ABS JEEP GRAND CHEROKEE 2017 WK2 / 4.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 198 of 372

2. Pull the bottom of the cover outward (to-wards you), pull downwards to disengage

the tabs located at the top of the hitch

receiver cover.

To reinstall the hitch receiver cover after

towing repeat the procedure in reverse order.

NOTE:

Be sure to engage all tabs of the hitch re-

ceiver cover in the bumper fascia prior to

installation.Trailer Hitch Receiver Cover Removal

(SRT Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.

1. Turn the two locking retainers located at the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

added leverage.

Hitch Receiver Cover

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

STARTING AND OPERATING

196

Page 199 of 372

2. Pull the bottom of the cover outward (to-wards you). 3. Lower back down to disengage the tabs

located at the top of the hitch receiver

cover and then pull outwards to remove.

Hitch Receiver Cover

1 — Hitch Receiver Cover Retaining

Tabs

2 — Hitch Receiver Cover

3 — Locking RetainersHitch Receiver Cover

Hitch Receiver Cover

1 — Hitch Receiver Cover Retaining

Tabs

2 — Hitch Receiver Cover

3 — Locking Retainer

197

Page 200 of 372

To reinstall the hitch receiver cover after

towing repeat the procedure in reverse order.NOTE:

Be sure to engage all tabs of the hitch re-

ceiver cover in the bumper fascia prior to

installation.

