multi function relay JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 315 of 2199

(5) Connect the two instrument panel wire harness

connectors to the BCM.

(6) Reinstall the instrument panel fuse cover to

the bottom of the BCM and JB unit. (Refer to 8 -

ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - INSTALLATION).

(7) Connect the battery negative cable.

COMMUNICATION

DESCRIPTION

The Programmable Communication Interface (PCI)

data bus system is a single wire multiplex system

used for vehicle communications. Multiplexing is a

system that enables the transmission of several mes-

sages over a single channel or circuit.

Many of the control modules in a vehicle require

information from the same sensing device. Multiplex-

ing reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

A multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. This system allows a control module to

broadcast message data out onto the bus where all

other control modules can read the messages that are

being sent. When a module reads a message on the

data bus that it requires, it relays that message to

its microprocessor. Each module ignores the mes-

sages on the data bus that it dosen't recognize.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The PCI data bus messages are

carried over the bus in the form of Variable Pulse

Width Modulated (VPWM) signals. The PCI data bus

speed is an average 10.4 Kilo-bits per second (Kbps).

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. The Powertrain

Control Module (PCM) is the only dominant node for

the PCI data bus system.

The PCI bus uses low and high voltage levels to

generate signals. The voltage on the buss varies

between zero and seven and one-half volts. The lowand high voltage levels are generated by means of

variable-pulse width modulation to form signals of

varying length.

When a module is transmitting on the bus, it is

reading the bus at the same time to ensure message

integrity.

Each module is capable of transmitting and receiv-

ing data simultaneously.

The PCI data bus can be monitored using the

DRBIIItscan tool. It is possible for the bus to pass

all DRBIIIttests and still be faulty if the voltage

parameters are all within the specified range and

false messages are being sent.

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

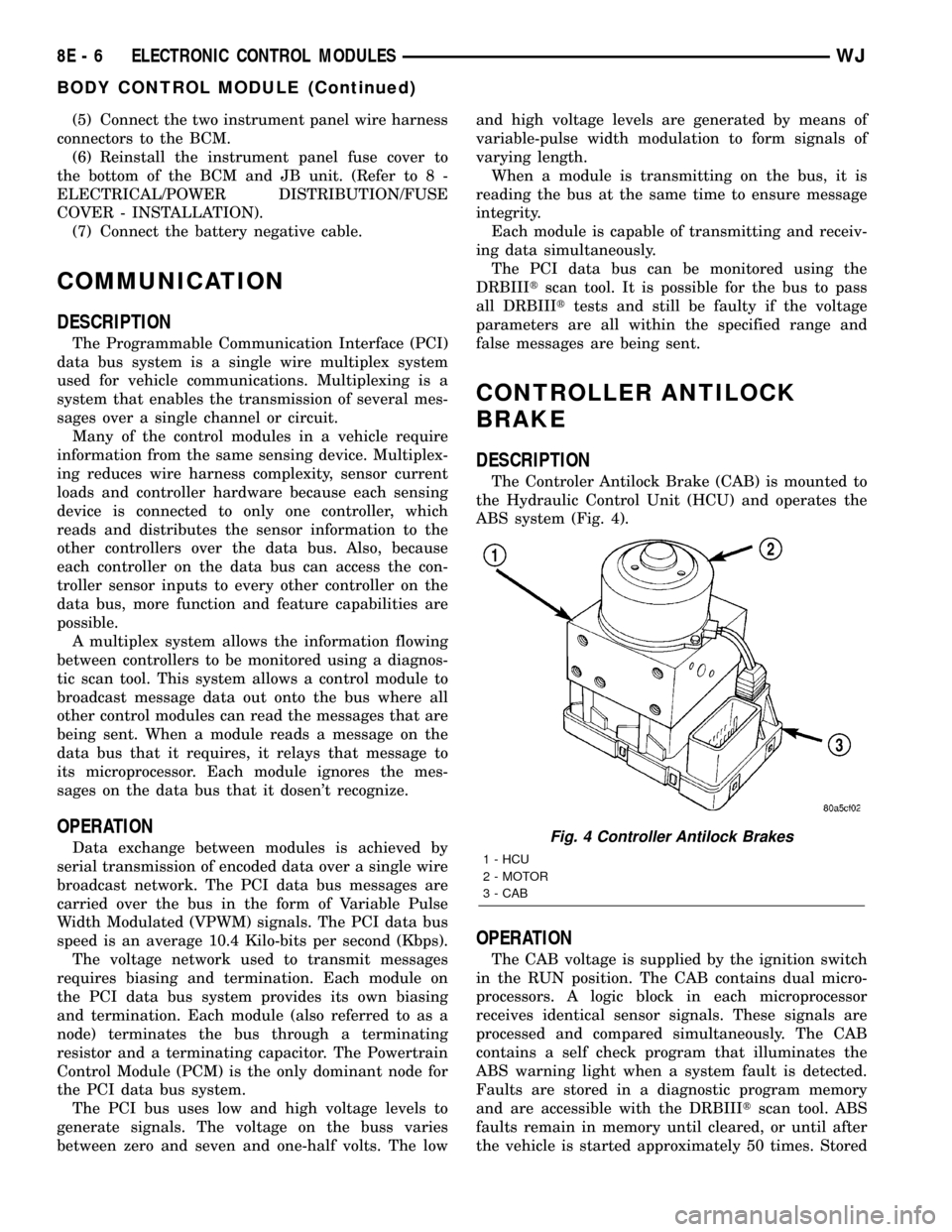

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system (Fig. 4).

OPERATION

The CAB voltage is supplied by the ignition switch

in the RUN position. The CAB contains dual micro-

processors. A logic block in each microprocessor

receives identical sensor signals. These signals are

processed and compared simultaneously. The CAB

contains a self check program that illuminates the

ABS warning light when a system fault is detected.

