service JEEP GRAND CHEROKEE 2017 WK2 / 4.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 182 of 372

• Clean the ParkSense sensors regularly,taking care not to scratch or damage them.

The sensors must not be covered with ice,

snow, slush, mud, dirt or debris. Failure to

do so can result in the system not working

properly. The ParkSense system might not

detect an obstacle behind the fascia/

bumper, or it could provide a false indica-

tion that an obstacle is behind the fascia/

bumper.

• Use the ParkSense switch to turn the ParkSense system OFF if objects such as

bicycle carriers, trailer hitches, etc. are

placed within 12 in (30 cm) from the rear

fascia/bumper. Failure to do so can result

in the system misinterpreting a close ob-

ject as a sensor problem, causing the

“PARKSENSE UNAVAILABLE SERVICE

REQUIRED” message to appear in the

instrument cluster display.

• ParkSense should be disabled when the liftgate is in the open position and the

vehicle is in REVERSE. An open liftgate

could provide a false indication that an

obstacle is behind the vehicle.WARNING!

• Drivers must be careful when backing upeven when using ParkSense. Always

check carefully behind your vehicle,

look behind you, and be sure to check

for pedestrians, animals, other vehicles,

obstructions, and blind spots before

backing up. You are responsible for

safety and must continue to pay atten-

tion to your surroundings. Failure to do

so can result in serious injury or death.

• Before using ParkSense, it is strongly

recommended that the ball mount and

hitch ball assembly is disconnected

from the vehicle when the vehicle is not

used for towing. Failure to do so can

result in injury or damage to vehicles or

obstacles because the hitch ball will be

much closer to the obstacle than the

rear fascia when the loudspeaker sounds

the continuous tone. Also, the sensors

could detect the ball mount and hitch

ball assembly, depending on its size and

shape, giving a false indication that an

obstacle is behind the vehicle.

CAUTION!

• ParkSense is only a parking aid and it isunable to recognize every obstacle, in-

cluding small obstacles. Parking curbs

might be temporarily detected or not

detected at all. Obstacles located above

or below the sensors will not be detected

when they are in close proximity.

• The vehicle must be driven slowly when

using ParkSense in order to be able to

stop in time when an obstacle is de-

tected. It is recommended that the

driver looks over his/her shoulder when

using ParkSense.

PARKSENSE FRONT AND

REAR PARK ASSIST

Sensors

The four ParkSense sensors, located in the

rear fascia/bumper, monitor the area behind

the vehicle that is within the sensors field of

view. The sensors can detect obstacles from

approximately 12 inches (30 cm) up to

STARTING AND OPERATING

180

Page 192 of 372

WARNING!

• Never have any smoking materials lit inor near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most state

and federal fire regulations and may

cause the “Malfunction Indicator Light”

to turn on.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Avoid Using Contaminated Fuel

Fuel that is contaminated by water or dirt can

cause severe damage to the engine fuel sys-

tem. Proper maintenance of the engine fuel filter and fuel tank is essential. Refer to

“Dealer Service” in “Servicing And Mainte-

nance” for further information.

Bulk Fuel Storage — Diesel Fuel

If you store quantities of fuel, good mainte-

nance of the stored fuel is also essential. Fuel

contaminated with water will promote the

growth of “microbes.” These microbes form

“slime” that will clog the fuel filtration sys-

tem and lines. Drain condensation from the

supply tank and change the line filter on a

regular basis.

NOTE:

When a diesel engine is allowed to run out of

fuel, air is pulled into the fuel system.

If the vehicle will not start, refer to “Dealer

Service / Priming If The Engine Has Run Out

Of Fuel” in “Servicing And Maintenance” for

further information.

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

WARNING!

fuel spray can cause serious injury or

death.

Diesel Exhaust Fluid

Your vehicle is equipped with a Selective

Catalytic Reduction system to meet the very

stringent diesel emissions standards re-

quired by the Environmental Protection

Agency.

