brake fluid JEEP GRAND CHEROKEE 2017 WK2 / 4.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 241 of 372

SCHEDULED SERVICING —

DIESEL ENGINE

Your vehicle is equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is

time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as fre-

quent short-trips, trailer tow, extremely hot or

cold ambient temperatures will influence

when the “Oil Change Required” message is

displayed. Severe Operating Conditions can

cause the change oil message to illuminate

as early as 3,500 miles (5,600 km) since last

reset. Have your vehicle serviced as soon as

possible, within the next 500 miles

(805 km).Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change. If a scheduled oil

change is performed by someone other than

your authorized dealer, the message can be

reset by referring to the steps described un-

der “Instrument Cluster Display” in “Getting

To Know Your Instrument Panel” in this

guide.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km)

or twelve months, whichever comes first.

Engine Oil Filter Replacement

Residual oil in the housing may spill from the

housing when the new filter is installed if the

residual oil is not either removed from the

housing or enough time has not elapsed to

allow the oil to drain back into the engine.

When servicing the oil filter on this engine,carefully remove the filter and use a suction

gun to remove any residual oil left in the

housing or wait about 30 minutes for the oil

to drain back into the engine.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look

for unusual wear or damage

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and fill as

needed

• Check function of all interior and exterior lights

239

Page 242 of 372

Required Maintenance

Refer to the Maintenance Schedules on the

following pages for required maintenance.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change oil and filter.

• Completely fill the Diesel Exhaust Fluid tank.

• Drain water from fuel filter assembly.

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

• Inspect battery and clean and tighten terminals as required.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions.