Faults are stored in a diagnostic program memory

and are accessible with the DRBIIItscan tool. ABS

faults remain in memory until cleared, or until after

the vehicle is started approximately 50 times. Stored

Fig. 4 Controller Antilock Brakes

1 - HCU

2 - MOTOR

3 - CAB

8E - 6 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 435 of 2199

the gauge needle at the last indication for about

twelve seconds or until a new engine temperature

message is received, whichever occurs first. After

twelve seconds, the cluster will return the gauge nee-

dle to the low end of the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the engine coolant

temperature sensor to determine the engine operat-

ing temperature. The PCM then sends the proper

engine coolant temperature messages to the instru-

ment cluster. For further diagnosis of the engine cool-

ant temperature gauge or the instrument cluster

circuitry that controls the gauge, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster moves the

engine coolant temperature gauge needle to indicate

a high or critical engine temperature, it may indicate

that the engine or the engine cooling system requires

service. For proper diagnosis of the engine coolant

temperature sensor, the PCM, the PCI data bus, or

the electronic message inputs to the instrument clus-

ter that control the engine coolant temperature

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

FRONT FOG LAMP INDICATOR

DESCRIPTION

A front fog lamp indicator is standard equipment

on all instrument clusters, but is only functional on

vehicles equipped with the optional front fog lamps.

The front fog lamp indicator is located on the left

edge of the instrument cluster, to the left of the

tachometer. The front fog lamp indicator consists of

an International Control and Display Symbol icon for

ªFront Fog Lightº imprinted on a green lens. The

lens is located behind a cutout in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. The icon

appears silhouetted against a green field through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by a replaceable

incandescent bulb and bulb holder unit located on

the instrument cluster electronic circuit board. When

the exterior lighting is turned On, the illumination

intensity of the front fog lamp indicator is dimmable,

which is adjusted using the panel lamps dimmer con-

trol ring on the control stalk of the left multi-func-

tion switch. The front fog lamp indicator lens isserviced as a unit with the instrument cluster lens,

hood and mask unit.

OPERATION

The front fog lamp indicator gives an indication to

the vehicle operator whenever the front fog lamps

are illuminated. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Body Control

Module (BCM) over the Programmable Communica-

tions Interface (PCI) data bus. The front fog lamp

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will allow

this indicator to operate whenever the instrument

cluster receives a battery current input on the fused

B(+) circuit. Therefore, the indicator can be illumi-

nated regardless of the ignition switch position. The

bulb only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the front fog lamp

indicator for the following reasons:

²Front Fog Lamp Indicator Lamp-On Mes-

sage- Each time the cluster receives a front fog

lamp indicator lamp-on message from the BCM indi-

cating that the front fog lamps are turned On, the

front fog lamp indicator will be illuminated. The indi-

cator remains illuminated until the cluster receives a

front fog lamp indicator lamp-off message from the

BCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the front fog lamp indica-

tor will be turned on for the duration of the test to

confirm the functionality of the bulb and the cluster

control circuitry.

The BCM continually monitors the exterior light-

ing (left multi-function) switch to determine the

proper outputs to the front fog lamp relay. The BCM

then sends the proper front fog lamp indicator

lamp-on and lamp-off messages to the instrument

cluster. If the front fog lamp indicator fails to light

during the actuator test, replace the bulb with a

known good unit. For further diagnosis of the front

fog lamp indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the front fog

lamp system, the BCM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the front fog lamp indicator, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

8J - 20 INSTRUMENT CLUSTERWJ

ENGINE TEMPERATURE GAUGE (Continued)

Page 437 of 2199

proper percent tank full messages to the instrument

cluster. For further diagnosis of the fuel gauge or the

instrument cluster circuitry that controls the gauge,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the fuel tank sender, the PCM, the PCI

data bus, or the electronic message inputs to the

instrument cluster that control the fuel gauge, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

HIGH BEAM INDICATOR

DESCRIPTION

A high beam indicator is standard equipment on

all instrument clusters. The high beam indicator is

located near the upper edge of the instrument clus-

ter, between the tachometer and the speedometer.

The high beam indicator consists of an International

Control and Display Symbol icon for ªHigh Beamº

imprinted on a blue lens. The lens is located behind a

cutout in the opaque layer of the instrument cluster

overlay. The dark outer layer of the overlay prevents

the indicator from being clearly visible when it is not

illuminated. The icon appears silhouetted against a

blue field through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. When the exterior lighting is

turned On, the illumination intensity of the high

beam indicator is dimmable, which is adjusted using

the panel lamps dimmer control ring on the control

stalk of the left multi-function switch. The high beam

indicator lens is serviced as a unit with the instru-

ment cluster lens, hood and mask unit.

OPERATION

The high beam indicator gives an indication to the

vehicle operator whenever the headlamp high beams

are illuminated. This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Body Control Module (BCM) over the Programmable

Communications Interface (PCI) data bus. The high

beam indicator bulb is completely controlled by the

instrument cluster logic circuit, and that logic will

allow this indicator to operate whenever the instru-

ment cluster receives a battery current input on the

fused B(+) circuit. Therefore, the indicator can be

illuminated regardless of the ignition switch position.

The LED only illuminates when it is provided a path

to ground by the instrument cluster transistor. Theinstrument cluster will turn on the high beam indi-

cator for the following reasons:

²High Beam Indicator Lamp-On Message-

Each time the cluster receives a high beam indicator

lamp-on message from the BCM indicating that the

headlamp high beams are turned On, the high beam

indicator will be illuminated. The indicator remains

illuminated until the cluster receives a high beam

indicator lamp-off message from the BCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the high beam indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The BCM continually monitors the exterior light-

ing (left multi-function) switch to determine the

proper outputs to the headlamp low beam and high

beam relays. The BCM then sends the proper high

beam indicator lamp-on and lamp-off messages to the

instrument cluster. If the high beam indicator fails to

light during the actuator test, replace the bulb with a

known good unit. For further diagnosis of the high

beam indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the headlamp

system, the BCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the high beam indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

