manual radio set JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 281 of 2199

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. The standard equipment

audio system includes an AM/FM/cassette (RBB sales

code) radio receiver, and speakers in six locations.

Several combinations of radio receivers and speaker

systems are offered as optional equipment on this

model. The audio system uses an ignition switched

control of battery current so that the system will only

operate when the ignition switch is in the On or

Accessory positions.

A Compact Disc (CD) changer with a ten disc mag-

azine, remote radio switches with six functions

mounted to the backs of the steering wheel spokes,

and a memory system that automatically stores and

recalls up to twenty radio station presets (ten AM

and ten FM) and the last station listened to for two

drivers are optional factory-installed equipment on

this model. Refer to Electrical, Power Seats for more

information on the memory system.

The audio system includes the following compo-

nents:

²Antenna

²Compact disc changer (available with RBP sales

code radio receivers only)

²Power amplifier (with premium speaker system

only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches

²Speakers

Certain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB scan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect audio

system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

The audio system includes the following major

components, which are described in further detail

elsewhere in this service information:

²Amplifier- On models equipped with the

optional premium speaker system, an audio power

amplifier is located on the rear floor panel under-

neath the right end of the rear seat cushion in the

passenger compartment.

²Antenna Body and Cable- The most visible

component of the antenna body and cable are the

antenna adapter and the antenna cap nut, which are

located on the top of the right front fender panel of

the vehicle, near the right end of the cowl plenum.

²Antenna Mast- The antenna mast is a metal

rod that extends upward from the antenna body and

cable on the top of the right front fender panel of the

vehicle, near the right end of the cowl plenum.

²Radio- The radio for this model is located in

the instrument panel center stack area, inboard of

the instrument cluster and above the heater and air

conditioner controls.

²Radio Noise Suppression Ground Strap-A

radio noise suppression ground strap is installed

between the rear of the engine cylinder head(s) and

the dash panel sheet metal in the engine compart-

ment.

²Speaker- The standard speaker system

includes six speakers in six locations, while the pre-

mium speaker system includes an amplifier for the

six speakers in six locations.

Hard wired circuitry connects the audio system

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

audio system components through the use of a com-

bination of soldered splices, splice block connectors

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information in this service manual for com-

plete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

8A - 2 AUDIOWJ

Page 282 of 2199

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges. Electromagnetic radio

signals that are broadcast from a radio station

induce electrical modulations into the audio system

antenna mast. The antenna body and cable conduct

these weak signals from the antenna mast to the

radio. The radio then tunes and amplifies these weak

radio frequency signals into stronger electrical audio

signals that are required in order to operate the

audio system speakers. The speakers convert these

electrical signals into air movement, which repro-

duces the sounds being broadcast by the radio sta-

tion.

Some audio systems also offer the user the option

of selecting from and listening to prerecorded audio

cassette tapes, audio compact discs, or both. Regard-

less of the media type, the audio system components

provide the user with the ability to electronically

amplify and adjust the audio signals being repro-

duced by the speakers within the vehicle to suit the

preferences of the vehicle occupants.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the On or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the BCM receives hard wired

resistor multiplexed inputs from the remote radio

switches. The programming in the BCM allows it to

process those inputs and send the proper messages to

the radio receiver over the PCI data bus to control

the radio volume up or down, station seek up or

down, preset station advance, and mode advance

functions.On vehicles equipped with the optional memory

system, when the DDM receives a Driver 1 or Driver

2 memory recall input from the memory switch on

the driver side front door trim panel or a memory

recall message from the Remote Keyless Entry (RKE)

receiver in the PDM, the DDM sends a memory

recall message back to the radio receiver over the

PCI data bus to recall the radio station presets and

last station listened to information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WJAUDIO 8A - 3

AUDIO (Continued)

Page 284 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

POOR RADIO RECEPTION 1. Antenna faulty. 1. (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA

BODY & CABLE - DIAGNOSIS AND TESTING).

2. Radio ground faulty. 2. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

3. Radio noise suppression

faulty.3. (Refer to 8 - ELECTRICAL/AUDIO/RADIO

NOISE SUPPRESSION - DIAGNOSIS AND

TESTING).