SERVICING AND MAINTENANCE

240

Page 243 of 372

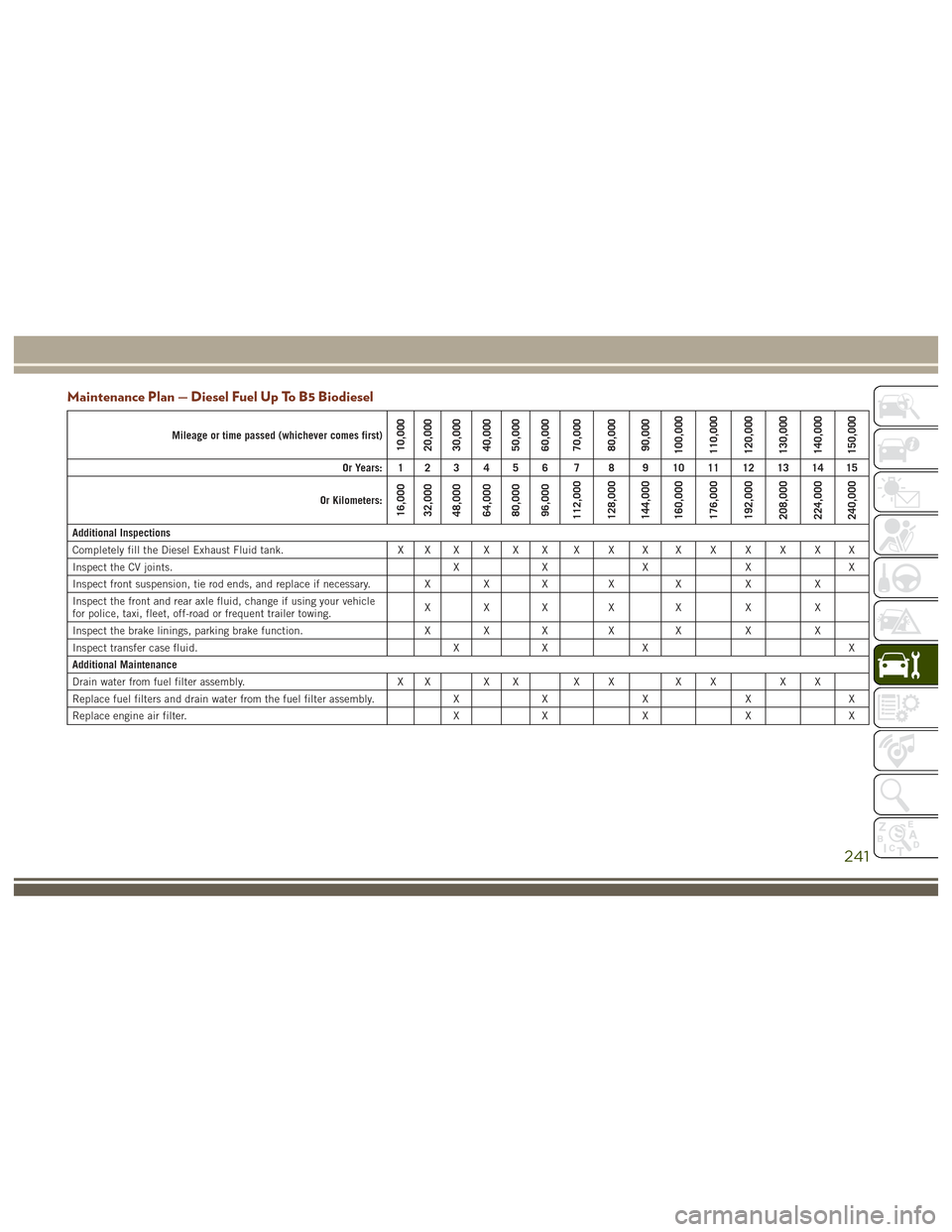

Maintenance Plan — Diesel Fuel Up To B5 Biodiesel

Mileage or time passed (whichever comes first)10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Completely fill the Diesel Exhaust Fluid tank. X X X X X X X X X X X X X X X