LOW FUEL INDICATOR

DESCRIPTION

A low fuel indicator is standard equipment on all

instrument clusters. The low fuel indicator is located

near the left edge of the instrument cluster, to the left

of the tachometer. The low fuel indicator consists of an

International Control and Display Symbol icon for

ªFuelº imprinted on an amber lens. The lens is located

behind a cutout in the opaque layer of the instrument

cluster overlay. The dark outer layer of the overlay

prevents the icon from being clearly visible when the

indicator is not illuminated. The icon appears silhou-

etted against an amber field through the translucent

outer layer of the overlay when the indicator is illumi-

nated from behind by a replaceable incandescent bulb

and bulb holder unit located on the instrument cluster

electronic circuit board. When the exterior lighting is

turned On, the illumination intensity of the low fuel

indicator is dimmable, which is adjusted using the

panel lamps dimmer control ring on the control stalk

of the left multi-function switch. The low fuel indica-

8J - 22 INSTRUMENT CLUSTERWJ

FUEL GAUGE (Continued)

Page 442 of 2199

pletely controlled by the instrument cluster logic cir-

cuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The bulb only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the overdrive off indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the overdrive off indicator

is illuminated for about three seconds as a bulb test.

²Overdrive Off Indicator Lamp-On Message-

Each time the cluster receives an overdrive off indi-

cator lamp-on message from the PCM or TCM indi-

cating that the Off position of the overdrive off

switch has been selected, the overdrive off indicator

will be illuminated. The indicator remains illumi-

nated until the cluster receives an overdrive off indi-

cator lamp-off message from the PCM or TCM, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the overdrive off indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The PCM or TCM continually monitors the over-

drive off switch to determine the proper outputs to

the automatic transmission. The PCM or TCM then

sends the proper overdrive off indicator lamp-on or

lamp-off messages to the instrument cluster. If the

overdrive off indicator fails to light during the bulb

test, replace the bulb with a known good unit. For

further diagnosis of the overdrive off indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the overdrive control system, the

PCM, the TCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the overdrive off indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

REAR FOG LAMP INDICATOR

DESCRIPTION

A rear fog lamp indicator is standard equipment on

all instrument clusters, but is only functional on

vehicles equipped with optional rear fog lamps,

which are available only in certain international

markets where they are required. The rear fog lampindicator is located on the left edge of the instrument

cluster, to the left of the tachometer. The rear fog

lamp indicator consists of an International Control

and Display Symbol icon for ªRear Fog Lightº

imprinted on an amber lens. The lens is located

behind a cutout in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. The icon appears sil-

houetted against an amber field through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by a replaceable

incandescent bulb and bulb holder unit located on

the instrument cluster electronic circuit board. When

the exterior lighting is turned On, the illumination

intensity of the rear fog lamp indicator is dimmable,

which is adjusted using the panel lamps dimmer con-

trol ring on the control stalk of the left multi-func-

tion switch. The rear fog lamp indicator lens is

serviced as a unit with the instrument cluster lens,

hood and mask unit.

OPERATION

The rear fog lamp indicator gives an indication to

the vehicle operator whenever the rear fog lamps are

illuminated. This indicator is controlled by a transis-

tor on the instrument cluster electronic circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Body Control

Module (BCM) over the Programmable Communica-

tions Interface (PCI) data bus. The rear fog lamp

indicator bulb is completely controlled by the instru-

ment cluster logic circuit, and that logic will allow

this indicator to operate whenever the instrument

cluster receives a battery current input on the fused

B(+) circuit. Therefore, the indicator can be illumi-

nated regardless of the ignition switch position. The

bulb only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the rear fog lamp

indicator for the following reasons:

²Rear Fog Lamp Indicator Lamp-On Mes-

sage- Each time the cluster receives a rear fog lamp

indicator lamp-on message from the BCM indicating

that the rear fog lamps are turned On, the rear fog

lamp indicator will be illuminated. The indicator

remains illuminated until the cluster receives a rear

fog lamp indicator lamp-off message from the BCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the rear fog lamp indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The BCM continually monitors the exterior light-

ing (left multi-function) switch to determine the

proper outputs to the rear fog lamp relay. The BCM

WJINSTRUMENT CLUSTER 8J - 27

OVERDRIVE OFF INDICATOR (Continued)