4. Radio faulty. 4. (Refer to 8 - ELECTRICAL/AUDIO/RADIO -

DIAGNOSIS AND TESTING).

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape head. 3. Clean head with Mopar Cassette Head

Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION, OR CD

SKIPPING SOUND1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. Faulty CD player. 4. Exchange or replace radio, if required.

NO COMPACT DISC

CHANGER OPERATION, OR

CD SKIPPING SOUND1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. CD changer connector

faulty.4. Check for loose or corroded CD changer

connections. Repair, if required.

5. Wiring faulty. 5. Refer to Compact Disc Changer in the

Diagnosis and Testing section of this group.

6. PCI data bus faulty. 6. Use DRB scan tool and the Diagnostic

Procedures manual to test PCI data bus. Repair,

if required.

7. CD changer faulty. 7. Refer to Compact Disc Changer in the

Diagnosis and Testing section of this group.

WJAUDIO 8A - 5

AUDIO (Continued)

Page 295 of 2199

(7) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the antenna coaxial cable connector halves.

(8) Install the trim panel onto the right inner cowl

side. (Refer to 23 - BODY/INTERIOR/COWL TRIM -

INSTALLATION) for the procedures.

(9) Install the scuff plate onto the right front door

sill. (Refer to 23 - BODY/INTERIOR/DOOR SILL

SCUFF PLATE - INSTALLATION) for the proce-

dures.

(10) Reconnect the battery negative cable.

QUARTER GLASS INTEGRAL

ANTENNA - EXPORT

DESCRIPTION

The integral radio antenna element is bonded to

the right rear quarter glass and is replaced with the

glass assembly only.

OPERATION

The integral antenna receives RF (Radio Frequen-

cies) and sends them to the antenna module for

amplification.

DIAGNOSIS AND TESTING - QUARTER GLASS

INTEGRAL ANTENNA - EXPORT

For complete circuit diagrams, refer to the Appro-

priate Wiring Information. To detect breaks in the

integral antenna elements, the following procedure is

required:

(1) Disconnect the antenna module connector from

the antenna.

(2) Using a Ohmmeter, place both leads onto the

connector pins on the integral antenna. If continuity

is present antenna grid is Okay. If continuity is not

present move one lead through the grid in progres-

sion until continuity is detected. A break in the

antenna grid can be repaired using a Mopar Rear

Window Defogger Repair Kit (Part Number 4267922)

or equivalent. (Refer to 8 - ELECTRICAL/WINDOW

DEFOGGER/REAR WINDOW DEFOGGER GRID -

STANDARD PROCEDURE)

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette with CD changer

control feature (RBB sales code), an AM/FM/CD/2-

band graphic equalizer with CD changer control fea-

ture (RBK sales code), or an AM/FM/CD/cassette/2-

band graphic equalizer (RBP sales code). All factory-

installed radio receivers can communicate on theProgrammable Communications Interface (PCI) data

bus network through a separate wire harness connec-

tor. All factory-installed receivers are stereo Electron-

ically Tuned Radios (ETR) and include an electronic

digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicle is

shipped from the factory. This fuse feeds various

accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The IOD fuse is removed to prevent battery

discharge during vehicle storage.

When removing or installing the IOD fuse, it is

important that the ignition switch be in the Off posi-

tion. Failure to place the ignition switch in the Off

position can cause the radio display to become scram-

bled when the IOD fuse is removed and replaced.

Removing and replacing the IOD fuse again, with the

ignition switch in the Off position, will correct the

scrambled display condition.

The IOD fuse should be checked if the radio or

clock displays are inoperative. The IOD fuse is

located in the Power Distribution Center (PDC).