Inspect the CV joints. X X X X X

Inspect front suspension, tie rod ends, and replace if necessary. X X X X X X X

Inspect the front and rear axle fluid, change if using your vehicle

for police, taxi, fleet, off-road or frequent trailer towing. XXX X X X X

Inspect the brake linings, parking brake function. X X X X X X X

Inspect transfer case fluid. X X X X

Additional Maintenance

Drain water from fuel filter assembly. X X X X X X X X X X

Replace fuel filters and drain water from the fuel filter assembly. X X X X X

Replace engine air filter. X X X X X

241

Page 246 of 372

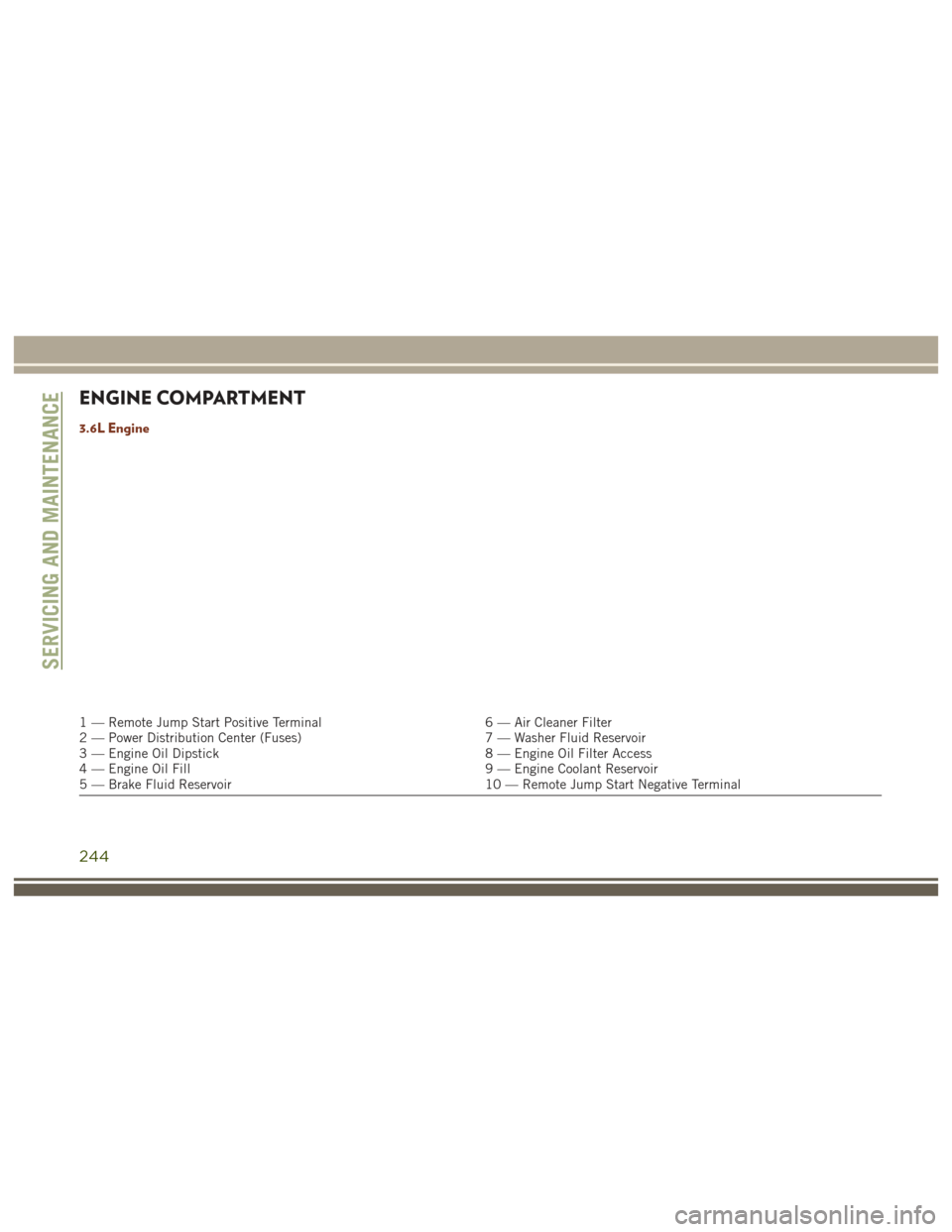

ENGINE COMPARTMENT

3.6L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Engine Oil Filter Access

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10 — Remote Jump Start Negative Terminal