The purpose of the SCR system is to reduce

levels of NOx (oxides of nitrogen emitted from

engines) that are harmful to our health and

the environment to a near-zero level. Small

quantities of Diesel Exhaust Fluid (DEF) is

injected into the exhaust upstream of a cata-

lyst where, when vaporized, it converts smog-

forming nitrogen oxides (NOx) into harmless

nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe.

You can operate with the comfort that your

vehicle is contributing to a cleaner, healthier

world environment for this and generations to

come.

STARTING AND OPERATING

190

Page 194 of 372

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in the

“Technical Specifications” section for the

correct fluid type.

1. Remove cap from DEF fill inlet (located infuel door). 2. Insert DEF fill adapter/nozzle into DEF fill

inlet.

NOTE:

• The DEF gauge may take up to five seconds to update after adding a gallon

or more of Diesel Exhaust Fluid (DEF) to

the DEF tank. If you have a fault related

to the DEF system, the gauge may not

update to the new level. See your autho-

rized dealer for service.

• The DEF gauge may also not immedi- ately update after a refill if the tempera-

ture of the DEF fluid is below 12F

(-11C). The DEF line heater will possi-

bly warm up the DEF fluid and allow the

gauge to update after a period of run

time. Under very cold conditions, it is

possible that the gauge may not reflect

the new fill level for several drives.

CAUTION!

•To avoid DEF spillage, and possible dam-

age to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

• DO NOT OVERFILL. DEF will freeze be- low 12ºF (-11ºC). The DEF system is

designed to work in temperatures below

the DEF freezing point, however, if the

tank is overfilled and freezes, the system

could be damaged.

• When DEF is spilled, clean the area immediately with water and use an ab-

sorbent material to soak up the spills on

the ground.

• Do not attempt to start your engine if DEF is accidentally added to the diesel

fuel tank as it can result in severe dam-

age to your engine, including but not

limited to failure of the fuel pump and

injectors.