Refer to the fuse layout label on the underside of the

PDC cover for IOD fuse identification and location.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory positions. The

electronic digital clock function of the radio operates

on fused battery current supplied through the IOD

fuse, regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

If the vehicle is equipped with the optional remote

radio switches located on the steering wheel and the

8A - 16 AUDIOWJ

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 299 of 2199

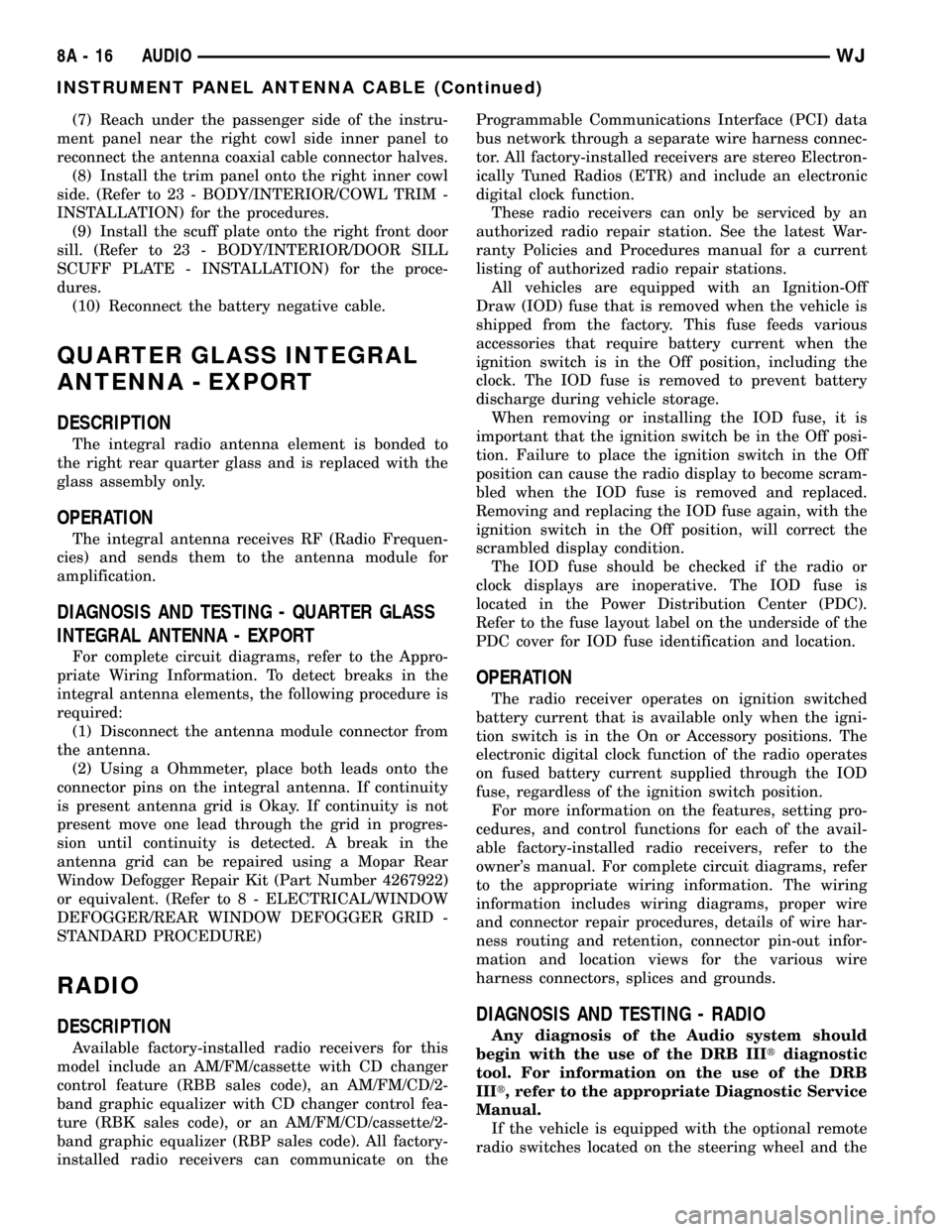

The two remote radio switch units share a common

steering wheel wire harness with the vehicle speed

control switches. The steering wheel wire harness is

connected to the instrument panel wire harness

through the clockspring. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - DESCRIPTION) for

more information on this component.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

OPERATION

The six switches in the two remote radio switch

units are normally open, resistor multiplexed

momentary switches that are hard wired to the Body

Control Module (BCM) through the clockspring. The

BCM sends a five volt reference signal to both switch

units on one circuit, and senses the status of all of

the switches by reading the voltage drop on a second

circuit.