Page 465 of 2199

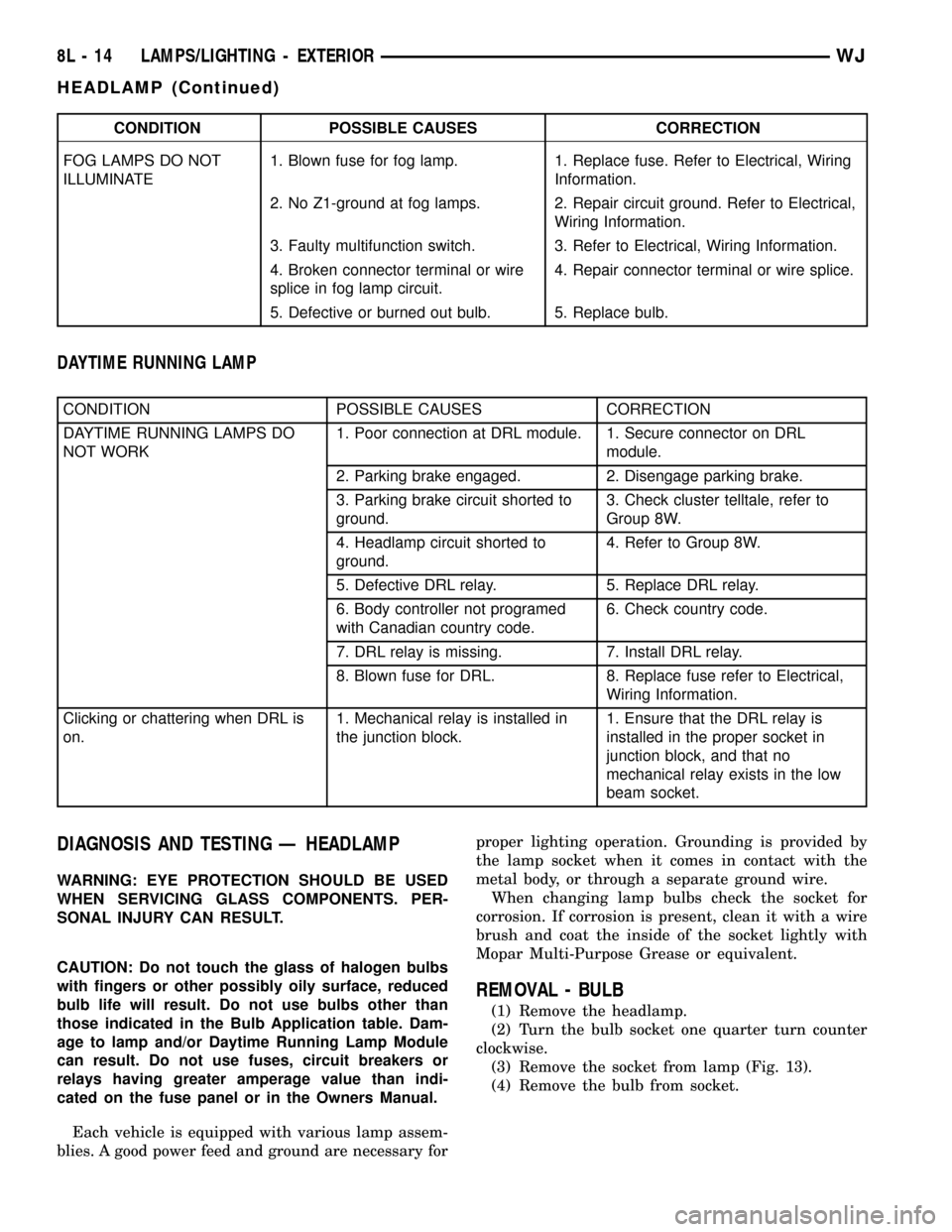

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty multifunction switch. 3. Refer to Electrical, Wiring Information.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Defective or burned out bulb. 5. Replace bulb.

DAYTIME RUNNING LAMP

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING LAMPS DO

NOT WORK1. Poor connection at DRL module. 1. Secure connector on DRL

module.

2. Parking brake engaged. 2. Disengage parking brake.

3. Parking brake circuit shorted to

ground.3. Check cluster telltale, refer to

Group 8W.

4. Headlamp circuit shorted to

ground.4. Refer to Group 8W.

5. Defective DRL relay. 5. Replace DRL relay.

6. Body controller not programed

with Canadian country code.6. Check country code.

7. DRL relay is missing. 7. Install DRL relay.

8. Blown fuse for DRL. 8. Replace fuse refer to Electrical,

Wiring Information.

Clicking or chattering when DRL is

on.1. Mechanical relay is installed in

the junction block.1. Ensure that the DRL relay is

installed in the proper socket in

junction block, and that no

mechanical relay exists in the low

beam socket.

DIAGNOSIS AND TESTING Ð HEADLAMP

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

Each vehicle is equipped with various lamp assem-

blies. A good power feed and ground are necessary forproper lighting operation. Grounding is provided by