DEF Filler Cap And Fuel Fill

1 — Diesel Fuel Filler

2 — Diesel Exhaust Fluid Filler

STARTING AND OPERATING

192

Page 207 of 372

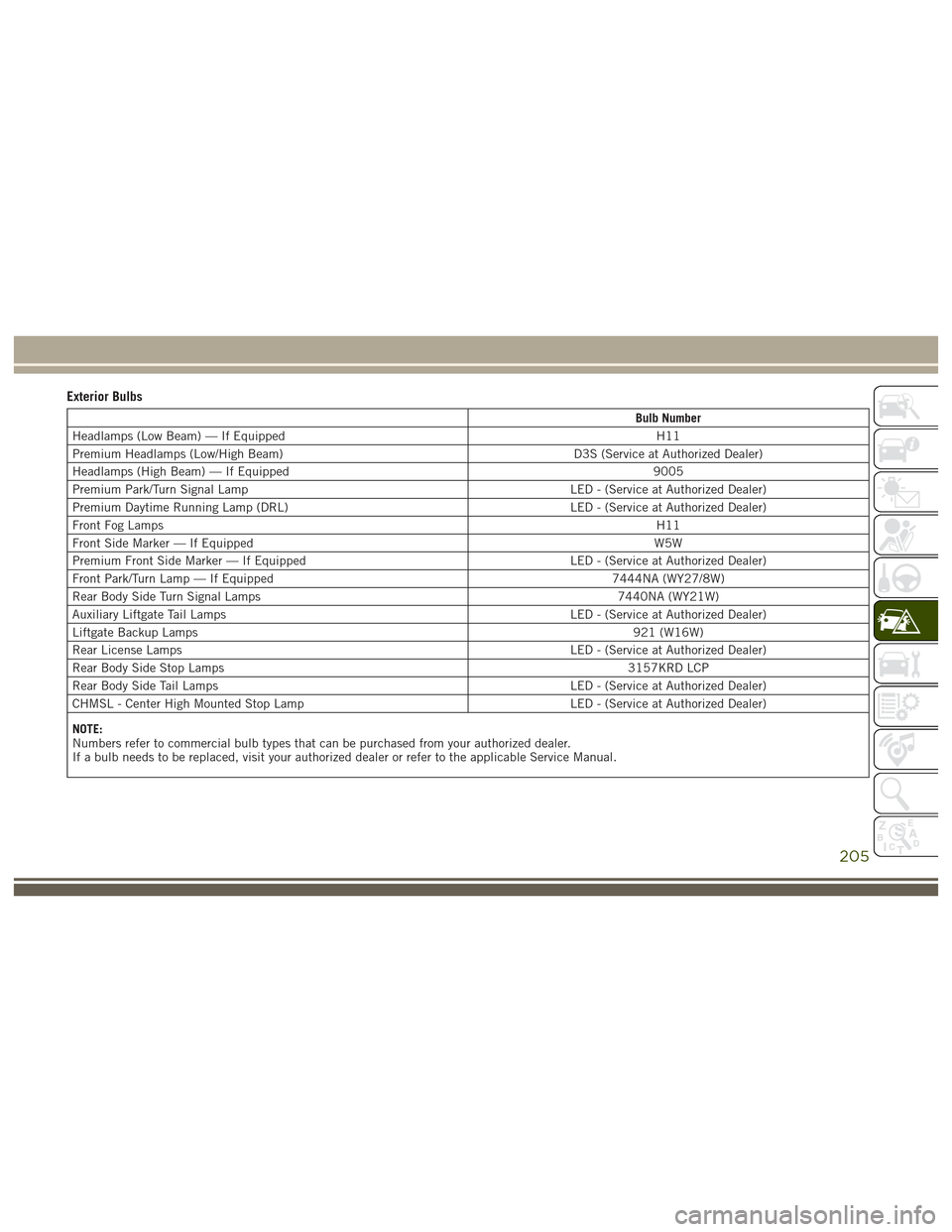

Exterior Bulbs

Bulb Number

Headlamps (Low Beam) — If Equipped H11

Premium Headlamps (Low/High Beam) D3S (Service at Authorized Dealer)

Headlamps (High Beam) — If Equipped 9005

Premium Park/Turn Signal Lamp LED - (Service at Authorized Dealer)

Premium Daytime Running Lamp (DRL) LED - (Service at Authorized Dealer)

Front Fog Lamps H11

Front Side Marker — If Equipped W5W

Premium Front Side Marker — If Equipped LED - (Service at Authorized Dealer)

Front Park/Turn Lamp — If Equipped 7444NA (WY27/8W)

Rear Body Side Turn Signal Lamps 7440NA (WY21W)

Auxiliary Liftgate Tail Lamps LED - (Service at Authorized Dealer)

Liftgate Backup Lamps 921 (W16W)

Rear License Lamps LED - (Service at Authorized Dealer)

Rear Body Side Stop Lamps 3157KRD LCP

Rear Body Side Tail Lamps LED - (Service at Authorized Dealer)

CHMSL - Center High Mounted Stop Lamp LED - (Service at Authorized Dealer)

NOTE:

Numbers refer to commercial bulb types that can be purchased from your authorized dealer.

If a bulb needs to be replaced, visit your authorized dealer or refer to the applicable Service Manual.

205

Page 208 of 372

Bulb Replacement

High Intensity Discharge Headlamps (HID)

—

If Equipped

The headlamps are a type of high voltage

discharge tube. High voltage can remain in

the circuit even with the headlamp switch off

and the key removed. Because of this, you

should not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your

vehicle to an authorized dealer for service.

WARNING!

A transient high voltage occurs at the bulb

sockets of High Intensity Discharge (HID)

headlamps when the headlamp switch is

turned ON. It may cause serious electrical

shock or electrocution if not serviced prop-

erly. See your authorized dealer for ser-

vice. NOTE:

On vehicles equipped with High Intensity

Discharge (HID) headlamps, when the head-

lamps are turned on, there is a blue hue to

the lamps. This diminishes and becomes

more white after approximately 10 seconds,

as the system charges.

Halogen Headlamps — If Equipped

1. Open the hood.

2. Turn the low or high beam bulb one–

quarter turn counterclockwise to remove

from housing.