When the BCM senses an input (voltage drop) from

any one of the remote radio switches, it sends the

proper switch status messages on the ProgrammableCommunication Interface (PCI) data bus network to

the radio receiver. The electronic circuitry within the

radio receiver is programmed to respond to these

remote radio switch status messages by adjusting the

radio settings as requested. For diagnosis of the

BCM or the PCI data bus, the use of a DRB scan tool

and the proper Diagnostic Procedures manual are

recommended.

For more information on the features and control

functions for each of the remote radio switches, see

the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

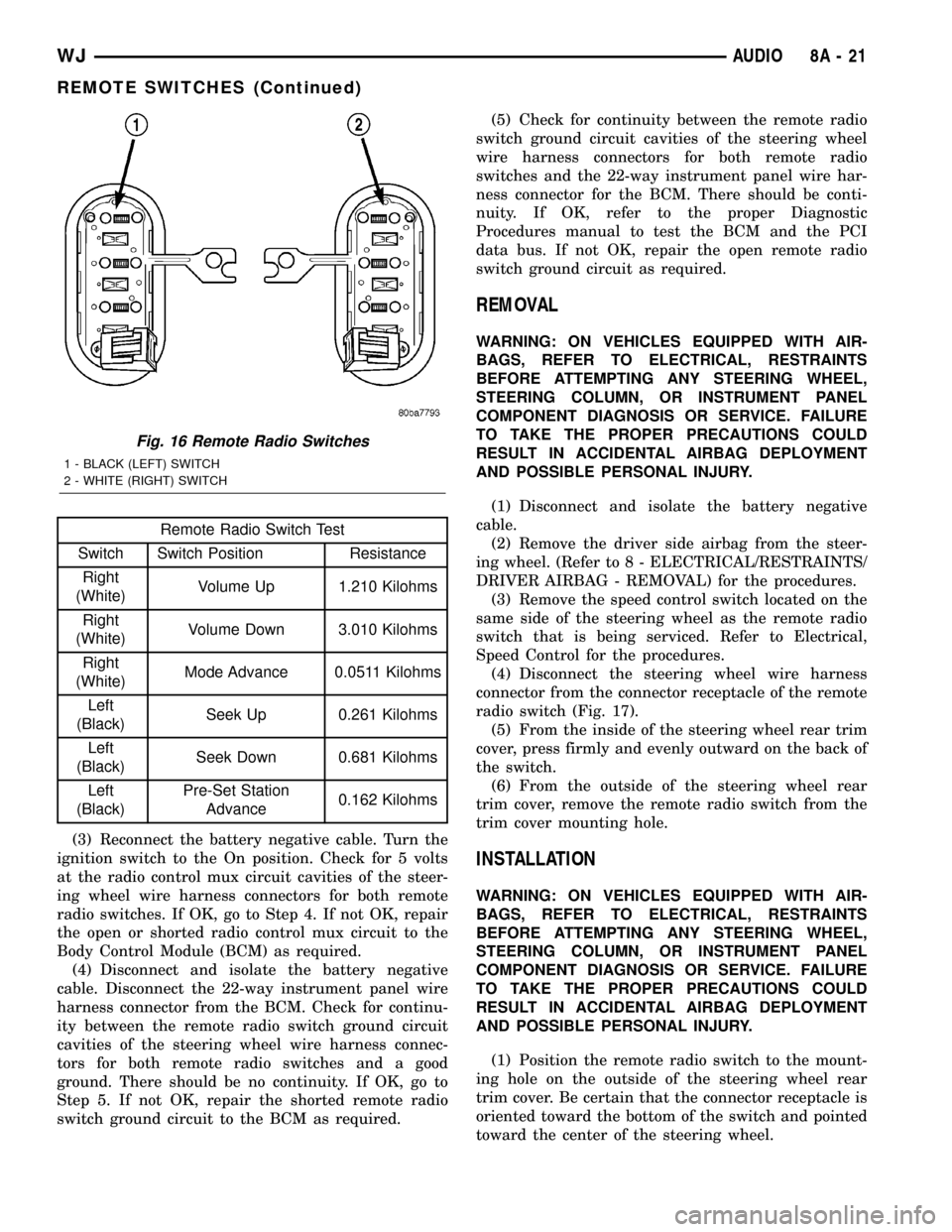

(1) Disconnect and isolate the battery negative

cable. Remove the remote radio switch(es) (Fig. 16)

from the steering wheel.