the lamp socket when it comes in contact with the

metal body, or through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

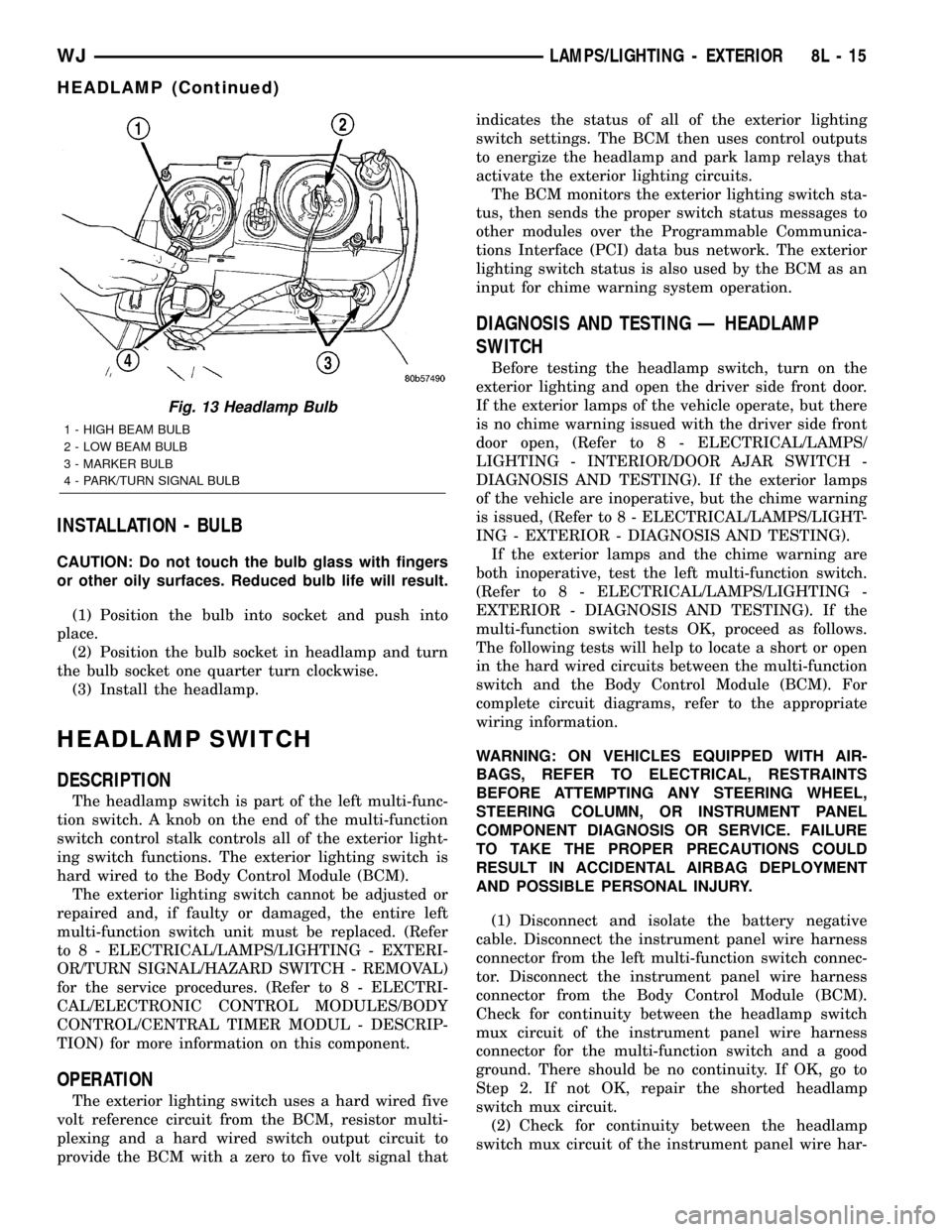

REMOVAL - BULB

(1) Remove the headlamp.

(2) Turn the bulb socket one quarter turn counter

clockwise.

(3) Remove the socket from lamp (Fig. 13).

(4) Remove the bulb from socket.

8L - 14 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)

Page 466 of 2199

INSTALLATION - BULB

CAUTION: Do not touch the bulb glass with fingers

or other oily surfaces. Reduced bulb life will result.

(1) Position the bulb into socket and push into

place.

(2) Position the bulb socket in headlamp and turn

the bulb socket one quarter turn clockwise.

(3) Install the headlamp.

HEADLAMP SWITCH

DESCRIPTION

The headlamp switch is part of the left multi-func-

tion switch. A knob on the end of the multi-function

switch control stalk controls all of the exterior light-

ing switch functions. The exterior lighting switch is

hard wired to the Body Control Module (BCM).

The exterior lighting switch cannot be adjusted or

repaired and, if faulty or damaged, the entire left

multi-function switch unit must be replaced. (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/TURN SIGNAL/HAZARD SWITCH - REMOVAL)

for the service procedures. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/BODY

CONTROL/CENTRAL TIMER MODUL - DESCRIP-

TION) for more information on this component.

OPERATION

The exterior lighting switch uses a hard wired five

volt reference circuit from the BCM, resistor multi-

plexing and a hard wired switch output circuit to

provide the BCM with a zero to five volt signal thatindicates the status of all of the exterior lighting

switch settings. The BCM then uses control outputs

to energize the headlamp and park lamp relays that

activate the exterior lighting circuits.

The BCM monitors the exterior lighting switch sta-

tus, then sends the proper switch status messages to

other modules over the Programmable Communica-

tions Interface (PCI) data bus network. The exterior

lighting switch status is also used by the BCM as an

input for chime warning system operation.

DIAGNOSIS AND TESTING Ð HEADLAMP

SWITCH

Before testing the headlamp switch, turn on the

exterior lighting and open the driver side front door.

If the exterior lamps of the vehicle operate, but there

is no chime warning issued with the driver side front

door open, (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - INTERIOR/DOOR AJAR SWITCH -

DIAGNOSIS AND TESTING). If the exterior lamps

of the vehicle are inoperative, but the chime warning

is issued, (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR - DIAGNOSIS AND TESTING).

If the exterior lamps and the chime warning are

both inoperative, test the left multi-function switch.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR - DIAGNOSIS AND TESTING). If the

multi-function switch tests OK, proceed as follows.

The following tests will help to locate a short or open

in the hard wired circuits between the multi-function

switch and the Body Control Module (BCM). For

complete circuit diagrams, refer to the appropriate

wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector from the left multi-function switch connec-

tor. Disconnect the instrument panel wire harness

connector from the Body Control Module (BCM).

Check for continuity between the headlamp switch

mux circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 2. If not OK, repair the shorted headlamp

switch mux circuit.

(2) Check for continuity between the headlamp

switch mux circuit of the instrument panel wire har-

Fig. 13 Headlamp Bulb

1 - HIGH BEAM BULB

2 - LOW BEAM BULB

3 - MARKER BULB

4 - PARK/TURN SIGNAL BULB

WJLAMPS/LIGHTING - EXTERIOR 8L - 15

HEADLAMP (Continued)