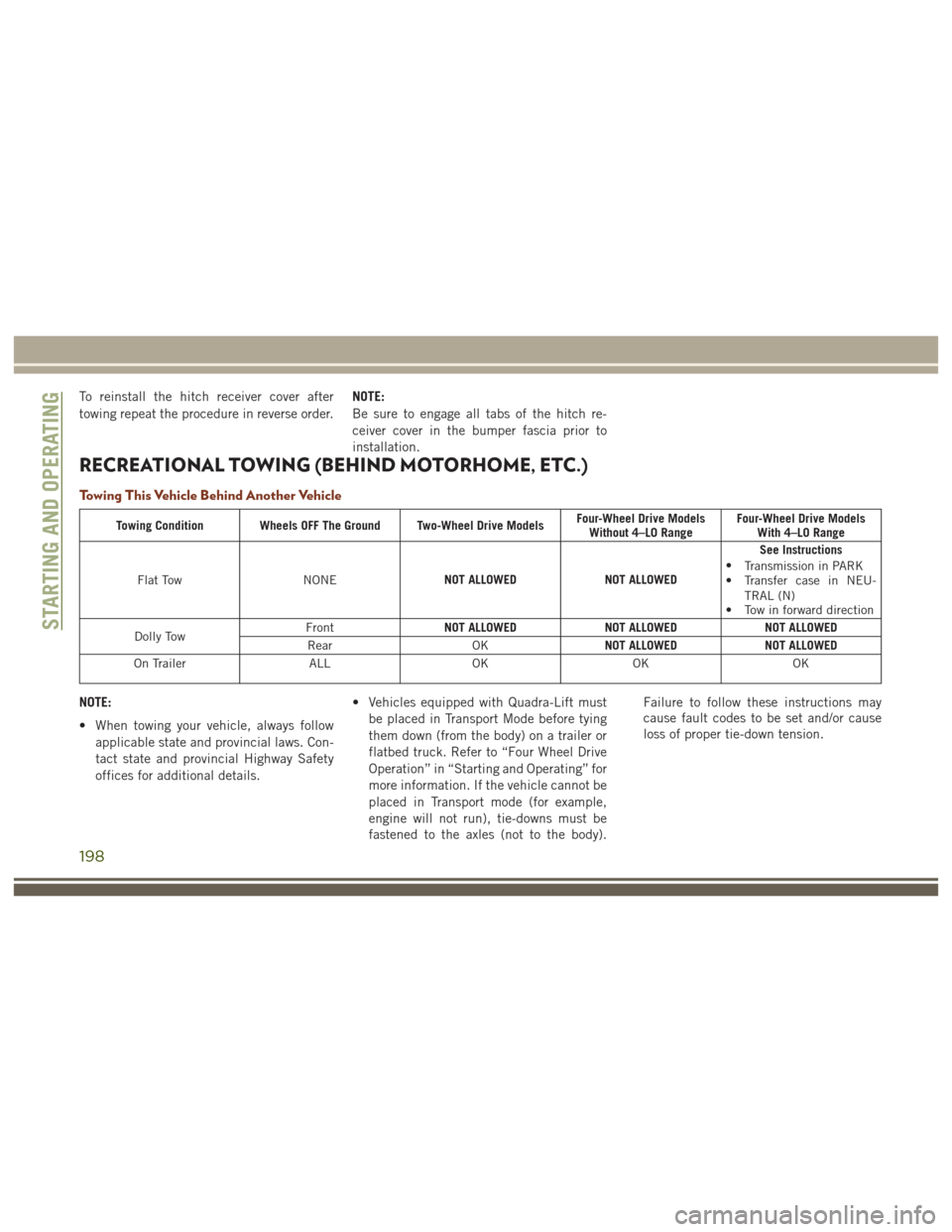

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

Towing Condition Wheels OFF The Ground Two-Wheel Drive Models

Four-Wheel Drive Models

Without 4–LO Range Four-Wheel Drive Models

With 4–LO Range

Flat Tow NONENOT ALLOWED

NOT ALLOWEDSee Instructions

• Transmission in PARK

• Transfer case in NEU-

TRAL (N)

• Tow in forward direction

Dolly Tow Front

NOT ALLOWED

NOT ALLOWEDNOT ALLOWED

Rear OKNOT ALLOWED

NOT ALLOWED

On Trailer ALLOKOKOK

NOTE:

• When towing your vehicle, always follow

applicable state and provincial laws. Con-

tact state and provincial Highway Safety

offices for additional details. • Vehicles equipped with Quadra-Lift must

be placed in Transport Mode before tying

them down (from the body) on a trailer or

flatbed truck. Refer to “Four Wheel Drive

Operation” in “Starting and Operating” for

more information. If the vehicle cannot be

placed in Transport mode (for example,

engine will not run), tie-downs must be

fastened to the axles (not to the body). Failure to follow these instructions may

cause fault codes to be set and/or cause

loss of proper tie-down tension.

STARTING AND OPERATING

198

Page 209 of 372

3. Pull the bulb straight out from the keyedopening in the housing.

CAUTION!

•Do not touch the new bulb with your

fingers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

• Always use the correct bulb size and type for replacement. An incorrect bulb size

or type may overheat and cause damage

to the lamp, the socket or the lamp

wiring.

4. Align the index tabs of the front fog lamp bulb with the slots in the collar of the bulb

opening on the back of the front fog lamp

housing.

5. Insert the bulb into the housing until the index tabs are engaged in the slots of the

collar.

6. Firmly and evenly push the bulb straight into the lamp housing until both tabs snap

firmly into place and are fully engaged. 7. Connect the wiring harness to the front fog

lamp connector.

Rear Tail, Stop, and Turn Signal Lamps

1. Raise the liftgate.

2. Remove the two push-pins from the taillamp housing.

3. Grasp the tail lamp and pull firmly rear- ward to disengage the lamp from the ap-

erture panel. 4. Twist socket counter clockwise and re-

move from lamp.

5. Pull the bulb to remove it from the socket.

6. Replace the bulb, reinstall the socket, and reattach the lamp assembly.

Tail Lamp Push Pins

Rear Of Tail Lamp

1 — Rear Stop Lamp Bulb Socket

2 — LED Tail Connector – Do Not Re-

move

3 — Rear Turn Signal Bulb Socket

207

Page 251 of 372

voir, take some washer fluid and apply it to a

cloth or towel and wipe clean the wiper

blades, this will help blade performance. To

prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the tempera-

ture range of your climate. This rating infor-

mation can be found on most washer fluid

containers.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite

and burn you. Care must be exercised

when filling or working around the washer

solution.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level to the full mark on the side of the

reservoir of the brake master cylinder. Be sure

to clean the top of the master cylinder area

before removing cap. With disc brakes, fluid

level can be expected to fall as the brake pads

wear. Brake fluid level should be checked

when pads are replaced. If the brake fluid is

abnormally low, check system for leaks.