(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

Fig. 15 Remote Radio Switches

1 - PRESET ADVANCE

2 - SEEK

3 - MODE ADVANCE

4 - VOLUME

8A - 20 AUDIOWJ

REMOTE SWITCHES (Continued)

Page 300 of 2199

Remote Radio Switch Test

Switch Switch Position Resistance

Right

(White)Volume Up 1.210 Kilohms

Right

(White)Volume Down 3.010 Kilohms

Right

(White)Mode Advance 0.0511 Kilohms

Left

(Black)Seek Up 0.261 Kilohms

Left

(Black)Seek Down 0.681 Kilohms

Left

(Black)Pre-Set Station

Advance0.162 Kilohms

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for 5 volts

at the radio control mux circuit cavities of the steer-

ing wheel wire harness connectors for both remote

radio switches. If OK, go to Step 4. If not OK, repair

the open or shorted radio control mux circuit to the

Body Control Module (BCM) as required.

(4) Disconnect and isolate the battery negative

cable. Disconnect the 22-way instrument panel wire

harness connector from the BCM. Check for continu-

ity between the remote radio switch ground circuit

cavities of the steering wheel wire harness connec-

tors for both remote radio switches and a good

ground. There should be no continuity. If OK, go to

Step 5. If not OK, repair the shorted remote radio

switch ground circuit to the BCM as required.(5) Check for continuity between the remote radio

switch ground circuit cavities of the steering wheel

wire harness connectors for both remote radio

switches and the 22-way instrument panel wire har-

ness connector for the BCM. There should be conti-

nuity. If OK, refer to the proper Diagnostic

Procedures manual to test the BCM and the PCI

data bus. If not OK, repair the open remote radio

switch ground circuit as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag from the steer-

ing wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL) for the procedures.

(3) Remove the speed control switch located on the

same side of the steering wheel as the remote radio

switch that is being serviced. Refer to Electrical,

Speed Control for the procedures.

(4) Disconnect the steering wheel wire harness

connector from the connector receptacle of the remote

radio switch (Fig. 17).

(5) From the inside of the steering wheel rear trim

cover, press firmly and evenly outward on the back of

the switch.

(6) From the outside of the steering wheel rear

trim cover, remove the remote radio switch from the

trim cover mounting hole.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the remote radio switch to the mount-

ing hole on the outside of the steering wheel rear

trim cover. Be certain that the connector receptacle is

oriented toward the bottom of the switch and pointed

toward the center of the steering wheel.

Fig. 16 Remote Radio Switches

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

WJAUDIO 8A - 21

REMOTE SWITCHES (Continued)

Page 502 of 2199

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power lock system.

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM

The Passenger Door Module (PDM) contains the

RKE system control logic and the RKE receiver.

When the RKE receiver recognizes a Lock, Unlock or

Panic message from a valid RKE transmitter, the

RKE receiver provides that input to the PDM. The

PDM circuitry and programming responds by sending

the proper messages to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus.

When an RKE lock message is received, the doors

and the liftgate lock, the interior lighting fades to off,

the horn chirps (if this feature is enabled), the exte-

rior lamps flash (if this feature is enabled) and, if the

vehicle is so equipped, the Vehicle Theft Security

System (VTSS) is armed. When an RKE unlock mes-

sage is received, the driver side front door (or all

doors and the liftgate if this feature is enabled)

unlock, the interior lighting is turned on and, if the

vehicle is so equipped, the VTSS is disarmed. If the

vehicle is equipped with the Memory System and the

RKE Linked to Memory feature is enabled, the RKE

unlock message also recalls the driver seat, outside

mirror and radio settings assigned to the RKE trans-

mitter that sent the unlock signal.

When an RKE panic message is received, it causes

the exterior lamps (including the headlights) to flash,

and the horn to pulse for about three minutes, or

until a second panic message is received. A vehicle

speed of about 24 kilometers-per-hour (15 miles-per-

hour) will also cancel the panic event.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the RKE system.