Page 470 of 2199

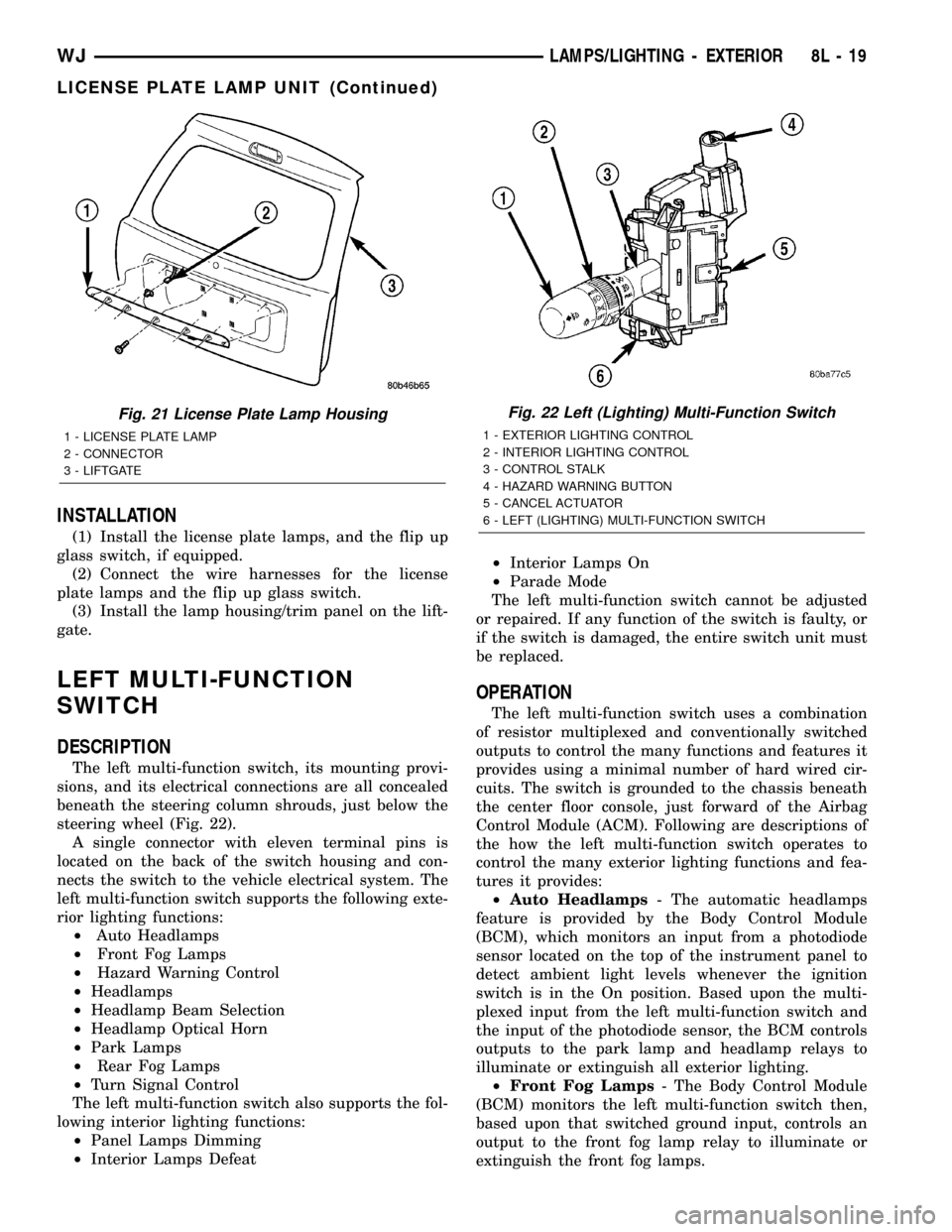

INSTALLATION

(1) Install the license plate lamps, and the flip up

glass switch, if equipped.

(2) Connect the wire harnesses for the license

plate lamps and the flip up glass switch.

(3) Install the lamp housing/trim panel on the lift-

gate.

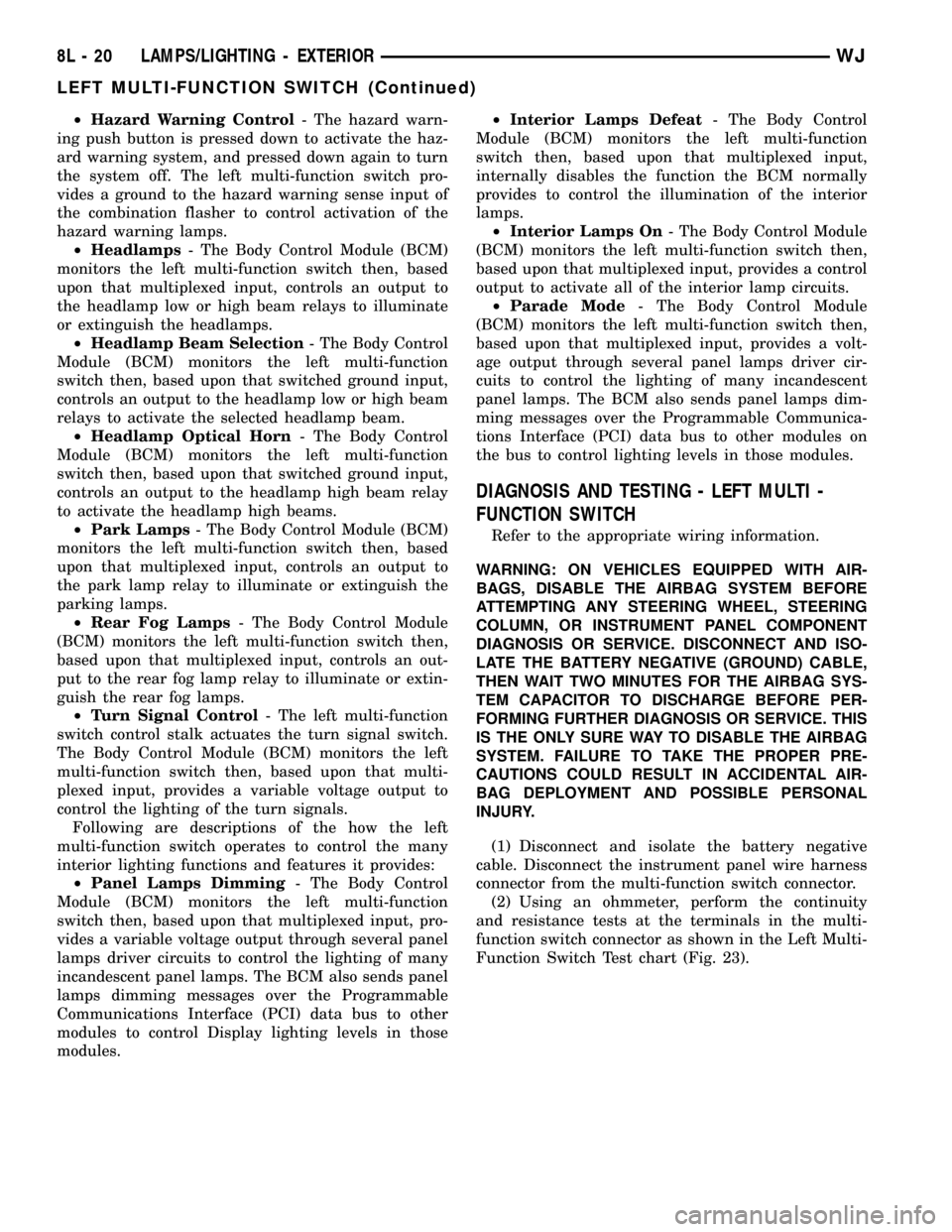

LEFT MULTI-FUNCTION

SWITCH

DESCRIPTION

The left multi-function switch, its mounting provi-

sions, and its electrical connections are all concealed

beneath the steering column shrouds, just below the

steering wheel (Fig. 22).