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for further information.

WARNING!

• Use only manufacturer's recommendedbrake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

249

Page 255 of 372

6. Remove the A/C air filter by pulling itstraight out of the housing.

7. Install the A/C air filter with the arrow on the filter pointing toward the floor. When

installing the filter cover, make sure the

retaining tabs fully engage the cover.

CAUTION!

The cabin air filter is identified with an

arrow to indicate airflow direction through

the filter. Failure to properly install the

filter will result in the need to replace it

more often.

8. Reinstall the glove compartment door on the glove compartment door hinge and

reattach the glove compartment tension

tether by inserting the tether clip in the

glove compartment and sliding the clip

away from the face of the glove compart-

ment door.

9. Push the door to the near closed position to reengage the glove compartment travel

stops.

NOTE:

Ensure the glove compartment door

hinges and glove compartment travel

stops are fully engaged.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades

and the windshield periodically with a sponge

or soft cloth and a mild nonabrasive cleaner.

This will remove accumulations of salt or road

film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using

the wipers to remove salt or dirt from a dry

windshield.

Avoid using the wiper blades to remove frost

or ice from the windshield. Keep the blade

rubber out of contact with petroleum prod-

ucts such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies de-

pending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary.

A/C Air Filter Cover

1 — Retaining Tab

2 — Mid Way Snap

3 — Filter Cover Hinge

253

Page 260 of 372

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of

the following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures and Tire Loading.

Tire Markings

NOTE:

• P (Passenger) — Metric tire sizing isbased on U.S. design standards. P-Metric

tires have the letter “P” molded into the

sidewall preceding the size designation.

Example: P215/65R15 95H. • European — Metric tire sizing is based on

European design standards. Tires de-

signed to this standard have the tire size

molded into the sidewall beginning with

the section width. The letter "P" is absent

from this tire size designation. Example:

215/65R15 96H.

• LT (Light Truck) — Metric tire sizing is based on U.S. design standards. The size

designation for LT-Metric tires is the same

as for P-Metric tires except for the letters

“LT” that are molded into the sidewall

preceding the size designation. Example:

LT235/85R16.

• Temporary spare tires are designed for temporary emergency use only. Temporary

high pressure compact spare tires have

the letter “T” or “S” molded into the

sidewall preceding the size designation.

Example: T145/80D18 103M.

• High flotation tire sizing is based on U.S. design standards and it begins with the

tire diameter molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — U.S. DOT

Safety Standards

Code (TIN) 4 — Maximum

Load

2 — Size Designa-

tion 5 — Maximum

Pressure

3 — Service De-

scription 6 — Treadwear,

Traction and Tem-

perature Grades

SERVICING AND MAINTENANCE

258

Page 357 of 372

FCA Canada Inc. Customer Center

P.O. Box 1621

Windsor, Ontario N9A 4H6

Phone: (800) 465-2001 English / (800)

387-9983 French

In Mexico Contact

Av. Prolongacion Paseo de la Reforma, 1240

Sante Fe C.P. 05109

Mexico, D. F.

In Mexico City: 5081-7568

Outside Mexico City: 1-800-505-1300

Puerto Rico And U.S. Virgin Islands

Customer Service Chrysler International Ser-

vices LLC

P.O. Box 191857

San Juan 00919-1857

Tel.: (787) 782-5757

Fax: (787) 782-3345

Customer Assistance For The Hearing Or

Speech Impaired (TDD/TTY)

To assist customers who have hearing diffi-

culties, the manufacturer has installed spe-

cial TDD (Telecommunication Devices for the

Deaf) equipment at its customer center. Any

hearing or speech impaired customer, who

has access to a TDD or a conventional tele-

typewriter (TTY) in the United States, can

communicate with the manufacturer by dial-

ing 1-800-380-CHRY.