OPERATION - LIFTGATE FLIP-UP GLASS

POWER RELEASE SYSTEM

When the liftgate mounted flip-up glass release

switch is depressed, battery current is directed to the

electric release motor that is integral to the flip-up

glass latch located inside the liftgate. When the

release motor is energized the latch releases and the

flip-up glass can be opened. A liftgate flip-up glass

limit switch is integral to the liftgate latch actuator

mechanism. The limit switch automatically enables

or disables the liftgate flip-up glass power release cir-

cuitry, depending upon the position of the liftgate

latch lock mechanism. When the liftgate latch is

unlocked, the limit switch closes and battery current

is available at the release switch. When the liftgatelatch is locked , the limit switch opens, and the

release switch is disabled.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the liftgate flip-up glass power release system.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER LOCK

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the power lock motors are being sent the proper

hard wired outputs by the door modules for them to

perform their power lock system functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the Power

Distribution Center. If the fuse is OK, proceed to

diagnosis of the door modules. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

DOOR MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS - DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY SYSTEM).

WJPOWER LOCKS 8N - 5

POWER LOCKS (Continued)

Page 516 of 2199

²Ten-way power drivers and passenger seats

with Memory- This power seat option is standard

on Overland models and optional on Limited models.

This option includes a six-way adjustable seat cush-

ion track with power seat back recliners and power

lumbar supports. Heated Seats are standard with

this option.

Refer toHeated Seat Systemfor more informa-

tion on the heated seat option. Refer toMemory

Systemin the Memory System section of this group

for more information on the memory system.

The power seat system includes the following com-

ponents:

²Power lumbar adjuster (ten-way power seat

only)

²Power lumbar switch (ten-way power seat only)

²Power seat recliner (ten-way power seat only)

²Power seat switch

²Power seat track.

Refer toPower Seatin Wiring Diagrams for com-

plete circuit diagrams. Following are general descrip-

tions of the major components in the power seat/

memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is standard equip-

ment on the Limited model. The memory system is

able to store and recall the driver side power seat

positions (including the power recliner position), and

both outside power mirror positions for two drivers.

For vehicles with a radio connected to the Program-

mable Communications Interface (PCI) data bus net-

work, the memory system is also able to store and

recall up to twenty - ten AM and ten FM - radio sta-

tion presets for two drivers. The memory system also

will store and recall the last station listened to for

each driver, even if it is not one of the twenty preset

stations.

The memory system will automatically return to

all of these settings when the corresponding num-

bered and color-coded button (Driver 1 - Black, or

Driver 2 - Gray) of the memory switch on the driver

side front door trim panel is depressed, or when the

doors are unlocked using the corresponding num-

bered and color-coded (Driver 1 - Black, or Driver 2 -

Gray) Remote Keyless Entry (RKE) transmitter. A

customer programmable feature of the memory sys-

tem allows the RKE recall of memory features to be

disabled in cases where there are more than two

drivers of the vehicle.

The memory system also has a customer program-

mable easy exit feature that will move the driver

seat rearward 55 millimeters (two inches) or to the

end of its travel, whichever occurs first, when the key

is removed from the ignition switch lock cylinder.A Memory Seat Module (MSM) or Memory Heated

Seat Module (MHSM) are used on this model to con-

trol and integrate the many electronic functions and

features included in the memory system. On vehicles

equipped with the heated seat system option, the

MHSM also controls the functions and features of

that system.

The memory system includes the following compo-

nents:

²Memory seat module (or memory heated seat

module)

²Memory switch

²Position potentiometers on both outside power

mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Radio receiver (if PCI data bus capable).

Certain functions and features of the memory sys-

tem rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRBtscan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²Driver Door Module (DDM)- Refer toDoor

Modulein Electronic Control Modules for more

information.

²Electronic Vehicle Information Center

(EVIC)- Refer toElectronic Vehicle Information

Centerin Overhead Console Systems for more infor-

mation.

²Passenger Door Module (PDM)- Refer to

Door Modulein Electronic Control Modules for

more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Radio Receiver- Refer toRadio Receiverin

Audio Systems for more information.