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Turn Signal Lamp

1. Open the hood.

2. Turn the turn signal bulb one–quarter turncounterclockwise to remove from

housing.

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

1. Reach through the cutout in the splashshield and disconnect the wiring harness

from the fog lamp connector.

2. Firmly grasp the bulb by the two latches and squeeze them together to unlock the

bulb from the back of the front fog lamp

housing.

IN CASE OF EMERGENCY

206

Page 211 of 372

Center High-Mounted Stop Lamp (CHMSL)

The center high mounted stop lamp is an

LED. Service at an authorized dealer.

Rear License Lamp

The rear license lamps are LEDs. See your

authorized dealer for service.

FUSES

WARNING!

• When replacing a blown fuse, always usean appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Failure to use proper fuses may

result in serious personal injury, fire

and/or property damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, gearbox system) or steering system

blows, contact an authorized dealer.

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work you must check

the electrical circuit inside the fuse for a

break/melt.

Also please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

Underhood Fuses

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.

Center High-Mounted Stop Lamp

209

Page 216 of 372

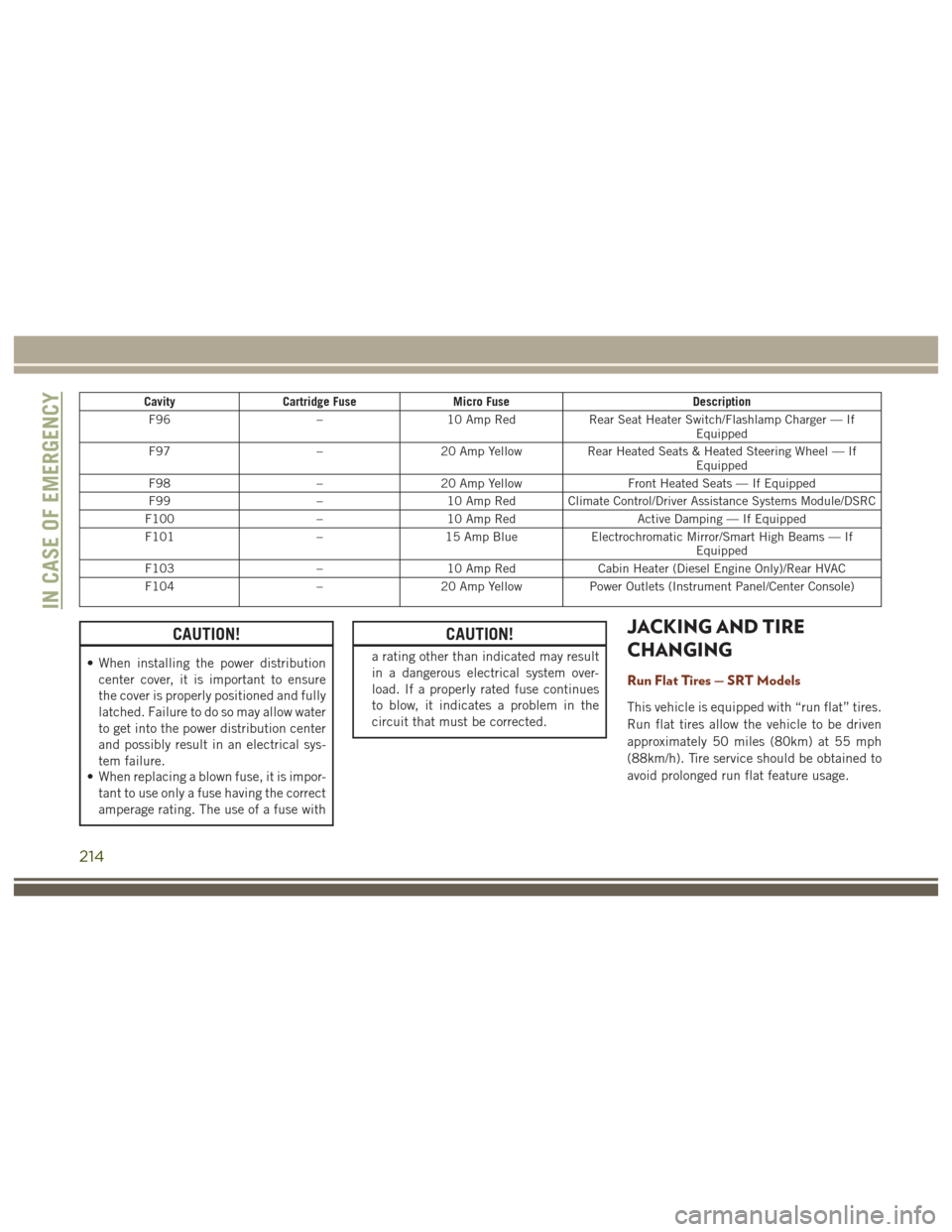

CavityCartridge Fuse Micro Fuse Description

F96 –10 Amp Red Rear Seat Heater Switch/Flashlamp Charger — If

Equipped

F97 –20 Amp Yellow Rear Heated Seats & Heated Steering Wheel — If

Equipped

F98 –20 Amp Yellow Front Heated Seats — If Equipped

F99 –10 Amp Red Climate Control/Driver Assistance Systems Module/DSRC

F100 –10 Amp Red Active Damping — If Equipped

F101 –15 Amp Blue Electrochromatic Mirror/Smart High Beams — If

Equipped

F103 –10 Amp Red Cabin Heater (Diesel Engine Only)/Rear HVAC

F104 –20 Amp Yellow Power Outlets (Instrument Panel/Center Console)

CAUTION!

• When installing the power distribution

center cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the power distribution center

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with

CAUTION!

a rating other than indicated may result

in a dangerous electrical system over-

load. If a properly rated fuse continues

to blow, it indicates a problem in the

circuit that must be corrected.

JACKING AND TIRE

CHANGING

Run Flat Tires — SRT Models

This vehicle is equipped with “run flat” tires.

Run flat tires allow the vehicle to be driven

approximately 50 miles (80km) at 55 mph