SERVICING AND MAINTENANCE

244

Page 247 of 372

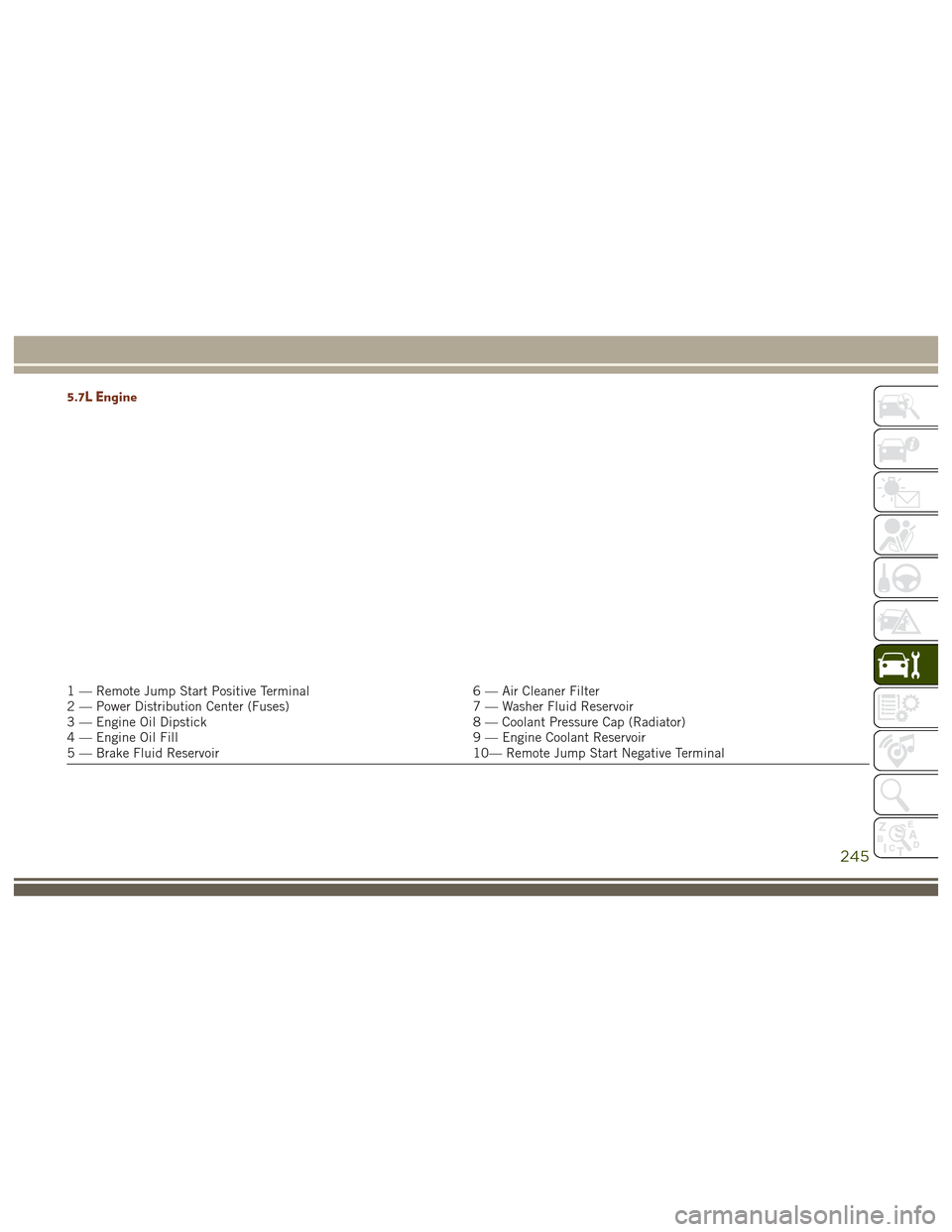

5.7L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Cap (Radiator)

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10— Remote Jump Start Negative Terminal

245

Page 248 of 372

6.4L Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Cap (Radiator)

4 — Engine Oil Fill 9 — Engine Coolant Reservoir

5 — Brake Fluid Reservoir 10 — Remote Jump Start Negative Terminal

SERVICING AND MAINTENANCE

246

Page 249 of 372

3.0L Diesel Engine

1 — Remote Jump Start Positive Terminal6 — Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir

3 — Engine Oil Dipstick 8 — Coolant Pressure Reservoir

4 — Engine Oil Fill 9 — Remote Jump Start Negative Terminal

5 — Brake Fluid Reservoir

247

Page 251 of 372

voir, take some washer fluid and apply it to a

cloth or towel and wipe clean the wiper

blades, this will help blade performance. To

prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the tempera-

ture range of your climate. This rating infor-

mation can be found on most washer fluid

containers.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite

and burn you. Care must be exercised

when filling or working around the washer

solution.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level to the full mark on the side of the

reservoir of the brake master cylinder. Be sure

to clean the top of the master cylinder area

before removing cap. With disc brakes, fluid

level can be expected to fall as the brake pads

wear. Brake fluid level should be checked

when pads are replaced. If the brake fluid is

abnormally low, check system for leaks.

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for further information.

WARNING!

• Use only manufacturer's recommendedbrake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

249

Page 252 of 372

WARNING!

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Automatic Transmission

Fluid Level Check

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required, therefore the trans-

mission has no dipstick. Your authorized

dealer can check your transmission fluid

level using special service tools. If you notice

fluid leakage or transmission malfunction,

visit your authorized dealer immediately to

have the transmission fluid level checked.

Operating the vehicle with an improper fluid

level can cause severe transmission damage.

CAUTION!

If a transmission fluid leak occurs, visit

your authorized dealer immediately. Se-

vere transmission damage may occur. Your

authorized dealer has the proper tools to

adjust the fluid level accurately.

Maintenance-Free Battery

Your vehicle is equipped with a maintenance-

free battery. You will never have to add water,

nor is periodic maintenance required.

WARNING!

• Battery fluid is a corrosive acid solutionand can burn or even blind you. Do not

allow battery fluid to contact your eyes,

skin, or clothing. Do not lean over a

battery when attaching clamps. If acid

splashes in eyes or on skin, flush the

area immediately with large amounts of

water. Refer to “Jump-Starting” in “In

Case Of Emergency” for further informa-

tion.

WARNING!

• Battery gas is flammable and explosive.Keep flame or sparks away from the

battery. Do not use a booster battery or

any other booster source with an output

greater than 12 Volts. Do not allow cable

clamps to touch each other.

• Battery posts, terminals, and related ac-

cessories contain lead and lead com-

pounds. Wash hands after handling.

CAUTION!

• It is essential when replacing the cableson the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the nega-

tive post. Battery posts are marked posi-

tive (+) and negative (-) and are identi-

fied on the battery case. Cable clamps

should be tight on the terminal posts

and free of corrosion.