A single connector with eleven terminal pins is

located on the back of the switch housing and con-

nects the switch to the vehicle electrical system. The

left multi-function switch supports the following exte-

rior lighting functions:

²Auto Headlamps

²Front Fog Lamps

²Hazard Warning Control

²Headlamps

²Headlamp Beam Selection

²Headlamp Optical Horn

²Park Lamps

²Rear Fog Lamps

²Turn Signal Control

The left multi-function switch also supports the fol-

lowing interior lighting functions:

²Panel Lamps Dimming

²Interior Lamps Defeat²Interior Lamps On

²Parade Mode

The left multi-function switch cannot be adjusted

or repaired. If any function of the switch is faulty, or

if the switch is damaged, the entire switch unit must

be replaced.

OPERATION

The left multi-function switch uses a combination

of resistor multiplexed and conventionally switched

outputs to control the many functions and features it

provides using a minimal number of hard wired cir-

cuits. The switch is grounded to the chassis beneath

the center floor console, just forward of the Airbag

Control Module (ACM). Following are descriptions of

the how the left multi-function switch operates to

control the many exterior lighting functions and fea-

tures it provides:

²Auto Headlamps- The automatic headlamps

feature is provided by the Body Control Module

(BCM), which monitors an input from a photodiode

sensor located on the top of the instrument panel to

detect ambient light levels whenever the ignition

switch is in the On position. Based upon the multi-

plexed input from the left multi-function switch and

the input of the photodiode sensor, the BCM controls

outputs to the park lamp and headlamp relays to

illuminate or extinguish all exterior lighting.

²Front Fog Lamps- The Body Control Module

(BCM) monitors the left multi-function switch then,

based upon that switched ground input, controls an

output to the front fog lamp relay to illuminate or

extinguish the front fog lamps.

Fig. 21 License Plate Lamp Housing

1 - LICENSE PLATE LAMP

2 - CONNECTOR

3 - LIFTGATE

Fig. 22 Left (Lighting) Multi-Function Switch

1 - EXTERIOR LIGHTING CONTROL

2 - INTERIOR LIGHTING CONTROL

3 - CONTROL STALK

4 - HAZARD WARNING BUTTON

5 - CANCEL ACTUATOR

6 - LEFT (LIGHTING) MULTI-FUNCTION SWITCH

WJLAMPS/LIGHTING - EXTERIOR 8L - 19

LICENSE PLATE LAMP UNIT (Continued)

Page 471 of 2199

²Hazard Warning Control- The hazard warn-

ing push button is pressed down to activate the haz-

ard warning system, and pressed down again to turn

the system off. The left multi-function switch pro-

vides a ground to the hazard warning sense input of

the combination flasher to control activation of the

hazard warning lamps.

²Headlamps- The Body Control Module (BCM)

monitors the left multi-function switch then, based

upon that multiplexed input, controls an output to

the headlamp low or high beam relays to illuminate

or extinguish the headlamps.

²Headlamp Beam Selection- The Body Control

Module (BCM) monitors the left multi-function

switch then, based upon that switched ground input,

controls an output to the headlamp low or high beam

relays to activate the selected headlamp beam.

²Headlamp Optical Horn- The Body Control

Module (BCM) monitors the left multi-function

switch then, based upon that switched ground input,

controls an output to the headlamp high beam relay

to activate the headlamp high beams.

²Park Lamps- The Body Control Module (BCM)

monitors the left multi-function switch then, based

upon that multiplexed input, controls an output to

the park lamp relay to illuminate or extinguish the

parking lamps.

²Rear Fog Lamps- The Body Control Module

(BCM) monitors the left multi-function switch then,

based upon that multiplexed input, controls an out-

put to the rear fog lamp relay to illuminate or extin-

guish the rear fog lamps.

²Turn Signal Control- The left multi-function

switch control stalk actuates the turn signal switch.

The Body Control Module (BCM) monitors the left

multi-function switch then, based upon that multi-

plexed input, provides a variable voltage output to

control the lighting of the turn signals.

Following are descriptions of the how the left

multi-function switch operates to control the many

interior lighting functions and features it provides:

²Panel Lamps Dimming- The Body Control

Module (BCM) monitors the left multi-function

switch then, based upon that multiplexed input, pro-

vides a variable voltage output through several panel

lamps driver circuits to control the lighting of many

incandescent panel lamps. The BCM also sends panel

lamps dimming messages over the Programmable

Communications Interface (PCI) data bus to other

modules to control Display lighting levels in those

modules.²Interior Lamps Defeat- The Body Control

Module (BCM) monitors the left multi-function

switch then, based upon that multiplexed input,

internally disables the function the BCM normally

provides to control the illumination of the interior

lamps.

²Interior Lamps On- The Body Control Module

(BCM) monitors the left multi-function switch then,

based upon that multiplexed input, provides a control

output to activate all of the interior lamp circuits.

²Parade Mode- The Body Control Module

(BCM) monitors the left multi-function switch then,

based upon that multiplexed input, provides a volt-

age output through several panel lamps driver cir-

cuits to control the lighting of many incandescent

panel lamps. The BCM also sends panel lamps dim-

ming messages over the Programmable Communica-

tions Interface (PCI) data bus to other modules on

the bus to control lighting levels in those modules.

DIAGNOSIS AND TESTING - LEFT MULTI -

FUNCTION SWITCH

Refer to the appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector from the multi-function switch connector.

(2) Using an ohmmeter, perform the continuity

and resistance tests at the terminals in the multi-

function switch connector as shown in the Left Multi-

Function Switch Test chart (Fig. 23).

