W - 15 - 1

Page 1255 of 2199

(7) Remove the fan assembly from the water pump

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(8) Remove the fan shroud.

(9) Disconnect the transmission fluid cooler lines

(automatic transmission).

(10) Discharge the A/C system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(11) Remove the service valves and cap the com-

pressor ports.

(12) Remove the radiator or radiator/condenser (if

equipped with A/C).

(13) Disconnect the heater hoses at the engine

thermostat housing and water pump.

(14) Disconnect the accelerator cable, transmission

line pressure cable and speed control cable (if

equipped) from the throttle body.

(15) Remove cables from the bracket and secure

out of the way.

(16) Disconnect the body ground at the engine.

(17) Disconnect the following connectors and

secure their harness out of the way.

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(18) Disconnect the coil rail electrical connections

and the oil pressure switch connector.

(19) Perform the fuel pressure release procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(20) Disconnect the fuel supply line at the injector

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(21) Remove the fuel line bracket from the intake

manifold.

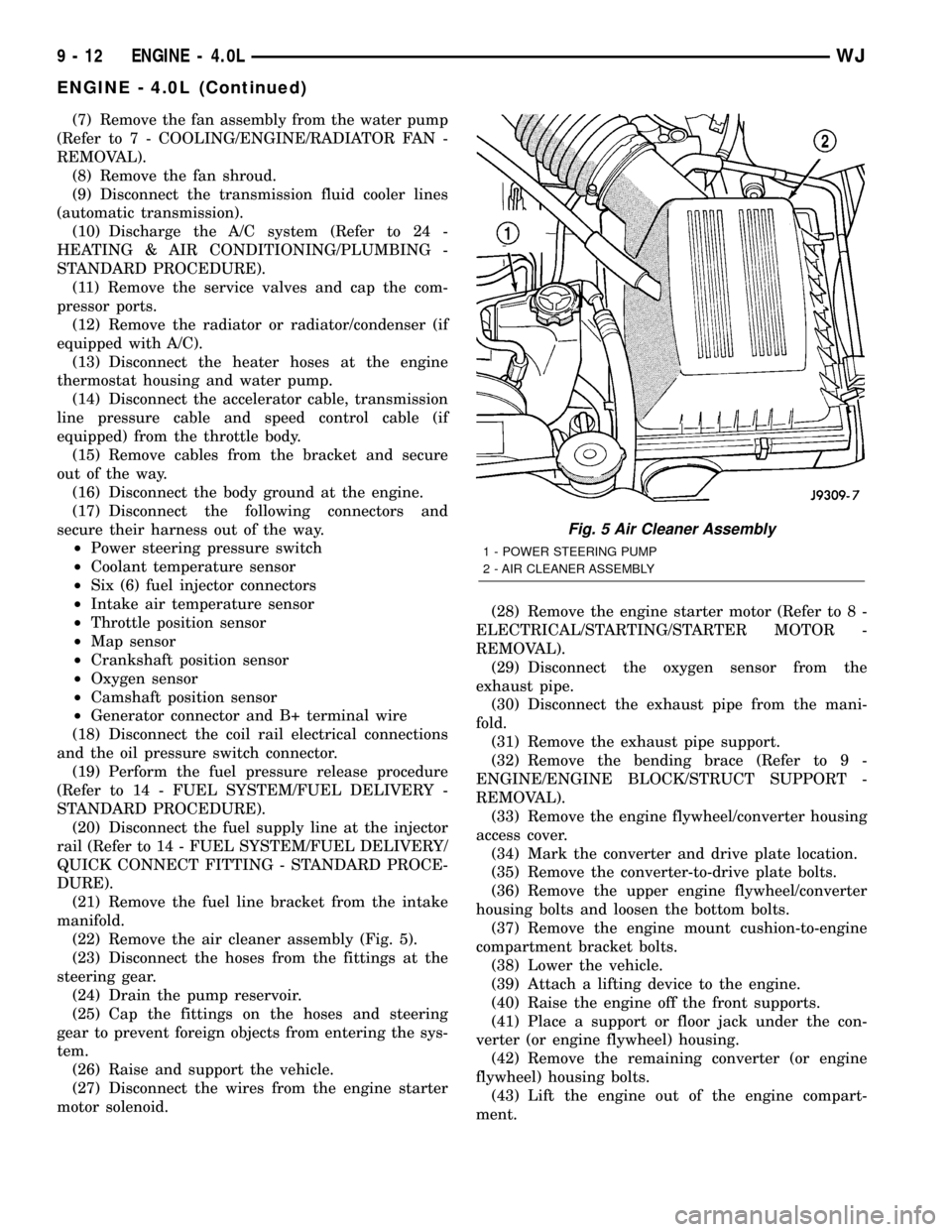

(22) Remove the air cleaner assembly (Fig. 5).

(23) Disconnect the hoses from the fittings at the

steering gear.

(24) Drain the pump reservoir.

(25) Cap the fittings on the hoses and steering

gear to prevent foreign objects from entering the sys-

tem.

(26) Raise and support the vehicle.

(27) Disconnect the wires from the engine starter

motor solenoid.(28) Remove the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

REMOVAL).

(29) Disconnect the oxygen sensor from the

exhaust pipe.

(30) Disconnect the exhaust pipe from the mani-

fold.

(31) Remove the exhaust pipe support.

(32) Remove the bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

REMOVAL).

(33) Remove the engine flywheel/converter housing

access cover.

(34) Mark the converter and drive plate location.

(35) Remove the converter-to-drive plate bolts.

(36) Remove the upper engine flywheel/converter

housing bolts and loosen the bottom bolts.

(37) Remove the engine mount cushion-to-engine

compartment bracket bolts.

(38) Lower the vehicle.

(39) Attach a lifting device to the engine.

(40) Raise the engine off the front supports.

(41) Place a support or floor jack under the con-

verter (or engine flywheel) housing.

(42) Remove the remaining converter (or engine

flywheel) housing bolts.

(43) Lift the engine out of the engine compart-

ment.

Fig. 5 Air Cleaner Assembly

1 - POWER STEERING PUMP

2 - AIR CLEANER ASSEMBLY

9 - 12 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)