• If a “fast charger” is used while the

battery is in the vehicle, disconnect both

vehicle battery cables before connecting

the charger to the battery. Do not use a

SERVICING AND MAINTENANCE

250

Page 281 of 372

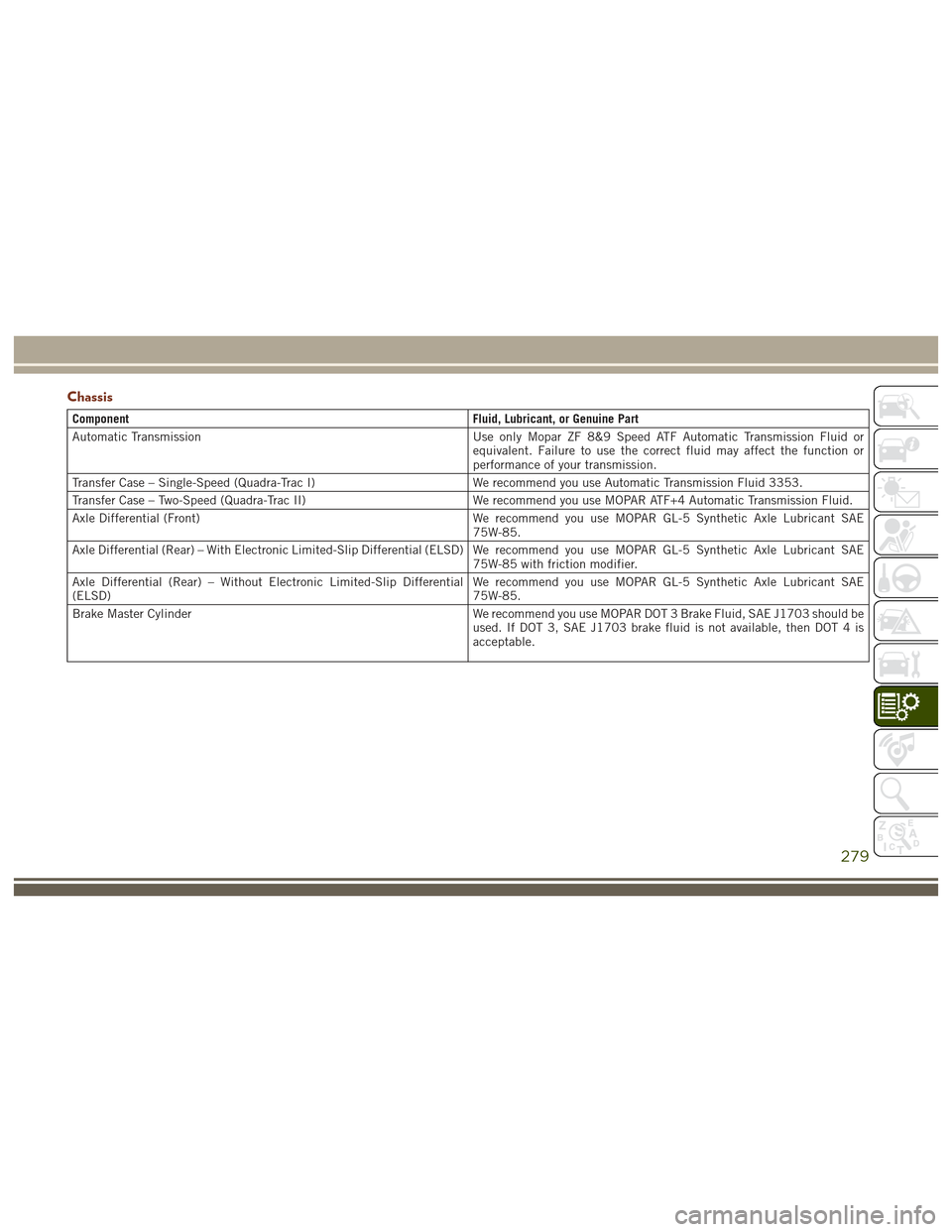

Chassis

ComponentFluid, Lubricant, or Genuine Part

Automatic Transmission Use only Mopar ZF 8&9 Speed ATF Automatic Transmission Fluid or

equivalent. Failure to use the correct fluid may affect the function or

performance of your transmission.

Transfer Case – Single-Speed (Quadra-Trac I) We recommend you use Automatic Transmission Fluid 3353.

Transfer Case – Two-Speed (Quadra-Trac II) We recommend you use MOPAR ATF+4 Automatic Transmission Fluid.

Axle Differential (Front) We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE

75W-85.

Axle Differential (Rear) – With Electronic Limited-Slip Differential (ELSD) We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE 75W-85 with friction modifier.

Axle Differential (Rear) – Without Electronic Limited-Slip Differential

(ELSD) We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE

75W-85.

Brake Master Cylinder We recommend you use MOPAR DOT 3 Brake Fluid, SAE J1703 should be

used. If DOT 3, SAE J1703 brake fluid is not available, then DOT 4 is

acceptable.

279