(88km/h). Tire service should be obtained to

avoid prolonged run flat feature usage.

IN CASE OF EMERGENCY

214

Page 219 of 372

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface asfar from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Remove the spare tire, jack, and tools from storage. 2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

3. Assemble the jack and jacking tools.

Warning Label

Jack And Tools Assembled

217

Page 222 of 372

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

9. Lower the vehicle by turning the jack screw counterclockwise, and remove the

jack and wheel blocks. 10. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice.

The correct tightness of each lug nut is

130 ft-lbs (176 N·m). If in doubt about

the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.

NOTE:

For the SRT model the correct wheel nut

tightness is 110 ft lbs (149 N·m).

11. Lower the jack to the fully closed posi- tion and return it and the tools to the

proper positions in the foam tray.

12. Remove the small center cap and se- curely store the road wheel in the cargo

area. 13. Have the aluminum road wheel and tire

repaired as soon as possible, properly

secure the spare tire with the special

wing nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit foam tray,

and latch the rear load floor cover.

NOTE:

Do not drive with the spare tire installed for

more than 50 miles (80 km) at a max speed

of 50 mph (80 km/h).

Installing Spare Wheel/Tire

Spare Tire

IN CASE OF EMERGENCY

220

Page 223 of 372

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Changing Procedure

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with thecone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. The correct

tightness of each lug nut is 130 ft-lbs

(176 N·m). If in doubt about the correct

tightness, have them checked with a

torque wrench by your authorized dealer

or service station.

NOTE:

For the SRT model the correct wheel nut

tightness is 110 ft lbs (149 N·m).

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.JUMP-STARTING

If your vehicle has a discharged battery it can

be jump-started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump-starting

can be dangerous if done improperly so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump-starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack

follow the manufacturer's operating instruc-

tions and precautions.

Preparations For Jump-Starting

The battery in your vehicle is located under

the passenger's front seat. There are remote

locations located under the hood to assist in

jump-starting.

221