8L - 20 LAMPS/LIGHTING - EXTERIORWJ

LEFT MULTI-FUNCTION SWITCH (Continued)

Page 608 of 2199

WIPERS/WASHERS

TABLE OF CONTENTS

page page

FRONT WIPERS/WASHERS.................. 1REAR WIPERS/WASHERS.................. 33

FRONT WIPERS/WASHERS

TABLE OF CONTENTS

page page

FRONT WIPERS/WASHERS

DESCRIPTION..........................2

OPERATION............................4

DIAGNOSIS AND TESTING - FRONT WIPER &

WASHER SYSTEM.....................6

CLEANING - FRONT WIPER & WASHER

SYSTEM.............................8

INSPECTION - FRONT WIPER & WASHER

SYSTEM.............................8

FRONT CHECK VALVE

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION.........................10

FRONT WASHER HOSES/TUBES

DESCRIPTION.........................10

OPERATION...........................11

FRONT WASHER NOZZLE

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

FRONT WASHER PUMP/MOTOR

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................13

FRONT WIPER ARM

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................14

FRONT WIPER BLADE

DESCRIPTION.........................14

OPERATION...........................15

REMOVAL.............................15

INSTALLATION.........................15

FRONT WIPER MODULE

DESCRIPTION.........................16OPERATION...........................16

REMOVAL.............................17

INSTALLATION.........................17

RAIN SENSOR MODULE

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................19

INSTALLATION.........................19

RIGHT MULTI-FUNCTION SWITCH

DESCRIPTION.........................20

OPERATION...........................21

DIAGNOSIS AND TESTING - RIGHT MULTI-

FUNCTION SWITCH...................22

REMOVAL.............................24

INSTALLATION.........................24

WASHER FLUID LEVEL SWITCH

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................26

INSTALLATION.........................26

WASHER RESERVOIR

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................28

WIPER HIGH/LOW RELAY

DESCRIPTION.........................29

OPERATION...........................29

DIAGNOSIS AND TESTING - WIPER HIGH/

LOW RELAY.........................30

REMOVAL.............................30

INSTALLATION.........................30

WIPER ON/OFF RELAY

DESCRIPTION.........................31

OPERATION...........................31

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY..............................32

REMOVAL.............................32

INSTALLATION.........................32

WJWIPERS/WASHERS 8R - 1

Page 610 of 2199

²Front Check Valve- The front washer system

check valve is integral to the wye fitting located in

the washer plumbing between the cowl plenum

washer hose and the front washer nozzles, and is

concealed beneath the cowl plenum cover/grille panel

at the base of the windshield.

²Front Washer Nozzle- Two fluidic front

washer nozzles are secured with integral snap fea-

tures to dedicated openings in the cowl plenum cover/

grille panel located near the base of the windshield.

²Front Washer Plumbing- The plumbing for

the front washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the left side of the engine compartment from the

washer reservoir, and through the dash panel into

the cowl plenum to the front washer nozzle fittings

beneath the cowl plenum cover/grille panel.

²Front Washer Pump/Motor- The front washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, behind

the inner fender liner ahead of the left front wheel.

The front washer pump is located ahead of and below

the rear washer pump.

²Front Wiper Arm- The two front wiper arms

are secured with nuts to the threaded studs on the

ends of the two wiper pivot shafts, which extend

through the cowl plenum cover/grille panel located

near the base of the windshield.

²Front Wiper Blade- The two front wiper

blades are secured to the two front wiper arms with

an integral latch, and are parked on the glass near

the bottom of the windshield when the front wiper

system is not in operation.

²Front Wiper Module- The front wiper pivot

shafts are the only visible components of the front

wiper module. The remainder of the module is con-

cealed within the cowl plenum beneath the cowl ple-

num cover/grille panel. The front wiper module

includes the module bracket, four rubber-isolated

wiper module mounts, the front wiper motor, the

wiper motor crank arm, the two wiper drive links,

and the two front wiper pivots.

²Rain Sensor Module- Models equipped with

the optional automatic wiper feature have a Rain

Sensor Module (RSM) located behind a trim cover on

a bracket bonded to the inside surface of the wind-

shield glass, just above the inside rear view mirror

mounting button.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column, just below the

steering wheel. Only the control stalk for the right

multi-function switch is visible, while the remainder

of the switch is concealed beneath the steering col-

umn shrouds. The right multi-function switch con-tains all of the switches and control circuitry for both

the front and rear wiper and washer systems.

²Washer Fluid Level Switch- The washer fluid

level switch is located in a dedicated hole near the

center of the forward surface of the washer reservoir,

behind the left front wheel house splash shield.

²Washer Reservoir- The washer reservoir is

concealed between the left inner fender shield and

the left outer fender panel, behind the inner fender

liner and ahead of the left front wheel. The washer

reservoir filler neck is the only visible portion of the

reservoir, and it is accessed from the left front corner

of the engine compartment.

²Wiper High-Low Relay- The wiper high-low

relay is an International Standards Organization

(ISO) micro relay located in the Power Distribution

Center (PDC) in the engine compartment near the

battery.

²Wiper On-Off Relay- The wiper on-off relay is

an International Standards Organization (ISO) micro

relay located in the Power Distribution Center (PDC)

in the engine compartment near the battery.

Hard wired circuitry connects the front wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the front wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATING MODES

The components of the front wiper and washer sys-

tem are designed to work in concert to provide the

following operating modes:

²Automatic Wiper- In models equipped with

the optional automatic wiper feature, the internal

circuitry of both the right (wiper) multi-function

switch, the rain sensor module, and the BCM work

in concert to provide an automatic wiper mode with

five sensitivity selections. The BCM tells the Rain

Sensor Module (RSM) when the automatic wiper

mode is selected and the manually selected sensitiv-

ity level, then the rain sensor module tells the BCM

each time enough water droplets have accumulated

within the wipe pattern on the windshield to require

front wiper operation. The BCM then automatically

WJFRONT WIPERS/WASHERS 8R - 3

FRONT WIPERS/WASHERS (Continued)