Refer toHeated Seat Systemfor more informa-

tion on this system. Refer toRemote Keyless Entry

Systemin Power Lock Systems for more information

on the RKE system. Refer toPower Mirrorin

Power Mirror Systems for more information on the

WJPOWER SEAT SYSTEM 8N - 19

POWER SEAT SYSTEM (Continued)

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

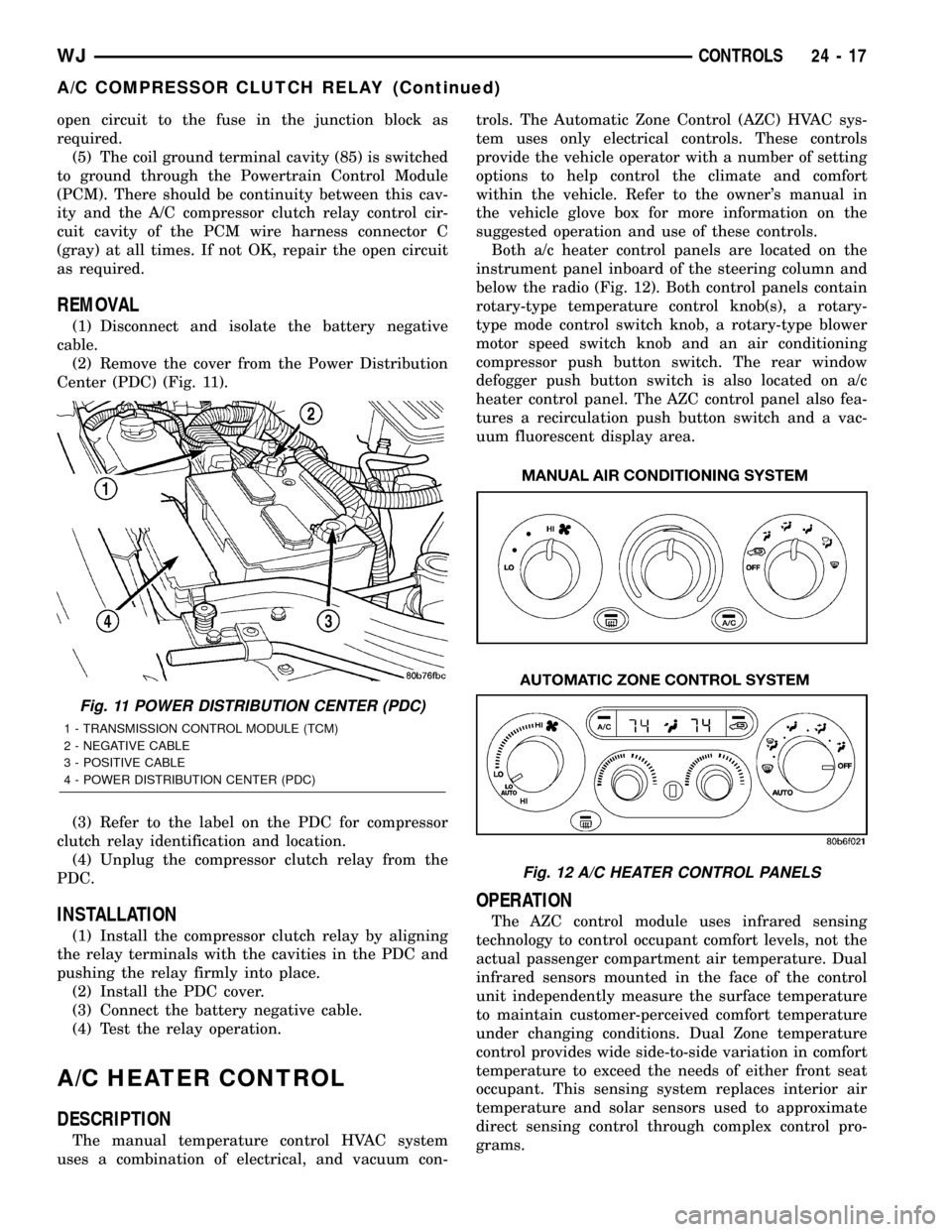

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)