Canadian residents with hearing difficulties

that require assistance can use the special

needs relay service offered by Bell Canada.

For TTY teletypewriter users, dial 711 and for

Voice callers, dial 1-800-855-0511 to con-

nect with a Bell Relay Service operator.

Service Contract

You may have purchased a service contract

for a vehicle to help protect you from the high

cost of unexpected repairs after the manufac-

turer's New Vehicle Limited Warranty expires.

The manufacturer stands behind only the

manufacturer's service contracts. If you pur-

chased a manufacturer's service contract,you will receive Plan Provisions and an Owner

Identification Card in the mail within three

weeks of the vehicle delivery date. If you have

any questions about the service contract, call

the manufacturer's Service Contract National

Customer Hotline at 1-800-521-9922 (Ca-

nadian residents, call (800) 465-2001 Eng-

lish / (800) 387-9983 French).

The manufacturer will not stand behind any

service contract that is not the manufactur-

er's service contract. It is not responsible for

any service contract other than the manufac-

turer's service contract. If you purchased a

service contract that is not a manufacturer's

service contract, and you require service after

the manufacturer's New Vehicle Limited War-

ranty expires, please refer to the contract

documents, and contact the person listed in

those documents.

We appreciate that you have made a major

investment when you purchased the vehicle.

An authorized dealer has also made a major

investment in facilities, tools, and training to

assure that you are absolutely delighted with

355

Page 361 of 372

AccessUconnect ..........291, 293, 298

Accessories ..................283

Mopar ...................283

Adaptive Cruise Control (ACC) Off .................175, 177

On..................175, 177

Adaptive Cruise Control (ACC) (Cruise Control) ..................174

Adding Fuel ..............186, 188

Additives, Fuel ................274

AirBag ....................122 Air Bag Operation ............124

Air Bag Warning Light .........121

Driver Knee Air Bag ...........124

Enhanced Accident Response .128, 229

Event Data Recorder (EDR) ......229

Front Air Bag ..............122

If A Deployment Occurs ........128

Knee Impact Bolsters .........124

Maintaining Your Air Bag System . .129

Redundant Air Bag Warning Light . .122

Side Air Bags ..............125

Transporting Pets ............142

Air Bag Light ...........80, 121, 144 Air Bag Maintenance

............129

Air Conditioner Maintenance .......251

Air Conditioning Filter .........51, 252

Air Conditioning, Operating Tips ......51

Air Conditioning Refrigerant ........251

Air Conditioning System .......50, 251

Alarm Arm The System .............18

Disarm The System ............18

Alarm (Security Alarm) .........17, 81

Alarm System (Security Alarm) .......17

Antifreeze (Engine Coolant) ........276

Capacities ................277

Anti-Lock Brake System (ABS) .......92

Anti-Lock Warning Light ...........86

APP Uconnect Access ............293

Arming System (Security Alarm) ......17

Assist, Hill Start ................94

Audio

Jack ..................322

Auto Down Power Windows .........53

Automatic Door Locks ............23

Automatic High Beams ...........38

Automatic Temperature Control (ATC) . . .50

Automatic Transmission ..........159 Adding Fluid

...........279, 281

Fluid Level Check ...........250

Fluid Type .........279, 281, 283

Auto Up Power Windows ...........53

Axle Fluid ...................283

Axle Lubrication ...........279, 281

Background Themes Uconnect 8.4N .............341

Back-Up Camera ..............185

Battery ..................82, 250

Charging System Light .........82

Belts, Seat ..................143

Blind Spot Monitoring ...........103

B-Pillar Location ..............261

Brake Assist System .............93

Brake Control System, Electronic .....93

Brake Fluid .......249, 279, 281, 283

Brake System ................249

Fluid Check ........249, 279, 281

Master Cylinder .............249

Warning Light ...............80

Brake/Transmission Interlock .......158

Break-In Recommendations, New Vehicle ...................155

INDEX

359